Introduction: Navigating the Global Market for color changing led strips

Color changing LED strips represent a transformative innovation in lighting technology, offering unparalleled flexibility, energy efficiency, and aesthetic appeal for a wide range of commercial and industrial applications. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—these versatile lighting solutions unlock new possibilities for branding, ambiance creation, and functional illumination. Understanding the nuances of sourcing quality color changing LED strips is essential to capitalize on their full potential while optimizing costs and ensuring durability.

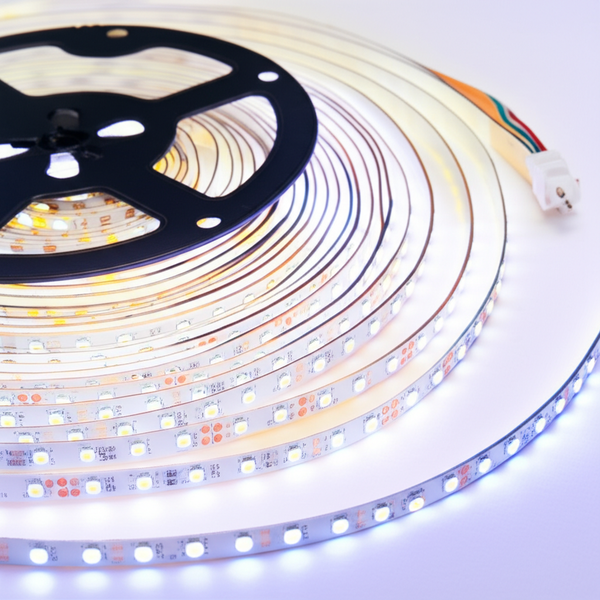

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to empower procurement professionals and business leaders with in-depth insights into the global market for color changing LED strips. It covers key aspects such as the various types and technical specifications, material quality considerations, manufacturing processes, and stringent quality control measures that influence product reliability. Buyers will also find detailed information on selecting reputable suppliers, navigating cost structures, and evaluating the latest market trends that impact supply and demand.

Additionally, the guide addresses frequently asked questions to clarify common concerns about installation, compatibility, and customization options. By synthesizing expert knowledge with practical sourcing strategies, this resource equips B2B buyers—whether based in Kenya, Brazil, Dubai, or Germany—with the tools necessary to make informed, confident purchasing decisions. Ultimately, leveraging this guide will help businesses secure high-performance color changing LED strips that meet their unique operational requirements and position them competitively in their respective markets.

Understanding color changing led strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| RGB LED Strips | Three primary color LEDs (Red, Green, Blue) with color mixing | Retail displays, hospitality, event lighting | + Versatile color options; – Limited to basic colors |

| RGBW LED Strips | RGB LEDs plus a dedicated white LED for pure white tones | Architectural lighting, residential, offices | + Better white light quality; – Higher cost than RGB |

| Addressable LED Strips | Individually controllable LEDs for dynamic effects | Entertainment, signage, large-scale installations | + Highly customizable effects; – More complex installation |

| Waterproof LED Strips | Encased in silicone or epoxy for outdoor/wet environments | Outdoor signage, landscape, marine applications | + Durable and weather-resistant; – Slightly higher price |

| Tunable White LED Strips | Adjustable color temperature from warm to cool white | Healthcare, offices, retail, museums | + Enhances ambiance and productivity; – Requires compatible controllers |

RGB LED Strips

RGB LED strips combine red, green, and blue LEDs to create a broad spectrum of colors through mixing. This type is highly popular for businesses seeking cost-effective, versatile lighting solutions for retail displays, event venues, and hospitality sectors. When purchasing, B2B buyers should consider the quality of color mixing and the compatibility with controllers to ensure smooth transitions. Bulk orders typically yield competitive pricing, making RGB strips attractive for large projects with dynamic lighting needs.

RGBW LED Strips

Adding a dedicated white LED to the RGB configuration, RGBW strips produce a cleaner and more natural white light alongside vibrant colors. This makes them ideal for architectural projects, office environments, and residential applications where both ambiance and task lighting are important. Buyers should assess the balance between color quality and cost, as RGBW strips tend to be pricier than standard RGB but offer superior lighting versatility and appeal to premium markets.

Addressable LED Strips

Addressable LED strips feature individually controllable LEDs that enable complex lighting patterns and animations. They are favored in entertainment venues, signage, and large-scale installations where customized effects are essential. B2B buyers must factor in the need for specialized controllers and potentially higher installation complexity. However, the ability to create unique lighting experiences can justify the investment, especially for branding or experiential marketing projects.

Waterproof LED Strips

Designed with protective coatings, waterproof LED strips withstand moisture, dust, and harsh weather conditions, making them suitable for outdoor signage, landscaping, and marine applications. For international buyers in regions with challenging climates, sourcing waterproof strips ensures durability and longevity. Though costlier than indoor variants, the reduced maintenance and replacement frequency provide strong value for commercial and industrial buyers.

Tunable White LED Strips

These strips allow adjustment of color temperature from warm to cool white, supporting environments that require adaptable lighting to influence mood or productivity, such as healthcare facilities, offices, retail spaces, and museums. B2B buyers should verify compatibility with tunable controllers and consider the application’s lighting control sophistication. This type caters well to markets emphasizing wellness and ambiance, offering a premium product line with growing demand.

Related Video: The Ultimate Guide to RGB LED Strips!

Key Industrial Applications of color changing led strips

| Industry/Sector | Specific Application of Color Changing LED Strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Dynamic storefront and interior lighting displays | Enhance customer engagement and increase foot traffic | Durable, high-CRI strips with customizable color settings and easy installation |

| Hospitality & Entertainment | Ambiance control in hotels, bars, theaters, and event venues | Create immersive environments that improve guest experience | Waterproof and flexible strips with smart control options for varied effects |

| Automotive & Transportation | Interior mood lighting for luxury vehicles and public transit | Differentiate products and improve passenger comfort | Low-voltage, vibration-resistant strips with consistent color output |

| Architecture & Urban Design | Façade lighting and public space illumination | Highlight structures, improve safety, and enable branding | Weatherproof, energy-efficient strips with long lifespan and color stability |

| Manufacturing & Warehousing | Safety and operational zone indication | Increase workplace safety and operational efficiency | Robust, easy-to-install strips with clear color differentiation and durability |

Color changing LED strips have become vital in retail and commercial spaces for creating eye-catching storefronts and dynamic interior displays. Businesses in regions such as Africa and South America benefit from the ability to adjust lighting schemes seasonally or for promotions, enhancing customer attraction and dwell time. Buyers should focus on sourcing high-CRI (Color Rendering Index) strips that provide vivid colors and reliable performance under diverse climate conditions, ensuring longevity and consistent color quality.

In the hospitality and entertainment sector, color changing LED strips enable hotels, bars, theaters, and event venues to craft customizable atmospheres that adapt to different moods and occasions. For international buyers in the Middle East and Europe, waterproof and flexible strips with smart app controls are essential to accommodate indoor and outdoor usage, while simplifying installation and maintenance. These features help venues elevate guest experiences and differentiate their services.

The automotive and transportation industry uses color changing LED strips predominantly for interior mood lighting in luxury vehicles and public transit systems. This application improves passenger comfort and adds a premium feel. Buyers from emerging markets, including Kenya and Indonesia, should prioritize strips that are low-voltage and resistant to vibrations, ensuring safety and durability in moving vehicles. Consistent color output is critical for maintaining brand image and passenger satisfaction.

In architecture and urban design, LED strips are used for façade illumination and public space lighting, enhancing the aesthetic appeal and safety of buildings and streetscapes. For B2B buyers in Europe and the Middle East, sourcing weatherproof, energy-efficient strips with long lifespans and stable colors is crucial due to variable weather conditions and regulatory standards. These installations also serve as branding tools for municipalities and commercial properties.

Finally, in manufacturing and warehousing environments, color changing LED strips are employed to indicate safety zones, operational areas, and workflow statuses through clear color coding. This use case drives operational efficiency and reduces accidents. Buyers should seek robust, easy-to-install strips that offer distinct, easily recognizable colors and can withstand industrial conditions. For international buyers, compatibility with existing safety systems and compliance with local industrial standards are important considerations.

Related Video: DIY Tutorial: Solder RGBW, RGB, and Single Color LED Strips

Strategic Material Selection Guide for color changing led strips

Key Materials for Color Changing LED Strips: Properties and B2B Considerations

1. Flexible Printed Circuit Board (FPCB) – Polyimide or PET Substrate

Key Properties:

FPCB substrates such as polyimide and polyethylene terephthalate (PET) offer excellent flexibility, thermal stability (typically up to 150°C for polyimide), and moderate chemical resistance. They support fine circuit patterns necessary for RGB LED control and are lightweight.

Pros & Cons:

– Pros: High flexibility enables installation in curved or tight spaces; polyimide substrates provide superior heat resistance and durability; PET is cost-effective and suitable for low-heat applications.

– Cons: Polyimide is more expensive than PET; PET has lower thermal tolerance and can degrade under prolonged heat exposure; both require precise manufacturing to avoid circuit damage.

Impact on Application:

FPCBs are ideal for indoor decorative lighting, architectural accents, and flexible installations. Polyimide-based strips are preferred for environments with moderate heat exposure, such as commercial lighting in warmer climates. PET-based strips suit cost-sensitive projects with less thermal stress.

International B2B Considerations:

Buyers from regions like Africa and South America should verify compliance with international standards such as IPC-2221 for flexible circuits. Polyimide substrates are favored in Europe due to stringent fire safety regulations (e.g., EN 60335). For Middle Eastern markets, attention to UV resistance is critical if strips are exposed to sunlight. Suppliers offering certifications like RoHS and REACH compliance enhance market acceptance globally.

2. Silicone Encapsulation

Key Properties:

Silicone encapsulants provide excellent waterproofing (IP67/IP68 ratings), UV resistance, and flexibility. They maintain elasticity across a wide temperature range (-40°C to 200°C), protecting LEDs from moisture, dust, and mechanical stress.

Illustrative Image (Source: Google Search)

Pros & Cons:

– Pros: Superior environmental protection, ideal for outdoor and harsh conditions; maintains color stability and light diffusion; flexible for curved surfaces.

– Cons: Higher material and manufacturing costs; more complex production process; potential for silicone yellowing over extended UV exposure if not properly formulated.

Impact on Application:

Silicone-encapsulated LED strips are optimal for outdoor signage, landscape lighting, and marine applications. Their robustness suits tropical and desert climates common in parts of Africa and the Middle East, where exposure to moisture and heat is significant.

International B2B Considerations:

Buyers should ensure silicone materials meet ASTM D2240 for hardness and ASTM G154 for UV resistance. In South America and Europe, compliance with environmental regulations and certifications like UL 2108 enhances product acceptance. Due to shipping costs, bulk orders with optimized packaging are recommended for remote African markets.

3. Epoxy Resin Coating

Key Properties:

Epoxy coatings provide a hard, protective layer with good adhesion and electrical insulation. They offer moderate waterproofing (typically IP65) and chemical resistance but are less flexible than silicone.

Pros & Cons:

– Pros: Cost-effective for indoor use; good mechanical protection; easy to apply in manufacturing.

– Cons: Rigid and prone to cracking under bending; limited UV resistance leading to yellowing; less suitable for outdoor or flexible installations.

Impact on Application:

Epoxy-coated strips are commonly used in indoor commercial lighting, retail displays, and industrial environments where flexibility is less critical. They are less suitable for outdoor or highly flexible applications.

International B2B Considerations:

European buyers often require compliance with EN 60598 for electrical safety. In Middle Eastern and African markets, epoxy coatings may be less favored due to environmental factors. Buyers should assess local climate impact on epoxy longevity and consider alternatives for outdoor projects.

4. Aluminum Channel Housing

Key Properties:

Aluminum channels serve as mounting and heat dissipation structures for LED strips. They provide mechanical protection, improve thermal management, and enhance aesthetic integration.

Pros & Cons:

– Pros: Excellent heat dissipation extends LED lifespan; protects strips from physical damage; available in various finishes for design flexibility.

– Cons: Adds to overall system cost and weight; requires additional installation steps; may limit strip flexibility.

Impact on Application:

Ideal for commercial and architectural lighting where durability and heat management are priorities. Aluminum channels are widely used in Europe and developed Middle Eastern markets for premium installations.

International B2B Considerations:

Buyers should verify that aluminum alloys meet standards like ASTM B221 or EN AW-6063 for extrusion quality. Surface treatments (anodizing or powder coating) should comply with corrosion resistance standards, especially for humid or coastal regions in Africa and South America.

Summary Table: Material Selection for Color Changing LED Strips

| Material | Typical Use Case for color changing led strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Printed Circuit Board (Polyimide/PET) | Indoor flexible installations, architectural accents | High flexibility and thermal stability (polyimide); cost-effective (PET) | PET has lower heat tolerance; polyimide costs more | Medium |

| Silicone Encapsulation | Outdoor, waterproof, and harsh environment lighting | Excellent waterproofing, UV resistance, and flexibility | Higher cost and complex manufacturing | High |

| Epoxy Resin Coating | Indoor commercial and industrial lighting | Cost-effective with good mechanical protection | Rigid, prone to cracking, limited UV resistance | Low |

| Aluminum Channel Housing | Commercial/architectural lighting requiring heat dissipation | Superior heat management and physical protection | Adds cost, weight, and reduces flexibility | Medium |

This guide equips international B2B buyers with actionable insights to select materials that align with their project requirements, regional climate conditions, and compliance needs, ensuring optimal performance and cost-efficiency in color changing LED strip applications.

In-depth Look: Manufacturing Processes and Quality Assurance for color changing led strips

Manufacturing and quality assurance of color changing LED strips involve precise, multi-stage processes designed to ensure product reliability, performance, and compliance with international standards. For B2B buyers, especially those operating across Africa, South America, the Middle East, and Europe, understanding these processes and quality checkpoints is critical to making informed sourcing decisions and maintaining supply chain integrity.

Key Stages in Manufacturing Color Changing LED Strips

-

Material Preparation

The process begins with sourcing high-quality raw materials such as flexible printed circuit boards (FPCBs), LED chips (typically RGB LEDs for color changing), resistors, and adhesives. The FPCBs are usually copper-clad with a flexible substrate, allowing the strip to bend and fit various installation scenarios. Material preparation also includes verifying the purity and specifications of raw components to avoid defects later in production. -

Forming and Circuit Printing

The flexible circuit board undergoes patterning via photolithography or screen printing to create copper traces that carry electrical signals. This step defines the electrical pathways and connection points for LEDs and other components. Precise formation is critical for consistent light output and durability. Advanced manufacturing may use automated machinery to print and etch circuits with high accuracy. -

Component Assembly

LEDs and electronic components are mounted onto the flexible board using surface mount technology (SMT). Automated pick-and-place machines position LEDs precisely, followed by soldering to ensure secure electrical connections. For color changing strips, microcontrollers or IC chips for controlling color changes are also installed during this phase. The assembly process often incorporates reflow soldering ovens to solidify connections without damaging components. -

Encapsulation and Finishing

To protect the delicate electronics, the strips are coated with silicone or epoxy resin, especially for waterproof or outdoor-rated products. This encapsulation provides resistance against moisture, dust, and mechanical stress. Finishing also involves cutting the strips to specified lengths, attaching connectors, and applying adhesive backing for easy installation.

Quality Assurance and Control Checkpoints

Robust quality assurance is essential to guarantee product consistency and compliance with international regulations. The manufacturing process integrates multiple quality control (QC) checkpoints:

-

Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to verify specifications, certifications, and absence of defects. IQC prevents substandard parts from entering production.

-

In-Process Quality Control (IPQC): During assembly, continuous checks monitor solder joint quality, LED placement accuracy, and electrical continuity. Automated optical inspection (AOI) systems are commonly used to detect assembly errors early.

-

Final Quality Control (FQC): Completed LED strips undergo functional testing, including brightness, color accuracy, and response to control signals. Visual inspections ensure no physical damage or coating defects. Packaging quality is also checked to prevent damage during shipping.

Relevant International Standards and Certifications

B2B buyers should prioritize suppliers who comply with recognized quality and safety standards:

-

ISO 9001: This international standard for quality management systems demonstrates a supplier’s commitment to consistent quality and continuous improvement.

-

CE Marking: Mandatory for products sold in the European Economic Area, CE marking certifies conformity with health, safety, and environmental protection standards.

-

RoHS (Restriction of Hazardous Substances): Ensures that LED strips are free from hazardous materials like lead and mercury, important for environmental compliance globally.

-

UL/ETL Certifications: Indicate compliance with North American safety standards, often required for products exported to or through countries with strict electrical safety regulations.

-

IP Ratings (e.g., IP65, IP67): Define the level of protection against dust and water ingress, crucial for outdoor or industrial applications.

-

EMC (Electromagnetic Compatibility) Compliance: Ensures LED strips do not emit or are not susceptible to electromagnetic interference, important in sensitive installations.

Common Testing Methods in QC

-

Electrical Testing: Checks voltage, current, and power consumption to ensure LEDs operate within design parameters.

-

Color Rendering and Chromaticity Testing: Measures the accuracy of color changes and uniformity across the strip using spectrometers or colorimeters.

-

Thermal Testing: Verifies heat dissipation and operating temperature ranges to prevent premature failure.

-

Durability Tests: Includes bending, vibration, and moisture resistance tests to simulate real-world usage.

-

Lifetime and Burn-in Testing: Running LED strips for extended periods to identify early failures and assess longevity.

How B2B Buyers Can Verify Supplier Quality Assurance

-

Factory Audits: Conduct on-site or third-party audits to evaluate manufacturing processes, equipment, and QC protocols. For buyers in emerging markets, partnering with local inspection agencies can reduce costs and language barriers.

-

Review of QC Documentation: Request detailed test reports, certifications, and batch records to confirm compliance with standards.

-

Third-Party Inspections: Independent labs or inspection firms can validate product quality before shipment, providing unbiased verification.

-

Sample Testing: Before large orders, buyers should test samples for color accuracy, durability, and compatibility with their systems.

-

Supplier Transparency: Suppliers committed to quality often share process videos, quality manuals, and allow virtual factory tours.

QC and Certification Nuances for International Buyers in Africa, South America, Middle East, and Europe

-

Regional Compliance Requirements:

Buyers must consider local regulations. For example, European buyers need CE and RoHS compliance, while Middle Eastern markets may require additional certifications related to electrical safety and energy efficiency. African and South American countries are increasingly adopting international standards but may have unique import requirements. -

Shipping and Handling Considerations:

LED strips must be packaged to withstand long transit times and varying climates. Buyers should confirm suppliers follow best practices for moisture-proof and anti-static packaging. -

After-Sales Support and Warranty:

Given long supply chains, buyers should negotiate clear warranty terms and post-sale support. This is critical in regions where replacement logistics can be challenging. -

Customization and Scalability:

Quality management systems should accommodate custom orders without compromising standards. Buyers planning large projects should verify supplier capacity and quality consistency across batches.

Summary for B2B Buyers:

When sourcing color changing LED strips, prioritize suppliers with transparent, standardized manufacturing processes and robust quality control aligned with international standards. Verify their certifications, request comprehensive QC documentation, and consider third-party audits to mitigate risks. Understanding these manufacturing and QA fundamentals will help buyers in Africa, South America, the Middle East, and Europe secure reliable products that meet their technical and regulatory requirements, ensuring successful project outcomes and customer satisfaction.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for color changing led strips Sourcing

Understanding the Cost Structure of Color Changing LED Strips

When sourcing color changing LED strips for international B2B purposes, it is essential to dissect the key components that contribute to the overall cost. This understanding enables buyers to negotiate effectively and optimize their procurement strategy.

- Materials: The primary cost driver includes the LEDs themselves (often RGB LEDs), flexible circuit boards, microcontrollers for color control, resistors, and protective coatings. Higher-quality LEDs and waterproof materials increase costs but enhance durability and performance.

- Labor: Labor costs vary widely depending on the country of manufacture. Assembly, soldering, testing, and packaging all require skilled labor. Countries with lower labor costs may offer more competitive pricing but must be balanced against quality assurance.

- Manufacturing Overhead: This encompasses factory utilities, equipment depreciation, and indirect labor. Efficient production lines and economies of scale can reduce overhead per unit.

- Tooling: Initial tooling costs for manufacturing customized strips or specific lengths can be significant but are amortized over large production runs.

- Quality Control (QC): Rigorous QC processes ensure product reliability, especially for color consistency and waterproof ratings. QC costs include testing equipment and labor for inspections.

- Logistics: Shipping, customs duties, and insurance add to the landed cost. For buyers in Africa, South America, the Middle East, and Europe, these can be substantial depending on the supply chain and chosen Incoterms.

- Margin: Supplier markup varies with brand reputation, product quality, and market positioning. Wholesale purchases typically enjoy lower margins compared to retail prices.

Key Pricing Influencers for Buyers

Several factors influence the final quoted price of color changing LED strips, which buyers should scrutinize:

- Order Volume and Minimum Order Quantity (MOQ): Larger volumes drastically reduce per-unit cost due to economies of scale. MOQ requirements can vary; negotiating smaller MOQs with suppliers or consolidating orders across projects can optimize costs.

- Product Specifications and Customization: Customized lengths, unique color profiles, integrated controllers, or proprietary packaging raise costs. Buyers should prioritize essential features to avoid unnecessary expenses.

- Material Quality and Certifications: LED strips certified for safety (e.g., CE, RoHS) and quality (e.g., UL) command higher prices but reduce risk and enhance market acceptance, especially in regulated European markets.

- Supplier Reputation and Location: Established suppliers with proven track records may charge premiums but offer reliability and better after-sales support. Geographical proximity affects logistics costs and delivery times.

- Incoterms and Shipping Terms: Terms like FOB, CIF, or DDP shift responsibility and cost between buyer and supplier. Understanding these terms helps buyers anticipate additional expenses such as import duties and local transportation.

Strategic Tips for International B2B Buyers

For buyers from regions such as Kenya, Brazil, the UAE, and Germany, a nuanced approach to pricing and sourcing can unlock significant value:

- Engage in Transparent Negotiations: Discuss volume discounts, payment terms, and after-sales service. Suppliers often accommodate buyers willing to commit to recurring orders.

- Evaluate Total Cost of Ownership (TCO): Beyond the unit price, consider installation ease, energy efficiency, warranty coverage, and expected lifespan to avoid hidden costs.

- Leverage Consolidated Shipping: Pooling shipments or partnering with freight forwarders can reduce per-unit logistics costs, especially for remote or less accessible markets.

- Request Samples and Pilot Orders: Testing samples before bulk purchase ensures product meets local environmental and technical requirements, reducing costly returns or failures.

- Understand Local Import Regulations: Duties, taxes, and certification requirements differ significantly. Working with customs brokers or local agents familiar with LED lighting products expedites clearance and avoids unexpected fees.

- Factor in Currency Fluctuations and Payment Methods: Exchange rate volatility can affect pricing. Negotiating contracts in stable currencies or using Letters of Credit mitigates financial risks.

Disclaimer on Pricing

Prices for color changing LED strips fluctuate based on raw material costs, geopolitical factors, and technological advancements. The figures discussed are indicative and should be verified directly with suppliers. Buyers are encouraged to conduct thorough due diligence and request updated quotations tailored to their specific project needs and regional considerations.

By carefully analyzing cost components, understanding pricing influencers, and applying strategic sourcing tactics, international B2B buyers can secure high-quality color changing LED strips at competitive prices, ensuring successful project outcomes across diverse markets.

Spotlight on Potential color changing led strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘color changing led strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for color changing led strips

Key Technical Properties of Color Changing LED Strips

When sourcing color changing LED strips, understanding critical technical specifications helps international buyers ensure product suitability and quality for their projects. Here are some essential properties to consider:

-

LED Chip Type and Quality

The LED chip (e.g., SMD 5050, 3528) determines brightness, color rendering, and lifespan. High-quality chips offer better color accuracy and longer durability, which is vital for commercial applications and resale. For B2B buyers, specifying chip type upfront prevents compatibility issues and supports premium branding. -

Color Modes and Control Compatibility

Color changing strips often support RGB or RGBW modes, enabling millions of colors and white light options. Compatibility with controllers (RF, Wi-Fi, DMX) is crucial for smooth color transitions and remote management. Buyers should confirm control protocol to match their project’s technical ecosystem. -

Power Consumption and Voltage

Typically, strips operate at 12V or 24V DC with varying wattage per meter. Lower power consumption means energy savings, an important factor for large-scale installations. Understanding voltage and wattage helps avoid electrical overload and ensures safe, efficient operation. -

IP Rating (Ingress Protection)

The IP rating (e.g., IP20, IP65, IP67) indicates resistance to dust and water. Outdoor or industrial applications require higher IP ratings for durability against weather and moisture. Selecting the correct IP rating minimizes maintenance and replacements, critical for buyers in diverse climates like Africa or the Middle East. -

Cutting and Length Tolerance

LED strips are designed to be cut at specific intervals without damaging functionality. Length tolerance reflects how precisely strips are manufactured to specified lengths, affecting installation fit. Accurate cutting and length control reduce waste and installation time for large projects. -

Material and Adhesive Quality

The flexibility and backing material (usually PCB with adhesive tape) impact ease of installation and strip longevity. Strong adhesives suited for various surfaces (metal, wood, glass) ensure firm placement. Buyers should verify material grades to guarantee performance in different environments.

Common Trade Terms in the LED Strip Industry

Navigating international trade requires familiarity with key industry jargon. Here are important terms that B2B buyers frequently encounter:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that can be rebranded or customized by buyers. OEM agreements allow buyers to create private label products, essential for businesses wanting unique branding or specialized features. -

MOQ (Minimum Order Quantity)

The smallest quantity of units a supplier will accept per order. MOQs vary widely and impact pricing and inventory decisions. Understanding MOQ helps buyers from emerging markets manage budget constraints and storage while negotiating favorable terms. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting detailed pricing and terms for specified products. RFQs are a critical step in sourcing, enabling buyers to compare offers and assess supplier capabilities before committing. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller (e.g., FOB, CIF, DDP). Clarity on Incoterms ensures smooth logistics and cost transparency, especially important for buyers importing across continents. -

IP Rating (Ingress Protection Rating)

Although a technical property, IP rating is often referenced in trade discussions to specify environmental suitability. Buyers should request IP ratings to align product specs with application requirements and regulatory standards. -

Lead Time

The period from order placement to delivery. Lead times influence project planning and inventory management. Buyers in regions with longer shipping times should negotiate realistic lead times to avoid delays.

Understanding these technical properties and trade terms empowers B2B buyers to make informed purchasing decisions, optimize costs, and ensure product performance tailored to their regional and application needs. This knowledge is especially valuable for buyers in Africa, South America, the Middle East, and Europe, where market conditions and project requirements can vary significantly.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the color changing led strips Sector

Market Overview & Key Trends

The global market for color changing LED strips is expanding rapidly, driven by increasing demand across commercial, industrial, and residential sectors. Energy efficiency mandates and the rise of smart lighting solutions are key global drivers shaping this market. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the adoption of color changing LED strips is closely tied to urban development, smart city initiatives, and growing consumer interest in customizable lighting environments.

Key market dynamics include:

-

Technological Innovation: Integration of IoT-enabled controls and smartphone app compatibility is becoming standard, enabling dynamic lighting scenes and remote management. This trend is especially attractive for commercial applications such as retail, hospitality, and entertainment venues seeking to enhance customer experience.

-

Customization & Scalability: B2B buyers are increasingly demanding customizable LED strips in terms of length, color capabilities (RGB, RGBW), brightness levels, and waterproofing. This flexibility supports diverse applications ranging from architectural accent lighting to industrial safety indicators.

-

Regional Demand Nuances: African and Middle Eastern markets show strong growth due to urban infrastructure projects and rising disposable incomes, while South America is witnessing increased adoption in hospitality and retail sectors. European buyers emphasize compliance with stringent energy and safety regulations, influencing supplier selection and product specifications.

-

Sourcing Trends: Bulk purchasing from manufacturers offering direct shipping is preferred to reduce costs and lead times. Buyers are also favoring suppliers who provide warranties, product certifications (CE, RoHS), and sample availability to verify quality before large orders.

-

Supply Chain Resilience: The recent global disruptions have underscored the importance of diversified sourcing strategies, including partnerships with manufacturers in multiple regions to mitigate risks related to shipping delays and tariffs.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers of color changing LED strips, driven by increasing regulatory pressures and corporate social responsibility commitments. LED technology inherently offers energy savings compared to traditional lighting, but the environmental impact of manufacturing, materials sourcing, and end-of-life disposal remains a focus.

Key sustainability insights for buyers include:

-

Material Selection: Opt for LED strips made with non-toxic, recyclable materials such as lead-free solder and halogen-free circuit boards. Suppliers who disclose material sourcing and manufacturing processes provide greater transparency and align with green procurement policies.

-

Energy Efficiency Certifications: Products meeting recognized standards like ENERGY STAR or equivalent regional certifications ensure lower operational energy consumption and reduced carbon footprint. Buyers should prioritize LED strips with high luminous efficacy and long lifespan to maximize sustainability benefits.

-

Ethical Supply Chains: Verifying that suppliers adhere to ethical labor practices and environmental standards throughout their supply chains is essential. Certifications such as ISO 14001 (environmental management) and SA8000 (social accountability) help mitigate risks associated with forced labor or unsafe working conditions.

-

End-of-Life Management: Encourage suppliers who offer take-back or recycling programs for LED strips to minimize electronic waste. Designing for disassembly and recyclability supports circular economy initiatives and reduces environmental impact.

-

Regional Sustainability Considerations: In regions like Europe, compliance with the Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE) regulations is mandatory. Buyers in Africa and South America should also consider emerging local environmental regulations and the potential for green incentives.

Evolution and Historical Context

Color changing LED strips have evolved significantly over the past two decades. Early LED strips were primarily single-color and limited in brightness, used mainly for simple accent lighting. The advent of RGB (Red-Green-Blue) LED technology introduced dynamic color mixing, enabling a spectrum of colors from a single strip.

As manufacturing processes improved, flexible circuit boards and waterproof coatings expanded applications to outdoor and industrial environments. Integration with digital controllers and wireless technologies further transformed LED strips into smart lighting solutions, allowing for programmable color sequences and synchronization with music or events.

For B2B buyers, understanding this evolution highlights the importance of selecting suppliers who keep pace with technological advancements and offer products that align with modern lighting standards and user expectations. The shift from basic illumination to intelligent, customizable lighting solutions presents lucrative opportunities across diverse industries worldwide.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of color changing led strips

-

How can I effectively vet suppliers of color changing LED strips for international B2B purchases?

When sourcing suppliers, prioritize those with proven experience in international trade and positive reviews from global clients, especially in Africa, South America, the Middle East, and Europe. Verify their certifications (e.g., CE, RoHS) and request product samples to assess quality firsthand. Investigate their production capacity to ensure they can meet your volume demands. Additionally, evaluate their communication responsiveness and after-sales support, which are critical for resolving issues across time zones and different languages. -

What customization options are typically available for color changing LED strips in bulk orders?

Most reputable manufacturers offer customization including specific color ranges (RGB, RGBW), strip lengths, waterproof ratings (IP65, IP67), and packaging tailored to your brand. Some suppliers also provide customizable control systems compatible with smart home or commercial automation. Clearly communicate your technical and branding requirements early to secure precise quotes and avoid costly revisions. Customization enhances product differentiation and can improve market competitiveness in your target region. -

What are common Minimum Order Quantities (MOQs), lead times, and payment terms when purchasing color changing LED strips internationally?

MOQs vary widely depending on supplier scale but typically range from 500 to 2,000 meters per SKU. Lead times average 3 to 6 weeks, factoring production and international shipping. Payment terms often include a 30% deposit upfront with the balance due before shipment, though some suppliers may accept letters of credit or escrow services for added security. Negotiate terms carefully, considering currency fluctuations and import regulations specific to your country. -

Which quality assurance certifications and testing should I require from suppliers to ensure product reliability?

Essential certifications include CE (European conformity), RoHS (restriction of hazardous substances), and UL or ETL for electrical safety, particularly for buyers in Europe and the Middle East. Request documentation of testing for color accuracy, brightness consistency, and waterproofing standards. Confirm that products undergo endurance and thermal stress tests to ensure longevity in diverse climates, which is crucial for markets like Kenya or Brazil with challenging environmental conditions. -

What logistics considerations should I be aware of when importing color changing LED strips from overseas manufacturers?

Choose suppliers experienced in global shipping who can handle customs clearance, documentation, and compliance with import/export regulations of your country. Opt for consolidated shipments to reduce freight costs and consider Incoterms that clearly define responsibilities (e.g., FOB, CIF). Factor in potential delays due to customs inspections or regional holidays. Also, verify packaging robustness to prevent damage during long transit, especially for fragile electronic components. -

How can I manage disputes or quality issues with suppliers after receiving bulk shipments?

Establish clear contractual terms outlining product specifications, inspection processes, and remedies for defects before ordering. Upon receipt, conduct immediate quality inspections and document any discrepancies with photos and reports. Promptly notify the supplier with evidence and request corrective actions such as replacements or refunds. Maintain a collaborative approach to dispute resolution, leveraging trade assurance services or third-party inspection agencies if necessary, to safeguard your investment.

-

Are there specific challenges for B2B buyers in Africa, South America, the Middle East, and Europe when sourcing color changing LED strips?

Buyers in these regions often face challenges like longer shipping times, import tariffs, and varying electrical standards. It’s important to verify that LED strips comply with local voltage and safety regulations. Language barriers and time zone differences can complicate communication, so working with suppliers who offer multilingual support and flexible hours is advantageous. Additionally, understanding regional demand trends helps in selecting products with the right features and certifications. -

What are best practices for ensuring smooth payment and financial security in international B2B transactions for LED strips?

Use secure payment methods such as letters of credit, escrow accounts, or trusted trade platforms to minimize risk. Verify supplier legitimacy through credit checks and references before transferring funds. Consider currency exchange risks and negotiate payment in stable currencies like USD or EUR. Establish clear payment milestones linked to production and shipment stages to maintain leverage. Always keep detailed records of all financial transactions for transparency and future audits.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for color changing led strips

Strategic sourcing of color changing LED strips offers international B2B buyers a distinct competitive advantage through cost efficiency, product variety, and access to cutting-edge technology. By prioritizing reliable suppliers who provide customization options, warranties, and scalable solutions, businesses can ensure consistent quality and meet diverse project demands across markets in Africa, South America, the Middle East, and Europe. Understanding specific application needs—whether for commercial, residential, or industrial use—enables buyers to optimize procurement decisions, reduce risks, and maximize ROI.

Key takeaways include leveraging bulk purchasing to lower unit costs, requesting product samples to verify quality, and choosing suppliers with robust after-sales support and transparent shipping policies. Staying informed about emerging trends such as smart app-controlled strips and enhanced waterproofing will position buyers to capitalize on evolving market demands and consumer preferences.

Looking ahead, the global momentum toward energy-efficient, customizable lighting solutions will continue to drive demand for color changing LED strips. For B2B buyers in dynamic regions like Kenya and Indonesia, embracing strategic sourcing practices now will unlock growth opportunities and strengthen supply chain resilience. Engage proactively with trusted wholesale partners to secure innovative products that align with your market’s unique needs and sustainability goals.