Introduction: Navigating the Global Market for boat led strips

The global marine lighting industry is undergoing a transformative shift, with boat LED strips emerging as a critical component for modern vessels. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing high-quality boat LED strips is essential. These lighting solutions not only enhance vessel safety and navigation but also contribute significantly to energy efficiency and durability in demanding marine environments.

This comprehensive guide offers a deep dive into the world of boat LED strips, covering everything from types and materials to manufacturing processes and quality control standards. Buyers will gain insights into selecting the right LED strip configurations—whether for deck illumination, navigation, or ambiance—tailored to diverse marine applications. Additionally, the guide addresses critical factors such as supplier evaluation, cost considerations, and emerging market trends that influence purchasing decisions globally.

By exploring practical aspects like compliance with maritime safety certifications and waterproofing standards, this guide equips buyers with actionable knowledge to mitigate risks and optimize procurement strategies. Whether sourcing from established European manufacturers or emerging suppliers in South America and the Middle East, readers will find targeted advice to navigate logistical challenges and ensure product reliability.

Ultimately, this resource empowers international B2B buyers to make informed, strategic decisions in acquiring boat LED strips that meet rigorous performance requirements while aligning with budget and operational goals. As the demand for advanced marine lighting solutions grows, understanding these critical dimensions will be key to maintaining competitive advantage in a global marketplace.

Understanding boat led strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof Marine LED Strips | High IP rating (IP65-IP68), corrosion-resistant coating, flexible design | Exterior boat lighting, deck illumination, underwater lighting | Pros: Durable in harsh marine environments, versatile installation; Cons: Higher cost, requires certified waterproofing standards |

| RGB Color-Changing LED Strips | Multi-color LEDs with controller compatibility, customizable lighting effects | Ambiance lighting in cabins, entertainment zones, yacht interiors | Pros: Enhances aesthetics, customizable; Cons: More complex installation, potential compatibility issues |

| High-Intensity White LED Strips | Bright white LEDs with high lumen output, energy-efficient | Navigation lighting, task lighting on decks, safety illumination | Pros: Energy efficient, improves safety; Cons: Limited color options, may require heat dissipation measures |

| Flexible LED Tape with Adhesive Backing | Thin, bendable strips with self-adhesive backing for easy mounting | Interior accent lighting, instrument panel backlighting, confined spaces | Pros: Easy installation, adaptable to various surfaces; Cons: Adhesive durability varies, not suitable for extreme wet areas |

| Rigid LED Light Bars for Boats | Solid, durable bars with integrated LEDs, often aluminum housing | Navigation lights, floodlights, spotlighting on commercial vessels | Pros: Robust, long-lasting, easy to mount; Cons: Less flexible, heavier than tape strips |

Waterproof Marine LED Strips are engineered specifically for harsh marine environments, featuring high ingress protection ratings (IP65 to IP68) and corrosion-resistant materials. These strips are ideal for exterior applications such as deck lighting or underwater illumination. For B2B buyers, ensuring compliance with international waterproof certifications and selecting suppliers with proven marine-grade products is crucial to reduce returns and warranty claims.

RGB Color-Changing LED Strips offer dynamic, customizable lighting with multi-color capabilities controlled via remote or smart systems. These are primarily used in yacht interiors or entertainment areas to enhance ambiance. Buyers should evaluate controller compatibility and software integration options, especially when outfitting luxury vessels destined for markets like Europe or the Middle East where customization is highly valued.

High-Intensity White LED Strips provide bright, energy-efficient illumination suitable for navigation lights and deck safety lighting. These strips support compliance with maritime safety regulations by improving visibility. For bulk procurement, buyers must assess lumen output, power consumption, and heat management features to ensure long-term reliability and adherence to local maritime standards.

Flexible LED Tape with Adhesive Backing is favored for its ease of installation in tight or irregular spaces such as instrument panels or cabin accents. While cost-effective and adaptable, buyers need to consider the adhesive quality and environmental suitability, as these strips may not withstand prolonged exposure to moisture or UV light common in marine settings.

Rigid LED Light Bars for Boats combine durability with high performance, often housed in aluminum casings for heat dissipation and impact resistance. Ideal for navigation and floodlighting on commercial vessels, these bars are less flexible but offer robust solutions. B2B buyers should focus on supplier certifications, mounting options, and warranty terms to optimize operational uptime in demanding marine applications.

Related Video: Installing LED Deck Lights on a Boat – How To

Key Industrial Applications of boat led strips

| Industry/Sector | Specific Application of boat led strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Transportation | Navigation and safety lighting on commercial vessels | Enhances vessel visibility and compliance with international maritime safety standards, reducing accident risks | Certification compliance (e.g., DNV), durability in harsh marine environments, energy efficiency |

| Yacht and Leisure Craft Manufacturing | Interior and exterior ambient lighting for yachts and pleasure boats | Improves aesthetic appeal and passenger comfort, increasing market competitiveness | Customizable designs, waterproof ratings (IP65+), flexible installation options |

| Fishing Industry | Deck and operational lighting on fishing boats | Facilitates night-time operations and improves crew safety, boosting operational efficiency | Robustness against saltwater corrosion, long lifespan, easy maintenance |

| Offshore Energy Sector | Lighting for offshore platforms and support vessels | Ensures operational safety and continuous work capability in low-light conditions | High IP ratings, explosion-proof options, compliance with offshore safety standards |

| Port and Harbor Facilities | Dock and pier illumination using boat LED strips | Enhances safety and operational efficiency during loading/unloading and night-time activities | Energy consumption, ease of installation and maintenance, compatibility with existing infrastructure |

Boat LED strips are integral to marine transportation, especially for commercial vessels requiring reliable navigation and safety lighting. These strips provide bright, energy-efficient illumination that complies with international maritime regulations, such as those from DNV. For B2B buyers in regions like Africa and South America, sourcing LED strips that withstand extreme weather and saltwater exposure is crucial to ensure longevity and reduce maintenance costs.

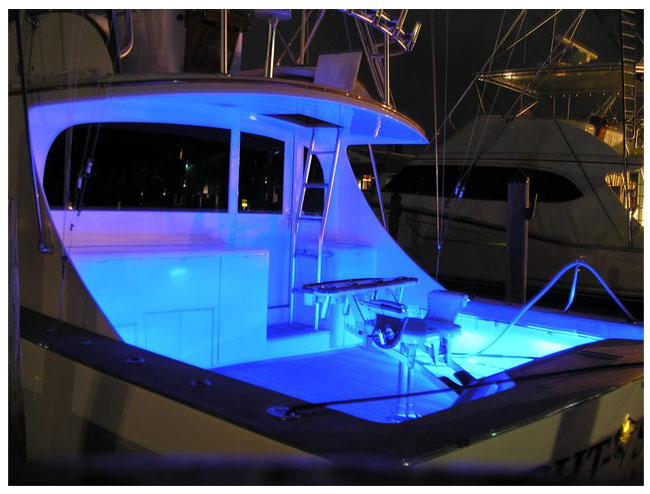

Illustrative Image (Source: Google Search)

In the yacht and leisure craft manufacturing sector, boat LED strips are widely used for both interior and exterior ambient lighting, enhancing the luxury experience for end-users. Manufacturers in Europe and the Middle East prioritize customizable LED solutions that offer waterproofing and flexible installation to meet diverse yacht designs and aesthetic preferences, helping them differentiate their products in a competitive market.

The fishing industry relies heavily on LED strips for deck and operational lighting, particularly for night fishing activities. These lights improve visibility and safety for crews working in challenging conditions, directly impacting productivity. Buyers from South America and Africa should focus on sourcing LED strips with corrosion-resistant materials and high durability to withstand the aggressive marine environment.

In the offshore energy sector, LED strips are essential for lighting offshore platforms and support vessels, enabling safe, 24/7 operations in remote and harsh environments. International buyers, particularly from Europe and the Middle East, must ensure their lighting solutions meet stringent safety certifications and offer explosion-proof features to comply with offshore regulations.

Finally, port and harbor facilities use boat LED strips for dock and pier illumination, which is vital for safe cargo handling and night-time operations. Businesses in ports across Africa and Europe benefit from LED strips that offer low energy consumption and easy integration with existing lighting infrastructure, helping reduce operational costs while improving safety standards.

Related Video: LED Strip Light Install on Jon Boat

Strategic Material Selection Guide for boat led strips

Polyvinyl Chloride (PVC)

Key Properties: PVC is widely used in LED strip casings due to its excellent chemical resistance, moderate temperature tolerance (typically -15°C to 60°C), and good electrical insulation. It offers decent flexibility, which is crucial for installation on curved boat surfaces.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for mass production. However, it has limited UV resistance and can become brittle over time when exposed to harsh sunlight and saltwater environments, common in marine applications. Its moderate temperature tolerance may restrict use in extreme climates.

Impact on Application: PVC is suitable for indoor or sheltered boat areas where direct exposure to harsh elements is minimal. Its chemical resistance makes it compatible with freshwater and mildly saline environments but less ideal for prolonged exposure to aggressive marine conditions.

Considerations for International Buyers: Buyers in regions like South America (e.g., Argentina) and parts of Africa should verify compliance with ASTM D1784 or DIN EN ISO standards to ensure material quality. PVC’s lower cost is attractive for budget-sensitive markets but may require additional protective coatings or UV stabilizers to meet durability expectations in Mediterranean or Middle Eastern climates.

Silicone Rubber

Key Properties: Silicone rubber offers superior flexibility, excellent thermal stability (-60°C to 230°C), and outstanding resistance to UV radiation, saltwater, and ozone. It also provides excellent water resistance and electrical insulation, making it ideal for marine LED strip applications.

Pros & Cons: While silicone is more expensive and complex to manufacture than PVC, its durability and performance in extreme environments justify the investment. It maintains elasticity over time without cracking or yellowing, ensuring long-term reliability.

Impact on Application: Silicone is highly suitable for exposed external boat LED strips, especially in regions with intense sun exposure and saltwater contact, such as the Middle East and coastal Europe. Its resistance to extreme temperatures also supports use in colder climates found in northern Europe.

Considerations for International Buyers: Buyers should ensure silicone materials meet international certifications such as ISO 10993 for biocompatibility and ASTM D2000 for rubber classification. The higher upfront cost is balanced by reduced maintenance and replacement frequency, appealing to buyers in premium markets like Spain or specialized marine suppliers in South Africa.

Polycarbonate (PC)

Key Properties: Polycarbonate is a tough, transparent thermoplastic with excellent impact resistance and good thermal stability (-40°C to 120°C). It provides superior clarity for LED light diffusion and strong resistance to saltwater corrosion and UV degradation when properly treated.

Pros & Cons: PC offers high durability and excellent optical properties but is more expensive and less flexible than PVC or silicone. It can be prone to scratching and may require coatings to enhance abrasion resistance.

Impact on Application: Polycarbonate is ideal for rigid LED strip housings or protective covers on boats that require robust protection against physical impacts and harsh marine environments. It is less suited for highly flexible installations but excellent for navigation or deck lighting.

Considerations for International Buyers: Compliance with standards such as DIN 7728 (marine-grade polycarbonate) and ASTM D3935 is critical. Buyers in Europe and South America should consider PC for premium, long-lasting installations where optical clarity and impact resistance are priorities, despite higher costs.

Aluminum Alloy

Key Properties: Aluminum alloys used in LED strip housings provide excellent heat dissipation, corrosion resistance (especially marine-grade alloys like 5052 or 6061), and mechanical strength. They operate well across a broad temperature range (-50°C to 150°C).

Pros & Cons: Aluminum offers superior thermal management, extending LED lifespan and performance. It is more expensive and heavier than plastic alternatives and requires precise manufacturing processes like extrusion or CNC machining.

Impact on Application: Aluminum is preferred for high-performance boat LED strips where heat dissipation and structural durability are critical, such as in navigation lights or high-output deck lighting. Its corrosion resistance makes it suitable for saltwater environments common in Africa and the Middle East.

Considerations for International Buyers: Buyers should verify alloy grade certifications (e.g., ASTM B209, EN AW standards) and consider the trade-off between cost and performance. Aluminum housings are favored in European markets for their premium quality and in regions with harsh marine conditions demanding durability.

| Material | Typical Use Case for boat led strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor or sheltered LED strip casings | Cost-effective and easy to manufacture | Limited UV resistance and moderate temperature tolerance | Low |

| Silicone Rubber | External flexible LED strips exposed to harsh elements | Excellent flexibility and UV/saltwater resistance | Higher cost and manufacturing complexity | High |

| Polycarbonate | Rigid housings and protective covers for LED strips | Superior impact resistance and optical clarity | Less flexible, prone to scratching | Medium |

| Aluminum Alloy | High-performance housings requiring heat dissipation | Excellent thermal management and corrosion resistance | Higher cost and heavier than plastics | High |

In-depth Look: Manufacturing Processes and Quality Assurance for boat led strips

Manufacturing boat LED strips involves a series of meticulously controlled stages to ensure durability, reliability, and performance in harsh marine environments. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these processes and quality assurance (QA) protocols is crucial to sourcing products that meet both local regulations and demanding operational conditions.

Core Manufacturing Stages of Boat LED Strips

1. Material Preparation

The manufacturing journey begins with sourcing high-quality raw materials. Key components include flexible printed circuit boards (PCBs), marine-grade LEDs, waterproof encapsulants (often silicone or epoxy), and corrosion-resistant connectors. Materials must be selected for resistance to saltwater, UV exposure, and temperature fluctuations common in marine environments.

2. PCB Forming and Circuit Assembly

Flexible PCBs are fabricated with copper traces optimized for low resistance and efficient heat dissipation. Automated surface-mount technology (SMT) machines place LEDs and other electronic components with precision. This stage demands a clean environment to prevent contamination that could impair solder joints or electrical performance.

3. Encapsulation and Waterproofing

Post-assembly, LED strips undergo encapsulation to ensure water and dust ingress protection, typically achieving IP65, IP67, or higher ratings. Techniques include silicone coating or embedding in polyurethane resin. Proper curing and sealing methods are essential to maintain flexibility without compromising waterproof integrity.

4. Finishing and Customization

Final steps involve cutting strips to length, adding connectors or adhesive backing, and packaging. Customization options such as color temperature tuning, brightness levels, and cuttable segments are often integrated here to meet specific buyer requirements.

Quality Assurance Protocols and Industry Standards

International Quality Management Systems

– ISO 9001: This globally recognized standard governs quality management systems, ensuring consistent manufacturing processes and continuous improvement. Suppliers certified under ISO 9001 demonstrate robust procedural controls and traceability.

Industry-Specific Certifications

– CE Marking: Crucial for European markets, this certification confirms compliance with EU directives, including electrical safety and electromagnetic compatibility.

– RoHS Compliance: Ensures restriction of hazardous substances, important for environmental regulations across Europe and increasingly in other regions.

– Marine-Specific Certifications: Depending on the buyer’s region, certifications like ABS (American Bureau of Shipping), DNV (Det Norske Veritas), or Lloyd’s Register may be required, attesting to product suitability for marine applications.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Incoming raw materials and components are inspected for specifications, defects, and compliance with standards. For LED strips, this involves verifying PCB quality, LED performance, and waterproof materials.

- In-Process Quality Control (IPQC): During assembly, critical parameters such as solder joint integrity, LED placement accuracy, and circuit continuity are monitored. Automated optical inspection (AOI) and in-line electrical testing are common methods.

- Final Quality Control (FQC): Completed strips undergo comprehensive testing, including waterproofing verification, luminous intensity measurement, color consistency checks, and endurance testing under simulated marine conditions.

Common Testing Methods for Boat LED Strips

- Waterproof Testing: Submersion or spray tests confirm IP ratings, ensuring strips maintain function after exposure to water and humidity.

- Thermal Cycling: Simulates temperature fluctuations to assess durability of solder joints and encapsulation materials.

- Electrical Safety Tests: Include insulation resistance and voltage withstand tests to prevent short circuits and ensure user safety.

- Photometric Testing: Measures brightness, color temperature, and uniformity to meet buyer specifications.

- Mechanical Flexibility Tests: Verify that strips can bend without damage, critical for installation on curved boat surfaces.

Verifying Supplier Quality: Actionable Steps for B2B Buyers

- Factory Audits: Conduct on-site or third-party audits to assess manufacturing capabilities, process controls, and workforce training.

- Review Quality Documentation: Request ISO 9001 certificates, test reports, and compliance declarations such as CE or RoHS certificates.

- Third-Party Inspections: Engage independent inspection agencies to verify product quality and conformity before shipment, minimizing risk.

- Sample Testing: Obtain pre-production or production samples for in-house or third-party laboratory testing aligned with buyer-specific requirements.

- Supply Chain Transparency: Evaluate supplier traceability systems for components and materials to ensure consistent quality and ethical sourcing.

QC and Certification Considerations for International Buyers

- Regional Regulatory Variations: Buyers from Africa and South America should verify that LED strips meet local electrical and safety regulations, which may differ from European or Middle Eastern standards. For example, some countries may require additional certifications or local testing.

- Customs and Import Compliance: Understanding documentation needed for customs clearance (e.g., CE declarations, test reports) is essential to avoid delays or penalties.

- Climate Adaptation: Buyers in hot, humid, or saline environments should prioritize suppliers with proven track records of marine-grade waterproofing and corrosion resistance tailored for those conditions.

- Language and Communication: Clear communication about quality expectations and documentation in languages common to the buyer’s region (Spanish for Argentina, Arabic for Middle East) facilitates smoother transactions and fewer misunderstandings.

By thoroughly understanding the manufacturing processes and implementing stringent quality assurance measures, international B2B buyers can confidently select boat LED strip suppliers that deliver reliable, compliant, and durable lighting solutions tailored to the demanding maritime sector. This knowledge empowers buyers in diverse regions to negotiate better terms, anticipate regulatory challenges, and ensure long-term satisfaction with their lighting investments.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for boat led strips Sourcing

When sourcing boat LED strips, understanding the detailed cost structure and pricing drivers is essential for international B2B buyers aiming to optimize procurement and ensure quality. The pricing of boat LED strips is influenced by multiple factors spanning from raw materials to logistics and supplier terms, which vary significantly depending on the buyer’s region and volume requirements.

Key Cost Components in Boat LED Strip Pricing

-

Materials: The primary cost driver is the quality and type of LEDs, flexible PCB substrates, waterproof coatings (e.g., silicone or epoxy), and connectors. Marine-grade materials that resist corrosion and saltwater exposure command higher prices but ensure longevity and compliance with maritime safety standards.

-

Labor and Manufacturing Overhead: Labor costs vary by manufacturing country. For buyers in Africa, South America, or the Middle East, sourcing from Asian or European manufacturers may incur different overheads due to wage disparities, factory automation levels, and production scale.

-

Tooling and Setup: Initial tooling for custom LED strip designs or specific boat applications (e.g., navigation lighting) can increase upfront costs. Custom molds, specialized circuitry, or certification testing setups contribute to these expenses.

-

Quality Control (QC): Rigorous QC is critical for maritime LED products to meet certifications such as IP67/IP68 waterproof ratings and marine safety standards. Quality assurance processes, including testing for durability, brightness, and power consumption, add to the cost but reduce long-term failures.

-

Logistics and Import Duties: International shipping, customs clearance, and import taxes significantly impact landed cost. Costs fluctuate based on the Incoterms agreed upon (e.g., FOB, CIF), shipping mode (air or sea freight), and regional trade agreements. Buyers in Argentina or Spain should consider local tariffs and possible delays affecting cost.

-

Supplier Margin: Suppliers factor in profit margins which can vary depending on their market positioning, exclusivity of technology, and after-sales services.

Price Influencers for International B2B Buyers

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce unit cost due to economies of scale. However, some suppliers impose high MOQs that may not align with smaller regional distributors or boat manufacturers, impacting cash flow and inventory costs.

-

Specifications and Customization: Customized lengths, colors, brightness levels, and control interfaces (e.g., DMX or Bluetooth) increase pricing complexity. Buyers requiring marine certification or enhanced durability pay a premium.

-

Material Quality and Certifications: Certified marine-grade LEDs with proven resistance to UV, saltwater, and vibrations typically cost more but offer better lifecycle value, crucial for professional buyers prioritizing reliability.

-

Supplier Reputation and Location: Established suppliers with a track record of compliance and technical support often price higher but reduce risk. Proximity to buyers in Europe or the Middle East can reduce lead times and shipping costs.

-

Incoterms and Payment Terms: Incoterms dictate which party bears shipping and insurance costs, influencing total cost. Favorable payment terms (e.g., LC, net 30) can improve cash flow for buyers in emerging markets.

Strategic Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Based on Total Cost of Ownership (TCO): Focus negotiations not just on unit price but on warranty terms, after-sales service, and replacement costs. Durable, certified products reduce long-term expenses.

-

Leverage Volume Consolidation: Buyers in regions like Africa or South America can collaborate with local partners to consolidate orders, reducing MOQ constraints and shipping costs.

-

Clarify Incoterms Early: Clearly define responsibilities for shipping, customs, and insurance to avoid unexpected costs. For example, CIF may be convenient but often includes hidden charges.

-

Verify Certifications and Quality Claims: Request third-party test reports and certifications to avoid substandard imports that could lead to operational failures or regulatory issues.

-

Consider Currency and Payment Risks: Fluctuating exchange rates and payment method fees affect landed cost. Using hedging strategies or negotiating payment in stable currencies can mitigate risks.

-

Factor in Local Regulations: Understand regional maritime and electrical standards which may necessitate additional testing or certification, impacting cost and delivery time.

Indicative Pricing Disclaimer

Pricing for boat LED strips varies widely based on specifications, certifications, order volume, and supplier location. Indicative unit prices can range from $5 to $30 USD per meter for standard marine-grade LED strips, excluding shipping and taxes. Buyers should obtain customized quotations reflecting their exact requirements and regional considerations.

By carefully analyzing these cost components and price influencers, international B2B buyers from Africa, South America, the Middle East, and Europe can strategically negotiate and source boat LED strips that balance quality, compliance, and cost-efficiency. This approach ultimately supports sustainable procurement decisions aligned with maritime industry demands.

Spotlight on Potential boat led strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘boat led strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for boat led strips

Key Technical Properties of Boat LED Strips

Understanding the critical technical specifications of boat LED strips enables international B2B buyers to select products that meet marine safety, durability, and performance requirements. Here are essential properties to consider:

-

Ingress Protection (IP) Rating

This rating defines the LED strip’s resistance to water and dust, crucial for marine environments. Common ratings for boat LED strips include IP65 (water jets) and IP67 (temporary immersion). Buyers should prioritize higher IP ratings to ensure longevity and safety under harsh sea conditions. -

Material Grade and Corrosion Resistance

Marine-grade materials such as marine-grade PVC or silicone coatings and corrosion-resistant copper or tinned copper conductors enhance durability. These materials withstand saltwater exposure, UV radiation, and temperature fluctuations, reducing replacement frequency and maintenance costs. -

Voltage and Power Consumption

Most boat LED strips operate on 12V or 24V DC systems compatible with standard marine electrical setups. Power consumption (watts per meter) affects energy efficiency and battery life on vessels, so selecting strips with optimized power ratings is essential for operational cost savings. -

Color Temperature and Lumens Output

Color temperature (measured in Kelvins) impacts visibility and ambiance. For navigation and safety, cool white (5000K-6500K) is common, providing bright, clear illumination. Lumens indicate brightness; higher lumens ensure better visibility but can increase power use, so balance is key. -

Cutting and Soldering Tolerance

Precision in cutting points and soldering quality affects installation flexibility and reliability. Good tolerance allows customization on-site without damaging the strip, a valuable feature for varied boat layouts and retrofits. -

Length and Flexibility

Flexible strips that can bend around curves and corners are preferred for boat contours. Length options and modular designs allow buyers to order according to specific vessel dimensions, reducing waste and simplifying installation.

Essential Trade Terminology for International Buyers

Navigating the procurement process for boat LED strips involves understanding common trade and industry terms. Here are key terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing LED strips that can be branded or customized for the buyer. OEM partnerships allow businesses to offer unique product specifications, branding, and packaging, enhancing market differentiation. -

MOQ (Minimum Order Quantity)

The smallest quantity of units a supplier is willing to sell per order. MOQs vary widely, so buyers from emerging markets or smaller fleets should negotiate MOQ terms to align with their budget and storage capabilities. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for detailed pricing, delivery terms, and specifications. RFQs are critical for comparing multiple suppliers objectively and ensuring competitive pricing and product compliance. -

Incoterms (International Commercial Terms)

Standardized terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding these terms helps buyers manage logistics and cost allocation effectively. -

IP Rating (Ingress Protection Rating)

Often used in trade documents to specify product suitability for environments exposed to water or dust. Familiarity with IP codes ensures buyers receive products compliant with marine safety standards. -

Lead Time

The period from order placement to delivery. Knowing supplier lead times is vital for planning installation schedules and inventory management, especially for buyers in regions with longer shipping durations like Africa or South America.

By focusing on these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and ensure they receive durable, compliant, and cost-effective boat LED strips tailored to their marine applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the boat led strips Sector

Market Overview & Key Trends

The global boat LED strips market is experiencing robust growth driven by increasing demand for energy-efficient, durable, and versatile lighting solutions in marine applications. Key market drivers include the rising adoption of LED technology for enhanced visibility, safety compliance, and aesthetic customization on recreational and commercial vessels. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly countries like Argentina and Spain—are capitalizing on these trends to upgrade fleets and meet evolving regulatory standards.

Emerging technological advancements are shaping sourcing strategies and product preferences. Flexible LED strips with waterproof ratings (IP65 and above), customizable color temperatures, and smart control capabilities are becoming industry norms. Buyers prioritize suppliers offering modular designs that simplify installation and maintenance, critical for vessels operating in challenging marine environments. Additionally, integration with IoT-enabled systems for remote monitoring and energy management is gaining traction, especially among commercial fleets aiming to optimize operational efficiency.

Market dynamics reveal a growing emphasis on supply chain resilience. Geopolitical factors and logistics disruptions have prompted buyers to diversify sourcing across multiple regions, balancing cost and reliability. For instance, European buyers often combine local high-quality manufacturing with Asian suppliers to maintain competitive pricing. Meanwhile, African and Middle Eastern buyers increasingly seek partnerships with manufacturers who demonstrate strong after-sales support and compliance with international maritime standards. Understanding regional regulatory frameworks and certification requirements (e.g., CE marking in Europe) is essential for successful procurement.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in the procurement of boat LED strips. The environmental impact of lighting products encompasses energy consumption, material sourcing, and end-of-life disposal. Buyers are increasingly demanding LED strips that not only reduce power usage but also incorporate recyclable or biodegradable components. This is particularly important in marine contexts where environmental regulations are stringent to protect aquatic ecosystems.

Ethical sourcing practices are critical to building trust and ensuring long-term supplier relationships. B2B buyers are scrutinizing supply chains to avoid conflict minerals and ensure fair labor practices. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 environmental management standards are often prerequisites for suppliers targeting European and South American markets. These certifications provide assurance that products meet rigorous environmental and safety benchmarks.

Illustrative Image (Source: Google Search)

Furthermore, the adoption of “green” materials, such as lead-free solder and halogen-free components, aligns with corporate social responsibility (CSR) goals and increasingly influences purchasing decisions. Buyers from regions with emerging environmental policies, like parts of Africa and the Middle East, are proactively seeking suppliers committed to sustainability to future-proof their operations. Partnering with manufacturers who invest in energy-efficient production processes and transparent reporting on environmental impact is a competitive advantage in this sector.

Evolution of Boat LED Strips: A Brief Overview

The transition from traditional incandescent and halogen marine lighting to LED technology marks a significant evolution in the boat lighting sector. Initially, LED strips were limited by brightness and durability, but rapid advancements in semiconductor technology have transformed them into reliable, high-performance solutions tailored for marine environments. Early adopters prioritized energy savings and longer lifespans, leading to widespread replacement of conventional bulbs.

Over the past decade, improvements in waterproofing, flexibility, and color customization have expanded applications from functional navigation and deck lighting to decorative and mood lighting on vessels. This evolution supports not only operational safety but also aesthetic enhancement, a key consideration for luxury yachts and commercial passenger vessels alike. Today’s boat LED strips embody a fusion of technological innovation and sustainability, reflecting broader trends in the marine industry toward smarter, greener solutions.

This comprehensive understanding of market dynamics, sourcing trends, and sustainability considerations equips international B2B buyers with actionable insights to make informed procurement decisions in the competitive boat LED strips sector.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of boat led strips

-

How can I effectively vet suppliers of boat LED strips to ensure reliability and quality?

To vet suppliers, start by requesting detailed product specifications, certifications (such as CE, RoHS, or marine-specific approvals), and quality assurance processes. Verify their manufacturing capabilities through virtual tours or third-party audits, especially if sourcing from regions unfamiliar to you. Check references and previous client feedback, focusing on their experience with international B2B transactions. Confirm their compliance with maritime safety standards relevant to your target markets, such as DNV or ISO certifications. Establishing clear communication channels and requesting samples for quality testing before large orders is essential for mitigating risk. -

What customization options are typically available for boat LED strips, and how should I approach this with suppliers?

Customization can include LED color temperature, strip length, waterproof ratings (IP65 to IP68), connectors, voltage compatibility, and adhesive backing types suitable for marine environments. When discussing with suppliers, provide detailed technical requirements and intended applications. Ask about their flexibility in minimum order quantities (MOQs) for custom specs and lead times. Ensure they can support product certifications for customized items. Request prototypes or samples of customized versions to validate performance under marine conditions before committing to bulk orders. -

What are common minimum order quantities (MOQs) and lead times for boat LED strip orders in international B2B trade?

MOQs vary widely depending on the supplier’s production scale and customization level but typically range from 500 to 5,000 meters per order. Lead times generally span 4 to 12 weeks, influenced by order complexity, customization, and shipping logistics. For buyers in Africa, South America, the Middle East, and Europe, factor in additional time for customs clearance and transportation. Negotiate MOQs based on your market size and explore suppliers offering tiered pricing or smaller initial orders to test product quality. Early engagement on delivery schedules helps align expectations and avoid supply chain disruptions. -

Which payment terms are standard for international purchases of boat LED strips, and how can I safeguard transactions?

Common payment terms include 30% upfront deposit with 70% balance paid upon shipment or letter of credit (L/C) to mitigate risk. For established suppliers, net 30 or 60-day payment terms may be possible. Use escrow services or trade finance solutions to protect funds. Always request proforma invoices detailing product specs and total costs. Verify supplier banking details independently to avoid fraud. Consider insurance for shipments and ensure contracts specify penalties for late delivery or quality issues to safeguard your investment. -

What quality assurance (QA) measures and certifications should I expect from reputable boat LED strip manufacturers?

Look for manufacturers with ISO 9001 certification, demonstrating consistent quality management. Marine-grade certifications such as DNV GL approval, IEC standards compliance, or IP68 waterproof ratings are critical for durability in harsh marine environments. Quality assurance should include in-line testing for brightness, color consistency, waterproof sealing, and electrical safety. Request batch test reports and certificates of conformity. Some suppliers offer third-party lab testing results for added assurance. QA transparency helps ensure products meet international safety and performance standards, reducing returns and warranty claims. -

How can I optimize logistics and shipping when importing boat LED strips from Asia or Europe to markets like Africa or South America?

Plan shipments considering port proximity, customs procedures, and local infrastructure. Use consolidated shipping to reduce costs for smaller orders and select reliable freight forwarders experienced in handling electronics and hazardous materials. Understand import duties, taxes, and compliance documentation required in your destination country to avoid delays. Incoterms like FOB or CIF should be clearly agreed upon to define responsibility for shipping risks and costs. Tracking shipments and maintaining clear communication with suppliers and logistics partners ensures timely delivery and inventory planning. -

What dispute resolution strategies are effective when dealing with international suppliers of boat LED strips?

Incorporate clear terms and conditions in contracts covering product specifications, delivery timelines, payment terms, and penalties. Specify governing law and preferred arbitration or mediation forums, such as ICC arbitration or local chambers of commerce. Maintain thorough documentation of communications, contracts, and quality inspections. Early engagement to resolve issues amicably often prevents escalation. For complex disputes, engage legal experts familiar with international trade law. Building long-term supplier relationships with mutual trust and transparency reduces the likelihood of conflicts. -

Are there specific regulatory or import restrictions I should be aware of when sourcing boat LED strips for markets like the Middle East or Europe?

Yes, many countries enforce strict regulations on electrical marine products, including compliance with CE marking in Europe and Gulf Conformity Mark (G-Mark) in the Middle East. Ensure products meet electromagnetic compatibility (EMC) and safety standards specific to each region. Some countries require environmental certifications related to hazardous substances (e.g., RoHS compliance). Customs may request technical documentation or testing certificates. Engage local import agents or consultants to navigate regulatory frameworks efficiently and avoid shipment rejections or fines. Staying informed on evolving standards helps maintain market access.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for boat led strips

In navigating the competitive landscape of boat LED strips, international B2B buyers must prioritize strategic sourcing to optimize cost, quality, and supply chain resilience. Key considerations include partnering with manufacturers who offer certified, energy-efficient LED solutions that comply with maritime safety standards, ensuring long-term durability and regulatory adherence. Leveraging insights on product specifications—such as visibility range, power consumption, and IP ratings—enables buyers to match offerings precisely with their market demands, particularly in diverse regions like Africa, South America, the Middle East, and Europe.

Strategic sourcing empowers buyers to:

- Secure reliable, scalable supply chains amid fluctuating global logistics.

- Access innovative LED technologies that enhance vessel safety and user experience.

- Optimize total cost of ownership through energy savings and reduced maintenance.

Looking ahead, the boat LED strip market is poised for growth driven by increasing demand for sustainable maritime lighting solutions and digital integration. Buyers from emerging and established markets alike should actively engage with trusted suppliers who demonstrate transparency, quality assurance, and adaptability to regional requirements.

To capitalize on these trends, international buyers are encouraged to:

- Conduct thorough supplier audits focused on compliance and innovation.

- Foster long-term partnerships that support customization and after-sales service.

- Stay informed on evolving maritime regulations and LED technology advancements.

By adopting a strategic sourcing mindset, buyers can confidently navigate complexities and secure competitive advantages in the dynamic global boat LED strip market.