Introduction: Navigating the Global Market for amber led strip

The global demand for amber LED strips is surging, driven by their versatile applications in automotive lighting, signage, architectural accents, and safety indicators. For international B2B buyers—especially those operating in diverse markets across Africa, South America, the Middle East, and Europe—navigating this dynamic sector requires a nuanced understanding of product specifications, manufacturing quality, and supply chain complexities. Amber LED strips combine aesthetic appeal with energy efficiency, making them a critical component in projects where reliability and performance cannot be compromised.

This comprehensive guide serves as an essential resource for procurement professionals, technical buyers, and distributors aiming to optimize their sourcing strategies. It delves into the various types of amber LED strips, including surface-mounted device (SMD) configurations and monochromatic variants, highlighting material compositions and the impact on luminosity and durability. You will find detailed insights into manufacturing processes, quality control standards such as CE, RoHS, and UL certifications, and how these benchmarks influence product longevity and safety compliance.

Moreover, the guide offers an in-depth analysis of the global supplier landscape, addressing key challenges like supply chain stability and logistics optimization that are particularly pertinent to emerging and established markets alike. Cost considerations are examined beyond initial pricing, emphasizing total cost of ownership including energy consumption and maintenance. Finally, a curated FAQ section addresses common concerns, helping buyers mitigate risks and make data-driven decisions.

By leveraging this guide, international B2B buyers can confidently source amber LED strips that meet stringent quality requirements, align with sustainability goals, and deliver superior value across varied market conditions.

Understanding amber led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMD Amber LED Strip | Surface-mounted diode technology, compact, bright | Automotive lighting, signage, displays | Pros: High brightness, energy-efficient; Cons: Requires good heat dissipation management |

| Flexible Amber LED Strip | Bendable PCB, customizable length, waterproof options | Architectural lighting, outdoor decor | Pros: Versatile installation, weather-resistant; Cons: Higher initial cost, complex installation for some applications |

| High-CRI Amber LED Strip | Enhanced color rendering index for natural hues | Retail lighting, museums, hospitality | Pros: Superior color accuracy; Cons: Slightly higher price, limited availability in some regions |

| Monochromatic Amber LED Strip | Single wavelength amber color, consistent hue | Signal lighting, warning indicators | Pros: Consistent color output, long lifespan; Cons: Limited color flexibility |

| COB Amber LED Strip | Chip-on-board technology, uniform light distribution | Film production, high-end displays | Pros: Smooth lighting with no hotspots; Cons: More expensive, less common in bulk supply |

SMD Amber LED Strip

SMD (Surface-Mounted Device) amber LED strips are among the most commonly sourced due to their compact size and bright output. They are ideal for automotive lighting and commercial signage where clarity and vibrancy are critical. B2B buyers should focus on verifying certifications like CE and RoHS to ensure quality and compliance. Proper heat dissipation solutions are essential to prolong lifespan, making supplier technical support a key consideration.

Flexible Amber LED Strip

Flexible amber LED strips offer adaptability with their bendable PCBs and often come with IP-rated waterproofing, making them suitable for architectural and outdoor applications. These strips allow for creative lighting designs but may incur higher initial costs due to customization and installation complexity. Buyers should evaluate supplier capabilities in customization and assess logistical support for shipping fragile, waterproof products to diverse markets.

High-CRI Amber LED Strip

High-CRI amber LED strips emphasize accurate color rendering, which is crucial in retail, hospitality, and museum settings where lighting quality directly impacts product presentation and ambiance. These strips typically command a premium price but can enhance brand perception and customer experience. For B2B buyers, sourcing from manufacturers with consistent CRI performance and reliable testing protocols is vital.

Monochromatic Amber LED Strip

Monochromatic amber LED strips emit a single, consistent wavelength of amber light, making them perfect for signal lighting and warning indicators. Their long lifespan and stable color output reduce maintenance costs. Buyers should prioritize suppliers with proven reliability in color consistency and durability, especially when sourcing for safety-critical applications in industrial or transportation sectors.

COB Amber LED Strip

COB (Chip-on-Board) amber LED strips provide uniform light without visible hotspots, favored in high-end displays and film production environments requiring smooth, continuous illumination. These strips often come at a higher price point and may have limited availability in bulk. B2B buyers must weigh the benefits of superior light quality against cost and supply chain considerations, ensuring manufacturers can meet volume demands with consistent quality.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of amber led strip

| Industry/Sector | Specific Application of amber led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Indicator and signal lighting on vehicles | Enhances visibility and safety with energy-efficient lighting | Compliance with automotive quality standards (ISO, CE), durability under heat and vibration |

| Retail & Commercial Signage | Backlighting and accent lighting for storefront displays | Attracts customers with vibrant amber hues, reduces energy costs | High CRI and consistent color output, long lifespan, and supply chain reliability |

| Hospitality & Interior Design | Ambient and decorative lighting in hotels and restaurants | Creates warm, inviting atmospheres that improve customer experience | Flexibility in strip length, dimmability, and certifications for indoor safety (RoHS, UL) |

| Industrial Safety & Warning Systems | Warning and hazard indicator lighting in factories and warehouses | Improves worker safety by providing clear, attention-grabbing signals | Robustness against dust and moisture (IP rating), stable supply for maintenance needs |

| Agriculture & Horticulture | Supplemental lighting for plant growth and pest control | Supports plant health and growth cycles, enhances yield quality | Specific wavelength accuracy, energy efficiency, and environmental compliance |

Automotive Industry Applications

Amber LED strips are widely used in automotive lighting systems for turn signals, side markers, and daytime running lights. Their vibrant amber color enhances visibility and safety on the road, which is critical for commercial vehicle manufacturers and fleet operators. For international buyers, especially in regions like Europe and the Middle East where regulatory compliance is strict, sourcing amber LED strips that meet automotive quality standards such as ISO and CE certifications is essential. Additionally, these strips must withstand harsh conditions including heat, vibration, and moisture to ensure durability and reliability.

Retail and Commercial Signage

In retail environments across Africa, South America, and Europe, amber LED strips are employed for backlighting signs, window displays, and architectural accents. The warm amber glow attracts attention and creates a distinctive brand presence while significantly reducing energy consumption compared to traditional lighting. Buyers should prioritize LED strips with high color rendering index (CRI) and consistent color uniformity to maintain brand aesthetics. Ensuring a stable supply chain is also vital for retailers to avoid disruptions during peak commercial seasons.

Hospitality and Interior Design

Hotels, restaurants, and lounges utilize amber LED strip lighting to establish warm, welcoming ambiances that enhance guest experience. These strips are often integrated into coves, underbars, and wall accents. For buyers in international markets such as Turkey and Germany, it is important to source products that offer flexible installation options, dimmability, and compliance with indoor safety standards like RoHS and UL. The ability to customize strip length and brightness levels allows designers to create tailored lighting schemes that meet diverse customer expectations.

Industrial Safety and Warning Systems

Amber LED strips serve as critical components in industrial safety lighting, marking hazardous zones, emergency exits, and machinery warnings in factories and warehouses. Their high visibility helps prevent accidents and improves worker safety compliance. Buyers must ensure that the LED strips have robust ingress protection ratings (IP65 or higher) to withstand dust, moisture, and temperature fluctuations common in industrial settings. A reliable supply chain is crucial for ongoing maintenance and replacement to avoid operational downtime.

Agriculture and Horticulture

In controlled-environment agriculture, amber LED strips contribute to plant growth by providing specific light spectra that influence flowering and pest deterrence. This application is gaining traction in South America and parts of Africa where modern farming techniques are expanding. Buyers should focus on LED strips that deliver precise wavelength control, energy efficiency, and meet environmental regulations. Consistency in lighting quality supports better crop yields and reduces energy costs, making it a valuable investment for commercial growers.

Related Video: USES OF ELECTROMAGNETIC WAVES

Strategic Material Selection Guide for amber led strip

When selecting materials for amber LED strips, international B2B buyers must weigh performance, durability, cost, and compliance factors carefully. The choice of material influences the product’s lifespan, efficiency, and suitability for diverse environments—critical considerations for markets in Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in amber LED strip manufacturing, highlighting their properties and strategic implications.

1. Flexible Polyimide (PI) Substrate

Key Properties: Polyimide substrates offer excellent thermal stability, withstanding temperatures up to 260°C. They exhibit strong chemical resistance and flexibility, allowing LED strips to bend around corners or curved surfaces without damage.

Pros & Cons: PI substrates are highly durable and maintain performance under mechanical stress, making them ideal for automotive and signage applications requiring flexibility. However, their manufacturing complexity and cost are higher compared to standard materials, which can affect pricing for bulk orders.

Impact on Application: The flexibility and heat resistance of PI substrates make them suitable for environments with fluctuating temperatures or where installation surfaces are irregular. This is particularly beneficial in Middle Eastern and African markets where ambient temperatures can be extreme.

International Buyer Considerations: Buyers from Europe (e.g., Germany, Turkey) will appreciate PI’s compliance with stringent standards like DIN and RoHS, ensuring environmental safety and high-quality manufacturing. In South America and Africa, where supply chain stability can be a challenge, sourcing from manufacturers with certified PI materials reduces risk of product failure.

2. Rigid FR-4 (Fiberglass Epoxy) PCB

Key Properties: FR-4 is a widely used rigid substrate known for its excellent mechanical strength, electrical insulation, and moderate thermal resistance (up to ~130°C).

Pros & Cons: The material is cost-effective and easy to manufacture, supporting high-volume production. However, FR-4 lacks flexibility and has lower heat tolerance compared to polyimide, limiting its use in applications requiring bending or high-temperature endurance.

Impact on Application: FR-4 is ideal for fixed installations such as architectural lighting or indoor decorative amber LED strips where rigidity is acceptable. Its lower thermal tolerance may restrict use in hot climates unless additional heat dissipation measures are implemented.

International Buyer Considerations: FR-4 substrates are compliant with international standards like ASTM and UL, making them attractive to European buyers focused on certification. For buyers in Africa and South America, FR-4’s affordability and availability are significant advantages, but attention must be paid to environmental conditions to avoid premature degradation.

3. Silicone Encapsulation (Coating)

Key Properties: Silicone coatings provide excellent UV resistance, waterproofing (IP65 and above), and flexibility. They maintain performance in temperature ranges from -60°C to 200°C and resist corrosion from chemicals and salt spray.

Pros & Cons: Silicone encapsulation enhances the durability and outdoor suitability of amber LED strips, protecting against moisture and physical damage. The downside is increased material and processing costs, as well as potential challenges in recycling.

Impact on Application: Silicone-coated amber LED strips are preferred for outdoor signage, marine applications, and harsh environments common in coastal regions of South America and the Middle East. Their robustness justifies higher upfront costs through extended product life.

International Buyer Considerations: Compliance with IP ratings and environmental standards (such as IEC and RoHS) is critical for buyers in Europe and Turkey, where regulatory scrutiny is high. African buyers benefit from silicone’s durability in humid or dusty environments, reducing maintenance costs.

4. Aluminum Alloy Backing

Key Properties: Aluminum backing serves as a heat sink, improving thermal management by dissipating heat away from LED chips. It is lightweight, corrosion-resistant (especially anodized variants), and mechanically robust.

Pros & Cons: Aluminum-backed amber LED strips offer enhanced lifespan and performance stability due to better heat control. However, the cost is higher than standard PCB substrates, and manufacturing complexity increases with the need for precise bonding and finishing.

Impact on Application: This material is ideal for high-power amber LED strips used in industrial or automotive lighting in Europe and the Middle East, where thermal management is critical. It also suits applications exposed to vibration or mechanical stress.

International Buyer Considerations: European and Turkish buyers often prioritize aluminum-backed strips for their superior heat dissipation and compliance with DIN and CE standards. In African and South American markets, the initial investment is higher, but the long-term benefits in reliability and reduced energy consumption are compelling.

| Material | Typical Use Case for amber led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Polyimide (PI) Substrate | Automotive lighting, flexible signage | High thermal stability and flexibility | Higher manufacturing complexity and cost | High |

| Rigid FR-4 (Fiberglass Epoxy) PCB | Indoor architectural and decorative lighting | Cost-effective and easy to manufacture | Limited flexibility and lower heat tolerance | Low |

| Silicone Encapsulation (Coating) | Outdoor signage, marine environments | Excellent waterproofing and UV resistance | Increased material cost and recycling challenges | Medium |

| Aluminum Alloy Backing | Industrial, automotive, high-power applications | Superior heat dissipation and mechanical strength | Higher cost and complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for amber led strip

Manufacturing Processes for Amber LED Strip

The manufacturing of amber LED strips is a precise and multi-stage process that ensures the final product delivers optimal performance, durability, and energy efficiency. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe evaluate suppliers more effectively.

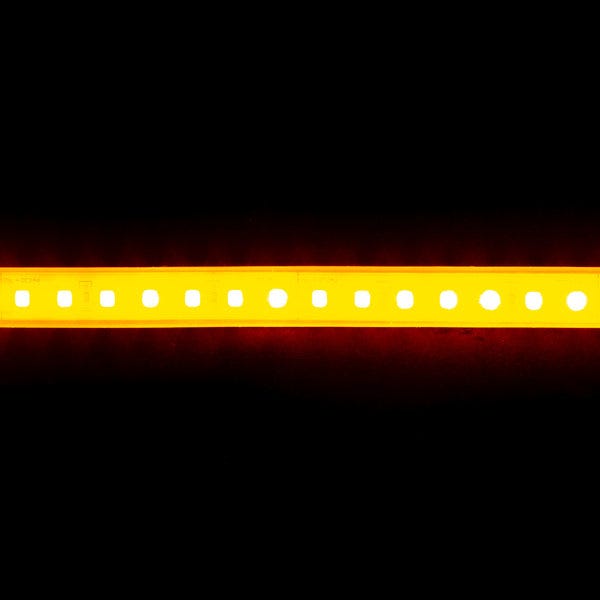

Illustrative Image (Source: Google Search)

1. Material Preparation

The process begins with sourcing high-quality raw materials, including LED chips (specifically amber wavelength LEDs), flexible printed circuit boards (PCBs), resistors, connectors, and adhesives. For amber LEDs, the semiconductor materials are carefully selected to achieve the desired wavelength (typically around 590–620 nm), ensuring consistent color output. Suppliers with robust procurement practices and transparent component traceability are preferable to mitigate risks related to counterfeit or substandard materials.

2. PCB Fabrication and Forming

The flexible PCB serves as the backbone of the LED strip. It is fabricated using copper-clad polyimide or similar flexible substrates, designed to accommodate the LED chips and circuitry. Precision etching and layering techniques form the conductive pathways. After fabrication, the PCB is cut and formed into the required strip lengths and shapes, often incorporating cutting marks for customization. The quality of the PCB affects heat dissipation and overall reliability of the strip.

3. Component Assembly and Soldering

LED chips and other electronic components are mounted onto the PCB using surface-mount technology (SMT). Automated pick-and-place machines position the components with micron-level accuracy, followed by soldering—usually via reflow soldering—to secure the connections. For amber LED strips, special attention is paid to the correct orientation and polarity of LEDs to maintain uniform light emission. High-precision assembly minimizes defects and enhances electrical performance.

4. Encapsulation and Finishing

To protect the LED strip from environmental factors such as moisture, dust, and mechanical damage, the strips are coated or encapsulated. Materials like silicone or epoxy resins are commonly used, providing flexibility and durability while maintaining light transmission. Additional finishing steps include attaching connectors, mounting clips, and sometimes integrating dimming or control modules. The finishing stage also involves labeling and packaging tailored for international shipping requirements.

Quality Assurance and Control in Amber LED Strip Production

Quality assurance (QA) and quality control (QC) are critical for ensuring amber LED strips meet international standards and perform reliably in diverse applications across different regions.

Relevant International and Industry Standards

– ISO 9001: A foundational quality management system standard that ensures consistent manufacturing processes and continuous improvement.

– CE Marking: Essential for products entering the European market, confirming compliance with EU safety, health, and environmental requirements.

– RoHS (Restriction of Hazardous Substances): Ensures that the LED strips do not contain harmful materials such as lead or mercury, important for environmental and health safety.

– UL Certification: Widely recognized in the Middle East and other regions, confirming electrical safety and performance.

– IP Ratings (Ingress Protection): For outdoor or industrial applications, IP65 or higher ratings guarantee resistance to dust and water.

– Industry-Specific Standards: Automotive-grade amber LED strips, for example, must comply with standards like SAE (Society of Automotive Engineers) for durability and color consistency.

Key Quality Control Checkpoints

1. Incoming Quality Control (IQC)

Raw materials and components undergo stringent inspection upon receipt. This includes verifying LED chip wavelength and intensity, PCB integrity, and component authenticity. B2B buyers should request IQC reports or certificates of conformity to verify supplier diligence.

2. In-Process Quality Control (IPQC)

During assembly, continuous monitoring ensures solder joint quality, component placement accuracy, and electrical connectivity. Automated optical inspection (AOI) and manual checks are common methods. IPQC reduces defect rates early, avoiding costly rework.

3. Final Quality Control (FQC)

Completed LED strips are tested for electrical performance (voltage, current, power consumption), luminous intensity, color consistency, and functional longevity (burn-in testing). Mechanical and environmental tests (e.g., bending, temperature cycling) validate durability. Suppliers should provide detailed test reports and batch traceability.

Common Testing Methods for Amber LED Strips

- Spectral Analysis: Verifies the amber color wavelength and uniformity, critical for applications requiring precise color rendering.

- Electrical Testing: Ensures the strip operates within specified voltage and current ranges without failure.

- Thermal Imaging: Detects hotspots during operation, which can indicate poor heat dissipation or faulty components.

- Mechanical Stress Testing: Assesses flexibility and resistance to bending or twisting, important for installation in varied environments.

- Environmental Testing: Includes humidity, salt spray, and UV exposure tests, especially for outdoor-rated strips.

How B2B Buyers Can Verify Supplier Quality Assurance

- Factory Audits: Conduct on-site or third-party audits to assess manufacturing capabilities, process controls, and worker training. This is especially important for buyers in Africa and South America who may face logistical challenges and want to mitigate risks upfront.

- Reviewing Quality Documentation: Request ISO 9001 certification, test reports, and compliance certificates (CE, RoHS, UL). Authentic documentation indicates adherence to rigorous quality standards.

- Third-Party Inspection Services: Utilize independent inspection agencies to perform random sampling and testing before shipment, ensuring product conformity and reducing disputes.

- Supplier Performance Monitoring: Track defect rates, delivery punctuality, and responsiveness to quality issues through ongoing communication. European buyers, such as those in Germany and Turkey, often emphasize continuous improvement and supplier accountability.

QC and Certification Nuances for International B2B Buyers

- Regional Compliance Requirements: European buyers must prioritize CE and RoHS compliance, while Middle Eastern buyers might focus on UL certification and IP ratings for harsh environments. African and South American markets may require additional certifications depending on local regulations, such as INMETRO in Brazil or SONCAP in Nigeria.

- Sustainability and Environmental Standards: Increasingly, buyers globally demand suppliers adopt eco-friendly manufacturing practices and energy-efficient products. Certifications related to sustainability can be a competitive advantage.

- Customization and Traceability: For large-scale projects, buyers often require bespoke amber LED strips with documented traceability for each batch to ensure consistent quality across shipments.

- Language and Documentation: Clear, multilingual documentation and transparent communication are crucial for smooth cross-border transactions, especially for buyers managing complex import regulations.

Conclusion

For international B2B buyers sourcing amber LED strips, a thorough understanding of the manufacturing processes and quality assurance protocols is essential to make informed purchasing decisions. Prioritizing suppliers who demonstrate rigorous process control, adhere to internationally recognized standards, and provide transparent QC documentation will ensure product reliability and long-term value. Leveraging factory audits, third-party inspections, and continuous supplier engagement helps mitigate risks associated with quality inconsistencies and supply chain disruptions, enabling buyers across Africa, South America, the Middle East, and Europe to confidently integrate amber LED strips into their applications.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for amber led strip Sourcing

When sourcing amber LED strips for international B2B procurement, understanding the detailed cost structure and pricing drivers is essential to make informed purchasing decisions. This analysis breaks down the key cost components, pricing influencers, and practical buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Breakdown of Cost Components

-

Materials: The core raw materials include LED chips (amber spectrum-specific), flexible PCBs, resistors, connectors, and encapsulation materials. Premium quality LEDs with higher lumen output and consistent color temperature typically command a higher price. Materials that comply with RoHS, CE, and UL certifications may increase costs but ensure compliance with international standards.

-

Labor: Labor costs vary significantly depending on the manufacturing location. Asian factories often offer competitive labor rates, while European manufacturers may have higher wages but provide closer proximity and faster turnaround times for buyers in Europe and the Middle East.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with automated assembly lines tend to reduce overhead per unit, positively impacting pricing.

-

Tooling and Setup Costs: For custom or low-volume orders, tooling fees (such as PCB design and stencil creation) can add to upfront expenses. High-volume buyers benefit from amortizing these costs over larger orders.

-

Quality Control (QC): Comprehensive QC, including photometric testing, color consistency checks, and electrical safety verification, adds to production costs but mitigates risks of defective products and returns.

-

Logistics and Shipping: Freight costs depend on shipment mode (air, sea, or land), distance, and customs duties. Buyers from Africa and South America may face higher shipping costs and longer lead times compared to European buyers, influencing landed cost calculations.

-

Supplier Margin: Manufacturers and distributors build in margins to cover profit and risk. Established suppliers with proven track records might price slightly higher but offer greater supply chain stability.

Key Pricing Influencers

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock better per-unit pricing due to economies of scale. However, some manufacturers enforce MOQs that may be challenging for smaller buyers, especially in emerging markets.

-

Product Specifications and Customization: Customized lengths, specific color temperatures (e.g., 1800K to 2200K amber), or integrated smart controls increase costs. Standardized products are generally more cost-effective.

-

Material Quality and Certifications: Certified components and eco-friendly materials often carry premiums but enhance product reliability and market acceptance, especially in regions with strict import regulations like the EU.

-

Supplier Reputation and Reliability: Trusted suppliers with consistent delivery and quality command pricing premiums but reduce risk and total cost of ownership.

-

Incoterms and Payment Terms: Pricing varies based on delivery terms (e.g., FOB, CIF, DDP). Buyers should clarify responsibilities for shipping, insurance, and customs to avoid unexpected costs.

Practical Buyer Tips for International B2B Purchasers

-

Negotiate Volume Discounts and Flexible MOQs: Even if your order is below typical MOQs, negotiate with suppliers for trial batches or phased deliveries to manage cash flow and inventory risks.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront price but also energy efficiency, product lifespan, and maintenance costs. Higher-quality amber LED strips may have a higher initial price but lower operating costs and replacement frequency.

-

Leverage Regional Logistics Partners: For buyers in Africa, South America, and the Middle East, partnering with local logistics and customs experts can reduce delays and hidden fees.

-

Factor in Currency Fluctuations and Payment Terms: Payment in stable currencies (USD, EUR) and favorable payment terms (e.g., letter of credit, net 30/60) can protect against exchange risks and improve cash flow.

-

Verify Supplier Certifications and Factory Audits: Request documentation of quality certifications and consider third-party factory inspections to ensure product compliance and quality.

-

Plan for Lead Times and Supply Chain Stability: Build buffer stock for critical projects due to potential global supply chain disruptions, especially relevant for buyers in remote or developing markets.

Disclaimer on Pricing

Prices for amber LED strips fluctuate based on raw material costs, geopolitical factors, and market demand. The cost components and pricing influencers discussed provide a general framework but should be validated through direct supplier quotations tailored to your order size, specifications, and delivery location.

By carefully analyzing cost drivers and pricing nuances, international B2B buyers can optimize sourcing strategies for amber LED strips, balancing cost-efficiency with product quality and supply reliability. This approach is particularly vital for buyers operating in diverse markets with varying logistical and regulatory challenges.

Spotlight on Potential amber led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘amber led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for amber led strip

Critical Technical Properties of Amber LED Strip

Understanding key technical properties helps international buyers make informed decisions that balance quality, cost, and performance in amber LED strips.

-

Color Temperature (K)

Amber LED strips typically emit light in the 1800K to 2200K range, producing a warm amber hue. This specification is crucial for applications requiring precise color matching, such as automotive lighting or hospitality environments. Buyers should verify the exact color temperature to ensure it fits the intended ambiance or signaling purpose. -

Luminous Intensity (Lumens per Meter)

This measures the brightness output of the LED strip. Higher lumens indicate a brighter strip, which is essential for visibility in signage or outdoor applications. For B2B buyers, understanding lumen output helps align product selection with lighting requirements while considering energy consumption. -

Power Consumption (Watts per Meter)

Power usage directly impacts operational costs and energy efficiency. Amber LED strips generally consume less power compared to traditional lighting, but variations exist based on LED density and driver efficiency. Buyers should evaluate power ratings to optimize long-term cost savings and sustainability goals. -

Material Quality and PCB Grade

The printed circuit board (PCB) material affects durability and heat dissipation. High-grade PCBs (e.g., FR4 or aluminum-backed) ensure better thermal management and longer lifespan. For B2B buyers, prioritizing quality materials reduces failure rates and maintenance costs, especially in demanding environments. -

Ingress Protection (IP) Rating

IP ratings define resistance to dust and moisture. Common ratings for amber LED strips include IP20 (indoor use) and IP65 or higher (waterproof for outdoor or industrial use). Selecting the appropriate IP rating is critical to avoid product damage and ensure compliance with regional standards. -

Color Rendering Index (CRI)

CRI indicates how accurately the LED light renders colors compared to natural light. Although amber LEDs have inherently lower CRI due to their narrow wavelength, buyers should assess CRI values when color fidelity is important, such as in retail or decorative lighting.

Key Industry and Trade Terms for Amber LED Strip Procurement

Navigating trade terminology is essential for smooth international transactions and clear communication with suppliers.

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products for other brands to sell under their own name. Many amber LED strip buyers engage OEMs for customized designs or private labeling, enabling tailored solutions and brand differentiation. -

MOQ (Minimum Order Quantity)

The smallest order volume a supplier is willing to accept. Understanding MOQ helps buyers plan inventory and cash flow, especially important for emerging markets or smaller enterprises in Africa, South America, and the Middle East. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, lead times, and terms based on specific product requirements. RFQs are a crucial step in the sourcing process, enabling buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities and risks between buyers and sellers during shipping. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms helps buyers manage logistics costs and import duties effectively. -

Lead Time

The period from order placement to product delivery. Shorter lead times are often preferred to maintain production schedules and reduce inventory costs. Buyers should clarify lead times upfront to avoid supply chain disruptions. -

Bin Code

A classification code indicating the brightness and color characteristics of LED chips within a batch. Consistency in bin codes ensures uniformity in lighting quality across multiple orders, which is vital for large-scale projects requiring color matching.

By mastering these essential technical properties and trade terms, B2B buyers across Africa, South America, the Middle East, and Europe can confidently source amber LED strips that meet performance expectations, comply with international standards, and optimize operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the amber led strip Sector

Market Overview & Key Trends

The global amber LED strip market is experiencing steady growth driven by rising demand in automotive lighting, signage, architectural accents, and outdoor applications. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe (including markets like Turkey and Germany), this growth is fueled by the need for energy-efficient, durable, and visually distinctive lighting solutions. Amber LEDs offer a unique wavelength range that enhances visibility and safety, making them highly sought after in vehicle indicator lights, warning signals, and decorative lighting.

Key market dynamics include increasing adoption of Surface-Mounted Device (SMD) technology, which provides superior brightness, energy efficiency, and design flexibility. Buyers are gravitating towards suppliers who can offer products with internationally recognized quality certifications such as CE, RoHS, and UL, ensuring compliance with regional safety and environmental regulations. Additionally, the trend toward customization is strong — B2B buyers seek amber LED strips with specific lumen outputs, voltage requirements, and color rendering indexes (CRI) tailored to diverse project needs.

Sourcing trends reveal a shift towards diversified supply chains to mitigate risks from global disruptions. Buyers in emerging markets emphasize partnerships with manufacturers who demonstrate supply chain resilience, including robust inventory management and reliable logistics. Digital procurement platforms and real-time supply chain visibility tools are increasingly leveraged to optimize ordering and reduce lead times. Moreover, collaboration with LED module suppliers is critical, as the quality of the core components directly impacts the performance and longevity of amber LED strips.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a core consideration in the sourcing of amber LED strips. Energy efficiency remains a top priority; amber LED strips consume significantly less power than traditional lighting, reducing operational costs and carbon footprint. B2B buyers are prioritizing suppliers who implement eco-friendly manufacturing processes, such as minimizing hazardous materials, reducing waste, and adhering to international environmental standards.

Illustrative Image (Source: Google Search)

Ethical sourcing is equally important, with buyers demanding transparency across the supply chain to ensure responsible labor practices and conflict-free materials. Certifications like ISO 14001 (Environmental Management), REACH compliance, and conflict minerals declarations provide assurance that products meet stringent ethical and environmental criteria. Incorporating amber LED strips made from recyclable materials and with longer lifespans supports circular economy principles and reduces electronic waste.

For buyers in regions with strong regulatory environments, such as the European Union, compliance with directives on hazardous substances (RoHS) and waste electrical and electronic equipment (WEEE) is essential. Selecting manufacturers with green certifications and demonstrated commitment to sustainability can also enhance corporate social responsibility profiles and satisfy increasingly eco-conscious end customers.

Evolution and Historical Context

Amber LED technology has evolved significantly since the early LED developments in the 1960s. Initially limited by low brightness and color consistency, amber LEDs have benefited from advances in semiconductor materials and chip design. The integration of SMD technology in the early 2000s marked a turning point, enabling compact, high-intensity, and energy-efficient amber LED strips suitable for diverse industrial applications.

Over the past two decades, the amber LED strip sector has transitioned from niche use in indicator lights to widespread adoption in architectural lighting, automotive safety systems, and smart city infrastructure. This evolution reflects broader trends in LED innovation, including enhanced color uniformity, improved thermal management, and the ability to produce custom wavelengths tailored to specific use cases. For B2B buyers, understanding this progression underscores the importance of sourcing from manufacturers with up-to-date production capabilities and quality assurance practices to meet modern performance demands.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of amber led strip

-

How can I effectively vet suppliers of amber LED strips to ensure product quality and reliability?

Begin by verifying suppliers’ certifications such as CE, RoHS, and UL, which confirm adherence to international quality and safety standards. Research the manufacturer’s reputation through client testimonials, case studies, and industry references, especially from regions similar to yours. Request detailed product specifications and sample batches to evaluate performance firsthand. Additionally, assess their production capacity and supply chain stability to ensure they can meet your volume and delivery timelines consistently. -

Is customization of amber LED strips available, and how can I ensure my specific requirements are met?

Most reputable manufacturers offer customization options including length, brightness, voltage, and IP rating for water resistance. Clearly communicate your technical requirements and intended application to the supplier upfront. Request technical drawings and prototypes before full production to validate design and functionality. Establish a formal agreement covering customization details, quality benchmarks, and after-sales support to avoid misunderstandings. -

What are typical minimum order quantities (MOQs) and lead times for amber LED strip orders in international B2B transactions?

MOQs vary widely depending on the supplier and customization level but generally range from 500 to 5,000 meters for standard products. Lead times typically span 3 to 8 weeks, factoring in manufacturing, quality control, and international shipping. For buyers in Africa, South America, the Middle East, and Europe, it’s advisable to negotiate MOQs aligned with your market demand and confirm lead times that accommodate local customs clearance and logistics. -

Which payment terms are commonly accepted for international orders of amber LED strips, and how can I protect my transaction?

Suppliers often accept wire transfers (T/T), Letters of Credit (L/C), and, less commonly, escrow services. To mitigate risks, negotiate partial upfront payment (e.g., 30% deposit) with the balance paid after inspection or upon delivery. Utilize trade assurance platforms or engage third-party inspection agencies to verify product quality before final payment. Clear contractual terms on payment schedules, penalties, and dispute resolution are essential for secure transactions. -

What quality assurance measures and certifications should I require when sourcing amber LED strips internationally?

Demand compliance with internationally recognized certifications such as CE for European markets, RoHS for hazardous substance restrictions, and UL for electrical safety. Insist on factory inspection reports and third-party testing results covering lumen output, color consistency, durability, and energy efficiency. Additionally, inquire about the supplier’s quality management system certifications like ISO 9001, which indicate standardized production and quality control processes. -

How can I optimize logistics and shipping for amber LED strips to minimize delays and costs?

Partner with suppliers experienced in international shipping and familiar with your regional import regulations, especially in Africa, South America, and the Middle East. Choose reliable freight forwarders offering tracking and consolidated shipping options to reduce costs. Plan shipments well in advance to accommodate customs clearance and avoid peak season congestion. Clarify Incoterms to understand responsibilities for shipping, insurance, and customs duties, ensuring smooth delivery and cost transparency. -

What strategies should I adopt to handle disputes or quality issues with amber LED strip suppliers?

Establish clear contractual clauses detailing product specifications, inspection rights, warranty periods, and remedies for defects. Engage third-party inspection services pre-shipment to identify issues early. In case of disputes, maintain open communication and document all correspondence and evidence. Utilize mediation or arbitration clauses included in contracts to resolve conflicts efficiently without resorting to costly litigation, especially in cross-border transactions. -

How can I ensure sustainability and environmental compliance when sourcing amber LED strips?

Select suppliers who prioritize energy-efficient LED technologies and demonstrate eco-friendly manufacturing practices, such as waste reduction and use of recyclable materials. Verify compliance with environmental standards like RoHS and look for manufacturers with sustainability certifications. Emphasizing green credentials not only meets increasing regulatory demands in Europe and other regions but also enhances your company’s corporate social responsibility profile and long-term cost savings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for amber led strip

A well-executed strategic sourcing approach for amber LED strips is pivotal to unlocking long-term value and operational excellence in diverse international markets. For B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing quality certifications, manufacturer reliability, and product specifications ensures that investments deliver superior performance and durability. Balancing cost considerations with energy efficiency and sustainability factors is essential to optimize total cost of ownership rather than focusing solely on upfront pricing.

Robust supply chain management—including supplier diversification, technology adoption, and logistics optimization—further strengthens resilience against disruptions and market fluctuations. Building strong partnerships with reputable LED module suppliers and manufacturers enables buyers to maintain consistent product availability while adapting swiftly to evolving demands.

Looking ahead, the amber LED strip market is poised for continued innovation driven by energy regulations and increasing demand for eco-friendly lighting solutions. Buyers who integrate strategic sourcing best practices and leverage data-driven supply chain insights will be well-positioned to capitalize on growth opportunities, reduce risks, and enhance competitive advantage.

International buyers are encouraged to engage proactively with trusted suppliers, prioritize transparency in sourcing, and invest in scalable supply chain solutions. Doing so will empower your business to confidently meet project requirements and exceed customer expectations in the dynamic global lighting landscape.