Article Contents

Industry Insight: Flat Led Light Strips

Industrial-Grade Flat LED Light Strips: Why Certification & Manufacturing Pedigree Matter in 2024

The Shift from “Strip Tape” to Engineered Linear Luminaires

Flat LED light strips have migrated from accent lighting to primary ambient and task layers in warehouses, clean rooms, retail boxes, and even food-processing plants. The driver is simple: a 24 V low-profile linear board can now deliver 1 100 lm/ft (3 600 lm/m) at 140 lm/W—figures that match a 4-ft T5HO but without mercury, ballast loss, or fixture bulk.

Yet the market is split into two supply chains:

| Channel Characteristic | Consumer “Tape” | Industrial Flat Strip |

|---|---|---|

| Typical Luminance | 200–400 lm/ft | 800–1 200 lm/ft |

| Test Protocol | Self-declared | ETL to UL 2108 + CSA 22.2 No. 250.0 |

| PCB Copper Wt. | 1 oz | 2 oz (min) 3 oz for ≥10 A |

| Binning & SDCM | 5-step MacAdam | 3-step, <3 SDCM |

| Operating Temp. | 0–40 °C | –30 °C to +60 °C |

| Warranty | 1 yr limited | 5 yr full-performance |

For importers, the right-hand column is the only one that satisfies code officials, insurers, and end-user RFPs. ETL (or UL) and CE (TUV) marks are therefore not “nice-to-have”—they are the gatekeepers to North-American and European tenders.

Certification Risk: What a Missing File Really Costs

A single missing LM-79 report or an incorrect UL rating can stall a $500 k roll-out for months. Customs may red-tag the shipment, but the bigger pain is downstream: once fixtures are installed, a failed field inspection triggers removal, re-labelling, and re-lamping—all at the distributor’s expense. Beauty (STC) keeps complete technical files (UL 1598 / UL 8750, EN 60598-2-20, RoHS, REACH, TM-21, ISTMT) under a controlled-document system so the paperwork is already on the inspector’s desk before the container hits the port.

Beauty STC Lighting – Factory Pedigree Since 1998

Located in Jiangmen’s National High-Tech Zone, our 28 000 m² campus has produced linear LED boards since the first 3528 SMD generation. Today we run six high-speed SMT lines (Yamaha & Juki) dedicated solely to strip products, giving us:

Monthly capacity: 1.2 million linear metres on 8-hour shifts

Copper-in-pool PCB up to 4 oz for 24 V constant-voltage runs ≤10 m with <5 % V-drop

In-house integrating-sphere lab (0.3 m to 2 m) calibrated to NVLAP—every reel ships with a bar-coded LM-79 report

Dual-certification line: ETL & TUV CE witnessed twice per quarter, not once per year

OEM/ODM Capability – Strip as a Building Block

Because we control the full stack—SMT, reflow, silicone extrusion, extruded-aluminium profile milling, and COB packaging—we can flatten the strip into whatever the project demands:

| Custom Parameter | Beauty STC Range | Typical Lead Time |

|---|---|---|

| Length | 50 mm – 50 m continuous | 7 days |

| Width | 4 mm – 28 mm | 5 days |

| CCT | 1 800 K – 10 000 K, Δuv ±0.003 | 3 days |

| CRI | Ra 70 – 97, R9≥90 (museum grade) | 5 days |

| Output | 200 – 1 400 lm/ft @ 24 V | 10 days |

| Profile | Flat, edge-lit, 45° bat-wing, 15° asymmetric | 12 days |

| IP Rating | IP20 – IP68 wet-location & NSF splash | 7 days |

| Control | 0-10 V, DALI-2, D4i, Tunable White, RGBW, RGBA | 14 days |

All variants ship with the same ETL/CB-scheme file package, eliminating re-submission costs for distributors.

Bottom Line

Flat LED light strips are no longer a commodity roll of tape; they are an engineered component that must carry third-party certification, documented thermal performance, and traceable binning. With 25 years of continuous operation and a UL & TUV witness-tested line, Beauty STC Lighting delivers industrial-grade linear platforms that install once and stay compliant for the full five-year warranty period.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Established in 1998, Beauty STC Lighting leverages over 25 years of manufacturing expertise to deliver LED strip solutions engineered for industrial and commercial applications. All products undergo rigorous certification testing for ETL (USA/Canada) and TÜV CE (Europe), ensuring compliance with regional regulatory requirements. Our OEM/ODM capabilities support custom configurations, including tailored PCB designs, specific IP ratings, and lumen output requirements, to match exact project specifications.

Comparative Quality Standards

Industrial lighting demands precise technical performance. The table below details key parameters where Beauty STC’s certified quality exceeds generic market alternatives:

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Luminous Efficacy | 80–100 lm/W | 120–140 lm/W (ETL/CE verified) |

| CRI (Ra) | 80–85 | >90 (CRI90+ for critical color accuracy) |

| PCB Copper Weight | 1oz (35µm) | 2oz+ (70µm+) for enhanced thermal dissipation |

| IP Rating Options | IP20 (indoor only) | IP20, IP65, IP67 (certified for wet/dusty environments) |

| Batch Consistency | ±10% variance in lumen output | ±3% variance with SPC monitoring |

| Certifications | Often incomplete or missing | Full ETL, TÜV CE, IEC 60598 compliance |

Consistency Through Rigorous Quality Control

Professional installations require uniform performance across large-scale deployments. Beauty STC maintains batch-to-batch precision through:

Automated SMT assembly lines with real-time defect detection

In-line photometric testing for lumen output, color temperature (CCT), and voltage tolerance

Statistical Process Control (SPC) tracking of critical parameters during production

100% final electrical and optical verification prior to packaging

Our quality protocols align with ISO 9001 principles, ensuring that every flat LED strip meets exacting industrial standards. This systematic approach eliminates common issues in generic products, such as inconsistent brightness, premature degradation, or thermal failure in high-density installations.

For detailed photometric data or project-specific technical validation, contact our engineering team at [email protected] or +86 13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Beauty (STC) Manufacturing Co., Ltd has operated from a single 28 000 m² campus in Jiangmen’s High-Tech Industrial Zone since 1998.

Every flat LED light strip that leaves our loading dock is built, aged and certified on-site—no subcontracted SMT or test cells.

Below is the routing we use for OEM/ODM programs that ship into ETL- or CE-regulated markets.

1. SMT & LED Placement Line

| Work cell | Key equipment | Typical spec window | Cert. reference |

|---|---|---|---|

| Solder-paste printer | DEK Horizon 03iX | 0.3 mm pitch, Pb-free SAC305 | IPC-J-STD-001 |

| Pick-and-place | Yamaha YSM-20R | 45 000 CPH, ±30 µm @ 3σ | — |

| Reflow | Vitronics Soltec XPM3 | 8-zone, N₂ atmosphere, ΔT ≤ 5 °C | IPC-A-610 |

| Optical inspection | Koh Young Zenith 2 | 15 µm resolution, closed-loop to SMT | IPC-9252 |

| Board input: 8–20 oz rolled-annealed copper, 1–4 oz Cu base for ≥ 24 V designs | |||

| LED binning: 3-step MacAdam ellipse, single reel per production lot to eliminate visible colour drift | |||

| Resistor network screened to ±1 % tolerance; maintains < 2 % flux drop from –40 °C to +90 °C junction |

2. Flat-Strip Build-Up & Mechanical Conversion

| Process | Capability | OEM notes |

|---|---|---|

| Extrusion | 180 °C PVC / 200 °C silicone, 5–25 mm width, 1.2–3.0 mm thick | Custom diffuser wall for dot-free optics |

| PCB slicing | CNC punch + V-cut, length tolerance ±0.5 mm | Any cut length 30 mm–5 000 mm |

| Lead-free wave (THT) | 250 °C pot, selective pallet | IP67 pigtails, AWG 18-22 |

| IP rating line | 2-component PU potting, vacuum chamber < 5 mbar | IP65–IP68 on request |

3. Aging & Reliability Protocol

| Test | Parameters | Duration | Acceptance |

|---|---|---|---|

| Burn-in | 25 °C, 1.05 × I-rated | 24 h | < 0.5 % dead LED |

| Thermal cycle | –40 ↔ +85 °C, 30 min dwell | 100 cycles | ΔL70 ≤ 5 % |

| Switch | 30 s ON / 30 s OFF | 5 000 cycles | No solder crack |

| Damp heat | 85 °C / 85 % RH | 1 000 h | L70 ≥ 94 % |

Data is logged via MES and attached to the barcode of every reel for traceability through ETL & TUV CE audits.

4. QC & Pre-Ship Inspection

- 100 % hi-pot: 1 500 Vac (Class II) / 4 000 Vac (Class I)

- 100 % flux & colour check on integrating-sphere system (Everfine ATA-500)

- AQL 0.65 Level II for carton drop, label accuracy, pull-test on connectors

- Photometric report (.ies/.ldt) and TM-30 data included in OEM dossier

5. OEM / ODM Configuration Matrix

| Attribute | Standard menu | Custom range | MOQ | Lead-time |

|---|---|---|---|---|

| Length | 5 m reel | 0.03–100 m continuous | 500 m | 10–12 days |

| Width | 10 mm | 5–25 mm | 1 000 m | 10 days |

| CCT | 2 700 K / 3 000 K / 4 000 K / 6 500 K | 1 800–10 000 K | 500 m | 7 days |

| CRI | 80 | 90, 95, Thrive 98 | 500 m | 7 days |

| Luminous flux | 600 lm/m @ 4.8 W | Up to 3 000 lm/m | 500 m | 12 days |

| Voltage | 24 Vdc | 12 V, 36 V, 48 V, 110 Vac, 230 Vac | 1 000 m | 14 days |

| PCB colour | White | Black, brown, custom mask | 1 000 m | 5 days |

| Packaging | Neutral brown box | Colour sleeve, private-label, barcode, QR | 500 pcs | 5 days |

Engineering package supplied:

STEP / DWG extrusion profiles

LM-80 & ISTMT for chosen LED package

Driver compatibility sheet (constant-voltage vs. constant-current)

Installation guide in 6 languages (EN, DE, FR, ES, IT, NL)

6. Compliance & Documentation

ETL listed to UL 2108 & CSA C22.2 #250.0 for 12–60 Vdc strips

TUV CE mark: EN 60598-1, EN 60598-2-20, EN 55015, EN 61000-3-2, EN 62368-1

RoHS & REACH declarations updated quarterly; SCIP database UUID on file

CB scheme certificate for 50 Hz/60 Hz markets, file No. CN-104555-ET

All certificates are downloadable 24/7 from our technical portal; originals ship with first container of every new OEM part number.

7. Logistics Snapshot

| Port | FOB option | Transit to LA | Transit to Rotterdam | Carton spec |

|---|---|---|---|---|

| Jiangmen (Shenzhen feeder) | 40 HC | 14 days | 26 days | 48 × 38 × 28 cm, 10 kg, 10 reels |

| Zhongshan (direct) | 40 HC | 13 days | 25 days | — |

Export papers: Bill of Lading, Form A (for Russia), COO, fumigation-free plywood pallet.

Next Step for Specifiers & Contractors

Send project lengths, CCT, IP rating and target lm/m to [email protected].

Our engineering team will return a datasheet, dialux file and 48-h sample quotation—fully aligned with the same ETL/TUV production line described above.

Installation & Application Scenarios

Application Scenarios for Flat LED Strip Lights

Flat LED strip lights offer versatile, high-performance illumination for diverse professional environments. Their slim profile, uniform light distribution, and robust engineering make them ideal for applications demanding precision, durability, and compliance with international standards. As a manufacturer with 25+ years of experience (established 1998) and ETL (USA/Canada) and TUV CE (Europe) certifications, Beauty STC Lighting delivers factory-direct solutions engineered for global project requirements.

Commercial Interiors & Retail Spaces

In retail and office environments, flat LED strips provide glare-free, energy-efficient illumination that enhances visual clarity and brand aesthetics. High CRI (90+) options ensure accurate color rendering for merchandise displays, while recessed or cove installations create seamless ambient lighting without disrupting architectural integrity.

Key installation considerations:

Use aluminum extrusion channels for heat dissipation and to maintain consistent lumen output over extended runs.

For installations exceeding 5 meters, calculate voltage drop using the formula:

$ \text{Voltage Drop} = \frac{\text{Current (A)} \times \text{Length (m)} \times \text{Resistance (Ω/m)}}{1000} $

Implement mid-point power injection where necessary to avoid dimming.

Integrate dimmable drivers compatible with DALI or 0-10V control systems for dynamic lighting scenarios.

Hospitality & Luxury Environments

Hotels, fine dining establishments, and upscale venues require lighting that complements sophisticated design while ensuring reliability. Flat LED strips deliver shadow-free illumination for cove lighting, under-bar accents, and feature walls, with customizable color temperatures (2700K–4000K) to match brand-specific ambiance.

Critical installation practices:

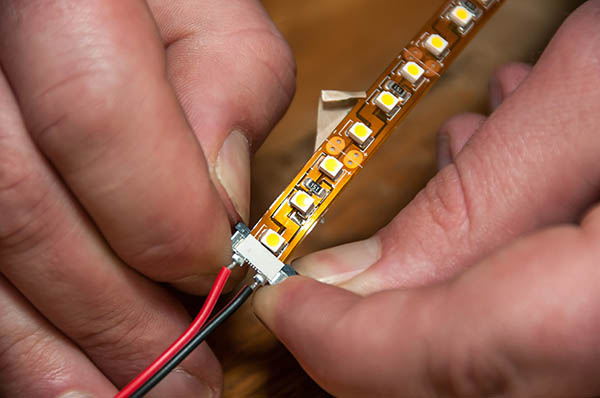

Precision-cut strips with pre-soldered connectors to eliminate visible joints in high-visibility areas.

Use dimmable drivers with 1–100% smooth dimming curves and compatibility with hotel management systems (e.g., Lutron, Crestron).

Ensure all components support 100% continuous load operation per hospitality industry standards for 24/7 reliability.

Architectural Facades & Exterior Applications

For building exteriors, bridges, or signage, IP67-rated flat LED strips provide weather-resistant illumination that withstands UV exposure, moisture, and thermal cycling. The slim profile enables discreet integration into architectural details while maintaining high visual impact.

Essential installation guidelines:

Secure strips using stainless steel mounting clips or adhesive-backed channels to resist wind load and thermal expansion.

Seal all electrical connections with silicone-filled waterproof junction boxes rated IP68.

Verify compliance with local electrical codes (e.g., NEC Article 411 for low-voltage systems); our ETL/TUV CE certifications guarantee adherence to international safety requirements.

Industrial & Functional Spaces

Warehouses, manufacturing facilities, and parking garages demand high-output, durable lighting for safety-critical tasks. Industrial-grade flat LED strips (1019+ lumens per foot) provide uniform illumination in tight spaces, with robust construction to withstand dust, vibration, and temperature extremes.

Technical installation requirements:

Mount strips within aluminum channels to enhance thermal management and physical protection.

Size power supplies to operate at ≤80% of maximum capacity (e.g., 24V/10A supply for ≤240W of strip load).

Ensure grounding and circuit protection per OSHA 1910.303 and NFPA 70 standards.

Technical Specifications Overview

| Parameter | Standard Range | Certification Compliance | OEM Customization |

|---|---|---|---|

| Luminous Flux | 1000–1500 lm/m | ETL (USA/Canada), TUV CE (Europe) | Adjustable per project requirements |

| CRI | 80+ (Standard), 90+ (Premium) | – | Available upon request |

| IP Rating | IP20 (Indoor), IP65/IP67 (Outdoor) | Certified for wet/damp locations | Custom ratings for specialized environments |

| Power Consumption | 10–20 W/m | – | Tailored for specific wattage needs |

| Color Temperature | 2700K–6500K | – | Full spectrum options available |

| Length Options | 1m standard, up to 100m continuous | – | Custom lengths from 1cm to 100m |

Beauty STC Lighting leverages 25+ years of engineering expertise and global certification compliance to deliver turnkey LED solutions for demanding commercial and industrial projects. Our OEM/ODM capabilities enable precise customization of electrical parameters, mechanical dimensions, and environmental ratings to meet exacting project specifications. All products are manufactured in our ISO-certified Jiangmen facility (41st Caihong Road, Jianghai District, Guangdong, China), ensuring consistent quality control from design to delivery.

Contact us for technical support and project-specific engineering:

[email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Flat LED Strip Engineering & Export Since 1998

Factory-Certified for North America & Europe

| Certification Body | Standard | Scope | File Reference |

|---|---|---|---|

| ETL (Intertek) | UL 2108 / CSA C22.2 No. 250.0 | Flexible LED Strip, Class 2, Dry/Damp | 5002201 |

| TÜV | EN 60598-2-20, CE-EMC & LVD | Flat strip & modular system | 44 21 170503 |

No re-testing, no customs delays—ship directly into US, Canada, EU projects.

25-Year OEM/ODM Track Record

1998 – first SMT line installed, still operating 24/7 at Jiangmen HQ

50+ countries on export manifest: Germany, USA, UAE, Australia, Korea, Brazil

Monthly capacity: 1.2 million metres SMD strip, 6000 m² dust-free workshop

Engineering team: 23 LED application engineers, 5 LM-80 & TM-21 specialists

Industrial-Grade Flat Strip Platform (Ex-Stock or Custom)

| Parameter | Standard Range | OEM Option |

|---|---|---|

| Width × Height | 8 × 1.4 mm | 5 – 25 mm × 0.6 – 3 mm |

| LED pitch | 60 LED/m | 30 – 240 LED/m, dot-free optics |

| CCT | 2700 – 6500 K | 1800 – 7500 K, 3- & 5-step MacAdam |

| CRI | Ra 80 | Ra 90 / 95, R9>50, TM-30 ready |

| Flux @ 4000 K | 1100 lm/m (14.4 W) | up to 2800 lm/m (28.8 W) |

| Binning | 3 SDCM | 2 SDCM, single bin shipment |

| Operating temp | –30 °C to +60 °C | –40 °C to +85 °C (automotive grade) |

| PCB copper | 2 oz, double layer | 3 – 4 oz, thermal vias, Al-core |

| IP rating | IP20 | IP65/IP67/IP68 silicone extrusion |

| Compliance | RoHS, REACH, Prop-65 | WEEE take-back, UL AWM style 21198 |

Why Contractors & Distributors Specify Beauty STC

- One-file submittal—ETL & CE test reports, IES files, LM-80 data, BIS, RoHS.

- 24 h quotation for custom lengths, connectors, constant-current boards.

- Door-to-door logistics—FOB Shenzhen, CIF DDP to 50+ countries, weekly consolidation.

- 5-year limited warranty, <0.2 % field return rate since 2017.

Next Step—Engineering Sample or Project Quote

Email technical drawings, lengths, and luminous requirements to:

[email protected] (English, Español, Русский)

Mob/WhatsApp: +86-13902885704

We will return a full datasheet, dialux layout, and landed price within 12 hours.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).