Introduction: Navigating the Global Market for led strip light connection diagram

In the rapidly evolving global LED lighting industry, understanding the intricacies of LED strip light connection diagrams is essential for B2B buyers seeking reliable, scalable, and efficient lighting solutions. These diagrams are more than just technical blueprints; they are foundational tools that ensure correct installation, optimal performance, and long-term durability of LED strip lighting systems. For international buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—mastering these connection details is critical to mitigating risks related to compatibility, safety, and energy efficiency.

This comprehensive guide offers an authoritative roadmap covering every aspect of LED strip light connection diagrams. You will gain expert insights into the various types of LED strips, including voltage specifications, connectors, and dimming options tailored to diverse regional requirements. The guide also delves into essential materials and accessories—from power supplies and connectors to mounting profiles—that impact system reliability and installation ease.

Furthermore, it highlights the significance of manufacturing standards and quality control processes, enabling buyers to evaluate suppliers rigorously and choose products that meet international safety and performance certifications. Market dynamics, cost considerations, and supplier selection strategies are analyzed with a focus on sourcing from regions like Mexico and Turkey, addressing logistical and regulatory challenges unique to these markets.

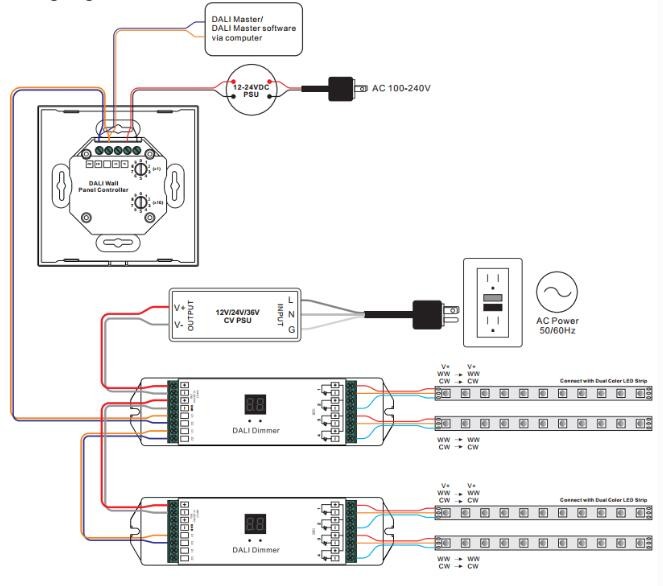

Illustrative Image (Source: Google Search)

By exploring detailed FAQs and practical tips, this guide empowers B2B buyers to make informed decisions, optimize procurement strategies, and establish strong partnerships with trustworthy manufacturers. Ultimately, it facilitates the acquisition of LED strip lighting solutions that combine innovation, quality, and cost-effectiveness for competitive advantage in global markets.

Understanding led strip light connection diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Soldered Connection | LED strips joined by soldering copper pads; requires skilled labor and precision | Custom installations, long continuous runs | + Reliable electrical connection – Labor-intensive; higher installation time and cost |

| Plug-and-Play Connectors | Pre-fabricated connectors (clip-on, snap-on) for quick joining without soldering | Retail lighting, modular displays, quick setup | + Fast, tool-free installation – May limit flexibility in complex layouts; potential contact issues |

| Connector Cables with Adapters | Flexible cables linking LED strips, allowing bends and distance between strips | Architectural lighting, irregular shapes, corners | + High flexibility and ease of maintenance – Slightly higher material cost; cable management needed |

| Corner and Multi-branch Connectors | Specialized connectors for 90° bends, T-junctions, and X-junctions in strip layouts | Complex lighting schemes, signage, large installations | + Enables versatile layout design – More expensive components; requires compatibility checks |

| Integrated Controller Connections | Connection diagrams including dimmers, color controllers, and smart system interfaces | Smart buildings, hospitality, entertainment lighting | + Enables advanced control and automation – Requires technical knowledge; higher upfront investment |

Direct Soldered Connection

This traditional method involves manually soldering LED strip copper pads to join strips. It ensures a robust and stable electrical connection ideal for long continuous runs without signal loss. B2B buyers should consider this when custom, seamless installations are required, such as in large commercial or industrial lighting. However, it demands skilled labor and increases installation time and cost, which may impact project timelines and budgets.

Plug-and-Play Connectors

These connectors allow quick and tool-free joining of LED strips, significantly reducing installation time. They are well-suited for retail displays, exhibitions, or temporary setups where speed and ease of installation are critical. Buyers focusing on rapid deployment and modularity will benefit, but should be aware that these connectors might not support complex layouts or long-distance connections and can sometimes lead to less durable contacts.

Connector Cables with Adapters

Flexible cables connecting LED strips enable installations around corners, across gaps, or in irregular shapes. This type is favored in architectural projects and custom designs requiring adaptability. For B2B buyers, these provide enhanced installation flexibility and easier maintenance, though they come with additional material costs and require careful cable management to maintain aesthetics and safety.

Corner and Multi-branch Connectors

Specialized connectors designed for creating 90-degree angles, T-junctions, and cross junctions facilitate complex lighting configurations. These are essential for large-scale signage, commercial facades, and intricate lighting designs. Buyers should evaluate compatibility with their LED strip types and expect higher component costs but gain significant design versatility and professional-grade results.

Integrated Controller Connections

These connection diagrams incorporate dimmers, color controllers, and smart system interfaces for advanced lighting control. Ideal for smart buildings, hospitality venues, and entertainment sectors, they enable dynamic lighting effects, energy savings, and automation. B2B buyers must consider the technical expertise required for integration and the higher initial investment, balanced against long-term operational benefits and enhanced user experience.

Related Video: How To Connect Strip Lights

Key Industrial Applications of led strip light connection diagram

| Industry/Sector | Specific Application of led strip light connection diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Storefront and in-store ambient lighting installation | Enhances product visibility, improves customer experience, and drives sales | Compatibility with local voltage standards, ease of installation, and durability under continuous operation |

| Hospitality & Leisure | Hotel room, lobby, and restaurant mood lighting systems | Creates customizable ambiance, supports energy efficiency, and reduces maintenance costs | Availability of dimming and color control options, integration with smart systems, and robust connection solutions |

| Industrial & Manufacturing | Task lighting and safety illumination in production lines | Improves worker safety and productivity, reduces downtime due to lighting failure | High IP-rated connectors for harsh environments, clear wiring diagrams for easy maintenance, and reliable power supply compatibility |

| Architecture & Interior Design | Decorative and accent lighting in commercial buildings | Adds aesthetic value, supports brand identity, and allows flexible design adaptations | Modular connection systems, heat dissipation solutions, and compliance with regional electrical codes |

| Transportation & Infrastructure | Lighting for tunnels, stations, and vehicle interiors | Enhances visibility and safety, supports energy savings, and facilitates maintenance | Robust, vibration-resistant connectors, clear connection diagrams for complex installations, and availability of long-life LED strips |

LED strip light connection diagrams play a crucial role in retail and commercial settings by guiding the precise wiring and connection of LED strips used in storefronts and interior displays. These diagrams help ensure seamless electrical integration, which is vital for consistent lighting quality that enhances product presentation and customer engagement. For international buyers, especially in Africa and South America, sourcing LED strips compatible with local voltage standards and ensuring easy-to-follow connection instructions reduces installation errors and downtime.

In the hospitality and leisure sector, LED strip light connection diagrams enable the installation of sophisticated mood lighting in hotels, restaurants, and lounges. These diagrams assist technical teams in integrating dimmers and color controllers, enabling dynamic ambiance control that elevates guest experiences while optimizing energy consumption. Buyers from regions like the Middle East and Europe must prioritize sourcing dimmable LED strips with flexible connection options compatible with smart home or building management systems.

For industrial and manufacturing environments, connection diagrams are essential for setting up task lighting and safety illumination along production lines. Clear, detailed wiring instructions ensure that LED strips are correctly connected to power supplies and controllers, minimizing risks of electrical faults that could cause costly downtime. International buyers should focus on products with high ingress protection (IP) ratings and connectors designed for harsh conditions typical in factories, ensuring longevity and safety compliance.

In architecture and interior design, LED strip connection diagrams facilitate the precise installation of decorative and accent lighting within commercial and public buildings. These diagrams allow designers and installers to create modular and scalable lighting solutions that complement aesthetic goals while maintaining technical reliability. Buyers in Europe and Turkey often require compliance with strict electrical and safety standards, making detailed connection documentation and heat dissipation features critical sourcing criteria.

Lastly, the transportation and infrastructure sector benefits from LED strip light connection diagrams in the installation of lighting systems for tunnels, transit stations, and vehicle interiors. These diagrams help ensure that LED strips and their connectors withstand vibration and environmental stresses, enhancing safety and reducing maintenance costs. For international buyers, sourcing vibration-resistant connectors and long-life LED strips with clear, user-friendly connection diagrams is essential for reliable, long-term operation in demanding settings.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for led strip light connection diagram

When selecting materials for LED strip light connection diagrams, it is essential to consider the electrical, thermal, mechanical, and environmental properties that influence performance and longevity. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding these materials’ characteristics and compliance requirements is crucial for optimizing product reliability and market acceptance.

Copper

Key Properties: Copper is widely used for electrical conductors in LED strip connections due to its excellent electrical conductivity (approximately 5.96×10^7 S/m) and good thermal conductivity. It withstands moderate temperatures up to around 200°C and exhibits good corrosion resistance when properly coated or alloyed.

Pros & Cons: Copper’s primary advantage is its superior conductivity, which reduces voltage drop and energy loss, enhancing LED strip performance. It is also relatively easy to solder and fabricate. However, copper is prone to oxidation and corrosion if not adequately protected, which can compromise connections over time. Additionally, copper is more expensive than some alternative metals, impacting cost-sensitive projects.

Impact on Application: Copper is ideal for indoor and controlled-environment installations where reliable electrical performance is critical. In humid or corrosive environments common in some African or Middle Eastern regions, copper connectors must be plated (e.g., with tin or nickel) or sealed to prevent degradation.

Considerations for International Buyers: Buyers should ensure copper materials comply with international standards such as ASTM B170 or DIN EN 13602 for copper conductors. In markets like Mexico and Turkey, copper is commonly accepted, but surface treatments to improve corrosion resistance are often mandated by local regulations or customer preferences.

Aluminium

Key Properties: Aluminium offers good electrical conductivity (about 61% that of copper) and excellent corrosion resistance due to its natural oxide layer. It is lightweight, with a melting point around 660°C, and has good thermal conductivity, though less than copper.

Pros & Cons: Aluminium is significantly lighter and generally less costly than copper, making it attractive for large-scale or weight-sensitive LED strip installations. However, it is more challenging to solder and requires specialized connectors or mechanical fastening methods. Aluminium also has a higher coefficient of thermal expansion, which can affect connection stability under temperature fluctuations.

Impact on Application: Aluminium is suitable for outdoor or humid environments, such as installations in South America or coastal Middle Eastern regions, where corrosion resistance is paramount. Its lower conductivity means thicker conductors are necessary to achieve the same electrical performance as copper.

Considerations for International Buyers: Aluminium materials should meet standards like ASTM B209 or EN AW-1050A for sheet and strip products. Buyers in Europe and Turkey often require certification for mechanical and thermal properties. Proper connector design is critical to avoid galvanic corrosion when aluminium interfaces with copper components.

Polyvinyl Chloride (PVC) Insulation

Key Properties: PVC is a common insulation material for LED strip wiring and connectors. It offers good electrical insulation, flame retardancy, and resistance to oils and chemicals. PVC typically operates safely up to 70–105°C depending on formulation.

Pros & Cons: PVC is cost-effective, widely available, and easy to process. It provides adequate mechanical protection and environmental resistance for many indoor applications. However, PVC is less flexible at low temperatures and can degrade under prolonged UV exposure, limiting outdoor use without additional protection.

Impact on Application: PVC insulation is ideal for indoor LED strip installations in temperate climates, such as many European countries. In hotter regions like parts of Africa or the Middle East, PVC’s thermal limits may necessitate alternatives for outdoor or high-temperature applications.

Considerations for International Buyers: Compliance with UL 94 flame retardancy standards and RoHS directives is often required in Europe and South America. Buyers should verify PVC grades for UV resistance if outdoor use is anticipated, especially in high-UV index regions.

Silicone Rubber Insulation

Key Properties: Silicone rubber insulation offers excellent thermal stability (operating temperatures from -60°C to +200°C), outstanding flexibility, and resistance to UV radiation, ozone, and moisture.

Pros & Cons: Silicone rubber is highly durable and ideal for harsh environments, providing long-term protection for LED strip connections exposed to outdoor elements. Its flexibility facilitates installation in complex geometries. The downside is a higher material and processing cost compared to PVC.

Impact on Application: Silicone rubber insulation is well-suited for outdoor LED strip lighting in demanding climates such as deserts in the Middle East or tropical zones in South America. It ensures reliable performance despite temperature extremes and exposure to sunlight.

Considerations for International Buyers: Buyers should look for silicone insulation that meets IEC 60502 or equivalent regional standards for electrical cables. In markets like Turkey and Europe, certifications for fire resistance and environmental safety are critical. The premium cost is justified by enhanced durability and reduced maintenance.

| Material | Typical Use Case for led strip light connection diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical conductors and connectors in indoor LED strip systems | Excellent electrical and thermal conductivity | Susceptible to corrosion without protection | High |

| Aluminium | Lightweight conductors and outdoor applications | Good corrosion resistance and low weight | Lower conductivity; requires special connectors | Medium |

| PVC Insulation | Indoor wiring insulation for LED strips | Cost-effective and flame retardant | Limited UV and high-temperature resistance | Low |

| Silicone Rubber Insulation | Outdoor and harsh environment wiring insulation | Superior thermal stability and UV resistance | Higher cost and processing complexity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip light connection diagram

Manufacturing Processes for LED Strip Light Connection Diagrams

The production of LED strip light connection diagrams involves a series of well-coordinated manufacturing stages designed to ensure precision, durability, and safety. For international B2B buyers, understanding these stages helps in selecting suppliers capable of delivering high-quality products that meet diverse regional requirements.

1. Material Preparation

Material preparation is foundational and includes sourcing high-grade components such as flexible printed circuit boards (PCBs), copper conductors, LED chips, resistors, connectors, and adhesives. The quality of raw materials directly impacts the reliability and lifespan of the LED strip connections.

- Flexible PCB fabrication: Copper-clad laminates are cut and cleaned, then coated with solder masks and silkscreens.

- LED chips and components: These are procured from certified suppliers adhering to RoHS (Restriction of Hazardous Substances) compliance.

- Connectors and cables: Must be robust, corrosion-resistant, and compatible with the strip voltage (commonly 12V or 24V DC).

2. Forming and Circuit Patterning

This stage involves patterning the copper conductors on the flexible PCB to create the electrical pathways for the LED strips and their connection points.

- Photolithography and etching: Copper layers are selectively etched to form circuit patterns corresponding to the connection diagram.

- Solder pad preparation: Specific areas for soldering connectors and components are defined and plated for optimal solder adhesion.

3. Assembly

Assembly integrates the LED chips, resistors, and connectors onto the prepared flexible PCB.

- Surface Mount Technology (SMT): Automated pick-and-place machines position components precisely on the PCB.

- Soldering: Reflow soldering ensures strong and consistent electrical joints.

- Connector integration: Connection points are either soldered or attached via specialized connectors designed for easy installation and maintenance.

- Encapsulation: Some strips may have protective coatings or silicone layers applied for water resistance and mechanical protection.

4. Finishing and Packaging

Post-assembly finishing prepares the product for shipment and end-use.

- Cutting and segmentation: LED strips are cut into standard or customized lengths with clear soldering points as indicated in the connection diagram.

- Adhesive backing: High-quality, heat-resistant adhesive tapes are applied for secure mounting.

- Labeling: Clear marking of polarity, voltage, and connection points aids in installation.

- Packaging: Anti-static, moisture-proof packaging protects the strips during transit.

Quality Assurance Framework for LED Strip Light Connection Diagrams

For B2B buyers across Africa, South America, the Middle East, and Europe, robust quality assurance (QA) and quality control (QC) are critical to ensure product safety, performance, and regulatory compliance.

Relevant International and Industry Standards

- ISO 9001: This is the global benchmark for quality management systems. Suppliers certified under ISO 9001 demonstrate consistent manufacturing processes, continuous improvement, and customer focus.

- CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements. Essential for buyers in Europe and regions recognizing EU standards.

- RoHS Compliance: Restricts hazardous substances in electrical products, crucial for environmental and health safety.

- UL or ETL Listings: Important for North American markets and valued globally as indicators of electrical safety.

- API and Local Certifications: Certain countries or regions may require additional certifications reflecting local safety and electrical standards. For example, buyers in Turkey or Mexico should verify compliance with national regulations alongside international ones.

Key Quality Control Checkpoints

Quality control is performed throughout the manufacturing cycle to detect and mitigate defects early.

- Incoming Quality Control (IQC): Verification of raw materials and components for conformity with specifications before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during assembly such as solder joint integrity, component placement accuracy, and functional tests.

- Final Quality Control (FQC): Comprehensive testing of finished products including electrical performance, visual inspection, and packaging verification.

Common Testing Methods

- Electrical Testing: Continuity checks, voltage and current testing to confirm correct circuit function and adherence to the connection diagram.

- Thermal Testing: Ensures the LED strip and connectors can withstand operating temperatures without degradation.

- Mechanical Testing: Adhesion tests for mounting tapes and physical stress tests on connectors to verify durability.

- Environmental Testing: Exposure to humidity, dust, and water (IP rating tests) to validate suitability for intended environments.

- Visual Inspection: Automated optical inspection (AOI) detects soldering defects, misalignments, or damages.

Verifying Supplier Quality: Practical Steps for B2B Buyers

For buyers in Africa, South America, the Middle East, and Europe, verifying supplier quality beyond certifications is key to reducing risk and ensuring smooth supply chains.

- Factory Audits: Conduct on-site or virtual audits to review manufacturing processes, equipment, and QC systems. Pay attention to cleanliness, worker training, and process documentation.

- Request QC Reports: Insist on receiving detailed inspection reports, including raw material certificates, in-process checks, and final test results.

- Third-Party Inspections: Engage independent inspection agencies for random batch testing or pre-shipment inspections to verify compliance with specifications and standards.

- Sample Testing: Obtain product samples for independent laboratory testing to confirm electrical safety, performance, and material quality.

- Supplier Track Record: Evaluate the supplier’s history of meeting international standards, delivery reliability, and responsiveness to quality issues.

QC and Certification Nuances for International Buyers

- Regional Regulatory Differences: Buyers in Mexico or Turkey should verify that CE marking is supplemented by local approvals such as NOM (Norma Oficial Mexicana) or TSE (Turkish Standards Institution) certifications.

- Voltage and Safety Requirements: Countries in Africa and the Middle East may have specific voltage regulations; ensure LED strip connection diagrams and power supplies conform accordingly.

- Climate Considerations: High temperature and humidity environments common in some regions demand higher IP ratings and quality adhesives resistant to environmental degradation.

- Documentation and Traceability: Insist on full traceability of components and production batches to facilitate after-sales support and warranty claims.

- Language and Communication: Ensure technical documentation, including connection diagrams and installation guides, are available in relevant languages and use internationally recognized symbols.

Conclusion

For international B2B buyers, a deep understanding of the manufacturing processes and quality assurance protocols behind LED strip light connection diagrams enables informed sourcing decisions. Prioritizing suppliers with transparent, certified, and verifiable QC systems aligned with international and regional standards mitigates risks and supports long-term partnerships. By focusing on material quality, process control, rigorous testing, and regional compliance, buyers can secure LED strip lighting solutions that deliver reliability, safety, and performance in their specific markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip light connection diagram Sourcing

Understanding Cost Components in LED Strip Light Connection Diagram Sourcing

When sourcing LED strip light connection diagrams and related components, international B2B buyers must dissect the cost structure to optimize procurement decisions. The primary cost components include:

- Materials: This encompasses the LED strips themselves, connectors, power supplies, dimmers, and aluminum profiles. Material quality, such as copper content in connectors or the phosphor layer in COB LED strips, significantly influences costs.

- Labor: Skilled labor for assembly, soldering, testing, and packaging is essential. Labor costs vary widely by region, impacting overall pricing.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor costs. Efficient factories with automation tend to lower this overhead.

- Tooling: Custom molds, connectors, or PCB designs require upfront tooling investments, which are amortized over production runs.

- Quality Control (QC): Rigorous testing for voltage consistency, adhesion strength, and durability under heat influences pricing but reduces defects and returns.

- Logistics: International freight, customs duties, warehousing, and last-mile delivery all contribute to landed costs, especially critical for buyers in Africa, South America, the Middle East, and Europe.

- Margin: Supplier profit margins vary depending on market competition, brand positioning, and after-sales service.

Key Price Influencers in LED Strip Light Connection Diagram Procurement

Pricing is dynamic and influenced by several factors that B2B buyers should evaluate carefully:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically secure better unit prices due to economies of scale and reduced per-unit tooling costs. MOQ requirements can range from hundreds to thousands of meters or units.

- Specifications and Customization: Custom lengths, specialized connectors (e.g., waterproof or flexible types), advanced dimming capabilities, or integrated smart controls will increase costs. Standardized products are generally more cost-effective.

- Material Quality and Certifications: Suppliers offering RoHS, CE, UL, or ISO certifications command premium prices but assure compliance with safety and quality standards crucial for many international markets.

- Supplier Location and Reliability: Proximity reduces logistics expenses and lead times. Established suppliers with proven track records may charge higher prices but mitigate risks related to quality and delivery delays.

- Incoterms: Terms such as FOB, CIF, or DDP affect who bears the shipping and customs clearance costs. Understanding these terms helps buyers avoid unexpected expenses.

Actionable Buyer Tips for Cost-Efficient Procurement

International B2B buyers, especially from emerging markets like Mexico, Turkey, or African nations, can leverage these strategies:

- Negotiate Beyond Price: Discuss payment terms, lead times, packaging options, and after-sales support. Suppliers often have flexibility in non-price terms that impact total cost.

- Consider Total Cost of Ownership (TCO): Factor in installation ease, energy efficiency, maintenance frequency, and warranty coverage. Cheaper upfront prices may incur higher lifecycle costs.

- Request Samples and Test Thoroughly: Verify product quality, adhesion strength of adhesive tapes, and compatibility with existing electrical infrastructure before bulk ordering.

- Consolidate Shipments: Combining orders of LED strips, connectors, and power supplies can reduce logistics costs and customs complexity.

- Leverage Local Partners: Work with regional distributors or agents familiar with import regulations and local market nuances to avoid delays and tariff pitfalls.

- Be Wary of Extremely Low Prices: Substandard materials or manufacturing shortcuts often lead to premature failures, negating initial savings.

Pricing Nuances for Diverse International Markets

- Africa and South America: Logistics and customs can add significant surcharges. Buyers should budget for longer lead times and potential import duties.

- Middle East: Demand for high-quality certifications is increasing, especially for commercial and luxury projects; prioritize suppliers with recognized compliance.

- Europe: Strict regulatory frameworks necessitate certified products. Although prices may be higher, compliance reduces legal risks and product returns.

- Mexico and Turkey: Growing manufacturing hubs with competitive pricing and proximity to major markets offer cost advantages, but verify supplier credibility.

Disclaimer on Pricing Information

Prices for LED strip light connection diagrams and components vary widely depending on supplier, product specifications, and market conditions. The insights provided serve as a guideline for buyers to understand typical cost drivers and negotiate effectively but do not represent fixed or guaranteed pricing.

By comprehensively analyzing cost components, recognizing key price influencers, and applying strategic sourcing practices, international B2B buyers can optimize procurement of LED strip light connection diagrams to achieve both cost-efficiency and high-quality outcomes.

Spotlight on Potential led strip light connection diagram Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip light connection diagram’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip light connection diagram

Key Technical Properties of LED Strip Light Connection Diagrams

When evaluating LED strip light connection diagrams for international B2B procurement, understanding critical technical properties ensures compatibility, safety, and performance. Here are the most important specifications buyers should consider:

-

Voltage Rating (e.g., 12V, 24V DC)

This defines the operating electrical voltage for the LED strip and its accessories. Selecting the correct voltage is vital to avoid damage or inefficient operation. For example, 24V systems are preferred for longer runs and better dimming control, which is common in commercial projects across Europe and the Middle East. -

Material Grade and Heat Dissipation

LED strips are often mounted in aluminium profiles which act as heat sinks. The grade of aluminium and thermal conductivity directly affect LED lifespan and performance. High-quality materials prevent overheating and extend service life, a crucial factor for buyers in hot climates such as Africa or South America. -

IP Rating (Ingress Protection)

This rating indicates the LED strip’s resistance to dust and moisture. For outdoor or industrial applications, IP65 or higher is recommended to ensure durability. Understanding IP ratings helps buyers specify products suitable for diverse environments, from humid coastal regions to dusty deserts. -

Cutting and Connection Tolerance

LED strips are designed with specific cutting points and connection methods (soldering, connectors). Precision in these tolerances ensures seamless electrical and mechanical connections. For B2B buyers, this translates to ease of installation, reduced labor costs, and minimized product returns. -

Dimming Compatibility and Control Protocols

Whether using PWM dimmers or smart controllers, knowing the dimming method and supported protocols (e.g., DMX, Zigbee) is essential for integration into existing lighting systems. Buyers in technologically advanced markets like Europe will benefit from products that support wireless and app-based control. -

Power Supply Specifications

Power supplies must match the LED strip’s voltage and current requirements, with sufficient wattage to handle total strip length. Over-specifying ensures reliability, while underspecifying risks failure. International buyers should also verify certifications (CE, UL) for compliance with local regulations.

Essential Trade Terminology for LED Strip Light Procurement

Understanding common industry terms facilitates smoother communication and negotiation between international buyers and suppliers:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce LED strips or components which other brands rebrand and sell. OEM partnerships can offer cost savings and customization options. Buyers seeking private label solutions should clarify OEM capabilities early. -

MOQ (Minimum Order Quantity)

The smallest batch size a supplier will accept. MOQs vary widely and impact inventory planning and pricing. Buyers from emerging markets like Mexico or Turkey often negotiate MOQs to balance costs with demand. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing and terms based on specified requirements. A detailed RFQ including technical specs and quantities helps suppliers provide accurate offers, speeding up procurement cycles. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs. Clear agreement on Incoterms avoids misunderstandings and unexpected costs in cross-border transactions. -

Lead Time

The period between order placement and delivery. Longer lead times may require advance planning, especially for large projects or markets with complex import regulations. -

Batch Consistency

Refers to uniformity in product quality across production runs. Consistency is critical for lighting projects requiring identical color temperature and brightness, ensuring brand reputation and customer satisfaction.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize supply chains, and foster successful partnerships in the competitive LED strip lighting market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip light connection diagram Sector

Market Overview & Key Trends

The global market for LED strip light connection diagrams is experiencing robust growth driven by increasing adoption of energy-efficient lighting solutions across commercial, industrial, and residential sectors. Key drivers include urbanization, smart city initiatives, and the rising demand for customizable and easy-to-install lighting systems. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Mexico and Turkey—understanding these dynamics is crucial to capitalizing on growth opportunities.

Technological advancements have significantly influenced sourcing trends. Modular connection systems, plug-and-play connectors, and wireless dimming controls are becoming standard features, enhancing ease of installation and integration with smart building management systems. Moreover, the shift towards 24V low-voltage LED strips is notable for safety, energy savings, and compatibility with advanced dimming technologies. Buyers should prioritize suppliers offering comprehensive accessory kits—power supplies, connectors, profiles, and dimmers—that ensure system reliability and scalability.

Market dynamics also reveal a growing preference for suppliers who can provide tailored solutions adapted to diverse climatic and infrastructural conditions prevalent in target regions. For example, moisture-resistant connectors and profiles with superior heat dissipation are critical for hot and humid environments common in the Middle East and parts of Africa. Additionally, the rise of e-commerce platforms and direct sourcing from manufacturers in Asia and Europe facilitates competitive pricing and faster lead times, but buyers must balance cost with quality and after-sales support.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly pivotal in the LED strip light connection diagram sector. International buyers are under pressure to reduce carbon footprints and ensure their supply chains adhere to environmental and social governance (ESG) standards. LED lighting inherently contributes to energy efficiency, but the sustainability of components—such as connectors, power supplies, and mounting profiles—varies widely.

Ethical sourcing begins with selecting suppliers who use recycled or low-impact materials, such as aluminum profiles produced with reduced energy consumption and lead-free soldering in connectors. Certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 (Environmental Management) are essential indicators of compliance with environmental and health safety standards. Buyers should request documentation and conduct audits to verify these credentials.

Moreover, sustainable packaging and reduced plastic usage are becoming important differentiators. Buyers from regions with stringent import regulations, like the European Union, must ensure products meet eco-design directives and extended producer responsibility (EPR) requirements. Partnering with suppliers committed to transparent labor practices and fair wages also mitigates reputational risks and supports long-term supply chain resilience.

Evolution and Historical Context

The LED strip lighting industry has evolved from basic single-color strips requiring complex wiring to sophisticated, multi-color, and programmable systems with simplified connection diagrams. Early challenges included limited lifespan, poor heat dissipation, and complicated installation processes. Innovations such as integrated aluminum profiles for heat management, modular connectors, and standardization of low-voltage power supplies have transformed the sector.

For B2B buyers, understanding this evolution highlights the importance of selecting modern connection systems that offer ease of installation, maintenance, and scalability. The move from 12V to predominantly 24V systems reflects a balance between safety and performance, enabling longer runs without voltage drop and better dimming control. This historical perspective underscores the value of partnering with suppliers who invest in continuous product development aligned with global standards and regional market needs.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip light connection diagram

-

How can I effectively vet suppliers of LED strip light connection diagrams for international trade?

To vet suppliers, request detailed product specifications, certifications (such as CE, RoHS, UL), and sample diagrams. Check their experience with international clients, especially in your region (Africa, South America, Middle East, Europe). Verify factory audits or third-party inspections to ensure production capabilities. Assess their communication responsiveness and technical support availability. Additionally, review references or case studies showcasing successful deliveries and customizations. A reliable supplier should provide clear documentation and demonstrate adherence to safety and quality standards relevant to your target markets. -

Is customization of LED strip light connection diagrams commonly available, and what should I consider?

Yes, many manufacturers offer customization including voltage options (e.g., 12V, 24V), connector types, and layout adjustments for specific installations. When requesting customization, clarify your technical requirements upfront, such as dimming compatibility, power supply integration, and environmental conditions (e.g., waterproofing). Ensure the supplier can provide engineering drawings and prototype samples before mass production. Customization agreements should define intellectual property rights and responsibilities to avoid disputes. Prioritize suppliers with flexible production lines and proven R&D capabilities. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for LED strip light connection diagrams?

MOQs vary by supplier but commonly range from 100 to 500 units for customized diagrams, while standard designs may have lower MOQs. Lead times typically span 3 to 8 weeks depending on order complexity and current demand. Payment terms often require a 30-50% deposit upfront with the balance before shipment or upon delivery. For new buyers, negotiating escrow or letter of credit payments can mitigate risks. Always confirm these terms in writing and factor in buffer time for customs clearance and transportation delays. -

What quality assurance processes and certifications should I expect from reputable LED strip light diagram suppliers?

Reputable suppliers implement strict quality control protocols including incoming material inspection, in-process testing, and final product verification. Look for certifications such as ISO 9001 for quality management, CE for European markets, RoHS for hazardous substance compliance, and UL for safety in North America. Request test reports for electrical safety, heat dissipation, and durability under operating conditions. Suppliers should also provide warranty terms and support for post-sale troubleshooting. Ensuring compliance with your regional regulations is critical for market acceptance. -

How should I manage logistics and shipping for international orders of LED strip light connection diagrams?

Work with suppliers experienced in international shipping who can handle export documentation, customs clearance, and freight forwarding. Choose the most cost-effective and reliable transport mode (air, sea, or express courier) based on urgency and order size. Verify packaging standards to protect delicate electronic components during transit. Use trackable shipping methods and consider insurance to cover potential damages or losses. Clear communication between your logistics team and supplier is essential to coordinate timing, especially for projects with tight deadlines. -

What strategies can mitigate disputes related to LED strip light connection diagram orders?

To prevent disputes, establish clear contracts detailing product specifications, delivery schedules, payment terms, and quality standards. Include clauses for handling defects, delays, and returns. Conduct pre-shipment inspections or request third-party quality audits. Maintain thorough documentation of communications and approvals. If disagreements arise, attempt resolution through negotiation or mediation before escalating to legal action. Leveraging international trade dispute resolution frameworks and working with suppliers who have a strong reputation reduces risks significantly. -

Are there regional considerations when sourcing LED strip light connection diagrams for markets in Africa, South America, the Middle East, and Europe?

Yes, regional factors such as voltage standards, climate conditions (humidity, temperature), and regulatory requirements must be considered. For example, Europe often requires CE marking and RoHS compliance, while Middle Eastern markets may prioritize IP-rated waterproof designs due to harsh environments. Logistics infrastructure and customs procedures vary widely, affecting lead times and costs. Partner with suppliers familiar with your target region’s standards and capable of providing tailored technical support to ensure smooth market entry. -

How can I verify the authenticity and reliability of LED strip light connection diagrams before committing to a bulk purchase?

Request sample diagrams and, if possible, prototypes for functional testing. Verify that diagrams correspond accurately to your LED strip models and installation environments. Utilize third-party labs or consultants to validate technical specifications and safety compliance. Check supplier references and online reviews for feedback on product reliability and after-sales service. Confirm the supplier’s willingness to provide comprehensive documentation and support for installation or troubleshooting. This due diligence helps avoid costly errors and enhances confidence in your procurement decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip light connection diagram

Strategic Sourcing Insights and Future Prospects for LED Strip Light Connection Solutions

In the dynamic market of LED strip lighting, understanding the intricacies of connection diagrams is pivotal for B2B buyers aiming to optimize product performance and installation efficiency. Key takeaways emphasize the importance of sourcing high-quality 24V LED strips paired with compatible power supplies, connectors, and profiles that ensure durability and effective heat dissipation. Prioritizing products that support modular connectivity—such as corner, T, and X connectors—enables flexible, scalable lighting solutions suitable for diverse applications across commercial and industrial sectors.

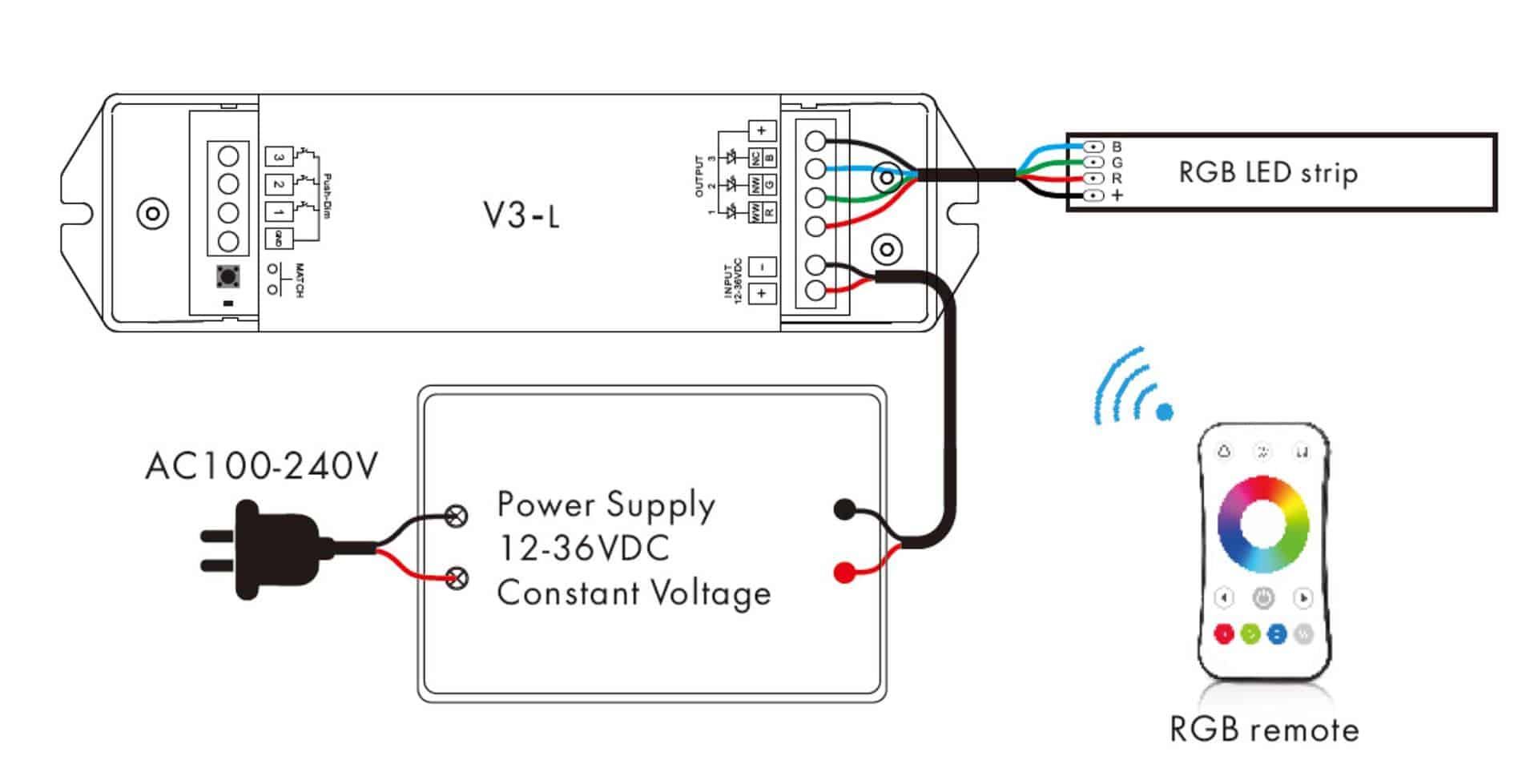

Illustrative Image (Source: Google Search)

Strategic sourcing extends beyond product selection; it involves partnering with suppliers who provide technical support, clear installation guidelines, and customizable options to meet regional electrical standards and environmental conditions. For buyers in Africa, South America, the Middle East, and Europe, this approach reduces risks associated with product incompatibility and enhances after-sales service responsiveness.

Looking ahead, the LED lighting industry is rapidly embracing smart integration, dimming technologies, and energy-efficient components. International buyers are encouraged to engage with suppliers who innovate in these areas, enabling future-proof installations that align with sustainability goals and smart building trends. By investing in strategic partnerships and comprehensive technical knowledge, businesses can confidently navigate complex sourcing landscapes and secure competitive advantages in their local markets.