Guide to Led Channels And Diffusers

- Introduction: Navigating the Global Market for led channels and diffusers

- Understanding led channels and diffusers Types and Variations

- Key Industrial Applications of led channels and diffusers

- Strategic Material Selection Guide for led channels and diffusers

- In-depth Look: Manufacturing Processes and Quality Assurance for led channels and diffusers

- Comprehensive Cost and Pricing Analysis for led channels and diffusers Sourcing

- Spotlight on Potential led channels and diffusers Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led channels and diffusers

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led channels and diffusers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led channels and diffusers

- Strategic Sourcing Conclusion and Outlook for led channels and diffusers

Introduction: Navigating the Global Market for led channels and diffusers

In today’s rapidly evolving lighting industry, LED channels and diffusers have become indispensable components that elevate both the performance and aesthetics of LED lighting systems. For international B2B buyers—particularly those operating across Africa, South America, the Middle East, and Europe—understanding the nuances of these products is critical to sourcing solutions that meet local market demands, regulatory standards, and project specifications.

LED channels serve as the structural backbone that houses LED strips, providing protection, heat dissipation, and streamlined installation options. Diffusers, meanwhile, are essential for optimizing light distribution, reducing glare, and enhancing visual comfort in commercial, industrial, and architectural applications. Together, they enable durable, efficient, and visually appealing lighting solutions that cater to diverse environments—from retail spaces in Johannesburg and Cairo to industrial facilities in São Paulo and Istanbul.

This comprehensive guide delves into the full spectrum of LED channels and diffusers, covering:

- Types and profiles suited for surface mounting, recessed installation, corners, and suspended applications

- Materials and finishes that balance durability, thermal management, and design flexibility

- Manufacturing processes and quality control standards to ensure product reliability and compliance

- Global supplier landscape with insights on sourcing from reputable manufacturers

- Cost factors and pricing benchmarks to optimize procurement budgets

- Market trends and regional considerations specific to emerging and mature markets

- Frequently asked questions addressing technical, logistical, and commercial concerns

By leveraging this guide, B2B buyers can make informed, strategic sourcing decisions that enhance product quality, reduce risk, and drive competitive advantage in their respective markets. Whether upgrading infrastructure or launching new projects, this resource empowers stakeholders to navigate the complexities of global LED channel and diffuser procurement with confidence and clarity.

Understanding led channels and diffusers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Mounted LED Channel | Mounted on surface, easy installation, visible profile | Retail displays, commercial lighting | Pro: Easy retrofit, versatile; Con: More visible, may affect aesthetics |

| Recessed LED Channel | Installed flush within surfaces, minimal visibility | Architectural lighting, office interiors | Pro: Sleek look, space-saving; Con: Requires installation effort, higher cost |

| Corner LED Channel | Designed for 90-degree angles, fits corners | Staircases, shelving, signage | Pro: Maximizes corner lighting, neat finish; Con: Limited to corner use |

| Suspended LED Channel | Hanging installation, allows downward light projection | Large commercial spaces, warehouses | Pro: High illumination, adjustable height; Con: Complex installation, higher cost |

| Diffuser Types (Milky, Clear, Frosted) | Covers LED strip, controls light diffusion and glare | All channel types, customizable lighting | Pro: Enhances light quality, protects LEDs; Con: Different diffusion levels affect brightness |

Surface Mounted LED Channel

Surface mounted channels are the most common and versatile type, designed to be installed directly onto surfaces such as walls, ceilings, or furniture. They are ideal for retrofit projects and commercial applications where ease of installation and accessibility are priorities. Buyers should consider the channel’s profile visibility and material quality, balancing aesthetic preferences with functional needs. This type suits retail and display lighting where moderate diffusion and accessibility are key.

Recessed LED Channel

Recessed channels are embedded into walls, ceilings, or furniture for a flush, seamless finish. They are favored in architectural and high-end commercial projects where a minimalist look is desired. These channels require precise installation, often during construction or renovation phases, making them more suitable for buyers with longer project timelines. The clean design enhances spatial aesthetics, but buyers must factor in installation complexity and potential higher costs.

Corner LED Channel

Corner channels are engineered to fit perfectly into 90-degree angles, such as staircases, shelving edges, or cabinetry corners. This specialization allows for effective illumination of typically challenging areas, improving visibility and design appeal. B2B buyers in retail or hospitality sectors find corner channels useful for accent lighting. The main limitation is their niche application, so buyers should assess project needs carefully to avoid over-specification.

Suspended LED Channel

Suspended channels hang from ceilings, providing direct downward illumination suitable for large spaces like warehouses, conference rooms, and open-plan offices. They offer adjustable height and powerful lighting, making them ideal for industrial or commercial facilities requiring broad coverage. Buyers should evaluate structural compatibility and installation logistics, as suspended systems demand secure mounting and professional setup.

Diffuser Types (Milky, Clear, Frosted)

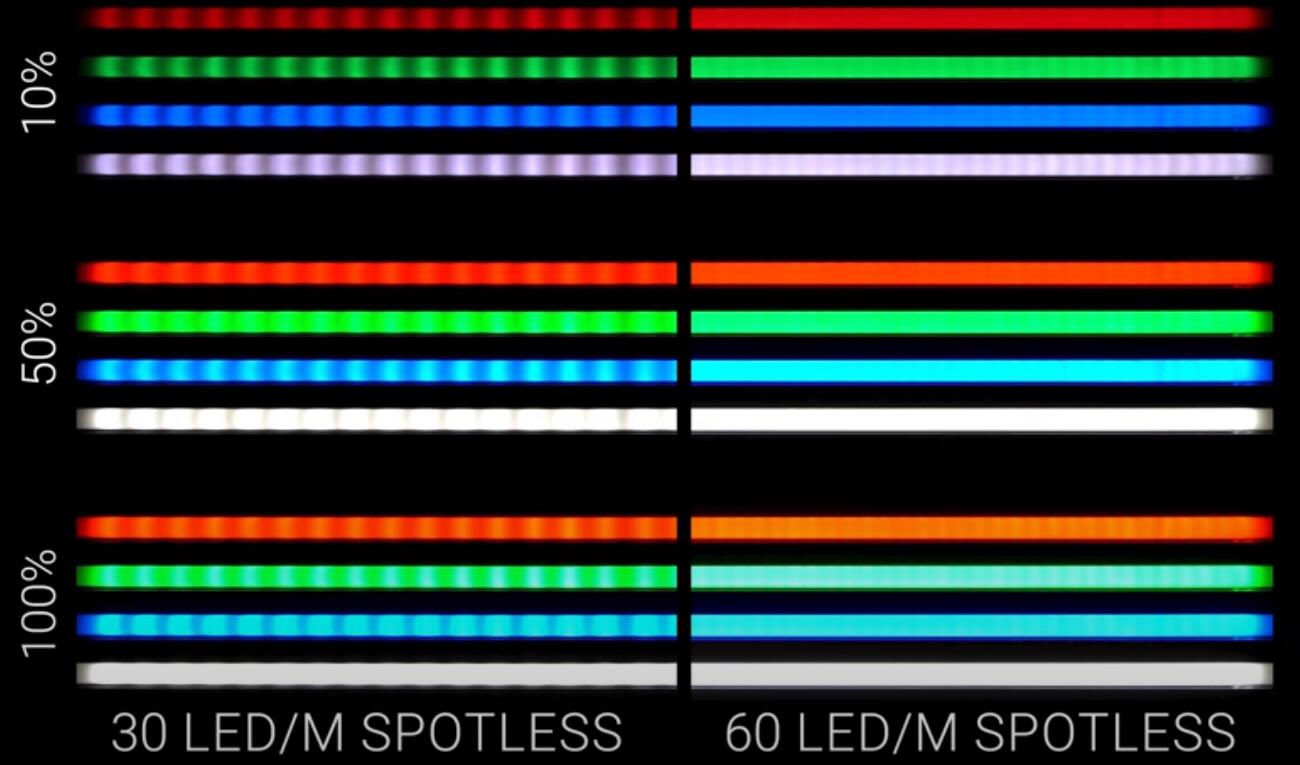

Diffusers are critical accessories that cover LED strips within channels, controlling light output and protecting delicate components. Milky diffusers soften light for an even glow, clear diffusers maximize brightness, and frosted diffusers balance glare reduction with light diffusion. Selecting the right diffuser depends on the application’s lighting quality requirements and environmental conditions. B2B buyers must weigh the trade-offs between brightness and glare for optimal visual comfort and energy efficiency.

Related Video: Samsung 2024 TV Buying Guide | New Lineup and Models Explained

Key Industrial Applications of led channels and diffusers

| Industry/Sector | Specific Application of led channels and diffusers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and accent lighting in display cases and shelving | Enhances product visibility and customer experience | Custom sizing, diffusion quality, durability, and ease of installation |

| Hospitality & Interior Design | Architectural lighting for hotels, restaurants, and lounges | Creates appealing atmospheres and energy-efficient lighting | Aesthetic finish, compatibility with dimming systems, and heat dissipation |

| Industrial & Manufacturing | Task and safety lighting in factories and warehouses | Improves worker safety and operational efficiency | Robustness, IP rating for dust and moisture, and thermal management |

| Automotive & Transportation | Interior and exterior lighting for vehicles and stations | Enhances safety and aesthetic appeal | Vibration resistance, weatherproofing, and compliance with regional standards |

| Healthcare & Laboratories | Cleanroom and examination lighting | Provides uniform illumination critical for precision work | Anti-microbial materials, high diffusion uniformity, and easy maintenance |

Retail & Commercial Applications

In retail environments, LED channels and diffusers are widely used to deliver uniform, glare-free lighting in display cases and shelving units. This application enhances product visibility, making merchandise more attractive and boosting sales potential. For B2B buyers from Africa, South America, the Middle East, and Europe, it is crucial to select LED channels that offer customizable lengths and high-quality diffusers to ensure consistent light distribution. Durability and ease of installation also matter, especially for large retail chains requiring scalable lighting solutions.

Hospitality & Interior Design

LED channels and diffusers play a vital role in creating inviting atmospheres in hotels, restaurants, and lounges. These lighting components help architects and designers produce smooth, ambient lighting that enhances the overall guest experience while reducing energy consumption. Buyers should focus on profiles with sleek finishes and compatibility with dimmable drivers to achieve versatile lighting effects. Heat dissipation features are important in warmer climates common in the Middle East and parts of Africa to maintain longevity and performance.

Industrial & Manufacturing Settings

In factories and warehouses, LED channels equipped with diffusers are essential for task lighting and safety illumination. They provide bright, uniform light that reduces shadows and improves visibility, directly impacting worker productivity and accident reduction. B2B buyers must prioritize rugged profiles with high IP ratings to resist dust and moisture, common in industrial environments across South Africa and Brazil. Additionally, thermal management capabilities ensure LED longevity under continuous operation.

Automotive & Transportation

LED channels and diffusers are increasingly used in vehicle interiors, station platforms, and transit hubs to enhance safety and aesthetics. These applications demand products that can withstand vibration, temperature fluctuations, and weather exposure. International buyers should verify compliance with local automotive and transportation lighting standards and seek weatherproof, shock-resistant profiles suitable for harsh environments, such as desert regions in the Middle East or coastal areas in Europe.

Healthcare & Laboratories

Uniform and hygienic lighting is critical in healthcare facilities and laboratories. LED channels with diffusers provide shadow-free illumination necessary for precision tasks and examinations. Buyers from regions like Egypt and Europe should select materials with anti-microbial properties and easy-to-clean surfaces to meet strict hygiene regulations. High diffusion uniformity reduces eye strain for medical personnel, while modular designs facilitate quick maintenance and upgrades in fast-paced clinical settings.

Related Video: Uses and Gratifications Theory

Strategic Material Selection Guide for led channels and diffusers

Aluminum

Aluminum is the most widely used material for LED channels due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. It efficiently dissipates heat generated by LED strips, prolonging their lifespan and maintaining performance. Aluminum channels are typically anodized or powder-coated, enhancing corrosion resistance and aesthetic appeal. For international buyers, especially in regions like Africa and the Middle East where high ambient temperatures prevail, aluminum’s thermal management is crucial. Compliance with international standards such as ASTM B221 (for aluminum extrusions) and EN 755 (European aluminum profiles) ensures quality and compatibility.

Pros:

– Superior heat dissipation

– Lightweight and durable

– Corrosion-resistant with proper finishing

– Easy to customize and install

Cons:

– Higher cost compared to plastic alternatives

– Requires surface treatment to prevent oxidation

– Manufacturing complexity can increase lead times

Application Impact: Aluminum channels are ideal for commercial and industrial lighting where heat management and durability are priorities. They suit outdoor or humid environments common in South Africa and Egypt, provided the finish is appropriate for local conditions.

Polycarbonate (PC)

Polycarbonate is a popular diffuser material due to its high impact resistance and excellent light transmission. It can withstand temperatures up to about 115°C, making it suitable for most LED strip applications. Polycarbonate diffusers offer superior UV resistance compared to acrylic, which is beneficial for outdoor installations in sunny climates like those in South America and the Middle East. Buyers should verify compliance with standards such as UL 94 for flammability and ISO 7823 for impact resistance to ensure safety and durability.

Pros:

– High impact resistance and toughness

– Good optical clarity and light diffusion

– UV resistant, suitable for outdoor use

– Lightweight and easy to fabricate

Cons:

– More expensive than acrylic

– Can yellow over time if not UV stabilized

– Slightly lower scratch resistance compared to acrylic

Application Impact: Polycarbonate diffusers are preferred in environments with high mechanical stress or outdoor exposure, such as public infrastructure projects in Europe and Africa, where durability and safety standards are stringent.

Acrylic (PMMA)

Acrylic is widely used for LED diffusers due to its excellent optical clarity and cost-effectiveness. It offers good light transmission and diffusion but is less impact resistant than polycarbonate. Acrylic can handle temperatures up to approximately 80°C, limiting its use in high-heat applications. It is more prone to yellowing under prolonged UV exposure unless treated with UV stabilizers. Buyers in regions with intense sunlight, like the Middle East and South America, should request UV-resistant grades. Compliance with ASTM D4802 (UV resistance) and ISO 1183 (density and optical properties) is common.

Pros:

– High light transmission and clarity

– Cost-effective and widely available

– Easy to cut and shape

– Good surface hardness and scratch resistance

Cons:

– Lower impact resistance than polycarbonate

– Less heat resistant, prone to deformation at high temperatures

– UV degradation without proper treatment

Application Impact: Acrylic diffusers are suitable for indoor applications or shaded outdoor environments, such as retail or office lighting projects in Europe and South Africa, where cost efficiency and aesthetics are important.

Silicone

Silicone is increasingly used for flexible LED channels and diffusers, offering excellent thermal stability and weather resistance. It can withstand extreme temperatures ranging from -60°C to over 200°C, making it ideal for harsh environments. Silicone is also highly resistant to UV radiation and chemicals, which is advantageous for outdoor and industrial applications in diverse climates like those found in Africa and South America. However, silicone’s manufacturing and tooling costs are higher, and it is less rigid than aluminum or plastics, which may limit structural applications.

Pros:

– Exceptional temperature and UV resistance

– Flexible and durable under mechanical stress

– Chemical resistant and weatherproof

– Suitable for curved or irregular installations

Cons:

– Higher cost and complex manufacturing

– Lower rigidity, not ideal for structural channels

– Limited availability in some markets

Application Impact: Silicone channels and diffusers are optimal for specialized outdoor or industrial lighting solutions, especially in regions with extreme climate variations or chemical exposure, such as mining or coastal areas in South Africa and Brazil.

| Material | Typical Use Case for led channels and diffusers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat-dissipating LED channels for commercial and industrial use | Excellent thermal management and durability | Higher cost, requires surface treatment | Medium |

| Polycarbonate | Impact-resistant diffusers for outdoor and high-stress areas | High impact and UV resistance | More expensive, potential yellowing | High |

| Acrylic | Cost-effective diffusers for indoor or shaded environments | High optical clarity and low cost | Lower heat and impact resistance | Low |

| Silicone | Flexible, weatherproof channels and diffusers for harsh environments | Outstanding temperature and chemical resistance | Higher cost, less rigid structure | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led channels and diffusers

Manufacturing Processes for LED Channels and Diffusers

The production of LED channels and diffusers involves a series of well-coordinated manufacturing stages designed to ensure durability, optical clarity, and compatibility with LED strip lights. For international B2B buyers, understanding these processes is crucial to assess supplier capabilities and product quality.

1. Material Preparation

- Raw Materials: Typically, aluminum or plastic (often polycarbonate or PMMA) are used for LED channels, while diffusers are made from high-transparency polymers with UV resistance.

- Selection Criteria: Materials are chosen based on thermal conductivity, impact resistance, and light diffusion properties. Aluminum alloys undergo surface treatment preparations; plastics are sourced with specific grades to prevent yellowing and brittleness.

- Pre-Processing: Aluminum profiles are cut and deburred; plastic resins are dried to remove moisture before extrusion or molding.

2. Forming and Shaping

- Extrusion: Aluminum channels are extruded through dies to create consistent shapes (surface-mounted, recessed, corner profiles). Plastic diffusers are typically extruded or injection molded to achieve precise thickness and diffusion characteristics.

- Cutting and Shaping: Profiles and diffusers are cut to customer specifications using CNC machines or automated saws, ensuring tight dimensional tolerances.

- Surface Treatments: Aluminum channels often receive anodizing, powder coating, or electrostatic painting to enhance corrosion resistance and aesthetics, especially important for outdoor or humid environments common in Africa and the Middle East.

3. Assembly

- Component Integration: Channels are assembled with end caps, mounting clips, and sometimes integrated diffusers. This stage may also include installation of LED strip holders or heat sinks.

- Customization: Many suppliers offer custom lengths, shapes, or additional features like silicone seals for waterproofing, catering to diverse regional requirements.

- Quality of Fit: Precision assembly ensures the diffuser fits snugly without gaps, preserving light diffusion and mechanical stability.

4. Finishing and Packaging

- Inspection of Finish: Visual and tactile inspection for surface defects, coating uniformity, and color consistency.

- Protective Packaging: Products are wrapped with protective films or foam and packed in sturdy cartons to prevent damage during international shipping.

- Labeling: Clear labels with batch numbers, dimensions, and certification marks help traceability and compliance verification.

Quality Assurance and Control (QA/QC) in LED Channels and Diffusers

Robust quality management is paramount in LED channel and diffuser manufacturing to meet international standards and ensure long-term performance. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers with transparent and comprehensive QC systems.

Illustrative Image (Source: Google Search)

International and Industry Standards

- ISO 9001: The foundational standard for quality management systems; ensures consistent process control and continuous improvement.

- CE Marking: Mandatory for products sold in Europe, indicating conformity with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances, critical for buyers mindful of environmental and health regulations.

- Additional Certifications: Depending on the application and region, certifications such as UL (safety), API (industrial standards), or local standards may be relevant.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components undergo dimensional checks, material verification, and visual inspections to prevent defective inputs.

- In-Process Quality Control (IPQC): Continuous monitoring during extrusion, cutting, coating, and assembly stages to detect deviations early. This includes thickness measurements, color consistency, and fitting accuracy.

- Final Quality Control (FQC): Comprehensive testing of finished products, including optical clarity tests for diffusers, mechanical strength tests for channels, and surface finish inspections.

Common Testing Methods

- Light Diffusion and Transmission Testing: Measures how evenly the diffuser scatters light and its transparency level, using photometers or integrating spheres.

- Thermal Conductivity and Heat Dissipation: For aluminum channels, ensuring effective heat sinking to prolong LED lifespan.

- Durability and Weather Resistance: Simulated environmental exposure tests (UV resistance, salt spray) especially important for buyers in harsh climates like the Middle East or coastal regions in South America.

- Dimensional and Mechanical Tests: Precision calipers and tensile testers verify adherence to specifications and structural integrity.

How B2B Buyers Can Verify Supplier Quality Control

Ensuring supplier QC practices meet your business requirements involves proactive engagement and verification:

- Factory Audits: Conduct or commission on-site audits to review manufacturing capabilities, quality procedures, and worker training. Virtual audits can be an alternative for remote buyers.

- Quality Reports and Certificates: Request detailed QC reports, including inspection checklists, test results, and copies of relevant certificates (ISO 9001, CE, RoHS).

- Third-Party Inspections: Employ independent inspection agencies to perform random sampling and testing before shipment, providing unbiased quality validation.

- Sample Evaluation: Obtain pre-production and production samples for testing within your local environment to verify performance and durability.

- Supplier Transparency: Engage with suppliers who openly share process flows, quality management documentation, and corrective action histories.

QC and Certification Nuances for International Buyers in Africa, South America, the Middle East, and Europe

- Regional Compliance Requirements: For Europe, CE marking and RoHS compliance are non-negotiable. Buyers in Africa and South America should verify if imported LED channels require additional local certifications or customs documentation.

- Climate Considerations: Suppliers must demonstrate that their materials and coatings withstand regional climates—high UV exposure in Egypt or humidity in South Africa affects product longevity.

- Logistical Impact on QC: Extended shipping routes necessitate robust packaging and shock-resistant assembly to prevent damage.

- After-Sales Support and Warranty: Choose suppliers providing clear warranty terms and accessible technical support, crucial for markets where local repair or replacement options are limited.

- Customization and Scalability: Suppliers capable of tailoring products to regional preferences (e.g., color temperature adaptation, waterproofing) and scaling production ensure smoother partnership growth.

By thoroughly understanding the manufacturing processes and quality assurance measures behind LED channels and diffusers, international B2B buyers can make informed sourcing decisions, mitigate risks, and foster long-term supplier relationships that meet both technical and commercial expectations.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led channels and diffusers Sourcing

Understanding the cost structure and pricing dynamics of LED channels and diffusers is essential for international B2B buyers aiming to optimize procurement strategies across diverse markets such as Africa, South America, the Middle East, and Europe. Below is a detailed breakdown of the key cost components, price influencers, and actionable buyer tips to help navigate this complex landscape effectively.

Key Cost Components in LED Channels and Diffusers

-

Materials: The primary cost driver includes aluminum for channels and polycarbonate or acrylic for diffusers. Variations in material grade, thickness, and optical properties significantly impact pricing. High-quality, certified materials often command premium prices but offer better durability and performance.

-

Labor: Manufacturing labor costs vary widely depending on the country of production. Labor-intensive processes such as extrusion, cutting, polishing, and assembly contribute to overall costs. Buyers sourcing from regions with lower labor costs may benefit from competitive pricing but should weigh quality considerations.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines and automation can reduce overhead costs, influencing the final price.

-

Tooling and Setup: Custom profiles or diffuser shapes require specific tooling and molds. Initial tooling costs can be substantial, particularly for bespoke designs, and are typically amortized over large production runs.

-

Quality Control (QC): Rigorous QC processes—such as dimensional inspections, light diffusion testing, and certifications—add to cost but are crucial for ensuring product reliability and compliance with international standards.

-

Logistics and Shipping: Freight charges, customs duties, and import taxes vary by destination. For buyers in Africa, South America, and the Middle East, logistics can represent a significant portion of landed cost due to longer shipping routes and variable port efficiency.

-

Supplier Margin: Manufacturers and distributors include profit margins that reflect their market positioning, brand reputation, and service level. Margins may be negotiable for large or repeat orders.

Influencing Factors on Pricing

-

Order Volume and Minimum Order Quantity (MOQ): Larger volumes typically yield lower unit prices due to economies of scale. MOQ requirements vary; international buyers should balance order size against storage capacity and cash flow.

-

Specifications and Customization: Tailored channel dimensions, diffuser types (frosted, clear, opal), and additional features like silicone seals or mounting accessories increase costs. Standardized products are generally more cost-effective.

-

Material Quality and Certifications: Products with certifications such as UL, CE, or RoHS often incur higher costs but facilitate smoother market entry and compliance, especially in Europe and the Middle East.

-

Supplier Reliability and Location: Proximity to manufacturing hubs (e.g., China, Southeast Asia) can reduce lead times and shipping costs. Trusted suppliers with proven quality records may price products higher but reduce risk and potential rework costs.

-

Incoterms and Payment Terms: Understanding terms like FOB, CIF, or DDP is critical as they determine who bears shipping and customs risks/costs. Favorable payment terms (e.g., letters of credit, net 30) can improve cash flow management.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Price: Engage suppliers on MOQ flexibility, payment terms, lead times, and after-sales support to optimize total value rather than just unit cost.

-

Consider Total Cost of Ownership (TCO): Factor in installation ease, product lifespan, warranty, and energy efficiency. Investing slightly more upfront in higher-quality channels and diffusers may reduce replacement and maintenance costs.

-

Leverage Regional Trade Agreements: Buyers in Africa (e.g., Egypt, South Africa) and South America can explore regional trade blocs to minimize tariffs and expedite customs clearance.

-

Request Samples and Certifications: Prioritize suppliers that provide product samples and verifiable certifications to ensure compliance with local regulations and customer expectations.

-

Plan for Logistics Variability: Account for potential delays and fluctuating freight rates, especially in regions with less predictable supply chains. Consolidate shipments where possible to reduce costs.

-

Monitor Market Trends: Stay informed on raw material price fluctuations (e.g., aluminum costs) and emerging technologies that could affect pricing and product offerings.

Disclaimer on Pricing

Prices for LED channels and diffusers vary widely based on specifications, volume, supplier, and market conditions. The information provided here is indicative and meant to guide strategic sourcing decisions. Buyers should obtain detailed quotations and conduct due diligence tailored to their specific project requirements and regional market dynamics.

By comprehensively understanding these cost and pricing factors, international B2B buyers can make informed sourcing decisions, secure competitive pricing, and establish resilient supply chains for LED channels and diffusers.

Spotlight on Potential led channels and diffusers Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led channels and diffusers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led channels and diffusers

Critical Technical Properties of LED Channels and Diffusers

-

Material Grade and Composition

LED channels are typically made from high-grade aluminum alloys, chosen for their excellent heat dissipation and corrosion resistance. Diffusers are usually crafted from polycarbonate or acrylic materials, valued for their light diffusion quality and durability. For B2B buyers, understanding material grade ensures product longevity and performance, especially in harsh environments common in Africa, the Middle East, or coastal Europe. -

Dimensional Tolerance

This refers to the allowable deviation from specified dimensions during manufacturing. Tight tolerance is crucial for seamless integration with LED strips and fixtures, affecting installation ease and final aesthetic. Buyers should prioritize suppliers with consistent tolerance control to avoid costly fitting issues or lighting inefficiencies. -

Heat Dissipation Efficiency

Effective heat management prevents LED strip overheating, extending lifespan and maintaining brightness. Aluminum channels with optimized thermal conductivity enhance heat dissipation. For buyers, especially in warm climates, selecting channels with proven heat dissipation properties reduces maintenance and replacement costs. -

Light Diffusion and Transmission Rate

Diffusers must balance light diffusion—eliminating hotspots and glare—with high transmission rates to maintain brightness. Different diffuser profiles (e.g., frosted, opal, clear) cater to varied lighting effects. Understanding these options helps buyers specify products that meet aesthetic and functional requirements in commercial or architectural projects.

-

Ingress Protection (IP) Rating

IP ratings indicate protection against dust and water. For outdoor or industrial applications common in South America or the Middle East, IP65 or higher is often necessary. Buyers should verify IP ratings to ensure product suitability for the intended environment, minimizing risk of damage and downtime. -

Compatibility with LED Strip Types

Channels and diffusers must accommodate various LED strip widths and power ratings (e.g., 12V, 24V strips). Compatibility affects installation versatility and lighting uniformity. Buyers should confirm product specifications align with their LED strip choices to optimize performance and reduce procurement complexity.

Common Trade Terminology for International LED Channel and Diffuser Procurement

-

OEM (Original Equipment Manufacturer)

This term refers to manufacturers who produce products based on another company’s design or brand. For B2B buyers, working with OEMs can offer customization and branding opportunities, critical for markets seeking unique or proprietary lighting solutions. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity a supplier will accept for an order. Buyers from emerging markets like Egypt or South Africa should negotiate MOQ carefully to balance inventory risks and unit pricing, especially when testing new products or scaling gradually. -

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers requesting pricing, lead times, and terms for specific products. Understanding how to draft clear RFQs helps buyers obtain competitive, comparable offers and streamline supplier selection. -

Incoterms (International Commercial Terms)

These standardized trade terms define the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties. Familiarity with common Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) enables buyers to negotiate favorable delivery terms and control logistics costs. -

Lead Time

Lead time is the period from order confirmation to product delivery. In international trade, especially with suppliers in Asia or Europe, lead times can vary widely. Buyers should incorporate lead time considerations into project schedules to avoid delays. -

Batch Consistency

This term describes the uniformity of products across different production batches. For lighting projects requiring color and brightness consistency, verifying batch consistency is critical. Buyers should request sample approvals or certifications to ensure quality uniformity over time.

Understanding these key technical properties and trade terms empowers international B2B buyers to make informed decisions, ensuring procurement of LED channels and diffusers that meet performance, quality, and logistical requirements across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led channels and diffusers Sector

Market Overview & Key Trends

The global market for LED channels and diffusers is experiencing robust growth, driven by increasing demand for energy-efficient lighting solutions across commercial, industrial, and residential sectors. International B2B buyers, especially from regions such as Africa (e.g., South Africa, Egypt), South America, the Middle East, and Europe, are actively seeking advanced LED channel systems that combine durability, aesthetic appeal, and ease of installation. Key market drivers include rising urbanization, government initiatives promoting LED adoption, and growing awareness of long-term operational cost savings.

Emerging sourcing trends reveal a strong preference for customization and modular LED channel profiles that cater to diverse architectural and design requirements. Buyers prioritize suppliers offering flexible manufacturing capabilities, allowing for tailored lengths, shapes (such as recessed, surface-mounted, or corner profiles), and diffuser materials that optimize light distribution and minimize glare. Furthermore, integrated smart lighting solutions with IoT compatibility are gaining traction, enabling enhanced control and energy management in commercial projects.

Market dynamics are influenced by global supply chain shifts, with many B2B buyers seeking reliable partnerships in Asia and Europe due to competitive pricing and quality certifications. However, geopolitical factors and logistics challenges have prompted buyers in Africa and the Middle East to diversify sourcing strategies, emphasizing local or regional suppliers where feasible to reduce lead times and import costs. Additionally, compliance with international standards and certifications (e.g., CE, RoHS) remains critical for market access and buyer confidence.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are increasingly central to procurement decisions in the LED channels and diffusers sector. The environmental impact of raw materials, manufacturing processes, and product lifecycle is scrutinized by B2B buyers aiming to align with corporate social responsibility (CSR) goals and regulatory mandates. Aluminum, a common material for LED profiles, is favored for its recyclability and lightweight properties, while innovations in diffuser materials focus on using recyclable or bio-based plastics to reduce carbon footprints.

Ethical sourcing extends beyond environmental factors to include labor standards and transparent supply chains. Buyers from Africa, South America, and the Middle East increasingly demand suppliers who adhere to fair labor practices and demonstrate traceability throughout the manufacturing process. Certifications such as ISO 14001 (environmental management) and SA8000 (social accountability) provide assurance of ethical compliance.

Green certifications specific to lighting products, such as ENERGY STAR and TUV Rheinland’s sustainability marks, help buyers identify products that meet stringent energy efficiency and environmental criteria. Incorporating these certified LED channels and diffusers not only supports sustainability commitments but also enhances brand reputation and meets growing end-customer expectations for eco-friendly solutions.

Evolution and Historical Context

The LED channels and diffusers sector has evolved significantly over the past two decades, transitioning from simple aluminum extrusions with basic plastic covers to highly engineered lighting components integral to modern architectural design. Initially developed to house and protect LED strip lights, channels now serve multifunctional roles—improving heat dissipation, enhancing light diffusion for uniform illumination, and providing aesthetic integration with building elements.

Advancements in extrusion technology and material science have enabled the production of varied profile shapes, sizes, and diffuser options that optimize lighting performance and installation flexibility. The rise of smart lighting and IoT integration marks the latest phase of evolution, where LED channels are not just passive housings but active components in intelligent lighting ecosystems. For B2B buyers, understanding this progression is essential to selecting products that meet current technical demands while future-proofing investments.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led channels and diffusers

-

How can I effectively vet LED channel and diffuser suppliers for international B2B purchases?

Start by verifying the supplier’s business license and certifications relevant to your region, such as CE for Europe or SABS for South Africa. Request product samples to assess quality firsthand. Check their production capacity, years of experience, and client references, particularly from your region or similar markets. Use platforms with verified supplier credentials and seek suppliers with transparent communication and clear warranty policies. This reduces risks associated with counterfeit or substandard products and ensures compliance with your local standards. -

What customization options are typically available for LED channels and diffusers, and how do they impact ordering?

Manufacturers often offer customization in dimensions, materials (aluminum, plastic, silicone), diffuser opacity, color, and mounting styles (surface, recessed, suspended). Custom engraving or branding may also be possible. Custom orders usually require clear technical drawings and specifications early in the process. Be aware that customization can increase lead times and minimum order quantities (MOQs), so discuss these factors upfront to align expectations and budgeting. -

What are common minimum order quantities (MOQs) and lead times for international LED channel and diffuser orders?

MOQs vary widely depending on the supplier and product complexity but typically range from 500 to 2,000 units for standard profiles. Customized products may require higher MOQs. Lead times generally span 3 to 8 weeks, factoring in production and shipping. Always clarify MOQs and lead times before finalizing orders and consider buffer times for customs clearance and local logistics. Negotiating staggered shipments or sample runs can help manage cash flow and inventory. -

Which payment methods are most secure and commonly accepted for international B2B transactions in LED lighting components?

Letter of Credit (L/C) is widely regarded as secure for large transactions, protecting both buyer and seller. Other common methods include Telegraphic Transfer (T/T), PayPal (for smaller amounts), and Escrow services. Confirm payment terms such as deposits (often 30%) and balance upon shipment. Ensure the supplier’s banking details are legitimate and avoid advance full payments without contracts. Using trade assurance platforms or involving reputable freight forwarders can add security. -

What quality assurance certifications should I look for when sourcing LED channels and diffusers internationally?

Look for ISO 9001 certification for quality management systems, CE marking for European compliance, RoHS for hazardous substance restrictions, and UL or ETL listings for safety standards, depending on your market. These certifications indicate adherence to international quality and safety benchmarks. Request test reports or certificates of conformity and verify them with issuing bodies when possible. Prioritizing certified products minimizes risks of regulatory issues or product failures. -

How can I manage logistics and shipping challenges when importing LED channels and diffusers from overseas suppliers?

Choose suppliers experienced with international shipping and who provide detailed Incoterms (e.g., FOB, CIF). Engage reliable freight forwarders familiar with your destination’s import regulations. Consider shipping modes—sea freight for cost-efficiency on large orders, air freight for urgency. Plan for customs duties, taxes, and import licenses required in your country. Clear communication with suppliers on packaging standards reduces damage risks. Tracking shipments and arranging local warehousing can smooth distribution. -

What steps should I take if there is a dispute or quality issue with my LED channel and diffuser order?

Immediately document the issue with photos and detailed descriptions. Contact the supplier to negotiate a resolution, referencing your contract terms and warranty policies. Use third-party inspection reports if available. For serious disputes, leverage trade dispute resolution mechanisms such as arbitration clauses in contracts or assistance from chambers of commerce. Maintain professional and timely communication. Prevention is best—ensure contracts clearly specify quality standards, inspection rights, and remedies. -

Are there region-specific considerations for B2B buyers in Africa, South America, the Middle East, and Europe when purchasing LED channels and diffusers?

Yes, regulatory standards, voltage requirements, and environmental conditions vary by region. For example, Europe mandates CE and RoHS compliance, while Middle Eastern buyers may require specific fire safety certifications. African and South American buyers should verify local import duties and certification equivalencies. Additionally, consider climate factors (humidity, temperature) that affect material choice. Partner with suppliers experienced in your region to navigate these nuances and facilitate smoother customs clearance and product performance.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for led channels and diffusers

Strategic sourcing of LED channels and diffusers presents a compelling opportunity for international B2B buyers seeking to enhance product quality, customization, and supply chain efficiency. By prioritizing suppliers with proven expertise in custom manufacturing and global distribution, buyers from regions such as Africa, South America, the Middle East, and Europe can secure competitive advantages in lighting innovation and application versatility.

Key takeaways for strategic sourcing include:

- Customization Capability: Select manufacturers offering tailored LED profiles and diffuser options to meet specific architectural and functional requirements.

- Quality Assurance: Emphasize suppliers with rigorous quality management systems to ensure durability, light diffusion uniformity, and compliance with international standards.

- Supply Chain Reliability: Partner with vendors providing transparent lead times, flexible MOQ (minimum order quantity), and logistics solutions tailored to your regional market.

- Sustainability Focus: Consider eco-friendly materials and energy-efficient designs that align with global sustainability trends and local regulations.

Looking ahead, the LED channel and diffuser market is poised for growth driven by expanding smart lighting applications and increasing demand for energy-efficient solutions. International buyers are encouraged to deepen collaborations with innovative manufacturers and explore emerging technologies such as integrated LED modules and advanced diffuser materials. Taking a strategic, informed approach to sourcing will empower your business to deliver cutting-edge lighting solutions that meet evolving market needs and regulatory landscapes.