Introduction: Navigating the Global Market for 110v led strip lights

The global demand for 110v LED strip lights is rapidly expanding, driven by their exceptional energy efficiency, adaptability, and cost-effectiveness. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing these lighting solutions is essential to unlocking competitive advantages in diverse applications, from commercial installations to industrial projects.

This comprehensive guide offers a deep dive into the critical aspects of the 110v LED strip lights market. It covers product types and specifications, including voltage compatibility and design variations, to help businesses identify the perfect fit for their unique lighting needs. Insight into material quality, advanced manufacturing processes, and rigorous quality control standards equips buyers with the knowledge to ensure durability and performance. Furthermore, the guide evaluates supplier selection criteria, emphasizing reliability, compliance, and value, which are pivotal for mitigating supply chain risks in international trade.

Cost structures and market trends are analyzed to support strategic budgeting and procurement planning, while a curated FAQ section addresses common buyer concerns, fostering confidence in decision-making. Whether sourcing for retail, architectural, or industrial lighting projects, this resource empowers buyers to navigate the complexities of the global market efficiently and secure LED strip lighting solutions that deliver both innovation and value.

By leveraging the insights provided, B2B buyers across continents can optimize their sourcing strategies, reduce operational risks, and capitalize on emerging opportunities in the evolving LED lighting landscape.

Understanding 110v led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 110v LED Strip | Operates directly on 110 volts AC, often with built-in resistors | Commercial lighting, retail displays, residential accent lighting | Pros: Easy installation without transformers; Cons: Limited flexibility in voltage adaptation |

| Waterproof 110v LED Strip | Encased in silicone or epoxy for moisture and dust resistance | Outdoor signage, landscape lighting, hospitality venues | Pros: Suitable for harsh environments; Cons: Higher cost and slightly reduced flexibility |

| RGB 110v LED Strip | Multi-color LEDs with integrated controllers for color changing | Event lighting, architectural highlights, entertainment venues | Pros: Dynamic lighting effects; Cons: Requires compatible controllers, increased complexity |

| Dimmable 110v LED Strip | Compatible with AC dimmers for adjustable brightness | Office lighting, restaurants, hotels, conference rooms | Pros: Energy savings and ambiance control; Cons: Requires compatible dimmer hardware |

| High Lumen 110v LED Strip | High brightness output with dense LED placement | Industrial task lighting, warehouses, manufacturing plants | Pros: Superior illumination; Cons: Higher power consumption and heat generation |

Standard 110v LED Strip

These LED strips operate directly on standard 110-volt AC power, eliminating the need for additional transformers or drivers. This simplifies installation and reduces upfront costs, making them ideal for commercial and residential projects that require straightforward lighting solutions. B2B buyers should assess the quality of built-in resistors and verify compliance with regional electrical standards, especially when sourcing for diverse markets like Europe or the Middle East.

Waterproof 110v LED Strip

Encapsulated in waterproof materials such as silicone or epoxy, these strips are designed for outdoor or humid environments. They are essential for businesses targeting outdoor advertising, landscaping, or hospitality sectors where durability against weather and dust is critical. When purchasing, buyers should confirm the IP rating and ensure that the supplier offers robust warranty terms reflecting outdoor use conditions.

RGB 110v LED Strip

Featuring multi-color LEDs and integrated control systems, RGB strips enable dynamic lighting effects and color changes. These are popular in event management, retail displays, and architectural projects seeking to create engaging atmospheres. B2B buyers must consider compatibility with controllers and the availability of customizable color presets, which can add value for end customers.

Dimmable 110v LED Strip

These strips support AC dimmers, allowing users to adjust brightness levels for energy efficiency and mood setting. They are commonly used in offices, hotels, and restaurants where lighting adaptability is a priority. Buyers should verify dimmer compatibility and request technical support from suppliers to ensure seamless integration into existing electrical systems.

High Lumen 110v LED Strip

Designed with a higher density of LEDs, these strips deliver intense brightness suitable for industrial and task lighting applications. They are favored in warehouses, manufacturing plants, and other commercial environments requiring powerful illumination. Buyers should weigh the trade-offs between brightness, energy consumption, and heat management when selecting these strips for large-scale projects.

Related Video: THE SECRET OF GREAT LED STRIP LIGHT INSTALLS – COB

Key Industrial Applications of 110v led strip lights

| Industry/Sector | Specific Application of 110v LED Strip Lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and display lighting in retail stores and malls | Enhances product visibility, creates inviting spaces, and drives customer engagement | Ensure high CRI for color accuracy, durability for continuous operation, and compliance with local voltage standards |

| Hospitality & Leisure | Decorative and functional lighting in hotels and restaurants | Improves guest experience, energy savings, and flexible design options | Waterproof or moisture-resistant strips, dimmable features, and customization for branding colors |

| Manufacturing & Warehousing | Task lighting for workstations and safety illumination | Boosts worker productivity and safety with reliable, consistent lighting | High lumen output, robust construction for industrial environments, and ease of installation |

| Transportation & Infrastructure | Accent and safety lighting in tunnels, platforms, and stations | Enhances safety, visibility, and reduces maintenance costs | Compliance with safety regulations, weatherproofing, and long lifespan LEDs |

| Agriculture & Horticulture | Supplemental lighting in greenhouses and vertical farms | Promotes plant growth, energy efficiency, and controlled light spectra | Spectrum-specific LEDs, waterproofing, and energy-efficient drivers |

Retail & Commercial

In retail environments across Europe, the Middle East, and emerging markets in Africa and South America, 110v LED strip lights are widely used for ambient and display lighting. Their ability to deliver consistent, high-quality light enhances product visibility, making merchandise more attractive to customers. Retailers benefit from the strips’ energy efficiency and long lifespan, reducing operational costs. Buyers should prioritize high Color Rendering Index (CRI) strips to ensure true color representation, which is crucial for fashion and electronics sectors. Compliance with local voltage standards and certifications is essential for smooth import and installation.

Hospitality & Leisure

Hotels, restaurants, and leisure venues utilize 110v LED strip lights to create inviting atmospheres and functional lighting solutions. These strips offer flexibility in design—allowing for accent lighting, backlighting, or mood lighting that can be dimmed or color-customized to match branding. For B2B buyers in humid or outdoor hospitality settings, especially in coastal regions of South America and the Middle East, sourcing waterproof or moisture-resistant LED strips is critical. Additionally, dimmable and smart control features help reduce energy consumption while enhancing guest comfort.

Illustrative Image (Source: Google Search)

Manufacturing & Warehousing

Industrial sectors rely on 110v LED strip lights for task lighting in manufacturing plants and warehouses. These strips provide bright, even illumination that improves worker productivity and reduces accidents by enhancing visibility. Buyers from regions with heavy industrial activity, such as Spain or South Africa, should seek strips with high lumen output and rugged construction to withstand dust, vibration, and temperature fluctuations. Easy installation and maintenance-friendly designs are important for minimizing downtime and operational disruption.

Transportation & Infrastructure

In transportation hubs like train stations, tunnels, and airports, 110v LED strip lights serve both decorative and safety purposes. They provide continuous illumination in critical areas, improving passenger safety and navigation. For international buyers, especially in Europe and the Middle East, sourcing LED strips compliant with stringent safety and environmental standards is mandatory. Weatherproofing and long operational life reduce maintenance frequency and costs, which is vital for infrastructure projects with tight budgets and timelines.

Agriculture & Horticulture

Emerging applications of 110v LED strip lights in agriculture focus on supplemental lighting in greenhouses and vertical farms to optimize plant growth. These strips can be tailored to emit specific light spectra that promote photosynthesis and flowering. Buyers from South America and Africa, where controlled environment agriculture is growing, should prioritize spectrum-specific LEDs and waterproof designs due to humid conditions. Energy-efficient drivers and compatibility with automated control systems are also key to maximizing operational efficiency and crop yield.

Related Video: How to Install LED Strip Lights

Strategic Material Selection Guide for 110v led strip lights

Aluminum PCB Substrate

Key Properties: Aluminum substrates offer excellent thermal conductivity (up to 2.0 W/mK), high mechanical strength, and good resistance to corrosion. They can withstand operating temperatures up to 130°C or higher, making them ideal for heat dissipation in 110v LED strip lights.

Pros & Cons: Aluminum substrates provide superior heat management, which enhances LED lifespan and performance. They are relatively lightweight and cost-effective compared to other metal substrates. However, manufacturing complexity is moderate due to the need for precise layering and insulation between the metal base and circuitry. Aluminum is less flexible than plastic substrates, limiting use in highly curved installations.

Impact on Application: Ideal for commercial and industrial lighting where heat dissipation is critical, such as retail displays or outdoor signage in hot climates. Aluminum’s corrosion resistance suits environments with moderate humidity but may require additional coatings for coastal or highly corrosive regions.

International Buyer Considerations: Buyers in Europe (UK, Spain) and the Middle East should verify compliance with EN standards (e.g., EN 60598 for luminaires) and RoHS directives for hazardous substances. African and South American buyers should consider local environmental conditions; aluminum’s corrosion resistance is beneficial but may need additional protective treatments to withstand tropical or saline environments. ASTM B209 standards for aluminum sheets are commonly referenced globally.

Flexible Polyimide (Kapton) Substrate

Key Properties: Polyimide substrates are highly flexible, with excellent thermal stability up to 260°C and outstanding chemical resistance. They offer electrical insulation and can endure bending without cracking, making them suitable for dynamic or curved installations.

Pros & Cons: The flexibility and high-temperature tolerance make polyimide substrates ideal for complex architectural lighting and wearable applications. However, they are more expensive than aluminum and less effective at heat dissipation, which can limit LED lifespan if not paired with additional cooling solutions.

Impact on Application: Best suited for indoor decorative lighting, flexible signage, or installations requiring frequent bending or shaping. Not recommended for high-heat environments unless integrated with heat sinks or cooling systems.

International Buyer Considerations: European buyers often require compliance with REACH and RoHS regulations, which polyimide substrates typically meet. Middle Eastern and African buyers should assess the cost-benefit ratio given the higher price point, especially for large-scale projects. Polyimide’s chemical resistance is advantageous in industrial settings with exposure to solvents or oils common in South America’s manufacturing sectors.

Silicone Encapsulation Material

Key Properties: Silicone encapsulants provide excellent UV resistance, flexibility, and waterproofing. They maintain performance across a wide temperature range (-60°C to 200°C) and offer strong protection against moisture and dust ingress (IP65 to IP68 ratings).

Pros & Cons: Silicone encapsulation significantly enhances LED strip durability in outdoor and harsh environments, making it ideal for waterproof 110v LED strips. It is flexible and resistant to yellowing over time. The downside includes higher material and processing costs and potential challenges in recycling or disposal.

Impact on Application: Perfect for outdoor lighting, architectural facades, and environments with high humidity or exposure to chemicals. Silicone encapsulated strips are favored in Middle Eastern and African markets where dust and heat are prevalent, as well as in European outdoor installations requiring stringent IP ratings.

International Buyer Considerations: Buyers should ensure compliance with international IP standards and local certifications such as CE marking in Europe. Silicone materials must meet fire safety standards (UL94 V-0 or equivalent) relevant to each region. South American buyers benefit from silicone’s resistance to UV degradation given high solar exposure in many areas.

Copper Foil Substrate

Key Properties: Copper substrates offer excellent electrical conductivity and good thermal management, with operating temperatures typically up to 105°C. They are heavier and less corrosion-resistant than aluminum but provide superior electrical performance.

Pros & Cons: Copper foil substrates enable efficient current flow and are often used in high-power LED strips. However, they are more expensive and prone to corrosion without protective coatings. Manufacturing complexity is higher due to the need for oxidation prevention and precise layering.

Impact on Application: Suitable for high-current, high-brightness 110v LED strip applications such as industrial lighting or specialized task lighting. Less ideal for outdoor use unless adequately sealed.

International Buyer Considerations: European and Middle Eastern buyers should verify compliance with electrical safety standards (IEC 60598) and corrosion resistance requirements. African and South American buyers must consider local humidity and environmental factors, as copper’s susceptibility to corrosion can reduce product longevity in tropical or coastal regions unless properly treated.

Summary Table

| Material | Typical Use Case for 110v led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum PCB | Commercial/industrial lighting with heat dissipation needs | Excellent thermal management | Limited flexibility, moderate complexity | Medium |

| Polyimide Substrate | Flexible, curved indoor decorative lighting | High flexibility and thermal stability | Higher cost, lower heat dissipation | High |

| Silicone Encapsulation | Outdoor, waterproof, and harsh environment lighting | Superior waterproofing and UV resistance | Higher material and processing cost | High |

| Copper Foil Substrate | High-power, high-current industrial LED strips | Excellent electrical conductivity | Corrosion prone, higher cost and complexity | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for 110v led strip lights

Manufacturing Processes for 110v LED Strip Lights

The production of 110v LED strip lights involves a multi-stage manufacturing process that ensures each unit meets performance and safety requirements. For B2B buyers, understanding these stages provides clarity on product quality and supplier capabilities.

1. Material Preparation

Raw materials include LED chips, flexible printed circuit boards (FPC), resistors, capacitors, drivers, connectors, and protective coatings. High-quality LED chips and FPCs are sourced from specialized suppliers. Material inspection at this stage is crucial to avoid defects downstream, focusing on the uniformity of LED chips, copper thickness on PCBs, and the consistency of solder paste.

2. Forming the Circuit Board

The flexible PCB is produced through a photolithography process where copper layers are etched to form electrical pathways. For 110v strips, special attention is given to the insulation and thickness of the substrate to safely handle the higher voltage. Some manufacturers apply additional layers or coatings to enhance durability and reduce heat dissipation.

3. Component Assembly

This stage involves surface mount technology (SMT) to place LEDs and other components onto the flexible PCB. Automated pick-and-place machines are typically used to ensure precision and repeatability. Soldering is done using reflow ovens, which solidify the connections while minimizing thermal stress. For 110v LED strips, assembly must comply with insulation standards to prevent electrical hazards.

4. Finishing and Protective Coating

Once assembled, strips undergo protective coating processes such as silicone encapsulation or polyurethane coating to enhance waterproofing and mechanical strength. For outdoor or industrial applications, IP65 or higher-rated coatings are common. The finishing stage also includes cutting the strips to standard lengths and attaching connectors or end caps as required.

Quality Assurance and Control (QA/QC) Framework

Quality assurance in 110v LED strip lights production is integral to guaranteeing safety, longevity, and performance. International B2B buyers should look for manufacturers with robust QA/QC systems aligned with global standards.

Relevant International Standards

– ISO 9001: The cornerstone for quality management systems, ensuring consistent manufacturing processes and continuous improvement.

– CE Marking: Mandatory for products sold in the European Economic Area, certifying compliance with health, safety, and environmental protection standards.

– RoHS Compliance: Restricts hazardous substances, important for European and some Middle Eastern markets.

– UL Certification: Particularly relevant for North American and some international buyers, ensuring electrical safety and fire hazard mitigation.

– API and IEC Standards: For electrical components and LED performance, these standards help verify product reliability and safety.

Critical QC Checkpoints

– Incoming Quality Control (IQC): Inspection of raw materials and components for defects or inconsistencies before production. This includes LED binning to ensure uniform brightness and color temperature.

– In-Process Quality Control (IPQC): Continuous monitoring during assembly, such as verifying solder joint quality, component placement accuracy, and electrical continuity testing.

– Final Quality Control (FQC): Comprehensive testing on finished products including visual inspection, functional testing, and packaging verification.

Common Testing Methods for 110v LED Strip Lights

To meet stringent B2B requirements, manufacturers perform a series of tests that verify both electrical and physical attributes:

- Electrical Safety Tests: High voltage withstand testing, insulation resistance, and leakage current measurement to ensure compliance with voltage ratings and safety norms.

- Photometric Testing: Measures luminous flux, color rendering index (CRI), and color temperature to guarantee lighting performance meets specifications.

- Thermal Testing: Assesses heat dissipation and operating temperature to prevent premature failure. This is especially critical for 110v strips due to higher voltage and potential heat generation.

- Waterproof and Environmental Tests: IP rating verification through immersion, condensation, or dust ingress tests, essential for outdoor or industrial applications.

- Mechanical Durability: Flexibility tests, vibration resistance, and adhesion strength of coatings to ensure longevity under various installation conditions.

How B2B Buyers Can Verify Supplier Quality Control

Given the complexity of manufacturing 110v LED strip lights, buyers should implement strategies to validate supplier quality:

- Factory Audits: Conduct on-site inspections or hire third-party auditors to review manufacturing processes, QA systems, and working conditions. Focus on production line cleanliness, equipment maintenance, and staff expertise.

- Review of Quality Documentation: Request ISO 9001 certificates, CE declarations, test reports, and batch inspection data. Confirm that these documents are current and issued by accredited bodies.

- Sample Testing: Before bulk orders, obtain samples for independent laboratory testing to verify electrical safety, luminous performance, and environmental resistance.

- Third-Party Inspections: Engage inspection agencies to perform random sampling and quality verification during production or pre-shipment stages, reducing the risk of receiving substandard products.

- Warranty and After-Sales Support: Assess the supplier’s warranty policies and responsiveness to quality issues, which are indicative of confidence in product quality.

QC and Certification Nuances for International Markets

For buyers from Africa, South America, the Middle East, and Europe, understanding regional compliance and certification requirements is critical:

- Africa & South America: Standards may vary widely; however, many countries accept CE and RoHS certifications as proof of safety and environmental compliance. Some nations require additional local certifications or customs inspections, so clarifying import regulations beforehand is essential.

- Middle East: Countries like the UAE and Saudi Arabia emphasize GCC Standards, which often align closely with IEC and CE requirements. UL certification may also be preferred for certain commercial applications.

- Europe (UK, Spain, EU): CE marking is mandatory, along with compliance to RoHS and WEEE directives. Buyers should ensure suppliers provide full documentation for customs clearance and market access. The UK requires UKCA marking post-Brexit, so suppliers should be prepared to meet both CE and UKCA standards if serving that market.

- Voltage and Safety Considerations: As 110v is not the standard mains voltage in many European countries (which use 220-240v), buyers must confirm that products are explicitly designed for 110v operation with appropriate certifications to avoid safety risks and regulatory non-compliance.

Key Takeaways for B2B Buyers

- Demand transparency in manufacturing processes and quality control documentation from suppliers.

- Prioritize suppliers with internationally recognized certifications like ISO 9001, CE, UL, and RoHS to ensure product safety and market acceptance.

- Leverage third-party inspections and sample testing to mitigate risks before large purchases.

- Understand regional certification nuances and ensure products comply with destination market regulations.

- Establish ongoing communication channels with suppliers for continuous quality monitoring and support.

By focusing on these manufacturing and quality assurance aspects, international B2B buyers can secure reliable, high-performance 110v LED strip lights that meet their operational and regulatory needs across diverse markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for 110v led strip lights Sourcing

Understanding the Cost Structure of 110v LED Strip Lights

When sourcing 110v LED strip lights for B2B purposes, it is essential to break down the cost components to better understand pricing dynamics and optimize procurement strategies. The typical cost structure includes:

- Materials: This is the largest cost driver, comprising LED chips, flexible PCB substrates, drivers, connectors, resistors, and protective coatings. The quality and type of materials (e.g., high-lumen LEDs, waterproof coatings) significantly influence the base cost.

- Labor: Skilled labor is required for assembly, soldering, testing, and packaging. Labor costs vary by manufacturing location, impacting the overall price.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and administrative expenses, which are allocated across production volume.

- Tooling: Initial setup costs for customized production runs, such as molds or specific cutting tools, can add to upfront expenses, especially for small or bespoke orders.

- Quality Control (QC): Rigorous testing for durability, brightness consistency, and safety certifications (e.g., CE, RoHS) adds to cost but ensures reliability.

- Logistics and Shipping: Transportation from manufacturer to buyer, customs duties, and insurance fees must be factored in, especially for international shipments.

- Profit Margin: Suppliers typically embed a margin to cover risk and ensure business sustainability, which can vary widely depending on supplier type and market conditions.

Key Price Influencers for International Buyers

Several factors influence the final price of 110v LED strip lights, especially for buyers from Africa, South America, the Middle East, and Europe:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders generally yield better unit prices due to economies of scale. Many suppliers set MOQs, which can impact cost-efficiency for smaller buyers.

- Product Specifications and Customization: Custom lengths, color temperatures, waterproof ratings, and packaging options increase production complexity and cost.

- Materials Quality and Certifications: Higher-grade LEDs and compliance with international standards (e.g., CE for Europe, ETL for Middle East) elevate costs but reduce risks of failure and regulatory issues.

- Supplier Reliability and Location: Established suppliers with stable supply chains might charge premium prices but reduce risks of delays or quality issues. Proximity to manufacturing hubs (e.g., China, Vietnam) affects shipping costs and lead times.

- Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) affects who bears shipping and customs costs, influencing the total landed cost. Favorable payment terms (e.g., letter of credit, net 30) can improve cash flow management.

Practical Tips for Buyers to Optimize Costs

- Negotiate Volume Discounts and Flexible MOQs: Engage suppliers early to explore discounts on larger volumes or request MOQs tailored to your project scale. Consolidating orders with other buyers or across product lines can unlock better pricing.

- Assess Total Cost of Ownership (TCO): Go beyond unit price by considering energy efficiency, lifespan, warranty coverage, and maintenance costs. Higher upfront costs for premium LEDs may reduce long-term expenses.

- Request Samples and Verify Certifications: Before committing to large orders, test product samples for quality and compliance. This reduces risks of costly returns or regulatory non-compliance.

- Leverage Local Partners for Logistics: Collaborate with freight forwarders or local distributors to optimize shipping routes and reduce customs clearance delays, especially important for regions with complex import regulations.

- Understand Pricing Nuances by Region: For instance, European buyers (UK, Spain) often require CE marking and RoHS compliance, which can increase costs but are mandatory. Buyers in Africa or South America should account for variable import duties and longer shipping times, which affect inventory planning and cash flow.

- Use Technology for Cost Analysis: Employ supply chain management software to track costs, forecast demand, and analyze supplier performance, enabling data-driven negotiation and procurement decisions.

Disclaimer on Pricing

The prices for 110v LED strip lights can vary significantly based on supplier, customization, and market conditions. The insights provided here are indicative and should be supplemented with direct supplier quotations and market research tailored to your specific sourcing needs.

By understanding these cost components and pricing influencers, international B2B buyers can strategically negotiate and optimize their procurement of 110v LED strip lights, ensuring cost-effective purchases without compromising on quality or compliance.

Spotlight on Potential 110v led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘110v led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 110v led strip lights

Critical Technical Properties of 110V LED Strip Lights

When sourcing 110V LED strip lights for international B2B projects, understanding the essential technical specifications is crucial. These properties impact product performance, safety, and compatibility, directly influencing purchasing decisions and long-term value.

-

Input Voltage (110V AC)

This defines the operating voltage of the LED strip light. 110V strips are designed to run directly on standard household or commercial AC power without requiring bulky transformers. For B2B buyers, verifying the voltage compatibility with local power infrastructure (especially in Africa, South America, Middle East, and Europe) ensures seamless installation and reduces retrofit costs. -

Material Grade and PCB Quality

The base material, typically flexible Printed Circuit Board (PCB), affects durability and heat dissipation. High-grade materials like FR4 or aluminum-backed PCBs enhance thermal management, extending LED lifespan. For bulk buyers, selecting strips with superior PCB quality minimizes failure rates and maintenance, which is critical in large-scale or commercial installations. -

Luminous Flux and LED Density

Luminous flux (measured in lumens) indicates brightness, while LED density (LEDs per meter) affects light uniformity. Buyers should match these specs to application needs—higher lumens and density suit task lighting or commercial spaces, whereas lower values might suffice for decorative use. Understanding these metrics helps optimize energy consumption and lighting quality. -

Color Temperature and Color Rendering Index (CRI)

Color temperature (Kelvin scale) determines the light’s warmth or coolness, influencing ambiance and visual comfort. CRI measures how accurately the light reveals colors compared to natural light, with values above 80 preferred for retail or hospitality. B2B purchasers should specify these to meet client expectations and comply with local standards. -

Ingress Protection (IP) Rating

IP ratings denote resistance to dust and water, essential for outdoor or industrial applications. For example, IP65 or higher ensures protection against jets of water and dust ingress. Selecting appropriate IP-rated strips prevents premature failures, critical for buyers serving markets with harsh environments or outdoor installations. -

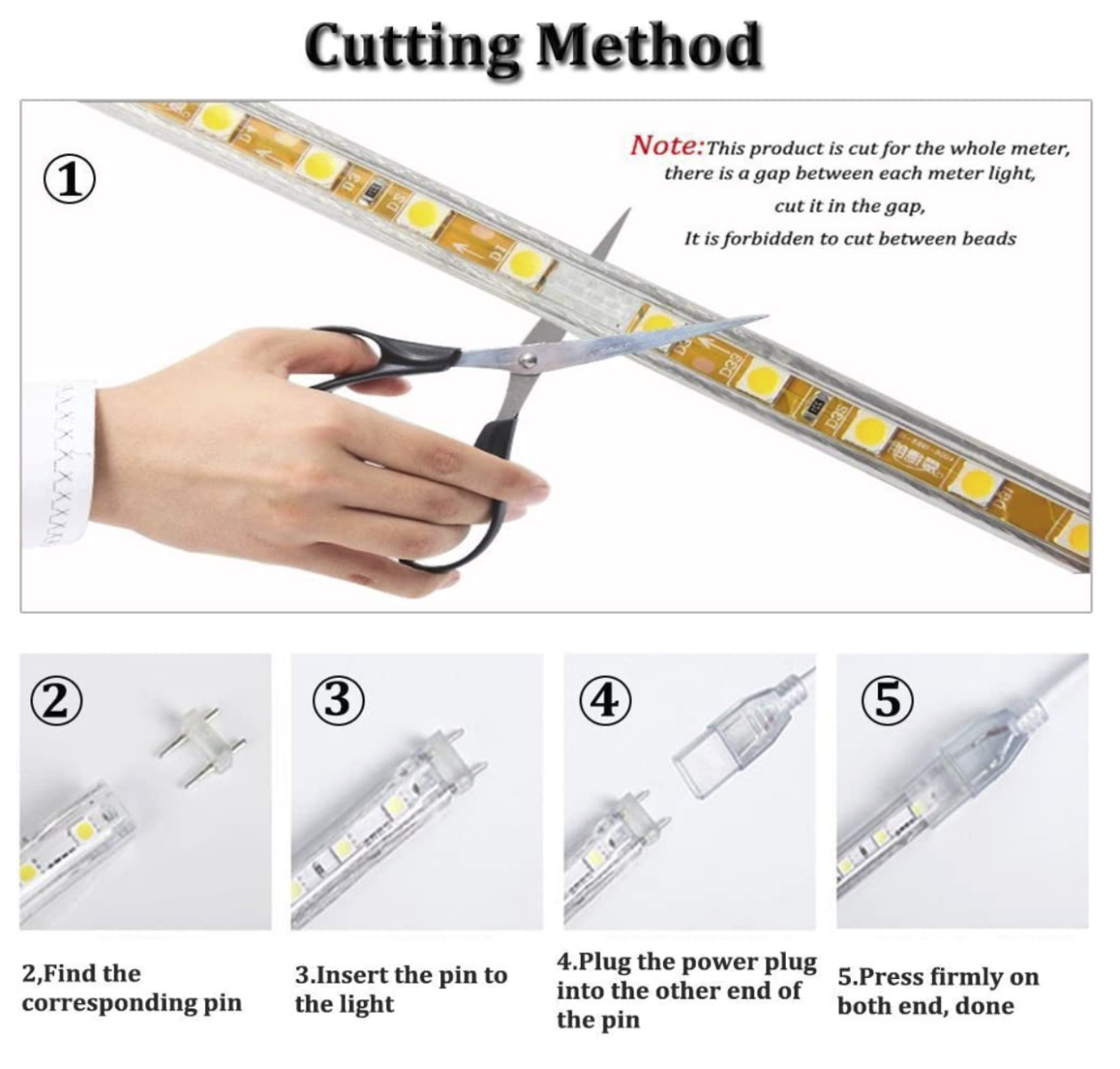

Cutting and Connection Tolerance

This defines the precision and flexibility in modifying strip lengths and connecting segments. High tolerance in cutting points and connector compatibility allows customization on-site, reducing waste and installation time—key advantages for large projects requiring tailored lighting solutions.

Key Trade Terms for International LED Strip Light Procurement

Navigating international LED strip light procurement requires familiarity with common industry jargon. These terms streamline communication and ensure clarity in contracts and negotiations.

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce LED strips that can be branded by the buyer. OEM arrangements enable businesses to customize product branding and specifications, supporting unique market positioning and private labeling strategies. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and budget effectively, especially when balancing initial investment against storage capacity and project timelines. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain price, lead time, and terms for a specific order. RFQs are essential in comparing multiple vendors, ensuring competitive pricing and clear delivery expectations in B2B procurement processes. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers for shipping, insurance, and customs clearance. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Knowing Incoterms prevents misunderstandings and clarifies cost allocation in cross-border transactions. -

Lead Time

The period from placing an order to receiving the goods. Accurate lead time estimates are vital for project scheduling, especially for large-scale or time-sensitive installations common in commercial and industrial sectors. -

Binning

The process of sorting LEDs by color and brightness consistency. Binned LED strips ensure uniform appearance and performance, a critical quality factor for buyers targeting high-end markets or requiring strict lighting standards.

For international buyers, especially in emerging and diverse markets, mastering these technical properties and trade terms empowers informed decisions, mitigates risks, and optimizes procurement outcomes for 110V LED strip lights.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 110v led strip lights Sector

Market Overview & Key Trends

The global market for 110v LED strip lights is expanding rapidly, driven by increasing demand for energy-efficient lighting solutions across commercial, industrial, and residential sectors. International B2B buyers from Africa, South America, the Middle East, and Europe are witnessing a surge in adoption due to LED technology’s superior energy savings, longer lifespan, and versatility compared to traditional lighting. In regions like Europe and the UK, stringent energy regulations and sustainability commitments accelerate the shift toward LED lighting. Meanwhile, emerging markets in Africa and South America are leveraging LED strips for cost-effective, scalable lighting infrastructure improvements.

Key sourcing trends in this sector emphasize customization and technological integration. Buyers increasingly seek suppliers offering tailored LED strip lengths, color temperatures, and smart capabilities such as app-controlled dimming and color changes. This trend aligns with growing demand for IoT-enabled lighting solutions in commercial real estate and hospitality industries. Additionally, waterproof and high-lumen LED strips are gaining traction for outdoor and industrial applications, especially in Middle Eastern and African markets with harsh environmental conditions.

Supply chain resilience remains a critical factor. B2B buyers are prioritizing suppliers with diversified component sourcing and robust manufacturing processes to mitigate disruptions. The rise of digital supply chain management tools enables real-time inventory tracking and demand forecasting, essential for managing large-scale orders efficiently. Furthermore, bulk purchasing from trusted wholesale suppliers is favored to optimize cost-efficiency and ensure consistent product quality across extensive projects.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in procurement decisions for 110v LED strip lights. Buyers across Europe and other regions increasingly demand products with reduced environmental impact throughout their lifecycle—from raw material extraction to manufacturing, usage, and end-of-life disposal. Energy-efficient LEDs inherently contribute to lower carbon footprints by reducing electricity consumption, but the focus now extends to sourcing eco-friendly materials such as lead-free solder, recyclable PCBs, and halogen-free components.

Ethical supply chains are critical to meeting corporate social responsibility (CSR) goals. International buyers look for suppliers who adhere to fair labor practices and transparency in their operations. Certifications such as RoHS (Restriction of Hazardous Substances), REACH compliance, and Energy Star ratings serve as benchmarks for environmental and product safety standards. Additionally, ISO 14001 environmental management certification indicates a supplier’s commitment to minimizing ecological impact.

Implementing circular economy principles—like modular designs for easy repair and recycling—adds value for B2B customers aiming to reduce waste and comply with evolving environmental regulations. Partnering with suppliers who prioritize sustainability not only aligns with global green initiatives but also enhances brand reputation and meets the growing demand from end consumers for responsible lighting solutions.

Brief Evolution of 110v LED Strip Lights

110v LED strip lights evolved from early low-voltage (12v/24v) designs, addressing the need for simpler installation without bulky transformers. By operating directly on standard 110v AC mains voltage, these strips reduce wiring complexity and installation costs, making them attractive for large-scale commercial and residential projects. Over the past decade, advancements in LED chip efficiency, flexible circuit materials, and waterproofing have broadened their application scope—from decorative lighting to task-specific illumination.

The integration of smart technology and improved thermal management has further enhanced product reliability and functionality. Today’s 110v LED strips combine high lumen output with energy savings and durability, positioning them as a preferred lighting choice for international B2B buyers seeking scalable, cost-effective, and sustainable lighting solutions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of 110v led strip lights

-

How can I effectively vet suppliers of 110v LED strip lights for international B2B purchases?

To vet suppliers, start by verifying their business credentials, such as valid export licenses and certifications like ISO or CE relevant to LED products. Request detailed product catalogs and inquire about their manufacturing processes. Check customer reviews and ask for references, especially from buyers in your region. Evaluate their communication responsiveness and transparency regarding pricing, MOQ, and lead times. Consider suppliers who offer product samples to assess quality firsthand. For buyers in Africa, South America, the Middle East, and Europe, also verify compliance with regional electrical standards to avoid import issues. -

What customization options are typically available for 110v LED strip lights in bulk orders?

Many wholesale suppliers offer customization including specific strip lengths, color temperatures, IP ratings (waterproof levels), and packaging branding. Some also provide options for smart features like dimmability or app control. Custom colors or logos on packaging can support brand differentiation. For large projects, tailored voltage compatibility and connector types may be requested to match regional electrical systems. When negotiating customization, clarify minimum order quantities and lead times as these vary widely and impact project timelines and costs. -

What are the common MOQ (Minimum Order Quantity) and lead time expectations when ordering 110v LED strip lights internationally?

MOQs typically range from 100 to 500 meters per SKU, though some suppliers may accommodate smaller trial orders, especially with sample fees. Lead times can vary from 2 to 6 weeks depending on customization, production capacity, and shipping method. Buyers should confirm these details upfront and factor in customs clearance time. Consolidating orders or choosing suppliers with regional warehouses can reduce lead times. Clear communication about order volume flexibility and phased deliveries can help manage inventory and cash flow efficiently. -

Which payment terms and methods are safest and most common for international B2B transactions of LED strip lights?

Common payment methods include wire transfers (T/T), letters of credit (L/C), and increasingly, trade assurance services offered by platforms like Alibaba. For new suppliers, a 30% upfront deposit with balance on shipment is standard, reducing risk for both parties. Letters of credit provide additional security but involve bank fees and paperwork. Always verify supplier banking details independently to prevent fraud. For buyers in regions with currency restrictions, negotiating payment in a stable currency (USD or EUR) or through escrow services can mitigate financial risks. -

What quality assurance certifications should I look for when sourcing 110v LED strip lights internationally?

Key certifications include CE (Europe), RoHS (restriction of hazardous substances), UL or ETL (North America, relevant for safety), and ISO 9001 (quality management). For buyers in Africa, South America, and the Middle East, check for compliance with local electrical and safety standards or regional marks like SABS (South Africa) or INMETRO (Brazil). Request test reports for photometric performance, IP ratings for waterproof products, and durability tests. Certified suppliers typically offer warranties, which are critical for after-sales support. -

How can I optimize logistics and shipping for bulk orders of 110v LED strip lights to Africa, South America, the Middle East, or Europe?

Select suppliers with experience shipping to your region to avoid customs delays and extra costs. Opt for consolidated shipments to reduce freight charges and consider sea freight for large volumes versus air freight for urgent orders. Ensure packaging is robust and moisture-resistant to protect delicate LED components during transit. Utilize freight forwarders familiar with local import regulations and tariffs. Implementing supply chain software or working with logistics partners can provide tracking visibility and streamline delivery timelines. -

What are best practices for handling disputes or quality issues with overseas LED strip light suppliers?

Document all communications and inspect shipments immediately upon arrival. If defects arise, notify the supplier with photographic evidence and detailed descriptions. Refer to agreed warranty and return policies. Attempt amicable resolution first, such as replacement or partial refund. For unresolved disputes, leverage third-party mediation services or trade platforms’ dispute resolution mechanisms. Maintaining clear contracts that specify quality standards, inspection procedures, and penalties helps protect your interests. Establishing strong relationships and ongoing supplier audits can prevent recurrent issues. -

How can I ensure product compatibility with local electrical standards when sourcing 110v LED strip lights internationally?

Confirm that the LED strips are designed specifically for 110v AC systems common in countries like the US, parts of South America, and some Middle Eastern regions. Check that the voltage rating matches your target market to avoid performance issues or safety hazards. Additionally, verify that connectors, plugs, and control systems comply with local standards and that any certifications cover your market’s regulations. When in doubt, request technical datasheets and consult local electrical experts or certification bodies before bulk purchasing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 110v led strip lights

In today’s dynamic global market, strategic sourcing of 110v LED strip lights is essential for international B2B buyers seeking competitive advantage and operational excellence. Prioritizing partnerships with reputable suppliers who offer quality components, reliable warranties, and flexible customization options ensures product consistency and scalability across diverse applications—from commercial installations to innovative architectural projects.

Illustrative Image (Source: Google Search)

For buyers in Africa, South America, the Middle East, and Europe, leveraging bulk purchasing benefits such as cost savings, access to cutting-edge LED technologies, and streamlined logistics can significantly enhance profitability and project delivery timelines. Moreover, integrating supply chain management best practices—like diversifying supplier bases and utilizing real-time inventory tracking—fortifies resilience against disruptions and market fluctuations.

Looking ahead, the LED lighting industry will continue evolving with smart, energy-efficient solutions shaping demand. Proactive sourcing strategies that emphasize quality, innovation, and supplier collaboration will empower businesses to meet growing sustainability standards and customer expectations. International buyers are encouraged to engage early with trusted manufacturers, request product samples, and explore tailored solutions to stay ahead in this competitive landscape.

Embrace strategic sourcing today to unlock the full potential of 110v LED strip lights and illuminate your business’s path to growth and innovation.