Introduction: Navigating the Global Market for led strip lighting wiring diagram

The wiring diagram for LED strip lighting is a foundational element that directly influences the performance, safety, and longevity of lighting installations. For international B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe—including rapidly growing economies like Poland and Turkey—mastering the technical intricacies of LED strip wiring is essential. A clear, accurate wiring diagram ensures seamless integration with power supplies, controllers, and accessories, minimizing costly errors and downtime in commercial and industrial projects.

This guide delivers an authoritative, end-to-end resource tailored to the needs of procurement professionals and technical decision-makers. It covers critical aspects including the various types of LED strips and their wiring requirements, selection of compatible materials, manufacturing standards, and quality control protocols that guarantee product reliability. Additionally, it provides insights into sourcing strategies, supplier evaluation, cost management, and emerging market trends that impact global supply chains.

By leveraging this comprehensive knowledge, buyers can confidently navigate complex technical specifications and vendor offerings to optimize their procurement processes. The guide also addresses frequently asked questions to clarify common challenges and support troubleshooting efforts. Whether managing large-scale installations or developing customized lighting solutions, businesses will find actionable intelligence to enhance operational efficiency, reduce risks, and secure competitive advantages in an evolving market.

Ultimately, this resource empowers international B2B buyers to make informed, strategic sourcing decisions for LED strip lighting wiring—ensuring projects meet stringent performance criteria while aligning with regional regulatory and environmental considerations.

Understanding led strip lighting wiring diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Color Wiring | Simple wiring with positive and negative leads; fixed color LED | Office lighting, retail displays, residential accent lighting | + Easy to install and cost-effective – No color flexibility |

| RGB Wiring | Multiple wiring channels (usually 4 wires: R, G, B, +12/24V) | Hospitality, event venues, advertising, architectural lighting | + Dynamic color control – Requires controllers and complex wiring |

| Addressable LED Wiring | Individual LED control via data line; requires data and power lines | Interactive displays, entertainment, signage | + High customization and effects – Higher cost and technical complexity |

| Waterproof Wiring | Encased wiring and LED strips with sealed connectors | Outdoor lighting, industrial, marine | + Durable in harsh environments – Slightly higher installation cost |

| High Voltage Wiring (110V/220V) | Direct connection to mains voltage with integrated resistors or drivers | Large-scale commercial, warehouse, street lighting | + Longer runs without voltage drop – Requires safety compliance and specialized connectors |

Single Color Wiring

Single color LED strip wiring is the most straightforward configuration, typically involving two wires: positive and negative. This type is ideal for projects requiring consistent, fixed-color illumination such as office lighting or retail displays. For B2B buyers, this option offers cost-effectiveness and ease of installation, minimizing the need for complex controllers. However, it lacks flexibility since color changes are not possible without rewiring or replacing the strip.

RGB Wiring

RGB LED strip wiring involves four wires corresponding to red, green, blue channels, plus a common positive voltage. This configuration enables the creation of millions of colors through mixing and is widely used in hospitality, event spaces, and advertising where dynamic lighting effects are essential. Buyers should consider the additional costs and technical requirements of controllers and more complex wiring setups, which may require specialized installation expertise.

Addressable LED Wiring

Addressable LED strips feature individual LED control via a dedicated data line alongside power lines. This wiring type supports highly customized lighting effects such as animations and color patterns, making it suitable for interactive displays and entertainment venues. From a B2B procurement perspective, these strips demand higher technical knowledge, advanced controllers, and greater investment but offer unmatched flexibility and visual impact.

Waterproof Wiring

Waterproof LED strip wiring includes protective silicone or epoxy coatings and sealed connectors to prevent moisture ingress. This makes them perfect for outdoor, industrial, or marine applications where environmental exposure is a concern. Buyers targeting these markets must ensure proper IP ratings and consider the slightly increased installation complexity and cost, which are offset by enhanced durability and reduced maintenance.

High Voltage Wiring (110V/220V)

High voltage LED strip wiring connects directly to mains power, usually 110V or 220V, with integrated resistors or drivers to regulate current. This type is advantageous for large-scale commercial or warehouse lighting where long runs are necessary without significant voltage drop. B2B buyers should prioritize compliance with regional electrical safety standards and invest in quality connectors and drivers to guarantee safe, reliable operation.

Related Video: Wiring Diagram Lighting Circuit Joint Box Method – Great for Wiring to LED Downlights (Spotlights)

Key Industrial Applications of led strip lighting wiring diagram

| Industry/Sector | Specific Application of led strip lighting wiring diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Retail | Illuminated product displays and shelving lighting wiring | Enhances product visibility, drives customer engagement, and boosts sales | Reliable wiring diagrams ensure seamless integration with existing electrical systems; compatibility with dimmers and controllers for ambiance control |

| Industrial Manufacturing | Task and safety lighting in assembly lines and warehouses wiring | Improves worker safety and productivity with consistent, bright illumination | Robust wiring solutions that support high power demands and withstand harsh environments; compliance with regional electrical standards |

| Hospitality & Tourism | Ambient and accent lighting in hotels, restaurants, and event venues wiring | Creates inviting atmospheres that enhance guest experience and brand appeal | Flexible wiring diagrams accommodating RGB controls and remote dimming for dynamic lighting effects |

| Architectural & Interior Design | Cove and accent lighting wiring in offices and residential buildings | Adds aesthetic value and energy-efficient illumination with low maintenance | Detailed wiring diagrams that allow for custom lengths and integration with smart home systems; focus on heat dissipation and safety |

| Outdoor & Landscape | Waterproof LED strip lighting wiring for signage, pathways, and outdoor facades | Durable and weather-resistant lighting solutions that ensure visibility and safety | Wiring diagrams must address waterproofing, UV resistance, and voltage drop over long outdoor runs |

Commercial retail environments depend heavily on well-planned LED strip lighting wiring diagrams to optimize product display illumination. These diagrams guide electricians and installers in configuring wiring routes and power supplies that ensure uniform light distribution. For international buyers in Africa, South America, and Europe, sourcing wiring diagrams that accommodate local voltage standards and integrate with smart lighting controls is critical to avoid costly retrofits. Proper wiring enhances lighting reliability and supports dimming features, which are essential for creating appealing retail atmospheres that increase shopper engagement.

In industrial manufacturing, LED strip lighting wiring diagrams are essential for designing task lighting that meets stringent safety and operational standards. These diagrams help specify wiring layouts that can handle high power loads and environmental stressors typical in factories and warehouses. B2B buyers from regions such as the Middle East and Turkey must prioritize wiring solutions compatible with industrial electrical codes and resistant to dust and vibration. Accurate wiring diagrams reduce downtime by simplifying maintenance and ensuring consistent illumination for critical production processes.

The hospitality and tourism sector leverages LED strip lighting wiring diagrams to create dynamic ambient and accent lighting in hotels, restaurants, and event spaces. These diagrams enable the integration of RGB LED strips with controllers and dimmers to produce customizable lighting scenes. International buyers should seek wiring diagrams that support flexible installation layouts and remote control capabilities, catering to diverse design concepts and guest preferences. Ensuring wiring compliance with local electrical regulations is vital to guarantee safety and operational efficiency in these high-traffic venues.

Architectural and interior design applications utilize LED strip lighting wiring diagrams for decorative and functional lighting such as cove and accent illumination in offices and residences. These diagrams guide the installation of LED strips within aluminum profiles or recessed channels, ensuring proper heat dissipation and electrical safety. Buyers in Europe and South America benefit from wiring diagrams that facilitate integration with smart home automation systems and provide detailed instructions on voltage requirements and connector types. This precision helps reduce installation errors and enhances the longevity of lighting installations.

Outdoor and landscape lighting applications require waterproof LED strip lighting wiring diagrams tailored to withstand environmental challenges like moisture, UV exposure, and temperature fluctuations. These diagrams detail wiring methods that maintain IP-rated protection and address voltage drop issues over extended runs common in outdoor signage and pathway lighting. For B2B buyers in regions with harsh climates such as parts of Africa and the Middle East, sourcing robust wiring diagrams ensures durability and reduces maintenance costs, supporting long-term outdoor lighting performance.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip lighting wiring diagram

When selecting materials for LED strip lighting wiring diagrams, understanding the properties and trade-offs of common materials is crucial for international B2B buyers. The choice directly impacts product reliability, installation ease, and compliance with regional standards, especially in diverse markets such as Africa, South America, the Middle East, and Europe. Below is an in-depth analysis of four widely used materials in LED strip lighting wiring systems.

1. Copper Conductors

Key Properties: Copper is renowned for its excellent electrical conductivity (~5.8×10^7 S/m), high thermal conductivity, and good mechanical strength. It withstands temperatures up to approximately 200°C in insulated forms and offers superior corrosion resistance when properly coated.

Pros & Cons: Copper wiring ensures minimal voltage drop and high efficiency, which is critical for long LED strip runs, especially in 24V systems common in commercial installations. It is relatively easy to manufacture and solder, supporting flexible wiring designs. However, copper is more expensive than alternatives and heavier, which can increase shipping costs for large orders.

Impact on Application: Copper is ideal for medium to long wiring runs where power loss must be minimized. Its durability suits harsh environments, including industrial and outdoor applications when paired with appropriate insulation.

International Buyer Considerations: European markets such as Poland and Turkey often require compliance with IEC and DIN standards for copper wiring, emphasizing purity and insulation quality. African and Middle Eastern buyers should verify corrosion resistance due to humid or saline conditions. ASTM standards are common in South America, where copper wiring quality and certification affect import approvals.

2. PVC (Polyvinyl Chloride) Insulation

Key Properties: PVC is a widely used thermoplastic insulation material with good electrical insulation, flame retardance, and resistance to moisture and chemicals. It typically withstands temperatures up to 70°C–105°C depending on formulation.

Pros & Cons: PVC insulation is cost-effective and flexible, making installation straightforward. It is suitable for indoor and dry environments but less ideal for high-temperature or UV-exposed outdoor applications due to potential brittleness and degradation over time.

Impact on Application: PVC-insulated wiring is common in residential and commercial LED strip lighting where environmental exposure is limited. It supports ease of handling and conforms to various wiring diagrams requiring flexible routing.

International Buyer Considerations: Buyers in Europe and the Middle East should ensure PVC insulation meets RoHS and REACH regulations limiting hazardous substances. In Africa and South America, verifying compliance with local fire safety standards (e.g., IEC 60332) is essential for safe installation.

3. Silicone Rubber Insulation

Key Properties: Silicone rubber insulation offers excellent thermal stability, operating between -60°C and +200°C, outstanding flexibility, and high resistance to UV, ozone, and moisture.

Pros & Cons: Silicone insulation is highly durable and ideal for harsh or outdoor environments. It maintains flexibility in cold climates and resists cracking. However, it is more expensive and complex to manufacture compared to PVC, potentially increasing overall product costs.

Impact on Application: Silicone-insulated wiring is preferred for outdoor LED strip lighting, industrial settings, and installations exposed to temperature extremes or frequent movement.

International Buyer Considerations: For markets in the Middle East and Africa with high ambient temperatures, silicone insulation ensures longevity and compliance with stringent safety standards. European buyers often require certifications such as VDE or UL for silicone-insulated cables, which can affect supplier selection.

4. Tinned Copper Conductors

Key Properties: Tinned copper wires are copper conductors coated with a thin layer of tin to improve corrosion resistance, especially in humid or marine environments. Electrical conductivity is slightly lower than pure copper but remains high.

Pros & Cons: Tinned copper combines copper’s conductivity with enhanced durability against oxidation and corrosion. This extends wiring lifespan in challenging environments but comes at a moderate cost premium over bare copper.

Impact on Application: Tinned copper wiring is essential for LED strip lighting installations in coastal areas, outdoor signage, or industrial plants with corrosive atmospheres.

International Buyer Considerations: Buyers in coastal regions of South America and Africa will benefit from tinned copper to reduce maintenance costs. Compliance with ASTM B33 or IEC 60228 standards is common in Europe and the Middle East, ensuring quality and traceability.

Summary Table of Materials for LED Strip Lighting Wiring Diagram

| Material | Typical Use Case for led strip lighting wiring diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Conductors | Medium to long wiring runs requiring high conductivity | Superior electrical and thermal conductivity | Higher cost and weight compared to alternatives | High |

| PVC Insulation | Indoor, dry environment wiring insulation | Cost-effective, flexible, flame retardant | Limited heat and UV resistance | Low |

| Silicone Rubber Insulation | Outdoor, industrial, or temperature-extreme environments | Excellent thermal stability and flexibility | Higher manufacturing complexity and cost | High |

| Tinned Copper Conductors | Corrosive or humid environments requiring durability | Enhanced corrosion resistance with good conductivity | Slightly reduced conductivity, moderate cost premium | Medium |

This strategic material selection guide empowers international B2B buyers to align product specifications with regional environmental conditions, regulatory requirements, and cost considerations. By carefully evaluating these materials, buyers in Africa, South America, the Middle East, and Europe can optimize LED strip lighting wiring solutions for performance, durability, and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lighting wiring diagram

Manufacturing Processes for LED Strip Lighting Wiring Diagrams

The production of LED strip lighting wiring diagrams, which serve as crucial blueprints for assembly and installation, involves a multi-stage manufacturing process. Each stage ensures precision, reliability, and adherence to design specifications critical for international B2B buyers sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

1. Material Preparation

The process begins with sourcing high-quality raw materials such as flexible printed circuit boards (FPCBs), copper traces, solder paste, and LED chips. For wiring diagrams, accurate and clear schematic layouts are digitally designed using CAD software. These digital files guide the physical layout and wiring harness assembly. Material inspection at this stage is vital to prevent defects downstream.

2. Circuit Forming and PCB Fabrication

The flexible PCB is fabricated through photolithography, etching, and plating to form precise copper wiring paths. Automated machinery ensures fine line accuracy and consistent copper thickness, which directly impact electrical performance and heat dissipation. This stage also includes the application of solder mask and silkscreen printing, which help identify wiring routes and component positions.

3. Assembly of Wiring Components

Following PCB fabrication, components such as LED chips, resistors, connectors, and wiring harnesses are mounted. Surface-mount technology (SMT) machines place components with high precision, followed by soldering—commonly reflow soldering for strong, reliable joints. Wiring harnesses corresponding to the wiring diagram are integrated to facilitate easy installation and maintenance.

4. Finishing and Protective Coatings

Once assembled, the LED strips and wiring harnesses undergo finishing processes including application of protective coatings like silicone or epoxy encapsulation for waterproofing and insulation. Labels and markings reflecting the wiring diagram details are printed or embedded for user reference. Final packaging protects the product during transport and handling.

Quality Assurance Frameworks and Standards

For B2B buyers, especially those operating across multiple continents, understanding the quality assurance (QA) protocols behind LED strip lighting wiring diagrams is essential to mitigate risks and ensure compliance.

International and Industry Standards

– ISO 9001: This globally recognized quality management system standard ensures manufacturers maintain consistent processes and continuous improvement. Buyers should verify that suppliers are ISO 9001 certified to guarantee systematic quality control.

– CE Marking: Mandatory for products entering the European market, CE certification confirms compliance with EU safety, health, and environmental protection directives. It is crucial for buyers in Poland, Turkey, and broader Europe.

– RoHS Compliance: Restricts hazardous substances in electrical products, critical for environmental and health standards in South America and Europe.

– UL and ETL Listings: Commonly required in North America but increasingly recognized globally, these certifications attest to electrical safety and performance.

– IP Ratings: For waterproof or dustproof LED strips, IP ratings (e.g., IP65, IP67) are tested and certified to ensure durability in harsh environments, relevant for Middle Eastern and African outdoor installations.

Quality Control Checkpoints and Testing Methods

Quality control (QC) in LED strip lighting wiring diagram production is multi-layered, ensuring every unit meets stringent specifications before shipment.

1. Incoming Quality Control (IQC)

Incoming materials such as PCBs, LED chips, and wiring components are inspected for defects, dimensional accuracy, and material certifications. IQC prevents substandard materials from entering production, reducing rework and failure rates.

2. In-Process Quality Control (IPQC)

During manufacturing, checkpoints include solder joint inspections, component placement accuracy, and wiring harness integrity tests. Automated optical inspection (AOI) systems and manual visual checks verify that assemblies match the wiring diagrams exactly.

3. Final Quality Control (FQC)

Completed LED strips undergo functional testing, including:

– Electrical continuity and insulation resistance tests to detect wiring faults or shorts.

– Luminosity and color consistency tests to ensure LEDs meet specified brightness and color temperatures.

– Thermal performance assessments to verify heat dissipation aligns with design parameters, preventing premature failure.

– Environmental stress tests such as vibration, humidity, and temperature cycling to simulate real-world conditions.

Verifying Supplier Quality Control for International Buyers

For buyers in regions like Africa, South America, the Middle East, and Europe, supplier QC verification is a critical step in procurement.

- Factory Audits: Conduct on-site or third-party audits to evaluate manufacturing capabilities, process controls, and compliance with ISO and industry standards. Audits provide transparency on supplier quality culture and operational consistency.

- Reviewing QC Reports: Demand detailed quality inspection reports, including IQC, IPQC, and FQC results. These reports should include pass rates, defect types, and corrective actions taken.

- Third-Party Inspections: Engage independent inspection agencies to perform pre-shipment inspections (PSI). These inspections validate product conformity to wiring diagrams, functional specifications, and packaging standards.

- Sample Testing: Request product samples to conduct laboratory tests aligned with international standards (e.g., CE, RoHS) to confirm quality claims before bulk orders.

- Certifications Verification: Verify authenticity and current status of supplier certifications (ISO 9001, CE, RoHS) through official registries or certification bodies.

Navigating Quality Assurance Nuances Across Global Markets

International B2B buyers must be aware of regional quality and regulatory nuances when sourcing LED strip lighting wiring diagrams:

- Africa and Middle East: Emphasis on ruggedness and IP-rated waterproofing due to harsh climates. Certifications like CE and RoHS are increasingly valued as markets mature. Importers should ensure suppliers meet local electrical safety standards.

- South America: Compliance with both international standards and local regulations (e.g., INMETRO in Brazil) is critical. Buyers should consider suppliers’ ability to provide bilingual documentation and certifications.

- Europe (Poland, Turkey, EU): Strict adherence to CE marking, RoHS, and REACH regulations is mandatory. Buyers should prioritize suppliers with transparent quality management systems and certifications recognized by European bodies.

- Cross-Regional Logistics: Quality assurance must also cover packaging standards to prevent damage during long shipping routes. Clear wiring diagrams and multilingual user manuals enhance installation accuracy and reduce after-sales issues.

Key Takeaways for B2B Buyers

- Prioritize suppliers with robust manufacturing processes featuring automated PCB fabrication, SMT assembly, and stringent finishing procedures to guarantee product consistency.

- Demand comprehensive quality management certifications such as ISO 9001 and CE to ensure regulatory compliance and product safety.

- Insist on multi-stage quality control documentation, including IQC, IPQC, and FQC checkpoints supported by testing data for electrical, optical, and environmental performance.

- Leverage third-party inspections and factory audits to independently verify supplier claims, especially when sourcing from new or remote manufacturers.

- Understand regional regulatory requirements and adapt sourcing strategies accordingly to avoid import delays and non-compliance penalties.

By integrating these manufacturing and quality assurance insights into their procurement workflows, international B2B buyers can secure reliable, high-performance LED strip lighting wiring diagram products tailored to their market needs.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip lighting wiring diagram Sourcing

When sourcing LED strip lighting wiring diagrams, understanding the underlying cost structure and pricing dynamics is crucial for international B2B buyers aiming to optimize procurement and total cost of ownership. The pricing of these wiring diagrams, often integrated with LED strip products or provided as standalone technical documentation, reflects multiple cost components and market factors that vary by supplier region, order scale, and customization level.

Key Cost Components in LED Strip Lighting Wiring Diagram Sourcing

- Materials: High-quality wiring diagrams typically require detailed, precise graphic design and technical drafting. This involves software tools and skilled engineers who translate complex electrical schematics into clear, usable formats. Costs also cover licensing for any proprietary symbols or standards.

- Labor: Technical expertise for wiring diagram development demands specialized labor, including electrical engineers and CAD technicians. Labor costs fluctuate depending on supplier location and skill level, with suppliers in Eastern Europe (e.g., Poland, Turkey) often offering competitive rates.

- Manufacturing Overhead: Though wiring diagrams are not physical products, overhead encompasses IT infrastructure, design software subscriptions, quality assurance processes, and project management.

- Tooling and Software: Investment in advanced design and simulation software (e.g., AutoCAD Electrical, EPLAN) is a significant cost driver, especially for custom or complex diagrams.

- Quality Control (QC): Ensuring accuracy and compliance with international electrical and safety standards (IEC, UL, CE) involves rigorous QC protocols, revisions, and validation by certified engineers.

- Logistics: For physical copies or bundled documentation with LED strip products, shipping and handling costs apply. Digital delivery reduces logistics costs but may incur secure transmission or licensing fees.

- Supplier Margin: Profit margins vary with supplier scale, brand reputation, and service scope. Established suppliers with certifications and after-sales support often command higher margins.

Influential Pricing Factors for Buyers

- Order Volume and Minimum Order Quantities (MOQ): Larger orders or long-term contracts can significantly reduce unit pricing through economies of scale, especially when wiring diagrams are bundled with LED strip lighting kits.

- Specification Complexity and Customization: Custom wiring diagrams tailored to specific project requirements (e.g., unique voltage configurations, advanced dimming controls) increase design time and cost. Standardized diagrams cost less but may lack project-specific nuances.

- Material and Quality Certifications: Diagrams that accompany products certified for international markets (CE for Europe, UL for Middle East/North Africa) typically cost more due to compliance documentation and testing.

- Supplier Location and Reputation: Suppliers in Asia may offer lower prices but require careful quality vetting. European and Middle Eastern suppliers provide closer cultural and regulatory alignment but at premium pricing.

- Incoterms and Delivery Terms: FOB, CIF, DDP, and other terms impact total landed cost. Buyers from Africa and South America should consider tariffs, customs clearance fees, and logistics reliability when evaluating final pricing.

Practical Tips for International B2B Buyers

- Negotiate Volume Discounts and Bundled Pricing: Combining wiring diagrams with LED strip lighting orders can unlock cost savings. Always request tiered pricing based on volume increases.

- Prioritize Total Cost of Ownership (TCO): Factor in not just upfront diagram costs but also potential savings from reduced installation errors, maintenance efficiency, and compliance risk mitigation.

- Verify Supplier Credentials and Certifications: Insist on proof of technical expertise, adherence to international standards, and sample diagrams before committing.

- Understand Regional Pricing Nuances: Buyers from Africa and South America should anticipate additional costs related to longer shipping routes and customs delays; negotiating favorable Incoterms can mitigate these.

- Leverage Local Partners: European buyers, especially from Poland and Turkey, benefit from sourcing suppliers within or near their regions to reduce lead times and communication barriers.

Indicative Pricing Disclaimer

Pricing for LED strip lighting wiring diagrams varies widely based on complexity, customization, and supplier region. Typical costs can range from a few hundred USD for standard diagrams bundled with product orders to several thousand USD for fully customized, multi-page schematic packages with engineering support. Buyers should request detailed quotations and confirm all cost components upfront to avoid unexpected expenses.

By carefully analyzing these cost and pricing factors, international B2B buyers can make informed sourcing decisions that balance quality, compliance, and cost-efficiency when procuring LED strip lighting wiring diagrams.

Spotlight on Potential led strip lighting wiring diagram Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip lighting wiring diagram’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lighting wiring diagram

Critical Technical Properties for LED Strip Lighting Wiring Diagrams

Understanding the key technical specifications behind LED strip lighting wiring diagrams is essential for international B2B buyers to ensure product reliability, installation efficiency, and long-term performance. Here are the most important properties to consider:

-

Voltage Rating (12V, 24V, or Constant Current)

The operating voltage dictates compatibility with power supplies and affects wiring complexity. For longer runs (over 3-5 meters), 24V or constant current systems minimize voltage drop, reducing brightness inconsistencies. Buyers should match voltage specs with project scale and electrical infrastructure to avoid costly rewiring or performance issues. -

Power Density (Watts per Meter)

Power density influences brightness and heat generation. High power density strips (20-30W/m) produce intense light but require robust heat management and thicker wiring. Lower power strips (8-15W/m) are easier to install and consume less energy but may not suffice for high-illumination needs. Accurate specification helps optimize energy costs and fixture lifespan. -

Material Grade and Thermal Management

The quality of the flexible circuit board and aluminum profiles directly affects durability and heat dissipation. High-grade materials prevent early LED degradation and maintain color consistency. Aluminum heat sinks integrated into wiring diagrams are critical for dissipating heat, especially in industrial or outdoor applications. -

Ingress Protection (IP Rating)

IP ratings (e.g., IP20, IP65, IP67) define the strip’s resistance to dust and moisture. Projects in humid or outdoor environments must specify wiring and sealing methods compatible with the IP rating to ensure safety and longevity. This property is vital for buyers sourcing for diverse climates, including tropical or desert regions. -

Color Temperature and CRI (Color Rendering Index)

Color temperature impacts ambiance and functionality—warm white (2700K-3000K) suits residential settings, neutral white (3500K-4500K) fits offices, and cool white (5000K-6500K) is ideal for industrial spaces. CRI values above 90 guarantee accurate color representation, crucial for retail or design-oriented projects. Wiring diagrams must accommodate controllers or dimmers if dynamic color or dimming is required. -

Tolerance and Wiring Specifications

Electrical tolerance (±5% typical) affects performance consistency and safety margins. Wiring gauge and connector type specified in diagrams must align with local electrical standards and load requirements to prevent overheating or voltage drop. Clear tolerance parameters reduce installation errors and warranty claims.

Key Industry and Trade Terms for LED Strip Lighting Sourcing

For international buyers, familiarity with common trade terminology streamlines communication with suppliers and facilitates smoother procurement processes:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing LED strips or components that other brands sell under their own labels. OEM partnerships allow buyers to customize specifications while leveraging established production expertise, reducing lead times and costs. -

MOQ (Minimum Order Quantity)

The smallest batch size a supplier will accept. Understanding MOQs helps buyers plan inventory and budget accordingly, especially when sourcing for multiple markets with varying volume demands. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain detailed pricing, lead times, and terms based on specific technical requirements. An effective RFQ includes wiring diagram specs, material grades, and certification needs, enabling accurate supplier comparisons. -

Incoterms (International Commercial Terms)

Standardized trade terms defining delivery responsibilities, costs, and risk transfer between buyer and seller (e.g., FOB, CIF, DDP). Clarity on Incoterms is critical for managing logistics, customs, and total landed costs in cross-border transactions. -

UL/CE Certification

Safety and quality certifications that indicate compliance with regional standards (UL for North America, CE for Europe). Buyers should verify that wiring diagrams and components meet relevant certifications to avoid import restrictions and ensure end-user safety. -

Voltage Drop

A technical term describing the reduction in voltage along the length of the wiring. Excessive voltage drop can cause dimming and uneven illumination. Wiring diagrams typically include calculations or recommendations to mitigate this effect, especially important for long LED strip installations.

By mastering these technical properties and trade terms, international B2B buyers from diverse regions can better evaluate LED strip lighting solutions, negotiate effectively with suppliers, and ensure their projects meet both performance and regulatory requirements. This knowledge ultimately leads to optimized sourcing strategies, reduced risks, and enhanced customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lighting wiring diagram Sector

Market Overview & Key Trends

The global market for LED strip lighting wiring diagrams is increasingly influenced by the rapid adoption of LED technology in commercial, industrial, and residential lighting across regions such as Africa, South America, the Middle East, and Europe. Key drivers include growing energy efficiency regulations, rising demand for smart and customizable lighting solutions, and the expansion of construction and renovation projects in emerging and developed markets alike.

For international B2B buyers, particularly in countries like Poland and Turkey, understanding the nuances of wiring diagrams is critical to ensuring seamless integration of LED strips into diverse applications—from architectural lighting to industrial automation. The complexity of wiring configurations is evolving with the rise of addressable LED strips, RGB control systems, and IoT-enabled smart lighting, which require more sophisticated wiring schematics and driver compatibility considerations.

Sourcing trends highlight a shift towards modular wiring solutions that simplify installation and maintenance, reducing labor costs and minimizing errors in large-scale projects. Buyers are increasingly prioritizing suppliers who provide detailed, standardized wiring diagrams that comply with international electrical safety standards such as IEC and CE certifications. This reduces risks associated with voltage drops, power supply mismatches, and heat dissipation issues.

Moreover, regional market dynamics influence procurement strategies. For instance, buyers in the Middle East and Africa often seek robust wiring solutions that withstand high temperatures and dust, whereas European buyers focus on precision and compliance with stringent environmental regulations. South American markets show growing interest in flexible wiring designs that support retrofit projects without extensive rewiring of existing infrastructure.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the procurement of LED strip lighting wiring components. B2B buyers are increasingly evaluating suppliers not just on product quality and price but also on their commitment to environmentally responsible manufacturing and ethical sourcing. Wiring materials with low environmental impact, such as halogen-free cables and recyclable aluminum profiles, are gaining traction to reduce the ecological footprint of lighting installations.

Illustrative Image (Source: Google Search)

Ethical sourcing in the wiring diagram supply chain ensures transparency regarding labor practices and material origins. Buyers from Europe and other regions with strict corporate social responsibility (CSR) mandates demand suppliers who adhere to fair labor standards and provide conflict-free sourcing of raw materials. This is especially relevant in markets sourcing components from Asia, where supply chain visibility can vary.

Green certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and UL Environment labels provide buyers with assurance that wiring materials and components meet environmental safety standards. Utilizing wiring diagrams designed for energy-efficient LED strips can also contribute to reduced power consumption and longer product lifespans, aligning with global sustainability goals.

Incorporating sustainability into sourcing decisions not only mitigates regulatory risks but also enhances brand reputation and meets the growing demand from end-users for eco-friendly lighting solutions. Buyers should seek suppliers who offer transparent lifecycle assessments and actively engage in waste reduction and recycling initiatives within their production processes.

Brief Evolution and Historical Context

The evolution of LED strip lighting wiring diagrams parallels the technological advances in LED lighting itself. Initially, wiring diagrams were straightforward, catering to single-color LED strips powered by simple 12V or 24V DC power supplies. These early diagrams focused on basic series and parallel connections, suitable for short runs and static lighting setups.

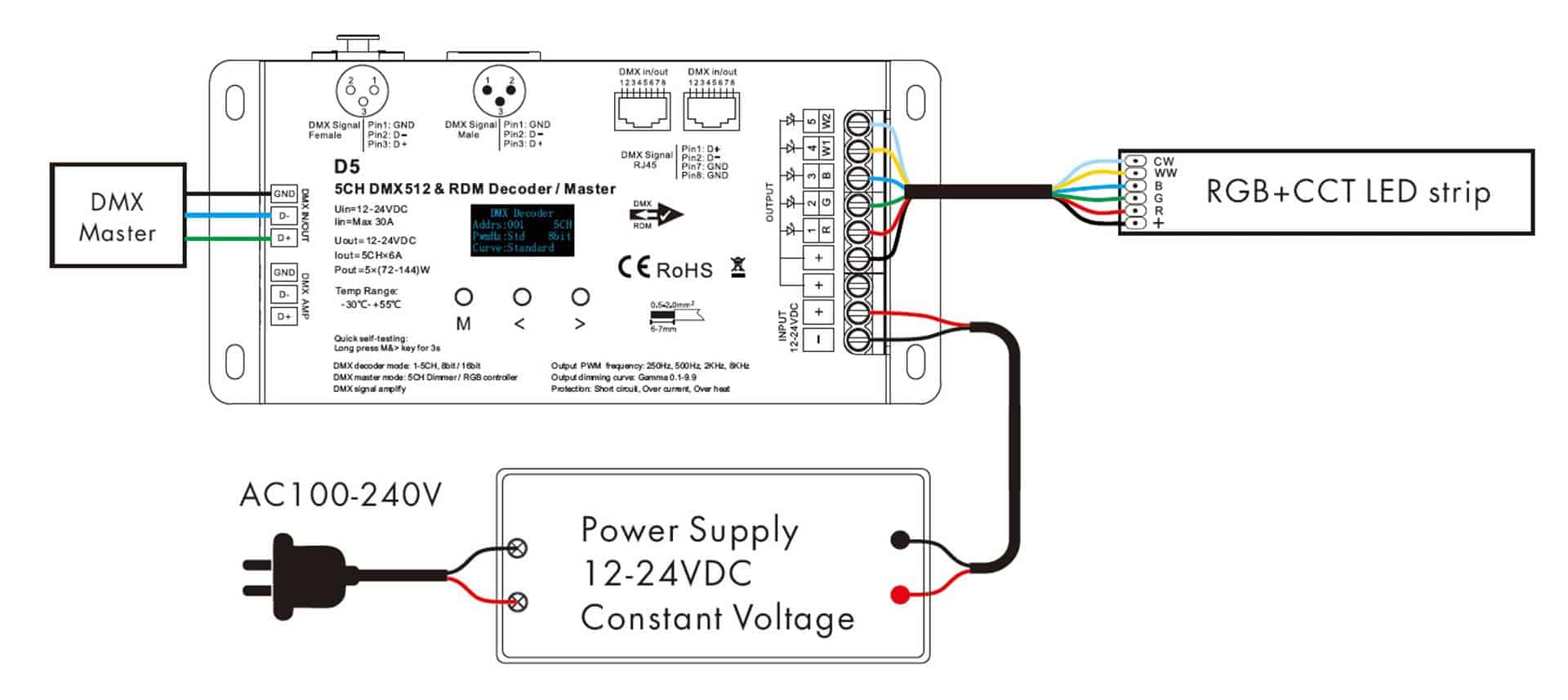

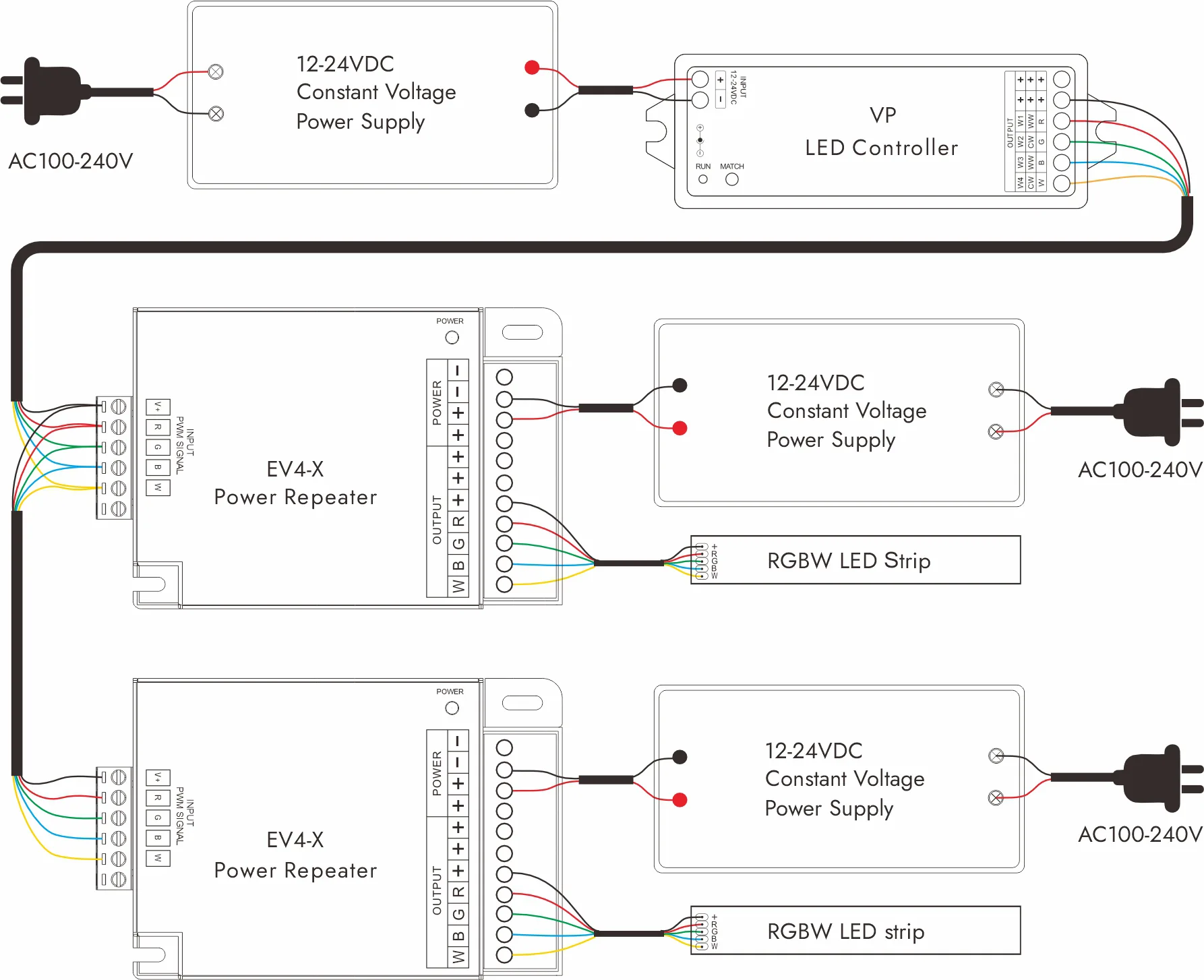

As LED technology matured, the introduction of multi-color RGB and addressable LEDs necessitated more complex wiring configurations involving controllers, signal data lines, and power management systems. This evolution has pushed the development of standardized wiring diagrams that accommodate digital control protocols like DMX and SPI, enabling dynamic lighting effects and integration with building automation systems.

Today’s wiring diagrams reflect a sophisticated balance between electrical safety, thermal management, and user-friendly installation. This historical progression underscores the importance for B2B buyers to stay current with wiring innovations to optimize system performance, reduce installation errors, and future-proof their lighting projects against emerging technologies.

By understanding these market dynamics, sourcing trends, and sustainability factors, international B2B buyers can make informed decisions that drive efficiency, compliance, and long-term value in the LED strip lighting wiring diagram sector.

Related Video: Ultimate Guide to Programming LED Strips with Arduino | Wiring, Powering & Code with FastLED

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lighting wiring diagram

-

How can international B2B buyers verify the credibility of suppliers providing LED strip lighting wiring diagrams?

To ensure supplier credibility, buyers should request detailed company profiles, certifications (ISO 9001, CE, RoHS), and samples of wiring diagrams before commitment. Verifying references from existing clients in similar markets (Africa, South America, Middle East, Europe) is crucial. Utilize third-party inspection services or platforms offering supplier audits. Transparent communication about manufacturing capabilities and quality assurance processes also signals reliability. Prioritize suppliers with technical support teams who can clarify wiring specifics, ensuring diagrams meet international electrical standards. -

Is it possible to customize LED strip lighting wiring diagrams for different regional voltage and installation requirements?

Yes, customization is essential for diverse markets. Suppliers should offer wiring diagrams adapted to local voltage standards (e.g., 110V in North America vs. 220-240V in Europe and parts of Africa). Custom diagrams must consider regional wiring codes, connector types, and safety regulations. Buyers should provide detailed project specs early, enabling suppliers to tailor diagrams for specific LED strip types, power supplies, and control systems. This reduces installation errors and compliance risks, enhancing end-user satisfaction across varied international markets. -

What are typical minimum order quantities (MOQs) and lead times for LED strip lighting wiring diagrams from international suppliers?

MOQs for wiring diagrams are generally low or negotiable since these are digital documents, but when bundled with physical LED strip orders, MOQs depend on the product type and supplier capacity. Lead times for customized wiring diagrams typically range from 3 to 10 business days, depending on complexity and approval cycles. Buyers should clarify these terms upfront, especially for bulk orders or projects across multiple regions. Early engagement with suppliers helps manage production schedules and shipping timelines, critical for markets with longer customs clearance like South America or the Middle East. -

Which quality assurance certifications should B2B buyers look for when sourcing LED strip lighting wiring diagrams?

Beyond the physical LED strips, wiring diagrams should comply with international electrical standards such as IEC, UL, or EN certifications relevant to the target market. Quality assurance for diagrams involves accuracy, clarity, and compliance with safety codes (e.g., CE marking in Europe). Buyers should request documentation proving that wiring instructions have undergone rigorous technical validation and field testing. Certifications ensure wiring diagrams support safe installations, reduce liability risks, and facilitate smoother regulatory approvals in diverse regions. -

What are best practices for managing logistics and shipping when sourcing LED strip lighting wiring diagrams and related components internationally?

Since wiring diagrams are typically delivered digitally, logistics mainly concern the physical LED strips and accessories. Buyers should coordinate shipments with suppliers experienced in handling customs regulations in Africa, South America, the Middle East, and Europe. Use reliable freight forwarders with expertise in electronics to mitigate delays and damage risks. Consolidating shipments and selecting Incoterms that clarify responsibilities (e.g., FOB, CIF) can optimize costs. For urgent projects, express shipping or local warehousing partnerships may be necessary to maintain supply chain agility. -

How should international buyers handle disputes related to LED strip lighting wiring diagrams accuracy or usability?

Disputes often arise from unclear or incompatible wiring instructions. Buyers should establish clear contractual terms specifying diagram standards, revision rights, and technical support availability. Maintain detailed communication records and request supplier confirmation on diagram applicability to the specific LED strip models ordered. If issues occur, seek prompt supplier collaboration for corrections or on-site technical assistance. Utilizing third-party arbitration or mediation services familiar with international trade can resolve conflicts efficiently, preserving long-term supplier relationships. -

Can suppliers provide multi-language LED strip lighting wiring diagrams to accommodate diverse workforces?

Yes, offering wiring diagrams in multiple languages is increasingly standard for global buyers. Suppliers should provide translations in widely spoken languages relevant to the buyer’s operational regions, such as English, Spanish, French, Arabic, Polish, or Turkish. Multi-language diagrams reduce installation errors, improve workforce training, and enhance compliance with local labor safety requirements. Buyers should verify translation accuracy and request diagrams with clear visual aids and standardized symbols to overcome language barriers effectively. -

What payment terms and methods are advisable for international B2B buyers sourcing LED strip lighting wiring diagrams and related products?

Common payment terms include 30% upfront deposit with balance upon delivery or net 30-60 days for established relationships. Buyers should negotiate terms balancing cash flow with supplier trust. Preferred payment methods include international bank transfers (SWIFT), Letters of Credit, and escrow services to mitigate risks. For buyers in emerging markets, partnering with suppliers offering flexible financing or trade credit can facilitate larger orders. Always ensure payment terms are clearly outlined in contracts, incorporating dispute resolution clauses to protect both parties.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip lighting wiring diagram

Effective sourcing of LED strip lighting wiring diagrams is pivotal for international B2B buyers aiming to optimize installation efficiency and ensure product reliability. Understanding the technical nuances—such as voltage compatibility, wiring layouts, and thermal management integration—enables buyers from diverse regions including Africa, South America, the Middle East, and Europe (notably Poland and Turkey) to make informed procurement decisions that align with their specific project requirements.

Key takeaways include:

- Prioritizing suppliers who provide clear, detailed wiring diagrams reduces installation errors and supports long-term system performance.

- Strategic collaboration with manufacturers that offer customizable wiring solutions can enhance adaptability across different electrical standards and environmental conditions.

- Investing in comprehensive documentation and training resources alongside the product ensures smoother deployment and maintenance cycles.

Looking ahead, the LED lighting industry continues to evolve rapidly with innovations in smart controls and energy-efficient designs. Buyers who adopt a strategic sourcing mindset—leveraging technical expertise and supplier partnerships—will position themselves to capitalize on these advancements, driving sustainable growth and competitive advantage. Embrace proactive engagement with trusted suppliers and stay abreast of emerging wiring standards to future-proof your lighting solutions.