Introduction: Navigating the Global Market for led strip lights blinking

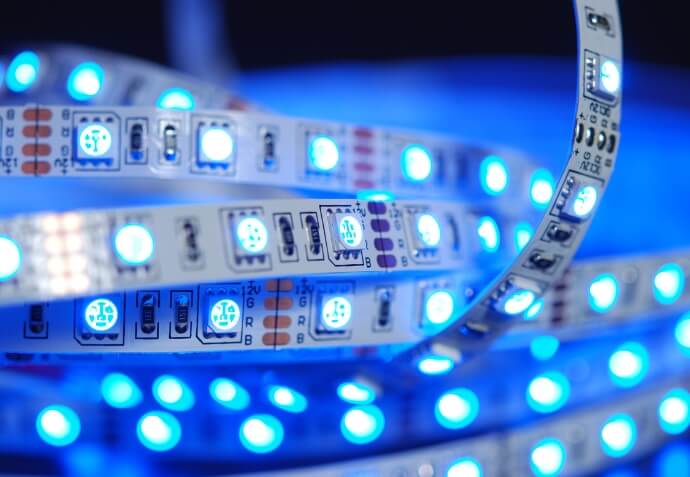

In today’s rapidly evolving lighting industry, led strip lights blinking has emerged as a pivotal feature that combines aesthetic appeal with functional versatility. For international B2B buyers—especially those in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of these LED solutions is essential to staying competitive and meeting diverse client demands. Whether for commercial installations, retail displays, or architectural accents, blinking LED strips offer unique opportunities to enhance environments with customizable lighting effects.

This comprehensive guide is designed to equip buyers with critical insights into the global led strip lights blinking market. It covers everything from types and materials—including flexible circuits and heat-dissipating aluminum profiles—to manufacturing standards and quality control protocols that ensure product reliability and longevity. In addition, the guide delves into supplier selection criteria, cost structures, and regional market trends, providing a holistic perspective tailored to the needs of businesses sourcing at scale.

By addressing common questions and challenges faced during procurement, this resource empowers buyers to make informed, strategic decisions. Key considerations such as voltage compatibility, color temperature options, and durability in varied climatic conditions are examined with international trade factors in mind. Ultimately, this guide offers actionable knowledge for B2B buyers aiming to optimize their supply chains, reduce risks, and capitalize on the growing demand for innovative, energy-efficient blinking LED strip lighting solutions worldwide.

Understanding led strip lights blinking Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Basic On-Off Blinking | Simple blinking pattern with fixed intervals, usually mono-color | Retail signage, event lighting, decorative accents | + Cost-effective, easy integration – Limited customization, less dynamic |

| RGB Color Blinking | Multi-color blinking with programmable color changes | Hospitality, entertainment venues, experiential marketing | + High visual impact, customizable – Requires advanced controllers, higher cost |

| PWM Dimming Blinking | Uses pulse-width modulation to vary brightness in blinking | Industrial indicators, automotive lighting, smart home systems | + Precise brightness control, energy efficient – Complex setup, potential flicker issues |

| Sound-Activated Blinking | Blinks in sync with audio input or ambient sound levels | Nightclubs, advertising displays, live events | + Engaging and interactive – Requires sound sensors and programming, environment dependent |

| Wireless/Smart Blinking | Controlled remotely via Wi-Fi/Bluetooth with app integration | Smart buildings, large-scale architectural lighting | + Flexible control, integration with IoT – Higher upfront cost, requires network infrastructure |

Basic On-Off Blinking

This is the most straightforward type of blinking LED strip light, operating on fixed on-off intervals with a single color. Its simplicity makes it highly cost-effective and easy to install, ideal for projects with strict budget constraints or where complex lighting effects are unnecessary. B2B buyers targeting retail displays, temporary event lighting, or simple decorative applications will find this type practical. However, its lack of dynamic features may limit appeal in more sophisticated or brand-centric environments.

RGB Color Blinking

RGB blinking LED strips can cycle through multiple colors or blink different hues in programmable sequences, offering significant creative flexibility. This variation suits hospitality, entertainment, and experiential marketing sectors where visual appeal drives customer engagement. Buyers should consider the need for compatible controllers and software, which increase initial costs but enable tailored lighting experiences. The enhanced aesthetics can justify the investment, especially in competitive markets like Europe and the Middle East.

PWM Dimming Blinking

Pulse-width modulation (PWM) controls the brightness of blinking LEDs by adjusting power delivery, resulting in smooth dimming and energy savings. This type is favored in industrial settings, automotive lighting, and smart home systems where precise brightness levels and energy efficiency are critical. B2B purchasers must evaluate technical complexity and ensure compatibility with existing control systems. While setup may be more involved, the benefits include reduced power consumption and enhanced lighting quality.

Sound-Activated Blinking

These LED strips respond to audio signals, synchronizing their blinking patterns with music or ambient sounds. This interactive feature is valuable for nightclubs, live events, and advertising displays aiming to captivate audiences. Buyers should factor in the additional components such as microphones or sound sensors and programming capabilities. Environmental noise can affect performance, so deployment in controlled acoustic settings is advisable for optimal results.

Wireless/Smart Blinking

Wireless blinking LED strips allow remote control via apps or integration with smart building systems, supporting complex schedules and scene settings. This variation appeals to modern architectural projects, smart offices, and large-scale installations requiring flexible, centralized lighting management. While the upfront cost and network setup are higher, the scalability and convenience offered make this a strategic choice for B2B buyers in technologically advanced markets across Europe, South America, and the Middle East.

Related Video: Beginner’s Guide to Using LED Strips with Arduino

Key Industrial Applications of led strip lights blinking

| Industry/Sector | Specific Application of led strip lights blinking | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Hospitality | Dynamic window displays and in-store ambiance lighting | Attracts customer attention, enhances brand image, drives sales | Durable, customizable blink patterns; energy efficiency; compliance with local lighting standards |

| Entertainment & Events | Stage lighting effects and architectural accent lighting | Creates immersive experiences, enhances event appeal | High brightness, color accuracy, easy integration with control systems, robust for frequent use |

| Manufacturing & Warehousing | Safety and alert signaling on machinery and storage zones | Improves workplace safety, reduces accidents, facilitates process monitoring | Reliable blinking control, visibility in harsh environments, long lifespan, compatibility with industrial controls |

| Transportation & Infrastructure | Signal and indicator lighting for vehicles, tunnels, and stations | Enhances safety and operational efficiency, reduces downtime | Weatherproof, vibration-resistant, energy-efficient, meets regional regulatory standards |

| Advertising & Signage | Eye-catching LED blinking signs and billboards | Increases advertisement visibility, engages target audience | High contrast, programmable blinking sequences, ease of maintenance, suitable for outdoor use |

Retail & Hospitality

In retail environments across Europe and emerging markets in Africa and South America, blinking LED strip lights are extensively used to create dynamic window displays and in-store lighting that catch the eye of passersby and shoppers. These blinking effects help businesses differentiate their brand and increase foot traffic by creating visually stimulating environments. Buyers should prioritize LED strips that offer customizable blinking patterns and energy-efficient drivers to keep operational costs low. Compliance with local electrical and lighting regulations is also crucial, especially for hospitality venues seeking certification or permits.

Entertainment & Events

The entertainment industry, particularly in regions like the Middle East and Italy, leverages blinking LED strip lights to produce dramatic stage effects and architectural lighting that elevate audience engagement. These applications demand high-brightness LEDs with excellent color rendering and precise blinking control for synchronized light shows. International buyers should focus on sourcing products compatible with existing DMX or other lighting control protocols. Durability and ease of installation are important since event setups often require rapid deployment and teardown.

Manufacturing & Warehousing

Blinking LED strip lights serve as critical safety indicators in manufacturing plants and warehouses, signaling hazardous zones, machine status, or emergency alerts. This application is vital in industrial hubs across Poland and South America where workplace safety regulations are tightening. Buyers must select LED strips with robust thermal management and high ingress protection ratings to withstand dust, moisture, and vibration. Integration with industrial automation systems is essential to ensure real-time responsiveness and minimize downtime.

Transportation & Infrastructure

In transportation sectors throughout Africa and Europe, blinking LED strips are used for signaling in tunnels, rail stations, and public transit vehicles to improve safety and operational communication. These lighting systems must be weatherproof and resistant to mechanical shocks, given the demanding environmental conditions. Energy efficiency is a priority for large-scale infrastructure projects to reduce maintenance and power costs. Compliance with regional safety standards and certifications ensures smooth project approvals and longevity.

Advertising & Signage

Blinking LED strip lights are increasingly popular for outdoor advertising in urban centers of the Middle East and South America, where vibrant, programmable signs can capture consumer attention effectively. These signs require high contrast and flexible blinking sequences to adapt to different marketing campaigns. International buyers should ensure that LED strips are UV-resistant and designed for easy maintenance to withstand harsh weather and reduce operational interruptions. Selecting suppliers who provide customization options and reliable after-sales support is a strategic advantage.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip lights blinking

Flexible Printed Circuit Boards (FPC) for LED Strip Lights Blinking

Flexible Printed Circuit Boards (FPCs) are the foundational substrate material for most LED strip lights, including blinking variants. They are typically made from polyimide or polyester films that provide excellent flexibility and electrical insulation. Key properties include high thermal resistance (up to 200°C for polyimide) and good dimensional stability under thermal cycling, essential for consistent LED performance.

Pros: FPCs enable compact, bendable designs suitable for curved or irregular installations, a significant advantage in architectural and retail applications common in Europe and the Middle East. They are lightweight and support high-density LED placement, which is critical for uniform blinking effects. Cons: FPCs are relatively delicate, requiring careful handling during manufacturing and installation to avoid damage. Cost-wise, they are moderate but can increase with higher thermal resistance grades.

Application Impact: FPCs are ideal for indoor and controlled-environment applications but may require additional protective coatings or encapsulation in humid or dusty environments prevalent in parts of Africa and South America.

International Buyer Considerations: Buyers from regions with stringent electrical and fire safety standards (e.g., CE marking in Europe, IEC compliance in the Middle East) should verify that FPC materials meet these certifications. Additionally, suppliers offering FPCs with RoHS compliance and halogen-free materials align well with environmental regulations in Italy and Poland.

Aluminum Profiles and Heat Sinks

Aluminum is widely used as a structural and thermal management material for LED strip lights, especially blinking types that generate variable heat loads due to dynamic operation. Aluminum profiles serve as heat sinks, enhancing thermal dissipation and prolonging LED lifespan.

Pros: Aluminum offers excellent thermal conductivity (up to 205 W/m·K), corrosion resistance with anodized finishes, and mechanical strength for robust fixture designs. It supports long runs of LED strips with stable blinking performance by preventing thermal degradation. Cons: Aluminum adds weight and cost relative to plastic alternatives and requires precise extrusion or milling processes, increasing manufacturing complexity.

Application Impact: Aluminum profiles are preferred for commercial and industrial applications in Europe and the Middle East, where durability and heat management are critical. In humid or coastal regions of Africa and South America, anodized or powder-coated aluminum ensures corrosion resistance.

International Buyer Considerations: Compliance with ASTM B221 (aluminum extrusion standards) and DIN EN 755 is common in Europe and Middle East markets. Buyers should assess anodizing quality and thickness for corrosion resistance, especially for outdoor or semi-outdoor installations.

Silicone and PVC Coatings for Waterproofing and Insulation

Silicone and PVC coatings are commonly applied over LED strips to provide waterproofing, electrical insulation, and mechanical protection. These materials are crucial for blinking LED strips used in outdoor or high-moisture environments.

Pros: Silicone offers superior flexibility, UV resistance, and temperature tolerance (-60°C to 200°C), making it ideal for harsh climates in Africa and the Middle East. PVC coatings are cost-effective and provide good electrical insulation but have lower UV and temperature resistance. Cons: Silicone coatings are more expensive and require specialized curing processes, while PVC can degrade under prolonged UV exposure, limiting outdoor lifespan.

Application Impact: Silicone-coated LED strips are preferred for outdoor signage and architectural lighting in regions with intense sun exposure or variable weather. PVC-coated strips are suitable for indoor or semi-protected environments with moderate cost constraints.

International Buyer Considerations: Buyers should ensure coatings meet IP65 or higher ingress protection ratings for outdoor use. Compliance with international standards such as UL 94 (flammability) and RoHS is essential. European buyers, particularly in Italy and Poland, often require REACH-compliant materials to meet environmental regulations.

Copper Conductors and Traces

Copper is the primary conductive material in LED strip lights, including blinking types, due to its excellent electrical conductivity and reliability. Copper traces embedded in the FPC or separate copper wires ensure consistent current delivery for stable blinking patterns.

Pros: Copper offers low electrical resistance, which minimizes voltage drop and supports longer strip runs, especially important in 24V systems favored in Europe and the Middle East. It is highly ductile, facilitating flexible designs. Cons: Copper is prone to oxidation if not properly coated, which can degrade performance. It also increases material costs compared to aluminum conductors.

Application Impact: High-quality copper conductors are essential for industrial and commercial installations requiring long LED strip runs with precise blinking control. In regions with high humidity or corrosive environments, copper traces must be protected with tin or gold plating.

International Buyer Considerations: Buyers should verify copper purity and plating standards (e.g., ASTM B187 for copper sheet and strip) to ensure durability. Compliance with IEC 60228 for conductor classification is also relevant. Suppliers offering traceability and certification are preferred in regulated markets like the EU.

Summary Table

| Material | Typical Use Case for led strip lights blinking | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Printed Circuit Boards (FPC) | Base substrate for flexible LED strips with blinking control | High flexibility and thermal resistance | Fragile, requires careful handling | Medium |

| Aluminum Profiles and Heat Sinks | Structural support and thermal management for LED strip fixtures | Excellent heat dissipation and corrosion resistance | Adds weight and manufacturing complexity | High |

| Silicone and PVC Coatings | Waterproofing and insulation for outdoor and humid environments | Superior environmental resistance (silicone) | Silicone is costly; PVC degrades under UV | Silicone: High; PVC: Low |

| Copper Conductors and Traces | Electrical conduction for consistent blinking performance | Low electrical resistance, supports long runs | Susceptible to oxidation without proper plating | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lights blinking

Manufacturing and quality assurance for LED strip lights with blinking functions involve meticulous processes and stringent control measures to ensure product reliability and performance. For international B2B buyers—especially from Africa, South America, the Middle East, and Europe—understanding these details is crucial for selecting suppliers who deliver consistent quality and compliance with regional regulations.

Manufacturing Processes for Blinking LED Strip Lights

The production of blinking LED strip lights typically follows a structured sequence of stages, each critical for the final product’s functionality and durability:

1. Material Preparation

- LED Chips and Components: High-quality semiconductor chips (often from brands like Samsung or LG) are selected for consistent brightness and color rendering. Resistors, capacitors, and microcontrollers for blinking control are sourced with attention to performance specs.

- Flexible Circuit Board (PCB): The base for the LED strip is a flexible PCB, usually made of polyimide or fiberglass with copper traces. Preparation includes cutting to size and applying solder masks.

- Protective Coatings: Materials such as silicone or epoxy coatings are prepared for encapsulating the strips, enhancing waterproofing and mechanical protection.

2. Forming and Circuit Assembly

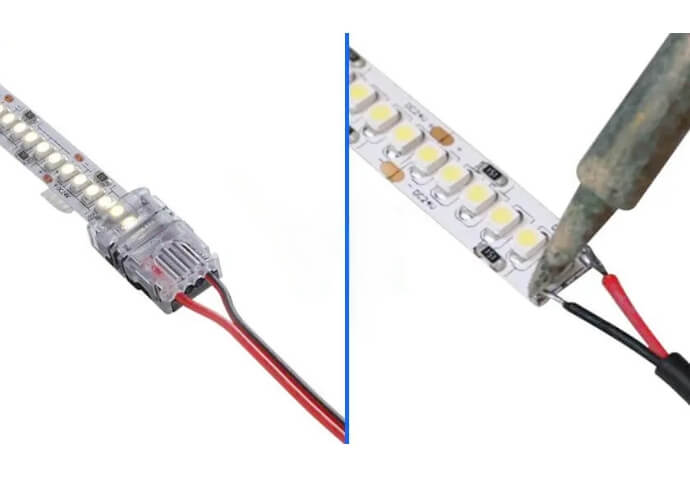

- Soldering Components: Surface mount technology (SMT) machines place LEDs, resistors, and microcontroller ICs accurately onto the PCB. Automated reflow soldering ensures strong, consistent electrical connections.

- Blinking Control Integration: The blinking effect is controlled either by onboard ICs or external controllers. Programming the microcontrollers is a critical step, often involving automated testing to verify correct blink timing and patterns.

- Cutting and Shaping: Post-soldering, strips are cut into designated lengths with precision laser or mechanical cutters, ensuring uniformity and reducing electrical shorts.

3. Assembly and Encapsulation

- Adhesive Backing Application: Double-sided adhesives are applied to the back of strips for easy installation in various environments.

- Protective Layering: Encapsulation with silicone or epoxy resin is applied, especially for outdoor or moisture-prone applications. UV-resistant coatings may also be added for longevity.

- Connector and Wiring: Custom connectors and cables are attached to enable easy integration with power supplies and controllers, ensuring compatibility with different voltage systems (e.g., 12V, 24V).

4. Finishing and Packaging

- Visual Inspection: Automated optical inspection (AOI) systems check for solder defects, component placement accuracy, and PCB integrity.

- Functionality Testing: Each strip undergoes dynamic testing for blinking patterns, brightness uniformity, and electrical safety.

- Packaging: Strips are carefully rolled or placed in anti-static trays, then sealed in moisture-proof packaging to prevent damage during shipping.

Quality Assurance and Control (QA/QC) Practices

Robust quality assurance is essential to meet international standards and buyer expectations. The following outlines key QA/QC stages and standards relevant for blinking LED strip lights:

International and Industry Standards

- ISO 9001: This global quality management standard ensures consistent manufacturing quality and continuous improvement processes. B2B buyers should verify supplier certification to ISO 9001 as a baseline.

- CE Marking (Europe): Indicates conformity with European health, safety, and environmental protection standards. Essential for buyers in Poland, Italy, and the broader EU market.

- RoHS Compliance: Restricts hazardous substances in electronics, critical for European and some Middle Eastern markets.

- UL and ETL Listings: Particularly relevant for North American exports but increasingly recognized worldwide for electrical safety assurance.

- IP Ratings: For outdoor or moisture-exposed products, IP65 or higher ratings confirm adequate ingress protection.

- Other Regional Certifications: Middle Eastern and South American buyers may also look for local standards such as SASO (Saudi Arabia) or INMETRO (Brazil).

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Raw materials, including LEDs, PCBs, and electronic components, undergo rigorous testing for specifications, defects, and authenticity before production.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly detects soldering defects, component misplacement, and blinking controller programming errors.

- Final Quality Control (FQC): Completed strips are tested for electrical functionality, blinking accuracy, brightness consistency, and durability under stress (thermal cycling, vibration).

- Reliability Testing: Extended life and endurance tests simulate real-world operating conditions to predict lifespan and failure rates.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and power consumption align with design specs.

- Optical Testing: Measures light intensity, color temperature, and blinking frequency using photometers and spectrometers.

- Environmental Testing: Includes thermal shock, humidity exposure, and UV resistance to ensure performance stability.

- Safety Testing: Insulation resistance, dielectric strength, and short-circuit testing confirm product safety compliance.

How B2B Buyers Can Verify Supplier Quality

For buyers sourcing blinking LED strip lights internationally, especially across diverse regions, supplier quality verification is vital:

- Factory Audits: On-site or third-party audits assess manufacturing capabilities, quality control systems, and compliance with ISO 9001 and other certifications.

- Quality Reports: Request detailed quality inspection reports including IQC, IPQC, and FQC data, along with test certificates for raw materials and finished products.

- Third-Party Inspection: Employ independent agencies (e.g., SGS, TÜV) to conduct random batch inspections and functional testing prior to shipment.

- Sample Testing: Obtain product samples for in-house testing to verify blinking patterns, durability, and compatibility with regional power standards.

- Certification Verification: Confirm the authenticity and validity of supplier certificates through official registries or certification bodies.

QC and Certification Nuances for International Markets

- Africa: Markets vary widely; buyers should focus on suppliers offering robust IP ratings for outdoor use and compliance with IEC standards. Certifications like CE and RoHS enhance product acceptability.

- South America: Brazil’s INMETRO certification is often mandatory; buyers should ensure compliance to avoid customs delays. Also, consider suppliers with UL or ETL marks for broader acceptance.

- Middle East: SASO certification is critical, alongside CE compliance for Gulf Cooperation Council (GCC) countries. Voltage compatibility (220-240V systems) and high IP ratings are important for harsh environments.

- Europe (Poland, Italy): Strict adherence to CE, RoHS, and REACH regulations is essential. Buyers should prioritize suppliers with ISO 9001 certification and comprehensive product testing aligned with EU directives.

Key Takeaways for B2B Buyers

- Understand the full manufacturing flow: From material selection through final packaging, each step affects blinking LED strip light quality.

- Demand transparency in QC processes: Verify IQC, IPQC, and FQC checkpoints and insist on detailed test documentation.

- Prioritize internationally recognized certifications: ISO 9001, CE, RoHS, and relevant regional standards safeguard product quality and regulatory compliance.

- Leverage third-party inspections and audits: These reduce risk and validate supplier claims before large-scale purchases.

- Consider regional requirements: Tailor supplier selection to specific market certifications and environmental conditions prevalent in Africa, South America, the Middle East, and Europe.

By rigorously evaluating manufacturing and quality assurance processes, B2B buyers can secure reliable blinking LED strip light products that meet performance expectations and regulatory demands worldwide.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip lights blinking Sourcing

Understanding the Cost Structure of Blinking LED Strip Lights

When sourcing blinking LED strip lights for international B2B procurement, it is essential to dissect the core components that contribute to the final pricing. The cost structure typically includes:

- Materials: High-quality LED chips (often from brands like Samsung or LG), flexible PCBs, resistors, capacitors, and diffusers. Specialized blinking control ICs and microcontrollers add to complexity and cost. Material choice significantly impacts durability, light quality, and lifespan.

- Labor: Skilled assembly for soldering, circuit testing, and integration of blinking control modules. Labor costs vary widely by country, influencing price competitiveness.

- Manufacturing Overhead: Factory utilities, equipment depreciation, and indirect labor contribute to overhead. Efficient manufacturing lines reduce these costs.

- Tooling and Setup: Custom tooling for LED strip shapes, connectors, and control units can involve upfront investment, especially for specialized blinking patterns or unique form factors.

- Quality Control (QC): Rigorous QC ensures blinking consistency, electrical safety, and compliance with international standards, which adds to cost but reduces returns and warranty claims.

- Logistics: Freight, import duties, customs clearance, and last-mile delivery affect landed cost. Shipping mode (air vs. sea) impacts timing and cost.

- Supplier Margin: Margins vary depending on supplier scale, exclusivity, and market positioning but typically range between 10-30% in competitive markets.

Key Pricing Influencers for Blinking LED Strip Lights

Pricing for blinking LED strips is influenced by multiple dynamic factors:

- Order Volume and Minimum Order Quantities (MOQ): Larger orders benefit from economies of scale, reducing per-unit cost. Many manufacturers set MOQs ranging from 500 to 5,000 meters depending on customization.

- Technical Specifications and Customization: Custom blinking patterns, color temperature options, waterproof ratings (IP65, IP67), and integration with smart controls increase complexity and price.

- Material Quality and Certifications: LED chips with high CRI, certified components (CE, RoHS, UL), and flame-retardant PCB materials command premium pricing but enhance reliability and market acceptance.

- Supplier Reputation and Location: Established suppliers with certifications and proven quality records often price higher but reduce risk. Sourcing from regions with lower labor costs (e.g., China, Southeast Asia) can be cost-effective but requires due diligence.

- Incoterms and Payment Terms: Terms like FOB, CIF, or DDP affect buyer’s cost exposure to freight, insurance, and customs duties. Favorable payment terms (e.g., letters of credit, net 30/60) improve cash flow management.

Practical Buyer Tips for Cost-Efficient Sourcing

For international buyers, especially from Africa, South America, the Middle East, and Europe, the following strategies help optimize procurement costs and value:

- Negotiate Volume Discounts and Flexible MOQs: Engage suppliers early to explore tiered pricing and reduced MOQs for trial orders, balancing risk and cost.

- Prioritize Total Cost of Ownership (TCO): Beyond unit price, consider energy efficiency, lifespan, maintenance costs, and warranty terms. High-quality blinking LED strips often save costs long-term through reduced replacements and energy consumption.

- Leverage Local Compliance and Certification Knowledge: Understand regional certification requirements (e.g., CE for Europe, SASO for Saudi Arabia) to avoid costly rejections or modifications post-import.

- Request Sample Testing and Factory Audits: Verify blinking patterns, color consistency, and build quality before large commitments. Factory audits help assess supplier reliability and QC rigor.

- Optimize Incoterms for Cost Control: Buyers in regions with complex customs processes may benefit from DDP (Delivered Duty Paid) to avoid unexpected charges, while experienced importers might prefer FOB to control shipping.

- Consider Freight and Lead Times in Pricing Negotiations: Longer lead times can reduce air freight costs but increase inventory holding; balance accordingly.

- Stay Alert to Currency Fluctuations: For buyers in volatile currency regions, negotiate pricing in stable currencies (USD, EUR) or include hedging clauses.

Indicative Pricing Overview

While prices vary widely depending on specifications and volume, typical FOB costs for blinking LED strip lights range approximately between $1.50 to $4.50 per meter. Higher-end, certified, or customized products command prices at the upper end of this range. Buyers should treat these figures as indicative and conduct direct supplier inquiries for precise quotes reflecting current market conditions.

By thoroughly understanding these cost elements and pricing drivers, international B2B buyers can strategically source blinking LED strip lights that meet quality expectations while optimizing investment and supply chain efficiency.

Spotlight on Potential led strip lights blinking Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip lights blinking’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lights blinking

Key Technical Properties of LED Strip Lights with Blinking Features

Understanding the critical technical specifications of blinking LED strip lights is essential for international B2B buyers aiming to source reliable and high-performance products. These properties directly influence product durability, functionality, and compatibility with various applications across Africa, South America, the Middle East, and Europe.

-

LED Chip Quality and Type

The core of any LED strip is its semiconductor chips, typically made by reputable brands such as Samsung or LG. High-quality chips ensure consistent brightness, color accuracy, and longer lifespans. For blinking LED strips, chip reliability is crucial to maintain uniform flashing patterns without flickering or failure over time. -

Power Density (Watts per Meter)

This indicates the energy consumption and light output per meter of strip. Higher power density can produce brighter light and more intense blinking effects but requires effective heat dissipation to prevent premature degradation. Buyers should balance power needs with energy efficiency and thermal management capabilities. -

Voltage and Current Requirements

Common voltages for LED strips include 12V and 24V DC. Blinking LED strips often use constant voltage drivers with PWM (Pulse Width Modulation) control to achieve precise blinking rates. Selecting the correct voltage system minimizes voltage drop over long runs, ensuring consistent blinking performance. -

Material Grade and IP Rating

The strip’s base material (usually flexible PCB) and protective coatings determine durability and resistance to environmental factors. An IP65 or higher rating signals water and dust resistance, essential for outdoor or humid environments common in many target regions. Proper material grade also affects thermal conductivity, influencing heat management. -

Blinking Control Technology

Blinking or flashing effects are controlled via integrated microcontrollers or external controllers using protocols such as DMX or RF wireless signals. Understanding the control method is vital for compatibility with existing lighting systems and ease of installation. -

Tolerance and Quality Assurance Standards

Manufacturing tolerances define how closely the actual product matches specifications (e.g., LED spacing, brightness uniformity). Tight tolerances are critical for applications requiring synchronized blinking patterns, such as advertising displays or architectural lighting. Compliance with international standards (CE, RoHS) also ensures product safety and market acceptance.

Common Industry and Trade Terminology for LED Strip Lights

Navigating the LED strip light market requires familiarity with essential trade terms. These terms help streamline communication with suppliers and ensure clarity in procurement processes.

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce LED strip lights based on another brand’s design or specifications. OEM partnerships allow buyers to customize products while benefiting from established manufacturing expertise and cost efficiencies. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. MOQ varies widely and affects pricing and inventory decisions. Buyers from emerging markets should negotiate MOQs aligned with demand to optimize cash flow and reduce storage costs. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, lead times, and terms for specific LED strip light configurations. A well-prepared RFQ with detailed technical requirements accelerates supplier responses and improves quote accuracy. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears risks and costs at each stage of delivery, crucial for international transactions. -

CRI (Color Rendering Index)

A metric indicating how accurately an LED light displays colors compared to natural light. For blinking LED strips used in retail or display applications, a CRI above 80 is generally preferred to ensure vivid and true color representation. -

PWM (Pulse Width Modulation)

A technique used to control LED brightness and blinking frequency by varying the electrical pulse duration. PWM allows precise control over blinking effects and energy efficiency, making it a key technical term in LED strip lighting.

By mastering these technical properties and trade terms, B2B buyers can confidently evaluate suppliers, specify the right blinking LED strips for diverse applications, and negotiate favorable terms that align with their regional market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lights blinking Sector

Market Overview & Key Trends

The global market for LED strip lights with blinking features is rapidly evolving, driven by increasing demand for dynamic lighting solutions across commercial, residential, and entertainment sectors. International B2B buyers, particularly from emerging markets in Africa, South America, the Middle East, and established European hubs such as Poland and Italy, are capitalizing on this trend to enhance their offerings in architectural lighting, retail displays, and event productions.

Key drivers include advances in LED technology enabling customizable blinking patterns, improved energy efficiency, and integration with smart control systems. This has expanded applications from simple decorative lighting to complex, programmable installations in hospitality, advertising, and urban beautification projects. The rise of IoT-enabled LED strips allows buyers to source products that can seamlessly integrate with building management and automation platforms, providing added value through remote control and adaptive lighting scenes.

Illustrative Image (Source: Google Search)

From a sourcing perspective, buyers are increasingly prioritizing suppliers who can offer flexible order volumes, rapid lead times, and support for technical customization. Supply chain resilience has become paramount due to recent global disruptions, prompting a shift toward diversified sourcing strategies that include regional manufacturers in Europe and the Middle East alongside traditional Asian suppliers. For instance, buyers in Poland and Italy benefit from proximity to European manufacturers that comply with stringent quality and safety standards, while African and South American buyers often seek cost-effective bulk sourcing with reliable logistics support.

Emerging trends also emphasize modular LED strip systems that simplify installation and maintenance, reducing total cost of ownership. Additionally, there is growing interest in advanced control protocols such as DMX and Zigbee, enabling sophisticated blinking effects synchronized with music or events. Buyers should closely monitor evolving technical standards and certifications that impact interoperability and compliance within their target markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in the procurement of LED strip lights with blinking capabilities. International buyers are increasingly aware of the environmental impact associated with electronic components, including energy consumption, material sourcing, and end-of-life disposal. Selecting LED strips designed for low power consumption not only reduces operational costs but also aligns with global carbon reduction goals, a critical consideration for buyers in Europe where regulatory frameworks are tightening.

Ethical sourcing is equally vital. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, ensuring conflict-free raw materials and adherence to labor standards. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and Energy Star signal compliance with environmental and safety benchmarks, offering reassurance to buyers seeking responsible partners.

Moreover, the use of recyclable materials in LED strip manufacturing, such as aluminum profiles and non-toxic diffusers, enhances product sustainability. Some suppliers are adopting circular economy principles by offering take-back programs or modular designs that facilitate repair and upgrade rather than disposal. For B2B buyers in Africa and South America, where e-waste management infrastructure may be limited, sourcing from manufacturers committed to sustainability can mitigate downstream environmental risks.

Illustrative Image (Source: Google Search)

Incorporating sustainability criteria into procurement decisions not only supports corporate social responsibility objectives but also strengthens brand reputation and market competitiveness. Buyers are advised to request detailed environmental impact assessments and audit reports as part of supplier evaluation processes.

Brief Evolution and Industry Context

The evolution of blinking LED strip lights parallels advancements in semiconductor technology and control electronics over the past two decades. Initially, LED strips offered fixed, static lighting primarily used for accent illumination. As microcontroller integration and driver ICs became more affordable, manufacturers introduced programmable blinking and color-changing effects, expanding the functional scope of these products.

This shift transformed LED strips from mere decorative elements into versatile lighting tools capable of dynamic visual storytelling and interactive environments. For B2B buyers, understanding this progression highlights the importance of selecting suppliers who stay abreast of technological innovations and can offer customizable solutions tailored to specific project requirements.

The sector’s growth also reflects broader trends in energy efficiency and smart building technologies, making blinking LED strips a strategic component in modern lighting design portfolios worldwide.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lights blinking

-

How can I effectively vet suppliers of blinking LED strip lights for international B2B purchases?

To ensure reliability, conduct thorough due diligence on potential suppliers. Verify business licenses, factory certifications (e.g., ISO 9001), and product quality certificates like CE, RoHS, or UL. Request samples to assess blinking functionality and build quality. Check references or reviews from other international buyers, especially those within your region such as Africa or Europe. Consider suppliers with transparent supply chains and robust after-sales support to minimize risks associated with cross-border transactions. -

What customization options are typically available for blinking LED strip lights, and how can they benefit my business?

Most manufacturers offer customization in blinking patterns, color temperature, LED density, length, and waterproof ratings. Customizing allows you to align products with your target market preferences or specific project requirements, enhancing your competitive edge. For example, Middle Eastern markets may demand higher IP ratings due to climate, while European buyers might prioritize energy efficiency and certifications. Early engagement with suppliers on customization feasibility and minimum order quantities (MOQs) is critical to optimize costs and delivery. -

What are common MOQ and lead time considerations when ordering blinking LED strip lights internationally?

MOQ varies widely but typically ranges from 100 to 500 meters per order, depending on customization and supplier scale. Lead times average 3 to 6 weeks, factoring in manufacturing, quality checks, and shipping. Buyers from South America or Africa should factor in additional time for customs clearance and inland logistics. Negotiating MOQs and partial shipments can improve cash flow and inventory management. Always clarify payment terms upfront—common options include 30% deposit with balance on shipment or letter of credit for secure transactions. -

Which quality assurance practices and certifications should I require from blinking LED strip light suppliers?

Demand suppliers provide product testing reports covering flicker rate, electrical safety, and durability under various environmental conditions. Certifications like CE (Europe), RoHS (environmental compliance), and UL (safety) are critical for regulatory compliance across different regions. Request factory audit reports or third-party inspections to verify production consistency. Implementing pre-shipment inspections reduces defective product risks and builds trust, especially vital when sourcing for large-scale projects in diverse markets. -

What logistical challenges should I anticipate when importing blinking LED strip lights from Asia to regions like Africa or Europe?

Logistics can be complicated by customs regulations, import duties, and transportation infrastructure disparities. For African buyers, port congestion and inland transport delays may impact delivery schedules. European buyers should consider VAT compliance and product labeling requirements. Choose suppliers familiar with international shipping documentation, Incoterms (e.g., FOB, CIF), and export controls. Partnering with experienced freight forwarders and understanding local import laws can mitigate delays and unexpected costs. -

How can I protect my business from disputes related to product quality or shipment delays in international LED strip light transactions?

Incorporate clear contractual terms covering product specifications, inspection protocols, delivery schedules, and penalties for non-compliance. Use internationally recognized arbitration clauses and payment instruments like letters of credit to secure transactions. Maintain detailed communication records and leverage third-party inspection services for impartial quality verification. Establishing trust through small initial orders before scaling up can also reduce exposure to disputes, especially when dealing with new suppliers from unfamiliar markets. -

Are there specific considerations for blinking LED strip lights related to electrical standards in different regions?

Yes, electrical standards such as voltage, frequency, and wiring vary significantly. Europe commonly uses 220-240V at 50Hz, while some African countries may have unstable power supplies. Ensure suppliers provide LED strips compatible with local voltage and include necessary drivers or transformers. Blinking patterns should not interfere with electrical safety or cause electromagnetic interference. Confirm compliance with regional electrical codes to avoid installation issues and regulatory penalties. -

What payment methods are safest and most practical for international B2B buyers of blinking LED strip lights?

Letters of credit (LC) offer strong security by linking payment release to shipment proof and contract terms, ideal for large orders. For smaller or repeat purchases, wire transfers (T/T) with partial upfront payment and balance upon delivery are common. Escrow services or trade platforms providing payment protection can add layers of security, especially for buyers in emerging markets. Always verify supplier bank details independently to prevent fraud and consider currency exchange risks when negotiating payment terms.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip lights blinking

Strategic sourcing of LED strip lights, particularly addressing issues like blinking, is a pivotal factor in ensuring product reliability and customer satisfaction in international B2B markets. Buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers with proven expertise in quality LED chip manufacturing, robust thermal management, and consistent power delivery systems. Such focus minimizes operational disruptions and extends product lifespans, critical in both commercial and industrial applications.

Key takeaways for B2B buyers include:

- Prioritizing high-quality components such as premium LED chips and aluminum profiles for effective heat dissipation.

- Ensuring compatibility of power supply systems to reduce voltage drop and prevent flickering or blinking.

- Demanding thorough quality assurance and testing to detect and resolve blinking issues before shipment.

- Leveraging supplier transparency and supply chain resilience to mitigate risks associated with logistics and manufacturing delays.

Looking ahead, international buyers should adopt a proactive sourcing strategy that integrates technological advancements and sustainability standards. Collaborating closely with manufacturers who invest in innovation and quality control will unlock competitive advantages, especially in emerging markets with growing infrastructure demands. Now is the time to deepen partnerships, refine procurement criteria, and capitalize on LED lighting’s evolving potential to drive efficiency and market growth globally.