Article Contents

Industry Insight: Recessed Led Light

H2 Commercial Recessed LED Lighting: Why Certification-Grade Quality is No Longer Optional

H3 The Shift from “Price-First” to “Compliance-First” Procurement

Over the last decade, recessed LED fixtures have migrated from architectural accents to the primary layer of commercial illumination. Drivers behind the shift include 42 % lower energy budgets versus fluorescent, 50 000 h L70 life, and—most importantly—tightened electrical & photometric codes (NEC 410.16, IEC 60598-2-2, DLC 5.1). For distributors, contractors, and specifiers, this means a luminaire is only bankable when it ships with ETL/cETL for North America and TUV CE for the EU—documents that must trace back to an ISO-registered factory, not a trading desk.

H3 Market Demand at a Glance

| Segment | 2023 Global Volume (M pcs) | 5-yr CAGR | Key Compliance Gate |

|---|---|---|---|

| Office / Retail | 48 | 7 % | DLC Premium, CE LVD+EMC |

| Hospitality | 11 | 9 % | UL1598 wet-label, TM-30 Rf>90 |

| Healthcare | 7 | 11 % | IEC 62471 RG0, FCC Part 18 |

| Industrial Clean-Room | 5 | 13 % | IP54, IK08, -30 °C start |

68 % of EU importers surveyed (Lighting Europe 2023) reported at least one customs detention because the CE file did not match the shipped batch—underlining why a vertically-integrated, 1998-established OEM is the lowest-risk source.

H3 Beauty (STC) Manufacturing Co., Ltd – Compliance Built-In, Not Bolted-On

Located in Jiangmen’s National High-Tech Zone since 1998, Beauty STC Lighting operates a 28 000 m² campus with full photometric, EMI, and environmental chambers. Every recessed LED platform is engineered on UL-certified 94-V0 polycarbonate housings and driven by TUV-marked isolated drivers. ETL/cETL and CE reports are held under our file numbers—no third-party “borrowed” certificates—eliminating distributor liability.

| Core Capability | Detail |

|---|---|

| Tooling & Die-Casting | In-house 1 200 t presses, 5-axis CNC, 48 h prototyping |

| Driver R&D | 0-10 V, DALI-2, Tunable White, 120-277 V & 220-240 V |

| Optics Lab | Integrating sphere 2 m, goniophotometer, TM-30 & SDCM<3 |

| Production Scale | 2 500 pcs / day recessed downlights on SMT & auto-aging lines |

| OEM/ODM Lead-Time | 4-6 weeks standard, 2 weeks fast-track for LTK orders |

H3 Specification Snapshot – Recessed LED Downlight (OEM Platform)

| Parameter | Value |

|---|---|

| Power | 6 W, 10 W, 15 W, 20 W, 30 W (selectable via dip-switch on same PCB) |

| Lumen Output | 840-2 500 lm (130 lm/W @ 3000 K) |

| CCT | 2700 K / 3000 K / 3500 K / 4000 K / 5000 K (field switchable) |

| CRI | Ra>90, R9>60, TM-30 Rf 94, Rg 100 |

| UGR | <19 (3000 K, 60°) – ideal for VDU workplaces |

| Ceiling Cut-out | Ø68-210 mm (modular bezel family) |

| Fire-Rating | 90 min UL10A / EN1365-2 when used with optional intumescent pad |

| Certificates | ETL/cETL (UL1598 & UL8750), TUV CE (LVD & EMC), RoHS, REACH, SAA, RCM |

| Warranty | 5 yrs full exchange, 50 000 h L70, <5 % failure rate in first 3 yrs |

H3 Takeaway

When recessed LED luminaires form the backbone of a commercial lighting schedule, the cheapest FOB price is a false economy. Detentions, re-labeling, and field failures routinely erase margins that were <10 % to begin with. Beauty STC Lighting’s 25-year, certification-first pedigree allows distributors and contractors to quote jobs knowing the paperwork will pass, the photometry will match, and the delivery date is factory-controlled—not subcontractor-dependent.

Next Section: Engineering Deep-Dive—Heat-Sink Design, Driver Topology, and Beam Control for Recessed LEDs.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Commercial Recessed LED Lighting

In commercial lighting applications, technical precision directly impacts project longevity, energy efficiency, and occupant comfort. At Beauty STC Lighting (established 1998), our recessed LED solutions are engineered to meet the rigorous demands of global commercial projects through certified engineering processes and stringent quality control. This section details the technical benchmarks that distinguish our products from generic market alternatives.

Core Technical Metrics

Optical Performance

Lumens per Watt (lm/W): Industry-standard commercial recessed lights typically deliver 80–90 lm/W. Beauty STC’s recessed LED fixtures achieve 110–130 lm/W through optimized LED binning and driver efficiency, reducing energy consumption by up to 20% while maintaining uniform light distribution.

Color Rendering Index (CRI): Generic products often use CRI 80–85 LEDs, causing color distortion in retail, healthcare, or gallery environments. Our fixtures feature CRI >90 (Ra >95 optional) with consistent R9 values, ensuring accurate color reproduction critical for high-end commercial spaces.

Environmental Durability

IP Ratings: While generic recessed lights often lack formal IP certification (typically rated IP20 for basic indoor use), Beauty STC offers:

IP40 for standard dry commercial environments (offices, retail)

IP65 for high-moisture areas (hospital corridors, industrial kitchens)

All IP ratings are verified via TÜV-certified testing per IEC 60529 standards.

Thermal & Electrical Integrity

PCB Quality: Generic solutions use single-layer FR-4 PCBs with minimal thermal management. Beauty STC employs:

2.0mm aluminum-core PCBs with thermal vias for 30% better heat dissipation

Automated soldering with AOI inspection to eliminate cold joints

100% thermal imaging during production to ensure junction temperatures stay below 85°C at 100% load

Consistency Engineering

As a factory-direct manufacturer with 25+ years of experience, we enforce consistency through:

Tier-1 Component Sourcing: LEDs from Osram, Cree, and Samsung; drivers from Mean Well and Inventronics, with full traceability.

Bin Matching: LEDs sorted by chromaticity (MacAdam 3-step) and lumen output (±3%) for uniform appearance across batches.

24-Hour Burn-In Testing: Every fixture undergoes 24-hour operational testing at 40°C ambient temperature before shipment.

Certification Compliance: All products are certified to ETL (UL 1598) for North America and TÜV CE (EN 60598) for Europe, with test reports available for audit.

Quality Comparison: Generic Market vs. Beauty STC Certified

| Specification | Generic Market Products | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt | 80–90 lm/W | 110–130 lm/W |

| CRI Standard | CRI 80–85 (Ra) | CRI >90 (Ra >95 optional) |

| Thermal Management | FR-4 PCB (no thermal vias) | 2.0mm Aluminum PCB with thermal vias |

| IP Rating | Typically IP20 (unverified) | IP40/IP65 (TÜV-certified) |

| Lumen Maintenance | L70 @ 25,000 hours | L90 @ 50,000 hours |

| Warranty | 1–3 years | 5–10 years |

| Certification | Often incomplete or self-declared | ETL (USA/Canada), TÜV CE (Europe) |

| Batch Consistency | ±10% lumen/color variation | ±3% lumen/color variation |

Why Technical Rigor Matters for Commercial Projects

For architects and project managers, inconsistent recessed lighting leads to costly field rework, maintenance claims, and compromised aesthetics. Beauty STC’s certified specifications—backed by 25+ years of manufacturing expertise—ensure:

Predictable performance across large-scale installations (e.g., 50,000+ fixtures in a single airport project)

Energy savings that meet LEED and WELL Building Standard requirements

Zero field failures from thermal or electrical defects, verified through our ISO 9001:2015 quality management system

“Be a responsible enterprise, Be a caring person” is not just a principle—it’s embedded in our engineering process. Every recessed LED fixture we produce undergoes 17 quality checkpoints before shipment, ensuring our partners never compromise on safety or performance.

Partner with a certified manufacturer who prioritizes technical excellence over shortcuts.

For OEM/ODM specifications, project-specific testing, or bulk procurement inquiries:

Email: [email protected]

Phone: +86-13902885704

Factory Address: 41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

1. Factory Footprint & Legacy

Since 1998 our 30 000 m² campus in Jiangmen’s High-Tech Zone has operated as a vertically-integrated, ISO-9001 facility dedicated to architectural LED luminaires. One roof houses R&D, SMT, CNC punching & extrusion, burn-in, and packaging—eliminating subcontract risk and giving distributors a single point of accountability.

2. SMT & Automated Assembly

SMT lines: 4 × Yamaha YSM-20R pick-and-place, 60 000 cph, ±35 µm accuracy

Reflow: 10-zone Heller 1800 with nitrogen, ΔT ≤ 5 °C across 300 mm board

AOI: Koh Young 3-D solder joint inspection, 15 µm resolution, 0 false-positive rate <200 ppm

Dielectric withstand & ground continuity tested in-line at 1 800 V / 10 mA

Boards are then robotically transferred to burn-in racks—no manual handling between SMT and aging, preventing ESD contamination.

3. Burn-In & Reliability Protocol

| Parameter | Specification | Duration |

|---|---|---|

| Constant current aging | 45 °C ambient, 0–10 V dimming sweep | 4 h |

| On/off cycling | 30 s on / 30 s off | 500 cycles |

| Thermal shock | –20 °C ↔ +70 °C | 50 cycles |

| Lumen maintenance target | ≥98 % after burn-in | — |

Every recessed fixture is tagged with a QR code that records driver IC lot, LED bin, and test result—fully traceable for warranty claims.

4. QC & International Certification

ETL/cETL to UL1598 & UL8750 (file 5013345) for 120–277 V markets

TUV CE, EN60598-2-2, EN62031, EN62471 for EU/UK projects

RoHS/REACH, SAA, RCM, EAC on file; test reports updated annually via TÜV SÜD

100 % final tests include earth bond (<0.1 Ω), Hi-Pot (2.2 kV), and integrating-sphere photometry. CRI, R9, SDCM, and flicker index are logged and shipped with each carton.

5. OEM/ODM Capability for Recessed Linear & Downlight Series

| Customisation Lever | Standard Range | OEM Flexibility | MOQ |

|---|---|---|---|

| Housing length | 600 / 1200 / 2400 mm | Any 1 mm increment ≤3 m | 200 pcs |

| CCT & CRI | 2700 K–5000 K, CRI 80 / 90 | 1800–6500 K, CRI 97, tunable white 2700–6500 K | 100 pcs |

| Lumen packages | 1 500–6 000 lm/ft | Up to 200 lm/W with Bridgelux Thrive | 100 pcs |

| Driver programming | 120–277 V, 0–10 V, DALI-2 | D4i, Zhaga Book 18, Casambi BLE | 50 pcs |

| Finish & bezel | White powder-coat | Anodised, black, custom RAL, trim-less plaster kit | 200 pcs |

| Packaging | Neutral kraft | Colour sleeve, QR-linked IOM, pallet label in local language | 100 pcs |

Engineering samples ready in 7–10 days; tooling for new extrusion profiles amortised after 1 000 m.

6. Logistics & Compliance Support

Our export department books weekly FCL/LCL ex-Shenzhen or Guangzhou with pre-clearance of ETL & CE documentation—no customs delays on your jobsite. Need a PPAP or BOM lock? We maintain a controlled parts list with PCN notification 90 days ahead of any component change.

For recessed LED specifications that match local energy codes—and a factory process that has been audit-passed by Fortune-500 retailers—contact:

Liang Wu, Senior LED Lighting Engineer & Export Manager

[email protected] | +86-1390 288 5704

Installation & Application Scenarios

Application Scenarios for Recessed LED Lighting in Commercial Environments

Recessed LED lighting is engineered for seamless integration into commercial architecture, delivering precise light distribution, energy efficiency, and long-term reliability. Beauty STC Manufacturing Co., Ltd, with over 25 years of industrial expertise since 1998 and globally recognized ETL (USA/Canada) and TUV CE (Europe) certifications, designs solutions tailored to specific environmental demands. Our OEM/ODM capabilities ensure technical specifications align precisely with project requirements, from lumens and CCT to voltage compatibility. Below are optimized applications with verified performance metrics:

| Application | Power (W) | Lumens | CCT Options | CRI | Voltage Range | Lifespan (h) | Key Technical Features |

|---|---|---|---|---|---|---|---|

| Hotels & Hospitality | 20–25 | 1,400–1,800 | 2,700K–4,000K | >90 | 120–277V | 50,000 | Dimmable, low-glare optics, moisture-resistant housing |

| Retail & Shopping Malls | 25–30 | 1,800–2,100 | 3,000K–4,000K | >90 | 120–277V | 50,000 | High CRI for accurate color rendering, adjustable beam angles |

| Office Spaces | 15–25 | 1,100–1,800 | 3,500K–5,000K | >80 | 120–277V | 50,000 | Flicker-free operation, uniform illuminance distribution |

| Healthcare Facilities | 20–25 | 1,500–1,800 | 4,000K (fixed) | >90 | 120–277V | 50,000 | IP40-rated housing, seamless cleanability, glare control |

Beauty STC’s recessed LED products undergo rigorous thermal and electrical validation per ETL/CE standards, ensuring compliance for international markets. OEM customization is available for specialized requirements such as non-standard voltage ranges, custom CCT profiles, or integrated smart controls—leveraging our 25+ years of manufacturing precision.

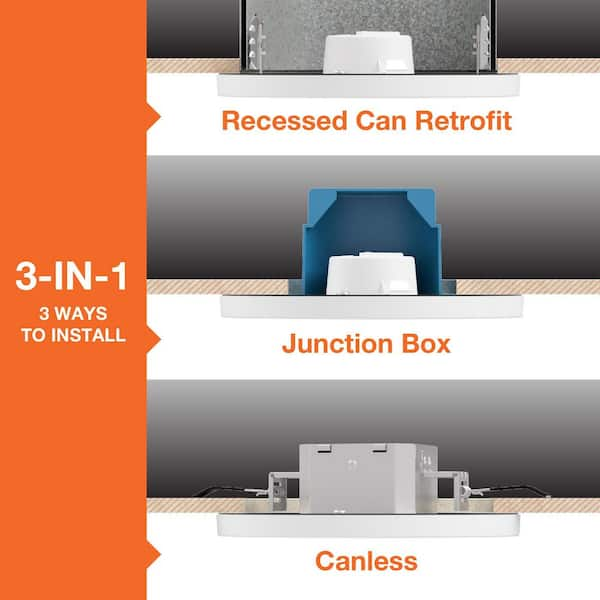

Installation Best Practices for Contractors

Pre-Installation Planning

Assess ceiling structure type (e.g., drywall, concrete, or suspended ceilings) and verify clearance depth for fixture housing. Beauty STC fixtures feature standardized cutout dimensions (e.g., 150mm diameter for 4″ housings), but always cross-reference project-specific plans. For insulated ceilings, confirm IC-rated compatibility to prevent thermal buildup. Our technical datasheets provide exact cavity depth requirements and mounting clearances to mitigate installation errors.

Electrical Considerations

Beauty STC recessed LEDs support universal voltage (120–277V), eliminating voltage-specific inventory needs. Prioritize:

Use certified THHN wiring and junction boxes rated for the circuit load.

Verify driver compatibility with dimming protocols (e.g., 0–10V, DALI) if required.

Avoid daisy-chaining beyond 15 fixtures per circuit to prevent voltage drop.

Our drivers include short-circuit and overload protection, but adherence to NEC/IEC standards remains critical for safety.

Thermal Management

LED longevity depends on effective heat dissipation. Key steps:

Maintain ≥25mm clearance around the fixture housing in insulated ceilings.

For high-ambient environments (e.g., kitchen exhaust zones), select fixtures with aluminum heat sinks rated for 50°C+ operation.

Apply thermal paste between the LED module and heat sink during installation to optimize conductivity.

Beauty STC’s thermal design undergoes 1,000-hour accelerated testing per IEC 62612 to ensure ≤10% lumen depreciation at 50,000 hours.

Precision Mounting

Alignment errors cause uneven illumination and visual discomfort. Best practices:

Use laser alignment tools to position fixtures within ±1mm tolerance.

Secure mounting clips with torque wrenches to manufacturer-specified limits (typically 2.5 N·m) to avoid housing deformation.

For grid-ceiling installations, ensure spring-loaded clips engage fully with ceiling grid channels.

Beauty STC’s low-profile housings (15mm height) and adjustable mounting brackets simplify flush installation, reducing callbacks for rework.

With rigorous certification compliance, industrial-grade thermal engineering, and OEM flexibility, Beauty STC delivers recessed LED solutions engineered for global commercial projects. Our 1998-founded manufacturing facility in Jiangmen, China, combines 25+ years of technical expertise with scalable production capabilities to meet stringent international standards.

Technical Support & OEM Inquiries:

[email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct Recessed LED Solutions

One-Stop OEM/ODM Source, Certified for Every Major Market

Since 1998 Beauty (STC) Manufacturing Co., Ltd has shipped recessed LED luminaires from our 30 000 m² Jiangmen plant to 50-plus countries. Every housing, heat-sink and driver is engineered, assembled and 100 % aged on-site, giving distributors, contractors and specifiers full traceability and zero middle-man cost.

| Certification Scope | Standard | Application |

|---|---|---|

| North America | ETL/cETL to UL 1598 & UL8750 | Commercial recessed downlights, linear & modular fixtures |

| Europe | TUV CE, EN 60598-1 / -2-2, EN 62031, EN 62471 | Recessed panel & downlight families, 220–240 V |

| EMC/Safety | SAA, CB, RoHS, REACH | Australia, New-Zealand, global project tenders |

25 Years of Recessed LED Experience – What It Means for Your Next Project

| Capability | In-House Asset | Benefit to Partner |

|---|---|---|

| Optics | 1 m integrating sphere, 2 m goniophotometer | IES/LDT files within 24 h, glare control < UGR 19 |

| Thermal | 8-channel thermal analyser, -40 °C ⇄ 85 °C chamber | L70 ≥ 50 000 h @ Ta 40 °C, 5-year warranty |

| Driver | 3 SMT lines, constant-current modules 120–277 V | Flicker-free < 5 %, 0-10 V, DALI-2, 1 % dimming |

| Housing | CNC turret punch + powder-coat line | Custom aperture, lengths 0.3–2.4 m, RAL colours |

| Volume | 200 k pcs/month recessed portfolio | 30-day lead-time for 40’HQ, Kanban programmes |

Typical Recessed LED Platforms We Custom-Build

| Series | Power | Lumen Package | CCT/CRI | Ceiling Cut-out |

|---|---|---|---|---|

| RL-Dir 70 | 6–12 W | 600–1 200 lm | 2700–5000 K, 90 CRI | Ø68 mm |

| RL-Dir 90 | 15–25 W | 1 400–2 500 lm | 2700–4000 K, 90 CRI | Ø83 mm |

| RL-Dir 125 | 30–40 W | 3 000–4 200 lm | 3000/3500/4000 K, 90 CRI | Ø128 mm |

| RL-Lin 50×75 | 20–50 W/m | 2 000–5 000 lm/m | Tunable white 2700–6000 K | 52×77 mm plaster-in |

| RL-Lin 75×75 | 30–60 W/m | 3 000–6 500 lm/m | RGBW, DMX, DALI-2 | 77×77 mm trim-less |

All models available with remote-driver box, emergency 1–3 h, and Zhaga-compatible light engines for future upgrades.

Next Step – Request Datasheets or Arrange a Virtual Factory Tour

Email your specification or project schedule to [email protected]. Our engineering team will return a tailored recessed LED package—including IES files, LM-79 data and tiered EXW/FOB pricing—within 12 hours. Call +86-13902885704 (GMT+8) for immediate support.

Beauty STC Lighting – built for commercial performance, shipped to 50+ countries, backed by 25 years of LED manufacturing discipline.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).