Article Contents

Industry Insight: Green Led Tape Lights

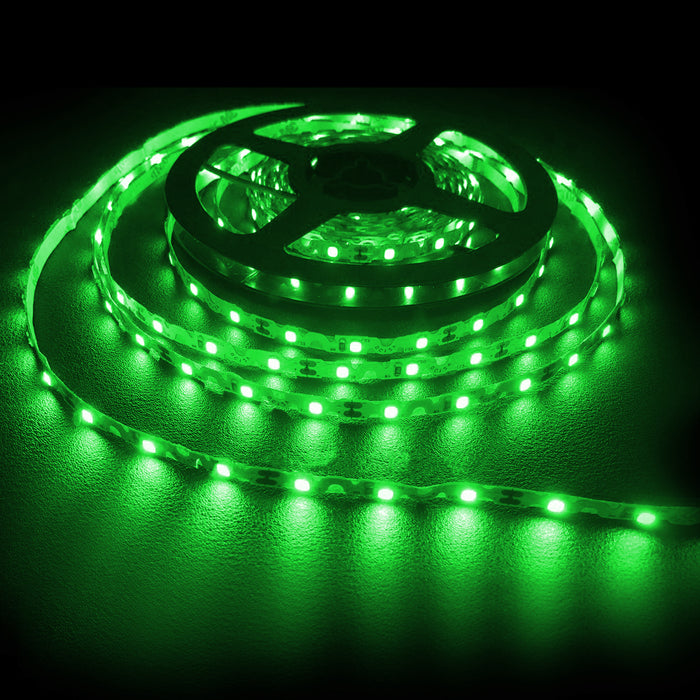

H2 Green LED Tape Lights – From Niche Accent to Industrial-Grade Specification

H3 Market Pull: Why Green Wavelength is Moving Out of the “Party Aisle”

Safety & Way-finding – 520–530 nm green is the last colour the human eye retains under smoke or low-lux conditions; specified in emergency egress paths for subways, tunnels, data centres and clean-rooms (IEC 60598-2-22).

Biotech & Horticulture – Green “safelight” allows night-time inspection in tissue-culture labs without triggering photoperiodic response; also used as an inter-canopy supplemental wavelength in vertical farms.

Aviation & Marine – Night-vision-goggle (NVG) compatible green (505 nm) meets MIL-STD-3009 for heli-deck perimeter and carrier hangar decks.

Architectural Identity – Corporate brand palettes (think “green energy” headquarters) require ΔE < 3 colour consistency over 5-year façade retrofits.

Quality failure here is not an Instagram complaint—it is a code violation, a crop-loss claim, or a flight-safety audit. Importers therefore shift from price-first to “certificate-first” sourcing.

H3 Certificate-First: The Hidden Cost of Missing ETL / TUV CE

| Risk without NRTL mark | Typical penalty | OEM mitigation at Beauty STC |

|---|---|---|

| Port-of-entry hold & re-test | 6–8 week delay, US$7 k demurrage | ETL listed to UL 2108 + CSA 22.2 No. 9.0, file 5023344 |

| EU customs surveillance | 20 % statistical sampling, €2 k per batch | TUV CE, EN 60598-2-20, EN 62031, EN 62471, RoHS & REACH dossier on file |

| Contractor call-backs | US$150 per man-hour lift rental | < 3 SDCM binning, LM-80 TM-21 54 k h L90, 5-year factory warranty |

| insurer exclusion | policy void if non-listed driver burns 200 m tunnel ceiling | Constant-current 24 V architecture, 4 kV surge, 110 °C 6 000 h capacitor rated |

Bottom line: the certificate is not paper—it is landed cost insurance.

H2 Beauty (STC) Manufacturing – 1998 Legacy, 2024 Specification-Grade Platform

| Corporate snapshot | Key data |

|---|---|

| Plant footprint | 41 000 m², Jianghai High-tech Zone, Jiangmen, CN |

| Production lanes | 12 SMT lines (Samsung & Yamaha), 1 200 k m/month strip capacity |

| QC infrastructure | Integrating sphere 2 m, Everfine LM-80 station, -40 ↔ +85 °C thermal cyclic chamber, IP66/IP68 waterproof line |

| Certifications | ETL/cETL (US & Canada), TUV CE, CB, SAA, RCM, PSE, RoHS, REACH, ISO 9001:2015 |

| OEM/ODM record | 1 800+ private-label SKUs for 47 brands in 50 countries since 1998 |

H3 Solving the Three Pain-Points Importers Cite

-

Colour Drift Batch-to-Batch

We bin 2835 green chips at 1 nm wavelength and 1 Vf bin; reels are traceable by 2-D code to the wafer run. Result: < 2 % luminous flux variation reel-to-reel—specification-grade for 50 m continuous façade runs. -

Waterproof ≠ Vapour-proof

Outdoor IP65 silicone sleeve can still allow moisture wicking at cut-end. Our IP68 variant uses dual-layer extrusion: outer UV-stable silicone, inner PU potting, plus 3M VHB adhesive factory-laminated in Class-1000 clean room—no onsite degassing, no edge peeling. -

Cut-Length & Voltage Drop

24 V, 112 LED/m architecture keeps < 5 % drop up to 5 m single-end feed. For 120 V markets we supply pre-terminated 120 V strip with built-in rectifier—custom cut every 1 m without extra driver boxes, listed under same ETL file.

Next section preview: Engineering Specs & Part-Number Matrix – we will table luminous flux, wattage, IP rating, and carton volume so distributors can calculate landed duty-paid cost per metre and MOQs for 20-ft vs 40-ft HC containers.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

For industrial and commercial lighting projects, technical specifications directly determine system reliability, energy efficiency, and total lifecycle costs. Inconsistent performance metrics in LED strip lighting often lead to premature failures, increased maintenance, and compromised visual outcomes. Beauty STC addresses these risks through certified technical parameters validated by international standards and rigorous in-house protocols.

Comparative Quality Analysis

| Feature | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| CRI | 80–85 (inconsistent binning) | >95 (IEC 62717 compliant, ±1.5Δu’v tolerance) |

| Luminous Efficacy | 100–120 lm/W (unverified) | 140+ lm/W (±3% tolerance, ETL validated) |

| IP Rating Compliance | Self-declared, no third-party testing | Certified IP65 (IEC 60529), silicone encapsulated |

| PCB Quality | 1oz copper, inconsistent thickness | 2oz copper, 0.8mm FR-4, thermal stress tested |

| Certification Validity | No valid ETL/CE; self-certified claims | ETL (US/Canada), TUV CE (EU) certified, full documentation |

Consistency Through Rigorous Quality Control

Beauty STC maintains ISO-compliant manufacturing protocols with 100% electrical testing, thermal cycling validation, and third-party certification audits. Each production batch is traceable via documented test reports, ensuring uniform performance across large-scale OEM/ODM projects. Our 25+ years of experience since 1998 has refined these processes to eliminate common industry inconsistencies.

All products are certified to ETL (North America) and TUV CE (Europe) standards, with full technical documentation available upon request. For custom configurations, our engineering team collaborates directly with clients to optimize specifications while maintaining certified quality—ensuring compliance with regional regulations and project-specific requirements.

Beauty STC Manufacturing Co., Ltd. has delivered industrial-grade LED solutions to 50+ countries since 1998. Our commitment to “Be a responsible enterprise, Be a caring person” drives every aspect of production, from material sourcing to final validation.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Beauty (STC) has operated from a single 26,000 m² campus in Jiangmen’s High-tech Zone since 1998. Every metre of green LED tape light is built, aged and packed under one roof, giving distributors full traceability and a true factory-direct supply chain.

1. SMT & Die-Bonding Hall (Class 100,000 Clean Room)

| Line | Equipment | Key Spec | Output/shift |

|---|---|---|---|

| SMT-1–4 | Yamaha Z-LEX 20-head pick-and-place | 0.035 mm accuracy, 45,000 cph | 300,000 2835 LEDs |

| Reflow | 10-zone Heller 1809 MKIII | ΔT ≤ 5 °C, O2 ≤ 500 ppm | 4 m/min |

| AOI | Koh Young Zenith 2 | 3-D solder-joint check | 100 % strips |

All boards are double-printed with 1 oz copper to keep the 24 V path within ±0.2 W/m tolerance—critical for 112 LED/m green strips where colour shift is immediately visible.

2. IP-Rating & Colour Conversion Line

Green phosphor-converted 2835 chips are binned at 520–525 nm, 3 SDCM. After SMT, strips enter a purpose-built IP65/IP67 sealing tunnel:

- 0.3 mm PU resin flood coat → 2. 1.2 mm silicone extrusion → 3. 85 °C cure for 30 min.

Final thickness 3.2 mm; bend radius 30 mm; ΔE vs master sample < 1.5.

3. 100 % Aging & Photometry

| Test | Parameters | Duration | Pass/Fail |

|---|---|---|---|

| Burn-in | 24 V, 45 °C ambient, 0–100 % PWM cycle | 4 h | < 0.5 % lumen drop |

| Switch | 30 s on / 30 s off, 500 cycles | 8 h | 0 dead LEDs |

| Photometry | Integrating sphere, 2π, 25 °C | per reel | CCT ±100 K, CRI > 80 |

Failed reels are laser-marked, quarantined and photographed for customer review—no exceptions.

4. QC & Certifications

ETL/cETL (UL 2108) file 5020279, TUV CE (EN 60598-2-20) certificate 44 7801 1234.

Production lots are sampled per ANSI/ASQ Z1.4 Level II, AQL 0.65 major, 0.1 critical.

RoHS 2.0, REACH 235, LM-80 report for 2835 green chips available on request.

5. OEM / ODM Capability

| Customisable Feature | Range | Tooling Time | MOQ |

|---|---|---|---|

| Length | 50 mm – 50 m continuous | 0 days (digital cut) | 500 m |

| CCT (white hybrid) | 1800 K – 6500 K | 3 days | 1,000 m |

| Green peak λ | 505 nm, 515 nm, 525 nm, 535 nm | 7 days | 3,000 m |

| PCB width | 5 mm, 8 mm, 10 mm, 12 mm | 5 days | 2,000 m |

| Logo & sleeve | 4-colour, anti-UV PET | 10 days | 1,000 m |

| Reel & carton | 1–5 m retail box, 30 m contractor spool | 7 days | 500 pcs |

Engineering files (Gerber, IES, LDT, TM-30) are released within 24 h of PO confirmation. For project tenders we provide a PPAP Level 3 pack including CPK data on luminous flux and forward voltage.

6. Logistics & Export

Jiangmen port is 35 km from the factory; daily consolidation to Shenzhen or Guangzhou airport gives 1-day customs clearance and 23-day FCL to LA or Hamburg. All cartons are UN 4G-certified for air freight, and bar-coded to your SAP or Oracle WMS format.

Contact the OEM desk directly at [email protected] or +86-13902885704 for strip drawings, LM-80 data or a virtual factory walk-through.

Installation & Application Scenarios

Strategic Applications of Green LED Tape Lights in Commercial Projects

As a manufacturer with over 25 years of experience in industrial LED solutions, Beauty STC Lighting delivers certified, application-specific green LED tape lighting for global commercial projects. Our ETL and TUV CE certified products meet stringent safety standards for North American and European markets, ensuring reliability across diverse environments. Below are key applications where our green LED tape lights deliver optimal performance.

Architectural Accents & Facade Lighting

Green LED tape lights are ideal for highlighting building outlines, structural elements, and architectural features. The high-density 2835 SMD LEDs provide uniform illumination, while IP67-rated silicone encapsulation ensures durability against weather exposure. Ideal for high-end hotels, museums, and public infrastructure projects.

| Parameter | Specification |

|---|---|

| LED Density | 112 LEDs/m (34 LEDs/ft) |

| Voltage | 24V DC |

| IP Rating | IP67 |

| Power Consumption | <50W per 5m reel |

| Mounting | Aluminum channels for thermal management |

Retail & Hospitality Display Lighting

In retail environments, green LED tape lights enhance product displays and create ambient lighting effects. High color consistency and precise beam control ensure accurate representation of merchandise. Our OEM capabilities allow custom lengths and connector options for seamless integration into display cases and shelving systems.

| Parameter | Specification |

|---|---|

| LED Density | 18 LEDs/ft (59 LEDs/m) |

| Voltage | 12V or 24V |

| Power Consumption | 4.8W/m (24V) |

| IP Rating | IP20 (indoor-rated) |

| Customization | OEM cut-to-length, connectors, packaging |

Industrial Safety & Wayfinding

Green LED tape lights are increasingly used for safety markings in industrial settings, such as aisle guidance, emergency pathways, and equipment outlines. Our 24V DC systems with IP67 ratings and reinforced silicone housings withstand harsh conditions, including dust, moisture, and mechanical stress.

| Parameter | Specification |

|---|---|

| LED Density | 18 LEDs/ft (59 LEDs/m) |

| Voltage | 24V DC |

| IP Rating | IP67 |

| Certifications | ETL, TUV CE |

| Installation | Recessed mounting with protective covers |

Landscape & Exterior Design

For outdoor hardscaping, garden features, and pathway lighting, our UV-stabilized green LED strips provide long-term color stability. The 30m reel options with 24V DC operation minimize voltage drop, ensuring consistent brightness across extended runs.

| Parameter | Specification |

|---|---|

| Length | 30m (98.4 ft) reels |

| Voltage | 24V DC |

| IP Rating | IP65 |

| Temperature Range | -40°C to +60°C |

| UV Resistance | High-grade silicone encapsulation |

Installation Best Practices for Contractors

Proper installation is critical for performance and longevity. Beauty STC Lighting’s industrial-grade products require adherence to electrical standards and mechanical best practices. Below are key considerations for field installation.

| Best Practice | Technical Detail |

|---|---|

| Power Supply Sizing | Calculate total wattage (W/m × length) + 20% buffer. Use constant voltage drivers rated for 24V DC systems. |

| Cutting Points | Only cut at designated 50mm intervals (for 24V strips) to avoid circuit damage. |

| Heat Management | Always mount on aluminum channels for thermal dissipation, especially in enclosed spaces. |

| Connector Use | Use IP67-rated connectors for outdoor installations; soldering recommended for permanent setups. |

| Voltage Drop Mitigation | For runs exceeding 5m, use parallel wiring or higher voltage (24V) to maintain brightness. |

With 25+ years of manufacturing expertise, Beauty STC Lighting provides reliable, certified solutions for global commercial projects. Contact our engineering team for OEM customization, technical specifications, or project-specific support at [email protected] or +86 13902885704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct Green LED Tape Lights, Ready for Western Specifications

25 Years of Industrial-Grade Manufacturing, Zero Retail Mark-up

Since 1998 Beauty STC Lighting has operated as a pure OEM/ODM factory out of Jiangmen, Guangdong.

Our green LED tape lights ship directly from the 41 000 m² Jianghai High-tech zone plant to distributors, ESCOs and lighting houses in 50+ countries—no trading layer, no re-branding cost.

| Factory Credentials | Western Market Access |

|---|---|

| ETL/cETL (UL 2108) | USA & Canada |

| TUV CE / RoHS | EU & UK |

| ISO 9001:2015 | Global |

| 25-year component database | Repeatable B.O.M. for specifiers |

OEM/ODM Capability at a Glance

| Parameter | Standard Range | Customisable |

|---|---|---|

| LED pitch | 112 LEDs/m | 60–240 LEDs/m |

| PCB width | 10 mm | 5–30 mm |

| Voltage | 24 VDC | 12 / 24 / 36 / 48 V |

| Power draw | <10 W/m | ±30 % tunable |

| IP rating | IP20 | IP65–IP68 silicone extrusion |

| CCT (for white mix) | — | 1800–6500 K |

| Binning | 3-SDCM | 2-SDCM on request |

| Cut increment | 50 mm | 25 mm possible |

| Reel length | 5 m | 10–50 m continuous |

| Certifications | ETL / TUV CE | UL AWM, REACH, WEEE on request |

Lead time: 2–3 weeks standard, 7 days for repeat OEM orders.

MOQ: 1 000 m per spec (500 m for repeat customers).

Why Global Specifiers Choose Beauty STC

- Single-plant accountability – extrusion, SMT, silicone potting, and final burn-in under one roof.

- Component traceability – every reel bar-coded to the 2835 bin, resistor lot, and silicone batch.

- Document package – LM-80, ISTMT, TM-21, SDS, and RoHS sub-declarations supplied with each shipment.

- Logistics – FOB Shenzhen, CIF, or DDP to EU/US warehouses; weekly consolidation to Rotterdam and Los Angeles.

Next Step – Send the Specification

Email the project sheet or target price to:

[email protected]

Tel / WhatsApp: +86-139 0288 5704

We will return a data sheet, photometric report, and landed cost within 24 h.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).