Introduction: Navigating the Global Market for drive led strip arduino

In today’s interconnected industrial landscape, sourcing reliable and efficient drive LED strip Arduino solutions is pivotal for businesses aiming to innovate in lighting technology, automation, and smart device applications. These components serve as the backbone for diverse projects—from architectural lighting in European smart cities to precision agricultural setups in South America and dynamic retail displays across the Middle East and Africa. Understanding the nuances of drive LED strip Arduino systems can dramatically enhance product performance and operational efficiency.

This comprehensive guide is designed specifically for international B2B buyers, with a keen focus on markets such as Argentina, Italy, Nigeria, and the UAE. It delves into the various types of LED strips compatible with Arduino, examining their materials, technical specifications, and the driving mechanisms that ensure optimal functionality. Additionally, it covers critical factors in manufacturing and quality control processes, enabling buyers to discern credible suppliers and mitigate risks associated with inferior components.

Key market insights include pricing structures, regional supply chain dynamics, and compliance considerations, empowering procurement professionals to negotiate favorable terms and ensure seamless integration into their product lines. The guide also features a detailed FAQ section addressing common technical and sourcing challenges, facilitating faster decision-making.

By leveraging this resource, international buyers can make well-informed sourcing decisions, optimize their inventory strategies, and build resilient partnerships with trusted manufacturers. This strategic approach not only reduces costs but also accelerates time-to-market, delivering competitive advantages in rapidly evolving global markets.

Understanding drive led strip arduino Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Digital Addressable LED Strips (e.g., WS2812) | Individually addressable LEDs with integrated drivers; requires precise timing control | Dynamic lighting displays, signage, interactive installations | + High customization; vibrant colors – Requires complex programming and power management |

| Analog LED Strips (e.g., 12V RGB) | Uniform color control along the entire strip; simpler wiring and control | Architectural lighting, ambient lighting, retail displays | + Easy to integrate; cost-effective – Limited effects; less flexible color control |

| High-Power LED Strips | Uses high-wattage LEDs for intense illumination; often needs external drivers | Industrial lighting, outdoor signage, high-brightness displays | + Bright output; durable – Higher energy consumption; more complex heat dissipation needed |

| Flexible LED Strips with Integrated Drivers | Built-in driver ICs on the strip for simplified Arduino interfacing | Prototyping, educational kits, small-scale decorative projects | + Simplifies integration; reduces additional components – Limited length; moderate brightness |

| Addressable LED Strips with SPI Interface | Uses SPI protocol for communication; faster data rates and precise control | Large-scale commercial displays, stage lighting, complex animations | + Fast refresh rates; scalable – Requires advanced controllers; higher cost |

Digital Addressable LED Strips such as WS2812 are highly favored in B2B sectors requiring intricate lighting effects and fine color control. Their individually addressable LEDs allow for complex animations and dynamic displays, making them ideal for advertising agencies and event organizers in regions like Europe and South America. Buyers should consider the need for advanced programming skills and adequate power supply solutions when sourcing these strips.

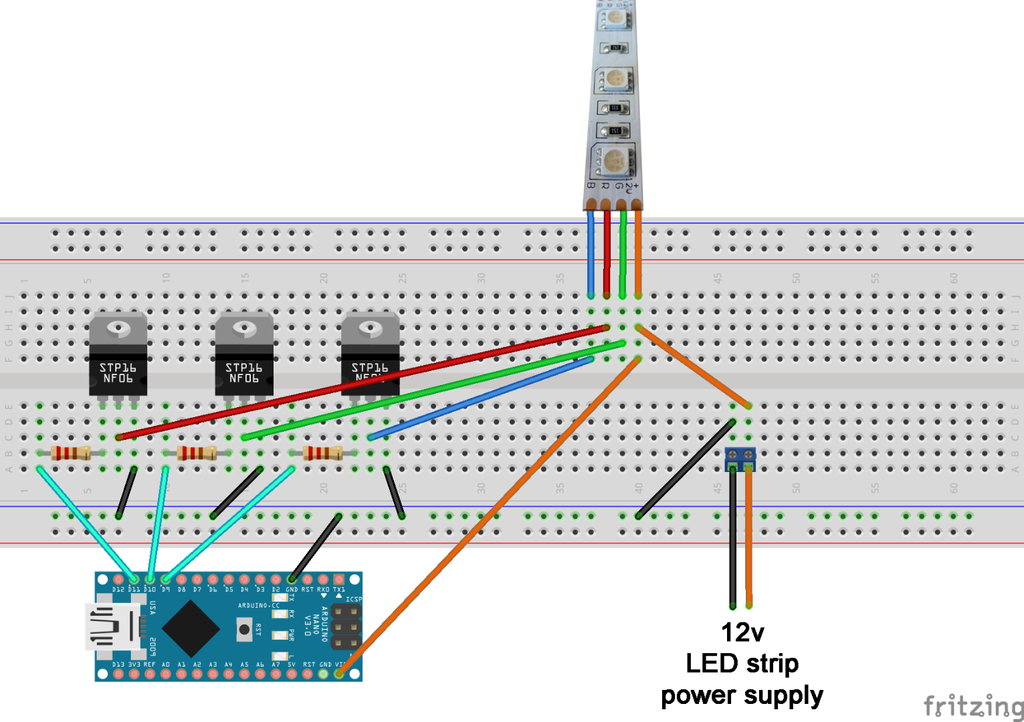

Analog LED Strips, typically running on 12V and controlling all LEDs uniformly, offer a straightforward and cost-effective solution for applications like architectural lighting and retail ambiance. Their simplicity makes them attractive for businesses in emerging markets such as Africa and the Middle East, where ease of installation and maintenance are priorities. However, their limited color flexibility may restrict creative lighting designs.

High-Power LED Strips cater to industrial and outdoor environments demanding intense brightness and durability. These strips often require external drivers and efficient heat management, factors that buyers in sectors like manufacturing or outdoor advertising must evaluate carefully. While offering superior illumination, their higher energy consumption and installation complexity should be weighed against project requirements.

Flexible LED Strips with Integrated Drivers reduce the complexity of Arduino interfacing by embedding driver ICs directly on the strip. This type is particularly suitable for educational institutions, prototyping labs, and small decorative projects where ease of use is essential. However, their limited length and moderate brightness may constrain large-scale commercial deployments.

Addressable LED Strips using SPI communication provide faster data transfer and more precise control, making them suitable for large-scale commercial displays and stage lighting in advanced markets such as Italy or Argentina. These strips support complex animations and scalability but require buyers to invest in sophisticated controllers and accept higher upfront costs.

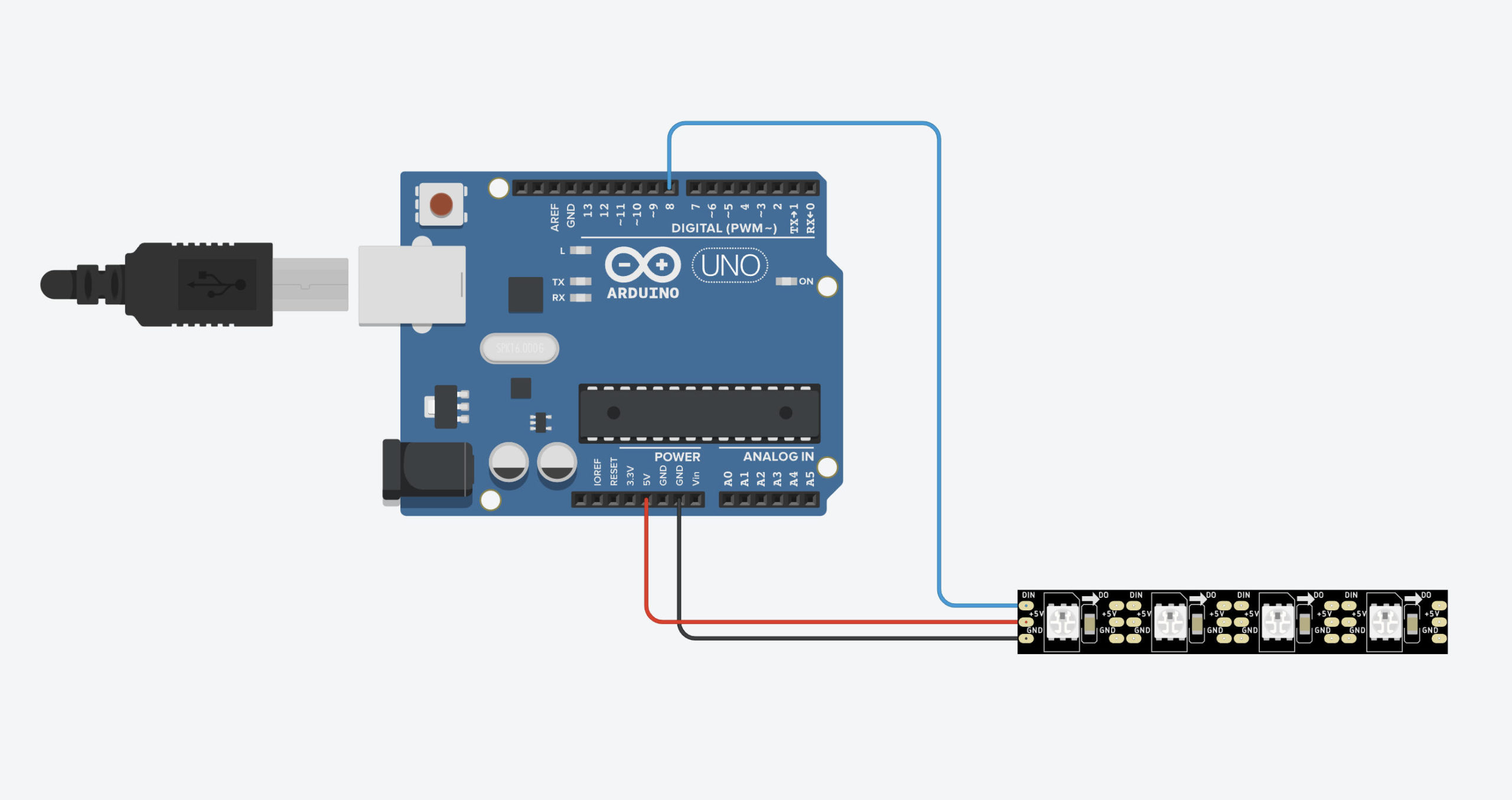

Related Video: Getting Started With Arduino To Control An Addressable LED Strip In This Beginner Project Tutorial

Key Industrial Applications of drive led strip arduino

| Industry/Sector | Specific Application of drive led strip arduino | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing & Automation | Status indication and machine feedback lighting | Enhances real-time monitoring, reduces downtime, and improves safety | Robustness, compatibility with industrial control systems, and ease of integration |

| Retail & Commercial Display | Dynamic product displays and ambient lighting | Attracts customers, increases engagement, and drives sales | Customizability, color accuracy, energy efficiency, and compliance with local standards |

| Smart Building & IoT | Adaptive architectural lighting and energy-efficient controls | Reduces energy costs, improves occupant comfort, and enables automation | Scalability, network compatibility, and long-term reliability |

| Automotive & Transportation | Interior mood lighting and dashboard illumination | Improves user experience and vehicle aesthetics | Vibration resistance, power consumption, and compliance with automotive regulations |

| Entertainment & Events | Stage lighting effects and interactive installations | Creates immersive environments and enhances audience engagement | High brightness, color versatility, and ease of programming |

Manufacturing & Automation

In manufacturing plants, drive LED strip Arduino systems are employed for machine status indication and feedback lighting. These LED strips communicate operational states such as errors, running conditions, or maintenance needs, enabling quick response and minimizing downtime. International buyers, especially in industrial hubs like Italy or South America, must ensure that LED strips meet industrial-grade durability and are compatible with existing PLCs or control systems. Sourcing considerations include resistance to harsh environments and ease of integration with automation protocols.

Retail & Commercial Display

Retailers in Africa, Europe, and the Middle East leverage Arduino-driven LED strips to create dynamic product displays and ambient lighting that adapt to different marketing campaigns or customer flows. This application boosts visual appeal and drives higher foot traffic. Buyers should prioritize LED strips with high color accuracy and energy efficiency, as well as the flexibility to customize lighting patterns remotely. Compliance with regional electrical safety standards is critical when sourcing for commercial environments.

Smart Building & IoT

Smart buildings utilize Arduino-controlled LED strips for adaptive architectural lighting that adjusts based on occupancy, daylight, or time of day. This not only enhances occupant comfort but also significantly reduces energy consumption—a crucial factor for sustainable construction projects in Europe and growing urban centers in South America and Africa. International buyers should focus on scalability, network communication protocols (e.g., Zigbee, Wi-Fi), and the long-term reliability of components under varying climatic conditions.

Automotive & Transportation

In automotive manufacturing and customization sectors, drive LED strip Arduino solutions provide interior mood lighting and dashboard illumination. These systems improve driver experience and vehicle aesthetics, which is highly valued in European and Middle Eastern markets. Buyers must ensure that LED strips have vibration resistance, low power consumption, and comply with automotive industry standards. Sourcing from suppliers with automotive certification can mitigate risks related to durability and safety.

Entertainment & Events

For event organizers and entertainment venues in regions like South America and Europe, Arduino-driven LED strips enable versatile stage lighting and interactive installations that captivate audiences. These LED systems offer high brightness and a broad color spectrum essential for creating immersive experiences. Key sourcing factors include ease of programming, robustness for frequent setup and teardown, and compatibility with DMX or other lighting control protocols widely used in the industry.

Related Video: How to use WS2812B RGB LED strip with Arduino | ws2811 ws2812 ws2813 ws2815 sk6812 sk9822 neopixel

Strategic Material Selection Guide for drive led strip arduino

When selecting materials for driving LED strips with Arduino, international B2B buyers must consider factors such as electrical performance, environmental durability, manufacturing feasibility, and regional compliance standards. The choice of materials directly influences product longevity, reliability, and cost-effectiveness, especially in diverse markets like Africa, South America, the Middle East, and Europe.

1. Copper (Cu) – Conductive Traces and Wiring

Key Properties:

Copper is renowned for its excellent electrical conductivity (~5.96×10^7 S/m), good thermal conductivity, and moderate mechanical strength. It withstands temperatures up to approximately 1085°C before melting, with good corrosion resistance when properly coated or alloyed.

Pros & Cons:

Copper’s superior conductivity ensures minimal voltage drop along LED strips, enhancing brightness uniformity. It is widely available and compatible with standard PCB manufacturing processes. However, pure copper is prone to oxidation, which can degrade performance unless protected by coatings like tin or gold. Copper also adds weight and cost compared to aluminum alternatives.

Impact on Application:

Copper is ideal for internal circuit traces and power lines in LED strip drivers, especially where stable current flow is critical. In humid or coastal environments common in parts of Africa and South America, corrosion-resistant coatings are essential to maintain longevity.

International Considerations:

Buyers in Europe (e.g., Italy) should verify compliance with RoHS and REACH directives restricting hazardous substances in copper alloys. In the Middle East and South America, ASTM B170 and IEC standards for copper purity and conductivity are commonly referenced. Procurement should ensure copper sourced meets these standards to avoid quality issues.

2. Aluminum (Al) – Heat Sinks and Substrates

Key Properties:

Aluminum offers excellent thermal conductivity (~205 W/m·K) and a good strength-to-weight ratio. It is corrosion-resistant due to a natural oxide layer and can operate effectively up to 660°C melting point.

Pros & Cons:

Aluminum is cost-effective and lightweight, making it suitable for heat dissipation in LED strip drivers. Its corrosion resistance reduces maintenance in harsh environments. However, aluminum has lower electrical conductivity than copper, so it is rarely used for wiring but mainly for structural components and heat sinks.

Impact on Application:

In regions with high ambient temperatures like the Middle East and parts of Africa, aluminum heat sinks improve thermal management, extending LED lifespan. Its corrosion resistance suits outdoor or industrial installations exposed to dust and moisture.

International Considerations:

European buyers should ensure aluminum components comply with EN 573 and EN 755 standards for alloy composition and mechanical properties. South American and African markets often refer to ASTM B221 for aluminum extrusion quality. Sourcing from suppliers adhering to these standards ensures consistent performance.

3. Polycarbonate (PC) – Protective Housing and Diffusers

Key Properties:

Polycarbonate is a transparent thermoplastic with high impact resistance, good UV stability, and operating temperature range from -40°C to 115°C. It offers excellent electrical insulation properties.

Pros & Cons:

PC is lightweight, easy to mold, and provides robust protection against mechanical damage and environmental factors. It is ideal for LED strip covers and housings. However, it can yellow over time under prolonged UV exposure unless UV-stabilized grades are used, increasing cost.

Impact on Application:

For outdoor LED strip installations in sunny climates such as South America and the Middle East, UV-resistant polycarbonate ensures long-term clarity and protection. Its electrical insulation reduces risk of short circuits in humid or dusty environments.

International Considerations:

Buyers should verify compliance with ISO 7823 (plastics for electrical applications) and regional fire safety standards like UL 94 V-0 or EN 13501-1. In Europe, REACH compliance and RoHS restrictions on additives are critical. African and South American markets may require certification for UV resistance and weatherability.

4. Silicone – Encapsulation and Waterproofing

Key Properties:

Silicone is a flexible, thermally stable polymer with excellent resistance to moisture, UV radiation, and temperature extremes (-60°C to 230°C). It provides electrical insulation and mechanical cushioning.

Pros & Cons:

Silicone encapsulants protect LED strips from water ingress, dust, and mechanical shock, essential for outdoor or industrial applications. It is chemically inert and durable but generally more expensive and requires specialized manufacturing processes.

Impact on Application:

In regions with high humidity or outdoor exposure such as coastal Africa and South America, silicone encapsulation extends product life and reliability. Its flexibility allows for varied form factors and ease of installation.

International Considerations:

Compliance with IEC 60529 (IP ratings for ingress protection) and UL 746C (polymer encapsulants) is important for international buyers. Europe’s REACH and RoHS regulations also apply to silicone additives. Buyers should ensure suppliers provide certifications to meet these standards for export and local market acceptance.

Summary Table

| Material | Typical Use Case for drive led strip arduino | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Conductive traces and wiring | Excellent electrical conductivity and reliability | Susceptible to oxidation without protective coating | Medium |

| Aluminum | Heat sinks and structural substrates | High thermal conductivity and corrosion resistance | Lower electrical conductivity; not suitable for wiring | Low |

| Polycarbonate | Protective housing and diffusers | High impact resistance and electrical insulation | UV degradation risk without stabilization | Medium |

| Silicone | Encapsulation and waterproofing | Superior moisture and UV resistance; flexible | Higher cost and specialized processing required | High |

This guide provides a strategic overview for B2B buyers to select materials that balance performance, cost, and compliance, tailored to the diverse environmental and regulatory landscapes of Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for drive led strip arduino

Manufacturing Process for Drive LED Strip Arduino

The production of drive LED strip Arduino units involves a multi-stage manufacturing process designed to ensure performance, durability, and compliance with international standards. Understanding these stages helps B2B buyers evaluate supplier capabilities and optimize procurement strategies.

1. Material Preparation

This initial phase focuses on sourcing and preparing the raw materials critical for LED strip drivers and Arduino control modules. Key components include:

- Printed Circuit Boards (PCBs): Usually made from FR4 or similar substrates, PCBs are pre-treated for solderability and electrical insulation.

- Electronic Components: Integrated circuits, resistors, capacitors, MOSFETs, microcontrollers (Arduino chips), and connectors are procured from certified suppliers.

- LED Strips: Often WS2812 or similar addressable LED strips, pre-tested for functionality.

Suppliers typically perform incoming quality control (IQC) here to verify component authenticity and basic quality parameters.

2. Forming and PCB Assembly

- PCB Fabrication: PCBs are fabricated using photolithography, etching, and layering processes to create precise circuit patterns.

- Surface Mount Technology (SMT): Automated pick-and-place machines place surface-mount components onto PCBs, followed by solder reflow ovens to secure parts.

- Through-Hole Assembly: For connectors and larger components, manual or wave soldering methods are used.

- Arduino Microcontroller Programming: Firmware is uploaded to the microcontroller during or after assembly, ensuring the drive logic aligns with LED strip specifications.

This stage demands stringent environmental controls (e.g., ESD protection) to prevent component damage.

3. Assembly and Integration

Once PCBs are populated, they are integrated with LED strips and additional hardware:

- Wiring and Connectors: Secure and standardized connectors ensure compatibility with various LED strips and power supplies.

- Enclosure and Heat Management: Depending on use cases, protective casings and heat sinks may be added to enhance durability and thermal dissipation.

- Functional Assembly: Final mechanical assembly is performed, including mounting brackets or adhesive backing for the LED strips.

4. Finishing and Packaging

- Visual Inspection: Ensures no physical defects or assembly errors.

- Labeling and Documentation: Compliance labels, serial numbers, and user instructions are affixed.

- Protective Packaging: Anti-static bags and shock-absorbent materials protect units during transit.

Packaging is often customized per buyer requirements, especially for international shipments.

Quality Assurance and Control (QA/QC)

Robust quality assurance frameworks are essential to maintain high standards and meet international buyer expectations. B2B buyers should prioritize suppliers with established QA processes aligned with recognized standards.

Relevant International and Industry Standards

- ISO 9001: This global quality management system standard ensures consistent manufacturing quality, process optimization, and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electronic components, crucial for European and international markets.

- UL Certification: Relevant for electrical safety in North America but often valued globally.

- Industry-Specific Standards: Depending on application, certifications like API (for industrial control environments) may apply.

B2B buyers should request documentation proving supplier compliance with these certifications.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Inspection and testing of raw materials and components to prevent defective parts entering production.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly phases, including solder joint inspection and functional tests of sub-assemblies.

- Final Quality Control (FQC): Comprehensive testing of fully assembled units, including firmware validation and performance under load.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and signal integrity of LED drivers and Arduino microcontrollers.

- Functional Testing: Confirms correct LED strip control sequences, color accuracy, and response times.

- Environmental Testing: Assesses resistance to temperature variations, humidity, and vibration for durability assurance.

- Visual and Mechanical Inspection: Detects solder defects, component misalignment, and enclosure integrity.

Verifying Supplier Quality Control for International B2B Buyers

For buyers from regions such as Africa, South America (e.g., Argentina), the Middle East, and Europe (e.g., Italy), ensuring supplier QC is crucial to avoid costly delays and product failures.

Recommended Verification Practices

- Supplier Audits: Conduct on-site or virtual audits to review manufacturing processes, QC documentation, and compliance with international standards.

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing before shipment.

- Review of QC Reports: Request detailed IQC, IPQC, and FQC reports, including test results and corrective actions taken.

- Sample Testing: Obtain product samples for in-house or third-party lab testing to verify specifications and performance claims.

- Certifications Validation: Confirm authenticity of ISO 9001, CE, RoHS, and other relevant certificates through official registries or certification bodies.

QC and Certification Nuances by Region

- Africa: Importers should verify compliance with local electrical safety and EMC regulations, which may differ from European standards. Partnering with suppliers familiar with regional certification requirements expedites customs clearance.

- South America (Argentina): Mercosur technical regulations require specific certifications; buyers should ensure suppliers provide documentation compliant with local standards like IRAM.

- Middle East: Regulatory frameworks vary; GCC countries often require SASO certification or equivalent. Suppliers with experience exporting to these markets typically handle such requirements.

- Europe (Italy and broader EU): Strict adherence to CE marking, RoHS, and WEEE directives is mandatory. Buyers must confirm suppliers’ environmental and safety compliance to avoid legal penalties.

Key Takeaways for B2B Buyers

- Engage with suppliers who demonstrate transparent manufacturing processes and provide detailed QC documentation aligned with international standards.

- Prioritize suppliers with certifications recognized in your target market to minimize compliance risks.

- Implement multi-level verification strategies, including audits and third-party inspections, to safeguard product quality and supply chain reliability.

- Consider regional regulatory nuances to ensure smooth market entry and sustained operational compliance.

By thoroughly understanding the manufacturing and quality assurance landscape for drive LED strip Arduino products, international B2B buyers can make informed sourcing decisions that enhance product reliability and competitive advantage.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for drive led strip arduino Sourcing

Understanding the cost structure and pricing dynamics for sourcing drive LED strip Arduino solutions is crucial for international B2B buyers aiming to optimize procurement strategies while maintaining product quality and supplier reliability. This section breaks down the primary cost components, key price influencers, and actionable buyer tips tailored to markets in Africa, South America, the Middle East, and Europe.

Core Cost Components in Drive LED Strip Arduino Sourcing

-

Materials:

The core raw materials include LED chips, flexible PCB substrates, Arduino-compatible microcontrollers, resistors, capacitors, connectors, and protective coatings. Costs vary by LED type (e.g., WS2812 vs. generic RGB LEDs), quality grade, and sourcing region. High-quality materials with certifications (RoHS, CE) command premium prices but ensure durability and compliance. -

Labor:

Labor costs encompass assembly, soldering, programming, and testing. Manufacturing hubs with lower labor rates (e.g., parts of Asia) offer cost advantages but may require stricter quality oversight. Skilled labor for precise Arduino integration can impact unit costs, especially for custom firmware or programming. -

Manufacturing Overhead:

Includes factory utilities, equipment depreciation, quality control processes, and indirect labor. Efficient production lines with automation reduce overhead, but bespoke or low-volume runs can increase per-unit overhead. -

Tooling and Setup:

Initial tooling for PCB fabrication, stencil creation for solder paste application, and programming jig development contribute to upfront costs. These are amortized over production volume, so larger orders reduce the impact on unit price. -

Quality Control (QC):

Testing LED function, Arduino code validation, and durability assessments add to cost but are critical for minimizing returns and ensuring product reliability, especially for demanding industrial or commercial applications. -

Logistics and Import Duties:

Freight charges (air, sea, land), customs clearance, tariffs, and local taxes vary significantly by destination. For African and South American buyers, import duties can substantially increase landed cost. Efficient logistics planning and use of favorable Incoterms (e.g., DDP vs. FOB) influence total cost. -

Supplier Margin:

Supplier pricing includes profit margin reflecting their risk, service level, and market positioning. Margins can be negotiated based on order volume and long-term partnership potential.

Key Price Influencers to Consider

-

Order Volume and Minimum Order Quantity (MOQ):

Higher volumes drastically reduce unit costs due to economies of scale. Many suppliers enforce MOQs, which can be a barrier for smaller buyers but also an opportunity for price breaks if consolidated. -

Specifications and Customization:

Custom LED densities, strip lengths, Arduino firmware modifications, or enhanced waterproofing increase costs. Buyers should balance feature requirements against budget constraints. -

Material Quality and Certifications:

Certified components ensure compliance with international standards and reduce liability, but they add to cost. European buyers often require CE marking, while Middle Eastern markets may demand specific certifications. -

Supplier Reliability and Location:

Established suppliers with proven track records may charge premiums but offer better quality assurance and delivery reliability. Proximity to buyer markets (e.g., European suppliers for Italy) can reduce logistics costs and lead times. -

Incoterms and Payment Terms:

The choice of Incoterms affects who bears shipping and risk costs. DDP (Delivered Duty Paid) offers convenience but at a higher price. Payment terms (e.g., Letter of Credit, Net 30) impact cash flow and supplier pricing flexibility.

Strategic Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership (TCO):

Look beyond unit price to include logistics, customs, quality assurance, and after-sales support. For example, a slightly higher unit price from a local European supplier might result in lower overall TCO due to reduced shipping times and duties. -

Leverage Volume Consolidation:

Buyers from regions like Africa and South America can collaborate to place joint orders, lowering MOQs and accessing better pricing tiers. -

Prioritize Quality and Certification:

In markets with stringent regulations (e.g., Europe), insist on certified components to avoid costly compliance issues. -

Understand Pricing Nuances by Region:

For example, import duties in Argentina can exceed 20%, significantly impacting landed cost. In the Middle East, free trade zones may offer duty exemptions. Tailor sourcing strategies accordingly. -

Build Long-Term Supplier Relationships:

Establishing trust and consistent order volumes can unlock better pricing, priority production slots, and customized service. -

Consider Local Assembly or Programming:

To reduce import duties on fully assembled units, consider importing components and performing final assembly or Arduino programming locally.

Indicative Pricing Disclaimer

Prices for drive LED strip Arduino assemblies vary widely depending on technical specifications, volumes, and supplier location. Typical unit costs can range from $5 to $20 per meter for standard LED strips integrated with Arduino control, excluding logistics and taxes. Buyers should request detailed quotations reflecting their precise requirements and factor in all ancillary costs for accurate budgeting.

By comprehensively analyzing these cost drivers and price influencers, international B2B buyers can craft informed sourcing strategies that optimize cost-efficiency, product quality, and supply chain resilience across diverse global markets.

Spotlight on Potential drive led strip arduino Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘drive led strip arduino’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for drive led strip arduino

Critical Technical Properties for Driving LED Strips with Arduino

Understanding the essential technical specifications of LED strip drivers compatible with Arduino is vital for B2B buyers aiming to ensure product quality, compatibility, and long-term reliability across diverse markets such as Africa, South America, the Middle East, and Europe.

-

Voltage and Current Ratings

LED strips typically operate at 5V or 12V, but the driver must support the required voltage and handle the current load of the entire strip. Under-specifying current capacity can lead to overheating or failure. For B2B buyers, verifying these ratings guarantees the driver meets the power demands of large-scale installations, avoiding costly returns or warranty claims. -

Signal Protocol Compatibility

Popular LED strips like WS2812 or SK6812 use specific digital protocols for color and brightness control. The driver must support these protocols to ensure seamless integration with Arduino microcontrollers. This property is crucial for international buyers to ensure interoperability with existing hardware and software ecosystems. -

Material Grade and Build Quality

Components such as PCB substrates, solder joints, and connectors should meet industrial-grade standards (e.g., FR4 for PCBs) to ensure durability and heat dissipation. This factor is particularly significant for buyers targeting harsh climates or demanding environments, ensuring longevity and reducing maintenance costs. -

Tolerance and Precision

Electrical components within the driver (resistors, capacitors, MOSFETs) must have tight tolerance levels (e.g., ±1%) to maintain consistent performance. Precision impacts LED color accuracy and driver reliability, which directly affects end-user satisfaction and brand reputation for B2B clients. -

Thermal Management Features

Efficient heat sinks or thermal pads integrated into the driver design prevent overheating during continuous operation. For buyers in regions with high ambient temperatures, this feature is critical to maintain safety standards and operational stability. -

Control Interface Options

Drivers may offer interfaces such as PWM input, serial communication (SPI, I2C), or analog control signals compatible with Arduino boards. Understanding these interfaces helps buyers select products that fit their automation and control requirements without additional adaptation costs.

Common Trade Terminology for B2B Transactions in LED Strip Arduino Drivers

Familiarity with key trade terms can streamline procurement, negotiation, and logistics processes for international buyers:

-

OEM (Original Equipment Manufacturer)

Refers to a company that produces components or products that other companies rebrand and sell. Buyers may seek OEM partnerships for custom driver designs or bulk manufacturing to differentiate their offerings in local markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQs vary by manufacturer and impact inventory planning and cash flow management. Buyers from emerging markets should negotiate favorable MOQs to balance cost efficiency with storage constraints. -

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain pricing, lead times, and terms for specified quantities and specifications. RFQs are essential for comparing multiple suppliers and securing competitive deals, especially when sourcing globally. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) that define responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Understanding Incoterms helps buyers from different regions manage import logistics and avoid unexpected costs. -

Lead Time

The duration from order placement to delivery. Lead time influences project scheduling and inventory turnover. Buyers should confirm realistic lead times to avoid production delays, particularly when dealing with international suppliers. -

RoHS Compliance (Restriction of Hazardous Substances)

Indicates that the product meets environmental standards limiting hazardous materials like lead or mercury. Many European buyers require RoHS compliance to meet regulatory standards, making it a critical specification for global trade.

By prioritizing these technical properties and mastering relevant trade terminology, international B2B buyers can make informed decisions, optimize supply chain efficiency, and secure high-quality Arduino-compatible LED strip drivers tailored to their market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drive led strip arduino Sector

Market Overview & Key Trends

The global market for drive LED strip Arduino solutions is experiencing robust growth driven by increasing automation, smart lighting, and IoT integration across various industries. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, this sector offers significant opportunities fueled by rising demand for customizable and energy-efficient lighting controls. Countries such as Argentina and Italy are witnessing a surge in smart city projects, architectural lighting, and industrial automation, all of which rely heavily on LED strip technology integrated with Arduino for flexible control.

Key market dynamics include a shift towards modular and scalable solutions that allow easy integration with other smart devices. Buyers are prioritizing suppliers who offer compatibility with popular microcontrollers and open-source platforms, ensuring adaptability and cost efficiency. Additionally, the rise of wireless and Bluetooth-enabled LED strip controllers enhances installation flexibility, which is crucial for diverse infrastructural landscapes seen in emerging markets.

Illustrative Image (Source: Google Search)

Sourcing trends indicate a growing preference for suppliers who provide comprehensive technical support, including firmware customization and troubleshooting, due to the technical nature of drive LED strip Arduino products. Regional buyers are also gravitating towards vendors with localized supply chains or distribution centers to reduce lead times and logistics costs. Furthermore, there is an increasing emphasis on quality certifications and compliance with international standards such as CE, RoHS, and FCC, which assure product reliability and safety.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the procurement of drive LED strip Arduino components. The environmental impact of LED production, including raw material extraction and electronic waste, is under scrutiny from global buyers. Ethical sourcing practices that emphasize conflict-free minerals and responsible labor conditions are essential to meet regulatory requirements and corporate social responsibility goals, especially for European and Middle Eastern buyers with stringent compliance frameworks.

Incorporating green certifications such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) ensures that products are free from harmful substances and align with environmental safety standards. Buyers should also seek suppliers committed to reducing carbon footprints through energy-efficient manufacturing processes and recyclable packaging.

Material innovation is another sustainability trend, with increasing use of biodegradable or recyclable substrates and low-power LED chips that extend product lifecycle while minimizing energy consumption. For B2B buyers, partnering with manufacturers who transparently disclose sustainability metrics and engage in circular economy practices can enhance brand reputation and meet growing end-customer demand for eco-friendly solutions.

Brief Evolution & Historical Context

The integration of Arduino microcontrollers with LED strip technology has evolved from simple DIY hobbyist projects to sophisticated industrial applications over the last decade. Initially, LED strips were controlled by basic hardware with limited programmability, but the advent of Arduino brought unprecedented flexibility, enabling programmable color patterns, brightness control, and synchronization with sensors or user inputs.

This evolution has opened new avenues for B2B buyers by facilitating rapid prototyping and customization, reducing time-to-market for innovative lighting solutions. The modular nature of Arduino platforms has also lowered barriers for companies in emerging regions to adopt advanced lighting controls without heavy investment in proprietary systems, democratizing access to smart lighting technology globally.

Frequently Asked Questions (FAQs) for B2B Buyers of drive led strip arduino

-

How can I effectively vet suppliers of drive LED strip Arduino modules for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications such as ISO or CE, which indicate quality and compliance. Request product samples to assess build quality and functionality. Check references or reviews from other international buyers, especially those in your region (Africa, South America, Middle East, Europe). Engage in direct communication to evaluate responsiveness and technical support capabilities. Finally, consider suppliers with transparent supply chains and proven export experience to mitigate risks related to customs and logistics. -

Is customization of drive LED strip Arduino solutions possible for bulk orders, and how should I approach it?

Yes, many manufacturers offer customization including length, LED density, power requirements, and control protocols. Clearly communicate your technical specifications and use cases upfront. Provide detailed documentation or reference designs if available. Negotiate minimum order quantities (MOQs) for customized runs early, as they tend to be higher than standard products. Request prototypes before full production to validate customization. Establish intellectual property agreements to protect your design and ensure confidentiality during development.

-

What are typical minimum order quantities (MOQs), lead times, and payment terms for international orders of drive LED strip Arduino products?

MOQs vary widely but typically range from 100 to 1,000 units depending on customization and supplier scale. Lead times can span 3-8 weeks, factoring in manufacturing, quality checks, and shipping. Payment terms often involve a 30-50% deposit upfront with the balance before shipment or upon delivery via irrevocable letter of credit. For buyers in regions like Africa and South America, negotiating flexible payment terms or escrow services can mitigate risks. Clarify these terms in the contract to avoid delays or disputes. -

What quality assurance standards and certifications should I expect when sourcing drive LED strip Arduino modules internationally?

Look for compliance with international standards such as CE (Europe), RoHS (hazardous substances restriction), and FCC (electromagnetic interference). Quality assurance should include in-line testing for LED brightness, color accuracy, and controller functionality. Suppliers should provide test reports or certificates of conformity. For critical applications, third-party inspection or factory audits can add confidence. Ensure the supplier has robust traceability and defect management processes to support after-sales service. -

What logistics considerations should I be aware of when importing drive LED strip Arduino products from overseas suppliers?

Plan for customs clearance by ensuring all product documentation (invoices, packing lists, certificates) is accurate and compliant with destination country regulations. Choose freight options balancing cost and delivery speed—air freight for urgent small shipments, sea freight for bulk orders. Be aware of any import restrictions or tariffs specific to electronic components in your country. Coordinate with freight forwarders experienced in handling electronics to minimize damage risks. Also, track shipments closely and prepare for potential delays in ports or customs. -

How can I manage disputes or quality issues effectively with international drive LED strip Arduino suppliers?

Establish clear contractual terms covering product specifications, delivery timelines, and penalties for non-compliance. Use Incoterms to define responsibility for shipping and risk. If issues arise, document defects thoroughly with photos and test data. Communicate promptly and professionally with the supplier to seek resolution, whether through replacement, repair, or refund. For recurring problems, consider third-party mediation or arbitration clauses in contracts. Maintaining a good relationship while enforcing quality standards is key to long-term success. -

Are there regional considerations for sourcing drive LED strip Arduino products from suppliers in Asia or Europe for markets in Africa, South America, or the Middle East?

Yes, regional factors impact sourcing decisions. European suppliers may offer superior certifications and shorter lead times for buyers in Europe and the Middle East, but at higher costs. Asian suppliers often provide competitive pricing and customization but require longer lead times and careful quality vetting. For Africa and South America, logistical infrastructure and customs complexity can affect delivery reliability. Buyers should balance cost, quality, and supply chain robustness, possibly diversifying suppliers across regions to mitigate risks. -

What technical support and after-sales services should I expect when purchasing drive LED strip Arduino products in bulk internationally?

Reliable suppliers provide technical documentation, firmware updates, and troubleshooting support remotely. They may offer training for your engineering teams on integration and programming. Warranty terms typically cover manufacturing defects for a defined period (e.g., 12 months). Confirm availability of replacement parts and repair services. For critical projects, consider suppliers with local or regional partners to speed up support. Proactive communication channels and clear escalation paths improve operational continuity and reduce downtime.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drive led strip arduino

In today’s competitive global market, sourcing drive LED strip Arduino solutions requires a strategic approach that balances quality, cost-efficiency, and supplier reliability. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the technical nuances—such as compatible drivers, power management, and programming flexibility—is essential to selecting the right products that meet specific project demands. Leveraging suppliers with proven expertise and robust supply chains can mitigate risks associated with component shortages and delivery delays.

Key takeaways for international buyers include:

- Prioritize suppliers offering customizable and scalable LED strip driver solutions compatible with Arduino platforms.

- Evaluate supplier capabilities in technical support and after-sales service to ensure smooth integration and troubleshooting.

- Consider regional logistics and compliance with local standards to optimize cost and reduce lead times.

- Embrace emerging innovations in LED driving technologies that enhance energy efficiency and expand functional possibilities.

Looking forward, the demand for intelligent lighting solutions powered by Arduino-controlled LED strips is set to grow, driven by smart city initiatives, industrial automation, and creative architectural projects. Buyers who adopt a strategic sourcing mindset—focusing on supplier partnerships, technological alignment, and supply chain resilience—will secure a competitive advantage. Engage proactively with suppliers and technology partners to explore customized solutions that can unlock new market opportunities in your region.