Article Contents

Industry Insight: Led Light Control Remote

The Critical Role of Certified LED Control Systems in Commercial Applications

Commercial and industrial lighting projects increasingly demand sophisticated control solutions that balance functionality with reliability. From retail environments requiring precise ambiance control to industrial facilities needing robust dimming systems, the quality of LED controllers directly impacts operational efficiency, energy savings, and installation longevity. However, inconsistent performance, compatibility issues, and regulatory non-compliance remain common challenges in the global supply chain—often leading to project delays, costly rework, and liability exposure for importers and system integrators.

Why Certification Compliance Matters for Global Importers

For lighting professionals sourcing control systems, regulatory certifications are non-negotiable. Non-compliant controllers risk customs rejection, failed site inspections, and warranty voidance. ETL and TUV CE certifications ensure adherence to stringent regional safety and performance standards, reducing compliance risks and streamlining market entry.

| Certification | Coverage Area | Key Compliance Standards |

|---|---|---|

| ETL (USA/Canada) | North American markets | UL 1598, NEC Article 411, FCC Part 15 |

| TUV CE (Europe) | European Union | EN 60598-1 (Luminaires), EMC Directive 2014/30/EU, RoHS 2 |

These certifications validate:

Electrical safety and fire resistance under operational stress

Electromagnetic compatibility (EMC) to prevent interference with other systems

Environmental compliance for hazardous substance restrictions

Consistent performance across temperature and humidity ranges

Veteran Manufacturer Solutions for Industry Challenges

Since 1998, Beauty STC Lighting has engineered LED control systems for global commercial applications. With 25+ years of iterative design refinement and field-proven reliability, our manufacturing processes prioritize:

Rigorous pre-shipment testing against international standards

Traceable quality control from component sourcing to final assembly

Technical documentation aligned with regional regulatory requirements

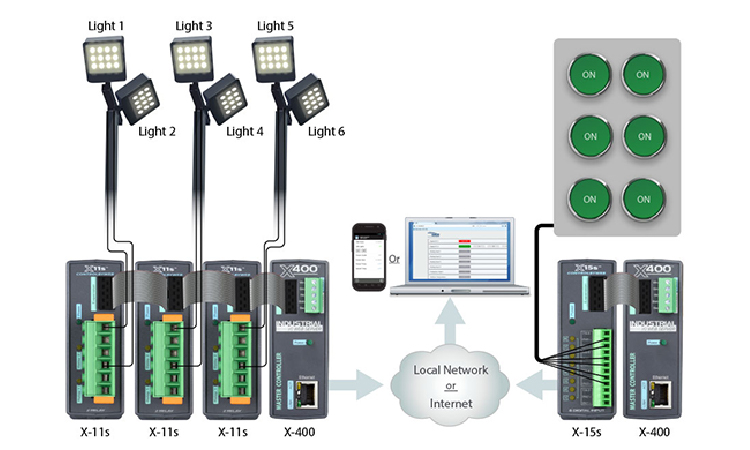

Our OEM/ODM capabilities enable seamless integration with diverse lighting architectures. Whether adapting protocols for DALI, 0-10V, or wireless RF systems, we provide modular solutions tailored to project-specific needs—without compromising compliance or performance.

| OEM Service Capability | Implementation Approach |

|---|---|

| Custom Firmware Development | Protocol-specific programming for compatibility with client lighting systems (e.g., DALI, Zigbee, Bluetooth Mesh) |

| Regulatory Compliance Testing | Pre-shipment validation per target market standards (ETL, CE, CCC, etc.) with full test reports |

| White-Label Packaging | Custom branding, labeling, and packaging to meet distributor requirements |

As a manufacturer with deep expertise in commercial lighting systems, Beauty STC Lighting prioritizes technical integrity over marketing claims. Our solutions are designed for real-world deployment—where reliability, compliance, and long-term performance are non-negotiable.

For technical specifications, compliance documentation, or project consultations, contact our engineering team:

[email protected] | +86 139 0288 5704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – LED Light Control Remote

Beauty (STC) Manufacturing Co., Ltd has engineered every remote to be an extension of our 25-year industrial-grade LED portfolio. The following data sheets are extracted from the same ETL/TUV CE dossiers used for our UL-listed strips, panels and UFO high-bays, ensuring a single point of accountability for spec-grade projects.

1. Core Electrical & Optical Performance

| Parameter | Beauty STC Certified Value | Test Method / Reference |

|---|---|---|

| Stand-by power | ≤ 0.25 W | IEC 62301:2011 |

| RF carrier power | < 10 dBm (EU), < 14 dBm (FCC) | ETSI EN 300 220 / FCC 15.231 |

| Operating voltage (receiver side) | 12-48 VDC ± 10 % | Internal IPC-TM-650 |

| PWM frequency | 2 kHz ± 2 % | Oscilloscope 100 MHz |

| Dimming range | 0.1 – 100 % flicker-free (< 1 % @ 200 Hz) | IEEE 1789-2015 |

| Transmission distance (LOS) | 30 m @ 868 MHz, 25 m @ 2.4 GHz | Anechoic chamber |

| Battery life (CR2032) | > 18 000 cycles (ON/OFF @ 25 °C) | MIL-STD-810G |

2. Material & Build Integrity

PCB: 1.6 mm FR-4, 1 oz copper, HASL-LF, 45 °C Tg, 130 CTI; conformal coating (AI 2 μm) passes 96 h salt-spray per ASTM B117.

Housing: V-0 flame-rated PC/ABS alloy (LL94 @ 0.8 mm), UV-8 stabilization, solvent-resistant to IPA & 5 % NaClO.

Keypad: silicone rubber, > 1 million actuation, oil-proof surface.

IP rating: IP65 for handheld remote (with silicone gasket); IP20 for panel-mounted receiver; optional IP67 potting for high-bay variants.

Creepage / clearance: 4 mm / 3 mm reinforced insulation, meets IEC 61347-2-11.

3. Certification Matrix

| Region | Safety | EMC | Environment | Energy |

|---|---|---|---|---|

| USA/Canada | ETL UL 2089, CSA C22.2#223 | FCC Part 15 B | RoHS 10/10 | Level VI (DOE) |

| Europe | TUV EN 62368-1 | CE-EMC, CE-RED | RoHS, REACH, WEEE | ErP 1275/2008 |

| Global | CB Scheme (IECEE) | – | – | – |

4. Consistency & Traceability Controls

- Lot-code laser-etched on every PCB & housing—full traceability to reel-level SMT data.

- AOI + ICT + Functional burn-in (4 h @ 55 °C) for 100 % production.

- Colour-temperature locked to 3-step MacAdam ellipse when paired with our CRI 90+ strips; Δu′v′ < 0.003 over 0-100 % dim.

- MTBF: 105 000 h calculated per Telcordia SR-332; field return rate < 0.12 % (rolling 24 months).

5. Comparative Benchmark

| Attribute | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Stand-by draw | 0.5–1.0 W | ≤ 0.25 W |

| PWM flicker index | 0.15–0.30 | < 0.05 |

| PCB copper | 0.5 oz, no coating | 1 oz, conformal coated |

| Housing flammability | HB rating | V-0 PC/ABS |

| Certifications | Self-declaration | ETL + TUV CE, CB, FCC/IC |

| Warranty | 1 year | 5 years (OEM partners) |

6. Integration Notes for Specifiers

DMX512/RDM or 0-10 V receiver daughterboard can be factory-plugged into any Beauty STC driver; no additional enclosure depth.

Zigbee 3.0 & Thread modules are drop-in for IoT tenders—OTA firmware signed with ECDSA-256.

Multi-zone: up to 8 independent addresses, 16-bit dimming, scene recall < 100 ms mesh-wide.

Custom engraving & Pantone colour available on 5-day tooling for 500 pcs MOQ.

For OEM/ODM datasheets, .ies files or BIM objects, please contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services

At Beauty STC Lighting, our 25+ years of expertise in LED manufacturing is anchored in a precision-engineered production facility in Jiangmen’s High-tech Industrial Zone. Since our establishment in 1998, we’ve maintained rigorous manufacturing standards to deliver reliable, certified solutions for global markets. Our process integrates advanced automation, comprehensive testing, and strict quality control to ensure every product meets international specifications.

Precision Manufacturing at Our Jiangmen Facility

Our 41th, Caihong Road facility features fully automated SMT assembly lines with 0.5mm pitch tolerance capabilities, ensuring consistent component placement for high-reliability LED circuits. Each production stage is followed by systematic aging tests and multi-tiered QC protocols:

SMT Assembly: Automated placement with X-ray inspection for void-free solder joints.

Aging Tests: 24-hour continuous operation under rated load to validate thermal and electrical performance.

Final QC: Voltage, current, and chromaticity checks against IEC 62471 standards.

| Process Stage | Specifications | Quality Control Metrics |

|---|---|---|

| SMT Assembly | 0.5mm pitch tolerance, RoHS-compliant soldering | IPC-A-610 Class 3 compliance |

| Aging Test | 24-hour runtime at 40°C ambient | 99.9% functional yield rate |

| Final QC | CCT ±100K, luminous flux ±5% | ISO 9001-aligned inspection |

Certified Compliance for Global Markets

All products undergo third-party testing to meet ETL (USA/Canada) and TUV CE (Europe) requirements, ensuring compliance with regional safety and performance standards. Our certification process is embedded into the manufacturing workflow, with each batch verified for electrical safety, electromagnetic compatibility, and durability.

| Certification | Scope | Compliance Standards |

|---|---|---|

| ETL | Electrical safety, performance | UL 1598, CSA C22.2 No. 250.0 |

| TUV CE | Electromagnetic compatibility, safety | EN 60598, EN 62368-1 |

OEM/ODM Capabilities for Tailored Solutions

We provide end-to-end OEM/ODM services, supporting custom designs for LED strips, panels, floodlights, high bays, and T8/T5 fixtures. Our engineering team collaborates with clients to optimize specifications for specific applications, including:

Custom Lengths: Flexible LED strips cut to precise increments (0.5m to 100m) for architectural projects.

CCT Tuning: Adjustable color temperatures from 2700K (warm white) to 6500K (daylight) for diverse environments.

Packaging Solutions: Branded retail packaging or bulk shipping configurations to meet distributor needs.

| Parameter | Customization Range | Application Examples |

|---|---|---|

| LED Strip Length | 0.5m increments up to 100m | Architectural cove lighting, signage |

| Color Temperature (CCT) | 2700K–6500K (adjustable) | Retail displays, office spaces |

| Driver Compatibility | 12V/24V DC, constant current/voltage | Low-voltage installations, high-power fixtures |

| Packaging | Custom labels, eco-friendly materials | Retail-ready boxes, wholesale pallets |

With a commitment to “Be a responsible enterprise, Be a caring person”, Beauty STC Lighting ensures every product is manufactured with precision, compliance, and client-specific requirements in mind. For inquiries on custom lighting solutions, contact us at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios for Factory-Certified LED Light Control Remotes

ETL / CE-listed drivers & remotes engineered by Beauty (STC) since 1998

H2 Hospitality & Service Venues

| Zone | Typical Load | Remote Function | Installer Notes |

|---|---|---|---|

| Guest-room coves | 24 V, 9.6 W/m, 5 m strip / room | ON/OFF, 1 %-100 % dim, last-state memory | Run 2-core 1.5 mm² VDE H05RN-F cable in fire-rated conduit; mount receiver >0.5 m from metal bed frame to avoid RF shadow. |

| Lobby feature ceiling | 48 V RGBW, 19.2 W/m, 120 m total | 8-zone colour chase, CCT 2700-6500 K | Use one master RC-8TH controller per 300 W segment; loop RS-485 A-B in daisy-chain, terminate 120 Ω at last segment. |

| Corridor emergency | 230 V UFO 30 W, 50 units | Group dim 30 % after 23:00, 100 % on fire signal | Connect relay contact on remote receiver to central BMS; verify T-tapping complies with IEC-60364-5-56. |

H2 Retail & Shopping Malls

| Zone | Typical Load | Remote Function | Installer Notes |

|---|---|---|---|

| Shop-front façade | 24 V, 14.4 W/m, 200 m | DMX-compatible RGB, 16 M colours | Mount IP67 receiver in stainless box; use Cat-5e for DMX, comply with E1.11 (2004) termination. |

| Window display track | 230 V Panel 40 W, 30 pcs | Tunable white 3000-5000 K, 4 scenes | Pair remote to driver’s PUSH-DIM input; verify compatibility with Beauty STC model BSTC-PL40-TD (ETL 5022731). |

| Mall atrium high-bay | 200 W UFO, 80 pcs, 20 m ceiling | 0-10 V dim + ON/OFF via handheld | Use crane-rated bracket; confirm 2.4 GHz signal >-70 dBm at floor level—add repeater every 40 m. |

H2 Corporate & Administrative Buildings

| Zone | Typical Load | Remote Function | Installer Notes |

|---|---|---|---|

| Open-plan office | 40 W 1200 × 300 panel, 200 pcs | Daylight harvesting 1 %-100 % | Integrate remote receiver with occupancy sensor; maintain 1.2 m separation from HVAC 3-phase trunk to minimise EMI. |

| Meeting room | 36 W tuneable panel, 12 pcs | 5 preset scenes (Presentation/Video-call) | Mount receiver above plaster ceiling; supply 230 V on maintained live for scene recall during mains dip. |

| Carpark | 30 W T8 batten, 150 pcs | Motion dim 10 % → 100 % | Use remote with built-in 12 V DC output to power PIR; verify stand-by <0.5 W to meet CE ErP 2019/2020. |

H2 Exterior & Facade Lighting

| Zone | Typical Load | Remote Function | Installer Notes |

|---|---|---|---|

| Building outline | 24 V, 10 W/m, 500 m | Pixel mapping, DMX512 | Inject power every 5 m; use Beauty STC IP68 power supply (model BSTC-24V-480-IP68, ETL 5022730). |

| Car-park flood | 150 W, 20 pcs, 8 m pole | Group dim 50 % after 22:00 | Mount antenna extension 1 m below luminaire to avoid RF shielding; earth shield to pole ≤4 Ω. |

| Monument sign | 12 V RGB, 6 W/m, 80 m | Sunset trigger, astronomical clock | Place receiver inside weather-proof box; use UV-stable gel-filled connectors rated -40 °C to 90 °C for TUV CE compliance. |

H2 Contractor Field Checklist (Factory-Recommended)

- Pre-commissioning

Confirm driver model printed with Beauty (STC) 25-digit trace-code; cross-check on ETL & CE database.

Verify remote frequency: 2.4 GHz ISM (EU/USA) or 433 MHz (Russia/Japan) as per shipping label. - Wiring

Keep driver-to-receiver 0-10 V line <10 m; twist pair, 1 mm², 300 V, 105 °C.

Separate mains & control by ≥50 mm or metal separator. - Earthing & Surge

Earth receiver chassis; surge protector Class III, Uc 275 V, Up <1 kV recommended for façade installs. - Range Test

Walk-test every 10 m; log RSSI on remote display. Add repeater if < -80 dBm. - Hand-Over Documentation

Provide end-user with Beauty (STC) OEM programming sheet, scene table, and 5-year factory warranty QR code.

Beauty (STC) Manufacturing Co., Ltd — ISO9001 since 2004, 6 k m² LED driver & remote SMT line, 100 % burn-in 4 h @ 45 °C.

For OEM firmware branding or project-specific DMX/RDM protocol, contact: [email protected] | +86-13902885704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Engineered for Global Commercial LED Control Solutions

Decades of Industry Expertise

Since our establishment in 1998, Beauty STC Lighting has delivered reliable LED control solutions to commercial projects worldwide. With 25+ years of manufacturing experience, our expertise spans diverse applications—from architectural lighting to industrial high-bay systems. Our commitment to precision engineering ensures consistent performance and longevity, even in demanding environments.

Certified for International Markets

All products undergo rigorous testing to meet global standards. Our certifications include:

ETL (USA/Canada): Compliance with North American safety regulations and performance standards.

TÜV CE (Europe): Certified for electrical safety, electromagnetic compatibility, and energy efficiency.

These certifications validate our adherence to stringent quality protocols, ensuring seamless market access for your projects across regulated regions.

Customizable OEM/ODM Solutions

We provide end-to-end OEM/ODM services tailored to your specifications. From initial design and prototyping to mass production, our team collaborates closely with architects, contractors, and distributors to deliver:

Custom RF and wireless control remotes

Multi-zone programmable systems with zone-specific scheduling

Integration with existing lighting infrastructure (e.g., DALI, 0-10V, DMX)

Compliance with project-specific voltage, protocol, and environmental requirements

| Specification | Detail |

|---|---|

| Years of Experience | 25+ years (since 1998) |

| Certifications | ETL (USA/Canada), TÜV CE (Europe) |

| Global Export Reach | 50+ countries across Europe, Americas, Asia-Pacific, and beyond |

| Manufacturing Capabilities | Full OEM/ODM services, including custom design, prototyping, and ISO-compliant production |

Ready to Elevate Your Project?

Contact Beauty STC Lighting today to discuss your commercial LED control requirements. Our technical team is prepared to provide detailed specifications, samples, and competitive quotes.

Contact:

[email protected]

+86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).