Introduction: Navigating the Global Market for autozone led light strips

The global automotive aftermarket is rapidly evolving, with LED light strips emerging as a vital component for vehicle customization, safety, and aesthetic enhancement. AutoZone LED light strips represent a leading choice due to their quality, versatility, and compatibility with a wide range of vehicles. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing these products is essential to remain competitive and meet diverse customer demands.

This guide offers a comprehensive exploration of AutoZone LED light strips, covering critical dimensions such as product types, materials, manufacturing standards, and quality control processes. Buyers will gain insights into supplier selection criteria, cost structures, and regional market trends, enabling them to navigate complex global supply chains confidently. Additionally, practical information addressing common challenges and frequently asked questions will empower procurement professionals to make well-informed decisions that optimize value and reliability.

By leveraging this resource, B2B buyers can strategically assess opportunities within their respective markets—whether enhancing fleet lighting solutions in Brazil, customizing vehicles in Spain, or expanding automotive accessory offerings in the Middle East and Africa. The guide’s authoritative, solution-oriented approach ensures that businesses are equipped to source AutoZone LED light strips efficiently, maintain product integrity, and capitalize on emerging market potentials worldwide.

Understanding autozone led light strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

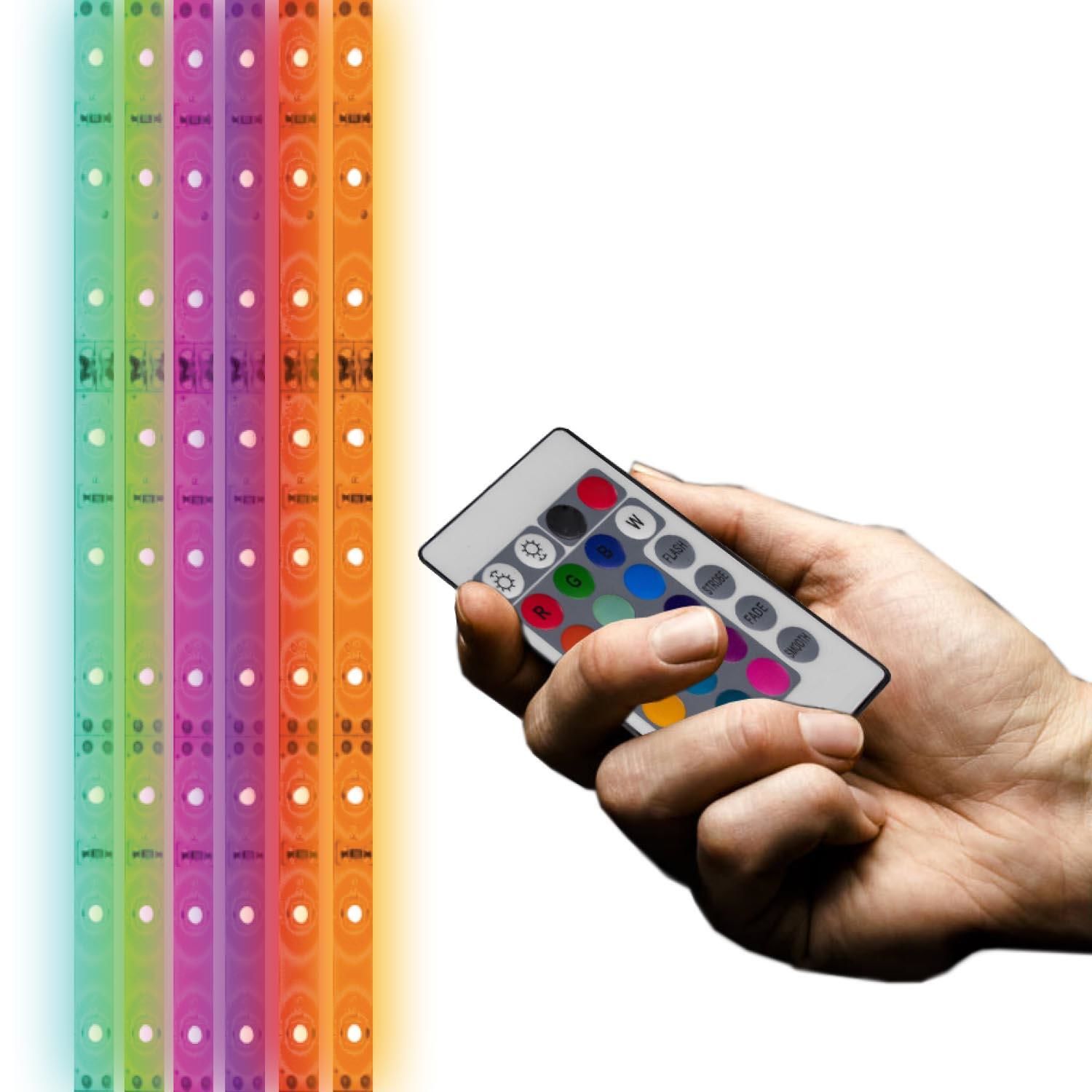

| Multi-Color LED Light Strips | Flexible color options with remote or app control | Automotive customization, fleet branding, and retail displays | Pros: Versatile color schemes, enhances brand visibility; Cons: Higher cost, requires compatible controllers |

| Single-Color LED Light Strips | Fixed color output (e.g., white, red, blue) | Basic vehicle lighting upgrades, commercial vehicle identification | Pros: Cost-effective, simple installation; Cons: Limited customization, less dynamic appeal |

| Waterproof/Rugged LED Strips | Enhanced durability with waterproof casing and robust design | Off-road vehicles, industrial equipment, outdoor applications | Pros: Long lifespan in harsh environments, reliable; Cons: Slightly bulkier, higher upfront cost |

| Plug-and-Play LED Strips | Pre-wired kits with connectors for easy installation | Aftermarket vehicle enhancement, quick fleet upgrades | Pros: Reduced installation time, less technical skill required; Cons: Limited length options, less flexible |

| Customizable Length LED Strips | Cut-to-size strips with adhesive backing | Tailored applications in automotive, marine, and architectural lighting | Pros: Highly adaptable, reduces waste; Cons: Requires technical knowledge for cutting and wiring |

Multi-Color LED Light Strips

Multi-color LED light strips offer dynamic lighting options controlled via remote or smartphone apps, allowing users to switch colors and lighting modes. These are highly suitable for automotive businesses seeking to provide customized vehicle aesthetics or fleet branding solutions. For B2B buyers, particularly in markets such as South America and the Middle East where customization trends are growing, these strips enable differentiation. Key purchasing considerations include compatibility with control units and ensuring supplier support for software integration. While more expensive, their versatility justifies investment for premium aftermarket offerings.

Single-Color LED Light Strips

Single-color LED strips provide a fixed light color, typically white, red, or blue, catering to basic lighting upgrades and compliance applications. They are ideal for commercial fleets and service vehicles requiring consistent and reliable illumination. For buyers in Europe and Africa aiming to optimize cost-efficiency, these strips offer a balance of affordability and performance. The simplicity of installation and fewer compatibility issues make them attractive for volume purchases. However, limited aesthetic flexibility may restrict appeal in markets with higher customization demand.

Waterproof/Rugged LED Strips

Designed with durable, waterproof casings, these LED strips withstand harsh environmental conditions, making them perfect for off-road vehicles, industrial machines, and outdoor lighting projects. B2B buyers targeting sectors such as mining in Africa or construction fleets in the Middle East will find these strips advantageous for their longevity and reliability. When sourcing, buyers should verify IP ratings and supplier quality certifications to ensure compliance with local regulations. The higher upfront cost is offset by reduced maintenance and replacement frequency.

Plug-and-Play LED Strips

Plug-and-play LED light strips come pre-assembled with connectors and are optimized for quick installation. This type suits businesses that require rapid fleet retrofitting or aftermarket vehicle upgrades with minimal downtime. Buyers from fast-growing automotive aftermarket sectors in Brazil and Spain can benefit from reduced labor costs and simplified logistics. While convenient, these strips may offer less flexibility in length and configuration, so buyers should assess their specific application needs before procurement.

Customizable Length LED Strips

Customizable length LED strips allow buyers to cut and tailor the strip length to precise specifications, ideal for specialized applications in automotive, marine, or architectural lighting. This flexibility is valuable for B2B clients requiring bespoke solutions, such as luxury vehicle modifiers or commercial lighting integrators in Europe. However, purchasers must ensure their technical teams have the expertise to handle cutting and wiring safely. Partnering with suppliers offering detailed technical support and quality adhesives is essential to maximize product performance and reduce installation errors.

Related Video: The Ultimate Smart Light Strip Comparison! (6 Popular Devices)

Key Industrial Applications of autozone led light strips

| Industry/Sector | Specific Application of autozone led light strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Accent and functional lighting for vehicle interiors and exteriors | Enhances vehicle aesthetics and safety; customizable for various models | Compatibility with vehicle models, durability under vibration, and weather resistance |

| Commercial Transportation | Interior lighting for buses, trucks, and cargo areas | Improves visibility and passenger comfort; energy-efficient lighting | Long lifespan, ease of installation, and compliance with transport lighting standards |

| Retail and Display | Illuminated signage and product displays | Attracts customer attention; flexible design options for branding | Color accuracy, brightness levels, and ability to operate in diverse climates |

| Industrial Facilities | Safety and task lighting in warehouses and production lines | Enhances workplace safety and productivity; reduces energy costs | Robustness, IP rating for dust and moisture, and ease of maintenance |

| Hospitality and Events | Ambient and decorative lighting for venues and exhibitions | Creates dynamic atmospheres; customizable color options | Flexibility in length, dimmability, and compatibility with control systems |

Automotive Manufacturing

In automotive manufacturing, autozone LED light strips are extensively used for both interior and exterior vehicle lighting. They provide accent lighting to enhance the aesthetic appeal of vehicles while also serving functional purposes such as footwell illumination and undercarriage lighting. For B2B buyers in Africa, South America, the Middle East, and Europe, sourcing LED strips that meet strict durability standards—withstanding vibrations and temperature extremes—is critical. Customization options to fit various vehicle makes and models are essential, ensuring seamless integration and compliance with regional automotive regulations.

Commercial Transportation

LED light strips are vital in commercial transportation sectors, particularly for interior lighting in buses, trucks, and cargo compartments. These strips improve visibility and safety for drivers and passengers while offering energy-efficient alternatives to traditional lighting. For international buyers, especially in regions with long transport routes like Brazil or the Middle East, key considerations include product longevity, ease of retrofit installation, and adherence to local transportation lighting standards. Durable, low-maintenance lighting solutions help reduce operational downtime and energy expenses.

Retail and Display

In retail environments, autozone LED light strips are used to illuminate signage and highlight product displays, enhancing brand visibility and customer engagement. Their flexible design and multiple color options allow businesses to create visually compelling marketing setups tailored to regional tastes and cultural preferences. Buyers from diverse markets such as Spain and South America must prioritize color accuracy and brightness to ensure displays stand out in competitive retail spaces. Additionally, sourcing products capable of withstanding varying climatic conditions is important for outdoor or semi-outdoor retail setups.

Industrial Facilities

Industrial sectors utilize LED light strips for safety and task lighting within warehouses and production lines. These strips improve visibility in critical areas, reducing accidents and increasing worker efficiency. For B2B buyers in industrial hubs across Africa and Europe, selecting LED strips with high IP ratings to resist dust and moisture ingress is crucial. Products should also be robust enough to endure harsh environments and facilitate easy maintenance to minimize operational disruptions and comply with workplace safety standards.

Hospitality and Events

In hospitality and event management, autozone LED light strips are used to create ambient and decorative lighting that enhances venue atmospheres. Their customizable colors and dimmability allow for dynamic lighting designs that cater to different themes and client preferences. Buyers in the Middle East and Europe benefit from sourcing LED strips compatible with various control systems for synchronized lighting effects. Flexibility in strip length and ease of installation are important to accommodate diverse venue layouts and event setups efficiently.

Related Video: LED – Light Emitting Diode | Basics, Characteristics, Working & Applications | LED Vs PN Diode

Strategic Material Selection Guide for autozone led light strips

When selecting materials for AutoZone LED light strips, international B2B buyers must carefully consider the performance requirements, environmental conditions, and regulatory standards specific to their markets. Below is an analysis of four commonly used materials in LED light strip manufacturing, focusing on their key properties, advantages, limitations, and regional considerations relevant to buyers from Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is widely used for LED strip casings and insulation due to its flexibility, good electrical insulation, and moderate temperature resistance (typically up to 60-70°C). It offers reasonable resistance to moisture and many chemicals but can degrade under prolonged UV exposure.

Pros & Cons:

PVC is cost-effective and easy to manufacture, making it suitable for large-scale production. However, it is less durable in harsh outdoor environments and can become brittle in cold climates. Its environmental impact is a concern due to chlorine content and potential release of harmful substances during disposal.

Impact on Application:

PVC is ideal for indoor or sheltered outdoor LED strips where moderate protection is sufficient. It is less suitable for applications requiring high UV resistance or extreme temperature tolerance.

International Considerations:

Buyers in regions with strong environmental regulations, such as the EU (REACH compliance), should verify PVC formulations to ensure low hazardous additives. In hot climates like the Middle East or parts of Africa, UV-stabilized PVC variants are preferable. South American buyers should consider local standards like ABNT for electrical safety and material compliance.

Silicone Rubber

Key Properties:

Silicone rubber offers excellent thermal stability (operating temperatures from -60°C to +200°C), outstanding flexibility, and superior UV and weather resistance. It is highly resistant to moisture, ozone, and many chemicals.

Pros & Cons:

Silicone rubber provides enhanced durability and longevity for LED strips exposed to outdoor or industrial environments. Its manufacturing cost is higher than PVC, and processing requires specialized equipment, which can increase lead times and unit costs.

Impact on Application:

Ideal for premium LED strips used in automotive exterior lighting or outdoor architectural installations where environmental exposure is significant.

International Considerations:

European buyers benefit from silicone’s compliance with stringent RoHS and REACH regulations. For Middle Eastern and African markets, silicone’s heat and UV resistance are advantageous given the harsh climates. South American buyers should confirm compliance with local electrical and chemical standards, such as INMETRO.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a tough, transparent thermoplastic with high impact resistance and good temperature tolerance (up to 115°C). It provides excellent optical clarity, making it suitable for protective covers and lenses on LED strips.

Pros & Cons:

PC offers superior mechanical protection and clarity but is more expensive and less flexible than PVC or silicone. It can yellow over time when exposed to UV light unless treated with UV stabilizers.

Impact on Application:

Best suited for LED strips requiring robust physical protection and high light transmission, such as vehicle accent lighting or decorative applications exposed to mechanical stress.

International Considerations:

European buyers should verify compliance with EN ISO standards for plastics and UV resistance. In regions with intense sunlight like the Middle East and Africa, UV-treated PC is essential. South American buyers should consider local certification for impact resistance and flammability.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU combines elasticity and toughness with excellent abrasion and chemical resistance. It operates effectively in temperatures ranging from -40°C to 80°C and offers good resistance to oils and solvents.

Pros & Cons:

TPU is more durable than PVC and more flexible than PC, providing a balanced option for LED strip casings. It is moderately priced but can be more complex to process due to its elastomeric nature.

Impact on Application:

Suitable for LED strips used in automotive interiors, marine applications, or environments requiring resistance to oils, chemicals, and mechanical wear.

International Considerations:

Buyers in Europe should check compliance with REACH and RoHS, especially for automotive applications. In South America and Africa, TPU’s chemical resistance is beneficial for industrial and marine uses. Middle Eastern buyers will appreciate TPU’s durability under high temperatures and exposure to automotive fluids.

| Material | Typical Use Case for AutoZone LED Light Strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Indoor or sheltered outdoor LED strip casings | Cost-effective and flexible | Limited UV and temperature resistance | Low |

| Silicone Rubber | Outdoor, automotive exterior, and industrial LED strips | Excellent thermal and UV resistance | Higher manufacturing cost and complexity | High |

| Polycarbonate (PC) | Protective covers and lenses requiring high impact resistance | Superior mechanical protection and clarity | Less flexible, prone to yellowing without UV treatment | Medium |

| Thermoplastic Polyurethane (TPU) | Automotive interiors, marine, and chemical-exposed environments | Balanced durability and chemical resistance | More complex processing, moderate cost | Medium |

This guide equips international B2B buyers with critical insights to select the optimal material for AutoZone LED light strips based on application demands, environmental conditions, and regional compliance requirements. Understanding these factors ensures procurement of products that meet quality expectations and regulatory standards across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for autozone led light strips

Manufacturing Processes of AutoZone LED Light Strips

The production of AutoZone LED light strips involves a series of carefully controlled stages to ensure consistent quality and performance. Understanding these stages helps B2B buyers evaluate supplier capabilities and anticipate product reliability.

Illustrative Image (Source: Google Search)

1. Material Preparation

The manufacturing process begins with sourcing and preparing high-quality raw materials, including:

- Flexible Printed Circuit Boards (FPCBs): These serve as the base for mounting LED chips. The selection of copper-clad substrates and flexible polymer films ensures durability and flexibility.

- LED Chips: Sourced from reputable semiconductor manufacturers, typically SMD (Surface Mount Device) LEDs are chosen for their compact size and high luminosity.

- Encapsulation Materials: Silicone or epoxy resins are prepared for protective coating, enhancing waterproofing and mechanical resistance.

- Connectors and Adhesives: High-grade connectors and double-sided adhesives are procured to facilitate installation and electrical connection.

Material preparation involves stringent quality checks to verify the purity, mechanical properties, and compatibility of components.

2. Forming and Circuit Fabrication

This stage includes:

- Circuit Patterning: Using photolithography or etching processes, the conductive copper traces are patterned onto the flexible substrate to create the electrical pathways.

- Component Placement: Automated pick-and-place machines position LED chips and passive components (resistors, capacitors) with high precision.

- Soldering: Reflow soldering techniques bond components to the FPCB, ensuring reliable electrical connections.

Advanced machinery and robotics are employed to maintain tight tolerances and minimize defects, critical for the fine pitch and density of LED strips.

3. Assembly

Assembly integrates functional and aesthetic elements:

- Encapsulation and Coating: LEDs are encapsulated with UV-resistant silicone or epoxy to protect from moisture, dust, and mechanical damage.

- Cutting and Shaping: The LED strips are cut into standard or customized lengths, with precision tooling to maintain electrical continuity and clean edges.

- Connector Attachment: Connectors or terminals are affixed, often via soldering or crimping, enabling easy integration with vehicle electrical systems.

Assembly lines often utilize inline inspection systems to detect misalignments, soldering defects, or missing components in real-time.

4. Finishing and Packaging

Final steps include:

- Waterproofing: For automotive exterior applications, additional sealing techniques such as overmolding or heat-shrink tubing are applied.

- Labeling and Coding: Each strip is labeled with batch numbers, manufacturing dates, and compliance marks for traceability.

- Packaging: Protective packaging, often anti-static and moisture-barrier, is used to prevent damage during transportation and storage.

This stage ensures the product meets both functional requirements and logistics standards.

Quality Assurance Protocols for AutoZone LED Light Strips

Quality assurance (QA) is integral throughout the manufacturing lifecycle, with multiple checkpoints and international standards guiding the process. For B2B buyers, comprehending these QA measures is essential to mitigate risks and ensure supplier reliability.

Key International and Industry Standards

- ISO 9001: This globally recognized quality management system standard ensures that manufacturers maintain consistent processes, continuous improvement, and customer satisfaction. Suppliers adhering to ISO 9001 demonstrate robust quality frameworks.

- CE Marking: Required for products sold in the European Economic Area (EEA), CE certification confirms compliance with EU safety, health, and environmental directives.

- RoHS Compliance: Restriction of hazardous substances is crucial for electronics to meet environmental and safety regulations, especially in Europe.

- UL Certification: While more common in North America, UL marks indicate rigorous electrical safety testing, which can be relevant for international buyers.

- Automotive Industry Standards: Some LED strips may comply with automotive-specific standards like ISO/TS 16949, indicating suitability for automotive applications.

Buyers from Africa, South America, the Middle East, and Europe should verify that suppliers can provide relevant certifications aligned with their regional regulations and import requirements.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components undergo inspection for dimensional accuracy, electrical properties, and defect rates before entering production.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly includes visual inspections, solder joint testing, and automated optical inspection (AOI) to detect defects early.

- Final Quality Control (FQC): Completed LED strips are tested for functional parameters such as brightness, color consistency, power consumption, and waterproofing integrity.

Illustrative Image (Source: Google Search)

Each checkpoint is documented with traceability records, enabling rapid response to any quality issues.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and resistance to ensure safe and efficient operation.

- Photometric Testing: Measures luminous intensity, color temperature, and uniformity to meet product specifications.

- Environmental Stress Testing: Includes thermal cycling, humidity exposure, and vibration tests to simulate real-world automotive conditions.

- Waterproof Testing: IP rating tests (e.g., IP65, IP67) confirm resistance to dust and water ingress.

- Mechanical Durability: Flexibility and adhesion tests assess the strip’s ability to withstand installation and operational stresses.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially in emerging markets and regulated regions, verifying supplier QA capabilities is critical to avoid costly disruptions.

1. Supplier Audits

- On-site Audits: Conduct or commission factory visits to review manufacturing processes, equipment, and QA systems.

- Remote Audits: Use video calls and digital documentation reviews when travel is impractical.

- Compliance Checks: Verify certifications like ISO 9001, CE, and automotive standards through official registries and certification bodies.

2. Documentation and Reporting

- Quality Control Reports: Request batch-wise IQC, IPQC, and FQC reports detailing inspection results and corrective actions.

- Test Certificates: Ensure suppliers provide third-party lab test certificates for electrical safety, photometric performance, and environmental compliance.

- Traceability Records: Confirm that products have lot numbers and manufacturing data for accountability.

3. Third-Party Inspection and Testing

- Engage independent inspection agencies to conduct random sampling, functional testing, and compliance verification before shipment.

- This is particularly valuable for buyers in Africa, South America, and the Middle East, where regulatory environments may require additional scrutiny.

QC and Certification Nuances for International Buyers

International B2B buyers must be aware of regional differences and import regulations affecting LED light strips:

- Africa: Many countries align with CE and RoHS standards, but customs may require additional documentation. Buyers should verify supplier compliance and consider local certification requirements.

- South America (e.g., Brazil): Brazil requires INMETRO certification for automotive lighting products, which may necessitate supplier cooperation for local testing and approval.

- Middle East: Gulf Cooperation Council (GCC) countries often require SASO certification and adherence to IEC standards. Buyers should ensure suppliers can navigate these regulatory frameworks.

- Europe (e.g., Spain): Strict adherence to CE marking, RoHS, and REACH regulations is mandatory. Buyers should insist on full certification and transparent documentation.

Understanding these regional nuances enables buyers to select suppliers who can provide compliant products, reducing the risk of customs delays and market entry issues.

Summary for B2B Buyers

- Evaluate supplier manufacturing capabilities by reviewing material sourcing, precision in forming and assembly, and finishing techniques.

- Demand transparency in quality assurance through adherence to ISO 9001, CE, RoHS, and automotive industry standards.

- Implement multi-level quality control oversight including IQC, IPQC, and FQC with comprehensive testing.

- Verify quality through audits, documentation, and third-party inspections to ensure compliance and traceability.

- Account for regional regulatory requirements by confirming supplier certifications and their ability to support import approvals.

By integrating these insights into supplier evaluation and procurement strategies, international B2B buyers can secure reliable, high-quality AutoZone LED light strips tailored to their regional market demands.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for autozone led light strips Sourcing

When sourcing AutoZone LED light strips for international B2B procurement, understanding the underlying cost structure and pricing dynamics is critical to making informed purchasing decisions. This section breaks down the key cost components, price influencers, and strategic buyer tips tailored to businesses in Africa, South America, the Middle East, and Europe.

Key Cost Components in AutoZone LED Light Strips

- Materials: The primary cost driver includes high-quality LEDs, flexible PCB substrates, waterproof coatings, and connectors. Variations in LED type (e.g., SMD vs. COB), color options, and durability features impact material costs significantly.

- Labor: Manufacturing labor costs vary depending on the region of production and the complexity of assembly, including soldering, wiring, and testing.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines with automated processes can reduce these expenses.

- Tooling: Initial tooling and mold creation for custom LED strip designs or housing components represent upfront capital costs that can be amortized over large production runs.

- Quality Control (QC): Rigorous inspection and testing protocols to ensure product reliability, longevity, and compliance with safety standards add to the cost but are essential for B2B credibility.

- Logistics: Freight, customs duties, and warehousing costs vary by destination, affecting landed cost. For international buyers, shipping terms and consolidation options influence final expenses.

- Margin: AutoZone and its suppliers incorporate markups to cover distribution, retail overhead, and profit. Margins may fluctuate based on brand positioning and market demand.

Influencing Factors on Pricing

- Order Volume and Minimum Order Quantities (MOQs): Bulk purchasing typically unlocks significant discounts. Buyers from emerging markets should negotiate MOQs carefully to balance inventory costs and price breaks.

- Product Specifications and Customization: Custom lengths, color options, integrated controllers, or specialized connectors increase unit costs. Standardized models generally offer better price points.

- Material Quality and Certifications: Products with certifications like CE, RoHS, or IP ratings command premium pricing but assure compliance with international standards, reducing risks in regulated markets such as the EU.

- Supplier Capabilities and Location: Manufacturers with advanced technology and proximity to shipping hubs may offer competitive pricing and faster lead times. Regional sourcing can reduce logistics costs.

- Incoterms: Shipping terms such as FOB, CIF, or DDP directly affect the buyer’s cost exposure to freight, insurance, and customs clearance. Understanding these is crucial to accurate landed cost estimation.

Strategic Buyer Tips for International B2B Procurement

- Negotiate Based on Total Cost of Ownership (TCO): Beyond unit price, factor in warranty terms, expected lifespan, energy efficiency, and after-sales support. Higher upfront costs may yield lower operational expenses.

- Leverage Group Purchasing: Businesses in Africa, South America, the Middle East, and Europe can collaborate through buying groups or trade associations to meet MOQs and negotiate better pricing.

- Request Detailed Cost Breakdowns: Transparency in cost components helps identify areas for negotiation, such as reducing tooling fees or optimizing packaging to cut logistics costs.

- Evaluate Supplier Certifications and Compliance: Prioritize suppliers who demonstrate compliance with relevant local and international standards to avoid customs delays and product rejections.

- Optimize Incoterms for Your Market: For buyers in regions with complex import regulations (e.g., Brazil), opting for DDP (Delivered Duty Paid) can simplify customs clearance despite higher upfront costs.

- Consider Currency Fluctuations: Engage in contracts that allow price adjustments or hedging mechanisms to mitigate risks from exchange rate volatility, especially important for buyers in emerging economies.

Indicative Pricing Overview

AutoZone’s LED light strips retail approximately between $15 to $40 per unit in consumer markets, depending on length, color, and features. For B2B buyers, bulk orders typically secure discounts ranging from 10% to 30%. However, prices vary widely based on customization, certification, and logistics factors. Buyers should treat these figures as indicative starting points and conduct direct supplier negotiations for tailored quotes.

By carefully analyzing cost components and price influencers, international B2B buyers can strategically source AutoZone LED light strips that balance quality, compliance, and cost-effectiveness. This approach ensures competitive pricing while meeting the specific requirements of diverse markets across Africa, South America, the Middle East, and Europe.

Spotlight on Potential autozone led light strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘autozone led light strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for autozone led light strips

Key Technical Properties of AutoZone LED Light Strips

When sourcing AutoZone LED light strips for automotive aftermarket or commercial applications, understanding the critical technical specifications is vital to ensure compatibility, durability, and performance across diverse markets such as Africa, South America, the Middle East, and Europe.

-

Material Grade and Durability

AutoZone LED strips typically use high-quality flexible PCB substrates combined with durable silicone or epoxy coatings. These materials provide resistance to moisture, dust, and UV exposure—essential for vehicles operating in harsh environments. For B2B buyers, verifying material grade ensures product longevity and reduces warranty claims. -

Voltage and Power Consumption

Most AutoZone LED strips operate on 12V DC, compatible with standard automotive electrical systems globally. Power consumption, measured in watts per meter, affects energy efficiency and heat generation. Understanding these parameters helps buyers assess electrical load requirements and compatibility with vehicle systems or aftermarket controllers. -

Color Temperature and Light Output

LED strips are offered in various colors and color temperatures, including white (cool to warm), red, blue, and multi-color options. Color temperature (Kelvin) impacts visibility and aesthetic appeal, while luminous intensity (lumens) affects brightness. Buyers should specify these to meet regulatory lighting standards and customer preferences in their target markets. -

Ingress Protection (IP) Rating

The IP rating defines the strip’s resistance to solids and liquids. Common ratings for AutoZone strips range from IP65 (dust tight, water jets) to IP67 (temporary immersion). This is crucial for buyers targeting regions with heavy rain or dusty conditions, ensuring reliable outdoor or vehicle exterior use. -

Cut-to-Length and Flexibility Tolerance

Many LED strips allow cutting at specified intervals without damaging the circuitry, enabling customization for different vehicle sizes or designs. Flexibility tolerance indicates the strip’s ability to bend around curves without cracking. These features are important for OEMs or distributors requiring adaptable lighting solutions. -

Connector and Socket Type Compatibility

AutoZone offers LED strips with standardized connectors compatible with common automotive wiring harnesses. Understanding connector types and socket compatibility simplifies installation and reduces integration costs, especially for large-scale fleet or aftermarket projects.

Essential Trade Terminology for AutoZone LED Light Strips Procurement

Navigating international B2B transactions for LED lighting requires familiarity with key industry terms. These terms facilitate clear communication, streamline negotiations, and reduce risks.

-

OEM (Original Equipment Manufacturer)

Refers to products made by the original manufacturer to be sold under another brand or directly to vehicle makers. AutoZone LED strips may be OEM or aftermarket parts. Buyers should clarify if products meet OEM standards, which often implies higher quality and regulatory compliance. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier will sell in one order. Understanding MOQ is critical for buyers in emerging markets or smaller businesses to balance inventory investment against demand. Negotiating MOQs can improve cash flow and reduce storage costs. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting price, delivery terms, and specifications for a product. RFQs are essential in comparing multiple AutoZone LED strip vendors or when sourcing customized lighting solutions, enabling competitive pricing and clear contract terms. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce (ICC) that define responsibilities for shipping, insurance, and tariffs. Common terms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting appropriate Incoterms impacts landed cost and logistics complexity. -

Lead Time

The time span from order placement to product delivery. For LED strip buyers, shorter lead times improve inventory turnover and responsiveness to market trends. Understanding supplier lead times also aids in planning promotional campaigns or seasonal sales. -

Product Liability Insurance

Insurance that covers damages caused by defective products. Many B2B buyers require suppliers like AutoZone to carry such insurance to mitigate risks associated with product failures, especially important in automotive lighting where safety is paramount.

By mastering these technical specifications and trade terms, international B2B buyers can make informed purchasing decisions, negotiate effectively, and ensure smooth supply chain operations for AutoZone LED light strips tailored to their regional market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the autozone led light strips Sector

Market Overview & Key Trends

The global market for AutoZone LED light strips is experiencing robust growth driven by increasing automotive customization, enhanced vehicle safety regulations, and rising demand for energy-efficient lighting solutions. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe (notably Spain and Brazil), are capitalizing on these trends to meet evolving consumer preferences and regulatory landscapes.

Key market drivers include:

-

Technological advancements: Innovations in LED technology have improved brightness, durability, and color options, enabling manufacturers to offer customizable and high-performance lighting solutions. Buyers benefit from a diverse range of products, including multi-color and app-controlled strips, which cater to various vehicle types and aesthetic requirements.

-

Regulatory compliance: Many countries are tightening automotive lighting standards to enhance road safety and reduce energy consumption. European markets, for instance, emphasize adherence to UNECE regulations, influencing sourcing decisions toward certified, compliant LED strips.

-

Growing automotive aftermarket: In emerging markets such as Brazil and South Africa, expanding vehicle ownership and rising disposable incomes fuel demand for aftermarket accessories like LED light strips. These regions offer significant growth potential for suppliers who understand local market nuances.

-

E-commerce and supply chain integration: The rise of digital procurement platforms and electronic data interchange (EDI) capabilities facilitates streamlined ordering and inventory management for B2B buyers worldwide. AutoZone’s supplier programs emphasize electronic cataloging and quick delivery options, enabling international buyers to optimize sourcing efficiency.

-

Customization and modularity: Increasing demand for customizable kits and modular light strips allows buyers to offer tailored solutions to their clients. This trend supports differentiation in competitive markets and encourages innovation in product design.

For B2B buyers, understanding these dynamics is crucial to selecting suppliers who offer not only quality and compliance but also agility in delivery and product customization to meet regional market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in B2B procurement decisions within the AutoZone LED light strip sector. International buyers are increasingly prioritizing suppliers who demonstrate environmental responsibility and ethical supply chain practices.

Environmental impact considerations:

-

Energy efficiency: LED light strips inherently consume less power than traditional lighting, reducing the carbon footprint of automotive lighting. However, buyers should assess suppliers’ adherence to energy efficiency standards and look for products designed to maximize lifespan and minimize waste.

-

Materials and recyclability: Sustainable sourcing involves selecting LED strips made with recyclable materials and minimal hazardous substances. Suppliers offering RoHS-compliant products ensure the reduction of toxic elements such as lead and mercury, critical for environmental compliance in Europe and other regions.

-

Packaging and logistics: Eco-friendly packaging and optimized logistics contribute to overall sustainability goals. Buyers should encourage vendors to use biodegradable or recyclable packaging and consolidate shipments to lower transportation emissions.

Ethical supply chain importance:

-

Buyers must verify that suppliers follow ethical labor practices, comply with international labor laws, and maintain transparency throughout the supply chain. AutoZone’s vendor certification programs emphasize these values, providing a benchmark for buyers seeking responsible partnerships.

-

Certification programs such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) offer assurance of sustainable and ethical operations. Engaging with suppliers holding these certifications mitigates reputational and operational risks.

By integrating sustainability criteria into sourcing strategies, B2B buyers not only align with global regulatory trends but also meet the increasing demand from end consumers for environmentally responsible automotive products.

Evolution and Industry Context

The evolution of LED light strips in the automotive aftermarket reflects broader trends in vehicle technology and consumer preferences. Initially used primarily for interior accent lighting, LED strips have expanded into exterior applications, including daytime running lights, turn signals, and decorative trims.

AutoZone’s leadership in providing a wide range of LED light strips aligns with the shift toward modular, customizable lighting solutions that enhance vehicle aesthetics and safety. Over the last decade, advancements in LED chip technology and flexible circuit designs have enabled the production of strips that are both durable and adaptable to diverse vehicle types.

This progression has opened opportunities for international B2B buyers to access sophisticated lighting products that comply with regional standards while catering to local tastes. Understanding the historical context helps buyers appreciate the technological maturity and quality benchmarks they should expect when sourcing AutoZone LED light strips globally.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of autozone led light strips

-

How can international B2B buyers from regions like Africa, South America, the Middle East, and Europe verify the reliability of AutoZone LED light strip suppliers?

To ensure supplier reliability, buyers should request comprehensive company profiles, including business licenses, Dun & Bradstreet ratings, and references from existing clients. Engaging suppliers who comply with AutoZone’s Vendor Code of Conduct and participate in their Supplier Certification Program provides an added layer of assurance. Utilizing third-party audits or certifications and evaluating the supplier’s history of on-time delivery and quality compliance are also essential steps. Additionally, leveraging platforms that facilitate verified supplier-buyer connections can mitigate risks in international transactions. -

Is customization of AutoZone LED light strips available for bulk international orders, and what is the typical process?

Yes, many suppliers offer customization options including color, length, power specifications, and packaging tailored to buyer needs. The process generally starts with submitting a detailed product specification or sample request. Suppliers then provide prototypes or samples for approval. For international buyers, it’s crucial to clarify customization capabilities upfront and discuss minimum order quantities (MOQs) tied to customized products. Establishing clear communication channels and timelines ensures expectations are aligned before production begins, minimizing delays and rework. -

What are the common minimum order quantities (MOQs), lead times, and payment terms for AutoZone LED light strips in international B2B deals?

MOQs vary by supplier but typically range from a few hundred to several thousand units, especially for customized products. Lead times can span from 2 to 8 weeks depending on order size, customization complexity, and logistics arrangements. Payment terms often require a deposit (30-50%) upfront, with the balance paid before shipment or upon delivery. International buyers should negotiate payment terms that balance risk and cash flow, such as using letters of credit or escrow services, and confirm all terms in a formal contract to avoid misunderstandings. -

What quality assurance measures and certifications should international buyers look for when sourcing AutoZone LED light strips?

Buyers should seek products that comply with internationally recognized standards such as CE (Europe), RoHS (environmental safety), UL or ETL (electrical safety), and ISO 9001 (quality management systems). Requesting detailed quality inspection reports, including testing for brightness, durability, and waterproof ratings, is essential. For B2B buyers in regulated markets, verifying compliance documentation can prevent customs issues and product recalls. Establishing periodic quality audits or third-party inspections further safeguards the supply chain. -

How can international buyers optimize logistics and shipping when importing AutoZone LED light strips?

Effective logistics planning involves selecting suppliers with robust export experience and established freight partnerships. Buyers should discuss shipping options (air, sea, or express courier) early, considering cost, delivery speed, and product fragility. Consolidating shipments to reduce freight costs and using Incoterms (like FOB or CIF) clarifies responsibility for shipping risks and expenses. Additionally, working with freight forwarders familiar with customs regulations in target markets (e.g., Brazil’s ANVISA or EU customs) helps avoid delays and extra charges. -

What dispute resolution mechanisms are recommended for international B2B buyers dealing with AutoZone LED light strip suppliers?

Contracts should clearly define dispute resolution procedures, including jurisdiction, governing law, and preferred arbitration or mediation venues. Many international buyers opt for arbitration through recognized bodies like the International Chamber of Commerce (ICC) to ensure neutrality and enforceability. Maintaining thorough documentation of all communications, agreements, and transactions is critical. Promptly addressing issues through direct negotiation before escalation can preserve business relationships and reduce costs associated with formal dispute resolution. -

Are there specific considerations for buyers from Africa, South America, the Middle East, and Europe regarding compliance and import regulations for LED light strips?

Yes, each region has unique import requirements. For example, European buyers must ensure CE marking and RoHS compliance; Brazilian importers need to comply with INMETRO certification and ANVISA regulations if applicable. Middle Eastern countries may require SASO certification (Saudi Arabia) or GSO conformity marks (Gulf Cooperation Council). African buyers should verify local standards and customs procedures, which can vary widely. Partnering with suppliers who understand these regional regulations or hiring local customs brokers can streamline import processes and avoid costly penalties. -

How can international B2B buyers assess the total cost of ownership when sourcing AutoZone LED light strips?

Beyond unit price, buyers should evaluate shipping costs, import duties, taxes, insurance, and potential currency fluctuations. Factoring in quality-related costs such as warranty claims, returns, and after-sales support is essential. Buyers should also consider supplier responsiveness, lead times, and reliability, as delays can impact downstream operations. Requesting detailed cost breakdowns and conducting a total landed cost analysis helps in making informed procurement decisions that align with budget constraints and operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for autozone led light strips

AutoZone LED light strips represent a compelling opportunity for international B2B buyers seeking reliable, customizable, and competitively priced automotive lighting solutions. Key sourcing takeaways include prioritizing suppliers who offer product quality certification, flexible customization options, and robust logistical support—including next-day delivery and comprehensive vendor compliance programs. These factors are especially critical for businesses operating in diverse markets across Africa, South America, the Middle East, and Europe, where supply chain resilience and product adaptability can significantly impact market success.

Strategic sourcing in this segment means leveraging partnerships with vetted suppliers who align with international quality standards and can support scalable order volumes. Buyers should also consider supplier capabilities in electronic cataloging and EDI integration to streamline procurement processes and enhance transparency. By embracing these best practices, businesses can reduce operational risk, optimize cost structures, and ensure timely market responsiveness.

Looking ahead, the demand for energy-efficient and visually appealing automotive lighting solutions is expected to grow steadily. International buyers are encouraged to engage proactively with AutoZone’s vendor programs and explore collaborative opportunities to tailor offerings for their regional markets. Establishing strong supplier relationships now will position buyers to capitalize on evolving automotive aftermarket trends and drive sustained competitive advantage in their respective regions.