Introduction: Navigating the Global Market for wiring led strip lights

In today’s rapidly evolving lighting industry, wiring LED strip lights has emerged as a foundational element for ensuring high-performance, energy-efficient, and visually striking lighting solutions across commercial, industrial, and architectural applications. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe (including Turkey and Brazil), mastering the intricacies of LED strip wiring is critical to sourcing products that deliver reliability, safety, and scalability.

This comprehensive guide delves deeply into every aspect of wiring LED strip lights, equipping buyers with the knowledge to make strategic procurement decisions. From understanding the various types of LED strips—single color, RGB, tunable white, and addressable variants—to selecting the correct wire gauge and power connection methods, this resource covers technical fundamentals and advanced installation practices. It also sheds light on essential manufacturing standards, quality control protocols, and supplier evaluation criteria to help buyers identify trustworthy partners and avoid costly mistakes.

Additionally, the guide explores the global market landscape, pricing trends, and region-specific challenges such as voltage compatibility and environmental considerations. Practical insights on troubleshooting, maintenance, and frequently asked questions further empower buyers to support long-term project success.

By leveraging this authoritative resource, international B2B buyers can confidently navigate supplier negotiations, optimize their wiring configurations for performance and safety, and ultimately secure LED strip lighting solutions that meet their precise operational demands and regulatory requirements worldwide.

Understanding wiring led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color LED Strips | Two-wire connection, fixed color output | Retail lighting, signage, basic architectural | Pros: Simple wiring, cost-effective; Cons: Limited control, no color variation |

| RGB LED Strips | Four-wire system, multi-color output with controller | Hospitality, entertainment venues, branding | Pros: Dynamic color options, customizable; Cons: More complex wiring, higher cost |

| Tunable White (CCT) LED Strips | Three or four wires, adjustable color temperature (warm to cool white) | Office lighting, healthcare, hospitality | Pros: Flexible ambiance control; Cons: Requires compatible drivers and controllers |

| Addressable LED Strips | Individually controllable LEDs via data lines | Large-scale displays, stage lighting, advertising | Pros: High customization, dynamic effects; Cons: Complex installation, higher investment |

| High-Voltage LED Strips | Operate on 120V or 230V AC directly, thicker wiring | Industrial, outdoor, large-area commercial | Pros: Reduced voltage drop over long runs; Cons: Requires safety expertise, higher installation standards |

Single-Color LED Strips

These strips use a straightforward two-wire system powering LEDs of a single color, typically 12V or 24V DC. They are ideal for projects requiring uniform lighting without color changes, such as retail shelf lighting or basic architectural accents. For B2B buyers, these strips offer ease of installation and lower costs but limit design flexibility. Careful consideration of power supply capacity and wire gauge is essential to ensure consistent performance in commercial environments.

RGB LED Strips

Featuring four wires—one common positive and three for red, green, and blue channels—RGB strips enable vibrant, multi-color lighting controlled via dedicated controllers. Their versatility suits hospitality, event venues, and brand-centric environments where dynamic lighting enhances customer experience. Buyers must account for more complex wiring, integration with control systems, and potentially higher initial costs, balanced against the value of customizable ambiance and marketing impact.

Tunable White (CCT) LED Strips

These strips incorporate two LED chips with different color temperatures and typically three or four wiring leads to allow smooth adjustment between warm and cool white light. They are increasingly popular in offices, healthcare, and hospitality sectors where lighting quality affects productivity and comfort. B2B buyers should ensure compatibility with dimmable drivers and controllers and recognize that initial investment is offset by enhanced user experience and energy efficiency.

Addressable LED Strips

Utilizing data and clock lines alongside power wires, addressable LED strips allow individual control of each LED, enabling complex lighting effects and animations. This makes them ideal for large-scale displays, theatrical productions, and advertising installations requiring high visual impact. For buyers, the complexity of wiring and programming demands skilled installers and higher upfront costs but delivers unmatched customization and engagement potential.

High-Voltage LED Strips

Unlike low-voltage strips, these operate directly on mains voltage (e.g., 120V or 230V AC), reducing the need for voltage converters and enabling longer uninterrupted runs with thicker gauge wiring. They are well-suited for industrial, outdoor, and expansive commercial spaces where minimizing voltage drop and wiring complexity is critical. Buyers must prioritize compliance with regional electrical standards and engage qualified professionals to ensure safety and reliability.

Related Video: How To Wire LED Strip Lights

Key Industrial Applications of wiring led strip lights

| Industry/Sector | Specific Application of wiring led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and Commercial Spaces | Accent and display lighting for product showcases and signage | Enhances product visibility, drives customer engagement, and improves ambiance | Requires flexible wiring solutions for complex layouts and reliable dimming controls; compliance with local electrical standards is crucial |

| Hospitality and Entertainment | Ambient and decorative lighting in hotels, restaurants, and theaters | Creates immersive environments, supports brand identity, and reduces energy costs | Needs robust wiring for variable control systems (RGB, tunable white); sourcing durable, heat-resistant cables for high-usage environments |

| Industrial and Manufacturing | Task and safety lighting in assembly lines and warehouses | Improves worker productivity, enhances safety, and lowers maintenance downtime | Must ensure wiring supports high-current loads with minimal voltage drop; prioritize easy maintenance and scalability for large installations |

| Transportation Infrastructure | Lighting in airports, train stations, and tunnels | Provides consistent illumination for safety and navigation, reduces operational costs | Focus on wiring that withstands harsh environments; adherence to international safety certifications is essential |

| Architectural and Urban Development | Façade and landscape lighting for commercial buildings and public spaces | Elevates aesthetic appeal, extends operational hours, and promotes sustainable energy use | Requires weatherproof wiring solutions and modular connection systems adaptable to diverse climates |

Retail and Commercial Spaces

In retail environments across Africa, South America, the Middle East, and Europe, wiring LED strip lights is essential for accentuating product displays and signage. Proper wiring ensures consistent brightness and enables integration with dimmable or color-changing controls, enhancing customer experience and boosting sales. International B2B buyers should prioritize wiring solutions that accommodate complex store layouts and comply with regional electrical codes to prevent voltage drops and maintain safety.

Hospitality and Entertainment

Hotels, restaurants, and entertainment venues rely heavily on ambient and decorative lighting to create memorable atmospheres. Wiring LED strip lights in these settings involves connecting multiple zones with precise control systems such as RGB or tunable white. Buyers from regions like Turkey and Brazil must source wiring components that resist heat and wear due to continuous operation, ensuring longevity and minimal maintenance in high-traffic areas.

Industrial and Manufacturing

In industrial facilities, LED strip lights are wired to provide focused task lighting and safety illumination along assembly lines and warehouse aisles. The wiring must handle higher current loads with minimal voltage drop to maintain brightness and system reliability. B2B buyers in emerging markets should consider scalable wiring architectures that simplify future expansions and facilitate quick troubleshooting to minimize costly production downtime.

Transportation Infrastructure

Airports, train stations, and tunnels use LED strip lighting wired for uniform illumination critical to passenger safety and operational efficiency. Wiring solutions must be durable and compliant with stringent international safety standards to withstand environmental stresses such as humidity and vibration. Procurement professionals should ensure that wiring kits are certified and adaptable to diverse infrastructure projects in their respective regions.

Architectural and Urban Development

For commercial façades and urban landscapes, wiring LED strip lights enables dynamic lighting designs that enhance building aesthetics and promote sustainability through energy-efficient solutions. Buyers targeting outdoor applications must select weatherproof wiring and modular connectors that can endure varied climates across continents. Emphasis on ease of installation and future maintenance is key for long-term value in large-scale urban projects.

Related Video: How to Install LED Strip Lights

Strategic Material Selection Guide for wiring led strip lights

When selecting materials for wiring LED strip lights in commercial and industrial projects, understanding the properties and trade-offs of common wiring materials is crucial. This ensures optimal performance, safety, and compliance with international standards, particularly for buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe.

Copper Conductors

Key Properties: Copper is the industry standard conductor material due to its excellent electrical conductivity, thermal resistance, and mechanical flexibility. It performs well under a wide temperature range (-40°C to 150°C) and has strong corrosion resistance when properly insulated.

Pros & Cons: Copper wiring offers superior durability and minimal voltage drop, which is critical for maintaining consistent brightness in LED strips over long runs. However, copper is relatively costly compared to alternatives and can be heavier, which may complicate installation in large-scale projects. Manufacturing complexity is moderate, with well-established global supply chains.

Impact on Application: Copper wiring is suitable for nearly all LED strip installations, including those requiring long cable runs or higher current loads. Its robustness makes it ideal for harsh environments found in parts of Africa and the Middle East, where temperature extremes and dust are common.

International Considerations: Copper wiring typically complies with ASTM B3/B8, DIN EN 60228, and IEC standards, which are widely accepted in Europe, Turkey, Brazil, and beyond. Buyers should verify local electrical codes and certification requirements to ensure compatibility, especially in regions with stringent safety regulations like the EU.

Aluminum Conductors

Key Properties: Aluminum wiring is lighter and less expensive than copper but has lower electrical conductivity (about 61% of copper). It is more prone to oxidation and requires specialized coatings or alloys to improve corrosion resistance.

Pros & Cons: Aluminum is cost-effective and reduces overall cable weight, beneficial for large installations or where shipping costs are a concern. However, it demands larger wire gauges to carry the same current as copper, increasing bulkiness. Its susceptibility to thermal expansion and oxidation can lead to reliability issues if not properly managed.

Impact on Application: Aluminum is best suited for low-current, short-distance LED strip installations or where budget constraints dominate. It is less ideal for high-humidity or corrosive environments without additional protective measures.

International Considerations: Aluminum wiring must meet standards such as ASTM B231 and IEC 60228. In South America and parts of Africa, aluminum wiring is sometimes preferred due to lower costs, but buyers should ensure connectors and terminals are compatible to avoid galvanic corrosion. Compliance with local electrical safety standards is critical.

Tinned Copper Conductors

Key Properties: Tinned copper wires have a thin layer of tin coating over copper, enhancing corrosion resistance, especially in humid or marine environments. The tin layer also improves solderability and reduces oxidation.

Pros & Cons: Tinned copper combines the conductivity of copper with superior durability against environmental degradation. It is more expensive than bare copper but offers longer service life and reduced maintenance costs. Manufacturing is slightly more complex due to the tinning process.

Impact on Application: Ideal for installations in coastal regions, humid climates, or industrial settings with exposure to chemicals—common in Middle Eastern coastal cities and parts of Europe. The tin coating ensures reliability in environments where bare copper would corrode.

International Considerations: Tinned copper wiring aligns with IEC 60092-350 and other marine-grade standards, which are increasingly relevant for international projects involving ports or offshore facilities. Buyers in Brazil and Turkey should verify local acceptance and certification for tinned copper conductors.

PVC-Insulated Wire

Key Properties: Polyvinyl chloride (PVC) insulation is widely used for its cost-effectiveness, flame retardancy, and chemical resistance. PVC can operate safely up to 70°C to 105°C depending on formulation.

Pros & Cons: PVC insulation provides good mechanical protection and electrical insulation at a low cost. However, it can become brittle over time, especially under UV exposure or extreme temperatures, limiting its lifespan in outdoor or high-heat applications.

Impact on Application: PVC-insulated wiring is suitable for indoor LED strip installations or controlled environments. For outdoor or harsh environments in Africa or the Middle East, UV-resistant or alternative insulation materials may be necessary to ensure longevity.

International Considerations: PVC insulation complies with IEC 60502 and UL standards commonly recognized worldwide. Buyers should confirm that the insulation grade matches the environmental conditions of the installation site, particularly in regions with high ambient temperatures or chemical exposure.

Summary Table

| Material | Typical Use Case for wiring led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Long runs, high current, indoor/outdoor commercial installs | Excellent conductivity and durability | Higher cost and weight | High |

| Aluminum | Budget-conscious, short runs, low current applications | Lightweight and cost-effective | Lower conductivity, prone to oxidation | Low |

| Tinned Copper | Coastal, humid, or chemically aggressive environments | Superior corrosion resistance and solderability | Higher cost, more complex manufacturing | High |

| PVC-Insulated Wire | Indoor, controlled environments | Cost-effective insulation with flame retardancy | Limited UV and temperature resistance | Low |

This guide equips B2B buyers with a strategic understanding of wiring material options tailored to their regional and project-specific needs. Selecting the right conductor and insulation material ensures LED strip lighting systems that are safe, reliable, and efficient across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for wiring led strip lights

Manufacturing wiring for LED strip lights is a technically precise process that demands strict control over materials, assembly, and testing to ensure durability, safety, and optimal performance. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding the production and quality assurance (QA) framework is essential for selecting reliable suppliers and minimizing risks in procurement.

Key Manufacturing Stages and Techniques

1. Material Preparation

The manufacturing process begins with sourcing high-quality raw materials:

– Copper-Clad Laminate (CCL) for flexible printed circuit boards (FPCBs), which form the base of LED strips.

– Conductive Copper Foil and solderable surfaces prepared through chemical cleaning and plating.

– LED chips and resistors selected based on electrical specifications.

– Wires and connectors—often tinned copper to improve solderability and corrosion resistance.

Material verification includes supplier audits and incoming quality control (IQC) to ensure materials meet electrical, mechanical, and chemical standards.

2. PCB Forming and Circuit Patterning

- Photolithography and Etching: The copper-clad laminate undergoes photolithographic masking and chemical etching to create precise circuit patterns.

- Plating: Additional metal plating (e.g., gold or silver) may be applied to enhance conductivity and durability.

- Cutting and Scoring: The PCB is cut into strips of predetermined length, with perforations or notches for easy installation and flexibility.

3. Component Assembly and Wiring

- Surface Mount Technology (SMT): LED chips, resistors, and capacitors are mounted on the PCB using pick-and-place machines followed by reflow soldering.

- Wiring Integration: Wires for power and control signals are attached via soldering or crimped connectors. Attention to wire gauge, insulation, and polarity is critical.

- Encapsulation and Coating: For protection against moisture and mechanical damage, strips may be coated with silicone or epoxy, or covered with a flexible PVC layer.

4. Finishing and Packaging

- Functional Testing: Each LED strip undergoes initial electrical testing for continuity, voltage, and brightness uniformity.

- Cut-to-Length and Connector Attachment: Final customization to client specifications, including connector types and lengths.

- Packaging: Strips are carefully wound, labeled, and packed in anti-static, moisture-proof materials to preserve quality during transit.

Quality Assurance Framework

International and Industry Standards

- ISO 9001: The cornerstone for manufacturing quality management systems, ensuring consistent production processes, documentation, and continuous improvement.

- CE Marking (Europe): Confirms compliance with EU safety, health, and environmental requirements.

- UL Certification (North America) & IEC Standards: Relevant for electrical safety and performance.

- RoHS Compliance: Restricts hazardous substances like lead and mercury, critical for environmentally conscious markets.

- API or Local Standards: Some regions, like the Middle East, may require adherence to specific electrical or safety standards.

B2B buyers should verify that suppliers hold these certifications and that their production lines are regularly audited for compliance.

Quality Control Checkpoints

-

Incoming Quality Control (IQC):

– Inspection of raw materials and components for conformity to specifications (e.g., wire gauge, LED binning, PCB integrity).

– Supplier material certificates and traceability are reviewed. -

In-Process Quality Control (IPQC):

– Monitoring critical manufacturing steps such as solder joint quality, wire attachment integrity, and coating thickness.

– Automated optical inspection (AOI) systems check for component placement accuracy and solder defects.

– Voltage and current tests on assembled strips to detect early electrical faults. -

Final Quality Control (FQC):

– Comprehensive functional tests including:- Voltage Drop Testing: Ensures wiring and connections maintain consistent voltage across the strip length.

- Brightness Uniformity and Color Temperature Verification: Using photometric tools.

- Durability Tests: Flexing, heat resistance, and moisture ingress tests (e.g., IP rating confirmation).

- Visual inspections for physical defects or contamination.

- Packaging verification to ensure protection during shipping.

Testing Methods and Verification for B2B Buyers

- Electrical Testing: Multimeters and specialized LED testers measure current, voltage, and resistance.

- Environmental Stress Screening: Simulated aging under heat, humidity, and vibration to identify early failures.

- Third-Party Laboratory Testing: Independent labs provide unbiased reports on compliance with IEC, CE, RoHS, and other standards.

How B2B Buyers Can Verify Supplier Quality Controls

- Factory Audits: On-site inspections to evaluate manufacturing processes, equipment, staff training, and QC documentation.

- Review of QC Reports: Request detailed IQC, IPQC, and FQC records for batches, including pass/fail rates and corrective actions.

- Third-Party Inspections: Engage independent inspection agencies to conduct random sample testing before shipment.

- Sample Testing: Order prototypes or pilot batches to verify compliance with specifications and performance requirements.

QC and Certification Nuances for International Markets

- Africa & Middle East: Regulatory environments vary; local certification may be required alongside international standards. Electrical safety and durability against harsh environmental conditions (heat, dust) are critical.

- South America: Import regulations often require certification equivalence (e.g., INMETRO in Brazil). Buyers should confirm suppliers can provide compliant documentation.

- Europe (Turkey and EU countries): Strict adherence to CE marking, RoHS, and REACH regulations is mandatory. Energy efficiency labeling may also be required.

- Documentation: Ensure suppliers provide traceable batch numbers, material certificates, and test reports in multiple languages if needed.

Strategic Recommendations for B2B Buyers

- Prioritize suppliers with ISO 9001 certification and recognized product certifications to reduce compliance risks.

- Insist on transparent QC documentation and conduct regular audits, especially for large-scale or long-term contracts.

- Consider environmental factors in your region when reviewing QC test results; for example, insist on heat and humidity resistance tests for Middle Eastern or African markets.

- Utilize third-party inspection services to independently verify product quality before shipment, mitigating disputes and ensuring contractual fulfillment.

- Foster supplier partnerships that emphasize continuous quality improvement and responsiveness to emerging standards and regulations.

By thoroughly understanding the manufacturing and quality assurance processes for wiring LED strip lights, international B2B buyers can make informed procurement decisions that safeguard product reliability, regulatory compliance, and overall project success.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for wiring led strip lights Sourcing

When sourcing wiring for LED strip lights in international B2B markets, understanding the comprehensive cost structure and pricing dynamics is essential for making informed purchasing decisions. This insight helps buyers from Africa, South America, the Middle East, and Europe optimize budgets while ensuring quality and reliability.

Key Cost Components in Wiring LED Strip Lights

- Materials: The primary cost driver includes copper or aluminum wiring, insulation materials (PVC, silicone), and connectors. High-quality copper with appropriate gauge and insulation rated for commercial use typically commands a premium but ensures safety and longevity.

- Labor: Skilled labor for manufacturing, including wire cutting, stripping, soldering, and assembly of connectors, contributes significantly to costs. Labor rates vary by country, impacting final pricing—manufacturers in Asia may offer lower labor costs than European or Middle Eastern counterparts.

- Manufacturing Overhead: This encompasses factory utilities, equipment depreciation, administrative expenses, and quality control processes. Efficient production lines reduce overhead impact, enabling more competitive pricing.

- Tooling and Equipment: Initial tooling for wire extrusion, connector molding, and automated assembly lines represents a fixed cost amortized over production volume. Custom wiring specifications or proprietary connectors increase tooling expenses.

- Quality Control: Rigorous testing for continuity, insulation resistance, voltage drop, and certifications (e.g., CE, RoHS, UL) adds to costs but guarantees compliance and product reliability, essential for B2B buyers aiming to minimize installation failures.

- Logistics and Shipping: Freight costs depend on shipment mode (air, sea), distance, fuel prices, and customs duties. For buyers in Africa and South America, longer shipping routes and port handling fees can significantly affect landed costs.

- Supplier Margin: Manufacturers and distributors include margins reflecting market conditions, demand, and exclusivity of product features.

Influencing Factors on Pricing

- Order Volume and MOQ: Larger purchase volumes typically unlock tiered pricing discounts. Minimum order quantities (MOQs) vary by supplier and product complexity; buyers from emerging markets should negotiate MOQs to align with project scale and inventory capacity.

- Technical Specifications and Customization: Custom wire gauges, insulation colors, connector types, or pre-assembled harnesses raise costs due to specialized tooling and production complexity.

- Material Quality and Certifications: Premium materials and compliance with international safety standards increase unit price but reduce risk and potential warranty claims.

- Supplier Reputation and Location: Established suppliers with proven track records and local presence often price higher but offer better after-sales support, essential for complex commercial installations.

- Incoterms and Payment Terms: Delivery terms (e.g., FOB, CIF, DDP) influence who bears logistics and customs costs. Favorable payment terms (letters of credit, net terms) affect cash flow and total cost of ownership.

Strategic Buyer Tips for Cost Efficiency and Negotiation

- Leverage Volume for Discounts: Consolidate orders across projects or partners to meet MOQs and negotiate better unit prices.

- Assess Total Cost of Ownership (TCO): Consider not just unit price but also installation ease, maintenance, potential downtime, and warranty support. Higher upfront costs can translate into long-term savings.

- Clarify Specification Details: Provide detailed wiring requirements upfront to avoid scope creep and unexpected customization charges.

- Request Samples and Certifications: Validate quality and compliance before committing to bulk purchases, especially for buyers in regulated markets like the EU.

- Negotiate Incoterms Wisely: For buyers in regions with complex customs procedures (e.g., Brazil, Turkey), DDP (Delivered Duty Paid) terms can simplify import but may be pricier than FOB or CIF.

- Build Supplier Relationships: Establish partnerships with reliable suppliers who understand local market needs, enabling better responsiveness and pricing flexibility.

- Factor in Currency Fluctuations: For international transactions, consider currency risks and negotiate contracts in stable currencies or include hedging clauses.

Pricing Nuances for International Buyers

- Buyers from Africa, South America, the Middle East, and Europe often face varied logistical challenges and regulatory environments that impact cost. For example, import duties and VAT in Brazil or Turkey can add 10-30% to landed costs.

- Local sourcing options may reduce shipping time and costs but could compromise on certification or quality. Balancing these factors is critical.

- Seasonal demand fluctuations and global supply chain disruptions (e.g., raw material shortages) can cause price volatility. Early procurement and flexible contracts mitigate these risks.

Disclaimer: Pricing insights provided are indicative and subject to change based on market conditions, supplier negotiations, and geopolitical factors. Buyers should conduct due diligence and request formal quotations tailored to their specific project requirements.

Spotlight on Potential wiring led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘wiring led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for wiring led strip lights

Critical Technical Properties for Wiring LED Strip Lights

When sourcing wiring solutions for LED strip lighting, understanding these key technical properties is essential to ensure product quality, safety, and long-term performance—especially in diverse international markets such as Africa, South America, the Middle East, and Europe.

1. Wire Gauge (AWG) and Current Capacity

Wire gauge refers to the thickness of the wire and is typically measured in American Wire Gauge (AWG). Selecting the correct gauge is crucial because undersized wires cause voltage drop, heat buildup, and potential fire hazards. For LED strip lighting, wire gauge must support the total current load while minimizing voltage drop (usually kept under 5%). B2B buyers must verify that suppliers provide wire gauges compatible with the length and power requirements of their installations, especially in large commercial projects.

2. Conductor Material and Grade

Copper is the industry standard for wiring due to its excellent electrical conductivity and durability. High-purity, oxygen-free copper conductors ensure better performance and longevity. In some markets, tinned copper is preferred for corrosion resistance, particularly in humid or coastal environments. Buyers should confirm the conductor material grade with suppliers to ensure compliance with local standards and environmental conditions.

3. Insulation Type and Temperature Rating

The insulation material protects wires from electrical shorts and environmental damage. Common insulation types include PVC, silicone, and cross-linked polyethylene (XLPE), each with different temperature ratings and flexibility. For example, silicone insulation offers high heat resistance and flexibility, beneficial in industrial or outdoor applications. Buyers must specify insulation types that match their operating environment and comply with safety regulations.

4. Voltage and Temperature Tolerance

Wiring for LED strips must accommodate the operating voltage (commonly 12V or 24V DC) and withstand ambient temperatures typical of the installation site. Voltage rating ensures safe operation without breakdown, while temperature tolerance guarantees performance under heat generated by the LED strips or external conditions. B2B buyers should request certifications or test reports confirming these ratings to reduce risks in demanding installations.

5. Tolerance and Quality Control Standards

Tolerance refers to the allowable deviation in wire dimensions and electrical properties. Tight tolerances indicate consistent quality, crucial for reliable electrical performance and fitting with connectors or terminals. International buyers should seek suppliers adhering to recognized quality standards such as ISO 9001 or UL certification, ensuring product consistency and regulatory compliance.

Key Industry and Trade Terms for LED Strip Light Wiring

Understanding common trade terminology helps international buyers communicate effectively and negotiate confidently when sourcing LED wiring components.

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce wiring or LED components to be branded and sold by other firms. For B2B buyers, working with OEMs can mean access to customized products and competitive pricing, but it requires clear specifications and quality agreements.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell in one order. Buyers from emerging markets or smaller projects should negotiate MOQs carefully to balance cost-effectiveness with inventory management, especially when testing new products or suppliers.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price and delivery information from suppliers based on detailed specifications. Providing accurate technical details about wire gauge, insulation, and certifications in an RFQ accelerates supplier responses and improves quotation accuracy.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for shipping, insurance, and customs clearance. Common terms include FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps B2B buyers from different regions manage logistics risks and costs effectively.

Voltage Drop

Voltage drop is the loss of voltage as electricity flows through wiring, affecting LED brightness and system efficiency. Minimizing voltage drop by selecting proper wire gauge and wiring configuration (parallel vs. series) is critical for consistent lighting quality in commercial installations.

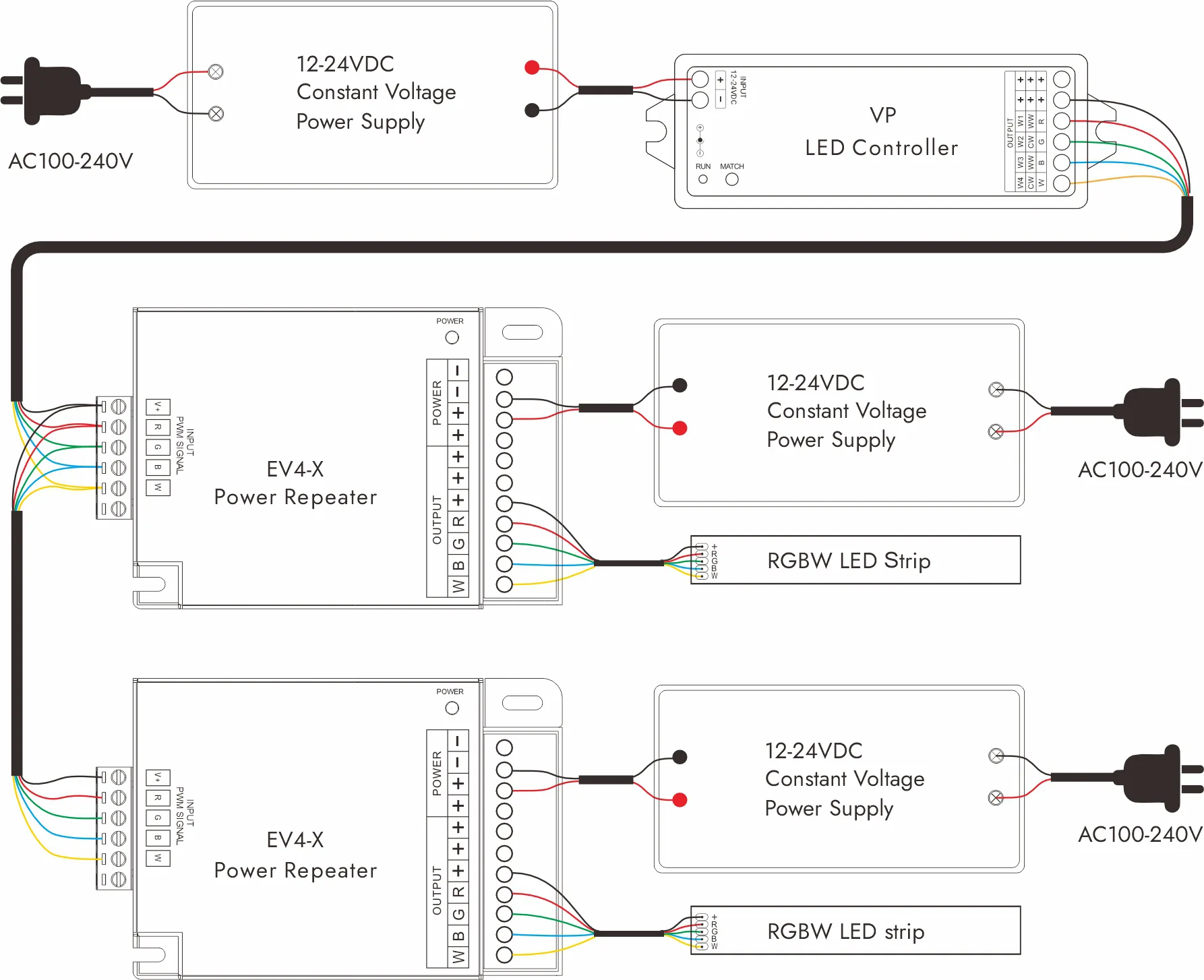

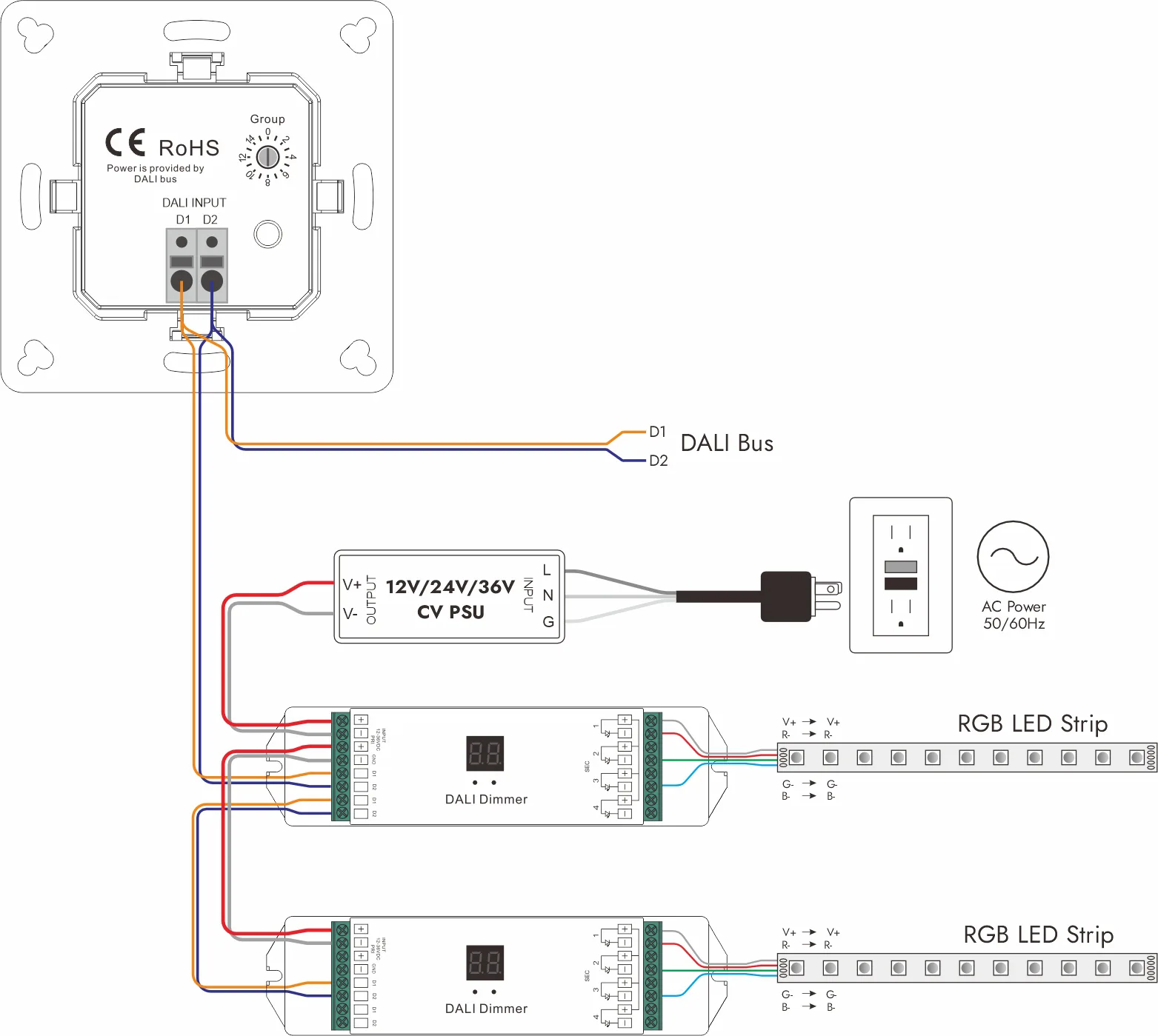

PWM (Pulse Width Modulation)

PWM is a dimming technique used in LED controllers to adjust brightness by rapidly switching the power on and off. Buyers should ensure wiring and connectors are compatible with PWM-controlled LED systems for smooth dimming performance.

By focusing on these technical properties and mastering essential trade terms, international B2B buyers can make informed decisions, ensure compliance with local standards, and optimize their LED strip lighting projects for reliability and cost efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the wiring led strip lights Sector

Market Overview & Key Trends

The wiring LED strip lights sector is experiencing robust growth driven by the global shift towards energy-efficient lighting solutions in commercial, industrial, and architectural applications. International B2B buyers from regions like Africa, South America, the Middle East, and Europe—including emerging markets such as Turkey and Brazil—are increasingly prioritizing LED strip lighting systems due to their versatility, low power consumption, and ease of integration.

Key market drivers include urban infrastructure development, modernization of commercial spaces, and growing awareness of energy-saving technologies. The demand for customizable lighting solutions—such as tunable white, RGB, and smart LED strips with advanced controllers—is accelerating, pushing manufacturers to innovate wiring configurations that optimize power distribution and reduce installation complexity. For example, parallel wiring architectures are becoming the preferred choice in large-scale projects to minimize voltage drop and ensure consistent brightness across long runs.

Sourcing trends reveal a diversification of supply chains, with buyers seeking suppliers offering comprehensive technical support, flexible customization, and compliance with international standards. In Africa and South America, local assembly and regional distribution hubs are emerging to reduce lead times and logistics costs. Meanwhile, in Europe and the Middle East, there is a marked preference for suppliers who provide robust documentation, professional-grade wiring components, and integrated control solutions tailored to complex lighting designs.

Technological advancements such as PWM amplifiers for scalable dimming control and smart lighting integration are reshaping procurement specifications. Additionally, there is an increasing demand for modular wiring systems that facilitate quick installation, maintenance, and scalability—critical factors for large B2B projects involving facility managers and electrical contractors.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the wiring LED strip lights sector, particularly for international buyers committed to reducing their carbon footprint and aligning with global environmental standards. The environmental impact of LED lighting extends beyond energy savings during operation to include material sourcing, manufacturing processes, and end-of-life recyclability.

Illustrative Image (Source: Google Search)

Ethical sourcing of wiring components and LED strips involves selecting suppliers who adhere to responsible mining practices for raw materials (such as copper and rare earth elements), minimize hazardous substances, and maintain transparent supply chains. Buyers in Europe and the Middle East often require compliance with regulations like RoHS (Restriction of Hazardous Substances) and REACH, which restrict toxic substances in electrical products.

Green certifications such as Energy Star, UL Environment, and ISO 14001 are increasingly demanded to validate the environmental credentials of wiring LED strip lighting products. These certifications assure buyers that the products meet rigorous standards for energy efficiency, reduced environmental impact, and sustainable manufacturing.

From a materials perspective, the use of halogen-free cables, low-smoke zero-halogen (LSZH) insulation, and recyclable packaging are becoming standard expectations. Sustainable procurement also involves evaluating the supplier’s commitment to circular economy principles, including take-back programs and end-of-life recycling services for wiring components and LED drivers.

For B2B buyers in emerging markets, partnering with suppliers who invest in sustainability not only mitigates regulatory and reputational risks but also enhances project eligibility for green financing and public infrastructure tenders increasingly focused on environmental responsibility.

Illustrative Image (Source: Google Search)

Evolution of Wiring LED Strip Lights in B2B Context

The wiring of LED strip lights has evolved from simple, short-run installations to complex, large-scale commercial systems requiring precise electrical engineering and robust control integration. Early LED strips were primarily low-power, single-color units wired in series, suitable for decorative lighting with minimal technical demands.

As demand grew for longer, brighter, and more versatile installations, the industry shifted towards parallel wiring configurations with centralized power distribution to combat voltage drop and improve system reliability. This evolution was driven by the need for consistent luminance across extended runs and the integration of advanced dimming and color control technologies.

Simultaneously, wiring standards have advanced to accommodate higher current loads, temperature considerations, and safety regulations, especially in industrial and public infrastructure projects. Modern wiring solutions now often include modular connectors, professional-grade cables with enhanced insulation, and compatibility with smart control systems, reflecting the sector’s maturation and the increasing technical sophistication expected by B2B buyers globally.

This progression highlights the importance for international buyers to prioritize suppliers with deep technical expertise and comprehensive product ranges that support scalable, energy-efficient, and sustainable LED strip lighting installations.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of wiring led strip lights

-

How can I effectively vet suppliers of wiring for LED strip lights in international markets?

Vet potential suppliers by verifying their business licenses and certifications such as ISO 9001 and CE. Request detailed product specifications and test reports to ensure compliance with your target market’s electrical standards (e.g., IEC in Europe, INMETRO in Brazil). Conduct factory audits or third-party inspections if possible, focusing on manufacturing processes, quality control systems, and raw material sourcing. Engage suppliers with proven export experience to regions like Africa, the Middle East, and South America, ensuring they understand local regulations and logistical challenges. -

What customization options should I consider when sourcing wiring for LED strip lights?

Customization can include wire gauge, insulation materials, connector types, and length tailored to your application and local standards. For example, in high-temperature environments typical in the Middle East or parts of Africa, thicker insulation or higher temperature-rated cables may be necessary. Additionally, customized packaging and labeling can facilitate compliance with import regulations and branding requirements. Engage suppliers early to discuss minimum order quantities (MOQs) for custom specs and to ensure they can meet your technical and certification needs. -

What are typical MOQs and lead times for wiring LED strip lights, and how can I manage them?

MOQ varies by supplier but typically ranges from 500 to 2,000 meters per wire type or batch. Lead times generally range from 3 to 8 weeks depending on customization, production capacity, and shipping method. To manage MOQs effectively, consolidate orders with other buyers or negotiate staggered deliveries. Early communication about demand forecasts helps suppliers plan production. For urgent projects, prioritize suppliers with local or regional warehouses in your target market to reduce lead times and shipping costs. -

Which payment terms are common for international B2B transactions in wiring LED strip lights?

Suppliers often request 30% upfront payment via wire transfer or letter of credit, with the balance paid before shipment or upon delivery. In markets like Europe or Turkey, open account terms with 30-60 day payment windows may be available for established buyers. For first-time or smaller buyers, consider escrow services or trade financing options to mitigate risks. Always clarify payment terms upfront, including penalties for delays, and use contracts that comply with international trade law to protect your interests. -

What quality assurance (QA) and certifications should I expect from wiring LED strip light suppliers?

Ensure suppliers provide QA documentation such as product inspection reports, electrical safety tests, and material certifications. Common certifications include CE (Europe), RoHS (restriction on hazardous substances), UL or ETL (North America standards), and ISO 9001 for manufacturing quality. For buyers in Brazil or South America, INMETRO certification is critical. Request batch traceability and factory test data to verify consistent quality. Conduct random third-party testing when possible to confirm compliance and reduce risks of substandard components.

-

How can I optimize logistics and shipping for wiring LED strip lights to Africa, South America, or the Middle East?

Choose suppliers experienced in international shipping and familiar with customs procedures in your target countries. Opt for consolidated shipments to reduce freight costs and consider Incoterms like FOB or CIF to clarify responsibilities. Air freight suits urgent orders but is costlier; sea freight is economical for bulk but requires longer lead times. Prepare all import documentation accurately to avoid delays. Partner with freight forwarders who have local presence and can assist with clearance and delivery, especially in regions with complex logistics like parts of Africa or the Middle East. -

What strategies can help resolve disputes with international wiring LED strip suppliers?

Prevent disputes by establishing clear contracts detailing product specifications, delivery schedules, payment terms, and quality standards. Use internationally recognized dispute resolution clauses, such as arbitration under ICC rules or mediation. Maintain transparent communication and document all interactions. If issues arise, engage suppliers promptly to negotiate solutions such as partial refunds, replacements, or technical support. In persistent cases, seek assistance from trade chambers or export promotion agencies in your region, which can mediate cross-border B2B conflicts. -

How do voltage drop and wiring configuration impact LED strip light installations I should consider when purchasing wiring?

Voltage drop affects brightness consistency, especially in long LED strip runs common in commercial projects. For international buyers, specifying wiring that supports parallel wiring configurations with adequate gauge reduces voltage drop and improves reliability. For 12V systems, runs longer than 5 meters require thicker wires (e.g., 16 AWG or thicker), while 24V systems allow longer runs with smaller gauge wires. Confirm with suppliers the wire’s current rating and insulation quality to ensure durability in your installation environment, considering local temperature and installation conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wiring led strip lights

Proper wiring of LED strip lights is pivotal for ensuring high performance, safety, and longevity in commercial applications. For international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—understanding the nuances of power distribution, wire gauge selection, and connection methods can dramatically reduce maintenance costs and enhance system reliability. Prioritizing parallel wiring configurations and selecting appropriately rated wires based on length and current load mitigates voltage drop and brightness inconsistencies, which are common challenges in large-scale installations.

Strategic sourcing plays a critical role in securing quality components such as power supplies, connectors, and control systems that comply with regional standards and environmental conditions. Engaging with suppliers who offer technical support and customizable solutions can streamline project execution and future scalability. Additionally, investing in advanced controllers and amplifiers enables precise lighting control, which adds value in competitive markets.

Looking ahead, the growing demand for energy-efficient and smart lighting solutions worldwide underscores the importance of sourcing LED strip lighting components that integrate seamlessly with IoT and automation platforms. Buyers are encouraged to partner with experienced manufacturers who understand diverse market requirements and provide robust after-sales service. By adopting a strategic sourcing approach today, businesses can future-proof their lighting infrastructure and capitalize on emerging opportunities in global commercial lighting projects.