Introduction: Navigating the Global Market for drive led strip with raspberry pi

The integration of LED strip technology with Raspberry Pi controllers represents a transformative advancement for industries ranging from smart lighting and advertising displays to automation and IoT-enabled infrastructure. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding how to effectively source and deploy drive LED strips with Raspberry Pi is critical to gaining competitive advantage and operational efficiency.

This guide delivers an authoritative roadmap to the global marketplace, addressing the diverse types of LED strips compatible with Raspberry Pi, including addressable and non-addressable variants, and the materials that affect durability, brightness, and energy consumption. It explores manufacturing standards and quality control protocols essential for ensuring reliability, along with insights into selecting reputable suppliers who can meet regional compliance and logistical requirements.

Cost considerations are examined in detail, highlighting price drivers such as component quality, volume purchasing, and shipping logistics, which are particularly relevant for buyers in emerging economies like South Africa and Colombia. Additionally, the guide offers a comprehensive market overview, showcasing trends and innovations that can influence procurement strategies.

By navigating through frequently asked questions and practical case studies, this resource equips international B2B buyers with the knowledge to make informed sourcing decisions—optimizing product performance, minimizing risks, and maximizing return on investment in their LED strip and Raspberry Pi projects. Whether upgrading existing systems or launching new solutions, businesses will find actionable insights tailored to their geographic and industry-specific needs.

Illustrative Image (Source: Google Search)

Understanding drive led strip with raspberry pi Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| WS2812 / NeoPixel Strips | Individually addressable RGB LEDs, single data line | Dynamic signage, interactive displays, event decor | Pros: Easy to program, flexible designs. Cons: Requires careful power management, limited data speed for large arrays. |

| APA102 / DotStar Strips | Individually addressable RGB LEDs with separate clock and data lines | High-speed animations, video walls, advanced lighting | Pros: Faster data transfer, smoother color transitions. Cons: Slightly higher cost, more complex wiring. |

| Analog LED Strips | Non-addressable, uniform color or RGB strips | Architectural lighting, ambient lighting, retail displays | Pros: Lower cost, simple control. Cons: Limited effects, less flexible customization. |

| RGBW LED Strips | Adds a dedicated white LED for better white light | Hospitality lighting, product showcases, office lighting | Pros: Improved white light quality, versatile color options. Cons: More complex driver requirements, higher price. |

| High-Power LED Strips | High brightness LEDs requiring external drivers | Industrial lighting, outdoor displays, automotive applications | Pros: High luminosity, durable. Cons: Requires robust power supply, heat dissipation considerations. |

WS2812 / NeoPixel Strips

These strips feature individually addressable RGB LEDs controlled via a single data line, making them highly popular for dynamic and customizable lighting projects. Their simplicity and compatibility with Raspberry Pi GPIO pins allow for quick integration. B2B buyers should consider power supply capabilities and the length of the strip to avoid voltage drop issues. Ideal for interactive retail displays or event environments where color effects are critical.

APA102 / DotStar Strips

With separate clock and data lines, APA102 strips offer faster and more reliable data transmission compared to WS2812. This makes them suitable for complex animations and video wall applications where smooth color transitions are essential. For B2B procurement, the slightly higher cost is offset by performance gains, especially in professional signage or exhibition setups requiring high refresh rates.

Analog LED Strips

These non-addressable strips provide uniform lighting with simpler control mechanisms, often using PWM dimming. They are cost-effective for applications like architectural or ambient lighting where dynamic effects are not necessary. Buyers should evaluate project requirements carefully to avoid overpaying for addressable features that are not needed, focusing on ease of installation and maintenance.

RGBW LED Strips

Incorporating a dedicated white LED alongside RGB LEDs, RGBW strips deliver superior white light quality, beneficial for hospitality or office environments where accurate color rendering and versatile lighting moods are required. These strips may demand more sophisticated drivers and control software, so B2B buyers should assess compatibility with existing Raspberry Pi setups and long-term operational costs.

High-Power LED Strips

Designed for industrial or outdoor use, these strips offer high brightness and durability but require external drivers and effective heat management solutions. They are suited for automotive lighting, outdoor advertising, or factory illumination. B2B buyers must consider infrastructure readiness for power delivery and cooling, as well as compliance with local safety standards, especially when deploying in harsh environments.

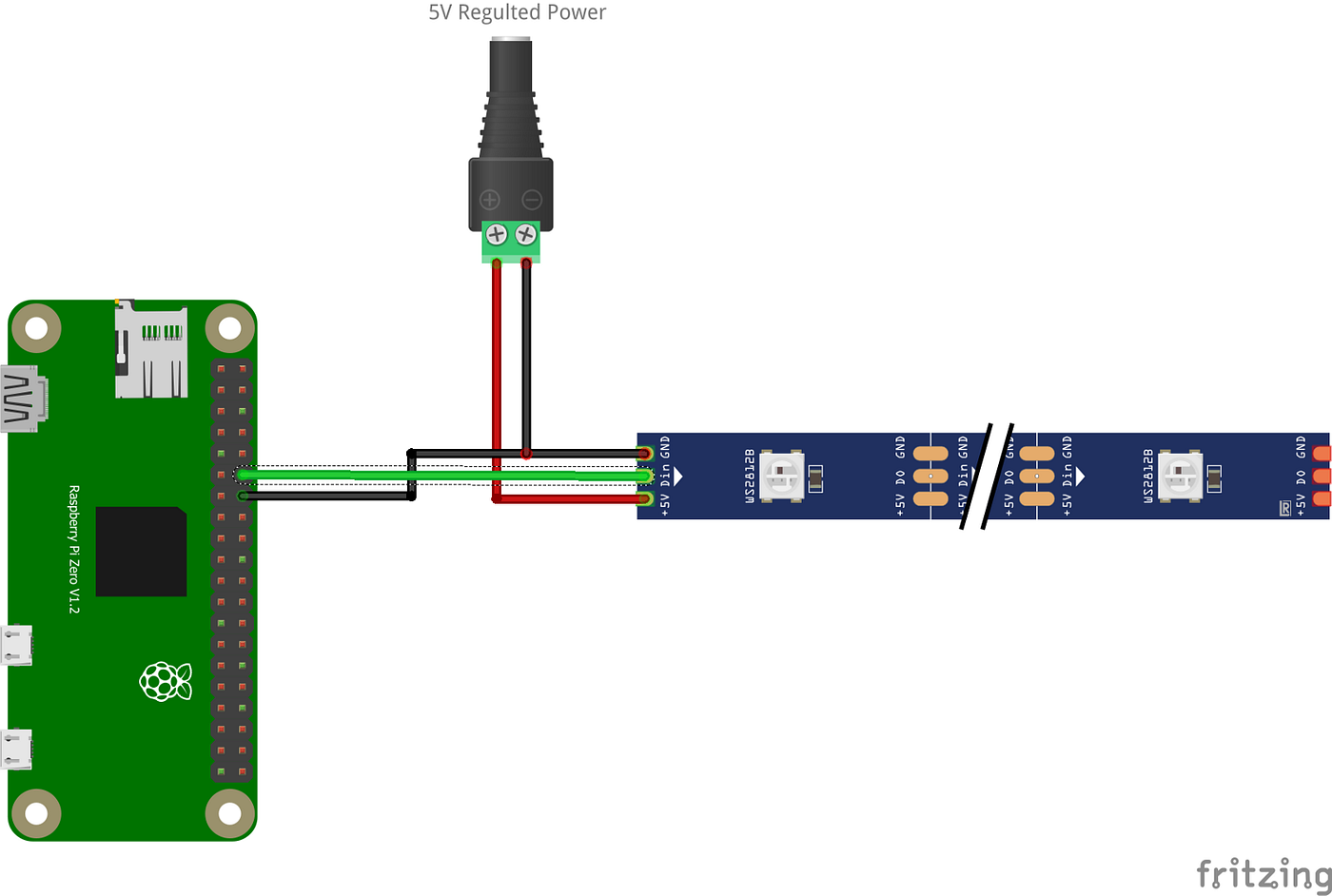

Related Video: How To Use Addressable RGB WS2812B LED Strips With a Raspberry Pi Single Board Computer

Key Industrial Applications of drive led strip with raspberry pi

| Industry/Sector | Specific Application of drive led strip with raspberry pi | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Advertising | Dynamic in-store lighting and interactive digital signage | Enhances customer engagement and boosts sales through visual appeal | Requires robust, scalable LED strips compatible with Raspberry Pi; energy efficiency and durability critical for continuous operation in diverse climates |

| Smart Building & IoT | Automated ambient lighting control and energy-efficient illumination | Reduces energy costs and improves occupant comfort and productivity | Prioritize compatibility with IoT protocols and ease of integration with existing building management systems; sourcing should consider local power standards |

| Entertainment & Events | Stage lighting and synchronized LED effects for live events and installations | Creates immersive experiences, increasing event value and audience satisfaction | LED strips must support high refresh rates and flexible programming; sourcing should ensure availability of technical support and customization options |

| Industrial Automation | Visual status indicators and machine feedback displays on production lines | Improves operational efficiency and safety by providing real-time visual alerts | Requires industrial-grade LED strips with high reliability and resistance to environmental factors; sourcing must consider compliance with regional industrial standards |

| Agriculture & Horticulture | Controlled spectrum LED lighting for plant growth monitoring and enhancement | Enhances crop yield and quality through optimized lighting conditions | LED strips should offer adjustable light spectrums and be compatible with Raspberry Pi for automation; sourcing must focus on durability in humid or dusty environments |

In the Retail & Advertising sector, drive LED strips controlled by Raspberry Pi are widely utilized to create dynamic and interactive lighting displays. These setups can adjust colors and patterns in real-time to attract customer attention and promote products effectively. For international buyers, particularly in regions like South Africa and Colombia, sourcing LED strips that are energy-efficient and capable of enduring local environmental conditions is essential to ensure long-term operational success.

Within Smart Building & IoT, LED strips integrated with Raspberry Pi enable automated ambient lighting systems that adapt to occupancy and daylight levels. This results in significant energy savings and improved occupant comfort, critical for commercial buildings across Europe and the Middle East. Buyers should focus on solutions that seamlessly integrate with existing building management systems and comply with local electrical standards for hassle-free deployment.

The Entertainment & Events industry benefits from the use of Raspberry Pi-driven LED strips for synchronized stage lighting and visual effects. These applications demand LED strips with high refresh rates and customizable programming to support complex lighting sequences. For B2B buyers in emerging markets, ensuring access to technical support and customization services is crucial for tailoring installations to diverse event requirements.

In Industrial Automation, LED strips serve as visual indicators for machine status and safety alerts on production lines. This application enhances operational efficiency by providing immediate visual feedback to workers and supervisors. International buyers must prioritize industrial-grade LED strips that withstand harsh factory environments and meet regional safety and compliance standards.

Lastly, in Agriculture & Horticulture, Raspberry Pi-controlled LED strips with adjustable light spectrums support plant growth by simulating optimal lighting conditions. This technology helps increase crop yields and improve quality in controlled environments such as greenhouses. Buyers from regions with challenging climates should seek durable, moisture-resistant LED strips compatible with automation systems to ensure consistent performance and return on investment.

Strategic Material Selection Guide for drive led strip with raspberry pi

When selecting materials for driving LED strips with Raspberry Pi in B2B applications, especially for buyers across Africa, South America, the Middle East, and Europe, it is critical to evaluate materials based on electrical performance, environmental durability, cost-effectiveness, and regional compliance standards. Below is an analysis of four common materials used in components and accessories for LED strip driving solutions.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is known for its excellent impact resistance, high temperature tolerance (up to ~135°C), and good electrical insulating properties. It is also resistant to UV radiation and offers moderate chemical resistance.

Pros & Cons:

– Pros: Durable and lightweight, ideal for protective housings or enclosures around LED drivers and Raspberry Pi units. It supports complex molding, allowing for custom shapes and integration.

– Cons: Susceptible to scratching and can yellow over time under harsh UV exposure. Cost is moderate compared to basic plastics.

Impact on Application:

Polycarbonate is well-suited for outdoor or semi-outdoor installations where environmental exposure is a concern, such as in South Africa or the Middle East, where high UV levels prevail. Its electrical insulation helps protect sensitive Raspberry Pi and LED driver electronics.

Regional Considerations:

Buyers should ensure compliance with international standards such as ASTM D3935 (UV resistance) and ISO 180 (impact resistance). Polycarbonate materials sourced from Europe often meet stringent REACH and RoHS directives, which is beneficial for buyers in the EU and countries with similar regulations.

2. Aluminum (Al)

Key Properties:

Aluminum offers excellent thermal conductivity, moderate corrosion resistance (especially when anodized), and good mechanical strength. It withstands temperatures up to 200°C and is lightweight compared to other metals.

Pros & Cons:

– Pros: Ideal for heat sinks and structural frames for LED strips and Raspberry Pi setups, improving thermal management and durability. Aluminum’s corrosion resistance can be enhanced with anodizing.

– Cons: Higher cost than plastics, requires specialized manufacturing processes like extrusion or CNC machining, which may increase lead times and minimum order quantities.

Impact on Application:

Thermal management is critical for long LED strip lifespans and stable Raspberry Pi operation. Aluminum’s heat dissipation properties make it preferred in hot climates such as Colombia or the Middle East. It also provides a premium aesthetic for commercial installations.

Regional Considerations:

International buyers should verify compliance with standards like DIN 17611 (aluminum alloys) and ASTM B221 (aluminum extrusions). In Europe, aluminum products often comply with EU environmental and recycling regulations, which can be a procurement advantage.

3. Flexible Printed Circuit Board (FPCB) Materials (Polyimide-based)

Key Properties:

Polyimide-based FPCB materials offer excellent flexibility, high thermal resistance (up to 260°C), and outstanding electrical insulation. They are chemically stable and resistant to solvents and oils.

Pros & Cons:

– Pros: Essential for flexible LED strips driven by Raspberry Pi, enabling installation in curved or tight spaces. High heat tolerance supports soldering and long-term operation.

– Cons: Higher manufacturing complexity and cost compared to rigid PCBs. Requires specialized suppliers and quality control.

Impact on Application:

FPCB materials are critical for applications requiring flexible LED strips, such as architectural lighting or automotive displays. Their durability under bending and heat stresses makes them suitable for diverse environments, including humid or dusty regions in South America and Africa.

Regional Considerations:

Buyers should ensure suppliers comply with IPC-2223 standards for flexible circuits and consider certifications like UL94 for flammability, which are increasingly demanded in European and Middle Eastern markets for safety compliance.

4. Silicone (for LED Strip Coating and Wiring Insulation)

Key Properties:

Silicone offers excellent flexibility, high temperature resistance (-60°C to 200°C), and outstanding weather and UV resistance. It is chemically inert and provides good electrical insulation.

Pros & Cons:

– Pros: Ideal for waterproof LED strips and wiring insulation, protecting components from moisture and dust. Silicone coatings enhance durability in outdoor and industrial environments.

– Cons: Generally more expensive than PVC or other common insulators. Manufacturing processes can be more complex.

Impact on Application:

Silicone-coated LED strips are preferred in regions with high humidity or outdoor exposure, such as coastal areas in South Africa and Colombia. They ensure longevity and reduce maintenance costs.

Regional Considerations:

International buyers should verify compliance with IEC 60529 (IP ratings for ingress protection) and regional environmental standards. Silicone materials sourced from Europe often meet stringent chemical safety and environmental regulations, which is advantageous for cross-border trade.

Summary Table

| Material | Typical Use Case for drive led strip with raspberry pi | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Protective enclosures and housings for LED drivers and Raspberry Pi | High impact resistance and UV stability | Prone to scratching and yellowing over time | Medium |

| Aluminum (Al) | Heat sinks, frames, and structural components for thermal management | Excellent heat dissipation and mechanical strength | Higher cost and complex manufacturing | High |

| Polyimide FPCB | Flexible LED strips and wiring for curved or compact installations | Superior flexibility and thermal resistance | Higher manufacturing complexity and cost | High |

| Silicone | Waterproof coating and insulation for LED strips and wiring | Outstanding weatherproofing and electrical insulation | More expensive than conventional insulators | Medium to High |

This guide enables international B2B buyers to make informed material selections tailored to their regional environmental conditions, compliance requirements, and cost constraints, ensuring optimal performance and longevity of Raspberry Pi-driven LED strip solutions.

In-depth Look: Manufacturing Processes and Quality Assurance for drive led strip with raspberry pi

Manufacturing Processes for Drive LED Strip with Raspberry Pi Integration

The production of drive LED strips designed for Raspberry Pi applications involves several critical manufacturing stages to ensure functionality, durability, and compatibility. Understanding these stages is essential for B2B buyers seeking reliable suppliers across Africa, South America, the Middle East, and Europe.

1. Material Preparation

- Selection of Components: High-quality LED chips, flexible PCB substrates (typically polyimide or fiberglass), and compatible connectors tailored for Raspberry Pi interfaces are sourced.

- Sourcing of Electronic Components: Drivers, resistors, capacitors, and microcontrollers are procured from vetted suppliers with certifications to ensure electrical compliance and longevity.

- Raw Material Inspection: Incoming materials undergo initial quality checks (IQC) for conformity in dimensions, electrical properties, and certifications such as RoHS compliance.

2. Forming and PCB Fabrication

- PCB Manufacturing: Flexible PCBs are fabricated using precise etching and layering techniques to support LED arrays and driver circuitry.

- Solder Mask and Silk Screening: Protective coatings and markings are applied to ensure durability and ease of assembly.

- Component Placement: Automated surface-mount technology (SMT) machines position LEDs and electronic components with micron-level accuracy to ensure consistent performance.

Illustrative Image (Source: Google Search)

3. Assembly

- Soldering: Reflow soldering is the predominant method, ensuring strong electrical connections without damaging sensitive components.

- Integration with Raspberry Pi Interfaces: Connectors and cables compatible with Raspberry Pi GPIO pins and power supply standards are assembled to facilitate plug-and-play functionality.

- Encapsulation and Sealing: Depending on application requirements, strips may be coated with silicone or epoxy for waterproofing and enhanced mechanical resilience.

4. Finishing and Packaging

- Functional Testing: Initial power-on tests to verify LED illumination and driver response.

- Cutting and Customization: Strips are cut to customer-specified lengths or patterns, ensuring adaptability for diverse projects.

- Packaging: Anti-static and moisture-resistant packaging materials are used, with labels indicating batch numbers and compliance certifications, essential for traceability.

Quality Assurance (QA) and Quality Control (QC) Framework

For international B2B buyers, robust QA/QC is paramount to mitigate risks associated with electronic product sourcing. Manufacturers of drive LED strips with Raspberry Pi integration typically adhere to a multi-layered QC process aligned with international standards.

International and Industry Standards

- ISO 9001: The foundational quality management system standard, ensuring consistent production quality and continuous improvement.

- CE Marking: Mandatory for European markets, indicating conformity with health, safety, and environmental protection directives.

- RoHS Compliance: Restricts hazardous substances in electronics, critical for environmental and regulatory adherence.

- UL Certification: Relevant for electrical safety, especially in markets with stringent safety requirements.

- Industry-Specific Standards: For certain applications, compliance with API (American Petroleum Institute) or IEC (International Electrotechnical Commission) standards may be necessary, especially in industrial or outdoor installations.

QC Checkpoints in Production

- Incoming Quality Control (IQC): Rigorous testing of raw materials and components for physical and electrical specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspections, component placement accuracy, and partial functional tests.

- Final Quality Control (FQC): Comprehensive testing of finished products, including full functional verification, visual inspection, and packaging checks.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and signal integrity across the LED strip and driver circuits.

- Optical Testing: Measures LED brightness, color consistency, and uniformity using spectrometers or photometers.

- Environmental Testing: Simulates temperature, humidity, and vibration stresses to ensure durability under diverse operating conditions.

- Safety Testing: Checks for electrical insulation, short circuits, and compliance with safety norms.

- Compatibility Testing: Ensures seamless integration with Raspberry Pi hardware and software, including GPIO pin compatibility and driver firmware performance.

How B2B Buyers Can Verify Supplier Quality

For buyers in Africa, South America, the Middle East, and Europe, verifying supplier quality is crucial to safeguard investment and ensure product reliability. Here are actionable strategies:

1. Supplier Audits

- On-Site Audits: Conduct physical inspections of manufacturing facilities to assess process controls, equipment condition, and worker expertise.

- Remote Audits: Utilize video conferencing and digital documentation reviews when travel is restricted.

- Third-Party Audits: Engage independent inspection agencies specializing in electronics manufacturing to provide unbiased assessments.

2. Documentation and Certification Review

- Request copies of ISO 9001 certificates, CE declarations of conformity, and test reports.

- Verify RoHS and UL compliance certificates, especially for products entering regulated markets.

- Review batch-specific QC reports detailing IQC, IPQC, and FQC results.

3. Sample Testing

- Obtain product samples for independent laboratory testing to confirm electrical, optical, and environmental performance.

- Validate Raspberry Pi compatibility by testing integration with standard Raspberry Pi models and software environments.

4. Continuous Quality Monitoring

- Establish KPIs with suppliers regarding defect rates, delivery timelines, and responsiveness to quality issues.

- Implement periodic re-inspection programs, particularly for repeat orders or new production batches.

QC and Certification Nuances for International B2B Buyers

International buyers face unique challenges related to standards harmonization, logistics, and regulatory compliance:

- Regional Certification Differences:

- Europe mandates CE marking and RoHS compliance, while Middle Eastern markets may require additional Gulf Conformity Mark (G-Mark) certifications.

-

South American countries like Colombia often align with international standards but may require local registration or customs documentation.

-

Import and Customs Compliance:

- Ensure that documentation such as the Certificate of Origin and test certificates accompany shipments to avoid customs delays.

-

Verify that packaging and labeling meet destination country regulations, including language and safety warnings.

-

Logistics and After-Sales Support:

- Prioritize suppliers offering warranty services and technical support within or near your region to minimize downtime.

-

Consider the supplier’s capability for timely spare parts supply and firmware updates compatible with Raspberry Pi ecosystems.

-

Cultural and Communication Considerations:

- Engage suppliers with multilingual capabilities and experience dealing with your region’s business practices to enhance collaboration.

- Leverage local agents or representatives who understand both the supplier’s manufacturing context and your market’s regulatory landscape.

Summary for B2B Buyers

Selecting a supplier for drive LED strips integrated with Raspberry Pi systems requires a comprehensive understanding of manufacturing processes and quality assurance protocols. Buyers should prioritize:

- Suppliers with transparent, documented manufacturing workflows covering material sourcing, PCB fabrication, assembly, and finishing.

- Strict adherence to international standards such as ISO 9001, CE, RoHS, and industry-specific certifications.

- Robust QC checkpoints at all production stages with detailed testing methodologies.

- Verification strategies including audits, certification reviews, and sample testing tailored to regional regulatory requirements.

- Awareness of regional nuances in certification, import regulations, and after-sales support to ensure seamless procurement and deployment.

By focusing on these aspects, international B2B buyers can secure high-quality, compliant, and reliable drive LED strips optimized for Raspberry Pi applications, fostering successful long-term partnerships and market growth.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for drive led strip with raspberry pi Sourcing

Breakdown of Cost Components in Drive LED Strip with Raspberry Pi Sourcing

When sourcing a drive LED strip integrated with a Raspberry Pi for B2B applications, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: This covers the LED strips (often addressable types like WS2812 or SK6812), Raspberry Pi boards (various models depending on processing needs), power supplies, connectors, wiring, and protective casings. Material costs fluctuate based on quality grade, LED density, and Raspberry Pi model selection.

-

Labor: Encompasses assembly, soldering, programming, and testing labor. Labor costs vary significantly by region, impacting the total cost especially when sourcing from countries with higher wages.

-

Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Overhead allocation depends on the production scale and facility efficiency.

-

Tooling: Initial setup costs for custom PCBs, injection molds for enclosures, and programming jigs. Tooling is a one-time or amortized expense that influences unit cost, particularly for lower volume orders.

-

Quality Control (QC): Testing for LED functionality, Raspberry Pi integration, firmware validation, and compliance with safety standards. Higher QC rigor increases cost but reduces defects and returns.

-

Logistics: Freight, customs duties, taxes, and insurance. Costs vary by shipping mode (air, sea, express), origin, and destination country, with additional considerations for import regulations and tariffs.

-

Margin: Supplier profit margin typically ranges from 10-30% depending on market competition, product complexity, and buyer relationship.

Key Price Influencers to Consider

Several factors influence the final pricing of drive LED strip solutions integrated with Raspberry Pi modules:

-

Order Volume / Minimum Order Quantity (MOQ): Larger volumes drastically reduce per-unit cost due to economies of scale. MOQ requirements differ by supplier; buyers from emerging markets should negotiate MOQ to avoid overstock.

-

Specifications and Customization: Custom LED configurations, enclosure designs, or software features increase cost. Off-the-shelf solutions are more cost-effective but may lack tailored functionality.

-

Material Quality and Certifications: Sourcing components with certifications like CE, RoHS, or FCC ensures compliance but may add to cost. For markets like Europe and the Middle East, certified products reduce regulatory risks.

-

Supplier Factors: Established suppliers with proven track records may charge premiums but offer reliability and support. New or local suppliers might offer lower prices but pose risks in quality and delivery.

-

Incoterms: Terms such as FOB, CIF, or DDP determine cost responsibility for shipping and insurance. Buyers should understand Incoterms to accurately assess landed cost and avoid hidden fees.

Strategic Buyer Tips for International B2B Procurement

For buyers in Africa, South America, the Middle East, and Europe, optimizing cost while ensuring quality demands a strategic approach:

-

Negotiate Beyond Price: Focus on total value—warranty, after-sales service, lead times, and payment terms. Volume discounts, bundled orders, or long-term contracts can unlock better pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider installation, maintenance, power consumption, and potential downtime costs. Higher upfront investment in quality components often reduces long-term expenses.

-

Leverage Local and Regional Distributors: Partnering with regional distributors can reduce logistics complexity, import duties, and lead times, particularly relevant for countries like South Africa and Colombia.

-

Understand Market-Specific Pricing Nuances: Currency volatility, import restrictions, and local taxes can influence final costs. Employ hedging strategies or local currency contracts where possible.

-

Request Samples and Pilot Runs: Testing samples ensures compatibility and quality before committing to bulk orders, reducing risk of costly returns.

-

Clarify Warranty and Support Terms: Clear agreements on technical support and replacement policies protect investments and improve supplier accountability.

Disclaimer on Pricing

All price indications are approximate and subject to change based on supplier negotiations, component market fluctuations, and geopolitical factors. Buyers should conduct due diligence with multiple suppliers and factor in all cost components, including hidden logistics and compliance fees, to obtain accurate total landed costs.

By thoroughly analyzing cost components and price influencers while employing strategic sourcing tactics, international B2B buyers can secure competitive pricing and reliable supply of drive LED strip solutions integrated with Raspberry Pi technology.

Spotlight on Potential drive led strip with raspberry pi Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘drive led strip with raspberry pi’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for drive led strip with raspberry pi

Key Technical Properties of Drive LED Strip with Raspberry Pi

When sourcing drive LED strips compatible with Raspberry Pi, understanding critical technical specifications ensures optimal integration and performance. Here are the essential properties to consider:

-

Voltage and Current Rating

The operating voltage (commonly 5V or 12V) and current capacity determine compatibility with Raspberry Pi’s power supply and GPIO pins. For B2B buyers, selecting LED strips with appropriate voltage ratings prevents damage and ensures stable operation in diverse markets with varying power standards. -

LED Type and Density

LED strips vary by diode type (e.g., WS2812B, SK6812) and density (LEDs per meter). Higher density offers finer lighting effects but increases power demand. Buyers must balance visual quality against power consumption and cost, particularly for projects requiring long runs or high brightness. -

Data Protocol and Compatibility

LED strips use specific communication protocols (such as SPI or one-wire) for data control. Ensuring the LED strip’s protocol matches Raspberry Pi’s supported interfaces simplifies development and reduces integration time, a crucial factor in large-scale deployments. -

Material Grade and Durability

The quality of PCB substrate and LED encapsulation affects heat dissipation and lifespan. For international buyers, especially in regions with harsh environments (e.g., high humidity in South America or dust in the Middle East), durable materials enhance reliability and reduce after-sales support costs. -

Color Accuracy and Brightness (Lumens)

Color fidelity and brightness levels impact the end-user experience, particularly in retail or architectural lighting applications. Buyers should verify manufacturer specifications and request samples to validate performance before bulk purchases. -

Tolerance and Quality Control Standards

Tolerance refers to allowable deviations in electrical and physical properties. Adherence to standards like RoHS or CE certification assures compliance with international regulations and helps avoid import restrictions or customs delays.

Common Trade Terms for International B2B Transactions

Understanding industry jargon streamlines communication with suppliers and supports effective negotiation. Here are key trade terms relevant to purchasing drive LED strips with Raspberry Pi:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or products to be rebranded and sold by another company. In LED strip sourcing, working with OEMs can offer customization options, better pricing on bulk orders, and direct quality control. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in one order. Buyers from emerging markets like Africa or South America should negotiate MOQs carefully to balance inventory costs with supplier terms, especially when testing new products. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for price and terms details based on specified product requirements. A clear and detailed RFQ accelerates supplier responses and helps buyers compare offers transparently. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyer and seller. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms helps buyers control logistics costs and risks in cross-border trade. -

Lead Time

The duration from order placement to product delivery. For LED strip projects tied to Raspberry Pi, shorter lead times are critical to meet tight production schedules or seasonal demands. -

Batch Testing / QA (Quality Assurance)

Refers to supplier processes for testing product batches before shipment. Buyers should request QA certifications or inspection reports to ensure product consistency, especially when ordering from new or overseas suppliers.

By mastering these technical specifications and trade terms, international B2B buyers can make informed purchasing decisions, optimize supply chain management, and foster successful partnerships in the drive LED strip and Raspberry Pi ecosystem.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drive led strip with raspberry pi Sector

Market Overview & Key Trends

The global market for drive LED strips integrated with Raspberry Pi controllers is expanding rapidly, driven by increasing demand for customizable lighting solutions across diverse sectors such as smart cities, retail, entertainment, and industrial automation. For international B2B buyers, especially in emerging markets like Africa (e.g., South Africa), South America (e.g., Colombia), the Middle East, and Europe, this sector offers substantial growth potential due to rising digital infrastructure investments and smart technology adoption.

Key market drivers include:

- Rising IoT and Smart Automation Adoption: The convergence of LED technology with Raspberry Pi microcontrollers enables programmable, scalable lighting systems that can be tailored to complex environments. This appeals strongly to industries seeking energy efficiency and enhanced user experience.

- Customization & Integration Flexibility: Raspberry Pi-based LED drivers allow buyers to develop bespoke solutions, integrating lighting with sensors, cameras, or other control systems, which is highly valued in sectors like architecture, agriculture, and event management.

- Cost-Effectiveness & Accessibility: The affordability and open-source nature of Raspberry Pi platforms reduce entry barriers for businesses in developing regions, facilitating innovation without heavy upfront investments.

Emerging B2B sourcing trends:

- Modular & Scalable Components: Suppliers increasingly offer modular LED strips and driver kits compatible with various Raspberry Pi models, enabling easy upgrades and maintenance.

- Local & Regional Distribution Partnerships: To overcome logistical challenges in Africa, South America, and the Middle East, buyers are prioritizing suppliers with regional warehouses or distributors, reducing lead times and import costs.

- Collaborative R&D and Custom Manufacturing: Buyers are engaging suppliers for joint development projects to tailor hardware and firmware, ensuring products meet specific regulatory and environmental standards.

Understanding these dynamics helps buyers optimize procurement strategies by selecting suppliers who combine technical expertise with regional support capabilities.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly critical in the sourcing of drive LED strips with Raspberry Pi integration. The environmental footprint of LED manufacturing, electronic components, and supply chain logistics must be carefully managed to align with global and regional sustainability goals.

Environmental impact considerations:

- Energy Efficiency: LED strips driven by Raspberry Pi controllers offer superior energy efficiency compared to traditional lighting, reducing operational carbon footprints, an attractive factor for buyers in regions with high energy costs or carbon regulations.

- Material Selection: Preference for components using lead-free solder, RoHS-compliant materials, and recyclable plastics helps mitigate hazardous waste issues and supports circular economy initiatives.

- Supply Chain Transparency: Ethical sourcing demands that suppliers provide clear documentation on labor practices, conflict-free minerals, and environmental certifications.

Green certifications and standards to look for:

- RoHS (Restriction of Hazardous Substances): Ensures components are free from harmful materials.

- ISO 14001 Environmental Management: Indicates a supplier’s commitment to minimizing environmental impact.

- Energy Star or Equivalent: Certification for energy-efficient electronic products.

- Conflict-Free Sourcing Certifications: Particularly important for regions like Africa, ensuring raw materials are ethically obtained.

For B2B buyers in Africa, South America, the Middle East, and Europe, prioritizing suppliers with recognized sustainability credentials not only reduces regulatory risks but also strengthens corporate social responsibility profiles, enhancing brand value and market competitiveness.

Evolution of Drive LED Strips with Raspberry Pi

The integration of drive LED strips with Raspberry Pi controllers has evolved significantly since the early 2010s. Initially, LED strips were simple, fixed-function lighting solutions with limited programmability. The advent of the Raspberry Pi microcomputer revolutionized this space by providing an affordable, versatile platform capable of running complex lighting control software and interfacing with various sensors and networks.

Over the years, advancements such as the introduction of addressable LEDs (e.g., WS2812b) and real-time control libraries have enabled dynamic lighting effects, data-driven automation, and seamless IoT integration. This evolution has empowered B2B buyers to move beyond basic illumination toward intelligent lighting ecosystems that enhance operational efficiency, user engagement, and energy savings.

Today, the market benefits from a robust ecosystem of hardware vendors, open-source software, and global communities driving continuous innovation, making the combination of drive LED strips and Raspberry Pi an indispensable solution for modern lighting applications worldwide.

Related Video: How to use WS2812B RGB LEDs with Raspberry Pi

Frequently Asked Questions (FAQs) for B2B Buyers of drive led strip with raspberry pi

-

How can I effectively vet suppliers of drive LED strips with Raspberry Pi integration for international B2B purchases?

To vet suppliers, request detailed company profiles, certifications (ISO, CE, RoHS), and client references. Verify their manufacturing capabilities and experience with Raspberry Pi-compatible LED products. Utilize platforms with verified reviews and check for responsiveness in communication. For buyers in Africa, South America, the Middle East, and Europe, consider suppliers who demonstrate understanding of your regional compliance and logistical requirements. Conduct sample testing before bulk orders to assess quality and compatibility. -

What customization options are typically available when sourcing drive LED strips with Raspberry Pi?

Most suppliers offer customization in LED types (RGB, addressable), strip length, voltage, and connector compatibility with Raspberry Pi GPIO pins. Firmware or control software customization may also be possible to suit specific application needs. For international buyers, clarify your exact technical requirements upfront to ensure the supplier can deliver tailored solutions. Custom packaging and labeling are often available for brand alignment, which is valuable for distributors in diverse markets. -

What are the usual minimum order quantities (MOQ), lead times, and payment terms for these products in B2B trade?

MOQs vary widely but typically range from 100 to 500 units depending on complexity and customization. Lead times can range from 3 to 8 weeks, influenced by order size, customization, and shipping method. Common payment terms include 30% upfront deposit with balance paid before shipment or upon delivery via Letter of Credit. Buyers should negotiate terms that balance cash flow with supplier confidence, especially when importing to regions like South Africa or Colombia where import regulations may affect timing. -

Which quality assurance standards and certifications should international buyers look for?

Look for products compliant with CE (Europe), FCC (US), RoHS (hazardous substances), and ISO 9001 quality management certifications. For African and Middle Eastern markets, ensure compliance with local electrical safety standards and EMC regulations. Request test reports for LED lifespan, color consistency, and Raspberry Pi compatibility. Quality assurance processes like in-line testing and batch inspection reduce defects, critical for maintaining supply chain reliability. -

What logistical considerations should B2B buyers keep in mind when importing drive LED strips with Raspberry Pi?

Consider shipping modes (air freight for speed, sea freight for cost efficiency), customs clearance processes, and import duties specific to your country. Confirm supplier’s experience with export documentation (commercial invoice, packing list, certificate of origin). For regions with complex import regulations, partnering with freight forwarders familiar with electronics imports can mitigate delays. Also, verify packaging robustness to prevent damage during long transit. -

How can buyers manage potential disputes or quality issues with overseas suppliers?

Establish clear contracts detailing product specifications, delivery schedules, and dispute resolution mechanisms such as arbitration clauses. Use escrow or milestone payments to reduce financial risk. Maintain documented communication and quality inspection records. In case of defects, negotiate returns, replacements, or refunds promptly. For recurring issues, consider third-party inspection services before shipment and build relationships with suppliers open to continuous improvement. -

Are there specific Raspberry Pi compatibility challenges to be aware of in international sourcing?

Yes, ensure the LED strips are compatible with the Raspberry Pi model and firmware versions used in your target market. Voltage and connector standards may differ regionally. Confirm that control software or libraries provided support your Raspberry Pi’s OS and version. Suppliers should offer technical support or documentation for integration. This reduces the risk of operational failures and costly redesigns after import. -

What payment methods are most secure and convenient for international B2B transactions in these regions?

Common secure methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), and Escrow services. L/Cs offer protection by involving banks but may incur additional fees and longer processing times. T/T is faster but requires trust in the supplier. Escrow platforms can provide neutral third-party holding funds until delivery confirmation. Evaluate local banking infrastructure and currency stability in your region to select the optimal payment method balancing security and cost.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drive led strip with raspberry pi

Strategic sourcing of drive LED strips integrated with Raspberry Pi technology presents a compelling opportunity for international B2B buyers aiming to innovate cost-effectively while maintaining quality and scalability. Key takeaways include the importance of selecting suppliers with proven expertise in IoT-enabled lighting solutions, ensuring component compatibility, and prioritizing flexible logistics tailored to regional markets such as Africa, South America, the Middle East, and Europe.

For buyers in dynamic markets like South Africa and Colombia, leveraging strategic partnerships with manufacturers who offer modular, customizable LED strip solutions can accelerate product development cycles and reduce time-to-market. Additionally, sourcing from vendors with robust after-sales support and technical resources enhances operational reliability and innovation capacity.

Looking ahead, the convergence of Raspberry Pi’s versatile computing platform with advanced LED strip technologies will continue to unlock new applications across smart cities, retail, and industrial automation sectors. International buyers are encouraged to adopt a forward-thinking procurement strategy that emphasizes sustainability, supplier diversification, and regional compliance standards to maximize ROI.

By embracing these strategic sourcing principles, businesses can not only meet current demand but also position themselves at the forefront of emerging digital lighting trends, driving competitive advantage in an increasingly interconnected global market.