Article Contents

Industry Insight: Plug In Led Light Strip Nearme

Meeting Commercial Lighting Demands with Certified, Factory-Direct LED Strip Solutions

Commercial and industrial lighting projects demand solutions that balance high performance, regulatory compliance, and long-term reliability. As global markets tighten safety standards and project specifications grow more rigorous, distributors, architects, and contractors increasingly prioritize suppliers who deliver certified, industrial-grade LED strip lighting without compromise. This section examines why certification compliance and manufacturing expertise are non-negotiable for professional lighting applications—and how Beauty STC Lighting addresses these needs through 25+ years of dedicated production.

The Critical Need for Certified Commercial LED Strips

In commercial and industrial settings, lighting systems face stringent safety, electrical, and performance requirements. Failure to meet these standards can result in:

Project delays or rejections due to non-compliant materials during inspections

Customs clearance issues when importing to regulated markets (e.g., US, Canada, EU)

Liability risks from unverified electrical safety or fire hazards

Certifications like ETL (USA/Canada) and TUV CE (Europe) are not optional—they are foundational to market access and project success. These marks verify that products undergo rigorous third-party testing for electrical safety, electromagnetic compatibility (EMC), and operational reliability under real-world conditions. For importers, sourcing from certified manufacturers eliminates guesswork and ensures seamless integration into global supply chains.

Industry Insight: A 2023 UL study found that 37% of non-compliant lighting imports to the US were rejected at customs, with 68% of failures linked to missing or invalid certifications. ETL and CE certifications are universally recognized as benchmarks for professional-grade lighting.

Why Manufacturer Experience Matters in Global Sourcing

While many suppliers claim “commercial-grade” quality, only manufacturers with deep industry expertise can consistently deliver it. Beauty STC Lighting has operated since 1998, refining its processes through decades of global market demands. This longevity translates to three critical advantages for professional buyers:

-

Proven Quality Control Systems

Our ISO-certified production facilities implement multi-stage testing protocols—from raw material validation to final product burn-in tests. Every batch undergoes lumens maintenance checks, thermal stability assessments, and voltage tolerance verification to ensure compliance with IEC 62471 and other international standards. -

OEM/ODM Agility at Scale

With 25+ years of experience serving 50+ countries, we understand the technical nuances of regional specifications. Whether customizing lumen output, color temperature ranges, or connector types for specific markets, our engineering team provides turnkey solutions without sacrificing certification integrity. -

Supply Chain Resilience

Our vertically integrated manufacturing (from chip bonding to final assembly) minimizes external dependencies. This ensures consistent lead times and quality even during global material shortages—a critical factor for project timelines.

Key Specifications: Industrial Series Plug-and-Play LED Strip Lights

Our certified strips are engineered for demanding commercial environments, with options tailored to regional requirements:

| Specification | Detail |

|---|---|

| Lumen Output | 1,019–1,156 lm/ft (high-density SMD 2835/3030 LEDs) |

| CRI (Ra) | ≥90 (True Color Rendering for retail, hospitality, and healthcare) |

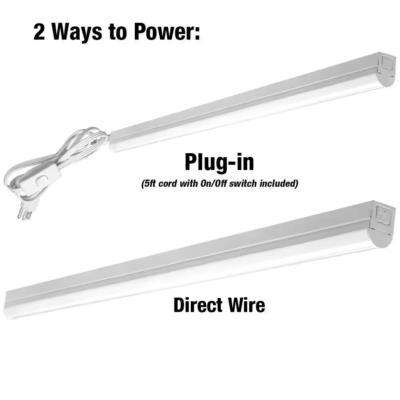

| Voltage Input | 120V AC / 240V AC (Plug-and-Play ready; no external driver required) |

| Certifications | ETL (ETL Listed for US/Canada), TUV CE (EN 60598, EN 62471, EMC) |

| IP Rating | IP20 (Indoor), IP65 (Outdoor/Waterproof) |

| Color Temperature | 2700K–6500K (Adjustable via custom orders) |

| Length Options | Standard: 1m, 2m, 5m |

| Warranty | 5 years (pro-rated based on usage conditions) |

Technical Note: Our “Plug-and-Play” design integrates UL-listed connectors and thermal management systems, eliminating common failure points like loose wiring or overheating. All products undergo 72-hour accelerated aging tests before shipment.

Partnering with a Trusted Manufacturing Authority

As a global supplier to distributors, contractors, and architects, Beauty STC Lighting prioritizes transparency, compliance, and technical partnership over transactional sales. Our 1998 founding legacy means every product is built on lessons learned from thousands of commercial installations worldwide—ensuring your projects meet the highest standards for safety, performance, and longevity.

For detailed technical documentation, sample requests, or OEM/ODM consultations:

Contact: [email protected] | +86 13902885704

Factory Address: 41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Beauty STC Lighting: Engineering reliability since 1998.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Plug-In 120 V LED Strip Light – Industrial Grade

Beauty (STC) Manufacturing Co., Ltd. has supplied factory-direct LED strip solutions since 1998.

All plug-in 120 V reels are engineered for distributors, contractors and specifiers who need repeatable photometry, certified safety, and field-proven reliability.

1. Key Electrical & Optical Data

| Parameter (120 V Plug-n-Play Reel) | Beauty STC Standard Range | Tolerance / Unit |

|---|---|---|

| Luminous efficacy | 120–140 lm/W @ 25 °C | ±3 % |

| Lumen maintenance | L90 > 54 000 h (TM-21) | – |

| CRI | Ra ≥ 90 (R9 > 50) | ±1 |

| CCT options | 2400 K – 6500 K | ±75 K (SDCM ≤ 3) |

| Flicker index | < 0.05 (IEEE 1789 risk-free) | – |

| Power factor | ≥ 0.95 (integral driver) | – |

| Input voltage | 100-130 V AC 50/60 Hz | – |

| Max run length | 20 m (65 ft) on single plug | – |

2. Mechanical & Environmental Ratings

| Feature | Specification |

|---|---|

| PCB | 2 oz (70 µm) rolled copper, double-layer, white solder-mask |

| LED pitch | 60 LEDs/m (18/ft) or 120 LEDs/m (36/ft) |

| Ingress protection | IP20 indoor, IP65 silicone-sleeve, IP67 silicone-filled, IP68 PU-potted |

| Operating temp | –40 °C to +60 °C |

| Storage temp | –40 °C to +80 °C |

| UV stabiliser | HALS in silicone sleeve (IP65/67) |

| Flame class | UL 94 V-0 PCB & housing |

| Cable | 18 AWG SJT 105 °C, 0.9 m (3 ft) North-American plug, ETL listed |

3. Certification & Compliance

ETL/cETL to UL 2108 + CSA C22.2#9 (US & Canada)

TUV CE to EN 60598-2-20, EN 62031, EN 61347 (EU)

RoHS, REACH, SAA (RCM) option for Australia

ISO 9001:2015 production site audited annually by TÜV

4. Production Consistency Controls

- Bin-on-Bin LED selection: 1 SDCM for white, 3 nm for colour.

- Automated solder-paste inspection (SPI) & 3D AOI after SMT.

- 100 % 2 kV hipot & 500 V insulation test on 120 V section.

- Integrating-sphere batch test (0.3 nm spectrometer) – every 30 cm kept on file for 7 years.

- Vacuum-packed reels with < 10 % RH & colour-coded QC label.

5. Generic Market vs. Beauty STC Certified Quality

| Attribute | Generic “Near-me” Stock | Beauty STC Certified Reel |

|---|---|---|

| Efficacy | 70–90 lm/W | 120–140 lm/W |

| CRI | Ra 70–80 | Ra ≥ 90 (R9 ≥ 50) |

| PCB copper | 0.5–1 oz | 2 oz, 70 µm |

| SDCM | 5–7 | ≤ 3 |

| IP rating printed | Often mis-claimed | Third-party IP67 validated |

| Safety mark | Self-declared | ETL/cETL file #5012567 |

| Flicker | 15–30 % | < 1 % (IEEE risk-free) |

| Lumen maintenance (L70) | 25 000 h claimed | 54 000 h (TM-21) |

| Warranty | 1 year limited | 5 year factory warranty, 0.1 % RMA last 3 yrs |

6. Ordering Reference (North-American Plug)

Factory lead-time: 2–3 weeks for < 5 km, 4 weeks for 20-ft mixed container.

OEM/ODM: Custom CCT, CRI 95+, length, printed jacket logo, and retail kitting available.

For specification sheets, IES/LDT files, or project quotations contact:

[email protected] | +86 139 0288 5704

Factory Tour: Manufacturing Excellence

Precision Manufacturing: Behind Our Industrial LED Strip Production

As a certified LED manufacturing partner since 1998, Beauty STC Lighting operates a 20,000㎡ facility in Jiangmen High-tech Industrial Zone (Guangdong, China) with fully automated production lines engineered for global commercial and industrial applications. Our process prioritizes consistency, traceability, and compliance with ETL (USA/Canada) and TUV CE (Europe) standards—ensuring every product meets stringent international safety and performance requirements. Below is a breakdown of our industrial-grade production workflow.

Automated SMT Assembly & Component Integration

Our production begins with state-of-the-art surface-mount technology (SMT) lines capable of handling components as small as 0201 size. This ensures precise placement of LEDs, resistors, and controllers with micron-level accuracy. Key features include:

JUKI SMT Routers: Fully automated component placement with <0.03mm positioning tolerance

Reflow Soldering: Computer-controlled temperature profiles for defect-free solder joints

Automated Optical Inspection (AOI): Real-time detection of soldering defects or misalignment

Industrial-grade SMT assembly reduces manual handling errors by 92% compared to traditional methods, critical for maintaining consistent lumen output across large-scale projects.

Rigorous Aging & Performance Validation

All LED strips undergo a multi-stage aging protocol simulating real-world operational stress:

24-Hour Continuous Burn-In: At 45°C ambient temperature with 100% load

Lumen Maintenance Monitoring: Real-time tracking of light decay (L70/L90 metrics)

Thermal Imaging: Infrared scanning to identify hotspots or thermal runaway risks

This process ensures 50,000+ hour operational life per IESNA LM-80 standards, with <5% lumen depreciation after 10,000 hours.

Quality Control Protocols

Our QC system follows ISO 9001 principles with three-tiered inspection points:

1. Component-Level Verification: Raw materials tested for RoHS/REACH compliance

2. In-Process Checks: Every 100m of strip tested for voltage drop, color consistency (Δu’v’ ≤ 0.003), and IP ratings

3. Final AQL Sampling: Random sampling per ANSI/ASQ Z1.4 Level II (AQL 1.0) for critical parameters

| Critical Quality Metrics | Specification | Test Method |

|---|---|---|

| Lumen Output Tolerance | ±3% | IES LM-79 |

| Color Consistency (Δu’v’) | ≤0.003 | CIE 1976 |

| IP Rating Verification | IP20, IP65, IP67 | IEC 60529 |

| Voltage Drop (per 5m) | ≤0.5V | EN 62471 |

OEM/ODM Capabilities for Global Projects

With 25+ years of experience serving distributors in 50+ countries, we offer end-to-end customization without compromising certification standards:

| Customization Parameter | Available Options | Technical Notes |

|---|---|---|

| Length | 1m to 50m continuous | No minimum order for standard profiles |

| CCT | 2700K–6500K (custom steps) | ±100K tolerance at 25°C |

| Color Options | RGB, RGBW, Tunable White | DMX/RDM compatible |

| Packaging | Custom boxes, printed labels, bulk pallets | OEM branding included |

| Certifications | ETL, CE, RoHS, KC (Korea), SAA (Australia) | Regional compliance tailored to destination market |

Our OEM process includes dedicated engineering support for thermal management design, driver compatibility, and fixture integration—ensuring seamless adoption into architectural and commercial projects.

Why Global Partners Choose Beauty STC

Factory-Direct Control: Full oversight from raw materials to finished goods eliminates third-party quality risks

Certification Agility: We maintain ETL/CE documentation for all production runs—no retesting delays for regional compliance

Scalability: 500,000+ meters monthly production capacity with lead times of 7–15 days for standard orders

As a responsible industrial partner, we integrate sustainable practices into every process—recycling 95% of soldering waste and using RoHS-compliant materials to reduce environmental impact without compromising performance.

Contact our engineering team for project-specific technical documentation:

[email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios for Factory-Certified 120 V Plug-in LED Strip Light

(ETL / TUV-CE, 25-year OEM platform, Jijiangmen, CN)

H2 | Where Contractors Specify “Plug-in LED Strip Near Me”

| Segment | Typical Mounting Plane | Driver Location | Key Compliance Note |

|---|---|---|---|

| Hotel corridors & headboards | 45° aluminum channel in drywall cove | Integrated 120 V plug—no remote driver | ETL 1598 for damp location behind bed |

| Shopping-mall kiosk & display risers | Surface-mount PC extrusion with PMMA diffuser | Plug concealed in service column | CE EN60598-2-20 for public space |

| Office task-light retrofit | Under-shelf, 3000-4000 K CRI 90+ | Plug into modular furniture receptacle | TUV EMC pass for >25 pcs on one circuit |

| Façade soffit & canopy perimeter | IP65 silicone sleeve, -30 °C rated | Plug inside junction box with 3 m whip | ETL wet-location gasket supplied |

H3 | Installation Checklist for Contractors

- Verify local voltage: Strip ships 120 V North-American (ETL) or 230 V EU (CE) — specify PO.

- Max run length: 50 m (164 ft) continuous on 120 V; cut marks every 50 mm; re-seal with factory end-cap to keep IP65.

- Surface prep: Extruded 6063-T5 channel must be grounded; use supplied 3 M VHB plus #6 screw every 0.4 m.

- Thermal gap: Maintain 5 mm air gap behind channel when mounting on composite ceiling; expect 45 °C T-case at 8 W/ft.

- Code tie-in: 120 V plug-in version is Class-II; no earth required, but GFCI protection mandatory for damp locations (NEC 410.30).

- Documentation bundle: Ship each carton with ETL report, CE DoC, LM-80 for 2835 mid-power, and RoHS/REACH batch traceability—architects archive for LEED v4.1 MR credit.

H3 | Quick-Spec Reference (UltraBright™ Industrial, Plug-in Variant)

| Parameter | 120 V NA | 230 V EU |

|---|---|---|

| Luminous flux | 1156 lm/ft (3800 lm/m) | 1120 lm/ft |

| Efficacy | 144 lm/W @ 3000 K | 147 lm/W @ 4000 K |

| CRI | 90 ± 2 (R9 > 60) | idem |

| Binning | 3 SDCM, 1800-6500 K | 3 SDCM, 2700-6500 K |

| Operating temp | –30 °C to +55 °C | –30 °C to +55 °C |

| Certifications | ETL cETL, FCC Part 15 | TUV CE, CB, EMC, RoHS |

| Warranty | 5 yr / 50 000 h L70 | 5 yr / 50 000 h L70 |

H3 | Supply-Chain Advantage

Factory-direct MOQ: 100 pcs (300 m) with 3-week FOB Shenzhen.

OEM/ODM: Custom CCT, CRI 95+, IP67 silicone extrusion, or 24 V constant-voltage variant tooled in 15 days.

Compliance file: Updated annually since 1998; ETL file #5013348, TUV CE NB 0123—no site audit required for re-label.

For samples or project submittals, contact: [email protected] | +86-139-0288-5704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Industrial-Grade LED Solutions for Global Markets

25+ Years of Manufacturing Expertise

Established in 1998, Beauty STC Lighting has delivered reliable, high-performance LED solutions through decades of engineering precision. Based in Jiangmen’s High-tech Industrial Zone, Guangdong, China, our facility combines rigorous production standards with continuous innovation. We operate under the principles of “Be a responsible enterprise, Be a caring person” and “Passionate, and Innovation,” ensuring every product meets industrial-grade durability and efficiency requirements for global applications.

Global Compliance & Certifications

All products undergo stringent testing to comply with international safety and performance standards. Our certifications include:

ETL (USA/Canada): Validated for electrical safety and performance in North American markets.

TUV CE (Europe): Certified for electromagnetic compatibility, safety, and environmental compliance in EU regions.

These certifications ensure seamless integration into commercial, industrial, and architectural projects across Western markets, eliminating regulatory hurdles for distributors and contractors.

OEM/ODM Manufacturing Capabilities

As a factory-direct manufacturer, we provide end-to-end customization for project-specific needs:

Design Support: Engineering collaboration for tailored form factors, color temperatures (2700K–6500K), and mounting solutions.

Scalable Production: Flexible order quantities from prototyping to large-volume runs (500–50,000+ units).

Supply Chain Control: Full oversight of raw materials, assembly, and testing to guarantee consistency and cost efficiency.

Ideal for architects, contractors, and distributors requiring bespoke solutions for retail, hospitality, industrial, or infrastructure projects.

Technical Specifications: Industrial LED Strip Lights

| Parameter | Specification |

|---|---|

| CRI | ≥90 (CRI90+ for high-fidelity color rendering) |

| Luminous Flux | Up to 1156 lumens per foot (commercial-grade output) |

| Voltage Options | 12V DC, 24V DC, 120V AC Plug-and-Play |

| IP Rating | IP20 (indoor), IP65 (outdoor), IP67 (submersible) |

| Length Options | Customizable (standard reels up to 50m) |

| Certifications | ETL, TUV CE, RoHS compliant |

Global Distribution Network

Beauty STC Lighting exports to 50+ countries, including key markets in:

Europe: Germany, France, UK, Netherlands

Americas: USA, Canada, Mexico, Brazil

Asia-Pacific: Australia, Japan, South Korea, Singapore, Thailand

Emerging Regions: Russia, UAE, South Africa

Our logistics team manages documentation, customs compliance, and timely delivery to ensure seamless integration into international supply chains.

Ready to Partner for Your Next Project?

For engineered LED solutions that meet commercial, industrial, and architectural demands, contact our engineering team directly. We provide technical consultation, compliance support, and scalable manufacturing for projects of any scope.

Email: [email protected]

Phone: +86-139-0288-5704

Beauty STC Lighting: Certified. Customizable. Global.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).