Introduction: Navigating the Global Market for ip68 led strip

The global demand for IP68 LED strips is surging as industries across Africa, South America, the Middle East, and Europe increasingly prioritize durable, high-performance lighting solutions that withstand extreme environmental conditions. IP68-rated LED strips, known for their exceptional waterproof and dustproof capabilities, are essential for applications ranging from outdoor architectural lighting to industrial installations and marine environments. For international B2B buyers, understanding the nuances of this specialized product is critical to securing reliable, cost-effective supplies that meet stringent quality standards.

This comprehensive guide is designed to empower procurement professionals and business decision-makers with deep insights into the types and materials of IP68 LED strips, highlighting how different silicone, epoxy, or polyurethane coatings affect durability and flexibility. It covers the entire manufacturing and quality control landscape, emphasizing the importance of certifications, testing protocols, and the role of experienced manufacturers in ensuring consistent product performance.

Additionally, the guide offers a detailed overview of global supplier networks, focusing on sourcing strategies tailored to diverse regional markets such as Poland and Germany in Europe, as well as emerging markets in Africa and South America. Cost considerations, including bulk purchasing, logistics, and import regulations, are addressed to help buyers optimize their supply chain and budgeting.

Finally, an extensive FAQ section answers common queries and clarifies technical specifications, enabling buyers to make well-informed sourcing decisions. By leveraging this knowledge, international B2B buyers can confidently navigate the complex IP68 LED strip market, securing products that align with their operational needs and sustainability goals.

Understanding ip68 led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicone Encapsulated IP68 | Fully coated with a flexible silicone layer, waterproof and dustproof | Outdoor lighting, architectural facades, marine environments | Pros: High flexibility, excellent waterproofing; Cons: Slightly higher cost, limited heat dissipation |

| Rigid PVC Coated IP68 | Encased in a rigid PVC shell for robust protection | Industrial sites, underground installations, harsh weather areas | Pros: Strong mechanical protection, durable; Cons: Less flexible, heavier, potential UV degradation |

| Epoxy Resin Filled IP68 | LED strips embedded in clear epoxy resin | Underwater lighting, aquariums, pools, fountains | Pros: Superior waterproofing and chemical resistance; Cons: Difficult to customize or cut, heavier |

| Dual-layer IP68 | Combines silicone and PVC layers for enhanced protection | Harsh outdoor environments, transportation hubs | Pros: Balanced durability and flexibility; Cons: Higher price, more complex installation |

| UV-Resistant IP68 | Special coatings to resist UV degradation | Desert or high-sunlight regions, outdoor advertising | Pros: Long lifespan under sun exposure; Cons: May have reduced flexibility, premium pricing |

Silicone Encapsulated IP68

These LED strips are enveloped in a flexible silicone layer that offers excellent waterproofing and dust resistance, ideal for applications requiring bending or shaping around corners. For B2B buyers in sectors like outdoor architectural lighting or marine installations, silicone encapsulated strips provide adaptability and resilience. When sourcing, consider the slightly higher price point and ensure suppliers provide quality silicone to avoid premature yellowing or degradation.

Rigid PVC Coated IP68

Designed for environments demanding robust mechanical protection, rigid PVC coated LED strips are less flexible but highly durable against impacts and harsh weather. Industrial buyers, especially in mining, underground, or heavy machinery contexts, benefit from their longevity and sturdiness. However, buyers should verify UV stability and weight constraints for their specific project requirements.

Epoxy Resin Filled IP68

Embedded in a solid epoxy resin, these LED strips excel in waterproofing and chemical resistance, making them perfect for underwater or wet applications such as pools and aquariums. B2B purchasers must account for the reduced ability to cut or customize these strips and potential challenges in installation due to rigidity and weight. Confirm epoxy quality and certification for safety compliance.

Dual-layer IP68

Combining silicone and PVC coatings, dual-layer IP68 LED strips offer enhanced protection suitable for extreme outdoor environments, including transportation and logistics hubs. This hybrid approach balances flexibility with durability, appealing to buyers needing versatile solutions. Pricing is higher, and installation may require specialized handling, so evaluate supplier expertise and support services.

UV-Resistant IP68

Specifically treated to withstand prolonged UV exposure, these LED strips are ideal for regions with intense sunlight, such as parts of Africa, South America, and the Middle East. They maintain color and performance longer in outdoor advertising and desert applications. Buyers should assess the trade-off between flexibility and UV protection and prioritize suppliers with proven UV-resistant materials and warranties.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of ip68 led strip

| Industry/Sector | Specific Application of ip68 led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Offshore | Underwater lighting for ships, docks, and offshore platforms | Enhances safety and operational efficiency with durable, waterproof lighting | Ensure IP68 certification, corrosion-resistant materials, and compliance with maritime standards |

| Food & Beverage | Hygienic, washable lighting in processing and packaging areas | Maintains strict sanitation standards while providing energy-efficient illumination | Look for food-grade materials, easy-to-clean surfaces, and certification for food safety compliance |

| Outdoor Architectural | Facade and landscape lighting exposed to harsh weather conditions | Provides long-lasting, weatherproof illumination that reduces maintenance costs | Confirm UV resistance, robust waterproofing, and adaptability to local climate conditions |

| Automotive & Transport | Exterior vehicle lighting and signage exposed to rain and dust | Improves visibility and safety with robust, waterproof lighting solutions | Verify vibration resistance, IP68 rating, and compatibility with automotive electrical systems |

| Industrial Manufacturing | Machine and work area lighting in wet or dusty environments | Increases productivity and safety by ensuring reliable lighting under harsh conditions | Prioritize durability, ease of installation, and adherence to industrial safety standards |

Marine & Offshore Applications

IP68 LED strips are extensively used in marine environments for underwater lighting on ships, docks, and offshore platforms. These strips provide reliable illumination despite constant exposure to water, salt, and harsh weather. For B2B buyers in Africa and the Middle East with growing maritime industries, sourcing IP68 LED strips with strong corrosion resistance and verified IP68 waterproof certification is crucial to ensure durability and compliance with international maritime safety standards.

Food & Beverage Industry

In food processing and packaging plants, IP68 LED strips offer hygienic, washable lighting solutions that withstand frequent cleaning and sanitation processes. Buyers from South America and Europe should prioritize food-grade materials and certifications that meet local food safety regulations. These LED strips help maintain compliance while reducing energy consumption and downtime caused by lighting failures in wet or steam-filled environments.

Outdoor Architectural Lighting

Architectural firms and contractors utilize IP68 LED strips for facade and landscape lighting that must endure rain, snow, and UV exposure. For European markets such as Germany and Poland, it is essential to source LED strips with UV-resistant coatings and proven weatherproofing to withstand diverse climates. The long lifespan and low maintenance requirements translate to cost savings and enhanced aesthetic appeal for commercial and public infrastructure projects.

Automotive & Transport Sector

IP68 LED strips are ideal for exterior vehicle lighting and transport signage, where exposure to dust, rain, and vibrations is common. Businesses in regions like the Middle East and Europe benefit from sourcing LED strips that meet automotive vibration and waterproof standards, ensuring durability and safety. These lighting solutions improve vehicle visibility and compliance with road safety regulations, critical for fleet operators and vehicle manufacturers.

Industrial Manufacturing Environments

Industrial settings often involve wet, dusty, or chemically aggressive environments where reliable lighting is vital for safety and efficiency. IP68 LED strips provide robust illumination for machinery and work areas, minimizing downtime and accidents. B2B buyers in South America and Africa should focus on sourcing products that combine durability with ease of installation and meet regional industrial safety certifications to optimize operational workflows.

Related Video: What is IP68 COB LED Strip Light with Extruding Waterproof Process?

Strategic Material Selection Guide for ip68 led strip

When selecting materials for IP68 LED strips, international B2B buyers must consider factors such as environmental exposure, durability, manufacturing complexity, and compliance with regional standards. The IP68 rating guarantees dust-tight protection and water immersion resistance beyond 1 meter, making material choice critical for long-term performance across diverse markets including Africa, South America, the Middle East, and Europe.

Silicone Rubber

Key Properties: Silicone rubber offers excellent flexibility, high temperature resistance (typically -60°C to 230°C), and outstanding UV and ozone resistance. It maintains elasticity under extreme conditions and provides superior waterproof sealing.

Pros & Cons: Silicone is highly durable and chemically inert, making it resistant to corrosion and environmental degradation. It supports complex manufacturing processes like extrusion and molding. However, silicone is generally more expensive than other materials and may require specialized equipment for processing.

Impact on Application: Silicone is ideal for outdoor and harsh environment applications, such as architectural lighting in Europe or outdoor signage in the Middle East, where UV exposure and temperature fluctuations are significant. Its chemical resistance suits industrial settings in South America where exposure to oils or solvents is common.

International Considerations: Buyers in Europe (e.g., Germany, Poland) value silicone for compliance with stringent RoHS and REACH regulations. In Africa and the Middle East, silicone’s durability justifies the higher cost due to challenging climates. ASTM D2000 and DIN standards often guide silicone quality, reassuring buyers of consistent performance.

Polyurethane (PU)

Key Properties: Polyurethane encapsulation provides excellent abrasion resistance, good flexibility, and moderate temperature tolerance (-40°C to 90°C). It offers strong mechanical protection and chemical resistance.

Pros & Cons: PU is less expensive than silicone and easier to process, allowing for efficient mass production. However, it is less UV stable, which can lead to yellowing or brittleness over time, limiting outdoor longevity without additional UV stabilizers.

Impact on Application: PU is suitable for indoor or semi-outdoor IP68 LED strips, such as in retail or automotive lighting in South America and Europe. Its abrasion resistance is beneficial in environments with physical wear, like warehouses or manufacturing plants.

International Considerations: Buyers should verify compliance with regional chemical safety standards, such as EU REACH or Middle Eastern environmental regulations. PU’s lower cost appeals to markets in Africa where budget constraints are significant, but buyers must weigh this against potential shorter lifespan in high UV exposure zones.

Epoxy Resin

Key Properties: Epoxy resin offers excellent chemical resistance, high mechanical strength, and good electrical insulation. It typically withstands temperatures up to 120°C but is rigid and less flexible.

Pros & Cons: Epoxy provides robust protection against moisture and chemicals, making it suitable for harsh industrial environments. However, its rigidity limits flexibility, which can be a drawback for applications requiring bending or shaping. Epoxy curing times can slow production cycles.

Impact on Application: Epoxy-coated IP68 LED strips are commonly used in fixed installations such as underwater lighting or industrial machinery in Europe and the Middle East. Its chemical resistance is advantageous in South American mining or chemical plants.

International Considerations: Compliance with ASTM D638 and DIN EN ISO 527 standards ensures epoxy quality. Buyers in Europe prioritize certifications for safety and durability, while those in Africa and South America benefit from epoxy’s protective qualities in corrosive environments despite higher production complexity.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a widely used thermoplastic with good chemical resistance, moderate flexibility, and temperature tolerance from -20°C to 60°C. It is cost-effective and easy to manufacture.

Pros & Cons: PVC is economical and suitable for large-volume production but offers lower UV and temperature resistance compared to silicone or PU. It can degrade under prolonged sun exposure and may emit hazardous fumes if burned.

Impact on Application: PVC is commonly used for indoor IP68 LED strips or short-term outdoor installations in controlled environments, such as retail displays or indoor signage in Europe and South America. It is less suited for extreme climates found in parts of Africa and the Middle East.

International Considerations: Buyers should ensure PVC materials meet local fire safety and environmental regulations, including EU RoHS and Middle Eastern standards. Its affordability makes PVC attractive for cost-sensitive markets, but buyers must consider lifecycle costs and potential replacement frequency.

| Material | Typical Use Case for ip68 led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Outdoor architectural lighting, harsh environments | Superior flexibility and UV resistance | Higher cost and specialized manufacturing | High |

| Polyurethane (PU) | Indoor/semi-outdoor retail and automotive lighting | Good abrasion resistance and cost-effective | Limited UV stability, shorter outdoor lifespan | Medium |

| Epoxy Resin | Fixed underwater or industrial lighting installations | Excellent chemical resistance and mechanical strength | Rigid, less flexible, slower production | High |

| Polyvinyl Chloride (PVC) | Indoor or controlled environment LED strips | Low cost and easy manufacturing | Poor UV resistance and lower temperature tolerance | Low |

This guide equips international B2B buyers with critical insights to select the optimal material for IP68 LED strips based on performance needs, environmental challenges, and regional compliance requirements. Prioritizing material properties aligned with application specifics ensures durability, regulatory adherence, and cost-effectiveness across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for ip68 led strip

Manufacturing Processes for IP68 LED Strip Lights

The production of IP68 LED strip lights involves a series of precise and controlled manufacturing stages designed to ensure durability, waterproofing, and consistent lighting performance. These stages can be broadly categorized into material preparation, forming, assembly, and finishing.

1. Material Preparation

This initial phase involves sourcing high-quality raw materials critical to achieving the IP68 waterproof rating and optimal LED performance. Key materials include:

- Flexible PCB substrates (usually copper-clad polyimide or fiberglass) designed for heat dissipation.

- High-grade LEDs with specific lumen output, color temperature, and efficiency.

- Encapsulation materials such as silicone or epoxy resins, which provide waterproofing and environmental protection.

- Copper connectors and solder materials compliant with RoHS standards.

Material suppliers are typically vetted for certifications and traceability to ensure consistent quality. For international buyers, understanding the provenance and compliance of these materials is crucial, especially for markets with strict import regulations like the EU.

2. Forming and Patterning

In this stage, the flexible PCB is patterned through photolithography and etching processes to define the circuit paths. Precision is essential to ensure the electrical pathways are robust and meet design specifications.

- Surface Mount Technology (SMT) is used to place LEDs and other components accurately on the PCB.

- Automated pick-and-place machines enhance precision and throughput.

- Soldering processes (e.g., reflow soldering) secure components firmly while minimizing thermal stress.

Ensuring consistent component placement and solder quality reduces failure rates during operation, a key consideration for buyers prioritizing product longevity.

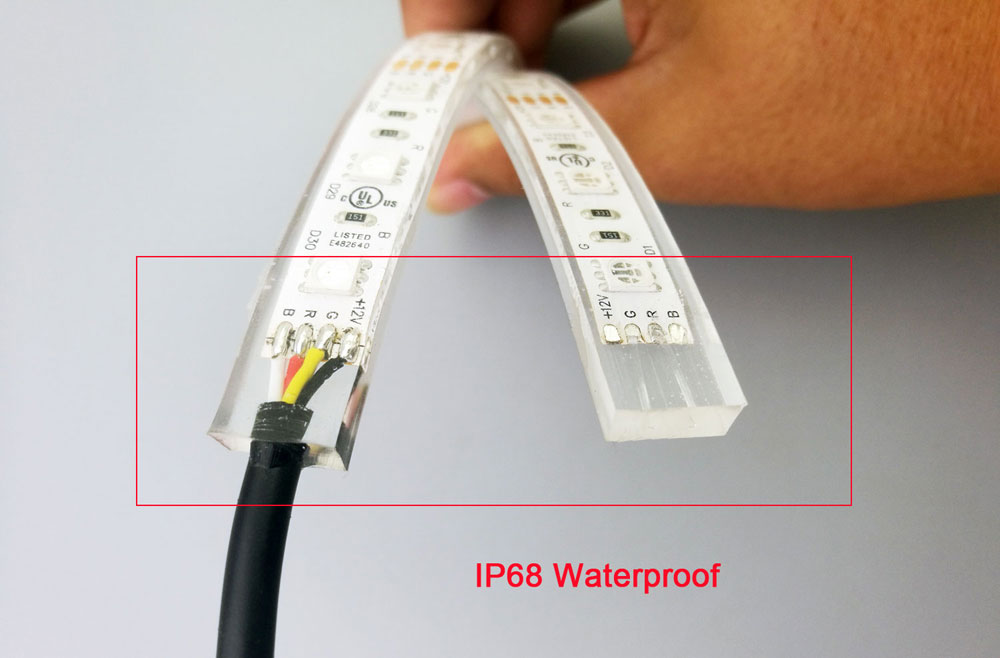

3. Assembly and Encapsulation

Assembly focuses on sealing the LED strip to meet the IP68 rating, which guarantees protection against dust ingress and water immersion beyond 1 meter.

- Encapsulation is performed using high-grade silicone or polyurethane gels, applied evenly over the LED strip.

- Advanced potting or coating techniques ensure no air bubbles or gaps, which could compromise waterproofing.

- The encapsulated strips undergo curing processes, often involving controlled temperature and humidity to stabilize the materials.

This stage also includes attaching connectors, cutting the strips to length, and adding any additional functional elements (e.g., controllers for dimming or color change).

4. Finishing and Packaging

Final steps involve:

- Cutting the strips to custom lengths and adding mounting options like adhesive backing or brackets.

- Applying protective coatings or films to enhance UV resistance and mechanical durability.

- Packaging designed to minimize damage during shipping, often including moisture barriers and anti-static materials.

For international shipments, packaging must comply with customs and transportation standards to prevent damage and contamination.

Quality Assurance (QA) and Quality Control (QC) Frameworks

Maintaining high standards throughout the manufacturing process is critical for IP68 LED strip lights, especially for B2B buyers who require reliable, long-lasting products for diverse markets.

Relevant International and Industry Standards

- ISO 9001: The global benchmark for quality management systems. Suppliers certified under ISO 9001 demonstrate consistent process control, documentation, and continuous improvement practices.

- CE Marking: Mandatory for products entering the European Economic Area, indicating compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical products, important for European and many international markets.

- IP68 Certification: Specific to ingress protection, ensuring waterproofing and dust resistance. Testing follows IEC 60529 standards.

- Other Regional Standards: Buyers in the Middle East, Africa, and South America should verify compliance with local regulations, which may include additional certifications or testing criteria.

Key QC Checkpoints During Manufacturing

-

Incoming Quality Control (IQC)

– Verification of raw materials and components upon arrival.

– Checks for material certificates, batch consistency, and physical inspections.

– Essential for preventing defects from entering the production line. -

In-Process Quality Control (IPQC)

– Continuous monitoring during PCB patterning, SMT placement, and soldering.

– Inspection of solder joints, component alignment, and encapsulation uniformity.

– Use of automated optical inspection (AOI) and functional testing at various stages. -

Final Quality Control (FQC)

– Comprehensive testing of finished products.

– Visual inspection for defects, measurement of electrical parameters (e.g., voltage, current, luminous intensity).

– Waterproof testing under pressure and immersion conditions to confirm IP68 compliance.

– Thermal cycling and durability tests simulate real-world usage.

Common Testing Methods for IP68 LED Strip Lights

- Waterproof Testing: Submersion in water tanks for extended periods, often under pressure, to simulate harsh environmental conditions.

- Electrical Testing: Verifying LED functionality, power consumption, and circuit integrity.

- Mechanical Stress Testing: Bending, twisting, and vibration tests to ensure flexible PCB resilience.

- Thermal Testing: Assessing heat dissipation and performance stability under elevated temperatures.

- Photometric Testing: Measuring light output, color consistency, and beam angle according to industry standards.

How B2B Buyers Can Verify Supplier Quality Control

International buyers, particularly from Africa, South America, the Middle East, and Europe, should adopt a multi-faceted approach to QC verification:

- Factory Audits: Conduct or commission on-site audits to review manufacturing processes, equipment, and QC protocols. Third-party inspection firms specializing in electronics manufacturing can provide unbiased assessments.

- Review of Quality Documentation: Request ISO 9001 certificates, CE documentation, RoHS compliance reports, and IP test certificates. Ensure these are current and issued by accredited bodies.

- Sample Testing: Obtain product samples for independent laboratory testing in the buyer’s country or region to validate waterproofing, electrical safety, and performance claims.

- Production Monitoring: Engage suppliers that provide real-time production updates, photos, and QC reports during key manufacturing stages.

- Third-Party Inspection Services: Utilize services that perform pre-shipment inspections covering quantity verification, packaging checks, and functional testing.

QC and Certification Nuances for International Markets

- Europe (e.g., Poland, Germany): Emphasis on CE marking, RoHS compliance, and adherence to strict environmental directives. Buyers should prioritize suppliers with transparent documentation and access to EU-based testing labs.

- Middle East and Africa: Regulatory requirements may vary widely; however, durability and IP ratings are critical due to harsh climates. Buyers often require extended warranties and robust after-sales support.

- South America: Import regulations may be less stringent but are evolving. Certification acceptance varies, so buyers should clarify requirements upfront and consider local testing to avoid customs delays.

- Cross-border Logistics: Packaging must meet international shipping standards to prevent moisture ingress or mechanical damage, which could invalidate IP68 claims.

Strategic Recommendations for B2B Buyers

- Partner with manufacturers offering customizable IP68 LED strips to meet specific environmental and application needs.

- Prioritize suppliers with integrated in-house testing labs and certifications aligned with your target markets.

- Implement a supplier qualification program that includes factory audits, sample testing, and continuous quality monitoring.

- Understand local and regional standards to avoid compliance pitfalls and ensure smooth market entry.

- Consider long-term relationships with manufacturers who demonstrate transparency, flexibility on MOQ, and proactive QC communication.

By thoroughly understanding the manufacturing processes and quality assurance frameworks, international B2B buyers can confidently source IP68 LED strip lights that meet demanding standards and perform reliably in diverse environments.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for ip68 led strip Sourcing

Cost Components in IP68 LED Strip Procurement

When sourcing IP68 LED strips, understanding the detailed cost breakdown is crucial for informed decision-making. The primary cost components include:

- Materials: High-grade waterproof silicone or epoxy coatings for IP68 rating, quality LED chips, flexible PCB substrates, and reliable connectors drive material costs. Premium materials increase durability and performance but raise upfront expenses.

- Labor: Skilled assembly, especially for waterproofing and sealing, involves higher labor costs compared to standard LED strips. Labor intensity varies by manufacturer location and expertise.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and quality assurance processes. Advanced testing for IP68 compliance (e.g., immersion tests) adds overhead.

- Tooling and Setup: Custom molds or extrusion tools for waterproof encapsulation and specialized assembly lines require initial investment, often amortized over large orders.

- Quality Control (QC): Rigorous QC is mandatory to ensure IP68 integrity. Costs involve both in-line inspections and final testing, including certifications.

- Logistics and Shipping: Waterproof LED strips are typically shipped in bulk, with packaging designed to prevent damage and moisture ingress. Shipping costs fluctuate based on destination, transport mode, and customs procedures.

- Supplier Margin: Manufacturer profit margins vary but typically range between 10-30%, influenced by order volume and relationship strength.

Key Price Influencers for IP68 LED Strip Sourcing

Several factors significantly affect pricing, and B2B buyers must carefully evaluate these to optimize procurement:

- Order Volume and Minimum Order Quantity (MOQ): Larger volumes usually attract substantial discounts. However, MOQ requirements can vary widely; buyers from smaller markets (e.g., certain African or South American regions) should negotiate flexible MOQs to reduce inventory risks.

- Specifications and Customization: Custom lengths, color temperatures, brightness levels, and additional features (like smart controls) increase costs. IP68-rated strips with enhanced durability and specialized coatings command premium pricing.

- Materials Quality: The choice between mid-range and premium LED chips or waterproofing materials directly impacts both cost and lifespan.

- Certifications and Compliance: Products certified for international standards (CE, RoHS, UL) may cost more but facilitate smoother market entry in Europe and the Middle East.

- Supplier Location and Capabilities: Established manufacturers with in-house engineering and testing facilities may price higher but provide reliability and faster turnaround. Sourcing from regions with lower labor costs can reduce prices but may increase risks related to quality or delivery.

- Incoterms and Payment Terms: Terms such as FOB, CIF, or DDP influence total landed cost. Buyers in Europe, Africa, or South America should assess import duties, taxes, and customs clearance complexities when comparing supplier quotes.

Strategic Buyer Tips for Cost-Efficient IP68 LED Strip Procurement

To maximize value and minimize risks in international B2B transactions, consider the following actionable insights:

- Negotiate MOQ and Pricing Tiers: Engage suppliers early to explore flexible MOQs and tiered pricing, especially if your market size is modest. This flexibility is often negotiable with reputable manufacturers.

- Evaluate Total Cost of Ownership (TCO): Beyond unit price, consider warranty terms, expected lifespan, maintenance costs, and energy efficiency. IP68 strips with slightly higher upfront costs but superior durability can reduce long-term expenses.

- Leverage Supplier Expertise: Prioritize manufacturers offering design support and fast prototyping to reduce development costs and accelerate time-to-market.

- Factor in Logistics and Customs: For buyers in Africa, South America, and the Middle East, shipping reliability and import procedures can add hidden costs. Collaborate with freight forwarders experienced in LED lighting products.

- Understand Pricing Nuances by Region: European buyers (e.g., Poland, Germany) often require strict compliance and documentation, potentially increasing cost but facilitating market acceptance. African and South American buyers may prioritize cost-efficiency and supplier responsiveness.

- Request Transparent Cost Breakdowns: Insist on detailed quotations to identify cost drivers and areas for negotiation. This transparency aids in benchmarking and supplier comparisons.

- Plan for Currency Fluctuations and Payment Security: Use contracts that mitigate currency risk and incorporate secure payment methods to protect investments in volatile markets.

Disclaimer on Pricing Information

Prices for IP68 LED strips vary widely depending on specifications, order size, supplier capabilities, and global market conditions. The information provided here serves as an indicative framework rather than exact pricing. Buyers are encouraged to conduct direct supplier inquiries and request customized quotations tailored to their specific requirements and regional considerations.

Spotlight on Potential ip68 led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ip68 led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ip68 led strip

Key Technical Properties of IP68 LED Strips

When sourcing IP68 LED strips for international B2B transactions, understanding critical technical properties ensures the product meets your operational and environmental requirements. Here are the essential specs to evaluate:

-

Ingress Protection Rating (IP68)

This rating certifies the LED strip’s resistance to dust ingress and prolonged water immersion (typically beyond 1 meter). For buyers in humid climates or outdoor applications—common in Africa, the Middle East, and South America—IP68 guarantees durability and longevity under harsh conditions, reducing maintenance and replacement costs. -

Material Grade and Encapsulation

High-quality IP68 LED strips use durable, UV-resistant silicone or polyurethane coatings for encapsulation. These materials protect internal components from corrosion, mechanical stress, and UV damage. For European markets with strict environmental standards, material compliance and longevity are crucial for warranty and regulatory adherence. -

Voltage and Power Specifications

Commonly available in 12V or 24V options, these affect installation complexity and energy consumption. Understanding voltage tolerance and power draw per meter helps buyers plan power supply logistics and ensures compatibility with existing electrical infrastructure, important for large-scale commercial projects. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvin) defines the light’s warmth or coolness, typically ranging from 2700K (warm) to 6500K (daylight). CRI measures color accuracy; a higher CRI (above 80) is vital for retail and hospitality sectors in Europe and the Middle East where lighting quality impacts customer experience. -

Cutting and Connection Flexibility

IP68 LED strips should allow cutting at designated points without compromising waterproofing. Additionally, connectors and soldering points must maintain IP68 integrity. This flexibility supports customized lengths and complex installations, which is particularly relevant for infrastructure projects in diverse geographic regions. -

Tolerance and Lifespan

Quality strips maintain consistent brightness and color over 30,000+ hours with minimal voltage drop. Tolerance to temperature fluctuations and electrical surges is also critical for regions with unstable power grids, such as some parts of Africa and South America.

Common Industry and Trade Terminology for IP68 LED Strips

Understanding key trade terms streamlines communication and negotiation with suppliers, minimizing misunderstandings and optimizing procurement processes.

-

OEM (Original Equipment Manufacturer)

This refers to companies that produce LED strips which can be rebranded or customized for different clients. Buyers seeking tailored solutions or private labeling in markets like Germany or Poland should clarify OEM capabilities early to ensure product differentiation and brand consistency. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity a supplier is willing to sell. For international buyers, especially startups or regional distributors in Africa and South America, negotiating flexible MOQs can reduce upfront investment and inventory risks while testing market acceptance. -

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers detailing product specifications and order quantities to receive pricing and terms. Precision in RFQs is crucial to obtain competitive offers and avoid costly discrepancies, particularly when sourcing from multiple countries with varying trade practices. -

Incoterms (International Commercial Terms)

These standardized trade terms define responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms like FOB (Free on Board) and CIF (Cost, Insurance, Freight) impact total landed cost. Understanding Incoterms helps buyers in Europe and the Middle East manage logistics efficiently and budget accurately. -

Bin Picking

A term related to automated assembly, referring to the process of picking components (like LED strips) from bulk packaging. For large-scale distributors, ensuring supplier packaging supports bin picking can enhance warehouse efficiency and reduce handling damage. -

DLC and CE Certifications

Certifications like DLC (DesignLights Consortium) and CE (Conformité Européenne) indicate compliance with energy efficiency and safety standards. These are essential for buyers targeting regulated markets such as the EU, ensuring products meet local legal requirements and customer expectations.

By focusing on these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing IP68 LED strips. This leads to optimized product performance, smoother supply chain operations, and better alignment with regional market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ip68 led strip Sector

Market Overview & Key Trends

The global IP68 LED strip market is experiencing robust growth driven by increasing demand for durable, waterproof lighting solutions across diverse industries including automotive, marine, architectural, and outdoor advertising. IP68-rated LED strips, known for their superior resistance to dust and water immersion, are particularly favored in regions with harsh environmental conditions such as Africa’s tropical climates, the Middle East’s desert environments, and Europe’s variable weather zones.

Key market drivers include the rising adoption of smart lighting technologies and the integration of LED strips with IoT systems for enhanced control and energy efficiency. Buyers in South America and Africa are increasingly prioritizing solutions that combine durability with smart features, enabling remote monitoring and customization. Meanwhile, European markets, especially in countries like Germany and Poland, focus heavily on compliance with stringent safety and energy standards, pushing suppliers to innovate in quality assurance and certification.

Sourcing trends highlight a growing preference for custom LED strip solutions tailored to specific industrial or architectural needs. B2B buyers are seeking manufacturers with in-house engineering capabilities that can offer flexible minimum order quantities (MOQs) and rapid prototyping. This flexibility is crucial for businesses in emerging markets where project scopes often evolve quickly. Additionally, supply chain resilience has become a focal point amid global disruptions, prompting buyers to vet manufacturers based on their logistics agility and local support networks.

For international buyers, market dynamics emphasize the importance of thorough supplier evaluation, including product testing certifications (e.g., CE, RoHS) and after-sales support. In regions like the Middle East and Europe, long-term partnerships with manufacturers who demonstrate technical expertise and environmental compliance are essential. The demand for IP68 LED strips is also influenced by growing infrastructure investments and urban development projects, particularly in South America and Africa.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor for B2B buyers in the IP68 LED strip sector, driven by increasing regulatory pressure and corporate social responsibility commitments. The environmental impact of LED strip production spans material sourcing, manufacturing processes, energy consumption during use, and end-of-life disposal.

Ethical sourcing begins with selecting manufacturers that prioritize eco-friendly materials such as lead-free solder, halogen-free substrates, and recyclable components. Buyers from Europe and the Middle East often require suppliers to adhere to strict environmental standards, including compliance with the EU’s RoHS and REACH directives, ensuring hazardous substances are minimized or eliminated.

Green certifications are a valuable differentiator in supplier selection. Certifications like ISO 14001 (Environmental Management Systems) and ENERGY STAR can assure buyers of a manufacturer’s commitment to reducing carbon footprint and energy-efficient product design. Additionally, sourcing IP68 LED strips with high luminous efficacy and long lifespan reduces waste and energy consumption, aligning with sustainability goals.

For emerging markets in Africa and South America, sustainable sourcing also means supporting local economies and ensuring transparent supply chains free from labor exploitation. Ethical supply chains improve brand reputation and mitigate risks associated with regulatory fines or consumer backlash. Buyers are increasingly conducting supplier audits and demanding full supply chain traceability to verify social and environmental compliance.

Brief Evolution and Historical Context

The evolution of IP68 LED strips reflects broader advancements in LED technology and waterproofing standards. Initially, LED strips were primarily designed for indoor use with minimal protection against moisture. However, growing demand for outdoor and industrial applications spurred innovations in encapsulation materials and sealing techniques, enabling the development of IP65, IP67, and ultimately IP68-rated products.

The IP68 rating, indicating protection against continuous immersion in water beyond one meter, became a benchmark for quality and durability in challenging environments. Over the past decade, manufacturers have integrated smarter control options and improved thermal management to enhance performance and lifespan. This evolution has made IP68 LED strips indispensable for sectors requiring reliable, energy-efficient lighting that withstands exposure to dust, water, and mechanical stress.

For B2B buyers, understanding this progression underscores the importance of selecting products from manufacturers with proven expertise in both LED technology and environmental protection standards, ensuring investments in IP68 LED strips yield long-term operational benefits.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of ip68 led strip

-

How can I effectively vet suppliers of IP68 LED strips for international B2B purchases?

To vet suppliers, start by verifying their manufacturing capabilities and certifications such as ISO, CE, or RoHS to ensure quality and compliance. Request product samples to assess build quality and IP68 waterproofing standards firsthand. Check their export experience, particularly with your region (Africa, South America, Middle East, Europe), to confirm familiarity with local regulations and logistics. Evaluate their communication responsiveness and after-sales support. Utilize third-party audits or inspections for added assurance. Finally, review client testimonials or case studies to verify reliability and reputation in the global market. -

What customization options are typically available for IP68 LED strips in B2B orders?

Manufacturers often offer customization in length, LED density, color temperature, voltage, and connector types to suit specific applications. You can also request customized silicone or PU coatings for enhanced waterproofing and durability in harsh environments. Smart features like DMX control, RGB color options, or integration with IoT systems are increasingly available. Branding options such as private labeling or custom packaging are common for larger orders. Always discuss your technical requirements early with the supplier to ensure feasibility and obtain accurate lead time and cost estimates. -

What are typical minimum order quantities (MOQs) and lead times for IP68 LED strips when sourcing internationally?

MOQs vary widely depending on the manufacturer’s scale and customization level, ranging from a few hundred meters to several thousand. For custom orders, expect higher MOQs and lead times of 4–8 weeks due to prototyping and testing. Standard products may ship faster, typically within 2–4 weeks. When ordering from suppliers in Asia or Europe, factor in additional time for international shipping and customs clearance, which can add 1–3 weeks. Negotiate with suppliers for flexible MOQs if you are entering new markets or testing product viability. -

Which payment terms are common and advisable when dealing with international IP68 LED strip suppliers?

Common terms include a 30%-50% deposit upfront with the balance paid upon shipment or receipt of goods. Letters of Credit (LC) provide security for both parties but may incur additional banking costs. For trusted suppliers, Net 30 or Net 60 payment terms can be negotiated to improve cash flow. Use secure payment methods like PayPal, T/T (telegraphic transfer), or escrow services to mitigate risk. Always confirm payment terms in your contract, and avoid full upfront payments without verified supplier credentials or references. -

What quality assurance measures should B2B buyers expect from IP68 LED strip manufacturers?

Reputable suppliers conduct rigorous testing, including waterproof testing (IP68 standard compliance), durability under temperature extremes, and electrical safety checks. They should provide certifications like CE, RoHS, UL, or equivalent that comply with your regional standards. Factory audits and third-party inspection reports add an extra layer of assurance. Request documentation of batch testing and traceability for components. Quality assurance should also cover packaging integrity to prevent damage during transit, especially for international shipments. -

How can I manage logistics and shipping challenges when importing IP68 LED strips internationally?

Choose suppliers experienced with international freight forwarding and customs processes. Determine the best shipping method based on cost, speed, and product sensitivity—air freight is faster but costlier, while sea freight is economical for large volumes but slower. Clarify Incoterms (e.g., FOB, CIF, DDP) to understand your responsibilities and costs. Work with freight forwarders who specialize in your target regions (Africa, South America, Middle East, Europe) to navigate customs efficiently. Plan for potential delays and ensure clear communication with suppliers about shipping schedules. -

What certifications are critical for IP68 LED strips to comply with regulations in Europe, the Middle East, Africa, and South America?

CE marking is essential for Europe, ensuring conformity with EU safety and environmental directives. RoHS compliance restricts hazardous substances and is widely required. UL or ETL certifications demonstrate electrical safety, important for Middle Eastern and North American standards. For Africa and South America, local certifications may apply, such as INMETRO in Brazil or SON in Nigeria. Confirm with your supplier that products come with valid certificates recognized in your target market to avoid customs issues and ensure market acceptance.

Illustrative Image (Source: Google Search)

- How should disputes or product quality issues be handled in international B2B transactions for IP68 LED strips?

Establish clear contractual terms outlining quality standards, inspection protocols, and dispute resolution mechanisms before ordering. Use third-party inspection agencies to verify product quality before shipment. In case of disputes, engage in direct negotiation first, supported by documented evidence such as inspection reports and communication records. Arbitration clauses can provide a neutral and enforceable resolution path. Maintain open communication with suppliers to resolve issues amicably and consider sourcing from manufacturers with proven track records in after-sales support and warranty services.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ip68 led strip

The strategic sourcing of IP68 LED strips presents a compelling opportunity for international B2B buyers seeking durable, high-performance lighting solutions that meet stringent environmental standards. Key considerations include selecting manufacturers with robust in-house engineering capabilities, flexible minimum order quantities, and proven expertise in delivering customized products tailored to diverse climatic and application needs. Buyers from Africa, South America, the Middle East, and Europe must prioritize partners who offer comprehensive testing, certification support, and fast prototyping to mitigate risks and accelerate time-to-market.

Key takeaways for B2B buyers:

- Customization and adaptability are critical to address regional environmental challenges and regulatory requirements.

- Supply chain resilience depends on transparent communication and strategic partnerships with manufacturers capable of flexible production and reliable delivery.

- Certification and quality assurance are non-negotiable to ensure compliance and long-term operational reliability.

Looking ahead, the demand for IP68 LED strips is expected to grow alongside increasing infrastructure development and smart city initiatives worldwide. Buyers should proactively engage with manufacturers who emphasize innovation, sustainability, and end-to-end service excellence. By adopting a strategic sourcing approach that balances quality, cost, and agility, international buyers can secure competitive advantage and future-proof their lighting investments in evolving markets.