Introduction: Navigating the Global Market for 12v power supply for led strip lights

In the fast-evolving landscape of LED lighting solutions, the 12v power supply for LED strip lights stands as a pivotal component that directly influences the efficiency, reliability, and safety of lighting installations. For international B2B buyers, especially those sourcing from dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of these power supplies is crucial to optimizing project outcomes and maintaining competitive advantage.

This comprehensive guide delves into the critical aspects that define high-quality 12v LED power supplies. It covers a broad spectrum—from the different types of power supplies tailored for various LED strip configurations, to the materials and manufacturing standards that ensure durability and performance. Additionally, it highlights the importance of stringent quality control practices and how they impact product longevity and safety certifications, which are vital for compliance in diverse international markets.

Buyers will gain actionable insights into supplier evaluation criteria, cost considerations, and the current global market trends shaping procurement strategies. The guide also addresses frequently asked questions, empowering buyers to troubleshoot common challenges and make informed decisions that align with their specific regional requirements and project scopes.

By navigating this detailed resource, international B2B buyers—from Nigeria to Argentina and beyond—can confidently select 12v power supplies that meet stringent quality benchmarks, optimize energy consumption, and support scalable LED lighting solutions tailored to their unique business needs. This strategic knowledge fosters smarter sourcing decisions that drive sustainable growth and operational excellence in a competitive global marketplace.

Understanding 12v power supply for led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plug-in 12V Power Supply | Compact, ready-to-use adapters with AC to DC conversion, often with built-in plugs | Retail lighting displays, small-scale commercial installations | + Easy installation – Limited power capacity and scalability |

| DIN Rail Mounted Power Supply | Industrial-grade, modular units designed for mounting on DIN rails in control panels | Manufacturing plants, large-scale LED installations in factories | + High reliability and durability – Requires technical installation expertise |

| Constant Voltage LED Driver | Provides stable 12V output regardless of load fluctuations, optimized for LED strips | Architectural lighting, commercial signage, hospitality venues | + Ensures consistent LED brightness – Higher upfront cost |

| Waterproof/Outdoor 12V Power Supply | Sealed enclosures with IP65+ ratings for outdoor and harsh environments | Outdoor advertising, landscape lighting, marine applications | + Weather-resistant and durable – Bulkier and more expensive |

| Dimmable 12V Power Supply | Supports dimming functions via PWM or analog control signals | Theatres, conference centers, upscale retail, and hospitality | + Flexible lighting control – Compatibility with dimming systems must be verified |

Plug-in 12V Power Supply

These are the most common and user-friendly power supplies, ideal for businesses requiring quick deployment of LED strip lights without complex wiring. Their compact design suits small retail outlets or office lighting where power demands are moderate. B2B buyers should consider the maximum wattage supported and regional plug compatibility, especially for markets like Nigeria or Argentina with varying socket standards.

DIN Rail Mounted Power Supply

Engineered for industrial environments, DIN rail mounted units provide robust power delivery with enhanced safety features. They are suitable for large manufacturing facilities or warehouses where LED lighting integrates with existing electrical control systems. Buyers should evaluate certifications and compliance with local electrical standards to ensure seamless integration and operational reliability.

Constant Voltage LED Driver

These power supplies maintain a steady 12V output, crucial for preventing flicker and ensuring uniform LED strip performance in commercial and architectural projects. B2B purchasers should focus on efficiency ratings and thermal management to optimize energy consumption and longevity in venues such as hotels or shopping malls.

Waterproof/Outdoor 12V Power Supply

Designed to withstand harsh weather conditions, these power supplies are essential for outdoor LED installations like signage or landscape lighting. Buyers targeting Middle Eastern or African outdoor markets should prioritize IP ratings, surge protection, and temperature tolerance to ensure durability and reduce maintenance costs.

Dimmable 12V Power Supply

Offering precise control over light intensity, dimmable power supplies cater to environments requiring dynamic lighting scenes, such as conference rooms or luxury retail stores. International buyers must verify dimming protocol compatibility (e.g., PWM, 0-10V) with their LED strips and control systems to avoid integration issues and maximize functionality.

Related Video: How to Install LED Strip Lights to Connectors and a Power Supply

Key Industrial Applications of 12v power supply for led strip lights

| Industry/Sector | Specific Application of 12v power supply for led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in stores and shopping centers | Enhances product visibility and customer experience | Reliable power supply with consistent voltage, scalability, and safety features |

| Hospitality & Tourism | Ambient and decorative lighting in hotels, restaurants, and resorts | Creates inviting atmosphere, reduces energy costs | Compact, energy-efficient power supplies with global certifications |

| Automotive & Transport | Interior and exterior lighting for vehicle customization and fleet branding | Improves brand visibility and vehicle aesthetics | Durable, vibration-resistant power supplies with IP rating for outdoor use |

| Architecture & Real Estate | Cove and façade lighting for commercial and residential buildings | Highlights architectural features, increases property value | Long lifespan, compatibility with dimmers and controllers, and warranty |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage facilities | Enhances worker safety and operational efficiency | Robust, industrial-grade power supplies with surge protection and certifications |

Retail & Commercial Lighting

In retail environments across regions such as Nigeria and Argentina, 12v power supplies for LED strip lights are widely used to illuminate product displays and create attractive store atmospheres. These power supplies must deliver stable voltage to prevent flickering and ensure consistent lighting quality. Buyers should prioritize power supplies that support scalability for expanding lighting installations and meet international safety standards to comply with local regulations.

Hospitality & Tourism Sector

Hotels, resorts, and restaurants in markets like South Africa and the Middle East leverage 12v LED strip lighting powered by reliable 12v power supplies to craft ambient environments that attract guests and reduce energy consumption. The power supplies used here need to be compact and energy-efficient, often with certifications such as CE or UL to assure quality and safety. International buyers should consider products that can handle voltage fluctuations common in these regions.

Automotive & Transport Applications

For vehicle customization and fleet branding in countries such as Brazil and the UAE, 12v power supplies enable LED strip lighting for interiors and exteriors. These power supplies must be rugged, resistant to vibration, and capable of withstanding outdoor conditions. Buyers sourcing for automotive applications should focus on power supplies with high IP ratings and robust build quality to ensure durability and compliance with automotive standards.

Architecture & Real Estate Lighting

In Europe and emerging African markets, 12v LED strip lights powered by specialized 12v power supplies are used to enhance architectural features through cove and façade lighting. These applications demand power supplies with long operational lifespans, compatibility with dimmers and smart controllers, and reliable warranties. Sourcing considerations include energy efficiency and adaptability to various lighting control systems for premium building projects.

Manufacturing & Warehousing

Industrial sectors across South America and the Middle East deploy 12v LED strip lighting powered by industrial-grade 12v power supplies to improve task lighting and safety in factories and warehouses. The power supplies must be robust, equipped with surge protection, and compliant with industrial safety certifications. Buyers should prioritize products that ensure uninterrupted operation and can withstand harsh environments to maximize worker safety and productivity.

Related Video: 12V DC versus 12V AC for LED Strip Lights

Strategic Material Selection Guide for 12v power supply for led strip lights

When selecting materials for 12V power supplies designed for LED strip lights, B2B buyers must consider factors such as durability, thermal performance, corrosion resistance, manufacturing complexity, and compliance with regional standards. These considerations are especially critical for buyers in diverse markets like Africa, South America, the Middle East, and Europe, where environmental conditions and regulatory frameworks vary widely.

Aluminum Alloy

Key Properties: Aluminum alloys used in power supply casings offer excellent thermal conductivity, lightweight properties, and good corrosion resistance. They typically withstand temperatures up to 150°C and resist oxidation, making them suitable for heat dissipation.

Pros & Cons: Aluminum is durable and aids in efficient heat management, which prolongs power supply lifespan. It is relatively easy to machine and extrude, allowing for customized designs. However, aluminum can be more expensive than plastic alternatives and may require anodizing or coating to enhance corrosion resistance in harsh environments.

Impact on Application: Aluminum enclosures are ideal for installations in warmer climates or where continuous operation generates significant heat. Their corrosion resistance suits coastal or humid regions common in parts of Africa and South America.

International Buyer Considerations: Aluminum casings must comply with ASTM B209 or EN 573 standards, which are widely recognized in Europe and increasingly adopted in Middle Eastern markets. Buyers in Nigeria and Argentina should verify supplier adherence to these standards to ensure quality and import compliance.

Polycarbonate (PC) Plastic

Key Properties: Polycarbonate is a high-impact, transparent thermoplastic with excellent electrical insulation properties and a temperature resistance range typically up to 120°C. It offers moderate UV resistance and is flame retardant.

Pros & Cons: PC is lightweight, cost-effective, and simplifies manufacturing through injection molding. Its electrical insulation makes it ideal for internal components. However, it is less effective at heat dissipation compared to metals and can degrade under prolonged UV exposure unless treated.

Impact on Application: Polycarbonate is suitable for indoor LED power supply applications where exposure to extreme temperatures or moisture is limited. It is favored in controlled environments such as offices or retail spaces.

International Buyer Considerations: Compliance with UL 94 V-0 flammability standards and IEC 60695 is critical for safety certification, especially in Europe and the Middle East. African and South American buyers should ensure suppliers provide documentation for these certifications to facilitate local approvals.

Stainless Steel

Key Properties: Stainless steel offers superior corrosion resistance, mechanical strength, and temperature tolerance, often exceeding 300°C. It is highly resistant to oxidation and chemical exposure.

Pros & Cons: While stainless steel provides excellent durability and protection in harsh environments, it is heavier and more costly than aluminum or plastics. Manufacturing complexity is higher due to machining and welding requirements.

Impact on Application: Stainless steel enclosures are ideal for outdoor or industrial LED power supplies exposed to corrosive environments, such as coastal regions or chemical plants prevalent in the Middle East and parts of Africa.

International Buyer Considerations: Buyers should look for compliance with ASTM A240 or EN 10088 standards to ensure material quality. In Europe, stainless steel power supplies often meet stringent IP ratings (e.g., IP65 or higher), which is a key selling point for international projects requiring weatherproofing.

Thermally Conductive Silicone

Key Properties: Used primarily as a thermal interface material inside power supplies, thermally conductive silicone offers excellent heat transfer capabilities and electrical insulation. It remains stable across wide temperature ranges (-50°C to 200°C).

Pros & Cons: Silicone enhances thermal management without adding significant weight or bulk. It is flexible and easy to apply but adds cost and requires precise manufacturing processes to ensure consistent performance.

Impact on Application: This material is critical in high-performance LED power supplies where efficient heat dissipation is necessary to maintain reliability, especially in hot climates like the Middle East and parts of Africa.

International Buyer Considerations: Buyers should verify compliance with RoHS and REACH regulations, particularly in European markets. Suppliers offering silicone materials with documented certifications facilitate smoother import and regulatory approval processes.

| Material | Typical Use Case for 12v power supply for led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Outdoor and high-heat environments requiring heat dissipation | Excellent thermal conductivity and corrosion resistance | Higher cost and requires surface treatment for corrosion | Medium |

| Polycarbonate (PC) | Indoor applications with controlled environments | Lightweight, cost-effective, and good electrical insulation | Lower heat dissipation and UV degradation risk | Low |

| Stainless Steel | Harsh, corrosive, or industrial outdoor environments | Superior corrosion resistance and mechanical strength | Heavy, costly, and complex to manufacture | High |

| Thermally Conductive Silicone | Internal thermal management in high-performance power supplies | Enhances heat dissipation without bulk | Adds manufacturing complexity and cost | Medium |

This guide provides a strategic overview for international B2B buyers to select materials that align with their specific operational environments, regulatory requirements, and cost constraints, ensuring optimal performance and compliance for 12V power supplies used in LED strip lighting projects.

In-depth Look: Manufacturing Processes and Quality Assurance for 12v power supply for led strip lights

Manufacturing of 12V power supplies for LED strip lights involves a carefully orchestrated sequence of steps designed to ensure both product performance and safety. For international B2B buyers—especially those operating in markets such as Africa, South America, the Middle East, and Europe—understanding these manufacturing processes and quality assurance (QA) protocols is crucial for sourcing reliable, compliant products.

Key Manufacturing Stages and Techniques

-

Material Preparation

The process begins with sourcing high-quality raw materials, including electronic components (transformers, capacitors, resistors, PCBs), metal casings, and insulating materials. Suppliers typically vet these inputs to meet required electrical and thermal specifications. For B2B buyers, verifying the origin and certification of these components can prevent counterfeit or substandard parts. -

Component Forming and PCB Fabrication

Printed Circuit Boards (PCBs) are fabricated using automated machinery to etch copper layers and apply solder masks. Surface-mount technology (SMT) is commonly used to place and solder components accurately, ensuring consistency and miniaturization. Buyers should inquire whether manufacturers use automated SMT lines versus manual assembly, as automation typically reduces human error and improves yield. -

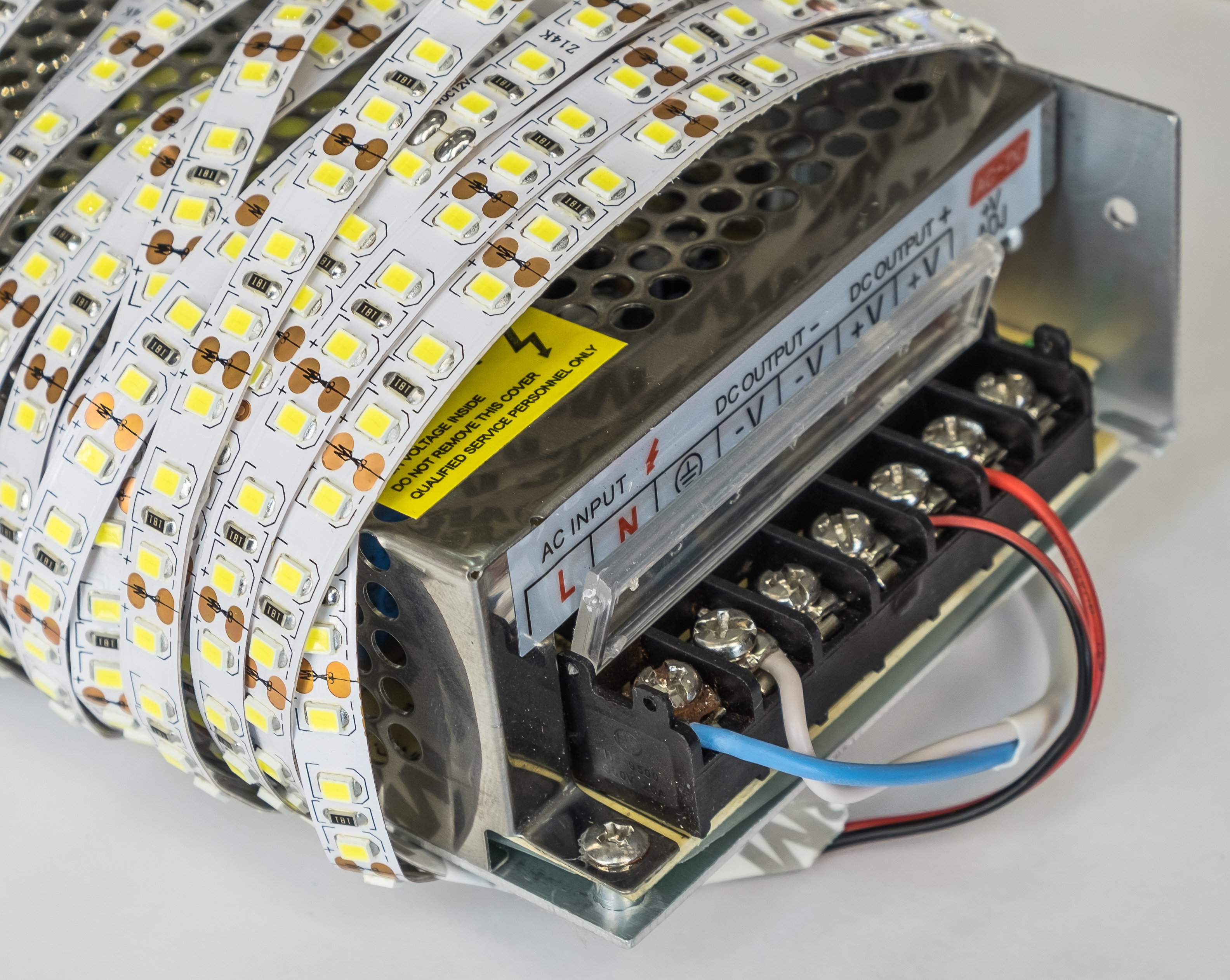

Assembly

Assembly involves mounting the PCBs into the power supply casing, connecting wiring harnesses, and integrating cooling elements such as heat sinks or fans. Assembly lines may be semi-automated or manual depending on production scale and complexity. For LED power supplies, tight assembly tolerances are essential to maintain electrical isolation and prevent short circuits.

Illustrative Image (Source: Google Search)

- Finishing and Encapsulation

The final stages include applying protective coatings, labeling, and sealing the power supply units. Some manufacturers use potting compounds or conformal coatings to protect against moisture and dust, especially for outdoor-rated power supplies. Finishing also includes installing connectors compatible with LED strips and final packaging tailored to international shipping requirements.

Quality Assurance and Control Framework

To ensure product reliability and compliance, manufacturers implement rigorous Quality Control (QC) at multiple stages:

-

Incoming Quality Control (IQC):

Raw materials and components undergo inspection and testing upon arrival. Checks focus on dimensional accuracy, electrical properties, and supplier certifications. For B2B buyers, requesting IQC reports or certificates of conformity can provide early assurance of component quality. -

In-Process Quality Control (IPQC):

During assembly, continuous monitoring ensures adherence to process parameters such as solder joint integrity, component placement, and torque settings on fasteners. Automated optical inspection (AOI) and in-line electrical testing are common techniques. Buyers should verify that manufacturers have documented IPQC procedures and maintain traceability. -

Final Quality Control (FQC):

Completed units are subjected to comprehensive testing including functional performance, safety, and environmental resistance. Typical tests include: - Electrical Safety Tests: Insulation resistance, dielectric strength, and earth continuity to comply with international standards.

- Load Testing: Verifying stable voltage output under rated current conditions to prevent LED strip damage.

- Thermal Testing: Ensuring power supplies operate within specified temperature ranges.

- EMC Testing: Checking electromagnetic compatibility to avoid interference with other devices.

Relevant International and Industry Standards

Compliance with established standards is critical for international trade and market acceptance:

-

ISO 9001:

The foundation for quality management systems, ISO 9001 certification demonstrates a manufacturer’s commitment to consistent product quality and continuous improvement. Buyers should prioritize suppliers with valid ISO 9001 certification audited by reputable bodies. -

CE Marking:

Required for sales within the European Economic Area, CE marking confirms conformity with EU safety, health, and environmental requirements. It includes compliance with directives such as Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. -

UL / ETL Certifications:

For markets like North America, UL or ETL certifications validate electrical safety according to recognized testing standards. While not always mandatory in other regions, these certifications indicate higher safety assurance. -

RoHS Compliance:

Restriction of Hazardous Substances (RoHS) compliance is important for environmental safety, limiting harmful substances like lead or mercury in electronic products. -

Other Regional Certifications:

Buyers in Africa, South America, and the Middle East should be aware of local certification requirements or import regulations, which may include national standards or customs-specific approvals. For example, Nigeria’s SONCAP or Argentina’s IRAM standards may apply.

How B2B Buyers Can Verify Supplier Quality Assurance

-

Factory Audits:

Conducting on-site factory audits—either in person or through third-party inspection firms—allows buyers to assess manufacturing capabilities, QC processes, and workforce competence firsthand. Audits can cover process flow, equipment calibration, documentation control, and employee training. -

Review of QC Documentation:

Requesting detailed QC documentation such as IQC, IPQC, and FQC reports, test certificates, and calibration logs provides transparency into the supplier’s quality system. Buyers should look for traceability of batches and components. -

Third-Party Inspections and Testing:

Engaging independent labs to perform random batch testing or certification verification adds an extra layer of confidence. This is especially valuable for buyers in regions with limited local enforcement or when sourcing from new suppliers. -

Sample Testing:

Ordering samples for in-house or third-party testing can validate performance claims under real-world conditions relevant to the buyer’s applications.

QC and Certification Nuances for International Buyers

-

Adaptation to Local Market Conditions:

Power supplies destined for different regions may require customization such as input voltage range adjustments or plug type variations. Buyers should confirm that QC includes verification of these adaptations. -

Documentation for Customs and Compliance:

Proper labeling, certification copies, and compliance declarations facilitate smoother customs clearance. Buyers should insist on receiving these documents upfront. -

After-Sales Support and Warranty:

Strong QA processes often correlate with reliable after-sales service. Buyers in emerging markets should clarify warranty terms and availability of replacement parts. -

Consideration of Environmental Factors:

Regions with high humidity, dust, or unstable power grids require power supplies with enhanced protection and robust QC testing. Buyers should evaluate suppliers’ experience in producing products suited for such environments.

For B2B buyers from Africa, South America, the Middle East, and Europe, partnering with manufacturers that maintain stringent manufacturing controls and internationally recognized certifications is vital. By understanding manufacturing workflows, QC checkpoints, and certification landscapes, buyers can mitigate risks, ensure compliance, and secure high-quality 12V power supplies tailored for LED strip lighting applications.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for 12v power supply for led strip lights Sourcing

Understanding the Cost Components of 12V Power Supplies for LED Strip Lights

When sourcing 12V power supplies for LED strip lights, international B2B buyers must grasp the multifaceted cost structure that influences pricing. The primary cost components include:

- Materials: Core raw materials such as copper for windings, semiconductors, capacitors, transformers, and durable plastic or metal casings. Material quality directly impacts product reliability and certifications.

- Labor: Skilled labor costs vary significantly by manufacturing location. Countries with lower wages may offer competitive pricing but potentially at the expense of quality control.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines and automation can reduce overhead.

- Tooling: Initial tooling and mold creation for casing and internal components represent upfront fixed costs, often amortized over large production runs.

- Quality Control (QC): Rigorous testing ensures compliance with safety and performance standards (e.g., CE, UL, RoHS). QC costs rise with tighter tolerances and certifications.

- Logistics: Freight charges, customs duties, insurance, and handling fees vary by shipping method and destination country.

- Margin: Suppliers typically include a markup to cover business operations and profit, which may fluctuate based on market demand and buyer-supplier relationships.

Key Price Influencers in Sourcing 12V Power Supplies

Several factors influence the final pricing of 12V power supplies, making it essential for buyers to evaluate these carefully:

- Order Volume and Minimum Order Quantity (MOQ): Higher volumes usually attract significant discounts due to economies of scale. MOQ requirements vary; negotiating smaller pilot orders may be possible with some suppliers.

- Product Specifications and Customization: Custom voltage outputs, wattage ratings, cable lengths, connectors, or casing designs increase complexity and cost. Standardized models are generally more cost-effective.

- Material Quality and Certifications: Certified components that meet international safety and electromagnetic compatibility standards command premium prices but reduce risk and liability.

- Supplier Location and Capabilities: Suppliers in Asia often offer lower prices but may have longer lead times. European or Middle Eastern suppliers may provide faster delivery and localized support but at higher costs.

- Incoterms and Shipping Terms: Understanding terms like FOB, CIF, or DDP is critical, as they dictate which party bears shipping, insurance, and customs risks and costs.

Practical Buyer Tips for International B2B Sourcing

For buyers, especially from Africa, South America, the Middle East, and Europe, optimizing cost-efficiency requires a strategic approach:

- Negotiate Beyond Price: Seek value-added services such as extended warranties, flexible payment terms, or bundled shipping discounts. Building long-term supplier relationships can improve pricing stability.

- Evaluate Total Cost of Ownership (TCO): Consider not just the unit price but also shipping costs, import duties, warranty claims, and energy efficiency. Higher upfront costs for premium power supplies may reduce operational expenses.

- Request Samples and Certifications: Verify quality and compliance upfront to avoid costly returns or regulatory issues in your region.

- Leverage Local Regulations and Incentives: Some regions offer tax breaks or incentives for energy-efficient products. Align sourcing choices accordingly.

- Understand Pricing Nuances: Currency fluctuations, regional taxes, and logistics disruptions can impact landed costs. Use forward contracts or local warehousing to mitigate risks.

- Plan for After-Sales Support: Availability of spare parts and technical assistance in your region can influence long-term costs and supplier selection.

Indicative Pricing Overview

While prices fluctuate based on specifications and sourcing conditions, typical 12V power supplies for LED strips range from approximately $5 to $30 per unit for standard models in bulk orders. Customized or certified units may command premiums upwards of 20-50%. Shipping and import duties add variable costs depending on destination and chosen Incoterms.

By thoroughly analyzing cost components, understanding key pricing drivers, and applying strategic sourcing practices, international B2B buyers can secure competitive pricing and superior quality for 12V power supplies tailored to LED strip lighting projects. This approach ensures not only immediate cost savings but also long-term value and operational reliability.

Spotlight on Potential 12v power supply for led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ’12v power supply for led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 12v power supply for led strip lights

When sourcing 12V power supplies for LED strip lights in international B2B markets such as Africa, South America, the Middle East, and Europe, understanding critical technical properties and trade terminology is essential. These insights enable buyers to make informed decisions, ensuring compatibility, safety, and cost-effectiveness in their projects.

Key Technical Properties of 12V Power Supplies for LED Strip Lights

-

Output Voltage Stability (12V DC)

– The power supply must consistently deliver a stable 12 volts DC output, as LED strips are designed to operate at this voltage. Voltage fluctuations can damage LEDs or reduce their lifespan. For B2B buyers, verifying voltage regulation is crucial to avoid costly returns or failures in installation. -

Wattage and Current Capacity

– Power supplies are rated by maximum wattage (W) and current (A). Buyers should select a unit with at least 20-30% higher wattage capacity than the total load of the LED strips to accommodate potential surges and ensure durability. Overloading a power supply risks overheating and premature failure. -

Efficiency Rating

– Efficiency indicates how well the power supply converts AC input to DC output without energy loss. Higher efficiency (typically 80% and above) means lower electricity costs and less heat generation. For large-scale installations common in commercial or industrial projects, energy efficiency directly affects operational expenses. -

Ingress Protection (IP) Rating

– The IP rating defines the power supply’s resistance to dust and water. For outdoor or humid environments (e.g., certain regions in Africa or the Middle East), an IP65 or higher rating is recommended to ensure longevity and safety. Indoor applications may accept lower IP ratings like IP20. -

Material and Build Quality

– Durable housing materials such as aluminum or high-grade plastics enhance heat dissipation and mechanical protection. Buyers should verify certifications (e.g., CE, UL) that attest to build quality and compliance with international safety standards. This is particularly important for importers targeting regulated markets in Europe. -

Tolerance and Ripple Voltage

– Tolerance refers to the allowable deviation in output voltage, typically ±5%. Ripple voltage is the small residual AC signal on the DC output. Low ripple and tight tolerance ensure stable LED performance without flicker, which is essential for professional lighting projects requiring high visual quality.

Illustrative Image (Source: Google Search)

Important Trade Terms for B2B Buyers

-

OEM (Original Equipment Manufacturer)

– OEM refers to manufacturers who produce power supplies that other brands repackage and sell under their own names. Buyers interested in custom branding or specifications often negotiate OEM contracts. This can reduce costs and create unique market offerings. -

MOQ (Minimum Order Quantity)

– MOQ specifies the smallest number of units a supplier is willing to sell in one order. Understanding MOQ helps buyers from emerging markets like Nigeria or Argentina plan inventory and budget accordingly, balancing between cost per unit and stock availability. -

RFQ (Request for Quotation)

– An RFQ is a formal inquiry sent to suppliers asking for detailed pricing, lead times, and terms based on specified requirements. International buyers use RFQs to compare multiple suppliers and negotiate the best deals for 12V power supplies. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers regarding shipping, customs clearance, and risk transfer. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Familiarity with Incoterms ensures buyers can accurately calculate landed costs and manage logistics. -

Lead Time

– Lead time is the period between placing an order and receiving the goods. For project planning, especially in fast-growing markets, knowing supplier lead times helps avoid delays and ensures timely installation. -

Certification and Compliance

– Certifications such as CE (Europe), UL (North America), and RoHS (Restriction of Hazardous Substances) are critical for regulatory compliance and market acceptance. Buyers should verify that power supplies meet relevant standards to avoid import restrictions or quality issues.

Actionable Tips for International B2B Buyers:

- Always request detailed technical datasheets to verify voltage stability, wattage, and efficiency before committing.

- Negotiate MOQs aligned with your market demand to optimize cash flow.

- Clarify Incoterms upfront to avoid unexpected logistics costs.

- Prioritize suppliers offering certifications recognized in your target region to facilitate smooth customs clearance.

- Consider power supplies with higher IP ratings for outdoor or harsh environmental projects common in regions like the Middle East or parts of Africa.

By mastering these technical and trade concepts, buyers can confidently source 12V power supplies that meet both performance and regulatory requirements, ensuring successful LED lighting deployments worldwide.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 12v power supply for led strip lights Sector

Market Overview & Key Trends

The 12V power supply segment for LED strip lights is witnessing robust growth driven by rising global demand for energy-efficient lighting solutions across commercial, industrial, and residential sectors. International B2B buyers from regions such as Africa (e.g., Nigeria), South America (e.g., Argentina), the Middle East, and Europe are increasingly adopting LED strip lighting systems for their versatility, low power consumption, and long lifespan. This trend is propelled by infrastructure development, urbanization, and government incentives promoting sustainable energy use.

Key market dynamics include the transition from traditional lighting to LED technology, which requires reliable and efficient 12V power supplies tailored to diverse applications. Buyers are prioritizing power supplies that offer stable voltage output, overload protection, and compatibility with dimmers and controllers to enhance lighting customization. Additionally, the demand for compact, waterproof, and high-efficiency power supplies is growing, especially for outdoor and industrial applications.

Sourcing trends show a preference for suppliers who provide comprehensive solutions, including matched LED strips and controllers, simplifying procurement and integration. Digital platforms and direct factory partnerships are becoming prominent, enabling buyers in emerging markets to access competitive pricing and faster lead times. Furthermore, the rise of smart lighting systems is influencing power supply specifications, with increasing requests for units supporting wireless controls and IoT connectivity.

For B2B buyers in developing regions, understanding import regulations, local standards, and the availability of after-sales support is critical to ensuring product reliability and compliance. Strategic sourcing from manufacturers with certifications like CE, UL, and RoHS can mitigate risks related to quality and safety.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a pivotal factor in the procurement of 12V power supplies for LED strip lights. The environmental impact of power supplies encompasses energy consumption, material use, and end-of-life disposal. B2B buyers are increasingly demanding products that minimize carbon footprints through high energy efficiency ratings (e.g., >85% efficiency), use of recyclable materials, and reduced hazardous substances.

Ethical sourcing is gaining traction as companies align their supply chains with global standards for labor rights, fair trade, and environmental stewardship. Buyers from regions with growing sustainability regulations, such as the European Union, are particularly attentive to suppliers who demonstrate transparency and accountability in sourcing components. Certifications like Energy Star, CE, RoHS, and TUV are often prerequisites, ensuring compliance with environmental and safety standards.

Green power supplies incorporate innovations such as low standby power consumption, environmentally friendly packaging, and modular designs that facilitate repair or upgrade rather than replacement. Choosing suppliers with robust sustainability policies not only supports corporate social responsibility goals but also enhances brand reputation and customer trust.

For international buyers, especially in Africa and South America, partnering with manufacturers who invest in sustainable manufacturing practices can reduce long-term costs and exposure to regulatory risks. Additionally, leveraging regional trade agreements that incentivize green technologies can optimize procurement strategies.

Evolution of 12V Power Supplies for LED Strip Lights

The evolution of 12V power supplies for LED strip lights reflects broader advancements in LED technology and power electronics. Initially, power supplies were simple, linear transformers with limited efficiency and bulkier form factors. As LED adoption surged, the industry shifted to switch-mode power supplies (SMPS), which offer higher efficiency, compact size, and better thermal management.

Over the past decade, integration of smart features such as dimming, remote control compatibility, and overcurrent protection has become standard, meeting the demands of increasingly complex lighting systems. The miniaturization of components and improved circuit design have enabled power supplies to support longer LED strip runs without voltage drop issues, a critical factor for large-scale commercial installations.

This technological progression has opened new market opportunities in emerging regions, where cost-effective, durable, and energy-efficient power supplies are essential for infrastructure projects and modernization efforts. The historical trend towards sustainability and interoperability continues to shape product development, making the 12V power supply market dynamic and innovation-driven for B2B buyers worldwide.

Related Video: How to Choose a Power Supply for LED STRIP

Frequently Asked Questions (FAQs) for B2B Buyers of 12v power supply for led strip lights

-

How can I effectively vet suppliers of 12v power supplies for LED strip lights in international markets?

To vet suppliers, prioritize those with verifiable certifications such as CE, RoHS, and UL that demonstrate compliance with international safety standards. Request detailed product datasheets and samples for quality assessment. Check their export history and client references, especially from your region (Africa, South America, Middle East, Europe). Utilize third-party inspection services to audit manufacturing facilities. Transparent communication and responsiveness are key indicators of reliability. Also, verify their ability to meet your customization, MOQ, and delivery requirements before committing. -

What customization options are typically available for 12v LED power supplies for bulk B2B orders?

Many manufacturers offer customization including voltage stabilization, current ratings, connector types, cable lengths, and enclosure materials (e.g., waterproofing for outdoor use). You can also request custom branding or labeling, specific certifications, and tailored packaging to suit your market needs. Ensure your supplier can support these customizations without compromising lead times or quality. Clarify all technical specifications upfront and verify prototype samples before full production to avoid costly reworks. -

What are common MOQ (Minimum Order Quantity) and lead time expectations when sourcing 12v power supplies internationally?

MOQ varies widely but typically ranges from 100 to 500 units depending on customization and supplier scale. Lead times generally span 3 to 8 weeks, factoring in manufacturing and international shipping. For buyers in regions like Nigeria or Argentina, consider additional time for customs clearance and inland logistics. Negotiate MOQ based on your forecast and supplier flexibility, and confirm lead times including buffer for unforeseen delays. Establish clear contract terms on production schedules to ensure timely delivery. -

Which payment methods are safest and most practical for international B2B transactions of LED power supplies?

Letter of Credit (L/C) is widely regarded as the safest for both parties, offering security on payment release upon meeting shipment terms. Other common methods include Telegraphic Transfer (T/T) with an upfront deposit and balance on delivery, and Escrow services for added protection. Avoid full upfront payments unless you have a longstanding relationship. Use payment platforms that support trade finance and consider currency fluctuation risks, especially for buyers in volatile currency markets like some African and South American countries. -

What quality assurance and certifications should I demand from suppliers to ensure product reliability?

Demand suppliers provide internationally recognized certifications such as CE (Europe), UL (North America), RoHS (hazardous substances compliance), and FCC (electromagnetic interference). Request test reports on electrical safety, thermal management, and lifespan under operational loads. Insist on ISO 9001 certification for manufacturing quality control. For markets with strict regulations, verify product compliance with local standards. Periodic factory audits and batch testing during production can further assure consistent quality. -

How can I optimize logistics and shipping for 12v LED power supply imports to Africa, South America, or the Middle East?

Choose suppliers near major ports or with experience exporting to your region to reduce transit times and costs. Consolidate shipments to lower freight expenses and use reputable freight forwarders familiar with customs regulations in your country. Factor in import duties, taxes, and required documentation (commercial invoice, packing list, certificate of origin). Negotiate Incoterms carefully—DDP (Delivered Duty Paid) offers simplicity but may be costlier, whereas FOB (Free on Board) requires you to manage shipping. Prioritize suppliers offering flexible shipping options and timely communication. -

What steps should be taken to resolve disputes or product issues after receiving 12v power supplies?

Establish a clear dispute resolution clause in your purchase agreement detailing timelines for reporting defects and remedies such as replacements, refunds, or discounts. Document all issues with photos and test data. Engage supplier representatives promptly and maintain professional communication. If direct negotiation fails, consider mediation or arbitration through international trade bodies. Retain all shipping and inspection records as evidence. Building long-term partnerships with suppliers who provide responsive after-sales support minimizes risk. -

Are there any region-specific considerations for B2B buyers from Nigeria, Argentina, or the Middle East when sourcing 12v LED power supplies?

Yes. For Nigeria and other African markets, power fluctuations require suppliers to offer surge protection and voltage regulation features. Argentina buyers should consider import restrictions and currency controls impacting payment and delivery. Middle Eastern buyers often require products with high IP ratings for desert environments and compliance with GCC electrical standards. Understanding local regulations, infrastructure constraints, and market preferences enables better specification and supplier selection. Partnering with suppliers experienced in your region can streamline compliance and logistics.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 12v power supply for led strip lights

Strategic sourcing of 12V power supplies for LED strip lights is a critical factor that directly influences product reliability, cost-efficiency, and market competitiveness. For international B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe, understanding supplier capabilities, certification standards, and supply chain resilience is paramount. Prioritizing suppliers who offer robust warranties, energy-efficient designs, and compliance with international safety standards will ensure long-term operational success.

Key takeaways for buyers include:

– Assessing power supply compatibility with specific LED strip models to optimize performance and longevity.

– Evaluating supplier logistics and lead times to avoid delays, particularly in emerging markets with complex import regulations.

– Leveraging bulk purchasing and strategic partnerships to negotiate favorable terms and access advanced technology.

Looking ahead, the 12V LED power supply market is poised for growth driven by increasing demand for energy-efficient lighting solutions and smart lighting integrations. Buyers should actively monitor innovations such as smart controllers and IoT-enabled power supplies that enhance functionality and user experience.

Actionable insight: Engage proactively with trusted manufacturers and distributors who demonstrate flexibility and a strong understanding of your regional market dynamics. This strategic approach will position your business to capitalize on evolving trends and deliver superior lighting solutions to your customers.