Introduction: Navigating the Global Market for adding led strip to skr mini e3 v2

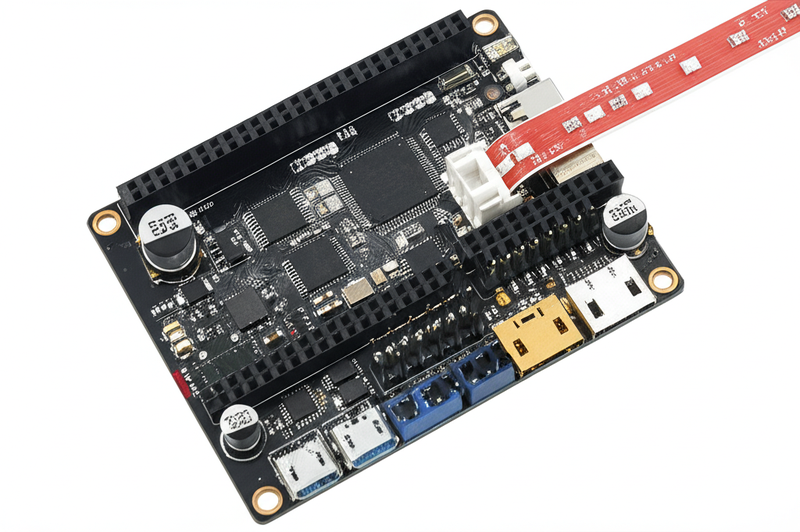

The integration of LED strips into the SKR Mini E3 V2 controller board represents a strategic enhancement for 3D printing operations, combining functional illumination with aesthetic appeal. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding the nuances of this upgrade is essential to making well-informed sourcing decisions. LED strips not only improve print visibility and workspace safety but also offer customization potential that can differentiate products in competitive manufacturing environments.

This guide delivers a thorough exploration of the entire value chain involved in adding LED strips to the SKR Mini E3 V2. It covers a spectrum of critical topics including types of LED strips suitable for 3D printers, essential materials and components, manufacturing and quality control standards, and supplier evaluation criteria tailored to global markets. Additionally, it addresses cost considerations and market dynamics relevant to regions such as Nigeria, Thailand, and beyond, enabling buyers to optimize procurement strategies.

By leveraging this comprehensive resource, B2B buyers will gain actionable insights into technical specifications, installation best practices, and troubleshooting protocols. This empowers procurement professionals and technical teams to assess product compatibility, verify supplier reliability, and ensure compliance with regional standards. Ultimately, the guide equips businesses with the knowledge to enhance their product offerings while managing risks and maximizing return on investment in the evolving global 3D printing landscape.

Understanding adding led strip to skr mini e3 v2 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard White LED Strips | Fixed white color, adhesive backing, simple wiring | Basic printer illumination, quality control stations | + Cost-effective, easy installation – Limited color customization |

| RGB LED Strips | Multi-color LEDs with controller for color changing effects | Branding, ambient lighting, advanced printer setups | + Customizable colors and effects – Requires additional control hardware |

| NeoPixel (Addressable) LED Strips | Individually addressable LEDs, integrated with firmware | Event notifications, status indication, premium models | + Dynamic lighting and status feedback – Firmware update and configuration needed |

| Waterproof LED Strips | Silicone or epoxy coated for moisture resistance | Humid or industrial environments | + Durable in harsh conditions – Higher cost, may reduce light intensity |

| High-Brightness LED Strips | Higher lumen output, often with better heat dissipation | Large-scale manufacturing, well-lit inspection areas | + Superior visibility in bright environments – Higher power consumption |

Standard White LED Strips

These strips offer consistent white lighting, ideal for illuminating the 3D printer workspace. Their adhesive backing simplifies installation, making them suitable for basic setups where visibility is the main concern. For B2B buyers in regions like Africa and South America, these strips provide a cost-effective solution to improve print monitoring without complex integration. When purchasing, ensure compatibility with the SKR Mini E3 V2’s power specifications and confirm adhesive quality for durable mounting.

RGB LED Strips

RGB LED strips enable multi-color lighting controlled via external controllers or the printer firmware, allowing businesses to customize the ambiance or integrate branding colors. This is especially attractive for B2B buyers in creative industries or showrooms in Europe and the Middle East, where aesthetics influence client perception. Buyers should consider the additional hardware requirements and ensure that control systems are compatible with existing printer setups.

NeoPixel (Addressable) LED Strips

NeoPixel strips stand out by allowing individual LED control, enabling complex lighting patterns and real-time event notifications through firmware integration. These are suited for advanced 3D printing environments where status indication is valuable, such as in industrial or educational settings across diverse markets including Nigeria and Thailand. B2B buyers must factor in the need for firmware updates, technical expertise for installation, and potential support services.

Waterproof LED Strips

Designed with protective coatings, waterproof LED strips are ideal for printers operating in humid or dusty environments, common in certain African and South American manufacturing facilities. Their durability ensures longer lifespan and reliability but comes at a premium cost. Buyers should evaluate environmental conditions carefully and balance upfront investment against maintenance savings and operational uptime.

High-Brightness LED Strips

These strips provide enhanced illumination through higher lumen output and improved heat dissipation, critical for large-scale production lines or detailed inspection tasks. European and Middle Eastern B2B buyers focused on industrial applications will benefit from superior visibility, reducing errors and improving quality control. However, buyers should assess power supply capabilities and potential increases in energy consumption when scaling these solutions.

Key Industrial Applications of adding led strip to skr mini e3 v2

| Industry/Sector | Specific Application of adding led strip to skr mini e3 v2 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Additive Manufacturing | Enhanced print monitoring and quality control through improved lighting | Enables real-time defect detection, reducing waste and reprints | Compatibility with SKR Mini E3 V2 firmware, reliable LED brightness and color consistency |

| Electronics Assembly | Visual status indicators and workspace illumination in PCB prototyping | Improves accuracy and reduces errors during assembly | Durability of LED strips under continuous use, ease of integration with existing control boards |

| Educational Institutions | Interactive learning tools with customizable lighting effects on 3D printers | Engages students and demonstrates printer status visually | Safe, low-voltage LED strips; easy installation and maintenance |

| Automotive Prototyping | Illuminated build chambers for complex part fabrication | Enhances precision and visibility in tight or intricate builds | Robust LED strips resistant to vibrations and temperature variations |

| Architectural Model Making | Ambient lighting for detailed model printing and presentation | Increases visual appeal and inspection capability | Flexible LED strips adaptable to diverse model geometries, consistent color rendering |

Additive Manufacturing

In the additive manufacturing sector, integrating LED strips with the SKR Mini E3 V2 controller enhances the print monitoring process by illuminating the build area. This lighting allows operators to detect print defects or extrusion issues in real time, minimizing material waste and costly reprints. For B2B buyers in regions such as South America and Africa, sourcing LED strips that offer consistent brightness and seamless firmware compatibility is crucial to maintain production efficiency. Furthermore, reliable technical support for firmware updates ensures smooth integration in diverse operational environments.

Electronics Assembly

Electronics manufacturers leverage LED strips connected to the SKR Mini E3 V2 for visual status notifications and improved workspace lighting during PCB prototyping. This setup helps technicians identify process stages or errors quickly, reducing assembly mistakes. International buyers, especially from the Middle East and Europe, prioritize durable LED strips capable of withstanding prolonged use and easy integration with existing control systems. Ensuring the LED strips meet industrial-grade standards and provide clear, consistent illumination is vital for operational reliability.

Educational Institutions

Educational organizations use LED strips on 3D printers like those controlled by the SKR Mini E3 V2 to create engaging, interactive learning environments. Customizable lighting effects help illustrate printer status and add visual appeal, enhancing student understanding of additive manufacturing processes. Buyers from countries such as Nigeria and Thailand should focus on sourcing LED strips that operate safely at low voltages and are simple to install or replace. This ensures ease of maintenance and safety compliance in classroom settings.

Automotive Prototyping

In automotive prototyping, precise fabrication of complex parts demands excellent visibility inside the build chamber. Adding LED strips to SKR Mini E3 V2 boards provides consistent illumination in confined spaces, allowing technicians to monitor intricate builds closely. B2B buyers in Europe and Africa must consider LED strips with high durability to resist vibrations and temperature fluctuations common in prototyping workshops. Additionally, sourcing from suppliers offering robust quality assurance helps maintain uninterrupted production cycles.

Architectural Model Making

Architectural firms and model makers utilize LED strips integrated with the SKR Mini E3 V2 to enhance both the printing process and the visual presentation of detailed models. Ambient lighting improves inspection accuracy and adds aesthetic value to presentations for clients. For international buyers in South America and the Middle East, selecting flexible LED strips that conform to varied model shapes and provide consistent color rendering is essential. This ensures that the lighting complements the architectural details without compromising print quality.

Related Video: Guide of replacing the motherboard of ender3 with BTT SKR MINI E3 V2.0 and BTT TFT35 E3 V3.0

Strategic Material Selection Guide for adding led strip to skr mini e3 v2

When selecting materials for integrating LED strips with the SKR Mini E3 V2 3D printer controller, it is essential to consider the operational environment, electrical compatibility, and durability. The choice of materials affects not only the performance and longevity of the LED installation but also compliance with international standards and ease of manufacturing. Below is an in-depth analysis of four common materials used in the installation and housing of LED strips tailored for B2B buyers across Africa, South America, the Middle East, and Europe.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance, excellent transparency, and good thermal stability (typically up to 115°C). It offers moderate chemical resistance and good dimensional stability under varying temperatures.

Pros & Cons:

– Pros: Durable and resistant to cracking, making it ideal for protective housings around LED strips. Its transparency allows for efficient light diffusion without significant loss. It is lightweight and easy to fabricate using injection molding or 3D printing.

– Cons: Polycarbonate can be prone to yellowing under prolonged UV exposure and may be more expensive than acrylic alternatives. It requires careful handling during manufacturing to avoid stress cracking.

Impact on Application:

Polycarbonate housings protect LED strips from mechanical damage and dust, crucial in industrial or workshop environments common in emerging markets. Its thermal resistance supports LED longevity by preventing heat buildup.

International B2B Considerations:

Polycarbonate complies with ASTM D3935 and ISO 1183 standards, widely recognized in Europe and increasingly in African and Middle Eastern markets. Buyers in regions like Nigeria and South America should verify local suppliers’ adherence to these standards to ensure quality and durability.

2. Flexible Printed Circuit Board (FPC) with Copper Traces

Key Properties:

FPCs are thin, flexible substrates typically made from polyimide or polyester films, embedded with copper conductive traces. They offer excellent electrical conductivity, flexibility, and thermal resistance up to 200°C depending on the substrate.

Pros & Cons:

– Pros: Enables compact and flexible LED strip designs that can conform to printer contours. High thermal tolerance supports stable LED operation. Copper traces ensure low electrical resistance and efficient power delivery.

– Cons: More costly than rigid PCBs and requires precise manufacturing. Susceptible to damage if bent excessively or exposed to corrosive environments.

Impact on Application:

FPCs allow seamless integration of LED strips into tight or curved spaces on the SKR Mini E3 V2 printer frame, enhancing aesthetics and functionality without compromising space. Their flexibility is advantageous in compact 3D printer designs.

International B2B Considerations:

FPC manufacturing standards such as IPC-2223 and IPC-6013 are critical for quality assurance. Buyers in Europe and the Middle East often demand compliance with RoHS and REACH directives, while African and South American markets may prioritize cost-effective certifications aligned with local import regulations.

3. Silicone Encapsulation (for LED Strip Protection)

Key Properties:

Silicone is a flexible, transparent polymer with excellent thermal stability (up to 250°C), UV resistance, and moisture sealing properties. It is commonly used as an encapsulant for LED strips to protect against dust and water.

Pros & Cons:

– Pros: Provides robust protection against environmental factors such as humidity, dust, and mechanical abrasion. Enhances LED lifespan by preventing corrosion and electrical shorts. Silicone’s flexibility accommodates thermal expansion without cracking.

– Cons: Adds to the overall cost and thickness of the LED strip. May require specialized equipment for application and curing.

Impact on Application:

Silicone encapsulation is particularly valuable in humid or dusty environments prevalent in many African and South American regions. It ensures reliability and reduces maintenance needs, which is critical for industrial customers.

International B2B Considerations:

Silicone materials typically meet ASTM D2240 (durometer hardness) and ISO 10993 (biocompatibility) standards. Buyers should ensure that suppliers provide certifications for electrical insulation and flame retardancy, especially for Middle Eastern and European markets with strict safety regulations.

4. Aluminum Channel Housing

Key Properties:

Aluminum channels provide a rigid, lightweight frame for mounting LED strips. Aluminum offers excellent thermal conductivity, corrosion resistance (especially anodized types), and mechanical strength.

Pros & Cons:

– Pros: Acts as a heat sink, dissipating heat from LEDs and prolonging their operational life. Provides a professional finish and structural protection. Easy to cut and customize for various printer models.

– Cons: Higher material and fabrication cost compared to plastics. Requires additional mounting hardware and may add weight to the printer.

Impact on Application:

Aluminum housings improve thermal management, which is critical for high-brightness LED strips used in continuous operation. This is beneficial for industrial users in Europe and the Middle East, where reliability and safety standards are stringent.

International B2B Considerations:

Aluminum products should comply with EN 573 (aluminum alloy standards) and ASTM B221 (extruded aluminum). Buyers in Africa and South America should verify corrosion resistance specifications, especially for coastal or humid environments.

Summary Table

| Material | Typical Use Case for adding led strip to skr mini e3 v2 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Protective transparent housing for LED strips | High impact resistance and good thermal stability | Prone to UV yellowing and higher cost than acrylic | Medium |

| Flexible Printed Circuit Board (FPC) | Flexible LED strip substrate for curved or compact installations | Flexibility with excellent electrical and thermal properties | Higher manufacturing complexity and cost | High |

| Silicone Encapsulation | Environmental protection (waterproofing, dust sealing) | Superior moisture and abrasion resistance | Adds thickness and cost, requires specialized application | Medium |

| Aluminum Channel Housing | Structural mounting and heat dissipation for LED strips | Excellent heat dissipation and mechanical protection | Increased weight and fabrication cost | High |

This material selection guide equips international B2B buyers with the knowledge to choose the most suitable materials for LED strip integration with the SKR Mini E3 V2, balancing performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for adding led strip to skr mini e3 v2

Manufacturing Processes for Adding LED Strip to SKR Mini E3 V2

The manufacturing of LED strips tailored for integration with the SKR Mini E3 V2 controller board involves several critical stages, each designed to ensure product reliability, performance, and compatibility. Understanding these processes equips international B2B buyers with the insights needed to evaluate suppliers effectively.

Illustrative Image (Source: Google Search)

1. Material Preparation

- Substrate Selection: High-quality flexible printed circuit boards (FPCBs) or rigid PCBs serve as the base for LED strips. Materials must offer excellent thermal dissipation and flexibility without compromising durability.

- LED Chip Procurement: Manufacturers source LEDs from reputable semiconductor producers, focusing on parameters such as luminous efficacy, color consistency, and lifespan.

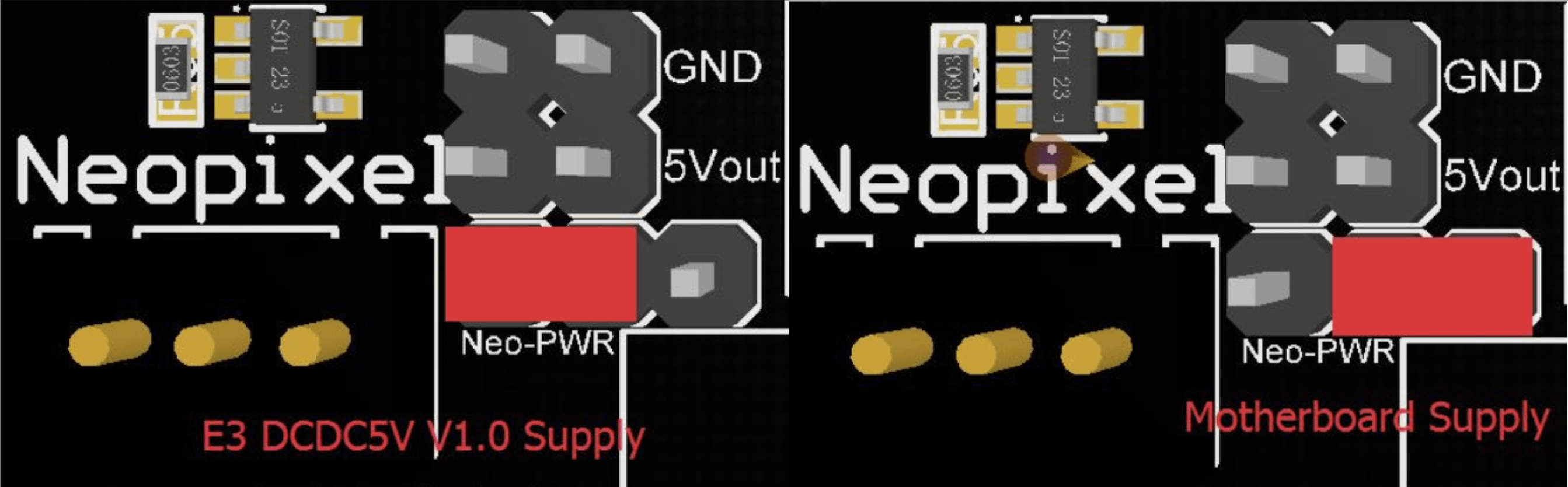

- Electrical Components: Resistors, capacitors (such as 1000uF capacitors for noise suppression), connectors (e.g., JST 3-pin), and protective elements like resistors (typically 380-400 Ohm) are selected to match the LED strip’s electrical design.

2. Forming and Assembly

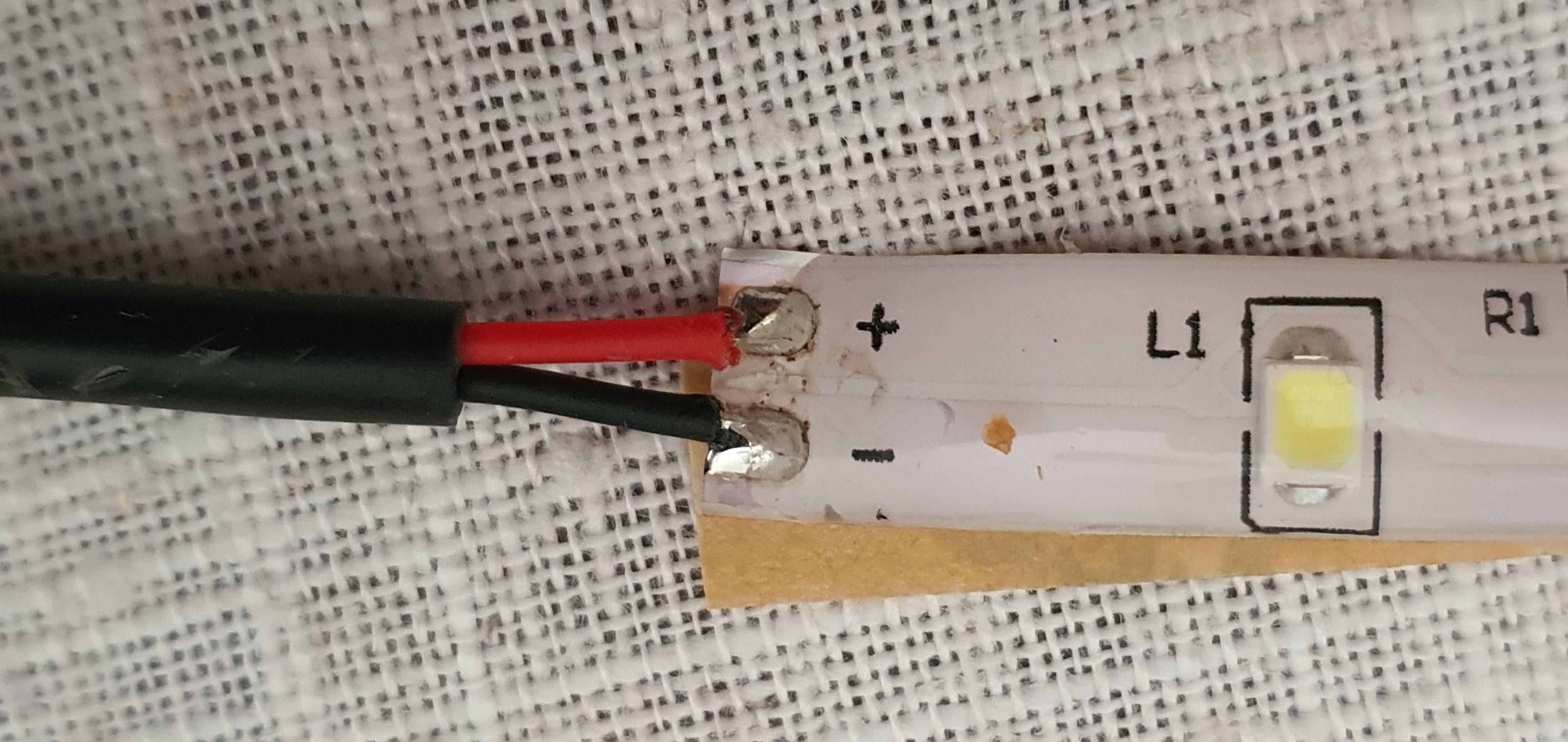

- Soldering and SMT (Surface Mount Technology): Automated SMT lines place LEDs and passive components precisely on the PCB substrate. This ensures uniformity and reduces human error.

- Cutting and Segmentation: LED strips are manufactured in continuous reels and then cut into specific lengths according to client requirements, with clear cutting marks to prevent damage.

- Connector Attachment: Crimping or soldering JST connectors or other relevant plugs is performed to facilitate easy integration with the SKR Mini E3 V2 board.

- Protective Coating: Some LED strips receive a silicone or epoxy coating for water resistance and enhanced durability, particularly important for industrial or dusty environments.

3. Finishing and Packaging

- Adhesive Application: High-quality adhesive backing is applied for easy mounting on the printer frame or other locations.

- Labeling and Instructions: Packaging includes detailed wiring diagrams, safety instructions, and integration guides tailored for SKR Mini E3 V2 compatibility.

- Batch Coding: For traceability, batch numbers and manufacturing dates are printed on packaging or the strip itself.

Quality Assurance and Control (QA/QC) Framework

Quality assurance in LED strip manufacturing for 3D printer integration is multifaceted, encompassing international standards, in-line inspections, and post-production testing. B2B buyers must prioritize suppliers demonstrating rigorous QC protocols.

Relevant International and Industry Standards

- ISO 9001: A fundamental quality management system standard ensuring consistent manufacturing processes and continual improvement.

- CE Marking: Mandatory for products entering the European market, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances like lead and mercury, essential for environmental safety.

- UL Certification: Especially relevant for electrical safety in North American and some international markets.

- Electromagnetic Compatibility (EMC) Standards: Ensures LED strips do not interfere with other electronic devices, critical for integration with sensitive electronics like the SKR Mini E3 V2.

- Industry-Specific Certifications: For example, IPC standards for PCB manufacturing quality and testing.

QC Checkpoints in Manufacturing

-

Incoming Quality Control (IQC):

– Verification of raw materials including LED chips, PCBs, connectors, and adhesives.

– Supplier certificates of analysis and material test reports are reviewed. -

In-Process Quality Control (IPQC):

– Monitoring soldering quality via automated optical inspection (AOI).

– Functional checks on LED placement and electrical continuity during assembly.

– Verification of connector crimps and adhesive application. -

Final Quality Control (FQC):

– Complete functional testing of LED strips under operational voltages.

– Visual inspections for defects such as cold solder joints, misaligned LEDs, or adhesive failure.

– Burn-in tests to detect early failures and ensure thermal stability.

Common Testing Methods

- Electrical Testing: Measuring voltage, current, and resistance to confirm adherence to design specs and prevent early device failure.

- Optical Testing: Assessing brightness, color temperature, and uniformity using spectrometers or photometers.

- Environmental Stress Testing: Simulating operational conditions including heat cycling, humidity exposure, and vibration to verify durability.

- Safety Testing: Ensuring insulation resistance and absence of shorts, particularly important when integrating with 3D printer electronics.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, especially in regions such as Africa, South America, the Middle East, and Europe, ensuring supplier reliability is paramount to avoid costly disruptions.

- Factory Audits: Conduct on-site or virtual audits focusing on manufacturing capabilities, QC processes, staff training, and facility cleanliness. Engaging third-party audit firms adds impartiality.

- Quality Documentation: Request detailed QC reports including IQC material certifications, in-process inspection records, and FQC test results. Look for adherence to ISO 9001 or equivalent management systems.

- Third-Party Inspections: Employ independent inspection agencies to perform pre-shipment inspections, functional testing, and packaging verification.

- Sample Testing: Prior to bulk orders, obtain samples for independent lab testing to validate compliance with electrical, optical, and safety standards.

- Supplier Certifications: Verify that suppliers maintain relevant certifications (e.g., CE, RoHS, UL) and can provide up-to-date certificates.

QC and Certification Nuances for International Buyers

-

Regional Regulatory Differences:

Buyers from Europe must prioritize CE and RoHS compliance, while those in Africa or the Middle East should ensure suppliers meet local import regulations and electrical safety standards. South American buyers might require additional INMETRO certification for Brazil or similar local approvals. -

Voltage and Power Compatibility:

Ensure LED strips are compatible with local voltage standards (e.g., 110V in Nigeria vs. 220-240V in Europe). This reduces the risk of component failure and safety hazards. -

Environmental Considerations:

Regions with high humidity or dust, such as parts of the Middle East or tropical Africa, require LED strips with enhanced protective coatings (IP65 or higher rating). -

Logistics and Documentation:

Proper labeling and compliance documentation are essential for customs clearance. B2B buyers should verify that suppliers provide complete export paperwork, including certificates of origin, compliance certificates, and test reports. -

After-Sales Support:

Reliable technical support and warranty terms are critical, especially for buyers in regions with less local technical expertise. Confirm supplier responsiveness and availability of replacement parts.

Summary

For international B2B buyers seeking to procure LED strips compatible with the SKR Mini E3 V2, an in-depth understanding of manufacturing and QC processes is vital. High-quality LED strips result from meticulous material selection, precision assembly, and stringent quality controls aligned with global standards. By leveraging factory audits, third-party inspections, and comprehensive documentation, buyers from Africa, South America, the Middle East, and Europe can mitigate risks and ensure seamless integration into their 3D printing solutions. Prioritizing suppliers who demonstrate robust quality assurance and compliance with regional requirements will safeguard investment and enhance operational success.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for adding led strip to skr mini e3 v2 Sourcing

When sourcing LED strips for integration with the SKR Mini E3 V2 controller board, understanding the full cost structure and pricing dynamics is crucial for international B2B buyers aiming for optimal value and supply chain efficiency. This analysis breaks down key cost components, price influencers, and strategic buyer considerations to support informed procurement decisions.

Key Cost Components

-

Materials: The LED strip’s base components include LEDs (often NeoPixel or similar addressable types), flexible PCB substrate, resistors, capacitors, connectors, and protective coatings. Higher quality LEDs with better color accuracy or durability typically increase material costs. For SKR Mini E3 V2 compatibility, specific connectors (e.g., JST 3-pin) and resistors (e.g., 380-400 Ohm) may be required.

-

Labor: Assembly labor involves cutting, soldering (if required), connector attachment, and quality checks. Labor costs vary significantly by region; for example, manufacturing hubs in Southeast Asia offer competitive rates, while Europe and the Middle East may incur higher labor charges.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Overhead costs rise with complexity—for instance, customized LED strip lengths, firmware compatibility testing, or integration-ready packaging increase overhead.

-

Tooling and Setup: Custom tooling for cutting LED strips to precise lengths or special connectors can add upfront costs. These are often amortized over large production runs, so initial MOQ (Minimum Order Quantity) commitments affect unit pricing.

-

Quality Control (QC): Rigorous QC processes ensure LEDs meet brightness, color consistency, and electrical safety standards. Certifications like CE (Europe), RoHS, and UL can add to QC costs but are often necessary for regulatory compliance in target markets.

-

Logistics and Import Duties: Shipping costs depend on volume, weight, and mode (air vs. sea freight). Buyers from Africa, South America, the Middle East, and Europe should factor in regional import tariffs, customs clearance fees, and inland transportation. For example, Nigeria and Brazil may impose higher duties on electronics, affecting landed cost.

-

Margin: Supplier margins typically range from 10% to 30%, influenced by order volume, product complexity, and competitive landscape.

Price Influencers

-

Volume and MOQ: Larger order volumes generally reduce per-unit cost due to economies of scale. Suppliers often set MOQs to cover tooling and setup expenses, so smaller buyers should negotiate for sample runs or consolidated orders.

-

Specifications and Customization: Custom lengths, color options, integrated firmware support (e.g., pre-configured for SKR Mini E3 V2 NeoPixel control), and enhanced durability features (waterproofing, heat resistance) increase cost. Standardized LED strips without custom firmware or connectors are more cost-effective but may require additional buyer-side integration.

-

Material Quality and Certifications: Certified LED strips with recognized quality marks cost more but reduce risk of failures and compatibility issues. Buyers targeting European markets should prioritize CE and RoHS compliance, while Middle Eastern buyers may require additional certifications.

-

Supplier Location and Reliability: Proximity to supplier impacts shipping cost and lead time. Established suppliers with transparent quality systems and warranty policies may command premium pricing but offer lower Total Cost of Ownership (TCO).

-

Incoterms and Payment Terms: Choosing favorable Incoterms (e.g., FOB, CIF, DDP) affects who bears shipping and import responsibilities, influencing overall cost. Negotiating payment terms (e.g., letters of credit, net 30) can improve cash flow management.

Buyer Tips for International Markets

-

Negotiate Based on Total Cost of Ownership: Look beyond unit price to factor in shipping, customs, potential rework, and warranty support. For African and South American buyers, longer shipping times and customs delays can increase holding costs.

-

Leverage Group Purchasing or Local Distributors: Pooling orders with other businesses or sourcing through regional distributors can reduce MOQ constraints and lower logistics expenses.

-

Prioritize Compatibility and Certification: Ensure the LED strips are fully compatible with SKR Mini E3 V2 firmware and hardware to avoid costly integration issues. Request certificates upfront to avoid non-compliance penalties, especially in Europe and the Middle East.

-

Consider Sample Testing: Before large-scale procurement, order samples to validate quality, firmware integration, and installation ease. This is particularly important in markets with variable supplier quality standards.

-

Plan for Currency and Payment Risks: International buyers from volatile currency regions (e.g., Nigeria, Brazil) should consider hedging strategies or negotiate pricing in stable currencies like USD or EUR.

Indicative Pricing Disclaimer

Due to variability in supplier pricing, order volume, customization, and regional logistics, LED strip sourcing costs for SKR Mini E3 V2 integration typically range from USD 5 to 15 per unit for standard lengths and configurations. Customizations and certifications can increase this cost by 20-50%. Prices fluctuate with global component shortages and freight rates, so buyers should request updated quotations tailored to their specific requirements.

By thoroughly analyzing these cost and pricing factors, international B2B buyers can strategically source LED strips that balance quality, cost-efficiency, and supply reliability for successful SKR Mini E3 V2 enhancements.

Spotlight on Potential adding led strip to skr mini e3 v2 Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘adding led strip to skr mini e3 v2’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for adding led strip to skr mini e3 v2

Critical Technical Properties for LED Strip Integration with SKR Mini E3 V2

When sourcing LED strips for integration with the SKR Mini E3 V2 3D printer mainboard, understanding key technical specifications is essential to ensure compatibility, durability, and optimal performance. Below are the most important properties to consider from a B2B procurement perspective:

-

Voltage and Current Ratings

LED strips typically operate at 5V or 12V DC. The SKR Mini E3 V2 supports 5V LED strips such as NeoPixel (WS2812) types. Ensuring voltage compatibility is crucial to prevent damage to both the LED strip and the mainboard. Additionally, current draw must be within the mainboard’s output limits to avoid overloads and ensure stable operation. -

LED Density (LEDs per Meter)

This defines the number of individual LEDs along the strip, commonly ranging from 30 to 60 LEDs per meter. Higher density offers smoother, more vibrant lighting effects but increases power consumption. B2B buyers should balance desired visual impact with power budget and thermal management. -

Color Type and Control Protocol

LED strips vary between single-color, RGB, and addressable RGB (e.g., NeoPixel/WS2812). Addressable LEDs allow per-LED color control via digital signals, which the SKR Mini E3 V2 supports through firmware customization. Choosing the correct protocol ensures seamless integration and advanced lighting effects. -

Material Grade and IP Rating

The strip’s base material (flexible PCB) and protective coating impact durability and suitability for different environments. For example, IP65 or higher ratings indicate water resistance, important for humid or dusty workshop settings. This influences longevity and maintenance costs for industrial customers. -

Connector Type and Wiring Configuration

LED strips come with various connectors (e.g., JST 3-pin) or bare wire leads. Compatibility with SKR Mini E3 V2 connectors simplifies installation and reduces labor costs. Wiring configuration (data, power, ground) must match the mainboard’s pinout to ensure error-free operation. -

Thermal Tolerance and Heat Dissipation

LEDs generate heat during operation, and poor heat dissipation can degrade performance or lifespan. Selecting strips with adequate thermal tolerance or integrating heat sinks can improve reliability, especially in high-use industrial environments.

Common Trade and Industry Terms Relevant to LED Strip Procurement

Understanding these key trade terms will empower B2B buyers to communicate effectively with suppliers, negotiate better deals, and manage logistics efficiently:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products to be rebranded by another firm. In LED strip sourcing, OEM suppliers may offer customized strips specifically designed to integrate with SKR Mini E3 V2 boards, enabling tailored solutions for your product line. -

MOQ (Minimum Order Quantity)

The smallest amount of product a supplier is willing to sell in one order. MOQ affects inventory management and cash flow. Buyers from emerging markets or smaller operations should negotiate MOQs that align with their demand forecasts to avoid overstocking. -

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain pricing, lead times, and terms for specified products. Clear RFQs that include technical specs such as LED density, voltage, and connector types help suppliers provide accurate, comparable bids. -

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities of buyers and sellers for shipping, insurance, and tariffs. Common terms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) clarify who manages transportation risks and costs, critical for cross-border procurement. -

Lead Time

The period from order placement to product delivery. Understanding supplier lead times enables better production planning and reduces downtime, especially when integrating components like LED strips into existing 3D printer assembly lines. -

ESD (Electrostatic Discharge) Protection

Refers to measures taken to protect sensitive electronic components from static electricity damage during handling and transport. LED strips and SKR Mini boards require ESD-safe packaging and procedures to maintain product integrity.

By focusing on these technical properties and trade terms, international B2B buyers can confidently source LED strips optimized for the SKR Mini E3 V2, ensuring seamless integration, operational reliability, and cost-effective procurement tailored to diverse markets such as Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the adding led strip to skr mini e3 v2 Sector

Market Overview & Key Trends

The global market for LED strips tailored for 3D printer controllers such as the SKR Mini E3 V2 is experiencing steady growth, driven by increasing adoption of 3D printing technologies across diverse industries including manufacturing, education, and prototyping. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, the demand is fueled by the need for enhanced printer functionality and improved user experience through customization.

Key market drivers include the rising trend of smart manufacturing and Industry 4.0, where integrated lighting solutions like NeoPixel LED strips provide visual feedback and improve operational efficiency. The customization capability of LED strips—such as color changes to indicate print status—adds value beyond mere illumination, making them attractive for OEMs and aftermarket suppliers.

From a sourcing perspective, international buyers are prioritizing suppliers who offer modular LED strips compatible with various firmware and mainboards, like the SKR Mini E3 V2. This compatibility reduces integration time and lowers technical support requirements. Additionally, the increasing availability of plug-and-play LED kits with pre-soldered connectors and comprehensive firmware support is a significant trend, facilitating smoother implementation and reducing installation errors.

Market dynamics also reflect regional nuances. In emerging markets such as Nigeria and Thailand, buyers often seek cost-effective LED solutions without compromising on quality, favoring suppliers who provide flexible order quantities and reliable after-sales support. European buyers, conversely, emphasize advanced features like firmware customization and compatibility with open-source ecosystems, reflecting higher technical maturity.

Finally, the growth of online B2B marketplaces and direct manufacturer partnerships is streamlining procurement processes, enabling buyers to access a wider variety of LED strip options with transparent pricing and faster delivery. This trend is particularly beneficial for regions with logistical challenges, ensuring consistent supply.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers investing in LED strips for 3D printer upgrades, including those compatible with SKR Mini E3 V2 boards. The environmental impact of LED manufacturing, from raw material extraction to electronic waste, necessitates careful supplier evaluation to align with corporate social responsibility goals.

Ethical sourcing involves partnering with manufacturers who implement responsible labor practices and adhere to environmental regulations. Buyers from Africa, South America, the Middle East, and Europe increasingly demand transparency in supply chains, including certifications such as RoHS (Restriction of Hazardous Substances) and REACH compliance, which ensure that LED components are free from harmful chemicals.

Moreover, the use of eco-friendly materials in LED strips—such as lead-free solder, recyclable circuit boards, and biodegradable packaging—is gaining traction. Suppliers offering energy-efficient LED strips with longer lifespans reduce waste and operational costs, supporting sustainable purchasing decisions.

B2B buyers are also interested in suppliers who invest in circular economy initiatives, including take-back programs for used LED components and refurbishment services. Such programs help mitigate electronic waste challenges prevalent in many regions, especially where e-waste infrastructure is limited.

Illustrative Image (Source: Google Search)

Incorporating sustainability into procurement strategies not only mitigates regulatory risks but also enhances brand reputation. Buyers can leverage green certifications as a differentiator when marketing their own products or services that integrate LED-enhanced 3D printers, appealing to environmentally conscious end-users.

Brief Evolution and Historical Context

The integration of LED strips into 3D printing hardware has evolved from purely aesthetic modifications to functional enhancements that improve user interaction. Initially, LED lighting served mainly decorative purposes, offering a visual “wow” factor. However, with the advent of addressable LED technologies like NeoPixels, manufacturers and users recognized their potential for status indication and real-time feedback.

The SKR Mini E3 V2 board, introduced as a compact, versatile controller, supports such LED integrations natively, marking a shift towards more intelligent lighting solutions in desktop 3D printers. This evolution reflects broader trends in embedded electronics, where lighting is increasingly used as an interface element rather than just illumination.

For B2B buyers, understanding this history is valuable as it highlights the growing sophistication of LED strip offerings, from simple strips to programmable, firmware-controlled lighting systems. This progression underscores the importance of selecting suppliers who stay abreast of technological advancements and firmware compatibility to future-proof their investments.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of adding led strip to skr mini e3 v2

-

How can international B2B buyers verify the credibility of suppliers offering LED strips compatible with SKR Mini E3 V2?

To ensure supplier credibility, B2B buyers should request company registration documents, certifications (e.g., ISO 9001), and client references. Conducting factory audits or virtual tours can reveal manufacturing capabilities and quality control processes. Checking for compliance with international standards such as CE, RoHS, or UL is crucial, especially for buyers in regulated markets like Europe and the Middle East. Engaging with suppliers who maintain transparent communication and provide detailed product datasheets reduces risk and builds trust for long-term partnerships. -

What customization options are typically available when sourcing LED strips for the SKR Mini E3 V2, and how can buyers leverage these?

Suppliers often offer customization in LED strip length, color temperature, brightness levels, and connector types to match specific printer models or branding needs. Buyers can request firmware compatibility adjustments, such as NeoPixel integration, or custom housings to fit printer frames. To maximize value, clearly communicate technical requirements upfront and negotiate minimum order quantities (MOQs) for custom runs. Customization enables differentiation in competitive markets, especially for resellers targeting diverse regions like Africa and South America. -

What are common MOQ and lead time expectations for LED strip orders compatible with SKR Mini E3 V2, and how can buyers optimize procurement?

MOQ for customized LED strips can range from 100 to 500 units, depending on supplier scale and complexity of customization. Lead times typically span 4 to 8 weeks, including manufacturing and shipping. Buyers should plan orders well in advance and consolidate shipments to reduce costs. Establishing flexible contracts with suppliers can allow scaling production as demand grows. For urgent orders, sourcing from suppliers with local warehouses or regional distribution centers in Europe or the Middle East can shorten delivery times. -

Which quality assurance certifications and testing protocols should buyers insist on when purchasing LED strips for 3D printers?

Buyers should prioritize suppliers that provide CE marking for European compliance, RoHS certification for hazardous substance control, and UL certification for safety standards. Testing protocols should include electrical safety tests, LED lifespan and brightness consistency checks, and environmental resistance (e.g., moisture, heat). Requesting sample inspections or third-party lab reports before full orders mitigates risks. Certifications not only ensure regulatory compliance but also enhance product reliability, crucial for international buyers serving demanding markets. -

What logistics considerations should B2B buyers keep in mind when importing LED strips to regions like Africa, South America, and the Middle East?

Buyers must consider import duties, customs clearance times, and local regulatory requirements that vary widely across these regions. Shipping methods—air freight for speed or sea freight for cost efficiency—should be selected based on urgency and budget. Packaging must be robust to prevent damage during long transit. Partnering with freight forwarders experienced in these markets helps navigate complex documentation and reduces delays. Additionally, buyers should verify if suppliers offer DDP (Delivered Duty Paid) terms to simplify cross-border logistics. -

How can B2B buyers mitigate payment risks when dealing with international LED strip suppliers for the SKR Mini E3 V2?

Utilize secure payment methods like letters of credit (LC), escrow services, or payment platforms that offer buyer protection. Avoid full upfront payments unless the supplier has an established reputation. Structured payment terms, such as deposits followed by balance upon delivery or inspection, reduce exposure. Conduct due diligence on the supplier’s financial stability and track record. For repeat business, negotiate credit terms to improve cash flow. Transparent contracts outlining payment milestones and penalties for non-compliance are essential safeguards. -

What dispute resolution mechanisms are recommended for international transactions involving LED strip supplies?

Contracts should specify governing law and dispute resolution venues, commonly favoring arbitration under ICC or UNCITRAL rules for neutrality and enforceability. Clear terms on product specifications, delivery schedules, and quality benchmarks minimize conflicts. Maintaining detailed communication records and conducting joint inspections upon delivery support evidence-based resolutions. For buyers in emerging markets, engaging local legal counsel familiar with international trade law enhances protection. Early mediation attempts can preserve business relationships before escalating to formal proceedings. -

How important is firmware compatibility when sourcing LED strips for the SKR Mini E3 V2, and what should buyers verify?

Firmware compatibility is critical since the SKR Mini E3 V2 requires specific firmware configurations to control NeoPixel LEDs correctly. Buyers should confirm that LED strips are compatible with the printer’s firmware version and that suppliers provide technical support for firmware updates or integration. Request documentation on wiring, resistor and capacitor specifications, and recommended firmware settings. Ensuring compatibility upfront prevents costly post-installation modifications and supports seamless functionality, enhancing end-user satisfaction across varied international markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for adding led strip to skr mini e3 v2

Adding LED strips to the SKR Mini E3 V2 presents a valuable opportunity for B2B buyers to enhance the functionality, safety, and visual appeal of 3D printing setups. From a strategic sourcing perspective, prioritizing quality components—such as reliable LED strips, compatible power supplies, and precision connectors—is essential to ensure long-term durability and customer satisfaction. Leveraging suppliers who offer technical support and customization options can further differentiate your product offerings in competitive markets.

For international buyers in regions like Africa, South America, the Middle East, and Europe, understanding local regulatory requirements and supply chain logistics is key to optimizing costs and minimizing delays. Partnering with manufacturers or distributors that provide clear documentation, scalable order volumes, and responsive after-sales service will streamline implementation and reduce operational risks.

Looking ahead, the integration of smart LED solutions that support firmware customization and dynamic lighting effects is poised to become a standard in advanced 3D printing applications. Buyers are encouraged to explore partnerships with innovative suppliers that invest in R&D and can adapt to evolving technology trends. By strategically sourcing LED components aligned with your business needs, you position your enterprise to deliver enhanced value and capture emerging growth opportunities in the global 3D printing ecosystem.