Introduction: Navigating the Global Market for led light strips for steps

In today’s dynamic architectural and commercial environments, LED light strips for steps have emerged as an indispensable solution for enhancing safety, aesthetics, and energy efficiency. For international B2B buyers across Africa, South America, the Middle East, and Europe, understanding the nuanced global market for these specialized lighting products is crucial. Whether upgrading public infrastructure, luxury residential staircases, or commercial venues, selecting the right LED strips ensures compliance with safety standards while delivering long-term cost savings through energy-efficient technology.

This comprehensive guide delves into every critical aspect of sourcing LED light strips for steps, empowering buyers to make well-informed procurement decisions. You will explore the diverse types and technical specifications of LED strips, including power density, color temperature, and voltage options tailored for step lighting applications. The guide also highlights essential material considerations, such as aluminum profiles for heat dissipation and durable diffusers that ensure uniform illumination and longevity.

Beyond product knowledge, this guide offers insights into manufacturing quality control standards, helping buyers identify reliable suppliers with consistent product performance. We analyze global market trends and pricing strategies, providing a transparent framework to evaluate cost versus value in different regions. Additionally, a detailed FAQ section addresses common challenges and clarifies technical jargon, smoothing the path to successful international transactions.

For B2B buyers from regions like Germany, France, Nigeria, Brazil, and the UAE, this resource is designed to streamline the sourcing process, reduce risks, and maximize ROI. By leveraging these expert insights, you can confidently navigate the complexities of the global LED step lighting market and secure high-quality, compliant products that meet your specific project requirements.

Understanding led light strips for steps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof LED Step Strips | IP65 to IP68 rated, silicone or epoxy encapsulation, resistant to moisture and dust | Outdoor staircases, commercial entrances, public spaces | Pros: Durable in harsh environments, low maintenance; Cons: Higher upfront cost, requires proper sealing during installation |

| RGB and RGBW LED Strips | Multi-color lighting with color-changing capabilities, often controllable via DMX or app | Hospitality venues, entertainment venues, retail steps | Pros: Customizable ambiance, enhances aesthetics; Cons: More complex installation, higher power consumption |

| High-CRI White LED Strips | High Color Rendering Index (>90), available in warm to cool white temperatures | Office buildings, luxury residential, museums, galleries | Pros: Accurate color representation, professional look; Cons: Slightly higher cost, requires quality LED chips |

| Low-Voltage Flexible LED Strips | Operate on 12V or 24V DC, flexible PCB for easy installation on curved or irregular steps | Residential projects, hotels, architectural features | Pros: Easy to install, energy-efficient; Cons: Limited maximum run length, potential voltage drop issues |

| Aluminum Profile LED Strips | Mounted in aluminum channels for heat dissipation and protection, various mounting styles (recessed, surface) | Industrial staircases, commercial buildings, transit stations | Pros: Extended lifespan, improved thermal management; Cons: Increased installation complexity and cost |

Waterproof LED Step Strips

Waterproof LED strips designed for steps feature robust IP65 to IP68 ratings, making them ideal for outdoor and high-moisture environments. Encased in silicone or epoxy, these strips resist dust and water ingress, ensuring longevity and consistent performance. B2B buyers targeting public infrastructure, hotels with outdoor stairways, or commercial entrances will value their durability and compliance with safety standards. When purchasing, emphasis should be placed on the waterproof rating, installation environment, and compatibility with existing power systems.

RGB and RGBW LED Strips

These strips provide dynamic color-changing capabilities, often integrated with smart controllers or DMX systems. They are especially suited for hospitality, retail, and entertainment sectors where visual impact and ambiance customization are crucial. For B2B buyers, factors such as controller compatibility, power requirements, and ease of programming must be evaluated. While they deliver high aesthetic value, buyers should also consider the increased complexity in installation and higher energy consumption compared to single-color strips.

High-CRI White LED Strips

High Color Rendering Index (CRI) LED strips offer superior color accuracy and are available in various white tones, from warm to cool. These are essential for environments where true color perception is critical, such as galleries, luxury residential projects, or corporate offices. B2B purchasers should prioritize LED chip quality and CRI ratings above 90 to ensure premium visual outcomes. Though these strips come at a premium, their impact on perceived quality and user experience justifies the investment.

Low-Voltage Flexible LED Strips

Operating at 12V or 24V DC, these flexible LED strips are designed for easy installation on curved or non-standard step profiles. Their low voltage operation enhances safety and reduces energy costs, making them favorable for residential and upscale commercial projects. However, buyers must account for voltage drop over long runs, which can affect brightness and uniformity. Selecting suppliers who offer high-quality flexible PCBs and appropriate power supplies is critical for optimal performance.

Aluminum Profile LED Strips

LED strips installed within aluminum profiles benefit from enhanced heat dissipation, protecting LEDs from thermal degradation and extending lifespan. Profiles come in various mounting options—surface, recessed, or corner—allowing seamless integration into architectural designs. This type is preferred for industrial and high-traffic commercial staircases where durability and consistent illumination are paramount. B2B buyers should consider profile design compatibility, installation complexity, and total cost of ownership when specifying these products.

Related Video: How to Install LED Light Strips

Key Industrial Applications of led light strips for steps

| Industry/Sector | Specific Application of led light strips for steps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Leisure | Staircase illumination in hotels, resorts, and casinos | Enhances guest safety and ambiance; reduces slip and trip risks | Durable, waterproof, and dimmable strips; compliance with local safety standards; ease of installation |

| Commercial Real Estate | Office building stairwells and emergency exits | Improves occupant safety and building aesthetics; energy savings | High CRI and consistent color temperature; long lifespan; energy-efficient drivers |

| Retail & Shopping Malls | Decorative and safety lighting on staircases | Attracts customers through enhanced visual appeal; reduces accidents | Flexible strips with customizable colors; integration with existing lighting systems; robust heat dissipation |

| Transportation Hubs | Airport, train station, and metro platform steps | Increases passenger safety during low visibility; guides traffic flow | High brightness and weather-resistant LED strips; compliance with international safety regulations |

| Healthcare Facilities | Hospital stairways and patient access ramps | Provides clear, hygienic, and safe lighting; supports 24/7 operations | Antimicrobial coatings; flicker-free and low-heat emission; easy maintenance and replacement |

Hospitality & Leisure

In the hospitality sector, LED light strips for steps are widely used to illuminate staircases in hotels, resorts, and casinos. These strips provide a dual function: enhancing safety by clearly defining step edges to prevent falls, and creating a sophisticated ambiance that elevates guest experience. For international buyers, particularly in regions like Europe and the Middle East, sourcing LED strips with waterproof ratings (IP65 or higher) and dimming capabilities is crucial to adapt lighting levels for different times of day or event moods. Compliance with local fire safety and electrical standards is also a critical consideration.

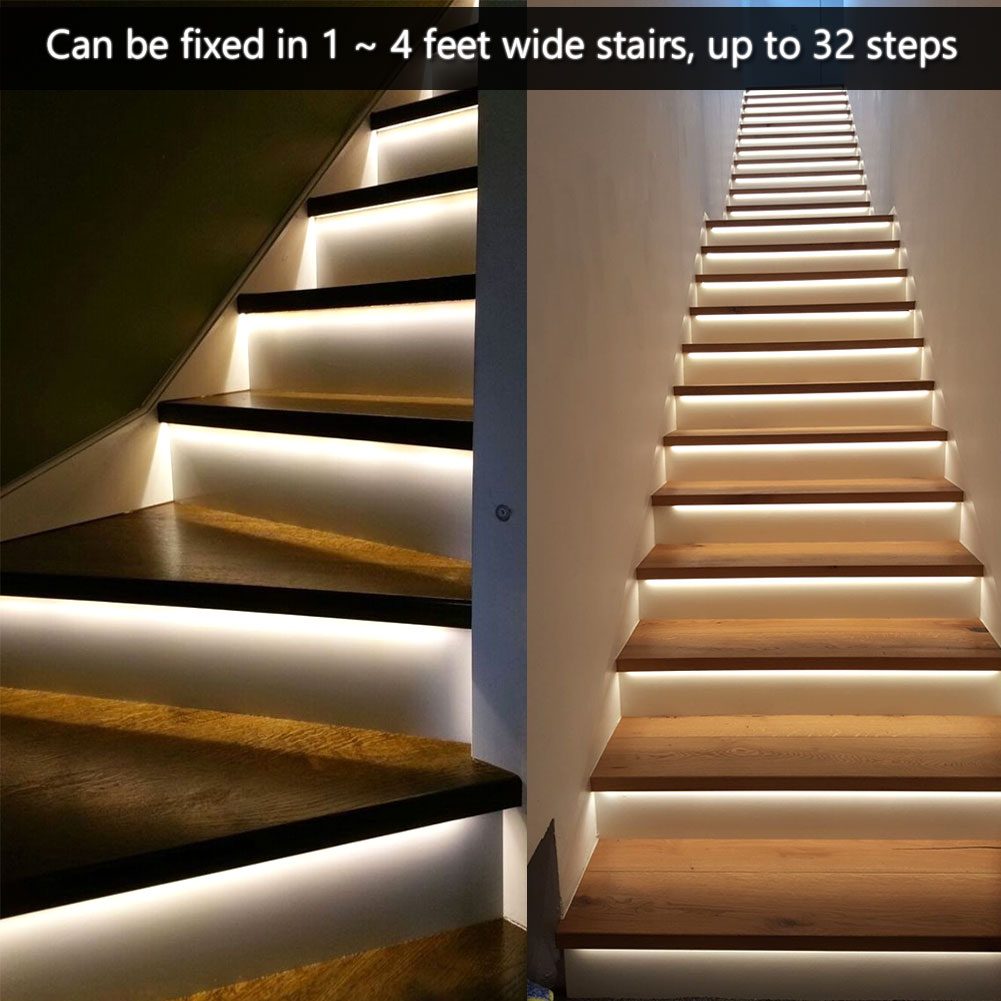

Illustrative Image (Source: Google Search)

Commercial Real Estate

Office buildings and commercial complexes benefit from LED step lighting by improving safety in stairwells and emergency exit routes while contributing to modern architectural aesthetics. International buyers, especially from Germany and France, often require LED strips with high color rendering index (CRI) values above 90 to ensure natural color perception and visual comfort. Energy efficiency and long operational lifespans reduce maintenance costs, which is a significant advantage for property managers overseeing large portfolios.

Illustrative Image (Source: Google Search)

Retail & Shopping Malls

Retail environments use LED light strips on staircases not only for safety but also as a design element that attracts and guides customers. Customizable color options and dynamic lighting effects can align with branding or promotional themes. Buyers from South America and Africa should focus on flexible LED strips that can be easily integrated with existing electrical infrastructure and have robust heat dissipation to maintain brightness and longevity in high-traffic areas.

Transportation Hubs

Airports, train stations, and metro platforms require high-visibility step lighting to ensure passenger safety, especially during night hours or low-visibility conditions. LED strips used in these environments must be highly durable, weather-resistant, and compliant with international safety regulations such as IEC standards. Buyers from the Middle East and Europe should prioritize suppliers offering products with certified brightness levels and proven resistance to dust, moisture, and temperature fluctuations.

Healthcare Facilities

Hospitals and healthcare centers demand LED strip lighting solutions that provide clear, flicker-free illumination on stairways and ramps while supporting hygienic environments. LED strips with antimicrobial coatings and low heat emission are preferred to minimize contamination risks and maintain patient comfort. International buyers must ensure easy maintenance and replacement options, as well as compatibility with hospital safety protocols, to support continuous 24/7 operations without disruption.

Strategic Material Selection Guide for led light strips for steps

Aluminum Profiles

Aluminum is the most prevalent material for LED strip housings on steps due to its excellent thermal conductivity, which is critical for heat dissipation and maintaining LED longevity. It offers high corrosion resistance, especially when anodized, making it suitable for both indoor and outdoor stair installations. Aluminum profiles are lightweight yet structurally robust, supporting the LED strips securely without adding significant weight.

Pros: Superior heat dissipation extends LED lifespan; corrosion resistance with anodizing; lightweight and easy to machine; recyclable and environmentally friendly.

Cons: Higher upfront cost compared to plastics; potential for surface scratches if not properly coated; requires precise extrusion tooling for complex profiles.

Impact on Application: Ideal for commercial and residential staircases where durability and thermal management are priorities. Aluminum profiles are compatible with various diffuser materials to optimize light distribution.

International Considerations: European buyers (Germany, France) often require compliance with DIN EN standards for aluminum products, emphasizing quality and sustainability. Middle Eastern and African markets value corrosion resistance due to harsh climates, making anodized aluminum preferable. South American buyers may focus on cost-effectiveness but increasingly demand compliance with ASTM standards for material quality.

Polycarbonate (PC) Diffusers and Covers

Polycarbonate is commonly used as a diffuser or protective cover for LED strips on steps. It offers excellent impact resistance and good optical clarity, which ensures uniform light diffusion while protecting LEDs from dust, moisture, and physical damage. Polycarbonate can withstand temperatures up to approximately 115°C, suitable for LED applications with moderate heat output.

Pros: High impact and shatter resistance; excellent light transmission; UV resistant grades available for outdoor use; relatively low cost and easy to mold.

Cons: Susceptible to scratching; lower heat resistance than aluminum; can yellow over time if not UV stabilized.

Impact on Application: Essential for outdoor or high-traffic staircases where physical protection and light diffusion are critical. It enhances safety by preventing direct LED exposure and glare.

International Considerations: Compliance with European REACH and RoHS directives is mandatory for polycarbonate materials in the EU. In Middle Eastern and African markets, UV resistance is a key factor due to intense sunlight exposure. South American buyers should verify local fire safety standards, as polycarbonate materials vary in flame retardancy.

Silicone Sealants and Coatings

Silicone materials are often used to encapsulate LED strips for steps, providing waterproofing and protection against dust and chemicals. Silicone offers excellent flexibility, temperature tolerance (typically -60°C to 200°C), and resistance to UV radiation and weathering, making it ideal for outdoor and industrial stair applications.

Pros: Superior waterproofing and weather resistance; high temperature tolerance; flexible and vibration-resistant; chemically inert.

Cons: Adds complexity to manufacturing; can increase overall product cost; requires precise application to avoid bubbles or gaps.

Impact on Application: Critical for outdoor stair lighting in environments exposed to rain, humidity, or chemical agents. Enhances durability in industrial or coastal settings.

International Considerations: European buyers expect compliance with REACH and ISO 10993 for biocompatibility if used in public spaces. Middle Eastern and African buyers prioritize UV and heat resistance due to harsh climates. South American markets may require certifications for chemical resistance due to industrial pollution exposure.

Stainless Steel Mounting Accessories

While not the primary housing material, stainless steel is frequently used for mounting brackets and fixtures for LED strips on steps. It offers excellent mechanical strength, corrosion resistance, and aesthetic appeal, especially in modern architectural staircases.

Pros: High corrosion and wear resistance; strong and durable; visually appealing finish; low maintenance.

Cons: Higher cost than aluminum or plastic mounts; heavier; may require specialized tools for installation.

Impact on Application: Suitable for premium installations where durability and design aesthetics are paramount, such as commercial buildings and luxury residential projects.

International Considerations: European markets demand compliance with EN 10088 for stainless steel grades. Middle Eastern and African buyers benefit from stainless steel’s corrosion resistance in humid or salty environments. South American buyers should consider local availability and cost implications of stainless steel components.

| Material | Typical Use Case for led light strips for steps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Profiles | Structural housing and heat dissipation for LED strips | Excellent thermal management and corrosion resistance | Higher initial cost and potential surface scratching | High |

| Polycarbonate | Diffusers and protective covers for LED strips | High impact resistance and optical clarity | Lower heat resistance; prone to scratching and yellowing | Medium |

| Silicone Sealants | Waterproofing and environmental protection | Superior waterproofing and flexibility | Increased manufacturing complexity and cost | Medium |

| Stainless Steel | Mounting brackets and fixtures | Exceptional corrosion resistance and strength | Heavier and more expensive than alternatives | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led light strips for steps

The manufacturing and quality assurance of LED light strips designed specifically for steps involve a series of precise processes and rigorous controls to ensure product reliability, safety, and performance. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding these processes and quality checkpoints is essential for selecting suppliers who meet stringent technical and regulatory requirements.

Key Stages in Manufacturing LED Light Strips for Steps

-

Material Preparation

The process begins with sourcing high-quality raw materials, including flexible printed circuit boards (FPCBs), LED chips (commonly Samsung, LG, or equivalent quality), resistors, capacitors, and protective coatings. Aluminum profiles and diffusers are also prepared if the strips include integrated housings for heat dissipation and light diffusion. Material suppliers are often pre-qualified to ensure consistency in electrical and mechanical properties. -

Forming and Circuit Assembly

The flexible circuit boards undergo surface mounting technology (SMT) to place and solder LEDs and electronic components accurately. Automated pick-and-place machines are widely used to achieve high precision and repeatability. The forming stage may also include cutting the strips to the required lengths and shaping the aluminum profiles to match stair dimensions for optimal installation. -

Encapsulation and Finishing

After assembly, LED strips for steps are often coated with protective layers such as silicone or epoxy resin to achieve water resistance and durability against dust, impacts, and temperature variations. This step is critical for stair lighting applications, where exposure to foot traffic and environmental factors is common. Additional components like connectors, mounting brackets, and end caps are attached at this stage to complete the product. -

Packaging and Labeling

The final products are carefully packaged to prevent damage during shipping. Packaging often includes anti-static bags, foam inserts, and moisture barrier materials. Clear labeling with batch numbers, certifications, and technical specifications facilitates traceability and compliance verification.

Quality Assurance Frameworks and Standards

International standards such as ISO 9001 set the baseline for quality management systems, ensuring manufacturers maintain consistent processes and continuous improvement. For LED light strips, additional certifications and standards are highly relevant:

- CE Marking (Europe): Confirms compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical products, critical for buyers in Europe and increasingly in other regions.

- UL Certification: Commonly required for North America but also valued internationally as a mark of safety.

- IP Ratings: Ingress protection ratings (e.g., IP65 or higher) validate dust and water resistance, essential for step lighting.

- Electromagnetic Compatibility (EMC) standards: Ensure LED strips do not interfere with other electronic devices.

Buyers in regions such as Africa, South America, and the Middle East should also verify compliance with local electrical safety regulations and any import-specific certifications.

Typical Quality Control Checkpoints

Incoming Quality Control (IQC):

– Verification of raw materials and components against specifications.

– Testing of LED chips for luminous flux, color temperature, and electrical parameters before assembly.

In-Process Quality Control (IPQC):

– Monitoring SMT placement accuracy and solder joint integrity during assembly.

– Thermal tests on assembled strips to check heat dissipation performance, critical for long-term LED lifespan.

– Visual inspections for uniformity in LED spacing and diffuser attachment.

Final Quality Control (FQC):

– Functional testing of assembled LED strips for brightness, color consistency, and electrical safety.

– Environmental stress tests including moisture resistance, temperature cycling, and mechanical shock to simulate real-world stair use.

– Measurement of voltage drop over length to ensure stable performance in installation scenarios.

– Packaging inspection to confirm protective measures and correct labeling.

Common Testing Methods for LED Step Light Strips

- Photometric Testing: Uses integrating spheres and spectrometers to measure luminous flux, color rendering index (CRI), and color temperature accuracy.

- Electrical Testing: Includes insulation resistance, dielectric withstand voltage, and current leakage tests to ensure safety and performance.

- Thermal Imaging: Identifies hotspots and verifies the efficiency of heat sinks or aluminum profiles.

- Ingress Protection Testing: Water spray and dust chamber tests to validate IP ratings.

- Durability and Aging Tests: Long-term operation tests simulate usage over thousands of hours to detect early failures or degradation.

How B2B Buyers Can Verify Supplier Quality Control

-

Factory Audits:

Conducting on-site audits to assess production capabilities, quality management systems, and worker training. Audits can be done independently or through third-party agencies specialized in supplier verification. -

Review of Quality Documentation:

Requesting and analyzing quality certificates, test reports, inspection records, and ISO 9001 compliance documents helps verify supplier claims. -

Third-Party Inspections:

Employing independent inspection companies to perform random batch testing and factory inspections before shipment adds an extra layer of assurance. -

Sample Testing:

Procuring product samples for independent laboratory testing in the buyer’s country or region to confirm compliance with local standards. -

Supplier Track Record:

Evaluating the supplier’s history with other international clients, including references and case studies, provides insight into reliability and consistency.

QC and Certification Nuances for International Buyers

-

Africa and South America:

Many countries in these regions have evolving regulatory frameworks. Buyers should prioritize suppliers who demonstrate compliance with internationally recognized standards like CE, RoHS, and UL to avoid import restrictions and ensure product safety. -

Middle East:

Local standards often align with European or American certifications. Buyers should verify conformity with Gulf Cooperation Council (GCC) standards and ensure products are certified for use in high-temperature environments common in the region. -

Europe (Germany, France, etc.):

European buyers face stringent requirements on energy efficiency, hazardous substances, and electromagnetic compatibility. CE marking and RoHS compliance are mandatory, and additional certifications like ENEC or TÜV may be required. Buyers should also consider environmental certifications reflecting sustainability practices, which are increasingly valued in European procurement.

Conclusion

For B2B buyers sourcing LED light strips for steps internationally, a thorough understanding of manufacturing processes and quality assurance practices is indispensable. Prioritizing suppliers who maintain robust quality management systems, comply with relevant international and local standards, and facilitate transparent QC verification will mitigate risks related to product failure, regulatory non-compliance, and customer dissatisfaction. Leveraging audits, third-party inspections, and detailed documentation review empowers buyers across Africa, South America, the Middle East, and Europe to make informed, confident procurement decisions that align with their market requirements and end-user expectations.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led light strips for steps Sourcing

When sourcing LED light strips for steps, understanding the detailed cost structure and pricing dynamics is crucial for international B2B buyers aiming to optimize procurement and total cost of ownership. The pricing landscape involves multiple interrelated components and market factors that vary by region, product specifications, and supplier terms.

Key Cost Components in LED Light Strip Production

-

Materials

The primary cost driver includes high-quality LED chips (e.g., Samsung, LG), flexible PCBs, aluminum profiles for heat dissipation, diffusers, and connectors. Premium materials with certifications such as CE, RoHS, and UL command higher prices but ensure durability and compliance, essential for markets like Europe. Material costs fluctuate with raw material prices (copper, aluminum) and global supply chain conditions. -

Labor and Manufacturing Overhead

Labor intensity depends on product complexity—custom lengths, color temperature variations, and waterproofing increase assembly time. Overhead costs encompass factory utilities, equipment depreciation, and quality control (QC) processes. Manufacturers in Asia often offer lower labor costs, but buyers should weigh this against QC standards and lead times. -

Tooling and Customization

Custom designs—such as specific step lighting profiles or integrated diffusers—require tooling investments. These are usually amortized over order volumes. One-off or small batch customizations significantly raise per-unit costs, making volume-based negotiations critical. -

Quality Control (QC)

Rigorous QC ensures long lifespan (50,000+ hours) and consistent light output, reducing returns and warranty claims. QC costs include testing equipment, labor, and certification processes. High QC standards are especially important for buyers targeting demanding markets in Europe or the Middle East. -

Logistics and Import Duties

Shipping costs vary by destination, mode (air, sea), and volume. For buyers in Africa, South America, and the Middle East, customs duties, VAT, and import regulations can add 10–30% to landed costs. Incoterms (e.g., FOB, CIF, DDP) significantly influence cost transparency and risk allocation. -

Supplier Margin

Margins depend on supplier positioning, product differentiation, and market competition. Established brands with certified products tend to have higher margins but offer reliability and warranty support.

Price Influencers and Buyer Considerations

-

Order Volume and MOQ

Larger volumes reduce unit costs through economies of scale. Minimum order quantities (MOQs) vary widely; negotiating MOQ flexibility can help buyers test products before large commitments. -

Specifications and Custom Features

Power density, color temperature, IP rating (waterproofing), and control systems (e.g., dimmable, RGB) affect pricing. More sophisticated features require advanced components and QC, increasing costs. -

Material Quality and Certifications

Certified, high-CRI LEDs with superior thermal management are more expensive but offer lower total cost of ownership through energy savings and longevity. -

Supplier Location and Reliability

Suppliers closer to buyer markets reduce lead times and logistics costs but may have higher labor costs. Verified suppliers with transparent production processes minimize risks. -

Incoterms and Payment Terms

Choosing appropriate Incoterms balances risk and cost. For example, DDP (Delivered Duty Paid) provides cost certainty but may include higher supplier margins. Payment terms (e.g., LC, T/T) impact cash flow and negotiation leverage.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Price

Focus on total value including quality certifications, warranty terms, and after-sales support. Request detailed cost breakdowns to identify negotiation levers. -

Consider Total Cost of Ownership (TCO)

Factor in energy efficiency (LED strips can save up to 70% energy), maintenance savings, and product lifespan rather than just upfront cost. -

Leverage Regional Trade Agreements

Buyers in Africa, South America, and the Middle East should explore preferential tariffs under regional trade agreements to reduce import duties. -

Plan for Logistics and Customs Clearance

Engage reliable freight forwarders familiar with local regulations. Transparent Incoterms reduce unforeseen costs. -

Sample and Test Before Bulk Purchase

Always request samples to verify product performance, color consistency, and durability, especially for safety-critical step lighting. -

Watch for Hidden Costs

Beware of pricing that excludes accessories like power supplies, connectors, and controllers, which are essential for installation.

Indicative Pricing Overview (Subject to Market Fluctuations)

- Basic LED strip light for steps: approximately $5–$15 per meter

- Premium, certified LED strips with aluminum profiles and waterproofing: $15–$30 per meter

- Custom or smart LED solutions with advanced controllers: $30+ per meter

These figures serve as general guidance. Actual costs depend on order volume, customization, and supplier negotiations.

By comprehensively analyzing cost components and market factors, B2B buyers from diverse regions can strategically source LED light strips for steps that balance cost efficiency, quality, and compliance, ensuring successful project outcomes and sustainable partnerships.

Spotlight on Potential led light strips for steps Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led light strips for steps’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led light strips for steps

Key Technical Properties for LED Light Strips for Steps

When sourcing LED light strips specifically designed for step illumination, understanding the critical technical properties ensures the right fit for safety, durability, and visual appeal. Below are the essential specifications B2B buyers should evaluate:

-

Ingress Protection (IP) Rating

Indicates the strip’s resistance to dust and water. For step lighting, an IP65 or higher rating is advisable to withstand outdoor exposure, cleaning, or accidental splashes. This ensures longevity and reduces maintenance costs in diverse climates, from humid tropical zones in Africa to wet European environments. -

Material Quality and Heat Dissipation

High-grade aluminum profiles or heat sinks integrated with the LED strip prevent overheating, which can degrade LED lifespan and performance. Quality materials extend operational life beyond 50,000 hours, critical for commercial projects where replacement downtime is costly. -

Color Temperature (Kelvin, K)

Defines the light’s hue and ambiance. Warm white (2700K-3000K) is preferred for residential or hospitality steps to create inviting atmospheres, whereas cool white (5000K-6500K) suits industrial or commercial staircases for enhanced visibility and safety. -

Power Consumption and Voltage

Typical LED strips for steps operate on 12V or 24V DC. Higher voltage (24V) systems reduce voltage drop over longer runs, important for extensive stair installations common in large public buildings or shopping centers. Power density (watts per meter) impacts brightness and energy efficiency. -

Luminous Intensity and Uniformity

Measured in lumens per meter, this dictates brightness. Uniform light distribution prevents shadows or hotspots on steps, reducing trip hazards. Diffusers and quality LED chips (e.g., Samsung or LG) contribute to consistent illumination. -

Cutting and Length Tolerance

LED strips often come in customizable lengths with designated cut points. Precise cutting tolerance and flexibility allow integration into varying step sizes and shapes, facilitating tailored installations in diverse architectural designs.

Essential Trade Terminology for International LED Strip Procurement

Understanding common trade and industry terms empowers buyers to negotiate effectively and avoid misunderstandings in global transactions:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that can be branded and customized for other companies. OEM options allow buyers to specify unique features, packaging, or certifications, ideal for building proprietary product lines or private labels. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce or sell in one order. MOQs vary widely; understanding them is crucial for budgeting and inventory planning, especially for buyers in emerging markets or smaller enterprises. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers to obtain pricing, lead times, and terms for specific LED strip configurations. A well-prepared RFQ accelerates sourcing processes and ensures competitive offers tailored to technical and commercial requirements. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) helps buyers manage logistics risks and costs across regions. -

CRI (Color Rendering Index)

A metric from 0 to 100 indicating how accurately a light source reveals colors compared to natural light. For step lighting, a CRI above 80 is recommended to enhance safety by improving color perception on stair surfaces. -

Dimming Capability

The ability of LED strips to adjust brightness through compatible drivers or controllers. Dimmable options provide energy savings and adaptable ambiance, important for hospitality or residential projects requiring dynamic lighting control.

By prioritizing these technical properties and mastering trade terminology, international B2B buyers—particularly in Africa, South America, the Middle East, and Europe—can make informed decisions, ensure compliance with local standards, and secure optimal value in LED light strip purchases for step lighting applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led light strips for steps Sector

Market Overview & Key Trends

The global market for LED light strips designed specifically for steps is experiencing robust growth, driven by increasing demand for energy-efficient, safe, and aesthetically pleasing architectural lighting solutions. International B2B buyers from Africa, South America, the Middle East, and Europe (notably Germany and France) are actively seeking innovative LED step lighting to enhance commercial, residential, and public infrastructure projects.

Key market drivers include heightened awareness of energy conservation, urban modernization efforts, and stricter building codes emphasizing safety and accessibility. LED step lights offer superior durability, low maintenance, and enhanced visibility, making them ideal for staircases in airports, hotels, shopping centers, and smart homes.

Emerging sourcing trends emphasize modular LED strip systems with integrated thermal management—such as aluminum profiles for heat dissipation—to ensure longevity and consistent performance. Buyers increasingly prefer LED strips with customizable color temperatures (2700K–6500K) and high color rendering indexes (CRI > 90) to tailor ambiance and meet specific regional preferences. Additionally, 24V and constant current LED systems are favored for longer step runs to minimize voltage drop and ensure uniform illumination.

Technological advances in flexible LED strips, including addressable RGB and RGBW options, enable dynamic lighting effects and integration with smart control systems, which are gaining traction in Europe and the Middle East. Meanwhile, African and South American markets show growing interest in cost-effective, durable, and waterproof LED strips suited for challenging environmental conditions.

Supply chain dynamics reflect a shift toward diversified sourcing beyond traditional East Asian manufacturers, with European and Middle Eastern suppliers offering higher customization and compliance with regional standards. This diversification helps mitigate risks linked to logistics disruptions and import tariffs.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to procurement decisions for LED light strips used in steps. Buyers from Europe, the Middle East, Africa, and South America prioritize products that align with environmental regulations and corporate social responsibility (CSR) goals. The environmental impact of LED manufacturing is mitigated by selecting suppliers committed to reducing carbon footprints, employing recyclable materials, and minimizing hazardous substances.

Ethical sourcing involves verifying supply chains for conflict-free minerals and fair labor practices, which is particularly important for buyers operating in regions with stringent compliance frameworks such as the EU’s Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) regulations. Certifications such as UL, CE, and Energy Star validate product safety, energy efficiency, and environmental responsibility.

Green materials like aluminum with high recyclability and low environmental impact, alongside lead-free solder and halogen-free substrates, are increasingly standard in premium LED strips for steps. Furthermore, energy savings of up to 70% compared to traditional lighting reduce operational carbon emissions, appealing to buyers committed to sustainability.

For B2B buyers, partnering with suppliers who demonstrate transparent environmental reporting and sustainability initiatives ensures alignment with global green procurement policies and enhances brand reputation. Additionally, sourcing from manufacturers that offer LED strips with longer lifespans (50,000+ hours) reduces waste and replacement frequency, delivering both economic and ecological benefits.

Brief Evolution and Historical Context

LED technology for step lighting has evolved significantly over the past two decades. Initially, step illumination relied heavily on incandescent or fluorescent fixtures, which were bulky, energy-intensive, and maintenance-heavy. The advent of surface-mounted device (SMD) LED strips revolutionized this sector by offering compact, flexible, and efficient lighting solutions.

Early LED strips were limited in brightness and color options, but advances in semiconductor chip quality—particularly from leading brands like Samsung and LG—have vastly improved light output, color accuracy, and lifespan. The integration of aluminum profiles for heat management emerged as a critical innovation, enabling longer and safer LED runs on steps without performance degradation.

Today’s LED step lighting combines energy efficiency with smart controls, modularity, and aesthetic versatility, reflecting the broader trend toward intelligent, sustainable building technologies. This evolution provides B2B buyers with a mature, reliable product category that supports modern design and regulatory demands worldwide.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led light strips for steps

-

How can I effectively vet LED light strip suppliers for steps in international markets?

To vet suppliers, start by verifying their manufacturing capabilities and quality certifications such as ISO 9001, CE, or RoHS compliance relevant to your region. Request product samples to assess build quality and lighting performance. Check references or reviews from other international buyers, particularly those in your continent, to understand reliability and after-sales support. Assess their ability to provide technical documentation and customization options. A factory audit or third-party inspection can further ensure supplier credibility and compliance with your standards. -

What customization options should I consider when sourcing LED light strips for steps?

Customization often includes length, color temperature, brightness (lumens), IP rating for water resistance, voltage options (12V, 24V), and aluminum profile designs for heat dissipation. Consider control features such as dimming, RGB color changing, or smart integration. Custom packaging and branding can also be negotiated. Ensure the supplier can accommodate your technical requirements and certifications for your target markets, such as CE for Europe or local safety standards in Africa and the Middle East. -

What are typical Minimum Order Quantities (MOQs) and lead times for LED step light strips from international suppliers?

MOQs vary widely but typically range from 500 to 2000 meters per order, depending on the supplier and customization level. Lead times usually span 4 to 8 weeks, including production and quality testing. Bulk orders may reduce per-unit costs but require upfront investment. Negotiate payment terms carefully, with common options including 30% deposit and 70% before shipment. For new buyers, smaller trial orders might be possible but expect higher unit prices. -

What quality assurance measures and certifications should I require from suppliers?

Request suppliers to provide certifications such as CE (Europe), UL (if applicable), RoHS compliance, and IEC standards. Quality assurance should include in-line testing during production, final inspection reports, and reliability tests like thermal cycling and waterproof testing for outdoor steps. Ask for warranty terms and defect rates. Engaging third-party inspection services pre-shipment can mitigate risks, especially for buyers in regions with strict import regulations. -

How should I plan logistics and shipping for LED strip orders to Africa, South America, the Middle East, or Europe?

Choose suppliers experienced in international shipping with knowledge of Incoterms (FOB, CIF, DDP). Sea freight is cost-effective for large volumes but slower; air freight suits urgent smaller shipments. Confirm packaging protects strips during transit, especially for fragile aluminum profiles. Understand customs duties, import regulations, and potential certification requirements in your country. Collaborate with freight forwarders familiar with your region to optimize delivery time and cost. -

What payment methods are safest and most common for international B2B purchases of LED light strips?

Common payment methods include Telegraphic Transfer (T/T), Letter of Credit (L/C), and Escrow services. T/T is widely used but requires trust; split payments (deposit and balance) reduce risk. L/C offers greater security by involving banks but may incur higher fees and longer processing. New buyers should consider escrow or third-party payment platforms for additional security. Always verify supplier bank details and avoid upfront full payments without contract protection. -

How can I handle disputes or quality issues with LED strip suppliers abroad?

First, document all communications and product discrepancies with photos and test results. Address issues promptly with the supplier to seek resolution such as replacements, refunds, or discounts. Having clear contract terms including warranty coverage and dispute resolution mechanisms (e.g., arbitration in a neutral location) is critical. Engage local trade chambers or export promotion agencies for mediation assistance. For high-value orders, consider legal counsel familiar with international trade law. -

What are key technical considerations for ensuring LED strip durability on steps in diverse climates?

Select LED strips with appropriate IP ratings (IP65 or higher) for moisture and dust protection, especially in humid or outdoor environments common in Africa and the Middle East. Aluminum profiles with good heat dissipation prevent thermal degradation in hot climates. Opt for LED chips with high-quality phosphor coatings for color stability and longevity. Verify power supply compatibility with local voltage standards. Consider UV-resistant materials if exposed to sunlight to avoid discoloration or brittleness.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led light strips for steps

Effective procurement of LED light strips for steps hinges on a strategic sourcing approach that balances quality, cost-efficiency, and compliance with regional standards. For international B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing suppliers who offer advanced thermal management, certified LED chips (such as those from Samsung or LG), and versatile aluminum profiles ensures durable, energy-efficient installations with minimal maintenance. Additionally, selecting products with appropriate voltage systems—favoring 24V or constant current configurations for longer runs—can significantly reduce operational issues like voltage drop, enhancing overall system reliability.

Understanding the unique lighting needs of diverse markets—from warm, inviting tones for residential staircases to bright, cool whites for commercial or industrial settings—enables buyers to tailor solutions that align with end-user expectations and regulatory environments. Strategic partnerships with manufacturers who provide customization, after-sales support, and transparent quality certifications will further mitigate risks and foster long-term value.

Looking ahead, the LED lighting industry is poised for continued innovation in smart controls, IoT integration, and sustainable materials. Buyers are encouraged to engage proactively with suppliers investing in these technologies to future-proof their offerings and gain competitive advantage. Embracing a forward-thinking sourcing strategy today will unlock efficiency, enhance safety, and elevate design in step lighting projects worldwide.