Introduction: Navigating the Global Market for led strip channel with diffuser

The global demand for LED strip channels with diffusers is rapidly accelerating as businesses across Africa, South America, the Middle East, and Europe embrace energy-efficient, customizable lighting solutions. For B2B buyers in these regions, sourcing the right LED channel system is pivotal—not only to ensure superior light diffusion and aesthetic appeal but also to optimize durability, installation ease, and compliance with regional standards. Understanding the nuances of product types, material quality, and manufacturing processes is critical to making informed procurement decisions that maximize value and performance.

This comprehensive guide serves as an essential resource for international buyers navigating the complexities of the LED strip channel market. It covers the full spectrum—from surface-mounted, recessed, corner, to suspended profiles—and details the advantages of various diffuser materials designed to enhance light uniformity and protect LED strips from dust and moisture. Additionally, the guide delves into manufacturing best practices and rigorous quality control measures that ensure product reliability and longevity.

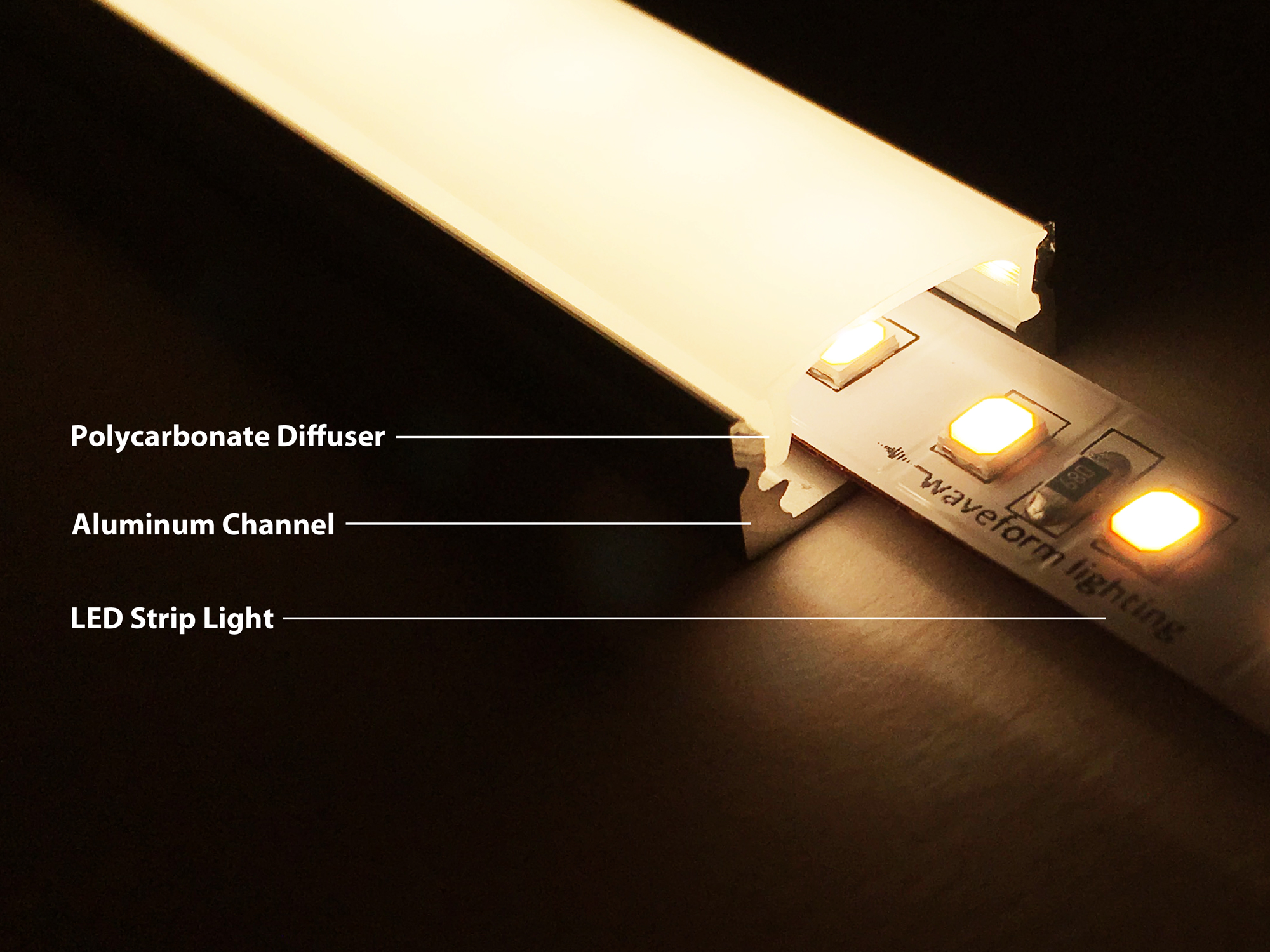

Illustrative Image (Source: Google Search)

Buyers will also gain insight into global supply chain dynamics, cost considerations, and trusted supplier networks that cater specifically to emerging markets such as Argentina, Mexico, Nigeria, and the UAE. A dedicated FAQ section addresses common concerns, empowering procurement professionals to mitigate risks and negotiate confidently.

By synthesizing technical knowledge with market intelligence, this guide equips B2B buyers with actionable insights to source LED strip channels with diffusers that meet their unique project requirements—driving innovation, efficiency, and competitive advantage in today’s evolving lighting industry.

Understanding led strip channel with diffuser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Mounted Channel with Frosted Diffuser | Mounted on surfaces; frosted diffuser softens light output | Retail displays, office lighting, residential under-cabinet lighting | Pros: Easy installation, good light diffusion; Cons: Visible profile may affect aesthetics |

| Recessed Channel with Clear or Opal Diffuser | Installed flush within walls or ceilings; clear or opal diffuser options | Architectural lighting, commercial spaces, museums | Pros: Sleek integration, customizable lighting effects; Cons: Installation complexity, higher cost |

| Corner LED Channel with Diffuser | Designed for 90-degree angles; diffuser ensures even light distribution | Staircases, shelving corners, display cases | Pros: Optimizes corner spaces, prevents harsh shadows; Cons: Limited to angle applications |

| Suspended LED Channel with Diffuser | Hanging installation with diffusers for ambient lighting | Conference rooms, galleries, open office areas | Pros: Modern aesthetics, flexible positioning; Cons: Requires ceiling support, higher installation effort |

| Waterproof LED Channel with Diffuser | Sealed channels with waterproof diffusers for moisture protection | Outdoor signage, wet areas, industrial environments | Pros: Durable in harsh conditions, safe for wet locations; Cons: Usually more expensive, limited diffuser styles |

Surface Mounted Channel with Frosted Diffuser

This type is widely favored for its straightforward installation on various surfaces such as walls and cabinets. The frosted diffuser is key for reducing glare and creating a smooth light output, making it ideal for retail and office environments where visual comfort is important. B2B buyers should consider the visibility of the profile, which might impact design aesthetics, and verify compatibility with their LED strip dimensions.

Recessed Channel with Clear or Opal Diffuser

Recessed channels are embedded into ceilings or walls, offering a minimalist look that integrates seamlessly with architectural elements. The choice between clear or opal diffusers allows buyers to tailor the light diffusion—clear for brighter, sharper illumination; opal for softer, more uniform light. These channels suit high-end commercial projects or museums. Buyers should plan for more complex installation and higher upfront costs balanced by superior design outcomes.

Corner LED Channel with Diffuser

Specifically engineered to fit at 90-degree angles, corner channels efficiently illuminate spaces that are typically challenging, such as staircases or display corners. The diffuser ensures even light spread without harsh shadows, enhancing spatial perception. This type appeals to buyers looking to maximize lighting in constrained or angular spaces. However, its specialized form factor limits use to corner applications only.

Suspended LED Channel with Diffuser

Suspended channels hang from ceilings, often featuring diffusers that provide ambient, glare-free lighting. This style is popular in modern office spaces, galleries, and conference rooms where adjustable lighting and contemporary aesthetics are desired. Buyers should assess ceiling structure compatibility and installation complexity. The suspended design allows for creative lighting layouts but requires professional installation.

Waterproof LED Channel with Diffuser

Designed for wet or harsh environments, waterproof channels come with sealed diffusers to protect LED strips from moisture and dust. These are essential for outdoor signage, bathrooms, kitchens, or industrial settings. B2B buyers targeting these markets must prioritize durability and compliance with safety standards. While generally more costly, these channels extend product lifespan and reduce maintenance costs in challenging conditions.

Related Video: BRILLIANT Design – Govee’s Complete LED + Diffuser System

Key Industrial Applications of led strip channel with diffuser

| Industry/Sector | Specific Application of led strip channel with diffuser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and accent lighting in storefronts, display cases, and shelving units | Enhances product visibility and customer experience, driving sales | Durability, uniform light diffusion, ease of installation, and compliance with local electrical standards |

| Hospitality & Leisure | Decorative lighting in hotels, restaurants, and lounges | Creates inviting atmospheres, improves brand image, and reduces energy costs | Customizable designs, heat dissipation, IP rating for moisture-prone areas, and long lifespan |

| Architectural & Interior Design | Cove lighting, stairway illumination, and feature wall backlighting | Provides sleek, modern aesthetics while reducing glare and hotspots | Compatibility with various LED strips, diffuser quality for smooth light, and adaptability to design specs |

| Industrial & Manufacturing | Task lighting in workstations and machine areas | Improves worker safety and productivity with consistent, glare-free lighting | Robust build, heat management, and resistance to dust and chemicals |

| Transportation & Infrastructure | Lighting for tunnels, corridors, and signage | Enhances visibility and safety, reduces maintenance frequency | High impact resistance, weatherproofing, and compliance with international safety standards |

Retail & Commercial Lighting

In retail environments across Africa, South America, the Middle East, and Europe, led strip channels with diffusers are vital for creating visually appealing product displays and storefronts. These channels provide uniform, glare-free lighting that highlights merchandise without harsh shadows, enhancing shopper engagement and increasing sales potential. B2B buyers should prioritize sourcing channels with high-quality diffusers that ensure consistent light distribution and easy installation to accommodate frequent layout changes common in retail spaces.

Hospitality & Leisure Ambience

Hotels, restaurants, and leisure venues rely heavily on lighting to create welcoming atmospheres that attract and retain customers. Led strip channels with diffusers offer customizable lighting solutions that soften and evenly spread light, avoiding hotspots and harsh glare. For businesses in regions with humid climates such as the Middle East or coastal areas in South America, selecting channels with high IP ratings and excellent heat dissipation is critical to maintain longevity and performance, while also reducing energy consumption.

Architectural & Interior Design

Architects and interior designers utilize led strip channels with diffusers to achieve clean, modern lighting effects in residential and commercial projects. Applications such as cove lighting, stair illumination, and feature walls benefit from the channels’ ability to provide smooth, diffused light that enhances architectural details without overwhelming the space. International buyers should seek versatile profiles compatible with various LED strips and customizable diffuser options to meet diverse design requirements and local standards.

Industrial & Manufacturing Workstation Lighting

In industrial settings, reliable and efficient task lighting is essential for worker safety and operational efficiency. Led strip channels with diffusers deliver consistent, glare-free illumination that reduces eye strain and improves precision in manufacturing or assembly lines. Buyers from industrial sectors in emerging markets like Africa and South America should focus on sourcing robust, dust-resistant channels with superior heat management to withstand harsh environments and extend service life.

Transportation & Infrastructure Illumination

Transportation hubs, tunnels, and pedestrian corridors require durable and high-visibility lighting solutions. Led strip channels with diffusers contribute to enhanced safety by providing uniform illumination that reduces shadows and glare, facilitating clear visibility. For infrastructure projects in Europe and the Middle East, it is crucial to select channels with high impact resistance, weatherproofing, and compliance with stringent safety regulations to ensure reliable performance and low maintenance costs over time.

Related Video: How To Use Flexible LED Filament Wire for Lighting Projects!

Strategic Material Selection Guide for led strip channel with diffuser

Aluminum LED Strip Channels with Diffuser

Aluminum is the most widely used material for LED strip channels due to its excellent thermal conductivity, which helps dissipate heat generated by the LED strips. It offers high corrosion resistance, especially when anodized, making it suitable for both indoor and outdoor applications. Aluminum channels typically withstand temperatures up to 150°C, ensuring durability under continuous operation.

Pros: Aluminum is lightweight, strong, and provides superior heat dissipation, extending the lifespan of LED strips. It is also recyclable and compatible with various diffuser materials. Manufacturing processes like extrusion allow for complex profiles and custom designs.

Cons: Aluminum channels can be more expensive than plastic alternatives and require surface treatment to prevent oxidation. In highly corrosive environments (e.g., coastal regions in Africa or the Middle East), additional protective coatings may be necessary.

Application Impact: Ideal for commercial, architectural, and industrial lighting where heat management and durability are critical. Aluminum channels are preferred in regions with stringent standards like DIN (Germany) and ASTM (USA), which are often referenced in Europe and parts of South America.

B2B Considerations: Buyers in Europe and Mexico benefit from aluminum’s compliance with international standards and ease of customization. African and Middle Eastern buyers should verify corrosion resistance treatments to ensure longevity in harsh climates. Aluminum channels typically align with green building certifications, an increasing demand in global markets.

Polycarbonate (PC) Diffusers for LED Strip Channels

Polycarbonate is a popular choice for LED diffusers due to its high impact resistance, excellent light transmission, and good thermal stability (up to 115°C). It offers superior UV resistance compared to other plastics, making it suitable for outdoor or semi-exposed installations.

Pros: Polycarbonate diffusers provide excellent protection against physical impacts and yellowing over time. They are lightweight and can be manufactured with various finishes (frosted, clear, opal) to control light diffusion and glare.

Cons: PC is more expensive than acrylic and can be prone to scratching. It requires careful handling during installation to avoid damage. Its thermal expansion rate is higher than aluminum, which can affect fitment in extreme temperature variations.

Application Impact: Best suited for applications requiring robust diffuser performance and outdoor durability, such as retail displays and architectural facades. It is widely accepted in markets with high UV exposure, including parts of South America and the Middle East.

B2B Considerations: International buyers should confirm compliance with standards such as ISO 7823 for light transmission and UV resistance. In Africa and South America, polycarbonate’s durability justifies higher upfront costs due to reduced maintenance. Buyers should also consider suppliers’ ability to provide consistent color and finish quality.

Acrylic (PMMA) Diffusers

Acrylic is a cost-effective diffuser material known for its excellent optical clarity and good weather resistance. It has a lower impact resistance than polycarbonate but offers superior light diffusion properties and can withstand temperatures up to 80-90°C.

Pros: Acrylic diffusers are less expensive and easier to fabricate, with good resistance to yellowing and UV degradation under moderate exposure. They provide a smooth, uniform light output, enhancing aesthetic appeal.

Cons: Acrylic is more brittle and prone to cracking under mechanical stress or rapid temperature changes. It is less suitable for outdoor applications in harsh climates without additional UV stabilizers.

Application Impact: Acrylic diffusers are ideal for indoor lighting applications such as office spaces, residential environments, and retail interiors. They are favored where cost efficiency and visual quality are priorities.

B2B Considerations: Buyers from Europe and South America often select acrylic for indoor projects due to its balance of cost and performance. African and Middle Eastern buyers should assess environmental conditions carefully before choosing acrylic, as extreme heat and UV exposure may reduce lifespan. Compliance with ASTM D4802 for weathering is recommended.

Silicone End Caps and Seals

While not a channel or diffuser material per se, silicone is commonly used for end caps and seals in LED strip channel assemblies. Silicone offers excellent flexibility, high-temperature resistance (up to 200°C), and outstanding resistance to moisture and chemicals.

Pros: Silicone seals provide superior protection against dust and water ingress, essential for IP65+ rated LED installations. They maintain elasticity over time and under temperature cycling, ensuring long-term durability.

Cons: Silicone components add to the overall cost and require precise manufacturing tolerances. Compatibility with certain adhesives or channel materials must be verified to avoid degradation.

Application Impact: Critical for outdoor, wet, or industrial environments, especially in regions with high humidity or dust such as parts of Africa and the Middle East. Silicone seals enhance the channel’s ingress protection rating, expanding application versatility.

B2B Considerations: Buyers should ensure that silicone components comply with international standards like UL 94 for flammability and RoHS for chemical safety. Sourcing from suppliers with proven quality control is key for maintaining product reliability in demanding markets like Europe and South America.

| Material | Typical Use Case for led strip channel with diffuser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Commercial, architectural, and industrial lighting | Excellent heat dissipation and durability | Higher cost and requires corrosion protection | High |

| Polycarbonate (PC) | Outdoor and high-impact environments with UV exposure | High impact resistance and UV stability | Prone to scratching and higher thermal expansion | Medium |

| Acrylic (PMMA) | Indoor lighting with focus on optical clarity and cost | Cost-effective with excellent light diffusion | Brittle, less impact resistant, limited outdoor use | Low |

| Silicone | End caps and seals for waterproof and dustproof installations | Superior flexibility and moisture resistance | Adds cost and requires compatibility checks | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip channel with diffuser

Overview of Manufacturing Processes for LED Strip Channel with Diffuser

The production of LED strip channels with diffusers involves a series of precise and controlled manufacturing stages to ensure product performance, durability, and aesthetic quality. Understanding these stages is essential for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe, to assess supplier capabilities effectively.

1. Material Preparation

- Aluminum Alloy Selection: High-quality aluminum alloys are chosen for the channel body due to their excellent heat dissipation and corrosion resistance. The selection depends on regional availability and compliance with environmental standards.

- Diffuser Material: Typically made from polycarbonate (PC) or acrylic (PMMA), the diffuser material must meet transparency and diffusion standards to ensure uniform light distribution and protection.

- Pre-treatment: Aluminum profiles often undergo surface treatments such as anodizing, powder coating, or painting to enhance durability and corrosion resistance, critical for applications in humid or outdoor environments prevalent in many target regions.

2. Forming and Extrusion

- Extrusion of Aluminum Profiles: Aluminum is heated and extruded through dies to form the precise channel shapes. This process requires strict dimensional control to accommodate LED strips and diffusers accurately.

- Diffuser Molding: Diffusers are either extruded or injection molded, depending on the design complexity. The process ensures optical clarity and uniform thickness, which are vital for consistent light diffusion.

- Cutting and Sizing: Both channels and diffusers are cut to standard or customized lengths, often with CNC precision cutting to maintain clean edges and ensure easy installation.

3. Assembly

- Component Integration: LED strips, channels, and diffusers are assembled with attention to alignment and fit. Some suppliers offer pre-assembled solutions, including LED strip mounting and wiring.

- Accessory Installation: End caps, mounting brackets, and connectors are added. These components must be compatible and durable to withstand installation and operational stresses.

- Sealing and Waterproofing: For outdoor or industrial applications, sealing with silicone or rubber gaskets is applied to ensure IP-rated waterproofing, a critical factor for buyer markets with harsh environmental conditions.

4. Finishing and Packaging

- Surface Finishing: Final surface inspection and treatments are performed to meet aesthetic and protective requirements.

- Labeling and Traceability: Products are labeled with batch numbers, certifications, and product codes to facilitate quality tracking.

- Packaging: Customized packaging solutions protect products during international shipping, considering factors like climate, handling, and transportation modes common in regions such as Africa and South America.

Quality Assurance and Control Protocols

Quality assurance (QA) and quality control (QC) are pillars in manufacturing LED strip channels with diffusers, ensuring product reliability and regulatory compliance. International B2B buyers should be familiar with supplier QC practices and standards to mitigate risks.

Key International and Industry Standards

- ISO 9001: The foundational quality management system standard that ensures consistent processes, continual improvement, and customer satisfaction.

- CE Marking: Essential for European markets, indicating compliance with EU safety, health, and environmental requirements.

- RoHS and REACH: Standards restricting hazardous substances, particularly relevant for Europe and increasingly adopted globally.

- IP Ratings (e.g., IP65, IP67): Define ingress protection against dust and water; critical for buyers in humid or outdoor environments.

- Additional Certifications: Depending on the region, suppliers may comply with UL (North America), SAA (Australia), or CCC (China). While not always mandatory for Africa or South America, these certifications can indicate higher quality standards.

QC Checkpoints in the Production Cycle

- Incoming Quality Control (IQC): Verification of raw materials and components for dimensional accuracy, chemical composition, and physical properties before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during extrusion, molding, assembly, and finishing stages to detect defects such as warping, surface imperfections, or improper fitting.

- Final Quality Control (FQC): Comprehensive testing of finished products including dimensional checks, optical performance of diffusers, waterproof testing, and mechanical strength.

Common Testing Methods

- Dimensional Inspection: Use of calipers, micrometers, and coordinate measuring machines (CMM) to ensure profile and diffuser tolerances.

- Light Diffusion and Transmission Tests: Spectrophotometers measure the diffuser’s light transmission rate and uniformity to guarantee consistent lighting effects.

- Environmental Testing: Temperature, humidity, and UV resistance tests simulate operating conditions to assess durability.

- Waterproof and Dustproof Testing: IP rating verification through spray or immersion tests.

- Mechanical Stress Tests: Impact resistance and bending tests ensure structural integrity during installation and use.

How B2B Buyers Can Verify Supplier Quality Control

For buyers from Africa, South America, the Middle East, and Europe, verifying supplier QC capabilities is crucial to secure reliable products and avoid costly delays or compliance issues.

1. Factory Audits and Inspections

- On-site Audits: Conduct or commission third-party audits to evaluate manufacturing facilities, QC processes, equipment, and workforce competency.

- Process Capability Review: Assess supplier’s process control charts, defect rates, and corrective action records.

- Compliance Verification: Confirm that the supplier holds valid certifications (ISO 9001, CE, RoHS) and that these are up-to-date.

2. Quality Documentation and Reporting

- Material Certificates: Request Certificates of Analysis (CoA) for raw materials and components.

- Inspection Reports: Review IQC, IPQC, and FQC reports with detailed defect analysis and measurement data.

- Test Certificates: Obtain third-party lab reports validating optical, mechanical, and environmental testing results.

3. Third-Party Inspection Services

- Engage independent inspection agencies to perform pre-shipment inspections, random sampling, and functional testing.

- This is especially recommended for buyers in regions with logistical challenges or limited direct access to supplier facilities.

QC and Certification Nuances for International Buyers

International buyers should be aware of specific considerations when dealing with LED strip channel suppliers:

- Regional Regulatory Differences: For instance, CE marking is mandatory in Europe but may be voluntary in Africa or South America. Buyers should clarify local import regulations to ensure compliance.

- Voltage and Safety Standards: Electrical safety standards vary; for example, 230V is common in Europe and some African countries, while 110-120V is standard in parts of South America and the Middle East. Suppliers should customize products accordingly.

- Environmental Standards: Some regions have stricter environmental controls (EU REACH) that may affect material choices and certifications.

- Language and Documentation: Ensure QC documents and certifications are available in the buyer’s preferred language or have certified translations, facilitating customs clearance and internal compliance.

- After-Sales Support: Confirm the supplier’s capability to provide technical support, warranty services, and spare parts availability across your region.

Summary for B2B Buyers

- Prioritize suppliers with transparent, documented manufacturing processes and robust QC systems aligned with international standards.

- Verify raw materials, extrusion quality, diffuser optical properties, and assembly precision through documented inspections and third-party testing.

- Understand regional certification requirements and ensure supplier compliance to avoid regulatory hurdles.

- Utilize factory audits, sample testing, and independent inspections to mitigate risks associated with cross-border procurement.

- Consider environmental and electrical standards specific to your target markets in Africa, South America, the Middle East, and Europe to ensure product suitability and longevity.

By thoroughly evaluating manufacturing and quality assurance processes, international B2B buyers can confidently source high-quality LED strip channels with diffusers that meet performance expectations and regulatory demands.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip channel with diffuser Sourcing

When sourcing LED strip channels with diffusers, understanding the detailed cost structure and pricing dynamics is crucial for making informed procurement decisions, especially for international B2B buyers from regions like Africa, South America, the Middle East, and Europe. This insight helps optimize budgets while ensuring product quality and supply reliability.

Breakdown of Cost Components

- Materials: The primary cost driver includes aluminum or plastic for the channel body, and polycarbonate or acrylic for the diffuser. Higher-grade materials improve durability and light diffusion but increase costs. The choice between standard and premium materials directly impacts pricing.

- Labor: Manufacturing labor costs vary by region and production complexity. Custom profiles or intricate designs require more skilled labor, pushing costs higher.

- Manufacturing Overhead: This covers factory utilities, equipment depreciation, and indirect labor. Efficient production facilities with automated processes can reduce overhead per unit.

- Tooling: Initial tooling and mold creation for extrusion or injection molding represent significant upfront expenses. These are usually amortized over large production volumes.

- Quality Control (QC): Rigorous QC processes, including material inspection and light performance testing, add to costs but are essential for consistent product reliability and certifications.

- Logistics: Shipping costs depend on the shipment size, weight, and destination. International freight, customs duties, and local import taxes significantly influence landed costs.

- Margin: Suppliers typically include a profit margin that reflects market positioning, brand reputation, and negotiation leverage.

Key Price Influencers

- Order Volume / Minimum Order Quantity (MOQ): Larger volumes reduce unit costs through economies of scale. Small buyers should be aware of MOQs that might affect pricing and consider group purchasing or negotiating smaller trial orders.

- Specifications & Customization: Custom channel sizes, diffuser shapes, or color options incur higher costs due to specialized tooling and longer production runs.

- Material Quality & Certifications: Buyers targeting markets with strict safety or environmental standards (e.g., CE in Europe) should expect higher prices for certified products.

- Supplier Reputation & Location: Established suppliers with strong quality assurance systems may price higher but offer better reliability. Proximity to the buyer reduces logistics costs and lead times.

- Incoterms: Shipping terms like FOB, CIF, or DDP impact who bears freight, insurance, and customs clearance costs, influencing the final price and risk exposure.

Practical Buyer Tips for International B2B Procurement

- Negotiate on Volume and Payment Terms: Use forecasted purchase volumes to negotiate better MOQs and discounts. Flexible payment terms can improve cash flow without necessarily increasing prices.

- Consider Total Cost of Ownership (TCO): Evaluate beyond the unit price. Factor in installation ease, durability, maintenance, and energy efficiency benefits of the diffuser design to justify upfront investment.

- Verify Supplier Certifications and Quality Guarantees: Insist on product certifications relevant to your region to avoid compliance issues and additional testing costs.

- Factor in Import Duties and Local Taxes: Understand your country’s tariff structure and include these in cost calculations to avoid surprises at customs.

- Request Detailed Quotes with Cost Breakdowns: Transparent supplier quotes help identify cost drivers and potential savings opportunities.

- Plan for Logistics Lead Times: Longer shipping times can disrupt project schedules; consider suppliers with regional warehouses or faster shipping options.

- Leverage Local Agents or Distributors: In markets like Argentina, Mexico, or the Middle East, local partners can help navigate import regulations, reduce freight costs, and provide after-sales support.

Indicative Pricing Disclaimer

Prices for LED strip channels with diffusers vary widely depending on product specifications, order size, and supplier location. This analysis serves as a general framework rather than fixed pricing guidance. Buyers should request customized quotations and perform due diligence to obtain accurate cost estimates tailored to their specific needs.

By dissecting the cost and pricing factors and applying strategic procurement practices, international B2B buyers can secure competitive deals on LED strip channels with diffusers that align with both budget constraints and quality expectations.

Spotlight on Potential led strip channel with diffuser Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip channel with diffuser’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip channel with diffuser

Critical Technical Properties for LED Strip Channel with Diffuser

When sourcing LED strip channels with diffusers, understanding key technical specifications is essential to ensure product performance, compatibility, and durability. These properties directly impact installation quality, lighting effects, and long-term value for international buyers.

-

Material Grade (Aluminum & Diffuser Plastic)

High-grade anodized aluminum is preferred for LED channels due to its superior heat dissipation and corrosion resistance, critical in harsh climates such as those found in Africa and the Middle East. The diffuser is typically made from polycarbonate (PC) or PMMA (acrylic), materials known for excellent light transmission and UV resistance. Selecting the right materials ensures longevity and consistent lighting quality. -

Tolerance and Dimensional Accuracy

Tolerance refers to the permissible deviation in channel dimensions (width, height, length). Tight tolerances (±0.2 mm or better) guarantee that LED strips fit securely and that diffusers snap on properly. For B2B buyers, this reduces installation issues and minimizes returns or rework, especially important when ordering large volumes for projects in Europe or South America. -

Diffuser Opacity and Light Diffusion

Diffusers come in several finishes—clear, frosted, or milky—that affect light diffusion and glare reduction. Frosted diffusers are popular for creating uniform light output without hotspots, enhancing visual comfort in commercial and residential applications. Understanding diffuser types helps buyers specify products that meet aesthetic and functional requirements. -

Channel Length and Customization Options

Standard channel lengths usually range from 1 meter to 2 meters, but many suppliers offer custom lengths to fit specific project needs. Customization can include cut-to-size, pre-drilled mounting holes, or integrated connectors. This flexibility is vital for projects in diverse markets like Argentina or the UAE, where architectural styles and installation methods vary widely. -

Heat Dissipation Capability

Efficient heat management extends LED strip lifespan and maintains brightness. Aluminum channels act as heat sinks, so their design (thickness, surface area) influences thermal performance. Buyers should confirm thermal specifications to ensure channels meet the power and wattage demands of their LED strips. -

Ingress Protection (IP) Rating

For outdoor or humid environments, IP-rated channels and diffusers protect against dust and water ingress. Ratings such as IP65 or higher indicate suitability for demanding conditions, a crucial factor for buyers in regions with challenging weather like coastal South America or Middle Eastern deserts.

Common Trade Terminology in LED Strip Channel Procurement

Familiarity with industry terms streamlines communication and negotiation with suppliers, reducing misunderstandings and expediting procurement.

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce LED channels and diffusers which can be rebranded or customized by the buyer. OEM partnerships are common for businesses seeking private label products tailored to their market specifications, allowing buyers in Africa or Europe to differentiate their offerings. -

MOQ (Minimum Order Quantity)

The smallest order volume a supplier will accept. MOQs vary widely depending on the manufacturer and customization level. Understanding MOQ helps buyers plan inventory and budget, especially important for smaller distributors or emerging markets with limited upfront capital. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers asking for price, lead time, and technical details based on specific product requirements. A detailed RFQ ensures suppliers provide accurate and comparable quotes, facilitating informed purchasing decisions across regions. -

Incoterms (International Commercial Terms)

Standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Clear understanding of Incoterms helps buyers from diverse locations like Mexico or Europe manage logistics and cost expectations. -

Lead Time

The period from order confirmation to product shipment. Lead times influence project scheduling and inventory management. Buyers should negotiate lead times aligned with their market demand cycles to avoid stockouts or delays. -

Certification Standards

Certifications such as CE (Europe), RoHS (restriction of hazardous substances), and UL (Underwriters Laboratories) indicate compliance with safety and environmental regulations. These are often mandatory for importing into certain markets and provide assurance of product quality and legal conformity.

By mastering these essential technical properties and trade terms, international B2B buyers can confidently evaluate suppliers, negotiate favorable terms, and ensure their LED strip channel with diffuser purchases meet both performance standards and regional market requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip channel with diffuser Sector

Market Overview & Key Trends

The global market for LED strip channels with diffusers is experiencing robust growth driven by increasing demand for energy-efficient, versatile lighting solutions across commercial, residential, and industrial sectors. Buyers from regions such as Africa, South America (including Argentina and Mexico), the Middle East, and Europe are witnessing diverse market dynamics shaped by infrastructure development, urbanization, and rising environmental awareness.

Illustrative Image (Source: Google Search)

Key Market Drivers:

– Energy Efficiency and Cost Savings: LED lighting offers substantial reductions in energy consumption compared to traditional lighting. This is particularly attractive in emerging markets where electricity costs and grid reliability are concerns.

– Customization and Design Flexibility: LED strip channels with diffusers enable tailored lighting effects and improved aesthetics, meeting growing architectural and interior design demands.

– Technological Advancements: Integration with smart lighting controls, IoT compatibility, and enhanced diffuser materials that improve light diffusion and reduce glare are becoming standard expectations.

Sourcing Trends for B2B Buyers:

– Global Supply Chain Diversification: Buyers are increasingly sourcing from multiple regions to mitigate risks related to geopolitical tensions, shipping delays, and tariffs. Asian manufacturers remain key suppliers due to competitive pricing and innovation, but local and regional suppliers in Europe and the Middle East are gaining traction for faster delivery and compliance assurance.

– Focus on Quality and Certification: International buyers prioritize suppliers with ISO certifications, RoHS compliance, and CE marking to ensure product safety, longevity, and regulatory adherence.

– Volume and Customization Balance: Large-scale projects favor bulk orders with standardized profiles and diffusers, while premium segments demand bespoke extrusion profiles and diffuser opacities for unique branding and lighting effects.

Regional Considerations:

– In Africa, infrastructure projects and increasing commercial real estate development fuel demand, with an emphasis on cost-effective and durable solutions.

– South American markets, particularly Argentina and Mexico, are driven by industrial modernization and retail sector growth, with buyers seeking reliable suppliers that can navigate import regulations efficiently.

– The Middle East prioritizes high-quality, premium LED channels suitable for luxury commercial and hospitality projects, often requiring bespoke finishes and advanced diffuser technology.

– European buyers emphasize sustainability, energy regulations (such as the EU’s Ecodesign Directive), and integration with smart building systems, pushing suppliers to innovate in eco-friendly materials and smart compatibility.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration for international B2B buyers in the LED strip channel with diffuser sector. The environmental impact of lighting products extends beyond energy consumption to include raw material sourcing, manufacturing processes, and end-of-life recyclability.

Environmental Impact Considerations:

– Material Selection: Aluminum profiles are widely used due to their recyclability and durability. Buyers should prioritize suppliers using recycled aluminum or those committed to circular economy principles.

– Diffuser Materials: Polycarbonate and PMMA (acrylic) diffusers vary in environmental footprint. Eco-conscious buyers seek diffusers produced with low-VOC resins and that are recyclable or biodegradable.

– Energy Efficiency: Opting for LED strips with high lumen-per-watt ratios combined with efficient diffusers reduces operational energy use, contributing to overall carbon footprint reduction.

Ethical Supply Chain Importance:

– Transparent supply chains ensure compliance with labor laws and fair working conditions, which is increasingly scrutinized in regions with strict import regulations.

– Certifications such as ISO 14001 (environmental management) and SA8000 (social accountability) provide buyers with confidence in supplier responsibility.

– Ethical sourcing also mitigates risks associated with conflict minerals and unsustainable mining practices, particularly relevant for components like phosphors and rare earth elements.

Green Certifications & Standards:

– Buyers should look for products that meet RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and Energy Star certifications.

– Emerging standards focused on circularity and lifecycle assessment (LCA) are gaining importance, particularly in Europe, encouraging suppliers to innovate in recyclable diffuser designs and modular LED channels that facilitate maintenance and upgrades.

By prioritizing sustainability and ethical sourcing, B2B buyers not only align with global environmental goals but also enhance their brand reputation and comply with evolving regional regulations.

Evolution of LED Strip Channels with Diffusers

The LED strip channel with diffuser sector has evolved significantly over the past decade, transitioning from simple aluminum channels with basic plastic covers to sophisticated lighting solutions integral to modern architectural design.

Initially, LED strips were installed without housing, leading to issues with heat dissipation, mechanical damage, and uneven light distribution. The introduction of aluminum channels addressed heat management and provided structural support, while diffusers improved light uniformity and reduced glare.

As demand for customization grew, manufacturers developed a variety of channel profiles—surface-mounted, recessed, corner, suspended—and diffuser options ranging from clear to frosted and opal finishes. This evolution was driven by the need to integrate LED lighting seamlessly into diverse environments such as offices, retail spaces, outdoor facades, and residential areas.

Advances in extrusion technology and materials science have enabled the production of lightweight, durable, and eco-friendly profiles with enhanced diffuser properties. Today, the sector continues to innovate with smart lighting compatibility and sustainable manufacturing practices, offering international B2B buyers comprehensive solutions tailored to their market’s specific needs.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip channel with diffuser

-

How can I effectively vet suppliers of LED strip channels with diffusers for international B2B purchases?

When sourcing LED strip channels with diffusers internationally, prioritize suppliers with verifiable certifications such as ISO, CE, or RoHS to ensure product quality and compliance. Request detailed product datasheets, samples, and references from existing clients, especially those in your region (Africa, South America, Middle East, Europe). Conduct due diligence by checking business licenses and exploring third-party audit reports if available. Additionally, evaluate the supplier’s responsiveness and after-sales support capabilities, as these indicate professionalism and reliability in handling international trade complexities. -

Is customization available for LED strip channels with diffusers, and what should I consider?

Most reputable manufacturers offer customization options including size, shape, diffuser opacity, and mounting styles to fit specific project requirements. When requesting customization, clearly specify your technical needs, such as LED strip compatibility, environmental conditions (e.g., outdoor use), and aesthetic preferences. Confirm the supplier’s capability to produce custom molds or profiles and inquire about minimum order quantities (MOQs) for custom products. Customization may impact lead times and pricing, so negotiate these terms upfront to align with your project timelines and budget. -

What are typical minimum order quantities (MOQs) and lead times for international orders?

MOQs for LED strip channels with diffusers vary widely based on the supplier and product type, typically ranging from 100 to 500 units. For custom profiles or diffusers, MOQs may be higher due to tooling costs. Lead times generally span 3 to 8 weeks, depending on order complexity, customization, and production schedules. For buyers in regions like Africa or South America, factor in additional time for shipping and customs clearance. Establish clear communication with suppliers about production timelines and request status updates regularly to avoid delays. -

Which payment methods are safest and most common in international B2B transactions?

Secure payment methods such as Letters of Credit (LC), Telegraphic Transfers (T/T) with staged payments, and escrow services are commonly used to protect both buyer and supplier interests. Many suppliers accept T/T with a 30% deposit upfront and 70% balance before shipment. For new suppliers or large orders, requesting a sample order or smaller initial shipment can mitigate risk. Avoid full upfront payments without verified trust. Additionally, confirm currency options and possible transaction fees to optimize costs. -

What quality assurance processes and certifications should I expect from LED strip channel suppliers?

Reliable suppliers implement stringent quality control procedures including raw material inspections, in-process checks, and final product testing. Certifications like ISO 9001 validate their quality management systems, while CE and RoHS ensure compliance with safety and environmental standards—critical for markets in Europe and increasingly demanded globally. Ask suppliers for test reports on diffuser light transmission, UV resistance, and impact strength to guarantee durability and performance. Regular factory audits and third-party inspections can further enhance confidence in product quality. -

How can I optimize logistics and shipping for LED strip channel imports?

Consider the shipment size, destination port infrastructure, and customs regulations when planning logistics. Bulk shipments by sea freight are cost-effective for large orders but require longer lead times, often 20-40 days depending on origin and destination. Air freight suits urgent deliveries but is more expensive. Engage freight forwarders experienced in handling lighting products and familiar with your region’s import procedures to avoid delays and extra charges. Clarify Incoterms with your supplier to understand responsibilities for shipping costs, insurance, and customs clearance. -

What should I do if I encounter product quality disputes or shipment issues?

First, document all discrepancies with photos and detailed descriptions. Review your purchase agreement for warranty terms and dispute resolution clauses. Engage the supplier promptly to negotiate solutions such as replacements, refunds, or discounts. Utilizing third-party inspection services before shipment can minimize disputes. For unresolved conflicts, consider mediation or arbitration under the agreed jurisdiction. Maintaining clear communication and comprehensive contract terms upfront reduces risks and facilitates smoother dispute resolution. -

Are there specific considerations for sourcing LED strip channels with diffusers in markets like Africa, South America, and the Middle East?

Yes, infrastructure and regulatory environments vary widely across these regions. Ensure your supplier’s products comply with local electrical and safety standards to facilitate customs clearance. Evaluate local climate impacts—such as high humidity or temperature extremes—and request materials and diffusers suited to these conditions. Also, consider after-sales service availability, including spare parts and technical support. Partnering with suppliers offering regional warehouses or distribution centers can improve delivery speed and reduce shipping costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip channel with diffuser

The global demand for LED strip channels with diffusers is rapidly growing, driven by their ability to enhance lighting aesthetics, protect LED strips, and improve light diffusion. For B2B buyers across Africa, South America, the Middle East, and Europe, strategic sourcing is essential to secure quality products that align with local market preferences and regulatory standards. Prioritizing suppliers with robust quality management systems, customizable options, and reliable logistics networks will mitigate risks and ensure timely delivery.

Key considerations include assessing supplier capabilities for custom diffuser designs, material durability, and compatibility with various LED strip types. Leveraging partnerships with manufacturers offering transparent communication and scalable production supports long-term growth and innovation. Additionally, understanding regional market trends—such as energy efficiency regulations and design preferences—can inform sourcing decisions and product selection.

Looking ahead, international buyers should embrace a proactive sourcing approach that balances cost, quality, and supplier reliability. By investing in strong supplier relationships and staying abreast of technological advancements, businesses can capitalize on emerging opportunities in architectural, commercial, and residential lighting markets. The time is ripe to engage with reputable LED strip channel manufacturers to enhance your product offerings and meet evolving customer demands globally.