Article Contents

Industry Insight: Trailing Edge Dimmer

Introduction & Market Demand for Trailing Edge Dimmers in Commercial Lighting

The Role of Trailing Edge Dimmers in Modern Commercial Lighting

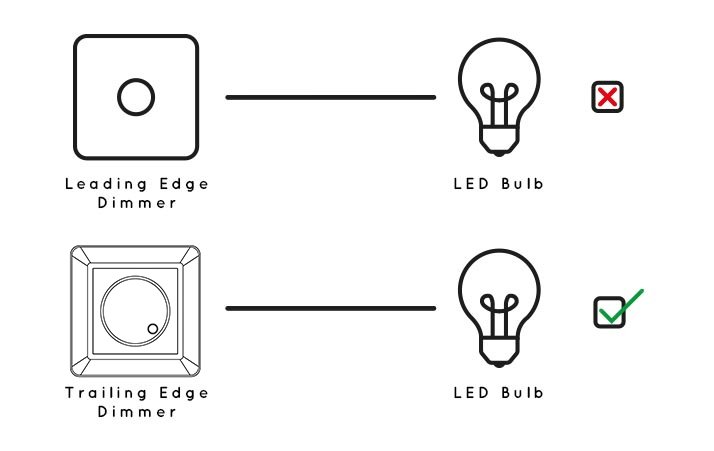

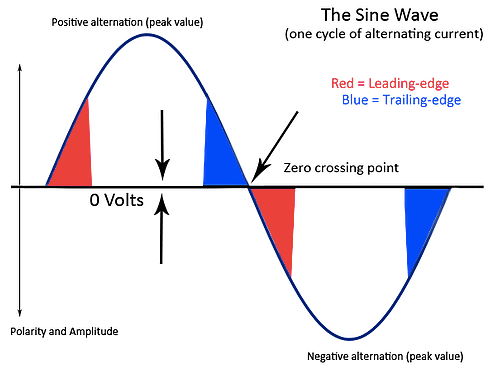

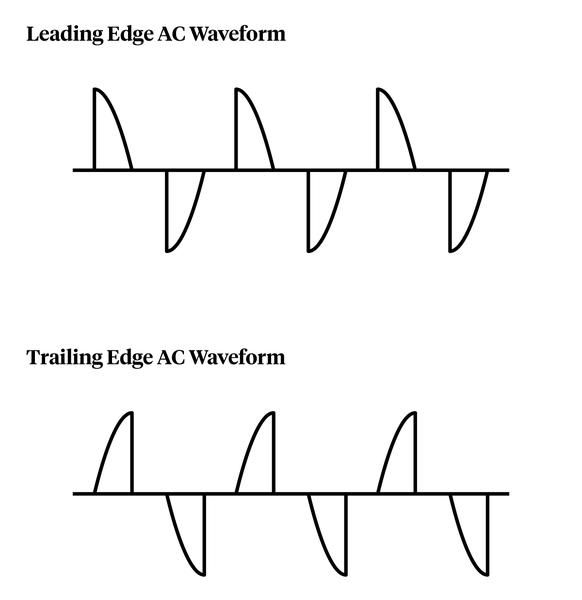

As LED adoption accelerates across commercial and industrial environments, precise dimming control has become critical for energy efficiency, occupant comfort, and system longevity. Trailing edge dimmers—also known as reverse phase or electronic low-voltage dimmers—are the industry-standard solution for LED lighting systems. Unlike leading edge dimmers designed for resistive loads (e.g., incandescent bulbs), trailing edge technology uses sophisticated phase-cut circuitry to smoothly reduce voltage without disrupting electronic drivers. This minimizes audible noise, eliminates flicker, and ensures compatibility with modern LED drivers, making them essential for applications in offices, retail spaces, healthcare facilities, and hospitality venues where consistent dimming performance is non-negotiable.

Critical Quality Considerations for Global Importers

For distributors and project managers sourcing dimming solutions, compliance with regional safety and performance standards is paramount. Products lacking ETL certification for North American markets or TUV CE for European Union requirements face significant risks, including:

Customs delays or rejection at ports of entry

Liability exposure for safety hazards (e.g., overheating, electrical faults)

Project delays due to non-compliant components

Reputational damage from inconsistent performance or premature failures

Quality issues such as unstable dimming curves, thermal runaway, or reduced service life often stem from substandard components or inadequate testing. Importers must prioritize suppliers with rigorous quality control processes and verified certifications to ensure products meet IEC 61000-3-2 (harmonic emissions) and IEC 60929 (ballast standards) requirements.

Beauty STC Lighting: A Trusted Partner for Certified Trailing Edge Dimmers

Established in 1998, Beauty STC Lighting has delivered engineering excellence in lighting solutions for 25+ years, with a focus on compliance-driven manufacturing for Western markets. Our trailing edge dimmers are designed and tested to meet ETL (USA/Canada) and TUV CE (Europe) standards, ensuring seamless integration into commercial projects worldwide. As an OEM/ODM specialist, we provide fully customizable dimming solutions tailored to regional electrical codes, load requirements, and aesthetic specifications. Every component undergoes strict validation for thermal stability, electromagnetic compatibility, and mechanical durability, aligning with our core principles of “Be a responsible enterprise, Be a caring person” and “Passionate, and Innovation.”

| Specification | Detail |

|---|---|

| Certifications | ETL (USA/Canada), TUV CE (Europe) |

| Input Voltage | 120V AC / 230V AC (Dual Voltage) |

| Maximum Load Capacity | 250W (LED) |

| Operating Temperature | -10°C to 40°C (14°F to 104°F) |

| Contact Material | High-purity copper alloy |

| Mounting Options | Surface mount or flush mount |

| Dimming Control Method | Trailing edge phase-cut technology |

| Service Life | 50,000+ hours |

For technical specifications, custom engineering support, or sample requests, contact our global sales team at [email protected] or +86 13902885704.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – Trailing-Edge Dimmer Platform

(Beauty STC Industrial-grade, 25-year OEM/ODM reference)

H2 1. Electrical & Dimming Architecture

| Parameter | Beauty STC Trailing-Edge Module | IEC 60669-2-1 Benchmark |

|---|---|---|

| Topology | Digital IGBT soft-switch, 180° phase-cut-off | 90°–180° trailing cut |

| Input Range | 110-130 VAC / 220-240 VAC, 50/60 Hz auto-detect | — |

| Rated Load (LED) | 60 W min. – 300 W max. (120 V) / 400 W max. (230 V) | 10–400 W |

| Stand-by Draw | <0.25 W | <0.5 W |

| Dimming Window | 3 %–100 % flicker-free (IEEE 1789) | 10 %–100 % |

| Control Interface | Triac, 0-10 V, Push, Zigbee 3.0 (OEM selectable) | — |

| Over-temp Fold-back | 85 °C linear de-rate, auto-recovery | — |

H2 2. Optical Integrity When Paired With Beauty STC LED Loads

| Metric | Beauty STC Certified Strip/Panel | Generic Market Strip/Panel |

|---|---|---|

| System Efficacy @ 3000 K | 125 lm/W (50 % dim) – 138 lm/W (100 %) | 90–105 lm/W |

| CRI | Ra ≥ 90 (R9 > 50) | Ra 80–82 |

| SDCM | ≤ 3-step MacAdam ellipse | 5–7 step |

| Flicker Index | <0.02 (trailing-edge mode) | 0.05–0.08 |

| Dimming Curve | Logarithmic or linear, factory-flash selectable | Fixed |

| PF (driver + dimmer) | ≥ 0.95 | 0.55–0.75 |

H2 3. Environmental & Construction Ratings

| Item | Beauty STC Specification | Test Protocol |

|---|---|---|

| PCB | Double-layer FR-4, 2 oz Cu, 130 °C TG, conformal coated | IPC-A-600, IPC-TM-650 2.3.28 |

| Moisture Sensitivity | IP20 control head, IP44 gasket kit option | IEC 60529 |

| Surge | 2 kV differential / 4 kV common-mode | IEC 61000-4-5 |

| ESD | ±8 kV contact, ±15 kV air | IEC 61000-4-2 |

| Thermal Cycle | -30 °C ⇄ 85 °C, 500 passes, ΔR <2 % | IEC 60068-2-14 |

| Lifetime | 50 000 h L70 @ 45 °C ambient | TM-21 calculator |

H2 4. Certification & Production Consistency

North America: ETL listed to UL 1472 & CSA C22.2 #184.1 (file 5015607)

Europe: TUV CE, EN 60669-2-1, EN 301 489, EN 62368, RoHS / REACH, SAA for AU/NZ

ISO 9001:2015 factory system since 2003; traceability barcode on every PCB (date + lot)

100 % burn-in: 4 h @ 265 VAC, 55 °C; automated hi-pot & curve logging before packing

MTBF: 230 000 h calculated (Telcordia SR-332, 25 °C GB)

H2 5. Quick-Compare Table – Generic vs Beauty STC Certified Quality

| Attribute | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Certification patchwork | CE self-declaration only | ETL + TUV CE, SAA |

| Min. dim level | 10 % visible step | 1 % (3 % LED) no flicker |

| Driver compatibility list | 6–8 brands | 50+ brands pre-tested |

| PCB copper weight | 1 oz, no coating | 2 oz, full conformal coat |

| Surge immunity | 1 kV | 4 kV (whole platform) |

| Production year start-up | — | 1998 (25 years) |

| OEM tooling time | 6–8 weeks | 3–4 weeks (in-house SMT) |

H2 6. Application Notes for Distributors & Specifiers

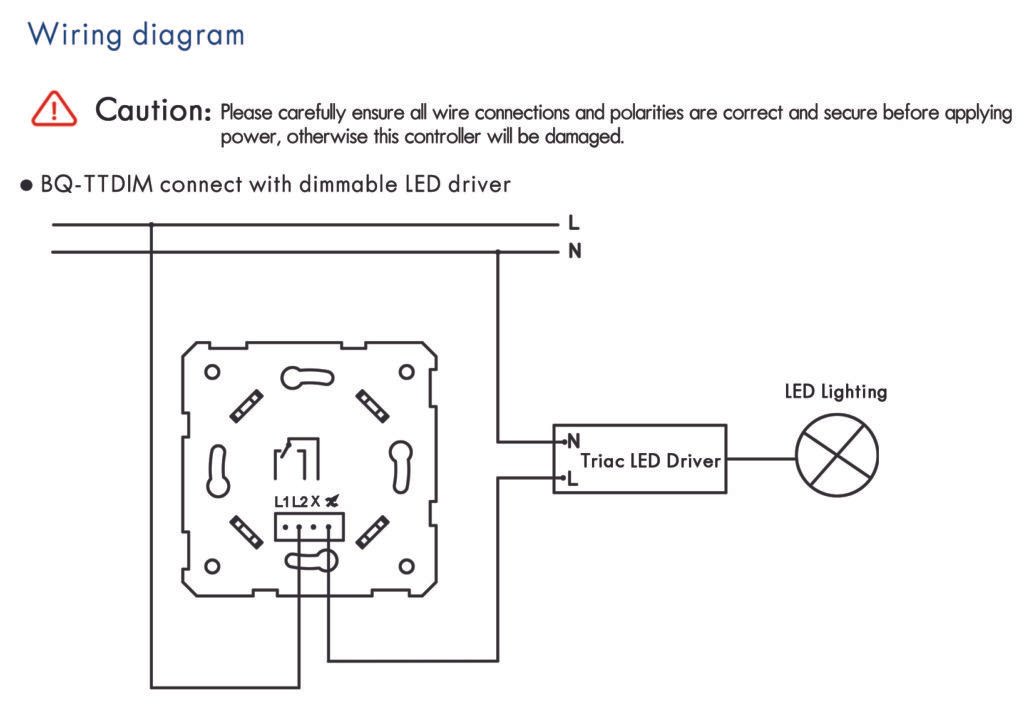

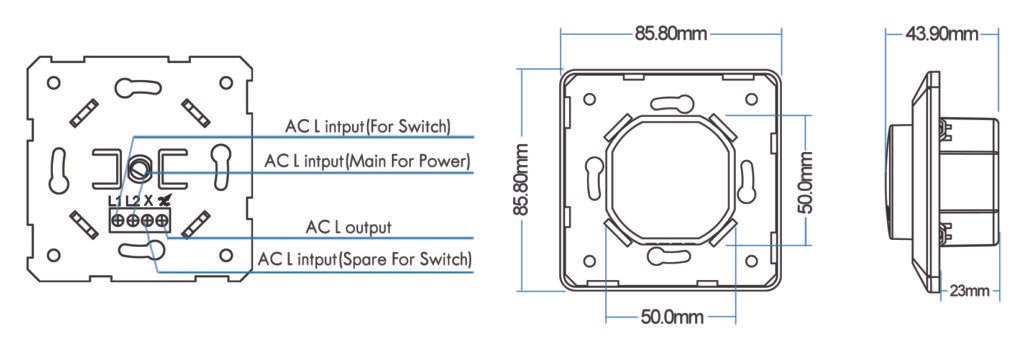

- Load Matching: Pair the dimmer with Beauty STC constant-voltage strips (24 V) or constant-current COB modules (350 mA–1400 mA) to guarantee <1 % flicker.

- Multi-way Circuits: Use slave key-switch wiring (no neutral) or Zigbee 3.0 mesh; max 15 units per DALI loop.

- Heat-sinking: De-rate 10 W/°C above 45 °C ambient; mount on steel back-box for 20 % extra headroom.

- Compliance Files: ETL & TUV CB reports available under NDA; LM-79, LM-80 for matched LED engines on request.

Contact Factory Engineering

[email protected] | +86-139-0288-5704

41F Caihong Rd, Jianghai Hi-Tech Zone, Jiangmen, Guangdong, CN

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services

Industrial-Grade Production at Jiangmen Facility

Beauty STC’s Jiangmen manufacturing facility, established in 1998, leverages 25+ years of industrial expertise to produce trailing edge dimmers for global markets. Our production line integrates advanced automation with rigorous quality control protocols to ensure compliance with ETL (USA/Canada) and TUV CE (Europe) standards.

SMT Assembly Line: Fully automated surface mount technology (SMT) machines with 0.01mm placement precision handle PCB fabrication, ensuring consistent component alignment and soldering reliability. Each board undergoes automated optical inspection (AOI) before proceeding to next stages.

Aging & Stress Testing: Every dimmer unit undergoes 48-hour continuous burn-in testing at 40°C ambient temperature, followed by thermal cycling from -10°C to 50°C. This validates operational stability and meets the 50,000+ hour rated lifespan standard.

Multi-Stage QC Protocol: Quality checks occur at four critical stages: incoming material inspection, in-process testing, final functional verification, and packaging audit. All tests align with ISO 9001 standards and specific client specifications.

OEM/ODM Capabilities for Global Projects

Beauty STC provides end-to-end OEM/ODM services for trailing edge dimmers, supporting custom designs for commercial and residential applications. Our flexible production system accommodates tailored electrical parameters, physical specifications, and branding requirements while maintaining full certification compliance. Our dimmers are engineered for compatibility with LED drivers supporting all CCT ranges, ensuring seamless integration with your lighting systems.

| Customization Parameter | Specification Options | Compliance Notes |

|---|---|---|

| Input Voltage | 120V AC, 230V AC, Dual Voltage | Certified for regional market requirements |

| Max Load Capacity | 150W – 500W (adjustable) | Configured for LED driver compatibility |

| Control Interface | Rotary, Touch, RS485, Rocker | Customizable for smart home integration |

| Physical Dimensions | Custom Length/Width/Height | Tailored to fixture design requirements |

| Material & Finish | Brass, Copper, Matte Black | TUV CE safety-certified materials |

| Packaging | Custom Branded, Eco-friendly | Compliant with client branding and shipping standards |

All OEM projects undergo the same 100% functional testing and certification validation as standard products, ensuring seamless integration into your lighting systems. With experience serving 50+ countries, we deliver solutions that meet local regulatory standards without compromising on performance.

Contact for Technical Specifications:

[email protected] | +86 13902885704

Installation & Application Scenarios

Application Scenarios & Contractor Guidelines

Factory-Direct Perspective – Beauty (STC) Manufacturing Co., Ltd. (Est. 1998, ETL/TUV-CE)

H2 Where Trailing-Edge Phase-Cut Dimming Adds Real Value

Trailing-edge (reverse-phase) dimmers are the default choice when the load is >80 % LED and the driver topology is either constant-voltage (24 V, 36 V, 48 V strips) or constant-current with active PFC. Below are the segments where our 25-year export data shows the highest ROI for the integrator and the lowest call-back rate for the contractor.

| Segment | Typical Load | Key Driver Requirement | Notes for Distributor/PM |

|---|---|---|---|

| Upscale Hotels | 24 V Cove Strips, 3 W/ft, 3000 K CRI 90+ | SELV, flicker-free <1 % at 10 % | Guest-room bedside <0,1 % noise; corridor emergency override at 1 % |

| Retail Flagships | 48 V Linear Track, 6 W/ft, 3000–4000 K | Active PFC >0,9, 220–240 V | Window display 1–100 %, no shimmer on phone camera |

| Boutique Offices | 40 W LED Panels, UGR <19 | CC 350 mA, ripple <5 % | Open-ceiling mount; daylight harvesting via 0–10 V parallel port |

| Facade Media Mesh | 24 V RGBW, 14 W/ft | Constant-voltage, 4-channel | Trailing-edge on white channel only; DMX for colour |

| Museums / Galleries | 24 V Tuneable White 1800–4000 K | SDCM ≤2, MacAdam 2-step | 100–1 %, no colour shift; CRI 97 option |

H2 Contractor Installation Checklist

(Field summary – keep in truck)

| Step | Action | Tool / Meter | Pass / Fail Criterion |

|---|---|---|---|

| 1 | Verify driver label “Trailing-Edge / R-C Phase-Cut Compatible” | Visual | Logo or wording present |

| 2 | Measure leakage to earth | Megger 500 V | <1 mA (hotel spec) |

| 3 | Confirm min. load 10 % of dimmer rating | Clamp meter | e.g. 250 W dimmer ≥25 W |

| 4 | Check neutral integrity | IR thermometer | ∆T <5 °C at terminations |

| 5 | Oscilloscope at 10 % & 90 % | Hantek 1008C | Flicker index <0,05 |

| 6 | Label circuit at panel | Engraved tag | “LED-TE dimming – no magnetic load” |

Tip: When retrofitting in 230 V markets, swap the 1-gang box for 35 mm deep to accommodate the snubber network inside our ETL-listed dimmer; no de-rating required up to 35 °C ambient.

H2 Certification & OEM Notes

All Beauty STC trailing-edge dimmer hardware is ETL (US/Canada) and TUV-CE (EU) listed as a system with our 24 V & 48 V strips, guaranteeing <1 % flicker and full 1–100 % range.

PCB assemblies are manufactured in-house Jiangmen since 1998; MOQ for private-label (OEM) faceplates or colour-matched rotary knobs = 500 pcs, 4-week lead-time.

Test reports on file: EN 60669-2-1, IEC 61000-3-2, FCC Part 15 Class A.

For project submittals or .dwg riser diagrams contact: [email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

Proven Expertise and Global Compliance

| Attribute | Details |

|---|---|

| Established | 1998 (25+ years of manufacturing expertise) |

| Certifications | ETL (USA/Canada), TÜV CE (Europe) |

| Global Reach | 50+ countries across Europe, Americas, Southeast Asia, Australia, Russia, Japan, and Korea |

| Manufacturing Services | Full OEM/ODM support with engineering and quality control |

As a factory-direct manufacturer, we deliver reliable, certified trailing edge dimmer solutions tailored to international market requirements. Our commitment to technical excellence and quality control ensures seamless integration into your projects while adhering to strict industry standards.

For OEM specifications and compliance inquiries, contact our global sales team:

[email protected] | +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).