Introduction: Navigating the Global Market for fixing led strip lights

In today’s rapidly evolving lighting industry, fixing LED strip lights is more than a technical necessity—it is a strategic imperative for businesses seeking to deliver durable, high-performance lighting solutions. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of LED strip light fixing is crucial to ensuring product longevity, customer satisfaction, and competitive advantage in their respective markets.

This comprehensive guide delves deeply into every aspect of fixing LED strip lights, providing actionable insights tailored to the global supply chain. Buyers will gain clarity on various types of LED strip lights, including waterproof, high-CRI, and color-changing options, alongside the critical materials and components required for effective installation and maintenance. We explore manufacturing standards and quality control protocols that distinguish reliable suppliers from less consistent vendors, empowering buyers to mitigate risks in sourcing.

Additionally, the guide covers cost considerations, market trends, and supplier evaluations, enabling buyers to optimize procurement strategies while navigating regional challenges such as logistics, compliance, and after-sales support. A dedicated FAQ section addresses common technical and commercial questions, streamlining decision-making for buyers across diverse industries and geographies.

By equipping you with this knowledge, the guide transforms the complex landscape of LED strip light fixing into a manageable, transparent process—helping you source confidently, reduce operational setbacks, and enhance your product offerings on a global scale. Whether your business operates in Colombia, Indonesia, or beyond, this resource is designed to support your success in the competitive international lighting market.

Understanding fixing led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adhesive-Backed LED Strips | Flexible strips with self-adhesive backing for easy mounting | Retail displays, office lighting, residential | Pros: Easy installation, cost-effective Cons: Adhesive may degrade in humid or dusty environments |

| Mounting Channel LED Strips | LED strips installed within aluminum or plastic channels | Commercial interiors, architectural lighting | Pros: Enhanced heat dissipation, professional finish Cons: Higher upfront cost, requires mounting hardware |

| Magnetic LED Strips | Strips with magnetic backing for attachment to metal surfaces | Industrial settings, temporary setups | Pros: Reusable, easy repositioning Cons: Limited to ferromagnetic surfaces, lower holding strength |

| Clip or Bracket Mounted | LED strips fixed using clips or brackets for secure hold | Outdoor lighting, signage, automotive | Pros: Strong mechanical hold, suitable for rough conditions Cons: More complex installation, additional hardware needed |

| Waterproof LED Strips | Encased in silicone or epoxy for water resistance | Outdoor, marine, wet environment lighting | Pros: Durable in harsh environments, IP rated Cons: Slightly reduced light output, higher cost |

Adhesive-Backed LED Strips

These are the most common type used in a variety of applications due to their flexibility and ease of installation. The self-adhesive backing allows quick mounting on smooth surfaces without additional hardware. For B2B buyers in emerging markets like Africa or South America, these strips offer a low-cost, scalable solution ideal for retail or residential projects. However, buyers should verify adhesive quality for environments with high humidity or dust to avoid premature detachment.

Mounting Channel LED Strips

Designed for professional-grade installations, these LED strips are housed in aluminum or plastic channels that protect the strips and aid heat dissipation, enhancing longevity. They are preferred in commercial and architectural projects across Europe and the Middle East where regulatory standards and aesthetics are critical. B2B buyers should consider the additional cost of channels and installation labor but benefit from improved durability and a premium finish.

Magnetic LED Strips

These strips come with magnetic backing, enabling quick attachment and removal on metal surfaces. Ideal for industrial or temporary lighting setups, magnetic strips provide flexibility and ease of repositioning. Buyers targeting industrial clients in regions like Indonesia or Colombia will appreciate the convenience, though magnetic strips are limited to ferromagnetic substrates and may not hold firmly under vibration or movement.

Clip or Bracket Mounted LED Strips

For applications requiring a robust and secure fixing, especially in outdoor or automotive environments, clips or brackets are used. This method ensures the strips remain firmly in place despite environmental stressors such as wind or vibration. B2B buyers focusing on outdoor infrastructure or vehicle lighting should prepare for a more involved installation process and factor in additional hardware costs.

Waterproof LED Strips

Encased in protective silicone or epoxy, waterproof LED strips are essential for outdoor, marine, or wet environment applications. They comply with IP ratings ensuring resistance to water and dust ingress, making them suitable for harsh climates prevalent in many African and Middle Eastern countries. While offering excellent durability, buyers should note these strips may have slightly lower brightness and come at a premium price, justified by their extended service life and reliability.

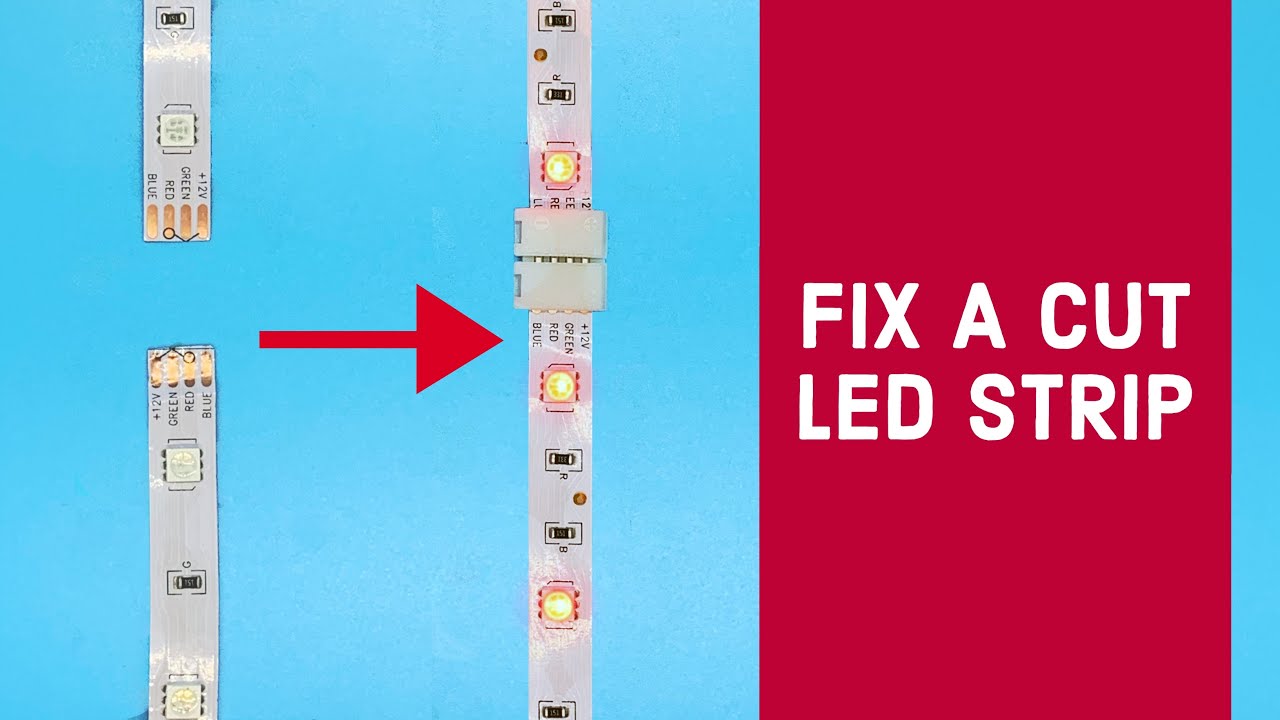

Related Video: How do I repair my damaged LED strip lights? Push connectors repair

Key Industrial Applications of fixing led strip lights

| Industry/Sector | Specific Application of fixing led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in retail fixtures and shelving | Enhances product visibility, attracts customers, and boosts sales | Durable, consistent color temperature, easy installation, and energy efficiency |

| Hospitality & Tourism | Ambient and decorative lighting in hotels, restaurants, and bars | Creates inviting atmospheres, improves guest experience | Waterproof options, customizable colors, compliance with local electrical standards |

| Manufacturing & Warehousing | Task and safety lighting in assembly lines and storage areas | Improves worker productivity and safety, reduces accidents | High brightness, robust mounting solutions, long service life |

| Architecture & Interior Design | Cove and under-cabinet lighting for aesthetic and functional purposes | Provides flexible design options and energy savings | Flexible mounting options, dimmability, color rendering index (CRI) |

| Transportation & Infrastructure | Lighting for signage, pathways, and vehicle interiors | Enhances safety and visibility, reduces maintenance costs | Weatherproofing, vibration resistance, compatibility with control systems |

Retail & Commercial Applications

In retail environments across Africa, South America, the Middle East, and Europe, fixing LED strip lights are widely used to highlight products on shelves and within display cabinets. These strips provide uniform, bright illumination that draws customer attention, increasing product appeal and sales potential. B2B buyers should prioritize strips with high color accuracy and energy efficiency to reduce operational costs. Additionally, ease of installation and maintenance is critical for stores with frequent layout changes.

Hospitality & Tourism Applications

Hotels, restaurants, and bars benefit from LED strip lights by creating ambient and decorative lighting that enhances the guest experience. Waterproof and customizable LED strips allow for creative lighting solutions in areas such as poolside bars or outdoor terraces, common in regions like the Middle East and South America. Buyers must ensure compliance with local safety standards and opt for strips with dimmable and color-changing features to adapt lighting moods efficiently.

Manufacturing & Warehousing Applications

In industrial settings, LED strip lights are fixed along assembly lines, workbenches, and storage racks to improve visibility and workplace safety. High brightness and durable mounting systems are essential to withstand harsh environments often found in manufacturing plants in Europe and Africa. International buyers should consider strips with long operational lifespans and robust heat dissipation to minimize downtime and maintenance expenses.

Architecture & Interior Design Applications

Architects and interior designers use fixing LED strip lights for cove lighting, under-cabinet illumination, and accentuating architectural features. These applications demand flexible strips that can conform to various surfaces and offer excellent color rendering to enhance interior aesthetics. For B2B buyers in regions like Colombia and Indonesia, it is important to source products that support dimming and can be integrated with smart control systems for modern building projects.

Transportation & Infrastructure Applications

LED strip lights are increasingly used in transportation for signage illumination, pathway lighting, and vehicle interiors, improving safety and visibility. This is particularly relevant in infrastructure projects across Europe and the Middle East where energy-efficient and weather-resistant lighting solutions are required. Buyers should focus on strips with strong waterproofing, vibration resistance, and compatibility with existing control systems to ensure long-term performance in demanding environments.

Related Video: Do LED strip lights get hot? – Why use a profile as a heatsink?

Strategic Material Selection Guide for fixing led strip lights

When selecting materials to fix LED strip lights, international B2B buyers must consider performance, durability, cost, and regional compliance. The choice of fixing material directly impacts installation efficiency, longevity, and suitability for diverse environmental conditions across Africa, South America, the Middle East, and Europe.

Aluminum Mounting Channels

Key Properties: Aluminum offers excellent thermal conductivity, aiding heat dissipation from LED strips, which enhances lifespan and performance. It has high corrosion resistance, especially when anodized, and can withstand temperatures up to 200°C. Aluminum is lightweight yet structurally robust, suitable for various mounting surfaces.

Pros & Cons: Aluminum channels provide a professional finish and protect LED strips from physical damage and dust. They simplify installation and improve heat management. However, manufacturing complexity and anodizing treatment can increase costs. In harsh environments with salt exposure (e.g., coastal regions in South America or the Middle East), anodized aluminum resists corrosion better than raw aluminum.

Impact on Application: Ideal for commercial and architectural lighting projects requiring clean aesthetics and durability. Aluminum channels are compatible with most LED strip types and can be cut to size easily, facilitating modular installations.

International Considerations: Buyers in Europe and the Middle East should verify compliance with EN and DIN standards for aluminum products, ensuring quality and safety. In Africa and South America, sourcing anodized aluminum locally may be limited, affecting lead times and cost. Importers should assess supply chain reliability and customs tariffs.

Double-Sided Adhesive Tapes (3M VHB and Equivalent)

Key Properties: High-bond acrylic adhesive tapes offer strong initial tack and long-term adhesion, with temperature resistance typically between -40°C and 150°C. They provide vibration damping and moisture resistance but have limited mechanical strength compared to rigid fixings.

Pros & Cons: Adhesive tapes enable quick, tool-free installation on smooth, clean surfaces, reducing labor costs. They are cost-effective and lightweight but may fail on rough, dusty, or oily surfaces common in industrial or outdoor settings. Prolonged UV exposure in equatorial regions (e.g., Indonesia or Colombia) can degrade adhesive strength.

Impact on Application: Best suited for indoor applications on non-porous surfaces like glass, metal, or polished wood. Not recommended for outdoor or high-humidity environments without additional protective measures.

International Considerations: Buyers should ensure tapes meet ASTM D1000 or equivalent standards for adhesive performance. In regions with high temperatures or humidity, testing adhesive durability before large-scale deployment is advisable. Local availability of branded tapes like 3M varies, so alternatives must be evaluated for quality consistency.

Plastic Mounting Clips (PVC or Polycarbonate)

Key Properties: Plastic clips are lightweight, electrically insulating, and resistant to moisture and many chemicals. Polycarbonate variants offer higher impact resistance and UV stability, with temperature tolerance up to 120°C, while PVC is less heat-resistant but more economical.

Pros & Cons: Clips allow easy removal and repositioning of LED strips, facilitating maintenance and upgrades. They are low-cost and simple to manufacture but may become brittle under prolonged UV exposure or extreme cold, limiting outdoor use. PVC clips may emit harmful gases if burned, raising environmental concerns.

Impact on Application: Suitable for flexible installations where strips need to be secured without adhesives or permanent fixtures, such as temporary displays or retail environments.

International Considerations: Compliance with RoHS and REACH regulations is critical in Europe to avoid restricted substances. For buyers in Africa and South America, local environmental regulations may be less stringent but should be anticipated for export markets. Polycarbonate clips are preferred in Middle Eastern markets for outdoor durability.

Stainless Steel Screws and Brackets

Key Properties: Stainless steel offers exceptional corrosion resistance, mechanical strength, and temperature tolerance beyond 300°C. Grades like 304 and 316 are common, with 316 preferred for marine or highly corrosive environments.

Pros & Cons: Screws and brackets provide the most secure fixing method, suitable for heavy-duty or outdoor installations. They resist deformation and environmental degradation but require more installation time and skilled labor. Cost and weight are higher compared to adhesives or plastic fixings.

Impact on Application: Ideal for industrial, outdoor, or architectural LED strip installations exposed to harsh weather or mechanical stress. They ensure long-term stability and safety.

International Considerations: Buyers in coastal or humid regions (e.g., parts of Africa and South America) should specify 316 stainless steel to prevent corrosion. Compliance with ASTM A276 or equivalent standards is essential for quality assurance. European buyers must also consider CE marking and environmental impact during procurement.

Summary Table

| Material | Typical Use Case for fixing led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Mounting Channels | Professional architectural and commercial lighting installations | Excellent heat dissipation and corrosion resistance | Higher cost and supply chain complexity | High |

| Double-Sided Adhesive Tapes | Indoor, smooth surface installations requiring quick application | Easy, fast installation with good adhesion | Limited outdoor durability and surface compatibility | Low |

| Plastic Mounting Clips | Flexible, temporary, or maintenance-friendly installations | Lightweight, reusable, and cost-effective | UV degradation and lower mechanical strength | Low |

| Stainless Steel Screws and Brackets | Heavy-duty, outdoor, and industrial LED strip fixings | Superior strength and corrosion resistance | Higher cost, heavier, and requires skilled installation | Medium |

This guide equips international B2B buyers with critical insights to select fixing materials tailored to their project environments and regional market demands, balancing performance, compliance, and cost-effectiveness.

In-depth Look: Manufacturing Processes and Quality Assurance for fixing led strip lights

The manufacturing and quality assurance of fixing LED strip lights involve a series of meticulously coordinated processes to ensure durability, performance, and compliance with international standards. For B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, understanding these processes is critical for selecting reliable suppliers and ensuring product longevity in diverse markets.

Manufacturing Process Overview

1. Material Preparation

The process begins with sourcing and preparing high-quality raw materials. This includes flexible printed circuit boards (PCBs), LED chips, resistors, capacitors, adhesives, and protective coatings. The PCB must be precisely engineered for optimal conductivity and flexibility, often using copper layers laminated onto flexible substrates such as polyimide or polyester films. Material suppliers should provide certifications confirming the purity and performance of components.

2. Forming and PCB Fabrication

Flexible PCBs are fabricated through photolithography and etching processes that define the LED circuit paths. Advanced techniques like surface mount technology (SMT) place LED chips and electronic components with high precision. Automated pick-and-place machines ensure consistent placement, which is vital for uniform light output and electrical reliability. For fixing LED strips, the PCB design often includes pre-cut segments and reinforced mounting points to facilitate installation and repairs.

3. Assembly

Assembly involves soldering the LED chips and components onto the PCB, followed by the integration of connectors, resistors, and sometimes control modules for dimming or color changing. The assembly line typically employs wave soldering or reflow soldering techniques to secure components efficiently. Protective elements such as silicone coatings or epoxy resins are applied to enhance waterproofing and mechanical strength, especially for outdoor or industrial applications.

4. Finishing and Packaging

The finishing stage includes cutting the strips to standard lengths, attaching adhesive backings, and applying protective films or housings. LED strips may be integrated into mounting channels or enclosures designed for heat dissipation and easy fixing. Packaging is done in anti-static, moisture-proof materials to preserve product integrity during transport, which is especially important for international shipments.

Quality Assurance and Control (QA/QC)

Quality assurance in LED strip manufacturing is comprehensive, addressing each stage from raw materials to final product testing. B2B buyers must insist on suppliers adhering to internationally recognized standards and employing rigorous QC checkpoints.

Relevant International Standards

- ISO 9001: This standard ensures a systematic approach to quality management, focusing on continuous improvement and customer satisfaction. Suppliers certified with ISO 9001 demonstrate robust process controls.

- CE Marking: Mandatory for products entering the European Economic Area, CE certification confirms compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical products, essential for buyers targeting environmentally conscious markets.

- UL Certification: Relevant for North American markets, UL tests electrical safety and performance.

- IP Ratings: Indicate the level of protection against dust and water ingress, crucial for LED strips used in outdoor or humid environments.

- Other Regional Certifications: Depending on the target market, certifications like SABS (South Africa), INMETRO (Brazil), or SASO (Saudi Arabia) might be required.

QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components before production to prevent defective parts from entering the assembly line.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including solder joint inspections, LED placement accuracy, and PCB integrity checks.

- Final Quality Control (FQC): Comprehensive testing of finished LED strips, including visual inspection, electrical performance, and functional tests.

Common Testing Methods

- Electrical Testing: Measures voltage, current, and resistance to ensure circuit integrity and safe operation.

- Lumen Output and Color Consistency: Using spectrometers and photometers to verify brightness and color temperature uniformity.

- Thermal Testing: Ensures LED strips operate within safe temperature ranges to avoid premature failure.

- Waterproof and Environmental Tests: For outdoor strips, tests such as salt spray, humidity exposure, and IP rating validation confirm environmental resilience.

- Mechanical Durability: Flexibility and adhesion tests simulate real-world fixing and handling stresses.

Verifying Supplier Quality Control

International B2B buyers should employ multiple strategies to verify supplier QC capabilities:

- Factory Audits: Conduct on-site or virtual audits focusing on manufacturing processes, equipment calibration, staff training, and QC documentation.

- Requesting QC Reports: Suppliers should provide detailed inspection and testing reports, including batch-level traceability.

- Third-Party Inspection: Engaging independent testing labs or inspection agencies to perform random sampling and compliance verification adds an extra layer of assurance.

- Sample Testing: Buyers can order samples for in-house testing to validate claims related to performance and durability.

- Supplier Certifications: Verification of ISO, CE, RoHS, and other relevant certifications through official registries or certification bodies.

QC and Certification Nuances for Buyers in Africa, South America, the Middle East, and Europe

- Africa & South America: Market entry often requires compliance with local standards such as SABS in South Africa or INMETRO in Brazil, alongside international certifications. Import regulations may demand additional documentation and testing, so buyers should ensure suppliers can support certification processes.

- Middle East: Certifications like SASO (Saudi Arabia) and GSO (Gulf Cooperation Council Standards) govern product acceptance. Due to climate extremes, buyers should prioritize LED strips with high IP ratings and thermal resilience.

- Europe: CE marking and RoHS compliance are mandatory. European buyers must also consider eco-design directives and energy efficiency requirements. The presence of REACH compliance (chemical safety) can be a differentiator.

- Indonesia and Southeast Asia: While not the primary focus, buyers dealing with suppliers in or shipping to Indonesia should be aware of SNI certification requirements and local safety standards.

Key Takeaways for B2B Buyers

- Prioritize suppliers with transparent manufacturing processes and multiple QC checkpoints.

- Insist on international and region-specific certifications relevant to your market.

- Utilize third-party inspections and factory audits to mitigate supply chain risks.

- Evaluate product testing documentation thoroughly before large orders.

- Consider environmental and installation conditions in your region when assessing product specifications.

By comprehensively understanding the manufacturing and quality assurance landscape, B2B buyers can make informed decisions that minimize risks and maximize the value of their LED strip light investments across diverse international markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for fixing led strip lights Sourcing

Breakdown of Cost Components in Fixing LED Strip Lights

When sourcing solutions for fixing LED strip lights, understanding the underlying cost structure is crucial for international B2B buyers aiming to optimize procurement and project budgets. The major cost components include:

- Materials: This covers LED strips, connectors, adhesives, mounting channels, power supplies, and protective casings. Material quality and type (e.g., waterproof vs. non-waterproof) significantly influence costs.

- Labor: Skilled labor is required for assembly, wiring, soldering, and testing. Labor costs vary widely depending on the supplier’s location and workforce expertise.

- Manufacturing Overhead: Factory utilities, equipment depreciation, and indirect labor fall under overhead. Efficient factories with automated processes can reduce these expenses.

- Tooling: Custom fixtures or specialized tools for cutting, soldering, or mounting LED strips add upfront costs, especially for customized solutions.

- Quality Control (QC): Rigorous testing to ensure durability, compliance with certifications (e.g., CE, RoHS), and performance reliability adds to total costs but reduces returns and failures.

- Logistics and Shipping: International freight, customs duties, and local delivery charges vary by region. For buyers in Africa, South America, the Middle East, and Europe, logistical complexity and tariffs can be significant cost drivers.

- Margin: Suppliers include profit margins that reflect market competition, brand positioning, and service levels.

Key Pricing Influencers for LED Strip Light Repairs

Pricing is dynamic and influenced by several critical factors:

- Order Volume / Minimum Order Quantity (MOQ): Larger volumes typically secure lower unit prices due to economies of scale. Some suppliers offer tiered pricing that benefits bulk buyers.

- Specifications and Customization: Custom lengths, color temperatures, waterproof ratings, and control options (e.g., dimmable, RGB) increase complexity and costs.

- Material Quality: Premium LEDs, durable adhesives, and certified components command higher prices but improve longevity and reduce maintenance.

- Certifications and Compliance: Products meeting international standards (UL, CE, RoHS) often cost more but ensure safety and market acceptance, critical for European and Middle Eastern buyers.

- Supplier Factors: Reputation, lead times, production capacity, and after-sales support influence pricing. Established suppliers may charge more but provide reliability.

- Incoterms: Terms like FOB, CIF, or DDP affect who bears shipping, insurance, and customs costs, impacting the landed price at the buyer’s location.

Strategic Tips for International B2B Buyers

To maximize cost-efficiency and value when sourcing LED strip light fixing solutions, buyers should consider the following:

- Negotiate MOQs and Pricing Tiers: Engage suppliers early to explore flexible MOQs or volume discounts, especially if testing new products or entering new markets like Colombia or Indonesia.

- Evaluate Total Cost of Ownership (TCO): Beyond upfront price, assess factors such as warranty terms, product lifespan, energy consumption, and expected maintenance costs. Higher-quality materials can reduce TCO substantially.

- Consider Regional Logistics and Import Duties: Factor in customs clearance times and costs, which can be substantial in Africa and South America. Opt for suppliers who understand local import regulations to avoid delays and extra charges.

- Request Transparent Cost Breakdowns: Seek detailed quotations showing material, labor, and logistics costs separately. This transparency aids negotiation and budgeting.

- Leverage Supplier Certifications: Prioritize suppliers with recognized certifications that align with your region’s regulatory requirements to reduce compliance risks.

- Use Incoterms Wisely: Depending on your logistics capabilities, select Incoterms that minimize risk and cost. For example, DDP (Delivered Duty Paid) can simplify procurement for buyers with less-developed import infrastructure.

- Plan for Seasonal Demand and Currency Fluctuations: International buyers should anticipate price changes due to exchange rates or peak demand seasons, adjusting order timing accordingly.

Indicative Pricing Disclaimer

Pricing for fixing LED strip lights varies widely based on customization, quality, volume, and supplier location. The figures discussed herein serve as general guidance and should be validated through direct supplier quotations tailored to specific project requirements and regional considerations.

This comprehensive cost and pricing analysis empowers international B2B buyers to make informed sourcing decisions, balancing quality, cost-efficiency, and logistical complexities in global LED strip light fixing projects.

Spotlight on Potential fixing led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘fixing led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for fixing led strip lights

Critical Technical Properties for Fixing LED Strip Lights

When sourcing LED strip lights for international B2B projects, understanding key technical specifications is essential to ensure product quality, compatibility, and longevity. Here are the most important technical properties to consider:

-

Material Grade and Substrate Quality

The base material of LED strips, often flexible printed circuit boards (FPC), impacts durability and heat dissipation. High-grade copper substrates improve conductivity and reduce voltage drop over long runs, which is crucial for installations in environments like warehouses or retail stores in Africa or Europe. Insisting on premium materials mitigates failures and reduces maintenance costs. -

Ingress Protection (IP) Rating

IP ratings define the strip’s resistance to dust and water. For outdoor or high-humidity environments common in South America or the Middle East, a minimum of IP65 (dust-tight and water-resistant) is recommended. This property ensures the LED strips withstand environmental factors, protecting your investment. -

Color Rendering Index (CRI)

CRI measures the accuracy of color appearance under the LED light compared to natural light. A CRI of 80+ is acceptable for general lighting, but for retail or hospitality sectors in Europe or Colombia, a high CRI (90+) enhances visual appeal and customer experience. B2B buyers should specify CRI to meet the lighting quality standards of their end markets. -

Voltage and Power Tolerance

LED strips typically operate at 12V or 24V DC. Understanding voltage tolerance and power consumption per meter is critical for designing compatible power supplies and avoiding overheating. This specification helps buyers in regions with unstable power grids, such as parts of Africa or the Middle East, plan for reliable electrical infrastructure. -

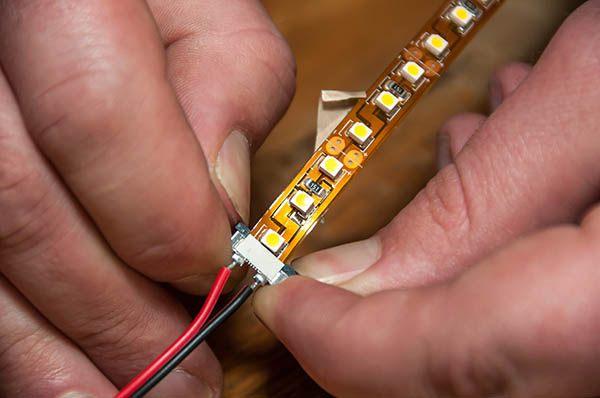

Cutting and Connection Points

The ability to cut LED strips at specified intervals without damaging circuits allows customization for varied installation sizes. Reliable solder pads or connectors facilitate easier fixing and reduce labor costs. Buyers should verify these points match installation requirements and available accessories to streamline assembly. -

Adhesive Quality and Mounting Options

Strong, industrial-grade adhesives or mechanical mounting channels ensure strips remain fixed securely over time, especially in humid or dusty environments. Understanding the adhesive type and compatibility with surfaces is vital for B2B buyers to avoid rework and product returns.

Key Trade Terminology for LED Strip Light Procurement

Navigating international LED strip light sourcing involves familiarity with common industry terms. Here are important trade terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce LED strips that can be rebranded or customized for a buyer. Engaging with OEMs allows buyers to specify unique features or packaging for their local markets in Africa or South America, enabling differentiation and control over product quality. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. Understanding MOQ helps buyers plan inventory and cash flow, especially when importing to regions with variable demand. Negotiating MOQ can be critical for startups or small distributors in emerging markets. -

RFQ (Request for Quotation)

A formal document sent to suppliers requesting pricing and delivery terms based on detailed product specifications. RFQs streamline supplier comparison and ensure transparency, which is particularly useful when dealing with multiple suppliers across continents like Europe and Asia. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, risks, and costs between buyers and sellers during shipping. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Correct use of Incoterms prevents misunderstandings and unexpected costs, especially in complex logistics for buyers in the Middle East or South America. -

Lead Time

The time between placing an order and receiving the goods. For LED strip light buyers, managing lead time is crucial to meet project deadlines and avoid stockouts, particularly in regions with longer shipping durations or customs delays. -

Batch Consistency

Refers to the uniformity of LED strip quality and performance across production batches. Ensuring batch consistency is important for large-scale projects or chains operating across multiple countries, maintaining consistent lighting quality and reducing installation issues.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge to make informed purchasing decisions. This foundation helps mitigate risks, optimize costs, and ensure successful LED strip light installations tailored to diverse international markets.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fixing led strip lights Sector

Market Overview & Key Trends

The global market for fixing LED strip lights is experiencing robust growth, driven by increasing demand for energy-efficient and customizable lighting solutions across commercial, industrial, and residential sectors. Key international drivers include urbanization, infrastructure development, and rising awareness of smart lighting technologies. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, these factors translate into diverse opportunities and challenges.

Illustrative Image (Source: Google Search)

Regional Market Dynamics:

– Africa & Middle East: Rapid urban expansion and government initiatives to improve energy access fuel demand for cost-effective LED solutions. Buyers prioritize durable, weather-resistant fixing LED strips suitable for harsh climates.

– South America: Growing commercial construction and retrofitting projects, especially in countries like Colombia, are driving adoption. Importers seek reliable suppliers offering flexible payment terms and localized support.

– Europe: Mature markets emphasize high-quality, energy-efficient, and smart-enabled LED strips with stringent compliance to EU regulations. Buyers focus on innovation, integration with IoT systems, and sustainability credentials.

Emerging B2B Sourcing Trends:

– Customization & Modular Design: Increasing preference for LED strips with adaptable fixing options to suit varied installation environments. Modular components reduce installation time and maintenance costs.

– Smart Controls Integration: Demand for LED strips compatible with wireless controls and automation platforms is growing, enabling energy management and enhanced user experience.

– Direct Sourcing & Digital Marketplaces: Buyers leverage online B2B platforms to connect directly with manufacturers, reducing intermediaries and improving cost transparency. This is particularly relevant for buyers in emerging markets seeking competitive pricing.

– Supply Chain Resilience: The COVID-19 pandemic highlighted the importance of diversified supplier bases and inventory strategies. Buyers now prioritize suppliers with proven logistical agility and transparent lead times.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central in the fixing LED strip lights sector, driven by regulatory pressures, corporate social responsibility, and buyer preferences. For international B2B buyers, adopting sustainable sourcing practices is not only an ethical imperative but also a strategic advantage in competitive markets.

Environmental Impact Considerations:

– LED strip lights inherently offer energy savings over traditional lighting, but sustainability extends to the entire product lifecycle—material sourcing, manufacturing, transportation, and disposal.

– Buyers should evaluate suppliers based on the use of recyclable materials, low-toxicity components (e.g., avoiding heavy metals), and energy-efficient manufacturing processes.

– Packaging reduction and eco-friendly shipping methods contribute to lowering the carbon footprint.

Ethical Supply Chains:

– Ensuring fair labor practices and compliance with international labor standards is critical, especially when sourcing from developing regions. Buyers must conduct due diligence and prefer suppliers with transparent auditing mechanisms.

– Certifications such as ISO 14001 (environmental management), RoHS (Restriction of Hazardous Substances), and UL sustainability marks enhance supplier credibility and product acceptability in regulated markets.

Green Certifications & Materials:

– Look for LED strips certified by recognized bodies (e.g., ENERGY STAR, TUV Rheinland) that guarantee energy efficiency and safety.

– Materials like lead-free solder and halogen-free components reduce environmental hazards.

– Suppliers offering take-back or recycling programs align with circular economy principles, appealing to buyers committed to long-term sustainability goals.

Evolution and Historical Context

The fixing LED strip lights sector has evolved significantly over the past two decades. Initially, LED strips were simple, low-intensity light sources used primarily for decorative purposes. Early products had limited durability and fixed mounting options, restricting their application scope.

Advancements in LED chip technology, flexible circuit boards, and adhesive backing revolutionized the market by enabling versatile fixing methods and improved longevity. The integration of waterproofing and high-CRI (Color Rendering Index) LEDs expanded their use into commercial and industrial lighting.

More recently, the incorporation of smart controls and IoT compatibility has transformed fixing LED strips into dynamic lighting solutions that support energy management and aesthetic customization. This evolution positions them as indispensable components in modern lighting infrastructure, especially for B2B buyers seeking adaptable, efficient, and sustainable lighting solutions across global markets.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of fixing led strip lights

-

How can I effectively vet LED strip light suppliers for international B2B sourcing?

Vet suppliers by verifying business licenses, certifications (e.g., CE, RoHS), and factory audit reports. Request samples to assess product quality and consistency. Check customer references and online reviews, especially from buyers in your region. For buyers in Africa, South America, the Middle East, and Europe, ensure the supplier understands regional standards and compliance requirements. Engage in video calls or factory visits if possible. Transparent communication and clear contract terms reduce risks and build trust in long-term partnerships. -

What customization options are typically available for LED strip lights in B2B orders?

Most suppliers offer customization including strip length, LED density, color temperature, waterproof rating, and connector types. Advanced options may include smart controls (e.g., DMX, Wi-Fi), flexible PCB designs, and packaging tailored to your branding. When negotiating, specify technical requirements and expected certifications. Custom orders usually require MOQ adjustments and longer lead times, so clarify these upfront. Customization ensures your product fits market needs in diverse regions like Indonesia or Colombia, enhancing competitiveness. -

What are common minimum order quantities (MOQs) and lead times for LED strip light orders?

MOQs vary widely, typically ranging from 500 to 5,000 meters per SKU, depending on customization and supplier capacity. Lead times often span 3 to 8 weeks, influenced by order size, customization, and shipping method. For international buyers, factor in additional time for customs clearance and inland transportation. Negotiate flexible MOQs or trial orders to minimize upfront investment. Establish clear timelines in contracts and monitor production progress closely to avoid costly delays. -

Which payment terms are standard for international B2B transactions of LED strip lights?

Common terms include 30% deposit upfront and 70% balance before shipment or upon delivery. Letters of credit (LC) and escrow services provide added security for large orders or new partnerships. For buyers in emerging markets, negotiating partial payments aligned with production milestones can mitigate risk. Always confirm payment methods accepted (e.g., wire transfer, PayPal) and currency used. Insist on detailed invoices and clear refund or dispute resolution clauses to protect your investment. -

How can I ensure quality assurance (QA) and compliance when importing LED strip lights?

Request detailed QA documentation such as test reports for brightness, color consistency, waterproof rating, and lifespan. Verify compliance with international standards like CE (Europe), FCC (USA), and local electrical safety regulations relevant to your market. Consider third-party inspections pre-shipment. Establish clear quality benchmarks in contracts and implement random batch testing upon receipt. For regions with variable power supply like parts of Africa, check voltage tolerance and surge protection features to avoid premature failures. -

What certifications should I require from LED strip light suppliers to meet international standards?

Essential certifications include CE, RoHS, UL or ETL (for safety), and ISO 9001 (quality management). For waterproof products, IP65 or higher ratings are critical. Some markets demand additional local certifications or energy efficiency labels. Insist on genuine, verifiable certificates to prevent counterfeits. Certifications not only ensure product safety and legality but also facilitate customs clearance and acceptance in regulated markets, reducing potential trade barriers. -

What logistics considerations should B2B buyers keep in mind when importing LED strip lights?

Choose suppliers experienced with international shipping and customs procedures specific to your region. Decide between air freight for faster delivery or sea freight for cost efficiency, balancing speed and budget. Confirm packaging protects fragile LED strips during transit and complies with import regulations. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and costs. Monitor shipment tracking and prepare for customs duties, taxes, and possible inspections to avoid unexpected delays or fees. -

How should disputes or quality issues be managed in international LED strip light transactions?

Establish a clear dispute resolution process in contracts, including timelines for reporting defects and steps for remediation. Maintain thorough documentation—photos, test reports, and communication records. Negotiate warranty terms covering defective products and agree on replacement or refund policies. Utilize third-party mediation if needed. Proactive communication and choosing reputable suppliers with strong after-sales support reduce conflict risks and preserve business relationships across continents.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fixing led strip lights

Strategic sourcing in the LED strip light repair market is crucial for international B2B buyers aiming to optimize cost-efficiency, quality, and supply chain resilience. Understanding the technical nuances of fixing LED strip lights—such as selecting compatible components, ensuring proper installation, and avoiding common pitfalls—empowers buyers to make informed procurement decisions that minimize downtime and enhance product longevity. Leveraging trusted suppliers with proven expertise in LED technology and repair solutions is vital to maintaining competitive advantage.

For businesses in Africa, South America, the Middle East, and Europe, tailoring sourcing strategies to regional market dynamics and infrastructure capabilities can unlock greater value. This includes prioritizing suppliers who offer comprehensive after-sales support, scalable logistics, and compliance with international quality standards. Additionally, adopting a proactive approach to inventory management and supplier diversification mitigates risks related to fluctuating demand and supply disruptions.

Looking ahead, the growing global emphasis on energy efficiency and smart lighting solutions will continue to drive innovation in LED strip technologies and repair methodologies. B2B buyers are encouraged to engage with manufacturers and distributors who invest in R&D and sustainable practices. By fostering strategic partnerships and embracing emerging trends, international buyers can confidently navigate the evolving LED strip lighting landscape and secure long-term business success.