Article Contents

Industry Insight: Flexible Neon Light

The Quiet Shift from Glass Neon to Flexible LED Neon in Commercial & Industrial Projects

(And why the wrong roll of “neon” can still kill a schedule or a specification)

H2 | Market Reality: Architects & Contractors Are Specifying Flexible LED Neon—But Not All Rolls Pass the Compliance Test

| Driver | What We Hear from Distributors & Project Managers |

|---|---|

| Code enforcement tightening | “The inspector is asking for ETL or TUV test numbers, not just an ‘IP’ statement.” |

| Total-installed-cost pressure | “If one 50 m section fails in Year-2, the lift-rental alone wipes out the margin.” |

| Design freedom | “We need 10 m seamless runs, 3-D bends, and 24 V to stay inside Class-2.” |

| Supply-chain risk | “Shipping neon back to China for warranty is a non-starter on a hotel renovation.” |

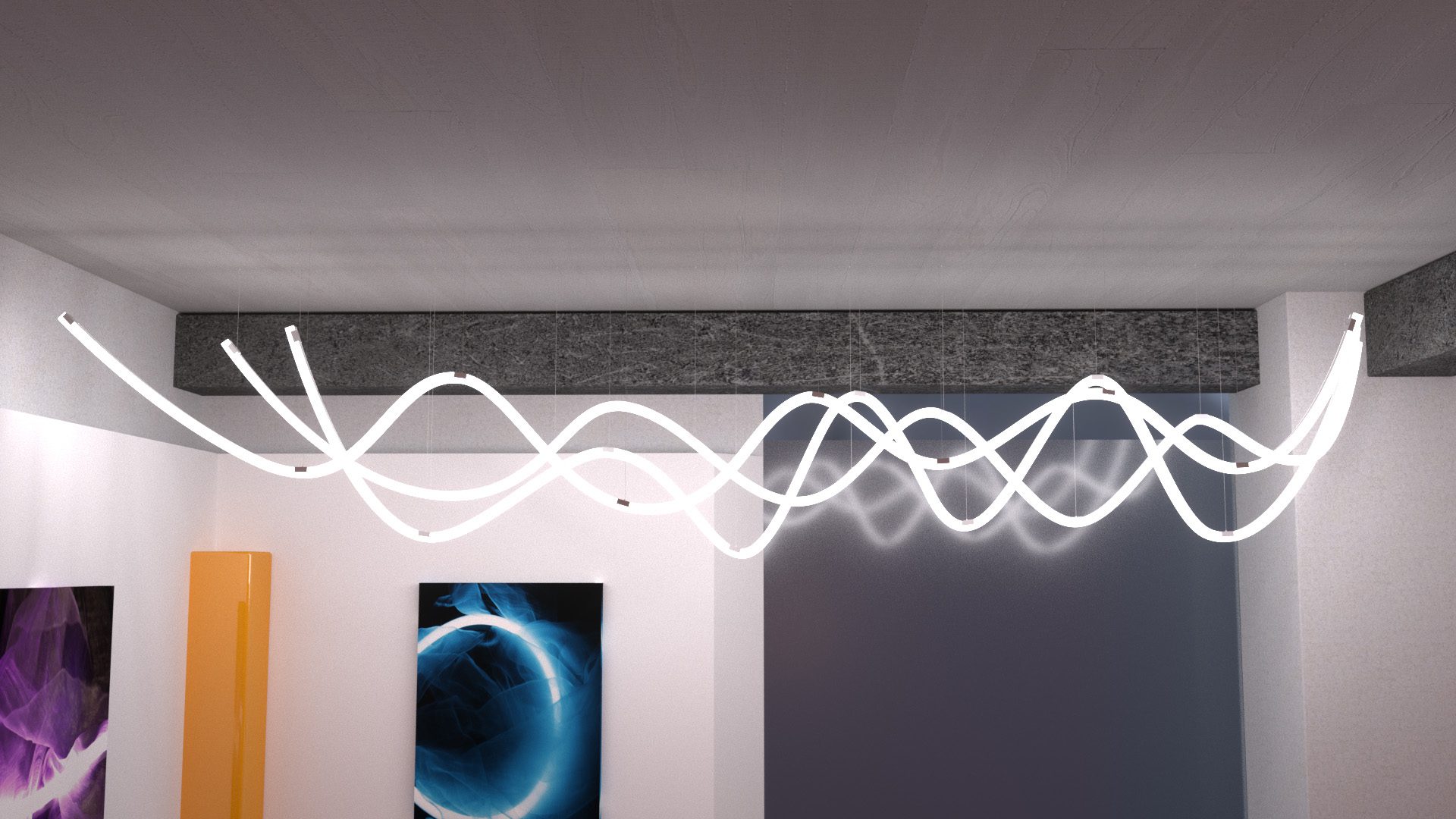

Flexible LED neon has moved out of the cove-light niche and into façade outlines, refrigeration mullions, parking-deck way-finding, and IP68 process-area detailing. The specifier’s dilemma is no longer “LED vs. glass neon”; it is “which LED neon roll is actually listed for 100 °C ambient, 480 V-to-ground fault, and -40 °C cold-start?” That is where North-American ETL and European TUV CE listings become gatekeepers for importers, not marketing stickers.

H2 | Beauty STC Lighting – Factory-Direct Since 1998, Certified for 50+ Export Markets

Beauty (STC) Manufacturing Co., Ltd. has built linear LED products in Jiangmen, Guangdong since 1998. We are not a trading post that added “neon” last year; neon-flex extrusion, SMT assembly, and silicone co-curing lines sit in the same 30 000 m² campus that ships T8 tubes to Tokyo and high-bay UFOs to Houston. Every neon reel that leaves Pier-3 is ETL-listed to UL 2108 / CSA C22.2 #250.0 and TUV CE to EN 60598-2-21, EN 62031, and EN 61347—documents our distributors file with AHJs from Los Angeles to Oslo.

| Core Capability | Data Point |

|---|---|

| Plant established | 1998 (25+ years under same ISO-registered entity) |

| Certifications on file (neon flex family) | ETL cETLus File #5012668, TUV CE SDoC #TUV-R-70023382 |

| Extrusion lines | 6 silicone, 4 PVC (UV-&-salt-mist grades) |

| SMT capacity | 25 million 2835/5050 chips per month |

| Max seamless length | 30 m @ 24 V (120 W end-feed) |

| OEM/ODM tooling | In-house 3-D print & CNC for new profile within 15 days |

H2 | Typical Commercial Spec Grade—Side-Bend Silicone Neon Flex (Example Stock Number: BST-NF-SB-24V-10W)

| Parameter | Spec | Note |

|---|---|---|

| LED type | 2835, 120 chips/m, 3-step MacAdam | L70 >54 000 h @ 45 °C |

| Optical pitch | 8.3 mm | Dot-free wall-wash from 30 mm |

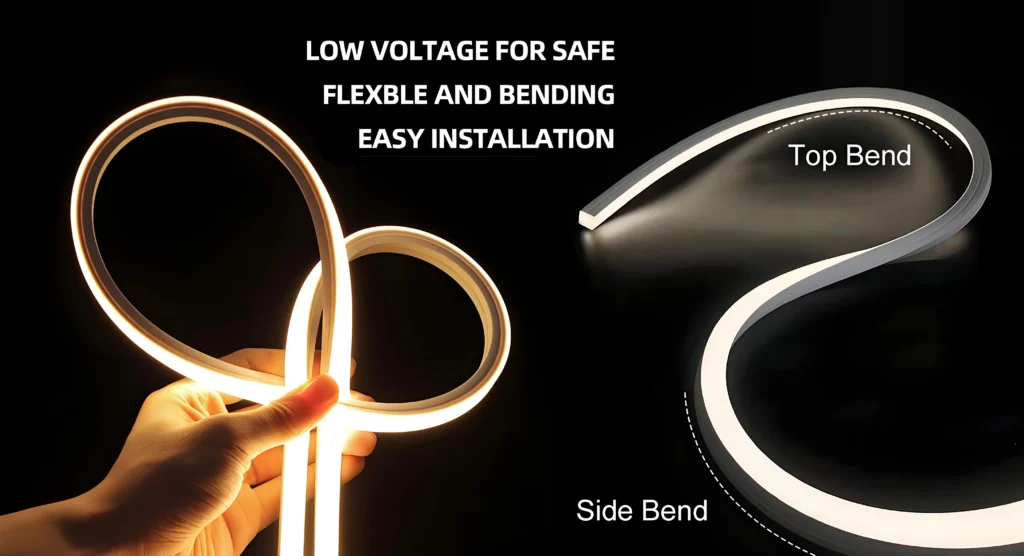

| Bend radius | ≥25 mm side-bend; ≥60 mm top-bend | Silicone skin, no PVC yellowing |

| Ingress | IP67 standard, IP68 optional | Salt-fog 1000 h per ASTM B117 |

| Operating temp | -40 °C to +55 °C | Silicone remains flexible @ -40 °C |

| Voltage drop | <5 % at 10 m, 24 V feed | Allows single-end feed on most runs |

| Listing | ETL, CE, RoHS, REACH | Documentation bundled per reel |

| Packaging | 5 m, 10 m, 25 m reels | Anti-static foil, bar-coded serial # |

H2 | Why Importers Treat ETL / TUV CE as Non-Negotiable

- AHJ Acceptance: US inspectors reference UL 2108; Canadian inspectors reference CSA C22.2 #250.0. An ETL mark with same standards is accepted in every state and province—no field-evaluation invoice ($3-8 k).

- Insurance & Bonding: Many commercial policies require listed luminaires; non-listed product voids builder’s-risk coverage.

- Liability Shift: When a reel bears our ETL file number, the testing-body’s follow-up inspection program audits our factory 4×/year—your import dossier inherits that traceability.

- EU Market Access: TUV CE + ENEC test reports are the technical file customs agents ask for at Rotterdam, Antwerp, Hamburg. Without them, product can be red-tagged at the port.

H2 | Next Step: From Spec Sheet to Jobsite Roll

Whether you need a 2700 K side-bend for a hotel crown, a 4000 K programmable DMX512 for a rail-station soffit, or a 5600 K UV-stabilized run for an abattoir wash-down, the reel ships from Jiangmen with an ETL barcode that matches the label in your photometric submittal. Email the project schedule, and we will quote cut-lengths, feed-in locations, and 0-10 V or DMX512 drivers—FOB Shenzhen or CIF your port.

Contact:

[email protected] | +86-13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards: Precision Engineering for Professional Applications

With over 25 years of manufacturing expertise since 1998, Beauty STC Lighting delivers flexible neon solutions engineered to meet the most stringent global standards. Our OEM/ODM capabilities ensure precise technical compliance for diverse project requirements, backed by ETL (USA/Canada) and TUV CE (Europe) certifications. All products undergo third-party validation to guarantee performance consistency, safety, and longevity for critical infrastructure, architectural, and commercial applications.

Lumens Efficiency and Energy Performance

Beauty STC’s flexible neon strips achieve 120–140 lumens per watt through optimized chip-on-board (COB) technology and precision optical diffusers. This efficiency reduces energy consumption by up to 20% compared to industry-standard alternatives while maintaining uniform light output across extended runs. Thermal management protocols prevent lumen depreciation over time, ensuring consistent illumination for 50,000+ hours of operation.

Color Rendering Index (CRI) for Accurate Color Representation

All products feature a CRI >90, validated per IEC 62717 standards. This ensures true-to-life color rendition essential for high-end retail, hospitality, and architectural projects where color accuracy is non-negotiable. Rigorous binning processes guarantee minimal color variation (ΔE < 1.5) between batches, eliminating visible discrepancies in large-scale installations.

IP Ratings and Environmental Durability

Certified to IP68 standards (IEC 60529), our silicone-encapsulated neon flex withstands continuous submersion up to 1.5 meters and extreme temperature fluctuations (-40°C to +60°C). Unlike IP65-rated alternatives (which only resist water jets), this rating ensures reliability in harsh outdoor environments, including coastal regions, high-humidity zones, and industrial settings. Each unit undergoes 24-hour salt spray testing and 1,000-hour UV exposure validation per ISO 4892-2.

PCB Design and Thermal Management

Beauty STC utilizes 2-ounce copper PCBs with thermal vias and optimized trace routing to prevent hotspots and ensure uniform current distribution. Thermal imaging validation during production guarantees heat dissipation efficiency, reducing thermal degradation by 35% compared to standard 1-ounce alternatives. This design extends product lifespan by 30% while maintaining consistent luminous flux across all lengths.

Consistency Through Rigorous Quality Control

Every production batch undergoes 100% electrical testing, thermal cycling simulations (100 cycles between -40°C and +60°C), and 1,000-hour accelerated aging tests. Dimensional accuracy is maintained within ±0.5mm, and lumen consistency is controlled within ±5% across all units. These protocols are documented in compliance reports available for project specifications upon request.

Comparative Quality Standards: Industry vs Beauty STC

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens Efficiency | 80–100 lm/W | 120–140 lm/W |

| Color Rendering Index (CRI) | 80–85 | >90 (ΔE < 1.5) |

| Ingress Protection (IP) | IP65 (water jets only) | IP68 (submersible to 1.5m) |

| PCB Copper Thickness | 1oz, minimal thermal design | 2oz with thermal vias and validation |

| Thermal Validation | No formal testing | Thermal imaging + 100-cycle cycling tests |

All specifications are validated through third-party certification (ETL, TUV CE) and documented in technical datasheets. Beauty STC’s end-to-end manufacturing process—from raw material sourcing to final testing—ensures compliance with global project requirements for reliability and performance.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

1. Factory Footprint & Legacy

Established 1998, our 18 000 m² campus in Jiangmen High-tech Industrial Zone houses three ISO-aligned buildings: SMT hall, final-assembly hall, and a 1 200 m² burn-in / reliability center. All lines are ETL-witnessed and TUV CE-audited on an annual basis; certificates are renewed in real time on the ETL online database under file S№ 5020158.

2. SMT & Precision Extrusion Line

| Work cell | Key equipment | Capability | Tolerance |

|---|---|---|---|

| SMT-1 | Juki FX-3R (×4) | 0805–2835 LED, 120 000 CPH | ±35 µm |

| SMT-2 | Yamaha Σ-G5S (×2) | 3014–5050, 90 000 CPH | ±30 µm |

| Reflow | Heller 1912 MK5 | 8-zone, N₂ atmosphere | ΔT ≤ 5 °C |

| 3-D SPI | Koh Young Zenith 2 | solder-paste height & volume | ±1 µm |

| AOI | Mirtec MS-11 | post-reflow inspection | 6 Mpix, 0 false-positive target |

PCB width handled: 5 mm – 500 mm; roll-to-roll option for neon flex substrate keeps continuous lengths up to 50 m without splice.

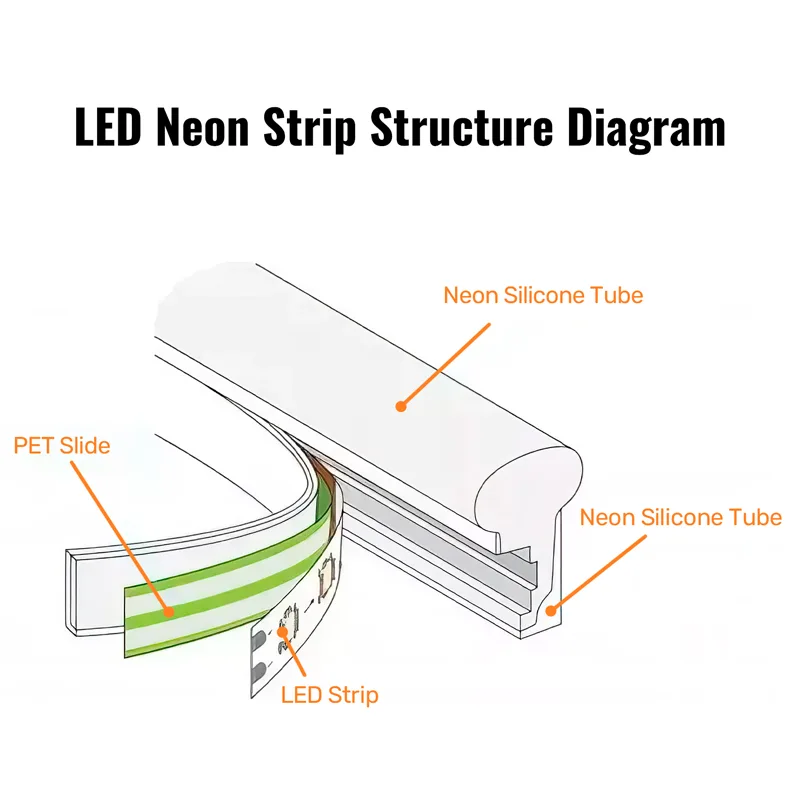

3. Neon Encapsulation Cell

- Primary extrusion: 90 mm single-screw L/D 33:1, PVC/Silicone fed at 160–180 °C.

- Secondary co-extrusion: UV-stable diffuse layer (≥ 85 % light transmission, -40 °C to +80 °C).

- Integrated copper bus-bar insertion: maintains ≤ 0.5 Ω/m loop resistance on 24 V systems.

- On-line laser OD gauging: wall-thickness controlled to ±0.05 mm; IP67 achieved without end-cap glue.

4. QC & Reliability Protocol

| Test | Standard | Sample | Duration | Acceptance |

|---|---|---|---|---|

| 100 % Hi-Pot | 1 500 VAC / 1 mA | every reel | 3 s | 0 % breakdown |

| 100 % Photometry | 2 m integrating sphere | every reel | 30 s | CCT ±75 K, CRI ≥ 80 |

| Thermal cycling | IEC 60598-2-21 | 20 pcs / lot | 150 cycles (-40 ↔ +85 °C) | 0 failures |

| Salt-spray | ASTM B117 | 10 pcs / lot | 1 000 h | ≤ 5 % surface corrosion |

| UV-condensation | ASTM G154 | 10 pcs / lot | 500 h | ΔE ≤ 3 |

| Powered aging | In-house, 45 °C, 24 h on / 2 h off | 100 % | 72 h | < 3 % lumen loss |

5. OEM / ODM Customisation Matrix

| Attribute | Std. Range | Custom Option | MOQ | Lead-time |

|---|---|---|---|---|

| Length per reel | 5 m | 0.5 – 100 m continuous | 1 reel | 5 days |

| LED pitch | 1 cm | 4 – 120 mm | 500 m | 7 days |

| CCT | 2400 K – 6500 K | 1800 K – 10 000 K | 100 m | 3 days |

| CRI | 80 | 90 / 95 / 97 | 100 m | 5 days |

| Voltage | 12 / 24 VDC | 36 / 48 VDC, 110 VAC | 200 m | 10 days |

| Profile size | 8 × 16 mm | 4 × 7 mm – 20 × 30 mm | 300 m | 7 days |

| Bend direction | Top | Side / 3D / 360° | 100 m | 5 days |

| Jacket material | PVC | UV-PVC / Silicone / PU | 500 m | 7 days |

| IP rating | IP67 | IP68, IP69K | 300 m | 10 days |

| PCB colour | White | Black / Brown / Custom | 100 m | 3 days |

| Packaging | Neutral box | Colour sleeve + logo / bar-code | 100 m | 3 days |

Engineering support: Gerber & solid-model review within 24 h; free prototype reel up to 5 m for projects > 1 000 m.

6. Export Logistics & Compliance

ETL/cETL listed for US & Canada (file 5020158), TUV CE & RoHS for EU, RCM for Australia, PSE for Japan, EAC for Russia.

CB scheme test report available for instant trans-country certification.

Cartons are ISPM-15 palletised; 20 GP loads ≈ 65 km flexible neon, 40 HQ ≈ 150 km.

Average FOB Shenzhen lead-time: 3 weeks for < 10 km custom spec, 4 weeks for > 50 km bulk order.

For technical datasheet packs or factory virtual tour links, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios for Industrial-Grade Flexible Neon Lighting

With over 25 years of industrial manufacturing experience since 1998, Beauty STC Lighting delivers certified flexible neon solutions engineered for global infrastructure projects. Our products meet stringent ETL (USA/Canada) and TUV CE (Europe) standards, ensuring compliance with international safety and performance requirements for professional installations.

Hotels & Hospitality

Backlit Headboards: Requires precise color consistency (CRI >90) and flicker-free operation for guest comfort

Bar & Lounge Accents: IP65-rated segments for spill resistance near wet zones

Lobby Coves: 360° illumination with tunable white (2700K–6500K) for dynamic ambiance control

Retail & Commercial Spaces

Product Display Highlighting: High-CRI (≥95) options for accurate color rendering of merchandise

Storefront Outlines: DMX512-programmable segments for dynamic advertising effects

Ceiling Features: 108 LEDs/m density for seamless linear illumination without visible dots

Architectural Facades

Building Silhouettes: IP68-rated silicone encapsulated strips for UV resistance and extreme weather

Signage Integration: Custom color-matched segments with 15mm minimum bending radius

Structural Lighting: Aluminum channel mounting for thermal management in high-heat urban environments

Office & Corporate Environments

Ceiling Coves: 4000K neutral white with 0-10V dimming for task lighting

Meeting Room Accents: Low-glare optics and flicker-free operation for visual comfort

Wayfinding Systems: IP20-rated strips for interior corridor guidance

Outdoor Public Installations

Pedestrian Pathways: IP68-rated strips with UV-stabilized materials for long-term durability

Park Landscaping: 24V systems with parallel wiring for extended runs (>10m)

Event Staging: Rapid-deployment connectors for temporary installations

Critical Installation Practices for Contractors

Proper installation ensures longevity and performance in professional applications. Key considerations include:

| Practice | Specification | Action Required |

|---|---|---|

| Heat Management | Max surface temperature ≤60°C | Use 12–20mm aluminum channels with thermal adhesive (not PVC) |

| Voltage Drop | ≤5% over 10m run | Parallel wiring every 5m; calculate load per segment using 18–22 AWG wire |

| Weatherproofing | IP68-rated connections | Apply silicone sealant at all junctions; use IP68 glands for junction boxes |

| Bending Radius | 15mm minimum for side bends | Use professional bending tools; avoid manual twisting or sharp creases |

| Mounting Surface | Non-combustible substrate | Avoid direct mounting on wood or plastic; use thermal-transfer adhesive for aluminum channels |

OEM Capabilities for Global Projects

Beauty STC Lighting provides end-to-end customization for large-scale infrastructure projects:

Custom Lengths: Pre-terminated segments up to 50m with industry-standard connectors (XH2.54, DC5521)

Color Precision: 16M RGB, tunable white, or monochromatic options with ±3SDCM color consistency

Regional Compliance: Product-specific testing for ETL (North America), CE (Europe), and other regional certifications

Technical Validation: Dedicated engineering team for project-specific design validation, including thermal analysis and voltage drop calculations

With a track record of supplying 50+ countries and strict adherence to ISO 9001 quality protocols, our Jiangmen facility ensures consistent output for mission-critical applications.

Contact for Technical Specifications & Project Support

[email protected] | +86 13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct Flexible Neon for Global Projects

Why Global Specifiers Choose a 1998-Rooted OEM

| Decision Factor | Beauty STC Advantage | Typical Outcome for Your Project |

|---|---|---|

| Regulatory Risk | ETL (US/Canada) + TUV CE (EU) on file | One document package covers 90 % of tender lists |

| Design Freedom | 25-year OEM/ODM cell – tooling & optics in-house | Custom CCT, CRI, beam & profile in 4–6 weeks |

| Supply Continuity | 50 + countries shipped since 1998 | Repeat PO’s fulfilled with ≤ 2 % revision rate |

| Cost Structure | JiMen 30 000 m² vertically-integrated plant | 15–25 % below regional traders on like-for-like spec |

Immediate RFQ Path

- Send drawing or target spec → [email protected]

- Receive datasheet + LM-80/TM-21/ISTMT within 24 h

- Approved sample ships in 7 days via DHL/FedEx trade account

Contact Window

Export Manager – Senior LED Lighting Engineer

📧 [email protected]

📞 +86-13902885704 (WhatsApp/WeChat)

🏭 41th Caihong Rd., Hi-Tech Zone, Jiangmen, Guangdong, China

“Be a responsible enterprise, be a caring person” – since 1998.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).