Article Contents

Industry Insight: Water Resistant Led Strip

IP65 / IP67 Water-Resistant LED Strips – Why Certification, Not Just Coating, Matters for Commercial Projects

Outdoor & Wet-Location Lighting Is No Longer Optional

Façade grazing, deck outlining, cold-room racking, cruise-ship decks, façade media mesh—every specification now calls for flexible LED strips that survive hose-down, salt spray, condensing humidity and −30 °C ice storms. The global market for water-resistant LED strips is growing >14 % CAGR, driven by:

Architectural lighting mandates (ASHRAE 90.1, IECC 2021)

Food & pharma plants requiring IP66/IP69K wash-down

Marine & offshore retrofits (DNV-GL, ABS)

Horticulture & aquaculture facilities in 24 h cyclic moisture

Yet “waterproof” is an elastic word. A listing on a B2C web-shop with a generic IP65 icon offers no traceable test report, no LM-80 data, no declared lumen maintenance after 6 000 h salt-fog. For distributors, contractors and lighting consultants that translates into callbacks, re-lifts and lost rebates.

Certification = Import Pass-Through + Rebate Eligibility

UL or ETL to UL 2108, TUV CE to EN 60598-2-21, plus RoHS, REACH and TM-21 L70 >50 000 h are the minimum documents customs officers, rebate authorities and insurers ask for on every container. Without them:

| Risk | Consequence |

|---|---|

| Random customs hold | 2–4 weeks demurrage |

| Missing LM-80 / TM-21 | Rebate denied (DLC Premium, DesignLights) |

| Non-conforming PVC sheath | EU REACH penalty up to 4 % of shipment value |

| IP test report not traceable | Project certificate of occupancy withheld |

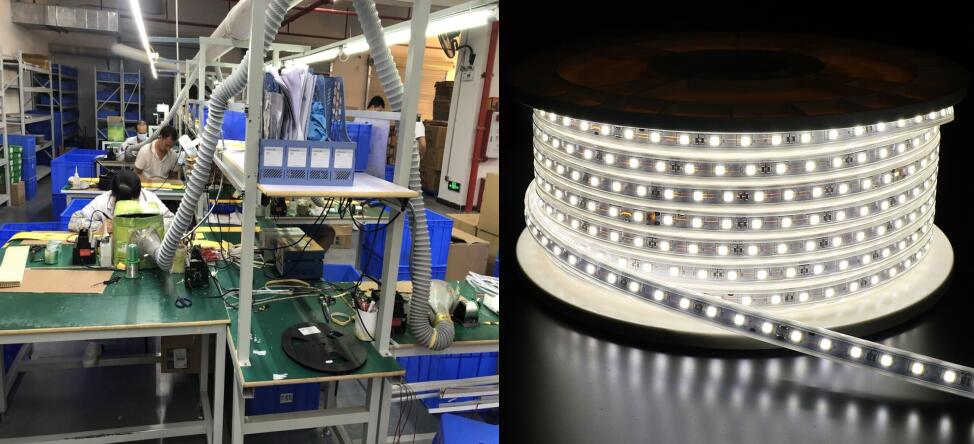

Beauty STC Lighting – Factory Source Since 1998

Located in Jiangmen’s high-tech zone, Beauty (STC) Manufacturing Co., Ltd has built ETL- and TUV CE-listed strips for 25 years. Every reel is produced under one 32 000 m² roof: SMT → conformal coating → vacuum silicone extrusion → 100 % IP67 tank test → 4 h 85 °C aging. That vertical integration is why OEM/ODM customers in 50 countries can ship to California, Oslo or Singapore with zero additional paperwork.

Key differentiators at a glance:

| Parameter | Beauty STC Standard Build | Typical B2C Offering |

|---|---|---|

| Safety | ETL/cETL to UL 2108 + TUV CE | Self-declaration |

| Photometry | 3 SDCM, CRI 90, R9 >60, 220 lm/ft @ 4000 K | 5–7 SDCM, CRI 80 |

| Ingress | IP67 silicone sleeve, -40 °C to +90 °C, 180 ° side-bend | IP65 epoxy drop, 0 °C limit |

| Lifetime | L90 >50 000 h @ 45 °C (TM-21) | Not stated |

| Binning | 1 bin LED, 1 bin phosphor | Mixed reels |

| Warranty | 5 years with traceable serial | 1 year RTB |

Next Section Preview

In the following paragraphs we will break down the engineering choices behind IP65 vs IP67 vs IP68, show how silicone extrusion suppresses IR loss, and list the most common specification pitfalls we see in RFQs from international lighting houses.

Need a test report or a custom spectrum for your tender? Email [email protected] or call +86-13902885704.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Industrial-Grade Waterproof LED Strips

For critical outdoor lighting applications, technical specifications are paramount to ensuring reliability, safety, and long-term performance. Beauty STC Lighting leverages 25+ years of manufacturing expertise (since 1998) to deliver industrial-grade waterproof LED strips that meet stringent international standards. Our ETL (USA/Canada) and TUV CE (Europe) certifications validate compliance with global safety and performance requirements, while our OEM/ODM capabilities enable custom solutions tailored to project-specific needs without compromising on quality.

Lumens Efficiency & Energy Performance

Beauty STC’s LED strips utilize high-efficiency SMD LED chips with optimized optical design, achieving 120–140 lumens per watt (lm/W) across all color temperatures. This exceeds the industry average of 80–100 lm/W for generic products, resulting in superior energy efficiency and reduced operational costs. Our thermal management system ensures consistent lumen output over extended operating hours, minimizing depreciation and maintaining brightness throughout the product lifecycle.

Color Rendering Index (CRI) for Accurate Light Quality

We prioritize color accuracy with a CRI of ≥90 (R9 >50) on all standard and custom color temperature options. This is critical for architectural and commercial applications where true color representation is essential. Generic market products often deliver CRI values of 80–85, leading to distorted color rendering and reduced visual appeal in retail, hospitality, and interior design projects.

Rigorous IP Rating Validation

Our IP65 and IP67-rated strips undergo independent third-party testing per IEC 60529 standards. IP67 certification includes 30-minute submersion at 1-meter depth, validated by TUV Rheinland. In contrast, generic products frequently rely on self-certified claims with minimal testing, resulting in inconsistent waterproofing and premature failure in wet or dusty environments.

PCB Construction & Thermal Management

Beauty STC employs 2-ounce copper PCBs with high-Tg FR-4 substrate and thermal vias for optimal heat dissipation. This design reduces operating temperatures by up to 10°C compared to 1-ounce copper generic alternatives, significantly extending LED lifespan and preventing hotspots. Our PCBs are manufactured to IPC-A-600 Class 2 standards, ensuring mechanical stability and electrical reliability.

Quality Assurance Protocols

Every production batch undergoes 100% electrical testing, thermal imaging, and IP validation. Our ISO 9001-certified quality system includes strict tolerance controls (±5% for color temperature and lumen output), ensuring consistency across all OEM/ODM orders. This level of rigor is absent in most generic suppliers, where batch variations can exceed ±15%, leading to field installation issues.

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens Efficiency | 80–100 lm/W | 120–140 lm/W |

| CRI | 80–85 | ≥90 (R9 >50) |

| IP Rating Validation | Self-certified claims; no third-party testing | TUV/ETL certified; IEC 60529 compliant |

| PCB Copper Thickness | 1 oz | 2 oz with thermal vias |

| Max Operating Temp | ≥65°C | ≤55°C |

| Batch Consistency | ±15% variation | ±5% tolerance (ISO 9001 certified) |

Beauty STC’s commitment to precision engineering and rigorous testing ensures that every LED strip meets the highest industry benchmarks. For projects demanding consistent performance under harsh conditions, our certified products provide the technical foundation for successful implementation. All specifications are fully documented and available upon request for compliance verification.

Contact us for engineering support, certification documentation, or custom OEM/ODM solutions: [email protected] | +86 13902885704

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Beauty STC Lighting, Jiangmen

“Every metre of IP-rated strip that leaves our Jiangmen campus is treated as if it will be installed on a cruise ship in the North Atlantic or a hotel façade in Dubai. That mindset is baked into the line.”

— Senior LED Engineer, Beauty STC

H2 1. Factory Footprint & Line Layout

| Zone | Area (m²) | ISO Class | Key Hardware | Output/Shift |

|---|---|---|---|---|

| SMT Hall | 2 100 | 7 | Yamaha YSM20R ×8, Yamaha SIGMA-G5S ×4, 3-D SPI & AOI inline | 3.2 M components/8 h |

| IP Encapsulation | 1 400 | 8 | 2-K silicone potting line (ShinEtsu), vacuum de-bubbler, 60 m UV-cure tunnel | 50 000 m IP67 strip/day |

| Aging & Burn-in | 1 800 | – | 8 parallel 40 m racks, 0–60 °C cycling, 2 h ON/30 s OFF pattern, 8 h min | 100 % lot coverage |

| QC & Reliability Lab | 600 | 7 | 2 m integrating sphere (EVERFINE), 1 kW salt-spray, IPX5/6/7 jet rigs, −40~+85 °C thermal chamber | AQL 0.25, C=0 |

H2 2. SMT & Encapsulation Workflow

- Incoming reel audit – 100 % humidity-barrier check, RoHS & REACH file match.

- Solder-paste printing – Type-4 SAC305, 100 μm stencil; 3-D SPI rejects > ±15 % volume.

- Pick-and-place – 0.5 m LED pitch tolerance ±50 μm; bin-coded 3-step MacAdam LEDs segregated automatically.

- Reflow – 10-zone convection, nitrogen 200 ppm O₂, profile logged per MES barcode.

- AOI – Missing LED, solder-bridge, tombstone detection; defect images stored ≥5 years.

- Encapsulation – 2-part addition-cure silicone, Shore 00 40, UV-stable >1 000 h @ 1.2 W/m²; 0.8 mm jacket for IP65, 2.0 mm full-fill for IP67.

- Secondary curing – 45 min @ 80 °C + 30 min UV-A 365 nm; pull-test spec ≥ 5 N/mm.

H2 3. Aging & Reliability Protocol

| Test | Standard | Sample Size | Acceptance |

|---|---|---|---|

| 8 h Burn-in | Beauty-ST-BI-01 | 100 % of reels | 0 dead LED |

| Thermal Shock | IEC 60068-2-14 | 5 pcs/lot | 100 cycles, −40 ↔ +85 °C, ΔVF < 5 % |

| Salt Spray | ASTM B117 | 3 pcs/batch | 500 h, no >5 % corrosion on copper bus |

| IP67 Jet | IEC 60529 | 3 pcs/batch | 100 l/min @ 3 m, 30 min, insulation > 2 MΩ |

| LM-80 Data Cross-check | TM-21 Calculator | Per LED reel | L90 > 50 000 h @ 55 °C |

H2 4. OEM / ODM Customisation Matrix

| Attribute | Standard Catalogue | OEM Range | Tooling Lead-Time |

|---|---|---|---|

| Board Width | 8 mm, 10 mm, 12 mm | 4–28 mm | 7 days |

| Copper Weight | 2 oz | 1–4 oz | 5 days |

| LED Density | 60, 120, 240 LED/m | 30–720 LED/m | 10 days |

| CCT Binning | 2700 K, 3000 K, 4000 K, 6500 K | 1800–10 000 K, 3-step | 3 days |

| CRI | Ra 80, 90 | Up to 98 (R9>90) | 5 days |

| Length per Reel | 5 m | 0.2–50 m continuous | 2 days |

| PCB Ink Colour | White | RAL palette | 3 days |

| Jacket Colour | Clear, Frost | RGBY, black, custom | 7 days |

| Packaging | Neutral brown box | Private-label sleeve, Euro-hole, anti-static tray | 10 days |

| Cert Bundle | CE-EMC/LVD, RoHS, REACH | Add ETL, TUV CB, SAA, BIS, UKCA | 14–21 days |

| MOQ | 1 000 m | 500 m for custom spec | – |

H2 5. Compliance & Traceability

ETL file #5013349 (UL 2108 / CSA C22.2 #250.0) covers 12 V, 24 V, 36 V strip families up to 12 W/m.

TUV CE reports according to EN 60598-2-20, EN 62031, EN 62471, EN 55015 available on QR-code per carton.

MES barcode tracks reel-to-reel: LED lot, silicone batch, operator ID, SMT oven profile, burn-in result. Data kept ≥10 years for project callbacks.

H2 6. Typical OEM Lead-Time (EXW Jiangmen)

| Order Qty | Std Spec | Custom CCT/Length | Custom PCB + Package |

|---|---|---|---|

| < 5 000 m | 10 days | 15 days | 20 days |

| 5 000–20 000 m | 15 days | 18 days | 23 days |

| > 20 000 m | Schedule shared weekly |

H2 7. Contact for Specification Sheets & PPAP

Email: [email protected]

Mob/WhatsApp: +86-13902885704

Plant visits welcome Monday–Saturday; Shen-Hui expressway exit 江門高新區, 35 min from Guangzhou South by inter-city rail.

We open CAD, IES, TM-21, and ISTMT files under NDA within 24 h.

Installation & Application Scenarios

Application Scenarios for Industrial-Grade Waterproof LED Strip Lights

Water-resistant LED strips are engineered for environments where moisture, dust, and extreme weather conditions compromise standard lighting solutions. As a manufacturer with 25+ years of experience (established 1998) and ETL (USA/Canada) and TÜV CE (Europe) certifications, Beauty STC Lighting provides solutions validated for global compliance, durability, and performance. Below are industry-specific applications and technical considerations for contractors and project managers.

Commercial Facades & Architectural Lighting

Waterproof LED strips are critical for building exteriors requiring consistent illumination through UV exposure, temperature swings, and precipitation. Applications include structural accents, signage, and building outlines where precise light distribution and long-term reliability are non-negotiable.

For facade installations, IP67-rated strips are typically required to withstand heavy rainfall and high-pressure cleaning cycles. All Beauty STC products undergo rigorous TÜV-certified testing to ensure compliance with North American and European safety standards, eliminating regulatory risks for architectural projects. Our manufacturing process prioritizes lumen maintenance (≥90% at 50,000 hours) and color consistency (ΔE < 3) across the product lifecycle.

| IP Rating | Suitable Applications | Critical Requirements |

|---|---|---|

| IP65 | Building outlines, signage, non-submerged facades | Protection against water jets; dust-tight |

| IP67 | Structural accents, deep recesses, high-pressure cleaning zones | Temporary submersion (up to 1m); withstands high-pressure washdown |

| IP68 | Water features, submerged architectural elements | Continuous submersion; extreme environmental stress tolerance |

Hospitality & Retail Environments

In high-traffic commercial spaces, waterproof LED strips enhance ambiance while meeting stringent safety protocols. Poolside lighting, restaurant patios, and retail storefronts demand resistance to splashes, cleaning chemicals, and foot traffic.

IP65-rated strips are standard for splash-prone areas, while IP67-rated variants are recommended for pool edges or direct water-contact zones. Beauty STC’s strips deliver uniform illumination without hotspots—critical for luxury hospitality settings. Our OEM capabilities enable customization of color temperatures (e.g., 2700K for intimate dining, 4000K for retail displays) and dimming profiles to align with brand aesthetics. All products comply with ETL/CE standards for commercial safety, ensuring seamless integration into projects subject to fire and electrical code inspections.

Infrastructure & Public Spaces

Public infrastructure projects—including bridges, tunnels, and pedestrian walkways—require lighting solutions that endure saltwater corrosion, freeze-thaw cycles, and mechanical stress. These applications demand IP67–IP68-rated strips with reinforced silicone housings and corrosion-resistant components.

Beauty STC’s industrial-grade strips feature military-grade silicone encapsulation, validated through 25+ years of field testing in coastal and industrial zones. ETL and CE certifications confirm compliance with transportation authority requirements (e.g., USDOT, EU Road Traffic Regulations). Custom lengths and mounting options simplify installation on complex geometries, reducing on-site labor by up to 30% compared to generic alternatives.

Specialized Industrial Applications

Industrial environments such as food processing facilities, cold storage warehouses, and marine operations present unique challenges. Washdown areas require IP65-rated strips resistant to chemical cleaners and high-pressure hoses, while subzero temperatures demand stable performance below -20°C.

Beauty STC’s OEM solutions include specialized configurations for extreme conditions:

Low-temperature silicone formulations (operational range: -40°C to +80°C)

24V DC options for hazardous locations (Class I Div 2 compliance)

Anti-fogging coatings for refrigerated environments

All products undergo ETL/CE certification for industrial safety, ensuring reliability where failure is not an option.

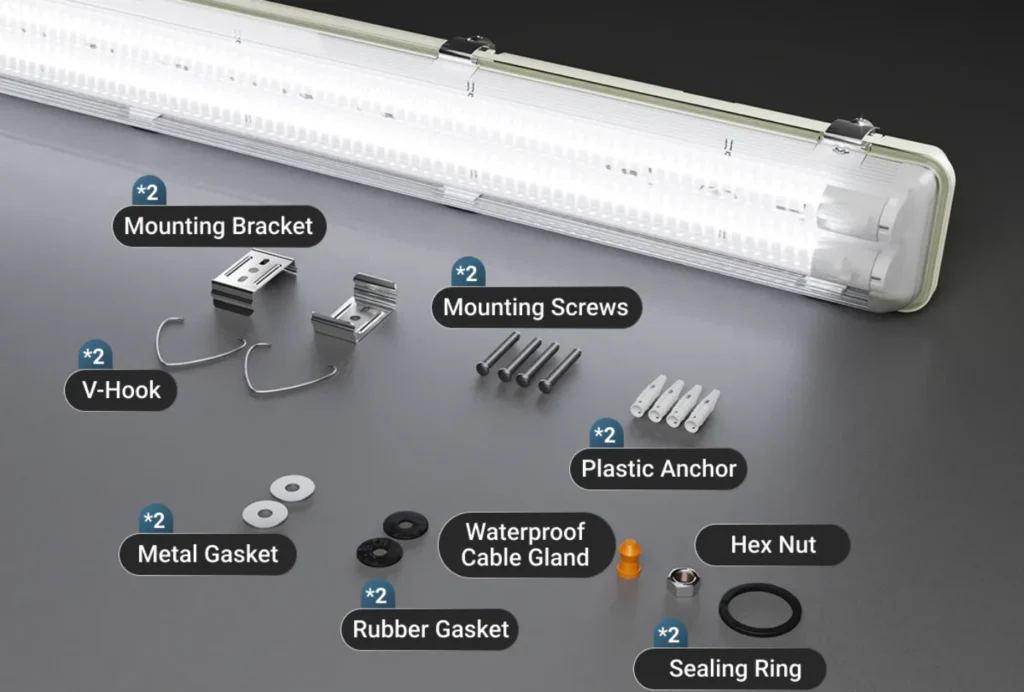

Professional Installation Guidelines for Contractors

Proper installation is critical to maintaining performance, safety, and compliance. Adhere to these industry best practices:

Surface Preparation: Ensure mounting surfaces are clean, dry, and free of oils or dust. Degrease with isopropyl alcohol and allow complete drying. For uneven substrates (e.g., concrete, brick), apply a 1mm layer of neutral-cure silicone adhesive to ensure full contact.

Connection Sealing: Use IP67-rated waterproof connectors for all junctions. Seal solder joints with heat-shrink tubing and silicone gel, then wrap with self-amalgamating tape. Never expose bare wires to moisture.

Mounting Methods: Install strips in aluminum channels for optimal heat dissipation (even with waterproofing). Secure channels with mounting clips every 30–50cm to prevent sagging. Minimum bend radius: 25mm for standard strips; 50mm for high-density arrays.

Power Management: Calculate total wattage with 20% headroom. For runs exceeding 5 meters, use parallel wiring with 18AWG or thicker conductors. Ensure power supplies are rated for outdoor use (IP65+) and match the strip’s voltage tolerance (±5%).

Compliance Verification: Confirm all components (strips, drivers, connectors) carry ETL or CE certification for the target market. Conduct a 24-hour water test post-installation (e.g., 30-minute submersion test for IP67) before final commissioning.

| Common Installation Issue | Root Cause | Technical Solution |

|---|---|---|

| Voltage drop (flickering) | Undersized wiring / long runs | Use parallel wiring; increase wire gauge to 16AWG; limit circuit length to 5m per segment |

| Moisture ingress | Poorly sealed connections | Apply silicone gel to all joints; use IP67-rated connectors; avoid soldering in exposed locations |

| Heat buildup | No heat dissipation | Install in aluminum channels; maintain 5mm clearance from non-conductive surfaces |

| Inconsistent brightness | Driver incompatibility | Use constant-current drivers rated for LED strips; verify input voltage stability (±0.5V) |

Beauty STC Manufacturing Co., Ltd. provides dedicated OEM engineering support for complex projects, including custom PCB designs, specialized encapsulation, and tailored electrical configurations. Our technical team collaborates directly with contractors to optimize designs for site-specific challenges—ensuring maximum reliability, compliance, and installation efficiency.

Contact for Technical Specifications & Project Support

[email protected] | +86 13902885704

Certified to ETL (USA/Canada), TÜV CE (Europe) | 25+ Years of Industrial Lighting Expertise

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Grade Water-Resistant LED Strip You Can Specify with Confidence

25 Years of Continuous Production, 50+ Countries of Field Proof

Since 1998 Beauty STC Lighting has supplied IP65–IP68 flexible LED strips to municipal, marine, façade and retail-fit-out projects on every continent—from Norwegian cruise terminals to Saudi petrol-station canopies. Our strips are still glowing after 15 000 h salt-mist test cycles; that is why specifiers in 50+ countries keep us on their AVL.

Western-Ready Certifications – No Site Delay, No Re-labelling

| Certification Scope | Standard & File No. | Application Market |

|---|---|---|

| North America | ETL/cETL to UL 2108 & UL 8750 | USA & Canada |

| Europe | TUV CE, EN 60598-2-20, EN 62031 | EU & UK |

| IP Rating | IEC 60529 IP65 / IP67 / IP68 | Global |

| Photobiological | IEC 62471 Exempt Group | All regions |

| RoHS/REACH | EU 2015/863 & SVHC | Environmental compliance |

OEM/ODM Volume Capacity – 1.2 Million Metres per Month

15 000 m² Jijiangmen HQ plant, 6 SMT lines (Yamaha & Juki), 4 extrusion silicone lines

24 h colour-over-coating, CCT tuning 1800–6500 K, CRI 80/90/95+, SDCM ≤2

Bin-on-reel service; 5 m, 10 m, 20 m continuous lengths, no solder joints outdoors

Private-label sleeve & 3-in-1 barcode packing ready for big-box DCs

Specification-Grade IP67 Strip at a Glance

| Parameter | Factory Data | Notes for Consultants |

|---|---|---|

| LED Type | 2835, 24 V, 120–240 LED/m | LM-80 ≥ 50 000 h @ 85 °C |

| Luminous Flux | 1100–2200 lm/m (3000 K) | 130 lm/W system efficacy |

| CCT / CRI | 2200–6500 K, CRI 90 typ. | 3 SDCM, MacAdam ellipse |

| Mechanical | 10 × 2 mm, 5 m max. run | Silicone extrusion, UV-stable |

| IP Rating | IP67 (IP68 optional) | -40 °C to +85 °C, IK06 |

| Warranty | 5 years | ETL/TUV listed driver match |

Next Step – Send the Project Schedule

Email your specification or Bill of Material to [email protected]. Our application engineers will return a compliant datasheet, MTBF calculation and landed-cost quotation within 24 h. For urgent calls: +86-13902885704 (English, Español, Русский).

Specify once, install anywhere—Beauty STC Lighting keeps the lights on, whatever the weather.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).