Introduction: Navigating the Global Market for zigbee led strip

Zigbee LED strips represent a transformative technology at the intersection of smart lighting and IoT connectivity, offering unparalleled flexibility, energy efficiency, and seamless integration for commercial and industrial applications worldwide. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of Zigbee-enabled LED strips is critical to sourcing solutions that meet diverse operational needs and regulatory requirements.

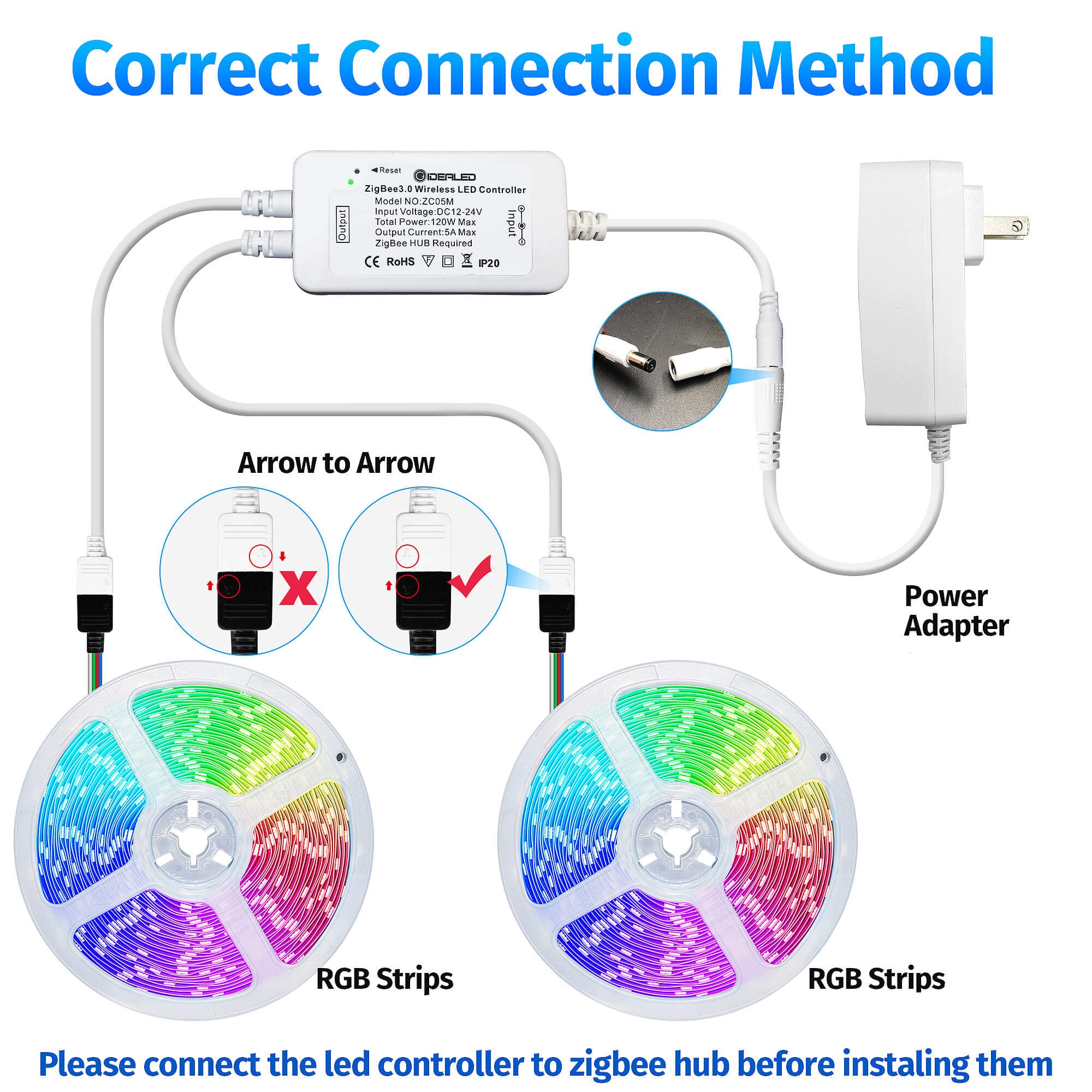

Illustrative Image (Source: Google Search)

This comprehensive guide delves deeply into the Zigbee LED strip ecosystem, covering essential aspects such as product types, material quality, manufacturing processes, and rigorous quality control standards. Buyers will gain insight into the significance of key components like high-performance LED chips and advanced PCBs, which directly impact durability and lighting efficiency. The guide also examines global supplier landscapes, cost considerations, and compliance certifications, enabling buyers to navigate complexities such as supply chain reliability, regional standards, and cost-effectiveness.

By equipping you with actionable intelligence on sourcing strategies and technical specifications, this resource empowers businesses in emerging and established markets—including Indonesia, Nigeria, and others—to make informed decisions that optimize product performance, reduce risk, and enhance competitive advantage. Whether upgrading existing installations or launching new projects, international buyers will find this guide indispensable for unlocking the full potential of Zigbee LED strips in today’s interconnected global marketplace.

Understanding zigbee led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Zigbee LED Strip | Basic Zigbee protocol integration, RGB or single-color options, flexible PCB | Retail lighting, office ambiance, hospitality | Pros: Cost-effective, easy integration; Cons: Limited advanced features, basic color control |

| Zigbee RGBW LED Strip | Includes dedicated white LEDs alongside RGB, enhanced color accuracy and brightness | Architectural lighting, commercial displays | Pros: Improved color rendering, versatile lighting; Cons: Higher cost, more complex installation |

| Zigbee Addressable LED Strip | Individually controllable LEDs with advanced effects, supports complex animations | Entertainment venues, advertising, exhibitions | Pros: High customization, dynamic effects; Cons: Higher price, requires sophisticated controllers |

| Waterproof Zigbee LED Strip | Encapsulated with silicone or epoxy, suitable for outdoor or wet environments | Outdoor signage, landscape lighting, industrial | Pros: Durable in harsh conditions, weather-resistant; Cons: Slightly reduced flexibility, cost premium |

| Flexible Zigbee LED Strip | Ultra-flexible PCB allowing bends and curves, lightweight | Custom installations, automotive, retail displays | Pros: Easy to install in complex shapes; Cons: May have lower heat dissipation, shorter lifespan if over-bent |

Standard Zigbee LED Strip

The Standard Zigbee LED Strip is the most widely used variation, featuring basic Zigbee connectivity for smart control with RGB or single-color LEDs. It suits applications requiring straightforward lighting control, such as retail environments and office spaces. For B2B buyers, this type offers a balance between cost and functionality, making it ideal for large-scale deployments where advanced effects are not critical. Consider compatibility with existing Zigbee hubs and ease of integration when sourcing.

Zigbee RGBW LED Strip

The RGBW variant integrates dedicated white LEDs in addition to RGB chips, delivering superior color accuracy and brightness. This makes it ideal for architectural projects and commercial displays where precise lighting tone is essential. Buyers should assess the increased power requirements and installation complexity, as these strips may require more sophisticated drivers and controllers. The enhanced lighting quality justifies the higher investment in premium applications.

Zigbee Addressable LED Strip

Addressable Zigbee LED strips allow individual control over each LED, enabling dynamic lighting effects and animations. This type is favored in entertainment venues, exhibitions, and advertising sectors where visual impact is paramount. For B2B buyers, it is crucial to consider the need for advanced control systems and software compatibility. Although the upfront cost is higher, the flexibility and customization potential can drive greater customer engagement and brand differentiation.

Waterproof Zigbee LED Strip

Encased in protective materials like silicone or epoxy, waterproof Zigbee LED strips are designed for outdoor and industrial environments exposed to moisture and dust. They are well-suited for landscape lighting, outdoor signage, and harsh industrial settings. Buyers must verify the IP rating and ensure compliance with regional standards. The durability and weather resistance come at a premium but reduce maintenance costs and extend product lifecycle in challenging conditions.

Flexible Zigbee LED Strip

Flexible Zigbee LED strips feature ultra-thin, bendable PCBs that accommodate curved and irregular surfaces. These strips are popular in automotive lighting, custom retail displays, and creative installations. When purchasing, B2B buyers should evaluate the mechanical flexibility limits and thermal management to avoid premature failure. Flexibility enhances installation options but may require more careful handling and design planning to maximize lifespan.

Related Video: Gledopto’s new ZigBee 3.0 Pro + 5 in 1 LED controller, easily connect your LED strip lights!

Key Industrial Applications of zigbee led strip

| Industry/Sector | Specific Application of zigbee led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Smart Manufacturing | Automated assembly line lighting and status indicators | Enhances operational efficiency with real-time lighting control and energy savings | Durability under industrial conditions, interoperability with existing Zigbee networks, compliance with safety standards |

| Retail & Commercial Spaces | Dynamic shelf and display lighting for customer engagement | Boosts product visibility and customer experience through customizable lighting scenes | Color accuracy, ease of integration with store management systems, scalability for large retail chains |

| Hospitality & Tourism | Ambient lighting in hotels and resorts | Creates customizable mood settings for guest comfort and energy optimization | Flexible installation options, wireless control reliability, aesthetic design compatibility |

| Warehousing & Logistics | Zone-based lighting for inventory management and safety | Improves worker safety and operational workflow with adaptive lighting zones | Robustness for harsh environments, low maintenance, long battery life for wireless setups |

| Healthcare Facilities | Patient room and corridor lighting with centralized control | Supports patient well-being and staff efficiency through responsive lighting | Compliance with healthcare lighting standards, ease of sanitation, seamless integration with building automation |

Smart Manufacturing

In smart manufacturing, Zigbee LED strips are deployed for automated lighting systems along assembly lines and machinery. These strips provide real-time visual status indicators—such as color-coded alerts for machine operation or faults—improving response times and reducing downtime. For international buyers, especially in regions like Nigeria or Indonesia, sourcing LED strips that withstand high temperatures and industrial dust is critical. Compatibility with existing Zigbee networks ensures seamless integration with factory IoT systems, optimizing energy consumption and operational efficiency.

Retail & Commercial Spaces

Retailers use Zigbee LED strips to enhance product displays and create dynamic lighting environments that attract customers. These strips enable customizable color and brightness control, allowing businesses to adapt lighting to promotional events or seasonal themes. For B2B buyers in South America or Europe, factors such as high color rendering index (CRI) for true product colors and ease of integration with retail management systems are paramount. Scalability is also vital for chains requiring uniform lighting solutions across multiple locations.

Hospitality & Tourism

Hotels and resorts leverage Zigbee LED strips for ambient and accent lighting that enhances guest experience through mood settings and energy-efficient control. These strips can be wirelessly managed to adjust lighting scenes according to time of day or occupancy. Buyers in Middle Eastern markets must prioritize flexible installation options to accommodate varied architectural designs and ensure wireless reliability amid complex building layouts. Aesthetic compatibility with interior design is also a key consideration to maintain brand standards.

Warehousing & Logistics

In warehousing, Zigbee LED strips facilitate zone-based lighting to improve visibility, safety, and workflow efficiency. Adaptive lighting helps workers quickly identify storage areas and navigate safely, reducing accidents and errors. For buyers in Africa and other emerging markets, sourcing durable LED strips with robust enclosures resistant to dust and moisture is essential. Long battery life and low maintenance requirements support cost-effective deployment in large, sometimes remote facilities.

Healthcare Facilities

Healthcare providers utilize Zigbee LED strips for patient rooms and corridors, enabling centralized lighting control that supports patient comfort and operational efficiency. Adjustable lighting can aid in circadian rhythm regulation and reduce staff fatigue. International buyers must ensure compliance with stringent healthcare lighting regulations and select products that are easy to clean and disinfect. Integration with hospital automation systems is crucial for seamless operation and energy management.

Related Video: How to use Tuya Smart’s ZigBee connection to control lights

Strategic Material Selection Guide for zigbee led strip

Printed Circuit Board (PCB) Material

The PCB is the backbone of any Zigbee LED strip, providing the physical platform and electrical pathways for LED chips and control circuitry. Common PCB materials include FR4 (fiberglass epoxy), aluminum-backed, and flexible polyimide substrates. FR4 offers excellent mechanical strength and flame retardancy, with temperature resistance typically up to 130°C. Aluminum PCBs enhance heat dissipation, critical for maintaining LED longevity and stable light output under continuous operation. Flexible polyimide boards allow bending and installation in curved or irregular surfaces, expanding application versatility.

Pros: FR4 is cost-effective and widely standardized, aluminum PCBs improve thermal management significantly, and flexible PCBs enable innovative design.

Cons: FR4 has limited heat dissipation, aluminum PCBs are more expensive and heavier, and flexible PCBs require more complex manufacturing processes.

Impact on Application: Aluminum PCBs are preferred in high-temperature or industrial environments common in Middle East and European markets, while flexible PCBs suit decorative or architectural lighting popular in South America and Africa.

B2B Considerations: Buyers should verify compliance with IPC-4101 (FR4) or IPC-2515 (aluminum) standards and ensure suppliers provide certifications like RoHS and UL. Regional preferences for flexible PCBs are rising but require sourcing from manufacturers experienced in polyimide handling to avoid quality issues.

LED Chips

LED chips are the core light-emitting components and directly influence brightness, color rendering, energy efficiency, and lifespan. High-quality chips from reputable manufacturers (e.g., Cree, Nichia, Osram) typically feature superior luminous efficacy and thermal stability. Chip materials often include gallium nitride (GaN) on sapphire or silicon carbide substrates, offering robust performance under varying electrical loads.

Pros: Premium LED chips deliver brighter light with lower power consumption and longer operational life, reducing maintenance costs.

Cons: High-grade chips increase upfront cost and may require precise thermal management. Lower-quality chips risk color shifting and early failure.

Impact on Application: In regions with unstable power grids like parts of Africa and South America, chips with higher tolerance to voltage fluctuations and heat are essential. Europe and the Middle East demand chips with consistent color temperature and compliance with stringent energy efficiency directives.

B2B Considerations: Buyers should request detailed datasheets and certifications such as Energy Star or IEC 62031 compliance. Sourcing from suppliers with proven supply chain transparency mitigates risks of counterfeit or substandard chips.

Adhesive Backing

The adhesive backing secures the LED strip in place and must withstand environmental factors such as humidity, temperature changes, and surface irregularities. Common adhesive types include 3M VHB (Very High Bond) tapes and silicone-based adhesives. These adhesives vary in peel strength, temperature resistance (often up to 80-120°C), and chemical resistance.

Pros: High-quality adhesives ensure long-term installation stability and resistance to peeling or degradation. Silicone adhesives offer superior resistance to moisture and UV exposure.

Cons: Lower-grade adhesives may fail in humid or hot environments, causing installation issues and increased warranty claims. Some adhesives may leave residue or damage surfaces upon removal.

Impact on Application: In tropical climates like Indonesia and Nigeria, adhesives with excellent moisture resistance are critical. For indoor European applications, ease of installation and clean removability may be prioritized.

B2B Considerations: International buyers should confirm adhesive certifications (e.g., ASTM D3330 for peel adhesion) and suitability for target environments. Packaging should protect adhesive integrity during transit, especially for shipments to humid or hot regions.

Protective Coating and Encapsulation Materials

Protective coatings such as silicone, epoxy, or polyurethane encapsulate LED strips to guard against dust, moisture, and mechanical damage. Silicone coatings are flexible and UV resistant, suitable for outdoor or harsh environments. Epoxy provides strong mechanical protection but is less flexible and can yellow over time. Polyurethane offers a balance of flexibility and chemical resistance.

Pros: Proper encapsulation extends product life, enables outdoor usage, and improves safety by insulating electrical components.

Cons: Coatings add cost and weight, and improper application can cause heat buildup or optical distortion. Epoxy coatings may degrade under prolonged UV exposure.

Impact on Application: Middle Eastern and African markets with high solar exposure benefit from UV-stable silicone coatings. South American buyers may prioritize waterproofing for outdoor installations. European buyers often require RoHS-compliant, eco-friendly encapsulants.

B2B Considerations: Verify compliance with IEC 60529 (IP rating) and regional environmental regulations. Request samples for performance testing under local climate conditions before large-scale procurement.

| Material | Typical Use Case for zigbee led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PCB Material (FR4/Aluminum/Flexible) | Structural foundation and electrical pathways | Thermal management (aluminum), flexibility (polyimide), cost-effectiveness (FR4) | Cost and manufacturing complexity vary by type | Med |

| LED Chips | Light emission and color quality | High luminous efficacy and long lifespan | Higher upfront cost, sensitive to heat | High |

| Adhesive Backing | Mounting and installation stability | Strong adhesion and environmental resistance | Potential failure in harsh environments | Low to Med |

| Protective Coatings | Environmental protection and durability | UV and moisture resistance, electrical insulation | Added cost and potential optical issues | Med |

In-depth Look: Manufacturing Processes and Quality Assurance for zigbee led strip

Manufacturing and quality assurance are critical pillars ensuring that Zigbee LED strips meet the demanding expectations of international B2B buyers. For buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding these processes helps in selecting reliable suppliers and securing products that comply with regional and global standards.

Key Stages in Zigbee LED Strip Manufacturing

-

Material Preparation

The manufacturing journey starts with sourcing high-grade components:

– LED Chips: Premium LED chips with high luminous efficacy and long lifespan are selected to ensure brightness and energy efficiency.

– Printed Circuit Boards (PCBs): Flexible or rigid PCBs are prepared, designed to provide optimal heat dissipation, which is vital for longevity and performance.

– Zigbee Modules: The wireless communication modules are integrated to enable smart control capabilities.

– Adhesive Backing and Protective Layers: High-quality adhesives ensure secure installation; protective coatings guard against moisture and dust. -

Forming and PCB Fabrication

PCBs are fabricated using precision etching and layering techniques. The choice between flexible PCBs for adaptable installations or rigid PCBs for structural stability depends on the target application. Advanced solder masks and copper thickness are applied to enhance electrical conductivity and durability. -

Component Assembly

Automated surface-mount technology (SMT) machines place LED chips and Zigbee modules accurately on the PCB. This is followed by reflow soldering to secure components. Manual inspection may supplement automation to ensure placement precision. -

Finishing Processes

Post-assembly, strips undergo:

– Encapsulation: Protective resins or silicone coatings are applied for environmental resistance.

– Cutting and Packaging: Strips are cut to standard lengths, packaged with anti-static materials, and labeled for traceability.

Quality Assurance Frameworks and Standards

For B2B buyers, supplier adherence to recognized quality management systems and certifications is paramount:

- ISO 9001: This global standard ensures systematic quality management across manufacturing processes, emphasizing continual improvement and customer satisfaction.

- CE Marking: Mandatory for products entering the European Economic Area, confirming compliance with safety, health, and environmental protection legislation.

- RoHS Compliance: Restricts hazardous substances in electrical products, essential for environmental safety and regulatory acceptance.

- UL Certification: Validates safety standards predominantly for North America but also recognized globally.

- Zigbee Alliance Certification: Ensures interoperability and reliability of Zigbee communication modules embedded in LED strips.

Quality Control Checkpoints and Testing Methods

Quality control (QC) is embedded at multiple stages to detect defects early and maintain consistent product performance:

-

Incoming Quality Control (IQC): Raw materials and components such as LED chips, PCBs, and Zigbee modules undergo rigorous inspection for dimensional accuracy, electrical properties, and certifications before entering production.

-

In-Process Quality Control (IPQC): During assembly, automated optical inspection (AOI) verifies component placement and solder quality. Functional tests on Zigbee connectivity and LED illumination are conducted to catch assembly faults.

-

Final Quality Control (FQC): Completed LED strips undergo:

- Electrical Testing: Verifying voltage, current, and power consumption to ensure energy efficiency.

- Environmental Stress Testing: Simulating temperature, humidity, and vibration conditions to guarantee durability.

- Communication Testing: Confirming Zigbee network integration and responsiveness.

- Visual Inspection: Checking for physical defects, color uniformity, and adhesive integrity.

Verifying Supplier Quality Assurance for International Buyers

B2B buyers, especially from regions like Nigeria, Indonesia, or Brazil, should adopt proactive verification approaches:

-

Supplier Audits: On-site or virtual audits assess manufacturing capabilities, QC processes, and compliance documentation. Audits help confirm the supplier’s adherence to international standards and production consistency.

-

Third-Party Inspections: Independent quality inspection agencies provide unbiased product evaluations, including random sampling, functional testing, and packaging verification before shipment.

-

Reviewing QC Reports: Detailed inspection and test reports—including certificates of compliance (CoC) and material traceability—should be requested to validate quality claims.

-

Sample Testing: Procuring pre-production samples for in-house or third-party testing allows buyers to verify performance and compatibility with their specific applications.

Navigating QC and Compliance Nuances Across Regions

-

Africa and Middle East: Regulatory landscapes may vary, but CE and RoHS compliance remain highly valued, especially for buyers targeting export markets. Certifications related to electromagnetic compatibility (EMC) and safety are critical to avoid customs delays.

-

South America: Import regulations often require conformity to local standards alongside international certifications. Buyers should ensure suppliers provide documentation in line with Mercosur or ANATEL requirements where applicable.

-

Europe: The EU’s stringent environmental and safety laws make CE marking and RoHS compliance non-negotiable. Buyers should verify the validity and scope of certifications, ensuring products meet the latest directives.

-

Southeast Asia (e.g., Indonesia): While local standards may be developing, international certifications facilitate smoother market entry. Buyers should confirm Zigbee certification for interoperability and seek suppliers with ISO 9001 quality management systems.

Strategic Recommendations for B2B Buyers

-

Prioritize Suppliers with Transparent QC Processes: Select manufacturers who openly share QC protocols, test data, and certifications, demonstrating commitment to quality.

-

Leverage Technology for Remote Verification: Use video audits, live factory tours, and digital QC reports to bridge distance gaps and maintain oversight.

-

Engage in Collaborative Quality Planning: Work with suppliers to align on testing parameters, acceptance criteria, and packaging standards tailored to your market needs.

-

Factor in Logistics and Packaging Quality: Ensure packaging protects the delicate Zigbee LED strips during long-distance shipping to prevent damage and returns.

By thoroughly understanding the manufacturing processes and quality assurance mechanisms behind Zigbee LED strips, international B2B buyers can make informed procurement decisions. This knowledge reduces risks, supports compliance, and fosters long-term partnerships that deliver reliable, high-performance smart lighting solutions worldwide.

Comprehensive Cost and Pricing Analysis for zigbee led strip Sourcing

When sourcing Zigbee LED strips, understanding the detailed cost structure and pricing dynamics is crucial for international B2B buyers. This knowledge empowers buyers from regions like Africa, South America, the Middle East, and Europe to negotiate effectively, optimize budgets, and ensure high-quality procurement.

Key Cost Components in Zigbee LED Strip Sourcing

-

Materials

The largest cost driver typically lies in the quality of core materials: LED chips, printed circuit boards (PCBs), adhesive backings, and Zigbee communication modules. Premium LED chips and advanced PCBs enhance brightness, longevity, and heat dissipation but come at a higher cost. Sourcing certified materials that meet RoHS, CE, or UL standards can increase upfront costs but reduce long-term risks. -

Labor

Labor costs vary significantly based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but it’s vital to balance cost savings against quality assurance. Skilled labor is essential for precision soldering of LED chips and module integration, impacting product reliability. -

Manufacturing Overhead

This includes factory utilities, equipment depreciation, and management expenses. High-tech factories investing in automation and quality control systems may have higher overhead but deliver better consistency and scalability.

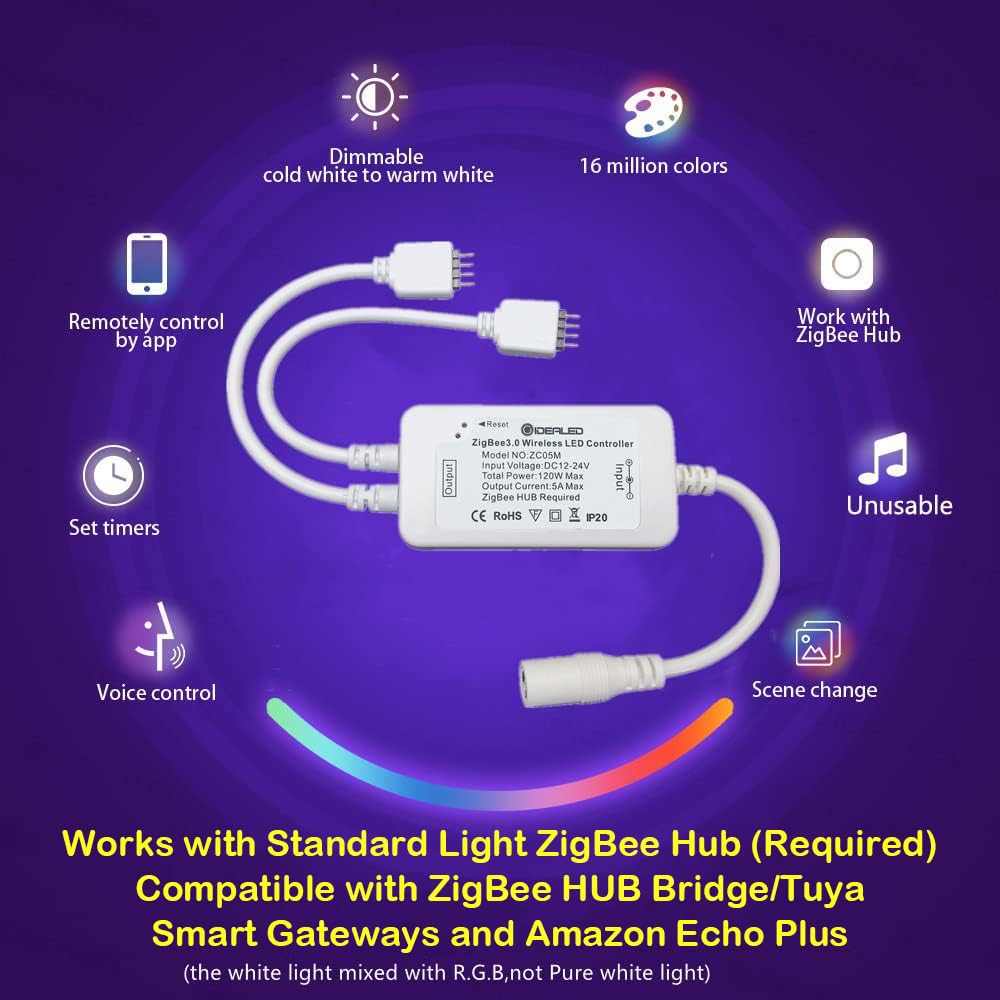

Illustrative Image (Source: Google Search)

-

Tooling and Setup

Custom Zigbee LED strip designs or specialized features require tooling investments—such as PCB design and mold creation. These are often one-time or amortized costs but affect pricing, especially for smaller order quantities. -

Quality Control (QC)

Rigorous testing protocols to ensure compliance and reliability add to costs. QC processes include stress testing, firmware verification for Zigbee modules, and final product inspections. Buyers should prioritize suppliers with transparent QC certifications to avoid hidden costs from product failures. -

Logistics and Import Duties

International shipping, customs clearance, and local taxes influence landed costs. Buyers must factor in Incoterms (e.g., FOB, CIF) which determine responsibility and cost allocation during transit. Efficient logistics partners and consolidated shipments can reduce per-unit costs. -

Supplier Margin

Supplier profit margins fluctuate based on brand reputation, order volume, and market demand. Established suppliers with strong certifications may command higher prices but offer greater reliability and support.

Price Influencers to Consider

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock volume discounts. Buyers from emerging markets should negotiate MOQs that align with demand forecasts to avoid overstocking or premium pricing on small runs.

- Specifications and Customization: Custom lengths, color temperatures, or integrated sensors increase complexity and cost. Standardized Zigbee LED strips are more cost-effective.

- Material Quality and Certifications: Certified components and compliance with international standards justify higher prices but reduce risks of regulatory issues and returns.

- Supplier Location and Reputation: Proximity to suppliers can lower logistics costs. However, buyers should weigh supplier reliability and after-sales support over mere geographic convenience.

- Incoterms Impact: Understanding terms like EXW (Ex Works), FOB (Free On Board), or DDP (Delivered Duty Paid) helps clarify which party bears shipping and customs costs, impacting total expenditure.

Practical Tips for International B2B Buyers

- Negotiate Based on Total Cost of Ownership (TCO): Don’t focus solely on unit price. Consider warranty terms, energy efficiency, lifespan, and after-sales service, which affect long-term value.

- Request Detailed Cost Breakdowns: Transparency on material, labor, and overhead costs helps identify negotiation levers and validate pricing fairness.

- Leverage Local Market Insights: Buyers in Africa, South America, the Middle East, and Europe should factor in regional import duties, currency fluctuations, and local standards compliance.

- Consolidate Shipments and Optimize Logistics: Combining multiple orders or sourcing from suppliers with global distribution centers can reduce freight costs and lead times.

- Verify Certification and Testing Documentation: Insist on certificates like CE, RoHS, and Zigbee Alliance compliance to avoid costly rejections in regulated markets.

- Consider Supplier Reliability Over Lowest Price: Cheaper products with poor quality or support can increase total costs through returns, replacements, and downtime.

Indicative Pricing Disclaimer

Pricing for Zigbee LED strips varies widely based on specifications, order size, and supplier terms. Buyers should treat initial quotations as indicative and conduct thorough due diligence. Market conditions, raw material price fluctuations, and logistics disruptions may also influence final costs.

By thoroughly analyzing these cost components and price influencers, international B2B buyers can make informed sourcing decisions, ensuring competitive pricing without compromising on quality or compliance. This approach is especially vital for emerging and diverse markets where supply chain nuances significantly impact procurement success.

Spotlight on Potential zigbee led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘zigbee led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for zigbee led strip

Critical Technical Properties of Zigbee LED Strips

1. Material Grade of PCB and LED Chips

The quality of the Printed Circuit Board (PCB) and LED chips directly influences the durability, heat dissipation, and luminous efficiency of Zigbee LED strips. High-grade PCBs ensure stable electrical connections and effective thermal management, which extends the lifespan of the product—crucial for commercial installations. Premium LED chips deliver brighter light output with lower power consumption, optimizing operational costs for businesses.

2. Power Consumption and Voltage Tolerance

Zigbee LED strips typically operate within specific voltage ranges (commonly 12V or 24V DC). Understanding voltage tolerance is essential to prevent damage from power surges or fluctuations, especially in regions with unstable electricity supply. Lower power consumption models reduce energy costs and are more environmentally friendly, aligning with global sustainability trends.

3. Wireless Communication Range and Protocol Compliance

Since Zigbee LED strips rely on Zigbee wireless technology, the communication range (usually up to 10-30 meters indoors) and compliance with Zigbee protocol versions (e.g., Zigbee 3.0) are critical. This ensures seamless integration with smart home or commercial automation systems, providing reliable remote control and interoperability with other Zigbee-enabled devices.

4. IP Rating (Ingress Protection)

The IP rating indicates the product’s resistance to dust and water. For indoor commercial use, an IP20 rating may suffice, but outdoor or industrial applications require higher ratings like IP65 or above. This specification is vital for buyers in regions with humid or dusty environments, such as parts of Africa or the Middle East, ensuring longevity and safety.

5. Color Rendering Index (CRI) and Color Temperature

CRI measures how accurately the LED light displays colors compared to natural light. A CRI above 80 is desirable for commercial and retail environments where color precision is important. Color temperature (measured in Kelvins) affects ambiance—warm white (~2700K) for cozy settings or cool white (~6000K) for task lighting. Customizable color temperatures add value for diverse applications.

6. Adhesive Quality and Flexibility

Adhesive backing quality affects installation ease and long-term adherence, especially on varied surfaces common in international markets. Flexibility of the strip (flexible vs. rigid PCB) determines suitability for curved or uneven surfaces. Both factors reduce installation time and costs, which is a significant consideration for large-scale projects.

Key Trade Terminology for International B2B Buyers

OEM (Original Equipment Manufacturer)

Refers to companies that produce products or components that are purchased by another company and retailed under that purchasing company’s brand. For B2B buyers, partnering with OEMs can enable customized Zigbee LED strips tailored to specific market needs or branding requirements, often at competitive pricing.

MOQ (Minimum Order Quantity)

The smallest amount of product a supplier is willing to sell in one order. Understanding MOQ is essential for inventory and budget planning, especially for buyers in emerging markets such as Nigeria or Indonesia, where upfront capital may be limited. Negotiating MOQ can impact pricing and supply chain flexibility.

RFQ (Request for Quotation)

A formal process where buyers request detailed pricing and terms from suppliers for specified quantities and product specifications. RFQs help businesses compare offers transparently and ensure that Zigbee LED strips meet technical and commercial requirements before committing to purchase.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers regarding shipping, insurance, and customs clearance. Common terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears costs and risks at different shipment stages, critical for international buyers navigating logistics.

Lead Time

The time period between placing an order and receiving the goods. For Zigbee LED strips, lead time impacts project timelines and inventory management. Buyers should confirm lead times upfront to align procurement with installation schedules and avoid costly delays.

Compliance Certifications (CE, RoHS, UL)

Certifications indicate that products meet regulatory safety, environmental, and performance standards. For B2B buyers in Europe, Africa, and the Middle East, certifications such as CE (European Conformity) and RoHS (Restriction of Hazardous Substances) are often mandatory. UL certification is important for North American markets. Ensuring compliance reduces risks related to product liability and market entry barriers.

Understanding these technical properties and trade terms equips international B2B buyers with the knowledge to make informed procurement decisions, optimize costs, and ensure seamless integration of Zigbee LED strips into their projects across diverse regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the zigbee led strip Sector

Market Overview & Key Trends

The Zigbee LED strip sector is experiencing robust growth driven by the increasing adoption of smart lighting solutions across residential, commercial, and industrial markets globally. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, this growth is propelled by demand for energy-efficient, scalable, and interoperable IoT lighting systems. Key market drivers include urbanization, smart city initiatives, and rising awareness of energy conservation, which align well with Zigbee’s low-power, mesh networking capabilities.

In emerging markets such as Nigeria, Indonesia, and parts of South America, infrastructure modernization and smart home penetration are accelerating Zigbee LED strip adoption. Buyers in these regions benefit from the technology’s compatibility with diverse smart home ecosystems, enabling integration with voice assistants and home automation hubs. Europe and the Middle East are witnessing increasing regulatory support for energy-efficient lighting, pushing procurement towards Zigbee-enabled LED strips that comply with strict energy and safety standards.

Current sourcing trends reveal a shift towards modular, customizable LED strips that can be tailored to specific project requirements, including length, color temperature, and control options. Suppliers increasingly offer Zigbee LED strips bundled with compatible gateways and hubs, simplifying deployment for integrators. Additionally, the industry is seeing a rise in demand for flexible PCBs and advanced LED chips that enhance durability and luminous efficacy, critical for commercial installations in harsh environments.

Supply chain dynamics emphasize the importance of reliable component sourcing, particularly for LED chips and PCBs, which directly influence product quality and lifespan. International buyers should prioritize vendors with transparent supply chains and robust quality control protocols to mitigate risks associated with counterfeit or substandard components. Given the global semiconductor and electronics component shortages, early engagement with suppliers and flexible order planning are recommended to secure timely delivery.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to procurement decisions in the Zigbee LED strip sector. The environmental impact of LED manufacturing, including raw material extraction, energy consumption during production, and end-of-life disposal, necessitates a strategic approach to sourcing. B2B buyers are urged to seek suppliers committed to reducing carbon footprints through energy-efficient manufacturing processes and the use of recyclable or bio-based materials.

Ethical sourcing is equally critical, as the LED strip supply chain often involves multiple tiers spanning different countries with varied labor and environmental regulations. Buyers should insist on certifications such as RoHS (Restriction of Hazardous Substances), CE (Conformité Européenne), and ISO 14001 (Environmental Management) to ensure compliance with international environmental and safety standards. These certifications provide assurance that products are free from hazardous substances and are manufactured with minimal environmental harm.

Moreover, the integration of “green” materials — for example, lead-free solder, halogen-free PCBs, and environmentally friendly adhesives — enhances the sustainability profile of Zigbee LED strips. Many suppliers now provide lifecycle assessments and transparent reporting on material sourcing, enabling buyers to make informed decisions aligned with corporate social responsibility (CSR) goals. Prioritizing vendors who actively participate in circular economy initiatives, such as product take-back or recycling programs, can further reduce environmental impact.

For buyers in regions with emerging sustainability regulations, partnering with suppliers who already comply with advanced eco-standards can future-proof investments and facilitate smoother market entry. Sustainability-focused sourcing also supports brand differentiation and meets the growing demand from end-users for environmentally responsible smart lighting solutions.

Evolution of Zigbee LED Strip Technology

Zigbee LED strip technology has evolved significantly since its inception, paralleling advancements in IoT and smart home ecosystems. Initially, LED strips were simple, manually controlled lighting solutions. The integration of Zigbee wireless communication protocols transformed them into intelligent lighting devices capable of mesh networking, remote control, and automation.

Early Zigbee LED strips focused on basic on/off and dimming functionalities. Over time, they incorporated color tuning, scene setting, and integration with voice assistants like Amazon Alexa and Google Assistant. The development of standardized Zigbee profiles and certified interoperability has enabled seamless multi-vendor ecosystems, a key advantage for B2B buyers seeking flexible and scalable smart lighting solutions.

Manufacturing advancements, including improved LED chip efficiency, flexible PCB designs, and enhanced adhesive technologies, have increased product reliability and installation versatility. Today’s Zigbee LED strips support firmware updates over the air (OTA), enabling ongoing feature enhancements and security improvements, crucial for long-term commercial deployments.

This evolution reflects a broader trend towards interconnected, sustainable, and customizable lighting infrastructure that meets the diverse needs of global markets, making Zigbee LED strips a compelling choice for international B2B buyers seeking innovation and reliability.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of zigbee led strip

-

How can I verify the credibility and reliability of a Zigbee LED strip supplier internationally?

To ensure you partner with a credible supplier, request detailed company credentials including business licenses, export records, and customer references. Verify certifications such as ISO 9001 for quality management and compliance with international standards like CE, RoHS, or UL. Use third-party inspection services or factory audits to assess manufacturing capabilities and quality control processes. Also, check for experience in exporting to your region, as familiarity with local regulations and logistics can mitigate risks in Africa, South America, the Middle East, or Europe. -

Is it possible to customize Zigbee LED strips to meet specific technical or branding requirements?

Yes, many manufacturers offer customization options such as LED color temperature, strip length, PCB type (flexible or rigid), adhesive backing, and packaging. You can also request firmware adjustments for Zigbee compatibility with your existing smart home or industrial IoT systems. Before finalizing, clarify minimum order quantities (MOQs), lead times, and any additional costs for custom features. Confirm that your supplier has R&D capabilities to support tailored solutions, which is crucial for differentiation in competitive markets. -

What are typical minimum order quantities (MOQs) and lead times for international orders of Zigbee LED strips?

MOQs vary widely depending on the supplier, customization level, and region, but generally range from 500 to 5,000 units per SKU. Lead times can span from 4 to 12 weeks, factoring in production, quality testing, and shipping. For buyers in regions like Nigeria or Indonesia, consider additional time for customs clearance and logistics delays. Negotiating flexible MOQs or phased delivery schedules can help manage cash flow and inventory risks, especially when entering new markets or launching new products. -

What payment terms are standard for international B2B purchases of Zigbee LED strips, and how can buyers protect themselves?

Common payment terms include 30-50% upfront deposit with the balance paid before shipment or via letter of credit (LC) to secure transaction safety. For new suppliers, using escrow services or trade assurance platforms reduces risks. Always request proforma invoices detailing product specifications and delivery terms. Establishing clear contractual terms including penalties for delays or non-compliance is crucial. For buyers in emerging markets, working with suppliers experienced in international trade finance can ease currency exchange and banking challenges. -

Which quality assurance certifications should I expect from Zigbee LED strip suppliers to ensure compliance and safety?

Key certifications include CE (European Conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and FCC (Federal Communications Commission) for electromagnetic compatibility. ISO 9001 certification indicates robust quality management systems. Additionally, Zigbee Alliance certification ensures device interoperability within Zigbee networks. Request test reports from accredited labs and confirm that products comply with your local import regulations. These certifications not only ensure product safety but also facilitate smoother customs clearance and market acceptance. -

What logistics considerations should I keep in mind when importing Zigbee LED strips to Africa, South America, the Middle East, or Europe?

Choose suppliers with experience shipping to your region to navigate customs duties, import taxes, and documentation requirements efficiently. Opt for reliable shipping methods balancing cost and speed, such as sea freight for large volumes or air freight for urgent orders. Verify packaging robustness to prevent damage during transit, especially in harsh climatic conditions common in some regions. Establish clear Incoterms (e.g., FOB, CIF) to define responsibilities and risks during shipping. Collaborating with local freight forwarders can streamline clearance and last-mile delivery. -

How should disputes or quality issues be managed in international Zigbee LED strip transactions?

First, ensure your contract includes clear clauses on quality standards, inspection rights, dispute resolution mechanisms, and warranty terms. On receiving goods, conduct prompt inspections and document any defects with photos and reports. Communicate issues immediately with the supplier and negotiate remedies such as replacement, refund, or repair. Utilizing third-party inspection agencies or arbitration services can provide impartial resolution. Building long-term relationships with transparent communication reduces the likelihood and impact of disputes. -

What trends should B2B buyers consider when sourcing Zigbee LED strips for evolving smart lighting markets globally?

Stay informed about emerging standards in Zigbee 3.0 and integration with other IoT protocols like Thread or Matter, which enhance device compatibility. Demand is growing for energy-efficient, longer-lasting LED chips and flexible PCBs enabling innovative installations. Buyers should prioritize suppliers who invest in R&D and can provide scalable, customizable solutions. Additionally, sustainability certifications and eco-friendly materials are increasingly important for compliance and brand positioning, especially in European and Middle Eastern markets. Keeping pace with these trends ensures competitive advantage and future-proof procurement.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for zigbee led strip

Key Takeaways for Strategic Sourcing of Zigbee LED Strips

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, strategic sourcing of Zigbee LED strips hinges on prioritizing quality, compliance, and supplier reliability. Selecting products with premium LED chips, robust PCB fabrication, and strong adhesive backing ensures durability and superior performance. Equally critical is partnering with manufacturers who adhere to international standards such as CE, RoHS, and UL, which not only guarantee safety but also facilitate smoother import and distribution across diverse regulatory environments.

Supply chain transparency and supplier expertise in IoT-enabled smart lighting solutions provide a competitive edge by reducing risks related to product inconsistencies and delivery delays. Leveraging suppliers with proven experience in Zigbee protocol integration and quality control testing enhances product compatibility and long-term operational efficiency.

Outlook and Strategic Recommendations

As smart lighting adoption accelerates globally, the demand for Zigbee-enabled LED strips will continue to grow, driven by increasing urbanization and energy efficiency initiatives. Buyers from emerging markets should focus on cultivating long-term partnerships with innovative manufacturers capable of delivering scalable solutions tailored to regional requirements.

To maximize value, buyers are encouraged to engage in thorough supplier audits, insist on sample testing, and negotiate flexible terms that accommodate evolving technology standards. Embracing strategic sourcing today will position your business to capitalize on the expanding smart lighting ecosystem and meet the rising expectations of modern consumers worldwide.