Introduction: Navigating the Global Market for led strip lighting clips

In the rapidly evolving landscape of LED lighting solutions, LED strip lighting clips stand out as indispensable components that ensure secure, reliable, and efficient installation of LED strips across diverse environments. For international B2B buyers, particularly in dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the critical role of these clips is key to optimizing product performance and customer satisfaction. Whether outfitting large commercial projects in Nairobi, retail spaces in Buenos Aires, or hospitality venues in Dubai and Berlin, the right clips guarantee longevity, safety, and ease of maintenance for LED strip installations.

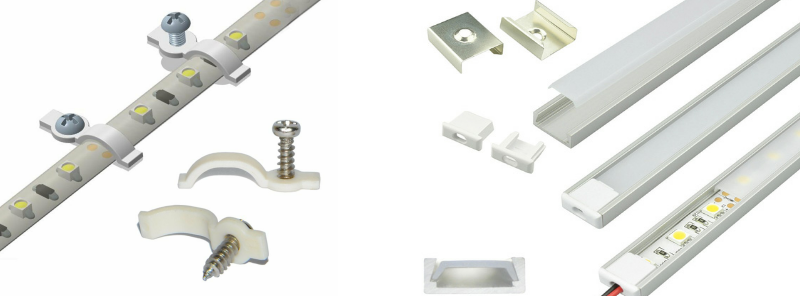

This comprehensive guide delves into every aspect essential to making informed sourcing decisions. It covers the various types of clips available, from plastic snap-on to aluminum mounting brackets, highlighting their suitability for different applications and environments. You will gain insights into the materials used, such as corrosion-resistant alloys and UV-stabilized plastics, which directly impact durability and performance in challenging climates. Additionally, the guide explores manufacturing processes and quality control measures that distinguish high-quality clips, ensuring compliance with international standards and reducing the risks of installation failures.

Illustrative Image (Source: Google Search)

For buyers navigating global supply chains, this resource offers practical advice on identifying reliable suppliers, evaluating cost structures, and understanding market trends. It also addresses frequently asked questions to clarify technical specifications and procurement strategies. Armed with this knowledge, B2B purchasers from regions like Kenya, Argentina, and beyond can confidently select LED strip lighting clips that align with their project demands and budget, ultimately driving greater value and operational efficiency.

Understanding led strip lighting clips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Snap-On Plastic Clips | Lightweight, easy snap-fit design, usually transparent or white plastic | Retail lighting displays, residential installations | Pros: Cost-effective, easy installation; Cons: Less durable under heavy strain or outdoor conditions |

| Metal Spring Clips | Made from stainless steel or aluminum, spring-loaded for firm grip | Commercial and industrial LED installations | Pros: High durability, secure hold; Cons: Higher cost, may require tools for installation |

| Magnetic Clips | Incorporate magnets for non-invasive mounting on metal surfaces | Temporary setups, exhibitions, automotive lighting | Pros: No drilling needed, reusable; Cons: Limited to ferromagnetic surfaces, weaker hold in vibration-prone areas |

| Adhesive-Backed Clips | Plastic or metal clips combined with strong adhesive pads | Indoor decorative lighting, quick retrofits | Pros: Tool-free installation, versatile placement; Cons: Adhesive may degrade over time, less suitable for humid environments |

| Adjustable Angle Clips | Clips designed with pivot or hinge mechanisms for angled LED strip placement | Architectural lighting, display cases, corners | Pros: Flexible positioning, enhances lighting effects; Cons: More complex design, slightly higher price point |

Snap-On Plastic Clips

These clips offer a straightforward solution for securing LED strips, especially in controlled indoor environments. Their snap-fit design allows quick installation without tools, making them ideal for retail and residential projects. B2B buyers should consider them for bulk purchases where cost efficiency and ease of installation are priorities. However, for outdoor or heavy-duty applications, their plastic build may not withstand environmental stress or mechanical strain.

Metal Spring Clips

Designed for robustness, metal spring clips provide a firm grip on LED strips and mounting surfaces, suitable for demanding commercial or industrial environments. Their corrosion-resistant materials like stainless steel ensure longevity, especially in regions with high humidity or temperature fluctuations. Buyers focusing on durable, long-lasting installations will find these clips valuable, though the higher unit cost and installation complexity require consideration in budgeting and labor planning.

Magnetic Clips

Magnetic clips facilitate quick, non-invasive mounting on metal surfaces, making them ideal for temporary or frequently changed setups such as exhibitions or automotive lighting. Their reusability and tool-free application reduce installation time and costs. However, their applicability is limited to ferromagnetic substrates, and buyers should evaluate the strength of magnetic hold in environments subject to vibrations or movement, common in transportation or industrial settings.

Adhesive-Backed Clips

Combining clips with adhesive pads offers flexibility for installation on various surfaces without drilling or hardware. This type is popular for indoor decorative lighting and retrofit projects where preserving surfaces is important. B2B buyers should assess the adhesive quality to ensure durability, especially in markets with high humidity or temperature extremes, which may degrade adhesives faster. This solution is best suited for short to medium-term installations.

Adjustable Angle Clips

These specialized clips allow LED strips to be mounted at variable angles, enhancing lighting design possibilities in architectural or display applications. Their pivoting mechanism supports creative lighting effects around corners or irregular surfaces. While they come at a premium compared to standard clips, buyers investing in high-end projects or custom installations will benefit from the added flexibility and aesthetic control. Installation may require more skilled labor, a factor to include in procurement planning.

Related Video: How to use LED Strip Light wire-to-tape light connectors

Key Industrial Applications of led strip lighting clips

| Industry/Sector | Specific Application of led strip lighting clips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Securing LED strips in display cases, shelving, and signage | Ensures stable, neat installation; enhances visual merchandising | Clips must support frequent maintenance access; corrosion-resistant for humid climates |

| Hospitality & Event Venues | Mounting LED strips in decorative architectural elements | Enables flexible, damage-free installations; quick reconfiguration | Durable clips compatible with various surfaces; easy to install and remove |

| Automotive Manufacturing | Fixing LED strips in vehicle interiors and exterior lighting | Provides reliable, vibration-resistant mounting; improves safety | High-heat and vibration-resistant clips; compliance with automotive standards |

| Industrial & Warehousing | Securing LED strips in harsh environments for task and safety lighting | Maintains secure lighting in dusty, high-vibration areas; reduces downtime | Clips with robust materials, resistant to dust, moisture, and temperature extremes |

| Residential Construction | Installing LED strips in kitchens, staircases, and cabinetry | Guarantees long-lasting, clean installations; supports energy-efficient lighting | Clips with strong adhesive backing and easy adjustability for retrofit projects |

In retail and commercial spaces, LED strip lighting clips are crucial for mounting LED strips securely within display units, shelving, and signage. These clips ensure that lighting remains stable and aesthetically pleasing, which is essential for enhancing product visibility and customer experience. For international buyers in regions like Kenya or Argentina, it’s important to select clips made from corrosion-resistant materials due to varying humidity levels and to prioritize suppliers offering clips designed for easy maintenance and replacement.

In the hospitality and event industry, LED strip lighting clips facilitate the mounting of strips onto decorative elements such as columns, ceilings, and stage setups. The clips enable quick installation and removal, allowing venues to frequently reconfigure lighting for different events without damaging surfaces. Buyers from the Middle East and Europe should focus on sourcing clips that are compatible with diverse materials (wood, plaster, metal) and offer durability under frequent handling.

For automotive manufacturing, LED strip lighting clips are used to affix LED strips inside vehicle cabins and on exterior surfaces. These clips must withstand vibrations, temperature fluctuations, and mechanical stress while ensuring the safety and reliability of lighting components. International B2B buyers should look for clips that meet automotive industry standards and offer heat resistance, which is particularly relevant for suppliers serving markets with extreme climates, such as parts of Africa and South America.

In industrial and warehousing environments, LED strip lighting clips secure lighting in areas exposed to dust, moisture, and mechanical vibrations. These clips help maintain consistent illumination critical for operational safety and productivity. Buyers should prioritize sourcing heavy-duty clips made from robust materials like stainless steel or reinforced plastics, ensuring compliance with industrial safety standards and compatibility with harsh environmental conditions common in manufacturing hubs across Europe and emerging markets.

Within residential construction, LED strip lighting clips support installations in kitchens, staircases, and cabinetry, providing clean and reliable mounting solutions that preserve the aesthetic integrity of the space. For B2B buyers in regions such as South America and Africa, clips with strong adhesive backing and flexible design are essential to accommodate retrofitting projects and various surface types. Additionally, sourcing from suppliers offering customizable clip sizes can help meet specific architectural requirements and improve installation efficiency.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip lighting clips

When selecting materials for LED strip lighting clips, B2B buyers must consider performance factors such as durability, environmental resistance, and compliance with regional standards. The choice of material directly impacts the longevity and reliability of the clips, especially in diverse climates and installation environments typical to markets in Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel clips offer excellent corrosion resistance, high tensile strength, and can withstand temperatures up to 800°C depending on the grade. Their robustness makes them ideal for harsh environments, including outdoor and industrial applications.

Pros:

– Superior durability and corrosion resistance, especially in humid or coastal regions common in Africa and the Middle East.

– High load-bearing capacity ensures secure mounting of LED strips without deformation.

– Resistant to UV and chemical exposure, extending service life.

Cons:

– Higher manufacturing costs due to material and machining complexity.

– Heavier than plastic alternatives, potentially increasing shipping costs for bulk orders.

– May require surface finishing (e.g., passivation) to maintain corrosion resistance.

Impact on Application: Stainless steel clips are preferred for outdoor installations, industrial settings, or locations with high moisture and temperature fluctuations. Their resistance to corrosion suits buyers in coastal cities like Durban (South Africa) or Buenos Aires (Argentina).

International B2B Considerations: Buyers should verify compliance with ASTM A240 or EN 10088 standards for stainless steel. In Europe, adherence to REACH and RoHS is critical. For African and South American markets, suppliers offering certification aligned with ISO 9001 quality management enhance trustworthiness.

2. Polycarbonate (PC)

Key Properties: Polycarbonate is a strong thermoplastic with high impact resistance, temperature tolerance up to 135°C, and excellent dimensional stability. It is naturally UV resistant and can be formulated for enhanced flame retardancy.

Pros:

– Lightweight and cost-effective compared to metals.

– Transparent or colored options allow aesthetic flexibility.

– Good electrical insulation properties, reducing risk of short circuits.

Cons:

– Less resistant to prolonged UV exposure unless specially treated, which may limit outdoor use in high-sunlight regions like the Middle East.

– Can become brittle under extreme cold, a consideration for colder European climates.

– Susceptible to chemical degradation from certain solvents or cleaning agents.

Impact on Application: Polycarbonate clips are ideal for indoor installations, commercial lighting, or decorative applications where weight and cost savings are priorities. Their electrical insulation makes them suitable for sensitive electronic environments.

International B2B Considerations: Buyers in regions with strict fire safety regulations, such as Europe, should ensure compliance with UL 94 V-0 flammability standards. For African and South American markets, sourcing polycarbonate clips with certifications like ISO 14001 (environmental management) can be advantageous.

3. Nylon (Polyamide)

Key Properties: Nylon clips are known for their toughness, flexibility, and resistance to abrasion. They typically endure temperatures between -40°C and 120°C and exhibit good chemical resistance.

Pros:

– Excellent mechanical strength with some flexibility, reducing breakage during installation.

– Resistant to oils, greases, and many solvents, suitable for industrial environments.

– Cost-effective and easy to manufacture in complex shapes.

Cons:

– Hygroscopic nature means nylon absorbs moisture, which can affect dimensional stability and mechanical properties.

– UV resistance is limited unless stabilized with additives, restricting outdoor usage without additional treatment.

– Lower heat resistance compared to metals and some engineered plastics.

Impact on Application: Nylon clips are well-suited for indoor commercial and residential LED strip installations where mechanical stress is moderate. Their chemical resistance benefits buyers in industrial sectors or automotive lighting projects.

International B2B Considerations: Buyers should request materials compliant with DIN 73378 or ASTM D4066 for nylon. In humid climates like parts of South America and Africa, moisture absorption must be considered in product specifications to avoid premature failure.

4. Aluminum

Key Properties: Aluminum clips provide good strength-to-weight ratio, excellent corrosion resistance with anodized finishes, and thermal conductivity beneficial for heat dissipation.

Pros:

– Lightweight yet sturdy, reducing shipping and handling costs.

– Naturally corrosion-resistant, especially with anodizing, suitable for diverse climates.

– Aesthetic appeal with metallic finish options for premium applications.

Cons:

– More expensive than plastic clips but generally less costly than stainless steel.

– Can be prone to scratching and denting if not handled carefully.

– Electrical conductivity requires insulation considerations in some installations.

Impact on Application: Aluminum clips are favored in architectural lighting projects and premium commercial installations. Their heat dissipation properties help maintain LED strip longevity in high-power applications.

International B2B Considerations: Compliance with EN 755 (aluminum profiles) and ASTM B221 is important. Buyers in Europe and the Middle East often require anodized finishes meeting ISO 7599 standards for corrosion protection. For African and South American buyers, availability of local anodizing services can reduce lead times and costs.

Summary Table

| Material | Typical Use Case for led strip lighting clips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor/industrial installations requiring high durability | Excellent corrosion and temperature resistance | Higher cost and weight, complex manufacturing | High |

| Polycarbonate | Indoor decorative and commercial lighting | Lightweight, electrical insulation | Limited UV and chemical resistance outdoors | Low |

| Nylon | Indoor commercial/residential with moderate mechanical stress | Tough, flexible, chemical resistant | Moisture absorption affects stability | Low |

| Aluminum | Architectural and premium commercial lighting | Lightweight, corrosion-resistant, good heat dissipation | Requires insulation due to conductivity, prone to surface damage | Medium |

This material selection guide empowers international B2B buyers to make informed decisions tailored to their specific environmental conditions, compliance needs, and budget constraints, ensuring optimal performance and longevity of LED strip lighting clips across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lighting clips

The manufacturing of LED strip lighting clips—a critical accessory for securing LED strips in place—requires precision engineering and stringent quality control to ensure durability, reliability, and ease of installation. For international B2B buyers across Africa, South America, the Middle East, and Europe, understanding the typical manufacturing stages and quality assurance measures is essential for making informed procurement decisions that align with project requirements and regulatory standards.

Manufacturing Process Overview for LED Strip Lighting Clips

LED strip lighting clips are typically made from metal or high-grade plastic materials designed to withstand mechanical stress and environmental factors. The manufacturing process generally consists of the following key stages:

1. Material Preparation

- Selection of Raw Materials: Manufacturers begin by sourcing high-quality metals (e.g., stainless steel, aluminum) or engineering plastics (such as polycarbonate or ABS) that offer corrosion resistance and strength.

- Material Conditioning: Metals undergo processes like cutting into sheets or wire drawing, while plastics are prepared in pellet form for molding. This stage ensures materials meet predefined mechanical properties and surface finish requirements.

2. Forming and Shaping

- Metal Clips: Use stamping, punching, or precision bending techniques to shape metal sheets into clip forms. CNC machines or progressive dies enable high-volume, consistent output.

- Plastic Clips: Utilize injection molding to create complex clip shapes with tight tolerances. Mold design is critical for dimensional accuracy and functional features like snap-fit mechanisms.

3. Assembly and Secondary Operations

- Component Assembly: Some clips may incorporate additional parts such as rubber pads or hinges. Automated or manual assembly lines join these components, ensuring secure fit and operational reliability.

- Surface Treatment: Metal clips often receive surface finishing like electroplating, powder coating, or anodizing to enhance corrosion resistance and aesthetic appeal. Plastic clips might undergo UV stabilization or flame retardant treatments.

4. Finishing and Packaging

- Quality Finishing: Deburring, polishing, or trimming remove sharp edges and imperfections to ensure safety and ease of use.

- Packaging: Clips are packaged in bulk or customized kits with protective packaging to prevent damage during transit. Packaging may also be tailored for branding or compliance labeling.

Quality Assurance and Control Measures

Robust quality assurance (QA) and quality control (QC) protocols underpin the manufacturing of LED strip lighting clips to meet international standards and buyer expectations.

Relevant International and Industry Standards

- ISO 9001: The globally recognized standard for quality management systems, ensuring consistent product quality and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), indicating compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical and electronic equipment, critical for environmental and health safety.

- UL Certification (where applicable): For clips integrated in lighting systems destined for markets requiring safety certification, such as North America.

- Industry-Specific Standards: Certain projects may require adherence to additional regional or sector-specific standards, such as API (American Petroleum Institute) standards for industrial lighting accessories used in hazardous environments.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Inspection of raw materials and components to verify chemical composition, dimensions, and mechanical properties before manufacturing begins.

- In-Process Quality Control (IPQC): Continuous monitoring during forming, molding, and assembly phases. Includes dimensional checks, visual inspections for defects (e.g., cracks, warping), and functional testing (clip tension and retention force).

- Final Quality Control (FQC): Comprehensive testing of finished clips including:

- Mechanical stress tests (bend, pull, and fatigue resistance)

- Corrosion resistance evaluation (salt spray tests for metal clips)

- Dimensional verification with precision measuring instruments

- Packaging inspection to ensure protection and labeling accuracy

Common Testing Methods

- Tensile and Compression Testing: Measures clip strength and elasticity to ensure clips will hold LED strips securely without deformation.

- Environmental Testing: Exposure to humidity, UV light, and temperature cycles to simulate real-world conditions, crucial for buyers in regions with harsh climates like the Middle East or parts of Africa.

- Surface Adhesion Tests: For clips with coatings or plating, ensuring finish durability and resistance to peeling or chipping.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially from emerging and diverse markets such as Kenya, Argentina, or the UAE, verifying supplier QC capabilities is key to mitigating risks associated with product quality and compliance.

Supplier Audits and Factory Visits

- Conducting on-site audits or virtual factory tours helps assess manufacturing capabilities, QC processes, and workforce expertise.

- Evaluate supplier certifications (ISO 9001, CE, RoHS) and review internal quality documentation.

Requesting Quality Reports and Certificates

- Obtain detailed QC inspection reports covering IQC, IPQC, and FQC stages.

- Ask for third-party testing certificates from accredited labs verifying mechanical and environmental compliance.

Third-Party Inspections

- Engage independent inspection agencies to perform random sampling and testing before shipment.

- This is particularly useful for buyers who cannot perform physical audits due to geographic constraints.

QC and Certification Nuances for International Markets

- Africa & South America: Buyers should prioritize suppliers with robust anti-corrosion treatments and environmental testing due to humid, tropical, or coastal climates common in countries like Kenya and Argentina.

- Middle East: Emphasis on UV resistance and high-temperature tolerance is critical for durability under intense sunlight and heat.

- Europe: Compliance with strict CE and RoHS directives is mandatory; buyers must verify up-to-date certifications and traceability documentation.

- Cross-Regional Logistics: Packaging and handling standards must accommodate long shipping times and variable storage conditions, ensuring clips arrive undamaged and ready for use.

Summary for B2B Buyers:

- Insist on suppliers with transparent, documented manufacturing and QC processes aligned with ISO 9001 and relevant regional certifications.

- Prioritize clips made from corrosion-resistant materials with proven mechanical strength through standardized testing.

- Use supplier audits, third-party inspections, and sample evaluations to verify quality before large-scale purchases.

- Consider environmental and regulatory requirements specific to your region to ensure product longevity and compliance.

- Strong quality assurance reduces risks, lowers return rates, and ensures your LED strip lighting installations perform reliably across diverse international markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip lighting clips Sourcing

Understanding the cost and pricing dynamics of LED strip lighting clips is essential for international B2B buyers aiming to optimize procurement strategies and ensure competitive margins. These small yet critical components involve multiple cost drivers and pricing influencers that vary by supplier, order volume, and customization level.

Key Cost Components in LED Strip Lighting Clips

-

Materials: The primary cost factor stems from the raw materials used—typically high-grade plastics or metals such as aluminum or stainless steel for durability and heat resistance. Quality of materials directly affects clip strength and longevity, impacting overall project reliability.

-

Labor: Labor costs fluctuate depending on the manufacturing country and the complexity of the clip design. Manual assembly or intricate molding processes increase labor expenses, particularly in regions with higher wage standards.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with advanced automation can lower overhead, providing cost advantages to buyers.

-

Tooling: Initial setup costs for molds and dies represent a significant upfront investment, especially for customized clip designs. These tooling costs are amortized over production volumes and can raise unit costs for smaller orders.

-

Quality Control (QC): Rigorous inspection and testing—such as dimensional checks and material strength tests—ensure product consistency and compliance with international standards. QC efforts add to production costs but reduce defects and returns.

-

Logistics: Shipping, customs duties, and import taxes vary widely depending on the supplier’s location and buyer’s country. Bulk shipments generally lower per-unit freight costs, but buyers must factor in last-mile delivery complexities, particularly in regions like Africa or South America.

-

Supplier Margin: Manufacturers and distributors include profit margins that reflect their market positioning, service level, and order volume. Established suppliers with certifications and proven quality often command premium pricing.

Influential Pricing Factors to Consider

-

Order Volume and Minimum Order Quantities (MOQ): Higher volumes significantly reduce per-unit costs due to economies of scale. Buyers in markets such as Kenya or Argentina should negotiate MOQ terms carefully to balance inventory costs against price benefits.

-

Product Specifications and Customization: Clips with specialized finishes, sizes, or branding incur additional costs for tooling, materials, and production complexity. Custom packaging or color matching further influences pricing.

-

Material Quality and Certifications: Clips made with flame-retardant, UV-resistant materials or those certified under standards like RoHS or CE typically cost more but provide long-term value through enhanced safety and durability.

-

Supplier Reputation and Capabilities: Suppliers offering faster lead times, superior quality assurance, and after-sales support may price their products higher. However, these factors reduce risk and total cost of ownership.

-

Incoterms and Payment Terms: Shipping terms (e.g., FOB, CIF, DDP) affect who bears freight and customs costs. Buyers should understand these to avoid unexpected expenses. Favorable payment terms can improve cash flow and reduce financing costs.

Practical Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership: Look beyond unit price to include shipping, customs, potential returns, and installation impacts. For example, a slightly higher-priced clip with better durability may reduce replacement frequency and labor costs.

-

Leverage Volume Consolidation: Pool orders across projects or partners to meet MOQ thresholds and unlock lower pricing tiers. This is particularly effective for buyers in emerging markets with smaller individual project sizes.

-

Request Samples and Certifications: Always validate product quality before committing to large orders. Confirm compliance certificates to avoid regulatory issues in your target market.

-

Consider Local Logistics and Import Regulations: Factor in customs clearance times and duties specific to your country. For buyers in Africa or South America, partnering with suppliers familiar with regional logistics can mitigate delays and hidden costs.

-

Understand Pricing Nuances by Region: Currency fluctuations, import tariffs, and local taxes can impact landed cost. For example, European buyers might benefit from suppliers with EU compliance, while Middle Eastern buyers should consider suppliers experienced with GCC import standards.

Indicative Pricing Disclaimer

Prices for LED strip lighting clips vary widely based on material selection, volume, customization, and supplier location. Typical unit costs can range from $0.05 to $0.50 or higher. Buyers should treat any quoted prices as indicative and conduct thorough due diligence through supplier quotations and cost breakdowns before finalizing purchases.

By comprehensively analyzing these cost components and pricing influencers, international B2B buyers can strategically negotiate and source LED strip lighting clips that align with budgetary constraints and quality expectations, ensuring successful project outcomes across diverse markets.

Spotlight on Potential led strip lighting clips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip lighting clips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lighting clips

Critical Technical Properties of LED Strip Lighting Clips

When sourcing LED strip lighting clips, understanding their key technical properties ensures you select products that meet your installation and durability requirements. Here are the most important specifications to consider:

-

Material Grade

Clips are typically made from stainless steel, aluminum, or high-grade plastic. Stainless steel offers superior corrosion resistance and strength, ideal for outdoor or humid environments common in regions like coastal Africa or the Middle East. Aluminum clips provide lightweight durability, while plastic clips suit indoor, low-stress applications. Choosing the right material impacts longevity and maintenance costs. -

Tolerance and Dimensions

Precision in clip dimensions (length, width, thickness) affects compatibility with various LED strip widths (commonly 8mm, 10mm, or 12mm). Tight manufacturing tolerances ensure a secure fit, preventing strip movement or damage during installation. This is critical for large-scale projects where uniformity reduces installation time and avoids costly rework. -

Mounting Type and Adhesion Compatibility

Clips may be screw-mounted or designed for adhesive backing. Screw-mounted clips offer stronger fixation suitable for industrial or commercial installations, whereas adhesive-compatible clips provide quick, non-invasive mounting for retail or home décor. Understanding your project’s mounting surface and environmental conditions guides the correct clip selection. -

Load Capacity and Flexibility

Clips must support the weight and flexibility of LED strips without deformation. For curved or irregular surfaces, flexible clips or those with slight elasticity are preferred to maintain strip positioning without damage. This property is especially relevant for architectural lighting projects common in European and South American urban environments. -

Temperature Resistance

The clips should withstand operating temperatures of LED strips, typically ranging from -20°C to 60°C or higher in outdoor settings. High temperature resistance prevents material warping or failure, ensuring safety and durability in harsh climates such as the Middle East or tropical Africa. -

Corrosion and UV Resistance

For outdoor or exposed installations, clips must resist corrosion from moisture, salt, and UV radiation. Stainless steel grades with anti-corrosion treatments or UV-stabilized plastics extend service life, reducing replacement frequency and enhancing ROI.

Common Trade Terminology in LED Strip Lighting Clips Procurement

Navigating international B2B purchases requires familiarity with key trade terms that affect pricing, delivery, and contract terms. Here are essential terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who manufacture products that can be branded and sold by another company. Choosing OEM clips allows buyers to customize branding and specifications, which is valuable for businesses seeking exclusive product lines or private labeling. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. MOQs vary widely and impact inventory costs and cash flow. Buyers from emerging markets like Kenya or Argentina should negotiate MOQs aligned with their sales volume and storage capabilities. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, lead times, and terms based on specified requirements. An effective RFQ includes detailed technical specs and quantities to ensure accurate and comparable supplier responses. -

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common terms include FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps buyers manage logistics costs and risks, especially for cross-continental shipments. -

Lead Time

The period from order confirmation to product delivery. Knowing lead times is crucial for project planning, especially for large-scale or time-sensitive installations common in commercial lighting projects across Europe and the Middle East. -

Batch Consistency

Refers to the uniformity of product quality and specifications across a production batch. For B2B buyers requiring large volumes, consistent batches ensure seamless installation and customer satisfaction, reducing returns and warranty claims.

Mastering these technical properties and trade terms empowers international B2B buyers to make informed decisions, optimize procurement strategies, and secure high-quality LED strip lighting clips tailored to their market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lighting clips Sector

Market Overview & Key Trends in the LED Strip Lighting Clips Sector

The global LED strip lighting clips market is experiencing steady growth driven by the broader adoption of LED lighting solutions across residential, commercial, and industrial sectors. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these market dynamics is crucial for strategic sourcing and procurement.

Key Market Drivers:

– Rising LED Adoption: As LED strip lighting gains popularity for its energy efficiency and design flexibility, demand for complementary accessories like clips and mounting hardware grows proportionally.

– Infrastructure Development: Emerging markets in Africa and South America, such as Kenya and Argentina, are investing heavily in infrastructure modernization, creating opportunities for large-scale lighting installations requiring reliable mounting solutions.

– Customization & Versatility: Buyers increasingly seek clips compatible with diverse LED strip profiles and installation environments — from flexible indoor setups to rugged outdoor applications requiring waterproof and UV-resistant clips.

– Technological Integration: The rise of smart LED strips with integrated sensors and controllers drives demand for clips that support secure, modular, and easy-to-service installations.

Emerging Sourcing Trends:

– Direct Manufacturer Partnerships: Buyers prioritize suppliers who can provide end-to-end solutions, including bespoke clip designs, to optimize installation efficiency and reduce inventory complexity.

– Regional Supplier Networks: To mitigate shipping delays and tariffs, companies in Europe and the Middle East often prefer sourcing from regional manufacturers with proven compliance to standards like CE or RoHS.

– Digital Procurement Platforms: Online B2B marketplaces are gaining traction, offering transparent pricing, verified supplier ratings, and streamlined bulk ordering, which is especially advantageous for buyers managing projects across multiple countries.

– Quality Certification Focus: Demand for clips certified for fire resistance, UV stability, and load capacity is increasing, reflecting a trend towards safer and longer-lasting installations.

For buyers in developing markets, balancing cost-efficiency with quality is critical. Leveraging supplier relationships that offer comprehensive quality assurance, customization options, and agile logistics will be key to navigating the competitive landscape effectively.

Sustainability & Ethical Sourcing in B2B Procurement of LED Strip Lighting Clips

Sustainability considerations are becoming integral to procurement strategies for LED strip lighting clips, reflecting a global push toward greener supply chains and responsible manufacturing.

Environmental Impact:

– The production of plastic and metal clips involves resource-intensive processes that contribute to carbon emissions and waste. Selecting clips made from recycled or bio-based materials can significantly reduce environmental footprints.

– Durable, high-quality clips extend the lifespan of LED installations, minimizing replacement frequency and associated waste, which aligns with circular economy principles.

Ethical Supply Chains:

– Transparency in sourcing raw materials such as metals and plastics is essential to avoid suppliers linked to unethical labor practices or conflict zones.

– Buyers increasingly require suppliers to demonstrate adherence to international labor standards, including fair wages and safe working conditions, which is particularly important when sourcing from regions with less regulated manufacturing sectors.

Green Certifications and Standards:

– Certifications like ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and UL Environment mark help buyers identify suppliers committed to sustainable practices.

– Some suppliers offer clips manufactured using low-VOC (volatile organic compounds) adhesives and non-toxic coatings, supporting healthier indoor air quality and compliance with stringent European Union environmental directives.

For B2B buyers in Africa, South America, the Middle East, and Europe, prioritizing sustainability not only fulfills corporate social responsibility goals but also meets increasing regulatory demands and end-customer expectations. Collaborating with suppliers who can verify their green credentials and provide lifecycle impact assessments will strengthen supply chain resilience and brand reputation.

Evolution of LED Strip Lighting Clips: A Brief Perspective

The evolution of LED strip lighting clips parallels the rapid development of LED lighting technology itself. Initially, LED strips were installed using basic adhesives or improvised mounting methods, which often compromised installation stability and longevity.

As LED strips became more sophisticated and widely adopted, the need for specialized clips emerged. Early clips were simple plastic or metal fasteners designed to secure rigid or semi-rigid strips. Over time, manufacturers innovated with materials such as UV-resistant plastics and corrosion-proof metals, enabling outdoor and industrial-grade applications.

Today, LED strip lighting clips are engineered with precision to accommodate flexible strips, support quick snap-in installation, and integrate with modular lighting systems. Their design evolution reflects increasing demands for ease of maintenance, aesthetic discretion, and compatibility with smart lighting technologies.

For B2B buyers, understanding this progression underscores the importance of sourcing clips that meet current installation standards and anticipate future technological advancements, ensuring both functional and economic value over the lifecycle of lighting projects.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lighting clips

-

How can I effectively vet suppliers of LED strip lighting clips to ensure product quality and reliability?

To vet suppliers, start by verifying their business credentials, such as licenses and certifications (ISO, CE, RoHS). Request product samples to evaluate material quality and durability. Check customer reviews and ask for references from other international buyers, especially those operating in similar markets like Africa or South America. Confirm that suppliers comply with relevant international standards and offer warranties. Lastly, assess their responsiveness and transparency during initial communications, as these are indicators of reliable long-term partnerships. -

Are customization options available for LED strip lighting clips, and how can they benefit my business?

Many manufacturers offer customization in clip sizes, materials (plastic, metal), colors, and packaging to fit specific installation or branding needs. Custom clips can improve installation efficiency, ensure compatibility with particular LED strips, and enhance product appeal to your customers. For international buyers, customized packaging with multilingual labels or branding can facilitate market acceptance. Engage early with suppliers to discuss minimum order quantities (MOQs) and lead times for custom orders to align with your project timelines. -

What are typical MOQs and lead times for bulk orders of LED strip lighting clips, especially for buyers in Africa, the Middle East, or Europe?

MOQ varies by supplier but generally ranges from 1,000 to 10,000 pieces, depending on clip complexity and customization. Lead times typically span 3 to 6 weeks, factoring in production and shipping. For buyers in regions like Kenya or Argentina, consider additional transit time and customs clearance. To optimize supply chain efficiency, negotiate MOQs based on your inventory capacity and forecast demand, and plan orders well in advance to accommodate longer international shipping schedules. -

Which payment terms are common for international B2B transactions involving LED strip lighting clips, and how can buyers protect themselves?

Common payment terms include 30% deposit upfront with balance paid before shipment or upon delivery. Letters of credit (LC) and escrow services provide added security by ensuring funds are released only after meeting agreed conditions. Use trade assurance platforms or request supplier bank references to mitigate risks. For buyers in emerging markets, negotiating flexible terms or partial payments after successful sample approval can help balance cash flow and reduce exposure. -

What quality assurance measures and certifications should I look for when purchasing LED strip lighting clips?

Look for suppliers who conduct rigorous quality control tests, including material strength, UV resistance, and durability under temperature variations. Certifications such as ISO 9001 (quality management), RoHS (restricted hazardous substances), and CE (European conformity) are critical for compliance and market acceptance. Request test reports and third-party inspection certificates to verify claims. Consistent quality assurance helps minimize returns, warranty claims, and installation failures, which is crucial for maintaining your business reputation.

Illustrative Image (Source: Google Search)

-

How can I navigate logistics challenges when importing LED strip lighting clips to countries in Africa, South America, or the Middle East?

Partner with freight forwarders experienced in your target region to manage customs clearance, tariffs, and regulatory compliance effectively. Opt for consolidated shipments to reduce costs and choose reliable shipping methods balancing speed and budget (sea freight for bulk, air freight for urgent orders). Understand local import regulations and documentation requirements to avoid delays. Establish clear communication channels with suppliers to track shipments and proactively handle potential disruptions. -

What steps should I take if I encounter disputes or product quality issues with my LED strip lighting clip supplier?

First, document all issues with photos and detailed descriptions. Communicate promptly and professionally with the supplier to seek resolution, referencing agreed contracts and quality terms. If unresolved, escalate through mediation or arbitration clauses in your contract. Maintain records of all correspondence and transactions to support claims. Involve trade associations or local chambers of commerce if necessary. Establishing clear dispute resolution mechanisms upfront minimizes risks and protects your investment. -

Are there specific considerations for sourcing LED strip lighting clips for different climatic conditions across regions like Europe versus Africa or the Middle East?

Yes, environmental factors such as humidity, temperature extremes, and UV exposure influence clip material choice. For hot, sunny climates in Africa or the Middle East, UV-resistant and heat-stable plastics or corrosion-resistant metals are preferred to ensure longevity. In Europe, where temperatures may fluctuate, flexible and durable materials that withstand cold and moisture are essential. Discuss these requirements with suppliers to select clips tested for your region’s conditions, ensuring reliable performance and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip lighting clips

When sourcing LED strip lighting clips, strategic procurement is essential to ensure quality, cost-efficiency, and supply chain reliability. Prioritizing suppliers with proven manufacturing standards and robust quality control—especially those offering certified products—helps mitigate risks related to durability and compatibility. For international buyers in Africa, South America, the Middle East, and Europe, understanding supplier capabilities, including customization options and compliance with local regulations, is key to aligning with diverse market needs.

Key takeaways for B2B buyers include:

- Supplier vetting: Choose partners with transparent production processes and certifications such as CE or RoHS to guarantee product safety and performance.

- Customization and scalability: Leverage suppliers who offer tailored clip sizes and materials to fit specific LED strip models and large-scale project demands.

- Cost optimization: Maximize value by negotiating bulk pricing combined with efficient logistics to reduce total landed cost.

- Future readiness: Opt for suppliers embracing innovative materials and designs that enhance installation ease and longevity.

Looking ahead, the growing adoption of LED lighting in commercial and residential sectors worldwide signals increasing demand for reliable mounting solutions like LED strip lighting clips. Buyers who adopt a strategic sourcing approach—balancing quality, price, and supplier partnerships—will position themselves competitively. For businesses in emerging and established markets alike, proactive engagement with trusted manufacturers will unlock new growth opportunities and foster long-term success in the evolving lighting industry.