Guide to Full Spectrum Led Strip Lighting

- Introduction: Navigating the Global Market for full spectrum led strip lighting

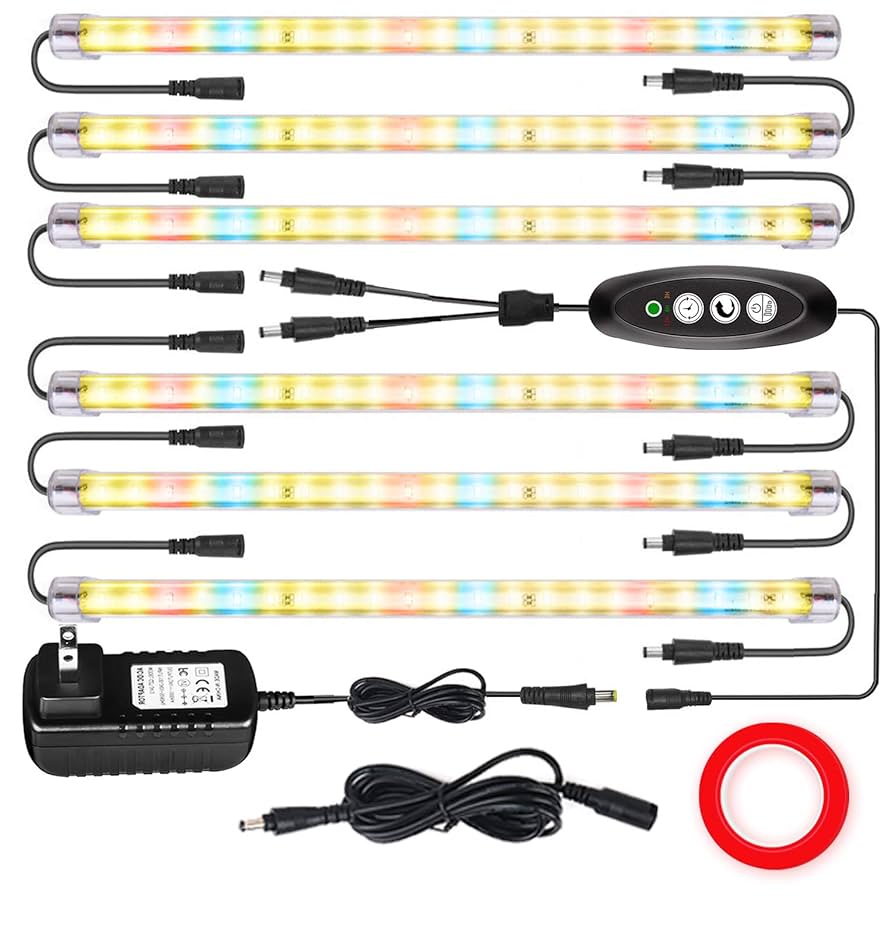

- Understanding full spectrum led strip lighting Types and Variations

- Key Industrial Applications of full spectrum led strip lighting

- Strategic Material Selection Guide for full spectrum led strip lighting

- In-depth Look: Manufacturing Processes and Quality Assurance for full spectrum led strip lighting

- Comprehensive Cost and Pricing Analysis for full spectrum led strip lighting Sourcing

- Spotlight on Potential full spectrum led strip lighting Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for full spectrum led strip lighting

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the full spectrum led strip lighting Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of full spectrum led strip lighting

- Strategic Sourcing Conclusion and Outlook for full spectrum led strip lighting

Introduction: Navigating the Global Market for full spectrum led strip lighting

In today’s rapidly evolving lighting industry, full spectrum LED strip lighting stands out as a transformative solution that delivers superior color accuracy, enhanced energy efficiency, and versatile application potential. For international B2B buyers—especially those operating in diverse markets across Africa, South America, the Middle East, and Europe—understanding the nuances of this technology is essential to securing competitive advantages and meeting varied client demands.

Full spectrum LED strips replicate natural sunlight more closely than conventional LEDs, making them invaluable for sectors ranging from retail and horticulture to healthcare and interior design. Their ability to render colors authentically and support human-centric lighting initiatives positions them as a critical investment for projects that prioritize quality and innovation.

This guide offers a comprehensive exploration of full spectrum LED strip lighting tailored to the needs of global buyers. You will find detailed insights on:

- Types and configurations of full spectrum LED strips and how to select the right product for specific applications

- Material quality and manufacturing standards, including crucial quality control benchmarks to ensure durability and performance

- Supplier evaluation criteria to identify reliable partners capable of consistent delivery and compliance with international certifications

- Cost considerations encompassing total cost of ownership, including installation and maintenance

- Current global market trends and regional factors impacting procurement strategies

- Frequently asked questions addressing common challenges and best practices in sourcing

Armed with this knowledge, B2B buyers can confidently navigate the complexities of the global marketplace, optimize their supply chains, and align purchasing decisions with both operational goals and sustainability commitments. Whether sourcing for large-scale commercial projects or specialized niche applications, this guide empowers buyers in South Africa, Spain, and beyond to make informed, strategic investments in full spectrum LED strip lighting technology.

Understanding full spectrum led strip lighting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Spectrum White LED | Emits broad white light covering visible spectrum closely matching natural daylight | Horticulture, retail displays, art studios | Pros: Accurate color rendering, versatile; Cons: Higher cost, moderate heat output |

| RGB + White Hybrid | Combines RGB color mixing with dedicated white LEDs for precise color tuning | Entertainment venues, architectural lighting | Pros: Flexible color options, dynamic ambiance; Cons: More complex control needed, higher power consumption |

| Tunable Full Spectrum | Adjustable spectrum and color temperature from warm to cool white and beyond | Medical facilities, photography, workspace lighting | Pros: Customizable lighting environment; Cons: Premium pricing, requires advanced controllers |

| High CRI Full Spectrum | High Color Rendering Index (90+) for true-to-life color accuracy | Retail, museums, galleries | Pros: Enhances product and artwork appearance; Cons: Usually higher upfront cost, limited color options |

| Waterproof Full Spectrum | Sealed LED strips designed for moisture resistance with full spectrum output | Outdoor landscaping, aquariums, wet industrial areas | Pros: Durable in harsh environments; Cons: Slightly reduced brightness, costlier sealing materials |

Full Spectrum White LED strips are engineered to mimic natural daylight by delivering a continuous spectrum of white light. This makes them ideal for applications requiring true color perception such as horticulture and retail displays. Buyers should prioritize suppliers offering consistent spectral output and verify CRI values to ensure color fidelity. These strips generally have moderate heat generation, so adequate thermal management is crucial for large-scale installations.

RGB + White Hybrid strips integrate standard RGB LEDs with dedicated white LEDs, allowing for both vibrant color effects and accurate white illumination. This versatility suits dynamic environments like entertainment venues and architectural projects. B2B buyers must consider the complexity of control systems and power requirements, ensuring compatibility with existing lighting controls and infrastructure to optimize performance.

Tunable Full Spectrum LED strips provide adjustable color temperature and spectral output, enabling customization from warm to cool white and beyond. These are particularly valuable in medical, photography, and workspace settings where lighting conditions must adapt to specific needs. When sourcing, buyers should focus on suppliers offering reliable dimming and tuning controls and evaluate warranty terms for advanced electronics.

High CRI Full Spectrum strips emphasize exceptional color rendering with CRI values above 90, enhancing the appearance of products and artworks. They are favored in retail, museums, and galleries where visual accuracy drives customer engagement. Although these strips come at a premium, investing in high-quality chips and verified certifications can reduce long-term costs by minimizing replacements and ensuring consistent output.

Waterproof Full Spectrum LED strips are designed with protective coatings or encapsulation to withstand moisture and harsh environments while delivering full spectrum light. Ideal for outdoor landscaping, aquariums, and wet industrial sites, these strips require careful selection regarding IP ratings and material durability. Buyers should also factor in slightly lower brightness levels due to sealing and plan accordingly for power and installation logistics.

Related Video: DON’T SPEND YOUR MONEY UNTIL YOU KNOW THIS! FULL SPECTRUM PANEL LED LIGHTS OR STRIP GROW LIGHTS?

Key Industrial Applications of full spectrum led strip lighting

| Industry/Sector | Specific Application of full spectrum led strip lighting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Horticulture | Controlled environment agriculture (greenhouses, vertical farms) | Enhanced plant growth and yield through optimized light spectrum | High CRI, customizable spectrum, waterproof rating, energy efficiency |

| Retail & Visual Merchandising | Product display lighting in stores and showrooms | Accurate color rendering to boost product appeal and sales | High CRI (>90), uniform light distribution, dimmable options, quality certifications |

| Healthcare & Medical Facilities | Therapy rooms and circadian rhythm lighting | Improved patient well-being and accelerated recovery | Tunable white spectrum, flicker-free operation, compliance with health standards |

| Film & Photography Studios | Studio and set lighting | Natural color rendering for true-to-life visuals | High CRI, adjustable color temperature, low heat emission, reliable dimming |

| Hospitality & Interior Design | Ambient and task lighting in hotels and restaurants | Enhanced atmosphere and guest experience with natural light | Flexible form factor, dimmability, long lifespan, compatibility with smart controls |

Agriculture & Horticulture

Full spectrum LED strip lighting is increasingly critical in controlled environment agriculture such as greenhouses and vertical farms, particularly in regions like South Africa and Spain where climate variability demands precise light management. These lights replicate natural sunlight, promoting photosynthesis and improving plant health and yield. Buyers should prioritize LEDs offering a balanced spectrum (including red, blue, and far-red wavelengths), waterproofing for humid environments, and energy-efficient operation to reduce operational costs. For international buyers, sourcing from suppliers with robust quality certifications and local after-sales support ensures reliability and compliance with regional agricultural standards.

Illustrative Image (Source: Google Search)

Retail & Visual Merchandising

In retail environments across Europe and the Middle East, full spectrum LED strip lighting is used to illuminate product displays, enhancing the true colors and details of merchandise. This accurate color rendering (high CRI) makes products more attractive to customers, directly impacting sales. Buyers must consider lighting uniformity to avoid shadows, dimmable features for flexible ambiance control, and certifications ensuring safety and longevity. Bulk purchasing should focus on consistent quality and color temperature to maintain a uniform brand aesthetic across multiple store locations.

Illustrative Image (Source: Google Search)

Healthcare & Medical Facilities

Full spectrum LED strips play a vital role in healthcare settings by supporting circadian rhythm lighting and therapeutic applications that improve patient comfort and recovery rates. Hospitals and clinics, especially in urban centers of South America and Europe, use tunable white LEDs to simulate natural daylight cycles. Key sourcing criteria include flicker-free technology to reduce eye strain, precise tunability between warm and cool light, and compliance with medical lighting standards. Buyers should verify certifications and warranties to ensure the lighting solutions meet stringent healthcare requirements.

Film & Photography Studios

For film and photography studios in creative hubs such as Spain and Dubai, full spectrum LED strip lighting delivers natural, high-fidelity light essential for accurate color reproduction. These LEDs reduce the need for post-production color correction and improve on-set working conditions. Buyers should seek strips with very high CRI values, adjustable color temperature, low heat emission to protect equipment and talent, and reliable dimming capabilities. Quality assurance and supplier transparency are crucial when importing these specialized lighting products internationally.

Hospitality & Interior Design

In the hospitality sector, including hotels and restaurants across Africa and Europe, full spectrum LED strip lighting enhances interior environments by providing both ambient and task lighting that mimics natural light. This elevates guest experience and supports staff productivity. Buyers should focus on flexible, easy-to-install strips with dimmable options and long lifespans to minimize maintenance. Integration with smart lighting controls is increasingly important for upscale venues aiming to offer personalized lighting scenes. Ensuring compatibility with local electrical standards and obtaining extended warranties are key factors for international procurement.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Strategic Material Selection Guide for full spectrum led strip lighting

Material Analysis for Full Spectrum LED Strip Lighting

1. Flexible Printed Circuit Board (FPCB) with Polyimide Substrate

Key Properties: Polyimide-based FPCBs are widely used as the base material for LED strips due to their excellent thermal stability (up to 260°C), high flexibility, and good electrical insulation. They resist moisture and chemicals moderately well, making them suitable for various environments.

Pros & Cons: Polyimide FPCBs offer excellent heat dissipation, which is critical for maintaining LED lifespan and performance. Their flexibility allows for curved or irregular installations. However, they tend to be more expensive than standard fiberglass PCBs and require precise manufacturing processes.

Impact on Application: Ideal for applications requiring flexible installation, such as architectural lighting or signage in commercial spaces. Their thermal properties support high-brightness full spectrum LEDs without overheating.

International B2B Considerations: Buyers in regions like South Africa and Spain must ensure suppliers meet standards such as IPC-2221 for PCB design and RoHS compliance for environmental safety. Polyimide substrates are preferred in Europe due to stringent environmental regulations, while in Middle Eastern markets, durability against heat is a priority. Importers should verify certifications and consider local climate impacts on material longevity.

2. Aluminum PCB (Metal Core PCB)

Key Properties: Aluminum PCBs provide superior thermal conductivity compared to traditional FR4 boards, efficiently dissipating heat generated by high-power full spectrum LEDs. They are rigid and have good mechanical strength, with typical operating temperatures up to 130°C.

Pros & Cons: The excellent heat dissipation extends LED lifespan and performance, making aluminum PCBs suitable for high-intensity lighting applications. However, they are less flexible and heavier, limiting use in curved or compact installations. Manufacturing costs are moderate but can increase with added surface treatments for corrosion resistance.

Impact on Application: Best suited for industrial, commercial, and horticultural lighting where heat management is critical. Their robustness makes them ideal for environments with moderate mechanical stress.

International B2B Considerations: European buyers often require compliance with EN standards and CE marking, while buyers in Africa and South America focus on corrosion resistance due to humid or coastal environments. Aluminum PCBs with anodized coatings are preferred to prevent oxidation. Buyers should assess supplier quality certifications like ISO 9001 to ensure consistent product performance.

3. Silicone Encapsulation Material

Key Properties: Silicone is used as a protective coating or encapsulant for LED strips, offering excellent UV resistance, flexibility, and waterproofing (IP65 to IP68 ratings). It withstands temperatures from -60°C to 200°C and provides good chemical resistance.

Pros & Cons: Silicone encapsulation enhances durability in outdoor and harsh environments, protecting LEDs from moisture, dust, and mechanical damage. It is more expensive than epoxy or PVC coatings and can complicate manufacturing due to curing times.

Impact on Application: Essential for outdoor, marine, or industrial full spectrum LED strip installations where exposure to elements is significant. Its flexibility supports installation on uneven surfaces while maintaining protection.

International B2B Considerations: Buyers in the Middle East and coastal regions of South America benefit from silicone’s UV and saltwater resistance. Compliance with IEC 60529 for ingress protection is critical. European buyers often require REACH compliance and low VOC emissions, influencing silicone grade selection.

4. PVC (Polyvinyl Chloride) Housing and Sheathing

Key Properties: PVC is commonly used for the outer housing or sheathing of LED strips, providing electrical insulation, moderate flexibility, and impact resistance. It typically operates safely up to 60°C and offers basic moisture protection.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it popular for indoor LED strip lighting. However, it has lower heat resistance and can degrade under prolonged UV exposure, limiting outdoor use. Environmental concerns over PVC additives and plasticizers also exist.

Impact on Application: Suitable for indoor ambient lighting, retail displays, and decorative applications where environmental exposure is minimal. Not recommended for high-temperature or outdoor installations.

International B2B Considerations: Buyers in Europe must consider strict environmental regulations restricting certain plasticizers in PVC (e.g., EU REACH). African and South American markets may prioritize cost but should balance it with durability needs. Certifications like UL 94 for flammability and RoHS compliance are important for market acceptance.

Summary Table of Materials for Full Spectrum LED Strip Lighting

| Material | Typical Use Case for full spectrum led strip lighting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide FPCB | Flexible installations in architectural and commercial lighting | Excellent thermal stability and flexibility | Higher cost and complex manufacturing | High |

| Aluminum PCB | High-power industrial, commercial, and horticultural lighting | Superior heat dissipation and mechanical strength | Rigid, less flexible, heavier | Medium |

| Silicone Encapsulation | Outdoor, marine, and harsh environment installations | UV resistant, waterproof, flexible | More expensive, longer manufacturing process | High |

| PVC Housing/Sheathing | Indoor ambient and decorative lighting | Cost-effective and easy to manufacture | Lower heat resistance, degrades under UV, environmental concerns | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for full spectrum led strip lighting

The manufacturing of full spectrum LED strip lighting involves a sequence of precise, technically demanding stages designed to ensure optimal light quality, durability, and performance. For international B2B buyers, especially those sourcing from or supplying to regions like Africa, South America, the Middle East, and Europe, understanding these processes and the quality assurance frameworks is critical for making informed procurement decisions that minimize risks and maximize value.

Manufacturing Processes of Full Spectrum LED Strip Lighting

1. Material Preparation

This initial phase involves selecting and preparing high-quality raw materials crucial for full spectrum performance: LED chips, flexible printed circuit boards (FPCBs), phosphor coatings, and encapsulation resins. LED chips—often sourced from leading manufacturers such as Samsung or Cree—are selected based on spectral output to achieve a balanced full spectrum light that mimics natural sunlight. The FPCBs are typically made from copper-clad polyimide or fiberglass to provide durability and excellent electrical conductivity.

2. PCB Forming and Circuit Printing

The prepared copper-clad boards undergo photolithography and etching to form precise circuit pathways. This stage must maintain tight tolerances to prevent electrical failures and ensure consistent current flow, which directly impacts the LED strip’s brightness and color uniformity.

3. Component Mounting and Soldering

Surface Mount Technology (SMT) machines accurately place LEDs and resistors onto the PCB. Automated soldering ensures strong electrical connections and minimal defects. For full spectrum strips, this step often involves mounting a mix of LED chips with different color temperatures or phosphor blends to cover the complete visible spectrum evenly.

4. Encapsulation and Coating

Encapsulation protects the LEDs from environmental factors such as moisture, dust, and mechanical shock. High-quality silicone or epoxy resins are used, especially for waterproof or outdoor-rated strips. The encapsulation must be optically clear and UV resistant to maintain light quality over time.

5. Cutting, Testing, and Finishing

After assembly, strips are cut into standard lengths (usually 5 meters) with designated cut points. Finishing includes adding connectors, adhesive backing, and protective covers. Each strip undergoes initial functional testing to verify electrical integrity and light output.

Quality Assurance and Control Frameworks

Ensuring consistent quality in full spectrum LED strip lighting is a multi-layered process aligned with international and regional standards, vital for B2B buyers targeting diverse markets.

Key International Quality Standards:

- ISO 9001: This globally recognized quality management system standard ensures that manufacturers implement robust processes for continuous improvement, defect prevention, and customer satisfaction.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), this certification confirms compliance with EU safety, health, and environmental requirements.

- RoHS (Restriction of Hazardous Substances): Ensures materials used are environmentally friendly and free from harmful substances like lead or mercury.

- UL Certification: Particularly relevant for North American markets but increasingly valued worldwide, UL marks verify product safety and performance.

- API Standards: While more common in industrial applications, some LED lighting manufacturers adopt specific API standards related to electrical components and safety.

Critical Quality Control Checkpoints

1. Incoming Quality Control (IQC):

Raw materials and components are inspected upon receipt. This includes verifying LED chip bin codes for color consistency, testing PCB material thickness and conductivity, and checking resin purity. IQC prevents substandard inputs from entering production.

2. In-Process Quality Control (IPQC):

During assembly, IPQC ensures solder joints meet strength and conductivity requirements, LED placement accuracy, and that no defects arise during encapsulation. Automated optical inspection (AOI) machines detect misalignments, solder bridges, and missing components.

3. Final Quality Control (FQC):

After assembly, FQC conducts comprehensive functional tests including:

- Electrical Testing: Verifying voltage, current draw, and power consumption to ensure operational safety and efficiency.

- Spectral Analysis: Using spectroradiometers to confirm the full spectrum light output meets specified color rendering index (CRI) and color temperature requirements.

- Durability Testing: Assessing waterproof ratings (IP65, IP67, IP68), thermal resistance, and mechanical flexibility.

- Lifespan Testing: Simulating extended use to detect early failures.

How B2B Buyers Can Verify Supplier Quality

For buyers in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance is essential to mitigate risks related to product failures, regulatory non-compliance, or shipment delays.

1. Supplier Audits:

On-site audits or virtual factory tours help assess manufacturing capabilities, quality management systems, and compliance with ISO 9001 or other certifications. Buyers should request documentation of process controls, equipment calibration, and employee training programs.

2. Quality Reports and Certificates:

Demand comprehensive test reports including batch-level spectral data, durability test outcomes, and certification copies (CE, RoHS, UL). These documents provide transparency and traceability.

3. Third-Party Inspections:

Engage independent inspection agencies to conduct pre-shipment inspections. These experts verify product conformity, packaging, and labeling compliance with import regulations, which vary by region—particularly critical for customs clearance in countries like South Africa or Spain.

4. Sample Testing:

Request samples for in-house or third-party lab testing before committing to large orders. Testing can validate claims on brightness, color accuracy, and operational lifespan under specific environmental conditions.

Quality Assurance Nuances for International Markets

Regulatory Variations:

While CE marking is essential for the European market, buyers in Africa or the Middle East might face additional local standards or import restrictions. For example, South African Bureau of Standards (SABS) certification may be required, and Middle Eastern countries often mandate Gulf Conformity Mark (G-Mark). Understanding these helps avoid shipment rejections and costly delays.

Environmental and Usage Conditions:

Regions like South America and the Middle East often experience high humidity, dust, or extreme temperatures. Buyers should prioritize LED strips with suitable IP ratings and thermal management features to ensure durability.

Warranty and After-Sales Support:

Given the logistical challenges in remote or emerging markets, choosing suppliers offering extended warranties (typically 2–5 years) and responsive technical support is critical to maintaining client satisfaction and reducing downtime.

Summary for B2B Buyers

- Understand the detailed manufacturing stages to assess supplier capability and product reliability.

- Ensure suppliers comply with international and regional quality standards relevant to your market.

- Implement rigorous quality verification protocols including audits, certification checks, and third-party inspections.

- Account for local environmental conditions and regulatory requirements when selecting full spectrum LED strip lighting.

- Prioritize suppliers with strong warranty terms and after-sales support to safeguard your investment.

By integrating these insights into your procurement strategy, B2B buyers across Africa, South America, the Middle East, and Europe can confidently source full spectrum LED strip lighting that meets stringent quality benchmarks and delivers consistent, high-performance lighting solutions.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for full spectrum led strip lighting Sourcing

Understanding the cost and pricing dynamics of full spectrum LED strip lighting is critical for international B2B buyers aiming to optimize procurement decisions. This section breaks down the key cost components, pricing influencers, and practical buyer tips to navigate the complexities of sourcing these advanced lighting solutions.

Key Cost Components in Full Spectrum LED Strip Lighting

-

Materials: The most significant cost driver, including high-quality LED chips (often from brands like Samsung or Cree), copper PCB boards for heat dissipation, phosphor coatings for full spectrum light output, and protective encapsulation materials. Premium raw materials directly affect light quality, durability, and color rendering.

-

Labor: Skilled labor is required for precise assembly, soldering, and testing of LED strips. Labor costs vary significantly by manufacturing location, impacting overall pricing.

-

Manufacturing Overhead: Includes factory utilities, equipment depreciation, and operational expenses. Efficient production lines and economies of scale can reduce these costs.

-

Tooling and Setup: Initial tooling for custom designs or specialized full spectrum formulations can add upfront costs. These are amortized over production volumes.

-

Quality Control (QC): Rigorous QC processes ensure consistent color temperature, brightness, and safety compliance. QC adds to cost but reduces returns and warranty claims.

-

Logistics and Shipping: Freight costs depend on shipment size, distance, and mode (air vs. sea). International buyers should factor in customs duties, import taxes, and local regulations, which vary by region.

-

Supplier Margin: Suppliers include their margin based on brand positioning, service level, and market competition. Margins can fluctuate with demand cycles.

Influential Factors Shaping Pricing

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically attract volume discounts. However, some suppliers maintain high MOQs, which can increase upfront investment for smaller buyers.

-

Specifications and Customization: Customized lengths, color temperatures, IP ratings, or special certifications (e.g., RoHS, CE, UL) increase unit costs. Buyers should balance customization needs with budget constraints.

-

Material Quality and Certifications: Certified, high-CRI full spectrum LEDs command premium pricing but offer superior performance and reliability—critical for sectors like horticulture, retail, or healthcare.

-

Supplier Reliability and Location: Established suppliers with proven track records and local or regional distribution centers often price higher but reduce risks related to delays or quality issues.

-

Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) affects who bears logistics costs and risks. Favorable payment terms (e.g., letters of credit, net 30/60) can improve cash flow management.

Practical Buyer Tips for International B2B Sourcing

-

Negotiate Beyond Price: Engage suppliers on warranty length, after-sales support, and replacement policies. These add value and reduce total cost of ownership (TCO).

-

Evaluate Total Cost of Ownership: Consider not only unit price but also installation costs, power consumption efficiency, lifespan, and maintenance. Full spectrum LED strips with higher upfront costs may deliver superior ROI through energy savings and longevity.

-

Leverage Regional Trade Agreements: Buyers in Africa, South America, the Middle East, and Europe should explore regional trade agreements or free trade zones to minimize tariffs and customs delays.

-

Request Samples and Certifications: Always request product samples and verify certificates to avoid costly quality issues later. Samples also help confirm color accuracy and brightness.

-

Factor Currency Fluctuations and Payment Risks: Use hedging strategies or work with suppliers offering flexible currency options to mitigate exchange rate volatility.

-

Plan for Logistics Lead Times: Account for longer transit times and potential customs clearance delays, especially when sourcing from Asia or distant manufacturing hubs.

Indicative Pricing Disclaimer

Pricing for full spectrum LED strip lighting varies widely based on specifications, order size, and supplier. Indicative wholesale prices typically range from $5 to $15 per meter, but buyers should obtain tailored quotes reflecting their project requirements and negotiation leverage.

By understanding these cost drivers and pricing variables, international B2B buyers can make informed decisions, ensuring cost-effective sourcing of high-quality full spectrum LED strip lighting tailored to their specific markets and applications.

Spotlight on Potential full spectrum led strip lighting Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘full spectrum led strip lighting’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for full spectrum led strip lighting

Key Technical Properties of Full Spectrum LED Strip Lighting

Understanding the critical technical specifications of full spectrum LED strip lighting empowers B2B buyers to make informed purchasing decisions, ensuring product performance aligns with project requirements.

-

Color Rendering Index (CRI):

CRI measures how accurately a light source reveals the true colors of objects compared to natural light. Full spectrum LED strips typically have a CRI of 90+ to replicate sunlight’s balanced spectrum. For buyers in retail, horticulture, or art display sectors, a high CRI ensures vibrant and natural color presentation, enhancing product appeal or plant growth. -

Spectral Distribution (Wavelength Range):

Full spectrum LEDs emit light across a broad range of wavelengths, often spanning 380 to 780 nanometers, covering UV to infrared. This wide spectral coverage is essential for applications like plant growth, health-focused lighting, and color-critical environments. Buyers should verify spectral data sheets to confirm the LED strip’s suitability for their specific needs. -

Luminous Flux (Lumens per Meter):

This indicates the brightness output of the LED strip. Full spectrum strips vary typically from 500 to over 1500 lumens per meter. Selecting the correct lumen output ensures adequate illumination without excess energy consumption, critical for large-scale installations across regions with varying power costs like Africa or Europe. -

Power Consumption (Watts per Meter):

Power rating affects operational costs and power supply requirements. Full spectrum LED strips usually consume between 7W to 20W per meter. Buyers should balance brightness needs with energy efficiency, especially in markets with high electricity tariffs or limited power infrastructure. -

Voltage and Length:

Common voltages are 12V and 24V DC. Higher voltage strips (24V) support longer continuous runs with reduced voltage drop, beneficial for extensive installations in commercial or architectural projects. Standard reel lengths (5m or 10m) simplify inventory planning and reduce waste. -

Material Quality and IP Rating:

The substrate and encapsulation materials impact durability and environmental resistance. High-grade copper PCBs improve heat dissipation and longevity. IP ratings (e.g., IP20 for indoor, IP65/IP67 for water resistance) guide buyers on suitability for humid or outdoor applications, crucial for diverse climates from the Middle East to South America.

Common Trade Terminology Explained

Navigating international B2B transactions for full spectrum LED strip lighting requires familiarity with key industry terms that affect procurement and logistics.

-

OEM (Original Equipment Manufacturer):

Refers to suppliers who produce LED strips that buyers can brand and sell under their own name. OEM arrangements offer customization options and cost advantages but require due diligence on quality standards. -

MOQ (Minimum Order Quantity):

The smallest quantity a supplier is willing to sell, often tied to production efficiency. Understanding MOQ helps buyers plan budgets and inventory, especially when managing multi-region distribution. -

RFQ (Request for Quotation):

A formal inquiry sent to suppliers requesting detailed pricing, lead times, and technical specifications. RFQs streamline supplier comparisons and are essential for transparent procurement processes. -

Incoterms (International Commercial Terms):

Standardized trade terms defining responsibilities and risks between buyers and sellers during shipment (e.g., FOB, CIF, DDP). Clarity on Incoterms prevents misunderstandings and helps buyers control costs and logistics across borders. -

Bin Codes:

Codes assigned to LED chips indicating specific binning in terms of brightness and color consistency. Buyers aiming for uniform lighting quality should specify bin codes to ensure batch consistency. -

Warranty Terms:

The supplier’s commitment regarding product lifespan and defect coverage, typically ranging from 2 to 5 years. Strong warranty policies reduce risk for large-scale investments and signal supplier confidence in product quality.

By mastering these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can confidently source full spectrum LED strip lighting that meets both performance and commercial expectations, optimizing value and minimizing risk.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the full spectrum led strip lighting Sector

Market Overview & Key Trends

The full spectrum LED strip lighting market is experiencing robust global growth driven by increasing demand for energy-efficient, customizable, and health-supportive lighting solutions. These lights, which replicate natural sunlight across the visible spectrum, are gaining traction in commercial, agricultural, healthcare, and retail sectors worldwide. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial to sourcing the right products efficiently.

Key Market Drivers:

- Energy Efficiency and Cost Savings: Full spectrum LED strips provide superior energy efficiency compared to traditional lighting, reducing operational costs—a major incentive for businesses in emerging markets like South Africa and Brazil.

- Health and Wellbeing Focus: There is growing adoption in healthcare, wellness centers, and office environments in Europe and the Middle East, where circadian lighting and visual comfort are prioritized.

- Agricultural Applications: In South America and parts of Africa, full spectrum LEDs are increasingly used in controlled-environment agriculture (CEA) for crop optimization, driving demand for high-quality, tunable lighting solutions.

- Smart Integration: IoT-enabled, programmable full spectrum strips offer enhanced control and automation, aligning with Industry 4.0 trends in European and Middle Eastern markets.

Emerging Sourcing and Technology Trends:

- Customization and Modularity: Buyers are seeking flexible solutions that can be tailored to specific wavelengths and intensities, allowing for precise application needs.

- Longer LED Lifespan and Improved CRI: Advanced chip technologies (e.g., Samsung, Cree) delivering high Color Rendering Index (CRI) values above 90 are becoming standard to ensure natural color perception.

- Supply Chain Localization: To mitigate global supply disruptions, companies in Europe and the Middle East are increasingly partnering with regional manufacturers or distributors, reducing lead times and logistics costs.

- Compliance and Certifications: Adherence to international standards such as CE, RoHS, and UL certifications is a must for buyers targeting multiple markets, ensuring product safety and reliability.

For B2B buyers, leveraging these insights can optimize procurement strategies by balancing cost, quality, and delivery reliability while aligning with local market expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration in the full spectrum LED strip lighting sector, especially for international buyers committed to reducing environmental footprints and promoting ethical business practices. LED lighting already offers a significant sustainability advantage through lower energy consumption and longer operational life compared to incandescent or fluorescent alternatives.

Environmental Impact and Green Certifications:

- Energy Consumption: Full spectrum LEDs consume up to 80% less energy, translating into lower carbon emissions—a compelling benefit for markets with increasing energy costs or stringent emissions regulations, such as the EU.

- Materials and Waste Reduction: Buyers should prioritize products using eco-friendly materials, such as lead-free solder and recyclable components, to minimize hazardous waste.

- Certifications to Watch: Look for suppliers offering Energy Star, TCO Certified, or EPEAT ratings, which ensure compliance with environmental and performance standards.

Ethical Supply Chains:

- Traceability: Ethical sourcing requires transparency across the supply chain, including conflict-free sourcing of raw materials like rare earth elements and responsible labor practices.

- Supplier Audits: Leading companies conduct regular social and environmental audits of their suppliers to ensure adherence to labor laws, fair wages, and safe working conditions.

- Circular Economy Initiatives: Some suppliers now offer take-back or recycling programs for end-of-life LED strips, supporting circular economy principles.

For B2B buyers in Africa, South America, the Middle East, and Europe, embedding sustainability into procurement policies not only fulfills regulatory and corporate social responsibility requirements but also enhances brand reputation and customer loyalty.

Evolution and Historical Context

The evolution of full spectrum LED strip lighting reflects broader advances in LED technology and growing awareness of lighting’s impact on human health and productivity. Originally, LED strips were predominantly single-color solutions used for decorative purposes. Over the past decade, innovation has driven the integration of multiple LED chips capable of emitting a wide range of wavelengths, closely mimicking natural sunlight.

Early adopters in Europe and North America pioneered the use of full spectrum LEDs in horticulture and circadian lighting applications, setting a precedent for other regions. As manufacturing costs declined and technology matured, markets in Africa, South America, and the Middle East began embracing these solutions for diverse sectors including commercial interiors, healthcare, and smart city infrastructure.

This historical progression underscores the importance of selecting full spectrum LED strips that combine cutting-edge technology with proven durability and performance—critical factors for international B2B buyers aiming to future-proof their investments.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of full spectrum led strip lighting

-

How can I effectively vet suppliers of full spectrum LED strip lighting to ensure reliability and quality?

Start by verifying supplier certifications such as CE, RoHS, and UL compliance, which indicate adherence to international safety and environmental standards. Request detailed product datasheets and samples for quality assessment, focusing on lumen output, CRI values, and build materials like copper PCB boards. Check supplier references and customer reviews, particularly from buyers in your region (Africa, South America, Middle East, Europe) to gauge service responsiveness and after-sale support. Engaging suppliers with transparent warranty policies (2–5 years minimum) and clear communication channels helps mitigate risks in international transactions. -

Is customization of full spectrum LED strip lighting feasible for bulk orders, and what should I consider?

Yes, many manufacturers offer customization options including LED density, strip length, color temperature tuning, waterproof ratings, and connector types. For international buyers, clarify customization capabilities upfront and request prototypes to verify specifications. Keep in mind that custom orders typically require higher minimum order quantities (MOQs) and longer lead times. Also, confirm if the supplier can provide technical documentation and certifications for the customized products, which is essential for regulatory compliance in your target markets. -

What are typical minimum order quantities (MOQs) and lead times for full spectrum LED strip lighting in international B2B transactions?

MOQs vary widely depending on supplier scale and customization level, commonly ranging from 500 to 5,000 meters per SKU. Lead times usually span 3 to 8 weeks, influenced by order complexity and shipping logistics. For buyers in Africa, South America, the Middle East, and Europe, it’s critical to factor in additional time for customs clearance and potential delays. Negotiate flexible MOQs for trial orders when possible, and confirm production schedules with your supplier to align delivery with project timelines. -

Which payment terms and methods are recommended when importing full spectrum LED strip lighting internationally?

Secure payment methods such as Letters of Credit (L/C), Escrow services, or PayPal (for smaller orders) are advisable to protect both parties. Suppliers often require a 30% deposit upfront with the balance paid upon shipment or receipt of documents. For new suppliers, consider third-party inspection or escrow arrangements to reduce risk. Establish clear payment milestones tied to production and delivery stages, and verify bank details carefully to avoid fraud. Transparent payment terms strengthen trust and facilitate smoother transactions across continents. -

What quality assurance (QA) measures should I insist upon for full spectrum LED strip lighting products?

Demand that suppliers conduct rigorous in-house testing for color consistency, lumen output, power consumption, and waterproof ratings (IP65/IP67). Ask for independent third-party test reports or factory audits where possible. Implement pre-shipment inspections by a trusted local agent to verify order accuracy and product integrity. Continuous QA monitoring is especially crucial for full spectrum LEDs, where precise color rendering and uniformity impact end-use effectiveness. Insist on traceability of components and compliance with your destination country’s safety standards.

-

How do international certifications affect the import of full spectrum LED strip lighting into regions like Africa, South America, the Middle East, and Europe?

Certifications such as CE (Europe), RoHS (global), UL (North America), and local standards (e.g., SABS in South Africa) are often mandatory or highly recommended for market entry. These certifications demonstrate product safety, electromagnetic compatibility, and environmental compliance, reducing customs clearance issues. Buyers should request up-to-date certificates from suppliers and verify their authenticity. Non-certified products risk rejection at ports, fines, or inability to sell legally. Investing in certified full spectrum LED strips ensures smoother cross-border trade and customer confidence. -

What logistics considerations should B2B buyers keep in mind when importing full spectrum LED strip lighting?

Plan for shipping options balancing cost and speed—sea freight is economical for large volumes but slower, while air freight suits urgent smaller shipments. Account for packaging that protects delicate LED strips from moisture, static, and physical damage during transit. Coordinate with freight forwarders experienced in handling electronics and understand import duties, taxes, and customs procedures specific to your country. Establish clear Incoterms (e.g., FOB, CIF) with suppliers to clarify responsibilities and avoid unexpected costs or delays. -

How should disputes or quality issues be managed with international suppliers of full spectrum LED strip lighting?

Establish clear contractual terms detailing quality standards, inspection rights, and remedies for non-compliance before placing orders. Maintain thorough documentation of communications, contracts, and shipment records. If defects arise, initiate dispute resolution by providing evidence (photos, test results) and requesting corrective actions such as replacement or refund. Engage third-party inspection agencies or mediation services if direct negotiation stalls. Building long-term relationships with reputable suppliers and using escrow payments can minimize disputes and foster mutual trust.

Strategic Sourcing Conclusion and Outlook for full spectrum led strip lighting

Strategic sourcing of full spectrum LED strip lighting offers international B2B buyers a powerful opportunity to enhance project outcomes while optimizing costs and supply reliability. Key takeaways for buyers from Africa, South America, the Middle East, and Europe include prioritizing suppliers with proven quality certifications, robust warranty terms, and strong after-sales support to mitigate risks in large-scale deployments. Understanding product specifications such as color rendering index (CRI), lumens per meter, voltage options, and environmental ratings ensures that lighting solutions align precisely with diverse application needs—from commercial retail environments to hospitality and industrial settings.

Emphasizing strategic partnerships with manufacturers and distributors who demonstrate supply chain transparency and flexibility will enable buyers to navigate fluctuating market demands and regional logistics complexities more effectively. Leveraging bulk purchasing power not only drives cost savings but also guarantees consistency in lighting quality across multiple installations, a critical factor for brand and operational coherence.

Looking ahead, the full spectrum LED strip lighting market is poised for continued innovation, driven by advances in energy efficiency, smart controls, and customizable lighting effects. International buyers are encouraged to engage proactively with trusted suppliers and invest in scalable solutions that future-proof their lighting infrastructure while supporting sustainability goals. Taking a strategic, informed sourcing approach today lays the foundation for competitive advantage and long-term success in evolving global markets.