Introduction: Navigating the Global Market for solar led strip lights waterproof

The global demand for solar LED strip lights with waterproof capabilities is rapidly increasing as businesses worldwide seek sustainable, durable, and versatile lighting solutions for outdoor and harsh-environment applications. For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of these products is essential to making procurement decisions that align with local climate challenges, regulatory standards, and project specifications.

Waterproof solar LED strip lights combine renewable energy efficiency with robust protection against moisture, dust, and extreme weather—key factors for installations ranging from commercial landscaping and architectural highlights to public infrastructure and recreational areas. However, the vast array of waterproof grades, solar integration options, voltage types, and material constructions can complicate sourcing.

This guide offers a comprehensive roadmap to help international buyers confidently navigate the complexities of the solar waterproof LED strip light market. It delves into critical product categories, including IP ratings and their real-world implications, solar panel and battery integration, manufacturing quality controls, and supply chain considerations. Moreover, it provides detailed cost analysis and market insights tailored to regional demand patterns and purchasing behaviors.

By equipping buyers with in-depth knowledge of product specifications, supplier vetting criteria, and industry best practices, this guide empowers stakeholders in Brazil, Spain, Nigeria, UAE, and beyond to optimize their procurement strategies. The result is a smarter sourcing process that ensures long-lasting, energy-efficient, and cost-effective lighting solutions tailored to their unique environmental and commercial needs.

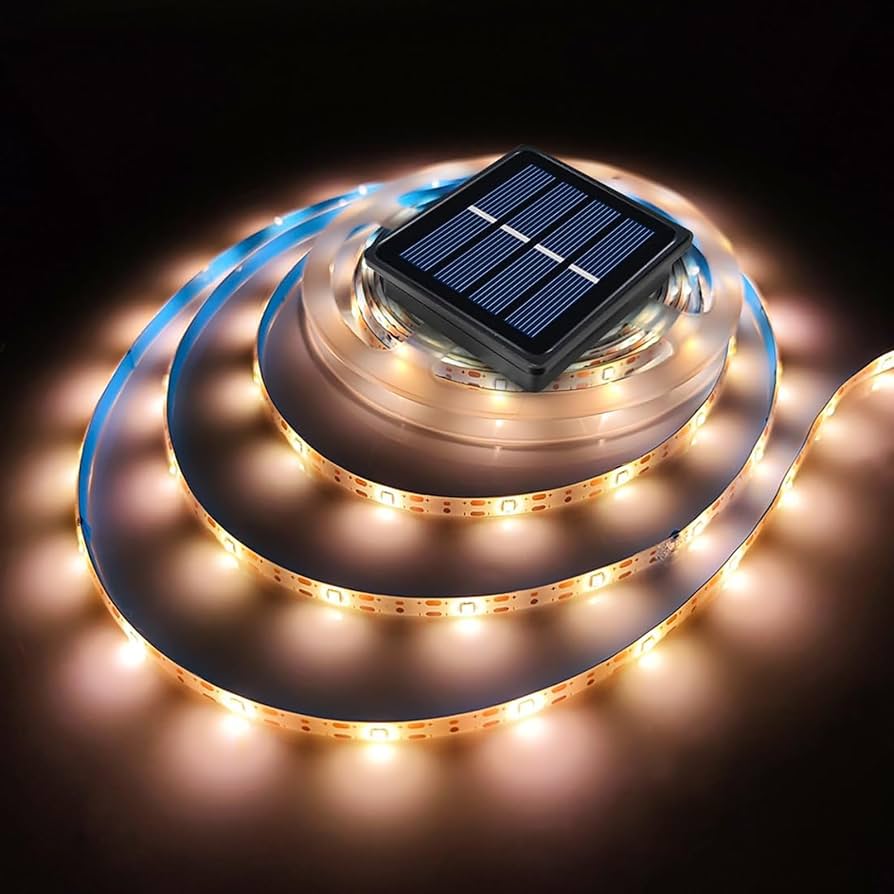

Illustrative Image (Source: Google Search)

Understanding solar led strip lights waterproof Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IP65 Silicone Coated Solar LED Strip | Silicone surface coating, splash-proof, lightweight | Outdoor patios, eaves, light rain-exposed areas | + Cost-effective, flexible; – Limited to splash resistance |

| IP67 Silicone Extrusion Solar LED Strip | Enclosed in hollow silicone extrusion with sealed ends | Garden borders, gazebos, heavy rain environments | + Strong water resistance, reusable housing; – Less flexible |

| IP68 Fully Silicone Filled Solar LED Strip | Fully filled with silicone gel, complete waterproofing | Underwater fountains, ponds, permanent immersion | + Ultimate waterproofing, durable; – Higher cost, harder to repair |

| IP65 Silicone Tube Solar LED Strip | LED strip inserted into a silicone tube, hollow protection | Decorative outdoor signage, indirect wet areas | + Good physical protection, easy replacement; – Not for submersion |

| IP24/Non-Waterproof Solar LED Strip | No waterproofing or minimal moisture resistance | Indoor solar-powered lighting | + Lowest cost, high flexibility; – Not suitable for outdoor use |

IP65 Silicone Coated Solar LED Strip

These strips have a thin silicone coating that offers splash-proof protection, making them ideal for outdoor areas exposed to light rain or moisture such as patios or eaves. They are lightweight and flexible, which facilitates installation in curved or irregular surfaces. For B2B buyers targeting residential landscaping or light commercial outdoor projects, IP65 strips provide a cost-efficient solution. However, they are not suitable for areas prone to heavy rain or immersion, limiting their durability in harsher climates.

IP67 Silicone Extrusion Solar LED Strip

IP67-rated strips are enclosed within a hollow silicone extrusion with sealed ends, providing robust protection against heavy rain and temporary water immersion. This type is highly suitable for commercial landscaping, outdoor signage, and garden installations where exposure to frequent moisture is expected. The reusable housing allows for easier maintenance and replacement. Buyers from regions with seasonal heavy rains or humid climates (e.g., parts of Africa and South America) will find these strips reliable for medium-term outdoor use.

IP68 Fully Silicone Filled Solar LED Strip

The highest waterproof rating, IP68 strips are fully encapsulated in silicone gel, providing complete protection against continuous water immersion. These are ideal for permanent underwater installations such as fountains, ponds, or pool lighting in luxury resorts or public parks. While offering superior durability and waterproofing, they come with higher upfront costs and are more challenging to cut or repair. B2B buyers focusing on premium outdoor aquatic projects or architectural lighting will benefit from this investment.

IP65 Silicone Tube Solar LED Strip

This variation places the LED strip inside a hollow silicone tube, offering better physical protection than a simple coating. It is well-suited for decorative outdoor lighting applications such as neon-like signage or accent lighting under eaves where occasional splashes occur but full submersion is unlikely. The tube design also allows for easier replacement or re-sleeving, which is advantageous for maintenance-heavy commercial projects in regions like the Middle East or Europe with moderate outdoor exposure.

IP24/Non-Waterproof Solar LED Strip

These strips lack waterproofing and are intended primarily for indoor use or protected outdoor areas. They offer the lowest cost and maximum flexibility, making them attractive for indoor solar lighting or temporary outdoor setups. However, they are unsuitable for direct exposure to moisture and outdoor elements. B2B buyers should avoid these for any outdoor or humid environment projects to prevent premature product failure and increased replacement costs.

Related Video: Govee Outdoor LED Strip Lights Waterproof | Review

Key Industrial Applications of solar led strip lights waterproof

| Industry/Sector | Specific Application of solar led strip lights waterproof | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Agritech | Solar-powered greenhouse and farm perimeter lighting | Enables energy-efficient, off-grid illumination for crop protection and security in remote areas | High IP rating (IP67/IP68) for dust and water resistance; durable materials for harsh outdoor conditions; compatibility with solar power systems |

| Hospitality & Tourism | Outdoor ambiance lighting for resorts, hotels, and eco-lodges | Enhances guest experience with sustainable, low-maintenance lighting that reduces operational costs | Aesthetic flexibility (color temperature and dimming options); robust waterproofing; ease of installation and maintenance in diverse climates |

| Urban Infrastructure | Solar LED lighting for pedestrian pathways, parks, and public spaces | Improves safety and visibility while reducing energy costs and carbon footprint in urban development | Compliance with local voltage standards (e.g., 220V in Europe, 110V in some regions); weatherproof rating suitable for local climate; long lifespan for public use |

| Retail & Commercial | Outdoor storefront and signage illumination powered by solar | Attracts customers with vibrant, eco-friendly lighting while minimizing electricity expenses | High brightness and color consistency; IP65+ rating for exposure to rain and dust; integration with solar battery storage for consistent operation |

| Transportation & Logistics | Solar LED strip lighting for loading docks, parking lots, and vehicle bays | Enhances operational safety and security in off-grid or remote transport hubs | Robust waterproofing (IP67+), resistance to physical impact; compatibility with existing solar infrastructure; ease of installation in large-scale sites |

Agriculture & Agritech

In agricultural sectors across Africa, South America, and the Middle East, solar LED strip lights waterproof are increasingly used to illuminate greenhouses and farm perimeters. These lights provide reliable, off-grid illumination crucial for protecting crops from pests and ensuring security in remote areas where grid access is limited. Buyers should prioritize IP67 or higher ratings to withstand dust, heavy rain, and irrigation water. Additionally, compatibility with solar panels and battery storage systems is essential to maximize energy independence and reduce operational costs.

Hospitality & Tourism

Resorts, eco-lodges, and hotels in regions like Spain and Brazil benefit from solar waterproof LED strips to create inviting outdoor atmospheres while showcasing environmental responsibility. These lights help reduce energy consumption and maintenance needs, particularly in remote or off-grid locations. Buyers must consider lighting flexibility, such as adjustable color temperature and dimming, to tailor ambiance for guest comfort. Robust waterproofing ensures longevity despite exposure to coastal humidity or desert heat.

Urban Infrastructure

Municipalities and urban developers are adopting solar waterproof LED strip lighting to enhance public safety in parks, pathways, and plazas. This application reduces dependency on grid electricity and lowers carbon emissions, aligning with sustainability goals prominent in European and Middle Eastern cities. International buyers should verify local voltage compatibility (often 220V in Europe, 110V in some areas) and ensure the product’s IP rating matches local climate challenges, such as heavy rainfall or dust storms.

Retail & Commercial

Outdoor retail spaces and commercial signage use solar-powered waterproof LED strips to attract customers with vibrant illumination while cutting electricity expenses. This is especially relevant in emerging markets in Africa and South America where energy costs are high or grid reliability is low. Buyers should seek products with consistent brightness and color fidelity, IP65 or above for weather resistance, and seamless integration with solar battery systems to maintain lighting during nighttime or cloudy conditions.

Transportation & Logistics

Loading docks, parking areas, and vehicle bays in logistics hubs benefit from solar LED strip lights with waterproofing to ensure safety and security. These lights support operations in off-grid or remote locations common in large transport networks across Africa and South America. Key sourcing factors include high IP ratings (IP67+), mechanical durability to withstand impacts, and compatibility with existing solar installations. Ease of installation and scalability are also critical for large facilities requiring extensive lighting coverage.

Related Video: 52.5 ft Waterproof Outdoor LED Kit from Novastella

Strategic Material Selection Guide for solar led strip lights waterproof

When selecting materials for solar LED strip lights designed to be waterproof, B2B buyers must carefully evaluate the properties that affect durability, performance, and suitability for diverse environmental conditions. The choice of material directly influences the product’s resistance to moisture, UV exposure, temperature extremes, and chemical corrosion, all of which are critical for outdoor solar lighting applications in regions like Africa, South America, the Middle East, and Europe.

Silicone

Key Properties:

Silicone is highly flexible, UV resistant, and exhibits excellent thermal stability, typically withstanding temperatures from -50°C to 200°C. It offers superior waterproofing due to its ability to form a seamless, airtight seal around LED strips. Silicone also resists many chemicals and environmental pollutants, making it ideal for harsh outdoor conditions.

Pros & Cons:

– Pros: Excellent waterproofing (up to IP68), high flexibility for installation on curved surfaces, strong UV and temperature resistance, and good longevity.

– Cons: Higher manufacturing complexity and cost compared to simpler coatings; silicone-filled strips can be difficult to cut or repair on-site.

Impact on Application:

Silicone-encased LED strips are well-suited for underwater installations (e.g., fountains, pools) and exposed outdoor environments with heavy rain or dust. However, in areas with high chlorine presence (e.g., some pool installations), silicone may degrade faster, requiring careful specification.

Considerations for International Buyers:

Buyers in regions with intense sunlight and high temperatures, such as the Middle East and parts of Africa, benefit from silicone’s UV resistance. European buyers should verify compliance with standards such as DIN 53504 for silicone rubber and ASTM D2000 for elastomers. In South America, where humidity and rain are prevalent, silicone’s waterproofing ensures reliability. Cost-conscious buyers must balance silicone’s premium price against its performance benefits.

Polyurethane (PU)

Key Properties:

Polyurethane is a versatile polymer known for its toughness, abrasion resistance, and chemical resistance. It maintains flexibility across a wide temperature range (-40°C to 90°C) but is less UV stable than silicone unless specially treated.

Pros & Cons:

– Pros: Strong mechanical protection, good waterproofing (commonly IP65 to IP67), abrasion and chemical resistance, and relatively easier to process than silicone.

– Cons: Susceptible to yellowing and brittleness under prolonged UV exposure; moderate temperature resistance limits use in extreme heat environments.

Impact on Application:

PU coatings or tubes are suitable for outdoor applications with moderate exposure to water and mechanical stress, such as garden lighting or patio installations. They are less ideal for underwater or very high-temperature environments.

Considerations for International Buyers:

In South America and Africa, where outdoor lighting may face dust and moderate moisture, PU offers a cost-effective waterproofing solution. However, buyers in the Middle East should consider the potential for UV degradation unless UV-stabilized PU is specified. Compliance with ASTM D412 (tensile properties) and ISO 527 (plastic tensile testing) is common for PU materials in Europe.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used plastic with good waterproofing properties and chemical resistance. It is rigid or flexible depending on plasticizers added and has moderate temperature resistance (-15°C to 60°C). PVC is also resistant to many acids and alkalis but can degrade under UV exposure without additives.

Pros & Cons:

– Pros: Low cost, easy to manufacture, good waterproofing for IP65 ratings, and widely available globally.

– Cons: Limited flexibility compared to silicone and PU, lower temperature tolerance, and potential environmental concerns due to plasticizers and chlorine content.

Impact on Application:

PVC-sleeved LED strips are suitable for sheltered outdoor use where direct sunlight and extreme temperatures are limited, such as under eaves or covered walkways. They are generally not recommended for underwater or highly exposed installations.

Considerations for International Buyers:

PVC’s affordability makes it attractive for large-scale projects in emerging markets across Africa and South America. However, buyers should ensure compliance with local environmental regulations regarding PVC use and disposal. European buyers may prefer alternatives due to stricter environmental standards (e.g., REACH). For Middle Eastern markets, temperature limitations should be considered carefully.

Epoxy Resin

Key Properties:

Epoxy resin coatings provide a hard, durable, and waterproof seal with excellent chemical resistance and electrical insulation. They typically withstand temperatures up to 120°C but are rigid and less flexible than silicone or PU.

Pros & Cons:

– Pros: Strong waterproofing (up to IP67), excellent adhesion to PCB surfaces, chemical and corrosion resistance, and cost-effective for mass production.

– Cons: Rigid and brittle, making installation on curved surfaces difficult; prone to cracking under mechanical stress or thermal cycling.

Impact on Application:

Epoxy-coated LED strips are ideal for fixed, flat installations where mechanical flexibility is not required, such as signage or architectural lighting. They are less suitable for dynamic or flexible solar lighting applications.

Considerations for International Buyers:

Epoxy resin coatings meet many international standards like ASTM D256 (impact resistance) and IEC 60529 (IP ratings). Buyers in Europe and South America often require certifications for chemical safety and environmental impact. In Africa and the Middle East, epoxy’s durability and low cost make it a practical choice for fixed outdoor lighting, but flexibility limitations must be accounted for.

Summary Table

| Material | Typical Use Case for solar led strip lights waterproof | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Underwater installations, exposed outdoor environments | Superior waterproofing, UV & temperature resistance | Higher cost, complex manufacturing, difficult repairs | High |

| Polyurethane (PU) | Outdoor areas with moderate moisture and mechanical stress | Good abrasion and chemical resistance, easier processing | UV degradation risk, moderate temperature tolerance | Medium |

| Polyvinyl Chloride (PVC) | Sheltered outdoor use, cost-sensitive projects | Low cost, good waterproofing, widely available | Limited flexibility, lower temperature tolerance, environmental concerns | Low |

| Epoxy Resin | Fixed, flat installations like signage and architectural lighting | Strong waterproof seal, chemical resistance, cost-effective | Rigid, brittle, poor flexibility | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for solar led strip lights waterproof

Overview of Manufacturing Processes for Waterproof Solar LED Strip Lights

The production of waterproof solar LED strip lights involves a series of meticulous stages designed to ensure durability, performance, and weather resistance. Given their outdoor application and exposure to elements, the manufacturing process prioritizes precision in material selection, assembly, and sealing techniques.

1. Material Preparation

- PCB Fabrication: High-quality flexible printed circuit boards (PCBs) form the base. These PCBs often use corrosion-resistant copper layers and are coated with solder masks suitable for outdoor use.

- LED Selection: LEDs are chosen based on brightness, efficiency, and color temperature. For solar LED strips, LEDs with low power consumption and high luminous efficacy are preferred to optimize solar energy use.

- Waterproof Encapsulation Materials: Silicone, polyurethane, or specialized epoxy resins are prepared for sealing. These materials are selected for UV resistance, flexibility, and waterproof properties aligned with the IP rating requirements (e.g., IP65, IP67, or IP68).

2. Forming and Assembly

- LED Mounting: Surface-mount technology (SMT) machines place LEDs and other components (resistors, ICs) on the PCB with high accuracy.

- Soldering: Automated reflow soldering ensures consistent electrical connections, critical for long-term reliability.

- Encapsulation: Depending on the waterproof rating:

- IP65: Silicone coating or tubing is applied, offering protection against splashes.

- IP67: Silicone extrusion with sealed ends or hollow silicone tubes filled with silicone gel for immersion protection.

- IP68: Complete silicone filling or extrusion methods provide the highest waterproofing for continuous underwater use.

- Solar Panel Integration: For solar-powered strips, photovoltaic cells are integrated, often connected via waterproof junctions and cables.

- Connector Assembly: Waterproof connectors and power inputs are installed, ensuring secure, moisture-proof electrical connections.

3. Finishing

- Cutting and Packaging: Strips are cut to standard or custom lengths, with clean edges to maintain waterproof integrity.

- Protective Layer Application: Additional layers like UV-resistant coatings or protective films may be applied to enhance longevity.

- Labeling: Compliance marks, batch numbers, and installation instructions are printed or attached.

Quality Assurance and Control (QA/QC) in Production

Robust quality control is essential in manufacturing waterproof solar LED strip lights, particularly for international B2B buyers who require consistent product performance across diverse climates and regulatory environments.

Relevant International and Industry Standards

- ISO 9001: Ensures the manufacturer maintains a comprehensive quality management system covering all production stages.

- CE Marking: Mandatory for European markets, confirming compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances, critical for environmentally conscious buyers globally.

- IP Certification (IEC 60529): Validates waterproof and dustproof performance, crucial for product claims like IP65, IP67, or IP68.

- Other Regional Certifications: For example, ANATEL in Brazil or SASO in the Middle East may require additional local compliance checks.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials such as PCBs, LEDs, silicone, and solar cells undergo inspection for conformity to specifications before production starts.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, component placement accuracy, and waterproof encapsulation integrity.

- Final Quality Control (FQC): Comprehensive testing of finished products, including waterproof tests, electrical performance, and visual inspection.

Common Testing Methods

- Waterproof Testing: Immersion or spray tests simulate real-world conditions to verify IP ratings. For example, IP67 strips are submerged in water up to 1 meter for 30 minutes.

- Electrical Testing: Voltage, current, and insulation resistance tests ensure electrical safety and efficiency.

- Luminosity and Color Consistency: Measurements with spectrometers confirm brightness levels and color temperature align with product specifications.

- Mechanical Durability: Flexibility tests, vibration, and impact assessments verify the strip’s resilience during installation and use.

- Solar Performance Testing: For solar-powered strips, charge and discharge cycles of integrated solar cells and batteries are evaluated.

Verification Strategies for B2B Buyers

To mitigate risks and ensure supplier reliability, international buyers should adopt a multi-layered approach to QC verification.

Supplier Audits

- Conduct on-site factory audits focusing on production processes, QC systems, and compliance with international standards.

- Verify certifications such as ISO 9001, CE, RoHS, and IP test reports.

- Assess supplier capabilities in handling environmental challenges specific to your region (e.g., high humidity in Africa or temperature extremes in the Middle East).

Documentation Review

- Request and review detailed QC reports, including batch test results, waterproof test certificates, and material traceability records.

- Evaluate the supplier’s process control documentation and quality manuals.

Third-Party Inspections

- Engage independent inspection agencies to perform random sampling and testing at the factory or pre-shipment.

- Verify the authenticity of test certificates and confirm IP ratings through recognized laboratories.

QC and Certification Nuances for Buyers in Africa, South America, the Middle East, and Europe

Regional Environmental Considerations

- Africa & South America: High humidity and tropical climates require LED strips with robust UV and moisture resistance; IP67 or higher is often advisable.

- Middle East: Extreme temperatures and sand exposure necessitate durable materials with excellent thermal stability and dust protection.

- Europe (e.g., Spain): Compliance with stringent EU regulations (CE, RoHS) is mandatory; European buyers also prioritize energy efficiency and environmental sustainability.

Regulatory Compliance

- Buyers should verify if suppliers have local certifications or approvals in their target markets, such as INMETRO in Brazil or Gulf Cooperation Council (GCC) conformity marks.

- Understanding import regulations and customs requirements helps avoid delays and additional costs.

After-Sales Support and Warranty

- Confirm the supplier offers warranties covering waterproof performance and solar charging efficiency.

- Check for availability of technical support and replacement parts, which is critical for maintaining installations in remote or challenging environments.

Actionable Takeaways for B2B Buyers

- Prioritize suppliers with comprehensive QC systems certified under ISO 9001 and relevant regional standards.

- Ensure waterproof ratings are verified by independent labs with clear IP certification aligned with your installation environment.

- Request detailed manufacturing process descriptions and QC checkpoints to understand supplier capabilities.

- Consider environmental factors specific to your region when selecting waterproof grades and materials.

- Leverage third-party inspections and factory audits to minimize risks associated with large-scale or long-term projects.

By understanding the manufacturing intricacies and quality assurance frameworks behind waterproof solar LED strip lights, international B2B buyers can make informed decisions, ensuring product reliability, regulatory compliance, and customer satisfaction across diverse global markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for solar led strip lights waterproof Sourcing

Understanding the cost and pricing dynamics of waterproof solar LED strip lights is crucial for international B2B buyers aiming to optimize procurement strategies, especially in diverse markets such as Africa, South America, the Middle East, and Europe. The pricing of these products is influenced by multiple factors, ranging from raw material inputs to international trade terms.

Key Cost Components in Waterproof Solar LED Strip Lights

- Materials: The primary cost driver includes high-quality LEDs, flexible PCB substrates, waterproof coatings or silicone encapsulation, solar cells, and batteries. Premium materials that meet IP65 to IP68 ratings ensure durability but increase unit costs.

- Labor: Manufacturing involves skilled labor for assembly, soldering, encapsulation, and quality checks. Labor costs vary by country and impact pricing, with suppliers in Asia typically offering more competitive rates.

- Manufacturing Overhead: Costs related to factory utilities, equipment maintenance, and production line management are embedded here. Efficient production processes reduce overhead and thus cost.

- Tooling and Setup: Initial tooling for extrusion molds, silicone injection, and PCB fabrication is capital intensive but amortized over production volume.

- Quality Control (QC): Rigorous QC processes, including waterproof testing and electrical safety verification, add to costs but are essential for certification and reliability.

- Logistics and Shipping: International freight, customs duties, packaging, and insurance influence landed costs. For remote regions or countries with complex import regulations (e.g., Brazil), logistics can significantly affect final pricing.

- Supplier Margin: Profit margins vary depending on supplier scale, market positioning, and negotiation leverage.

Influential Pricing Factors for Buyers

- Order Volume and MOQ: Larger orders typically secure better per-unit pricing due to economies of scale. MOQ requirements can vary widely; buyers should assess realistic demand to avoid excess inventory.

- Specifications and Customization: Higher IP ratings (IP67, IP68), longer run lengths, integrated solar panels, or smart control features increase costs. Custom colors, lengths, or branding add further premiums.

- Material Quality and Certifications: Products with certifications such as CE, RoHS, or UL command higher prices but reduce compliance risks in regulated markets like the EU.

- Supplier Reliability and Location: Established suppliers with proven track records may price higher but offer better quality and after-sales support. Proximity to buyer markets can reduce lead times and shipping costs.

- Incoterms: Terms such as FOB, CIF, or DDP affect how much logistical risk and cost the buyer assumes. For example, DDP (Delivered Duty Paid) includes all charges to the buyer’s doorstep, simplifying import but increasing upfront cost.

Strategic Buyer Tips for Cost Efficiency and Negotiation

- Negotiate Beyond Price: Discuss payment terms, volume discounts, and bundled services (e.g., free samples, extended warranty) to add value.

- Evaluate Total Cost of Ownership (TCO): Consider installation costs, product lifespan, energy savings from solar integration, and maintenance needs, not just upfront prices.

- Leverage Regional Trade Agreements: Buyers in Africa or South America should explore preferential tariffs or trade agreements to reduce import duties.

- Assess Supplier Certifications: Prioritize suppliers with relevant certifications to avoid costly compliance issues, especially important for buyers in the EU or Middle East.

- Understand Pricing Nuances: Beware of hidden costs such as packaging upgrades for fragile waterproof products or surcharges for urgent shipments.

- Plan for Currency Fluctuations: Exchange rate volatility can impact final costs. Consider forward contracts or multi-currency negotiations to mitigate risk.

Indicative Pricing Disclaimer

Prices for waterproof solar LED strip lights can range widely based on specifications and order size. For example, basic IP65 solar LED strips might start at approximately USD 5–10 per meter, while high-end IP68 products with integrated solar panels and smart controls may exceed USD 20–30 per meter. These figures are indicative and subject to market fluctuations, supplier negotiations, and regional factors.

By comprehensively analyzing these cost elements and pricing influencers, international B2B buyers can make informed sourcing decisions that balance quality, durability, and cost-effectiveness tailored to their regional market needs.

Spotlight on Potential solar led strip lights waterproof Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘solar led strip lights waterproof’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for solar led strip lights waterproof

Critical Technical Properties for Waterproof Solar LED Strip Lights

1. Waterproof Rating (IP Code)

The Ingress Protection (IP) rating is paramount for solar LED strip lights used outdoors or in wet environments. It consists of two digits: the first denotes protection against solids like dust, and the second against liquids such as water. Common ratings include IP65 (splash-proof), IP67 (temporary immersion), and IP68 (continuous underwater use). For B2B buyers, selecting the correct IP rating ensures product longevity, reduces maintenance costs, and aligns with the installation environment—whether a rainy outdoor pathway or a decorative pond feature.

2. Voltage Specification

Solar LED strips typically operate on low-voltage DC power (commonly 12V or 24V) supplied by integrated solar panels and batteries. Understanding voltage is critical because it affects installation safety, compatibility with power sources, and energy efficiency. Lower voltages are safer and easier to install but may require shorter strip lengths or additional power boosters. Buyers should evaluate voltage needs based on project scale and local electrical standards to avoid voltage drop and ensure consistent illumination.

3. Material Grade and Encapsulation Method

The durability of solar LED strips depends on the quality of materials, especially the encapsulation method that provides waterproofing. Options include silicone coatings, silicone tubes, and full silicone filling. Higher-grade silicone extrusion and filling methods offer superior protection against UV rays, temperature fluctuations, and mechanical damage. B2B buyers should prioritize materials that withstand harsh climates, especially in regions with intense sun exposure or heavy rainfall, to minimize product failures.

4. Luminous Efficiency and Color Temperature

Luminous efficiency (measured in lumens per watt) indicates the brightness relative to energy consumption, a key factor for solar-powered lighting where energy is limited. Color temperature (measured in Kelvins) affects the ambiance, ranging from warm (2700K) to cool white (6000K). Buyers should balance brightness and color temperature according to application — warm tones for hospitality and residential, cooler tones for commercial or pathway lighting — while ensuring efficient energy use to maximize solar battery life.

5. Cuttable and Linkable Lengths

Solar LED strip lights often come in standardized lengths with designated cut points and connectors to customize installation size. Understanding these specifications allows buyers to plan installations precisely, reducing waste and cost. Flexible linking options facilitate easy expansion or modular replacement, which is advantageous for large-scale projects across diverse geographies.

6. Operating Temperature Range

The operating temperature range indicates the environmental conditions the LED strips can endure without performance degradation. This is especially important for buyers in regions with extreme climates, such as the Middle East’s high heat or Europe’s cold winters. Ensuring the product meets or exceeds local temperature extremes guarantees reliability and reduces warranty claims.

Key Industry and Trade Terms for B2B Buyers

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers who produce goods that other companies rebrand and sell. For buyers, OEM partnerships can mean customized solar LED strips tailored to specific design or performance requirements, often at competitive pricing and with scalable production.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers manage inventory investment and negotiate better terms, especially when testing new products or entering new markets.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to obtain pricing, lead times, and terms for specific products. Clear RFQs streamline the procurement process, enabling buyers to compare offers efficiently and secure the best deal for waterproof solar LED strip lights.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for shipping, insurance, and customs clearance. Familiarity with common terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) empowers buyers to control logistics costs and risks when sourcing internationally.

IP Rating (Ingress Protection Rating)

As introduced above, IP ratings are standardized codes that specify the level of protection against solids and liquids. This term is critical in product specifications and contracts, ensuring that the supplier’s product meets the buyer’s environmental requirements.

Lead Time

Lead time indicates the duration from order placement to product delivery. For international buyers, particularly in markets with seasonal demand or infrastructure projects, understanding and negotiating lead times is vital to avoid delays and ensure timely project completion.

By mastering these technical specifications and trade terms, international B2B buyers can make informed purchasing decisions, optimize supply chain management, and ensure the successful deployment of waterproof solar LED strip lighting solutions tailored to diverse climates and applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the solar led strip lights waterproof Sector

Market Overview & Key Trends

The global market for waterproof solar LED strip lights is experiencing robust growth, driven by increasing demand for sustainable and energy-efficient outdoor lighting solutions. Key drivers include rising urbanization, government incentives for renewable energy adoption, and growing awareness of the benefits of solar-powered lighting in regions with limited or unreliable grid access. For international B2B buyers from Africa, South America, the Middle East, and Europe — including countries like Brazil and Spain — these products offer an attractive combination of cost savings, ease of installation, and adaptability to diverse climatic conditions.

Emerging B2B Trends:

- Integration with Smart Controls: Buyers increasingly seek solar LED strip lights compatible with IoT-enabled control systems, allowing remote management, dimming, and energy optimization.

- Modular and Scalable Designs: Flexible configurations facilitate tailored solutions for commercial projects ranging from landscaping to large-scale architectural illumination.

- Enhanced Waterproofing Standards: IP67 and IP68 rated products dominate markets requiring heavy rain protection and occasional submersion, especially in coastal or tropical zones.

- Hybrid Power Systems: Solutions combining solar with backup battery or grid power are gaining traction to ensure consistent illumination regardless of weather variability.

- Localized Sourcing and Assembly: To reduce lead times and tariffs, buyers prefer suppliers with regional manufacturing hubs or assembly lines in key markets like Europe and the Middle East.

Market Dynamics:

- Cost Sensitivity vs. Quality: While price competitiveness remains critical, there is a rising preference for premium products that offer durability in harsh environments, reducing total cost of ownership.

- Regulatory Compliance: Buyers must navigate different electrical safety and environmental standards, such as CE certification in Europe and INMETRO in Brazil.

- Supply Chain Resilience: Global disruptions have heightened focus on diversified sourcing strategies, including multiple supplier partnerships and buffer inventories.

- Customization Demand: Increasingly, B2B clients require bespoke solutions — from specific color temperatures to custom lengths and mounting options — to differentiate their projects.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a fundamental criterion in the procurement of waterproof solar LED strip lights. These products inherently contribute to environmental goals by harnessing renewable solar energy, thereby reducing carbon footprints and dependence on fossil fuels. However, the sustainability profile extends beyond energy efficiency to encompass responsible sourcing of materials, manufacturing practices, and end-of-life management.

Illustrative Image (Source: Google Search)

Environmental Impact Considerations:

- Material Selection: Buyers should prioritize products using recyclable or biodegradable components and low-toxicity materials, such as lead-free solder and halogen-free plastics.

- Energy-Efficient Manufacturing: Demand is growing for suppliers who implement renewable energy in production processes and minimize water and chemical usage.

- Lifecycle Management: Modular designs that facilitate repair, upgrading, and recycling reduce waste and improve overall sustainability performance.

Ethical Supply Chains:

- Transparency in the supply chain is critical. Buyers should seek suppliers who provide verifiable certifications such as ISO 14001 (Environmental Management), SA8000 (Social Accountability), and adherence to the Responsible Minerals Initiative.

- Labor practices, fair wages, and safe working conditions are increasingly scrutinized, particularly for suppliers operating in regions with less stringent labor laws.

- Ethical sourcing also mitigates risks related to regulatory compliance and brand reputation, which are vital for international buyers operating across multiple jurisdictions.

Green Certifications and Standards:

- Look for solar LED strip lights certified with global eco-labels like Energy Star, TÜV Rheinland’s green product certifications, or regional equivalents.

- IP rating certifications not only assure waterproof performance but also signal product longevity, reducing replacement frequency and associated environmental costs.

- Certifications related to solar panel efficiency and battery sustainability can further enhance product appeal in environmentally conscious markets.

Brief Evolution and Industry Milestones

The evolution of waterproof solar LED strip lights reflects broader advances in LED technology, solar power integration, and materials science. Initially, LED strips were primarily indoor, low-voltage decorative products with limited protection against moisture. The introduction of robust IP65 and higher-rated waterproofing methods in the late 2000s enabled outdoor and industrial applications, expanding market reach.

Solar integration emerged as a natural progression, combining LED efficiency with renewable energy to create off-grid lighting solutions. Over the past decade, improvements in flexible solar cells, battery storage, and smart controls have transformed these products into versatile, reliable lighting systems suited for diverse environments — from urban landscapes in Europe to remote rural areas in Africa and South America.

Today, the sector is characterized by innovation in waterproofing techniques (e.g., silicone extrusion, gel filling), energy management, and customized solutions, positioning solar waterproof LED strips as a cornerstone technology for sustainable outdoor illumination worldwide.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of solar led strip lights waterproof

-

How can I effectively vet suppliers of waterproof solar LED strip lights for international B2B trade?

To vet suppliers, request detailed product datasheets, including IP ratings and solar integration specifications. Verify certifications such as CE, RoHS, and IEC standards relevant to your region. Ask for references or case studies from similar markets like Africa or South America. Conduct factory audits or request video tours to assess manufacturing capabilities and quality control. Confirm supplier experience with export logistics and compliance with your country’s import regulations to avoid delays. -

Is customization of solar waterproof LED strip lights feasible, and what should I consider?

Customization is common for B2B buyers, including length, IP rating, voltage, light color temperature, and solar panel integration. Ensure your supplier can provide prototypes and samples for quality verification. Clarify the minimum order quantities (MOQs) and additional costs for custom features. Confirm lead times for custom orders, as they tend to be longer. For international buyers, verify that custom products comply with local safety and environmental standards. -

What are typical MOQ and lead times for solar waterproof LED strip lights in global sourcing?

MOQs vary widely depending on product complexity and supplier scale but typically range from 500 to 2,000 meters per order for standard strips. Custom or solar-integrated models may require higher MOQs. Lead times generally range from 4 to 8 weeks, influenced by production capacity and customization. For buyers in Africa, the Middle East, or South America, factor in additional time for shipping and customs clearance. Always negotiate clear delivery schedules to align with your project timelines. -

Which payment terms are standard for international purchases of solar LED strip lights?

Common payment terms include 30% deposit upfront and 70% balance before shipment or upon delivery. Letters of Credit (LC) and escrow services are popular for mitigating risks in new supplier relationships. For established partnerships, Net 30 or Net 60 terms may be negotiated. Ensure payment methods comply with your country’s foreign exchange regulations. Use secure platforms and insist on transparent invoicing to avoid fraud. -

What quality assurance (QA) and certifications should I insist on when buying waterproof solar LED strip lights?

Insist on ISO 9001 certified manufacturing to ensure consistent quality management. Key product certifications include CE for Europe, FCC for electromagnetic compliance, RoHS for hazardous substances, and IP ratings (IP65, IP67, IP68) verified by independent labs. Solar components should meet IEC 61215 and IEC 61730 standards. Request batch test reports and photometric data to verify performance. Consider third-party pre-shipment inspections to reduce defects and returns. -

How can I optimize logistics and shipping for solar waterproof LED strip lights internationally?

Choose suppliers with experience in shipping to your region, familiar with local customs and import duties. Decide between air freight for speed or sea freight for cost efficiency, balancing your project urgency and budget. Confirm packaging is robust to protect strips and solar panels from moisture and mechanical damage. Request consolidated shipments if ordering multiple product types to reduce costs. Track shipments closely and prepare documentation to avoid customs delays. -

What strategies help resolve disputes or quality issues with international suppliers?

Establish clear contract terms covering product specifications, delivery, and quality standards upfront. Use independent third-party inspections before shipment to catch defects early. Maintain detailed communication logs and photographic evidence of issues. Negotiate dispute resolution mechanisms such as arbitration or mediation in a neutral jurisdiction. Develop contingency plans including partial refunds, replacements, or future order discounts. Building long-term relationships based on trust can also minimize conflicts. -

Are there region-specific considerations for sourcing solar LED strip lights in Africa, South America, the Middle East, and Europe?

Yes. Africa and South America often require products resilient to high humidity and dust (IP67 or above). The Middle East demands UV-resistant materials and high-temperature tolerance due to harsh sunlight. Europe requires strict adherence to CE, RoHS, and WEEE directives, as well as energy efficiency standards. Also, consider voltage compatibility—Europe uses 220V AC, while some African countries may use 110V or 220V. Understanding local infrastructure and import regulations ensures smooth procurement and installation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solar led strip lights waterproof

In navigating the dynamic market of waterproof solar LED strip lights, strategic sourcing emerges as a critical success factor for international B2B buyers. Understanding product specifications such as IP ratings, voltage compatibility, and waterproofing methods allows buyers to align lighting solutions precisely with their project requirements—whether for outdoor patios in Spain, garden installations in Brazil, or commercial landscapes in the Middle East and Africa. Prioritizing suppliers who demonstrate transparency in quality certifications and offer customizable options enhances both reliability and cost-efficiency.

Key takeaways include:

- Selecting the appropriate IP rating based on environmental exposure ensures longevity and reduces maintenance costs.

- Matching voltage requirements to local infrastructure and installation scale optimizes energy efficiency and safety.

- Evaluating supplier capabilities on innovation, scalability, and after-sales support strengthens supply chain resilience.

Looking ahead, the growing emphasis on sustainable and off-grid lighting solutions in emerging and mature markets alike presents lucrative opportunities. Buyers who engage in thorough market research, foster long-term supplier partnerships, and embrace evolving technologies will gain competitive advantages. For businesses across Africa, South America, the Middle East, and Europe, now is the opportune moment to invest strategically in waterproof solar LED strip lights, driving both environmental impact and commercial growth.