Guide to Flexible Neon

- Introduction: Navigating the Global Market for flexible neon

- Understanding flexible neon Types and Variations

- Key Industrial Applications of flexible neon

- Strategic Material Selection Guide for flexible neon

- In-depth Look: Manufacturing Processes and Quality Assurance for flexible neon

- Comprehensive Cost and Pricing Analysis for flexible neon Sourcing

- Spotlight on Potential flexible neon Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for flexible neon

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the flexible neon Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of flexible neon

- Strategic Sourcing Conclusion and Outlook for flexible neon

Introduction: Navigating the Global Market for flexible neon

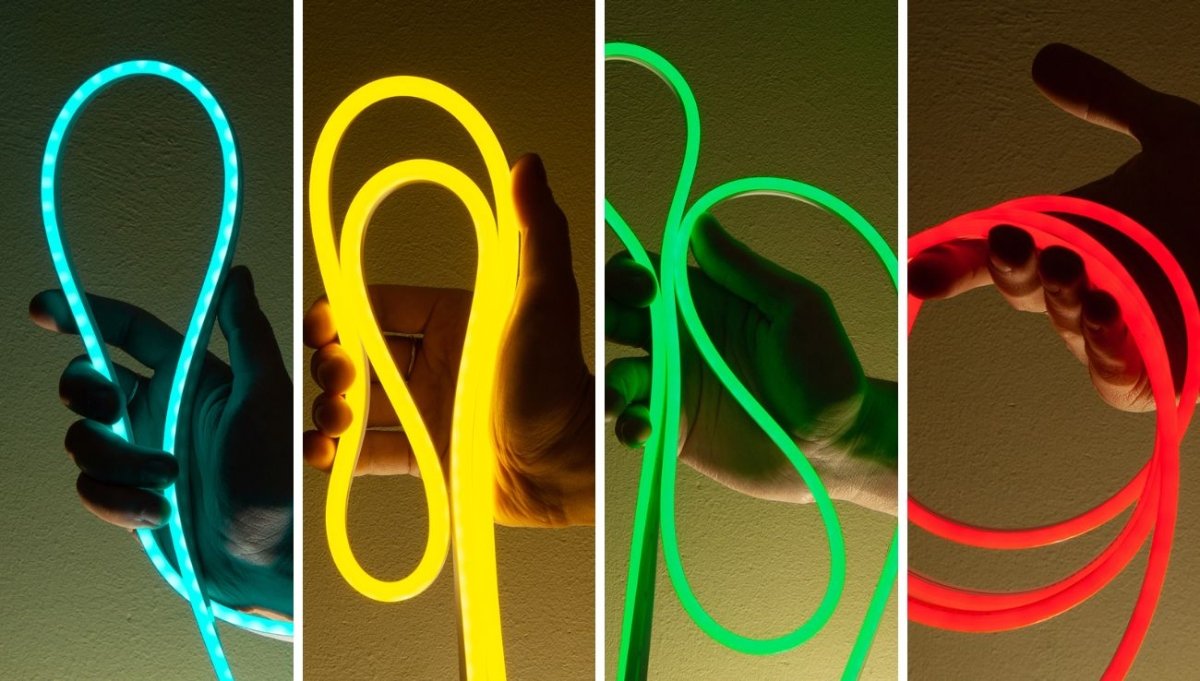

Flexible neon lighting is revolutionizing the way businesses across the globe approach visual communication and ambiance creation. Its unique combination of flexibility, energy efficiency, and vibrant illumination makes it an indispensable asset for industries ranging from retail and hospitality to architecture and event management. For international B2B buyers—especially those operating in dynamic markets within Africa, South America, the Middle East, and Europe—leveraging flexible neon solutions can unlock new opportunities for brand differentiation and customer engagement.

This guide offers a thorough exploration of the flexible neon landscape, providing critical insights into the various types and materials available, from LED-based neon flex strips to customizable configurations tailored to specific business needs. We delve into manufacturing processes and quality control measures that ensure durability and performance, essential for maintaining brand reputation in diverse climates and regulatory environments.

Understanding how to evaluate suppliers is paramount, particularly when sourcing from regions like Vietnam or Mexico, where production capabilities and standards may vary widely. This guide also breaks down cost structures, helping procurement professionals balance budget constraints with quality expectations. Furthermore, an analysis of current market trends empowers buyers to anticipate shifts in technology and consumer preferences.

By addressing frequently asked questions and common challenges, this resource equips international buyers with actionable knowledge to make confident, informed decisions. Whether upgrading existing signage or embarking on new lighting projects, businesses will find strategic guidance to navigate the complexities of the global flexible neon market effectively and sustainably.

Understanding flexible neon Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LED Neon Flex Strips | Flexible, bendable LED strips mimicking traditional neon glow | Retail signage, architectural accents, events | Pros: Energy-efficient, durable, customizable; Cons: Slightly lower color vibrancy than glass neon |

| Silicone Neon Tubes | Soft, flexible silicone tubes housing LED lights | Outdoor signage, hospitality, branded displays | Pros: Weather-resistant, robust, long lifespan; Cons: Higher upfront cost compared to PVC alternatives |

| PVC Neon Rope Lights | Flexible PVC tubes with embedded LEDs, cost-effective | Temporary displays, event lighting, indoor decor | Pros: Affordable, lightweight; Cons: Less durable and less bright than silicone or LED flex |

| RGB Flexible Neon | Multi-color LED neon strips with programmable color control | Dynamic advertising, entertainment venues, exhibitions | Pros: Versatile color options, programmable effects; Cons: More complex installation and higher cost |

| Neon Effect Acrylic Tubes | Acrylic tubes with LED backlighting to simulate neon glow | Indoor retail, decorative lighting, exhibitions | Pros: Lightweight, modern look; Cons: Less authentic neon appearance, limited flexibility |

LED Neon Flex Strips

LED Neon Flex Strips are the most popular type of flexible neon lighting, designed to replicate the appearance of traditional neon signs using energy-efficient LEDs encased in a flexible, durable material. They are ideal for B2B buyers seeking long-lasting, customizable solutions for retail signage, architectural accents, and event decoration. Key considerations include verifying LED quality, flexibility for complex shapes, and supplier certifications to ensure durability and color consistency. Their low power consumption and ease of installation make them especially attractive for markets prioritizing sustainability and cost efficiency.

Silicone Neon Tubes

Silicone Neon Tubes consist of flexible silicone housing that protects internal LED lights, offering superior weather resistance and durability. These tubes are well-suited for outdoor signage, hospitality environments, and branded displays requiring high reliability in harsh climates common in regions such as the Middle East and parts of Africa. Buyers should weigh the higher initial investment against the long-term benefits of reduced maintenance and extended lifespan. Ensuring compliance with local safety and electrical standards is critical when importing these products.

PVC Neon Rope Lights

PVC Neon Rope Lights are a budget-friendly flexible neon option, featuring LEDs embedded in lightweight PVC tubing. Their affordability and ease of handling make them popular for temporary displays, indoor decor, and event lighting in emerging markets across South America and Europe. However, buyers must be aware of their relatively lower durability and brightness compared to silicone or LED flex alternatives. Evaluating supplier quality and warranty terms is essential to mitigate risks associated with cheaper materials.

RGB Flexible Neon

RGB Flexible Neon incorporates multi-color LEDs with programmable controllers, enabling dynamic lighting effects and color changes. This type is highly favored by entertainment venues, dynamic advertising campaigns, and exhibition spaces seeking to captivate audiences with vibrant, customizable displays. B2B buyers should assess the compatibility of control systems with their existing infrastructure and consider the technical support offered by suppliers to handle installation complexity and maintenance.

Neon Effect Acrylic Tubes

Neon Effect Acrylic Tubes use acrylic materials combined with LED backlighting to simulate the glow of traditional neon. These are typically employed in indoor retail settings and decorative applications where a lightweight, modern aesthetic is preferred over authentic neon vibrancy. Buyers should consider the trade-off between visual appeal and flexibility since acrylic tubes are less adaptable to complex shapes. Understanding the quality of light diffusion and supplier customization capabilities is vital for achieving the desired effect.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of flexible neon

| Industry/Sector | Specific Application of flexible neon | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Storefront signage and interior accent lighting | Enhances brand visibility, attracts customers with dynamic lighting | Customization capabilities, durability under varied climates, energy efficiency |

| Hospitality & Events | Decorative lighting for hotels, restaurants, and events | Creates immersive ambiance, flexible design for themed environments | Compliance with safety standards, ease of installation, color consistency |

| Architecture & Interior Design | Architectural highlights and mood lighting | Adds aesthetic value, highlights design elements, energy savings | Flexibility of material, waterproofing, supplier design support |

| Food & Beverage | Kitchen and bar lighting, under-cabinet illumination | Improves operational lighting, enhances customer experience | Heat resistance, hygiene compliance, ease of cleaning |

| Advertising & Exhibitions | Custom signage and branded displays | Captures attention, supports brand messaging, portable and reusable | Lightweight materials, color accuracy, modular design for transport |

Retail & Commercial Applications

Flexible neon lighting is extensively used in retail environments for storefront signage and interior accents. Its adaptability allows businesses to create eye-catching signs and decorative elements that can be tailored to regional preferences and cultural aesthetics across Africa, South America, the Middle East, and Europe. For international buyers, sourcing neon flex with strong customization options and robust durability against varying weather conditions is critical. Energy efficiency also matters, as it reduces operational costs in markets with high electricity prices or unstable supply.

Hospitality & Events

In hospitality, flexible neon lights are prized for their ability to transform spaces such as hotels, restaurants, and event venues with vibrant, customizable lighting solutions. These lights can be shaped to fit thematic designs, enhancing guest experience and brand identity. B2B buyers should prioritize suppliers who ensure compliance with international safety standards, offer consistent color quality, and provide easy installation systems, which are especially important for event managers and hotel chains operating in multiple countries with different regulations.

Architecture & Interior Design

Architects and interior designers leverage flexible neon lighting to accentuate building features and create mood lighting that elevates spaces. The flexibility of the material allows intricate installations that traditional lighting cannot achieve. For buyers in diverse climates—from humid coastal cities in South America to arid Middle Eastern environments—waterproofing and material resilience are vital. Suppliers offering technical support for bespoke designs help ensure smooth project execution and client satisfaction.

Food & Beverage Industry

Flexible neon lighting finds practical use in kitchens and bars, providing under-cabinet illumination and accent lighting that enhances both functionality and ambiance. For B2B buyers in the foodservice sector, selecting neon flex that withstands heat, moisture, and frequent cleaning is essential to meet hygiene standards. In regions like Vietnam or Mexico, where kitchens may face high humidity, sourcing products with proven durability and certifications for food safety compliance can prevent costly replacements and downtime.

Advertising & Exhibitions

The advertising and exhibition sector benefits from flexible neon’s portability and ease of customization, making it ideal for creating branded displays and temporary signage. These lighting solutions enable companies to capture attention at trade shows or promotional events with vibrant, reusable designs. Buyers should focus on lightweight materials for ease of transport, precise color matching to maintain brand integrity, and modular construction to simplify setup and breakdown—critical factors for international buyers managing logistics across continents.

Related Video: Everyday Applications of Magnets

Strategic Material Selection Guide for flexible neon

When selecting materials for flexible neon lighting solutions, international B2B buyers must carefully consider performance characteristics, manufacturing feasibility, and regional compliance standards. The choice of material directly influences durability, energy efficiency, installation ease, and overall product appeal. Below is an analysis of four common materials used in flexible neon production, highlighting their properties, pros and cons, and relevance for buyers in Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is widely used as the outer sheath for flexible neon strips due to its excellent electrical insulation, chemical resistance, and moderate temperature tolerance (typically up to 60-70°C). It offers good flexibility and resistance to UV radiation when properly formulated.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it ideal for large-scale production. It provides adequate protection against moisture and abrasion but can become brittle over time, especially under intense UV exposure or extreme cold. Additionally, PVC is less environmentally friendly compared to newer alternatives, which may affect buyers with sustainability mandates.

Impact on Application: PVC sheathing works well in indoor and semi-outdoor applications, such as retail signage and architectural accents. However, in harsh outdoor environments typical in parts of Africa and the Middle East, enhanced UV-stabilized grades or alternative materials may be preferred to ensure longevity.

International Buyer Considerations: Compliance with international standards like ASTM D1784 (PVC compounds) and DIN EN ISO 4892 (UV resistance) is crucial. Buyers from Europe and South America often require RoHS and REACH compliance, while African and Middle Eastern markets may prioritize flame retardancy certifications. Sourcing from suppliers who can provide detailed material certifications is recommended.

Thermoplastic Polyurethane (TPU)

Key Properties: TPU offers superior flexibility, abrasion resistance, and elasticity compared to PVC. It withstands a wider temperature range (-40°C to 90°C) and exhibits excellent resistance to oils, greases, and weathering.

Pros & Cons: TPU’s durability and clarity make it ideal for premium flexible neon products requiring intricate bends and long service life. However, TPU is more expensive and complex to process than PVC, which can increase manufacturing lead times and costs.

Impact on Application: TPU is favored in high-end architectural lighting, outdoor signage, and environments with mechanical stress or exposure to chemicals. Its robustness suits the demanding climates of South America’s tropical zones and the Middle East’s desert conditions.

International Buyer Considerations: TPU materials must meet standards such as ISO 527 for tensile properties and ISO 868 for hardness. Buyers in Europe and Vietnam often seek suppliers with ISO 9001 quality management certification and compliance with environmental regulations. For African and Middle Eastern markets, TPU’s flame retardancy and UV resistance certifications are critical.

Silicone Rubber

Key Properties: Silicone rubber is prized for its exceptional thermal stability (operating temperatures from -60°C to 200°C), flexibility, and outstanding resistance to UV radiation, ozone, and moisture. It also offers excellent electrical insulation.

Pros & Cons: Silicone’s premium properties ensure longevity and performance in extreme environments, but it comes at a higher cost and requires specialized manufacturing techniques. Its softness can sometimes limit mechanical protection unless reinforced.

Impact on Application: Silicone is the material of choice for flexible neon applications exposed to extreme temperatures or outdoor conditions, such as architectural facades in Europe or outdoor event lighting in harsh climates. Its inertness also makes it suitable for food-related or medical advertising environments.

International Buyer Considerations: Compliance with FDA regulations (for food contact), UL 94 flame ratings, and ISO 10993 biocompatibility standards may be relevant depending on application. Buyers from Europe and South America often prioritize eco-friendly silicone grades with low VOC emissions. For Middle Eastern markets, certifications for heat resistance and flame retardancy are essential.

Polyethylene (PE)

Key Properties: PE is a lightweight, chemically resistant polymer with good electrical insulating properties and moderate flexibility. It typically withstands temperatures up to 80°C and offers decent moisture barrier qualities.

Pros & Cons: PE is relatively inexpensive and easy to process but is less flexible and durable than TPU or silicone. It has limited UV resistance unless specially treated, which can restrict outdoor use.

Impact on Application: PE is commonly used in cost-sensitive projects where moderate flexibility and protection are sufficient, such as indoor retail signage or temporary event lighting. Its limited UV resistance makes it less suitable for prolonged outdoor exposure in regions like Africa or the Middle East without additional protective coatings.

International Buyer Considerations: Buyers should verify compliance with ASTM D3350 (PE pipe and tubing specifications) and regional environmental standards. In Europe and South America, recycled PE options are gaining traction for sustainability reasons. For buyers in Africa and the Middle East, UV-stabilized PE grades with flame retardant additives are preferred.

| Material | Typical Use Case for flexible neon | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Indoor and semi-outdoor signage, retail displays | Cost-effective, good electrical insulation | UV degradation risk, less eco-friendly | Low |

| Thermoplastic Polyurethane (TPU) | Outdoor signage, high-flex applications, harsh environments | Excellent flexibility and abrasion resistance | Higher cost and complex manufacturing | Medium |

| Silicone Rubber | Extreme temperature and outdoor applications, food-related lighting | Superior thermal stability and UV resistance | High cost, requires specialized manufacturing | High |

| Polyethylene (PE) | Cost-sensitive indoor signage, temporary event lighting | Lightweight, chemical resistant | Limited UV resistance, less flexible | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for flexible neon

Flexible neon lighting has become an essential component for modern signage and architectural lighting due to its versatility, energy efficiency, and aesthetic appeal. For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance protocols is critical to ensuring product reliability, compliance, and long-term value. This section provides a detailed overview of the typical manufacturing workflow, key quality control (QC) standards, and practical guidance for verifying supplier quality.

Manufacturing Process of Flexible Neon Lighting

The production of flexible neon lighting involves a series of meticulously controlled stages designed to transform raw materials into durable, customizable LED neon strips that mimic traditional neon aesthetics while enhancing flexibility and safety.

1. Material Preparation

- Raw Materials: The process begins with sourcing high-grade LED chips, flexible PCB substrates, silicone or PVC encapsulation materials, and power supply components. The choice of materials impacts durability, brightness, and flexibility.

- Quality Verification: Incoming raw materials undergo initial quality checks (Incoming Quality Control – IQC) to verify electrical characteristics, tensile strength of flexible substrates, and chemical purity of encapsulants.

- Customization Inputs: For bespoke orders, color filters, specific LED wavelengths, or unique strip dimensions are prepared based on client specifications.

2. Forming and Assembly

- LED Mounting: Surface mount technology (SMT) machines place LEDs precisely on flexible printed circuit boards (FPCBs). This automated process ensures consistent spacing and alignment critical for uniform illumination.

- Encapsulation: The LED-mounted FPCBs are then coated or overmolded with flexible silicone or PVC materials, providing waterproofing, UV resistance, and mechanical protection while maintaining bendability.

- Wiring and Connectors: Power leads and connectors are attached, often with options for plug-and-play compatibility or custom wiring lengths. This step includes soldering and sealing to maintain electrical integrity.

- Curing and Shaping: Encapsulation materials are cured (e.g., heat or UV curing) to solidify the protective layers. The strips are then formed into coils or cut to length as per design requirements.

3. Finishing and Packaging

- Surface Treatment: Additional surface treatments may be applied to enhance scratch resistance or improve light diffusion.

- Marking and Labeling: Each batch or individual strip is marked with batch numbers, voltage ratings, and safety certifications.

- Packaging: Flexible neon strips are carefully rolled or laid flat with protective layers to prevent deformation during transit. Packaging often includes anti-static and moisture-resistant features to preserve product quality.

Quality Assurance Framework and Standards

For B2B buyers targeting global markets, understanding relevant quality standards and QC checkpoints is vital to mitigate risks such as product failure, non-compliance, or shipment delays.

International Quality Standards

- ISO 9001: The foundational quality management system standard, ISO 9001 ensures that manufacturers maintain consistent production processes, document control, and continuous improvement practices. Buyers should request certification evidence to confirm supplier adherence.

- CE Marking: Mandatory for products sold within the European Economic Area (EEA), CE certification guarantees compliance with health, safety, and environmental protection legislation. It is especially relevant for electrical components like flexible neon.

- RoHS Compliance: Restriction of Hazardous Substances (RoHS) compliance is critical for electronics, limiting toxic materials such as lead and mercury. This is often required by European and international buyers.

- UL and ETL Listings: Particularly important for North American and some Middle Eastern markets, these certifications attest to electrical safety and fire hazard standards.

- API and IEC Standards: Depending on the application (e.g., architectural lighting, industrial signage), buyers might require adherence to specific industry standards from the American Petroleum Institute (API) or the International Electrotechnical Commission (IEC).

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Verification of raw materials and components before production to prevent defects from entering the assembly line.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including LED placement accuracy, encapsulation thickness, and electrical continuity tests.

- Final Quality Control (FQC): Comprehensive testing of finished products, including visual inspections, functional testing, and packaging checks.

Common Testing Methods

- Electrical Testing: Verifying voltage, current, and power consumption to ensure product meets design specifications and safety margins.

- Environmental Testing: Simulated exposure to moisture, UV light, and temperature extremes to assess durability in diverse climates—critical for buyers in Africa, the Middle East, and South America.

- Flexibility and Durability Tests: Repeated bending and twisting cycles to confirm that the neon strips maintain functionality without cracking or LED failure.

- Color Consistency Measurement: Spectrophotometers or colorimeters assess uniformity of light output and color temperature to meet branding requirements.

- Safety Tests: Insulation resistance, leakage current, and fire retardancy are evaluated to comply with regional electrical safety regulations.

Verifying Supplier Quality: Best Practices for B2B Buyers

International buyers face unique challenges in ensuring supplier quality due to geographic distance, cultural differences, and varying regulatory environments. The following strategies can help mitigate risks:

1. Supplier Audits and Factory Visits

Conducting on-site audits is the most direct method to evaluate manufacturing capabilities and QC processes. Key audit focus areas include:

- Verification of ISO 9001 and other certifications.

- Inspection of production equipment and cleanliness.

- Review of QC documentation and traceability systems.

- Interviews with production and QC personnel.

For buyers unable to visit physically, hiring local third-party inspection agencies or consultants is a viable alternative.

2. Requesting Detailed QC Reports and Certifications

Buyers should require suppliers to provide:

- Batch-level test reports showing electrical, mechanical, and environmental test results.

- Material certificates confirming compliance with RoHS and other standards.

- Photographic or video evidence of production and testing stages.

- Certificates of conformity for CE, UL, or other relevant marks.

Reviewing these documents helps verify supplier claims and supports regulatory compliance in the buyer’s country.

3. Third-Party Inspections and Testing

Engaging independent laboratories or inspection bodies to perform random sampling and testing before shipment offers an added layer of assurance. This is particularly important for buyers in emerging markets such as Vietnam or Mexico, where local regulatory enforcement may be evolving.

4. Understanding Regional QC Nuances

- Africa and South America: Import regulations may require additional certifications or customs inspections. Buyers should confirm supplier familiarity with local requirements to avoid delays.

- Middle East: Electrical safety and quality standards can vary significantly; sourcing from suppliers with GCC or SASO certifications can facilitate smoother market entry.

- Europe: Stringent environmental and safety regulations necessitate suppliers with full CE compliance and RoHS adherence.

- Vietnam and Mexico: These growing manufacturing hubs increasingly demand adherence to international standards, but buyers should verify consistency through audits and sample testing.

Summary Recommendations for B2B Buyers

- Prioritize suppliers with ISO 9001 certification and relevant electrical safety marks (CE, UL).

- Insist on comprehensive IQC, IPQC, and FQC documentation to track quality throughout production.

- Utilize third-party inspections and lab testing to independently verify product quality, especially for first-time suppliers.

- Understand and account for regional certification requirements to streamline importation and market compliance.

- Engage suppliers early in the design phase to ensure manufacturability and QC feasibility for custom flexible neon orders.

By thoroughly assessing manufacturing processes and quality assurance protocols, international B2B buyers can confidently source flexible neon lighting solutions that meet performance expectations, regulatory standards, and budgetary constraints across diverse markets.

Related Video: Glenroy’s Flexible Packaging Manufacturing Process

Comprehensive Cost and Pricing Analysis for flexible neon Sourcing

Understanding the Cost Components in Flexible Neon Sourcing

When sourcing flexible neon lighting solutions, B2B buyers must dissect the cost structure carefully to optimize procurement strategies and ensure competitive pricing.

- Materials: The primary cost driver includes high-quality LED strips, flexible silicone or PVC housing, and electronic components. Premium materials that enhance durability, color vibrancy, and energy efficiency typically come at a higher price but reduce long-term operational costs.

- Labor: Skilled labor is essential for cutting, assembling, and wiring flexible neon strips, especially for customized or intricate designs. Labor costs vary significantly by manufacturing location, impacting overall pricing.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and quality control processes. Efficient factories with modern automation can lower overhead, passing savings to buyers.

- Tooling and Setup: Custom designs require tooling and setup expenses for molds, cutting dies, or programming flexible circuits. These costs are often amortized over order volumes but increase unit cost for small or prototype runs.

- Quality Control (QC): Rigorous QC ensures compliance with safety standards, color consistency, and product lifespan. Certifications such as CE, RoHS, or UL add value but may raise costs due to additional testing.

- Logistics and Shipping: International freight, customs duties, and insurance significantly affect landed cost, especially for buyers from Africa, South America, the Middle East, and Europe. Choosing optimal Incoterms (e.g., FOB, CIF, DDP) is critical to managing these expenses.

- Supplier Margin: Finally, supplier profit margins reflect market positioning, brand reputation, and after-sales support. Buyers should balance cost with supplier reliability and service quality.

Key Price Influencers for Flexible Neon Products

Pricing for flexible neon solutions is dynamic and influenced by several critical factors:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock volume discounts, reducing per-unit cost. However, buyers from emerging markets must balance MOQ requirements against inventory and cash flow constraints.

- Specifications and Customization: Custom colors, lengths, and integrated control systems increase complexity and price. Off-the-shelf standard products often offer better pricing but less branding flexibility.

- Material Quality and Certifications: Higher-grade LEDs, weatherproof materials, and international safety certifications command premium pricing but ensure durability and regulatory compliance.

- Supplier Location and Capabilities: Manufacturers in Asia (e.g., Vietnam) may offer cost advantages due to lower labor costs, while European suppliers may excel in quality and certification but at higher prices.

- Incoterms and Shipping Routes: The choice of Incoterms affects who bears shipping risk and costs. For example, DDP (Delivered Duty Paid) simplifies import processes for buyers in Africa or South America but may carry a premium compared to FOB (Free on Board).

- Currency Fluctuations: Exchange rate volatility can impact pricing for international buyers, necessitating careful financial planning and possible hedging strategies.

Practical Tips for International B2B Buyers

To maximize value and cost-efficiency when sourcing flexible neon products, buyers should consider the following:

- Negotiate Beyond Price: Engage suppliers on payment terms, lead times, warranty, and after-sales service. Bundling orders or committing to long-term partnerships can unlock better terms.

- Assess Total Cost of Ownership (TCO): Evaluate initial purchase price alongside installation, energy consumption, maintenance, and replacement costs. Flexible neon’s energy efficiency often results in long-term savings.

- Leverage Local Partners: Collaborate with local agents or distributors familiar with import regulations and logistics to reduce delays and unexpected costs.

- Request Sample Orders: Before committing to large orders, test samples for quality, color accuracy, and durability, especially when dealing with new suppliers or unfamiliar markets.

- Understand Regional Import Duties and Compliance: Ensure products meet local electrical and safety standards to avoid customs holds or penalties. In some regions, certifications can affect both price and market acceptance.

- Be Wary of Extremely Low Prices: Prices significantly below market norms may indicate substandard materials or hidden costs. Verify supplier credentials and request detailed quotations.

Indicative Pricing Disclaimer

Prices for flexible neon lighting products vary widely based on specifications, order size, and supplier location. As a general reference, standard flexible neon LED strips range from approximately $10 to $30 per meter FOB Asia, with customization and certification adding to costs. Buyers should request detailed quotes tailored to their project requirements to obtain accurate pricing.

By thoroughly analyzing cost components and price influencers, international B2B buyers can strategically source flexible neon lighting solutions that balance quality, compliance, and budget—empowering their businesses to deliver visually compelling and energy-efficient lighting installations worldwide.

Spotlight on Potential flexible neon Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘flexible neon’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for flexible neon

Critical Technical Properties of Flexible Neon

Understanding the technical specifications of flexible neon is crucial for international B2B buyers to ensure product quality, compatibility, and long-term performance. Here are the key properties to consider:

-

Material Grade (Silicone or PVC): Flexible neon lighting typically uses either high-grade silicone or PVC for the outer casing. Silicone offers superior flexibility, heat resistance, and durability, making it ideal for outdoor or high-temperature environments. PVC is more cost-effective but less resistant to UV and extreme conditions. For buyers, selecting the right material grade impacts the lifespan and maintenance costs of the lighting solution.

-

IP Rating (Ingress Protection): The IP rating indicates the product’s resistance to dust and water. Common ratings for flexible neon include IP65 (dust-tight and water jets) and IP67 (dust-tight and temporary immersion). For businesses operating in humid or outdoor environments (e.g., outdoor retail signage in Africa or Middle East), higher IP ratings ensure reliability and reduce replacement frequency.

-

Voltage & Power Consumption: Flexible neon uses low voltage LED technology, commonly 12V or 24V DC, which enhances safety and energy efficiency compared to traditional neon. Power consumption is measured in watts per meter (W/m). Lower power consumption translates to cost savings in energy bills, a critical consideration for large-scale installations in retail or architectural projects.

-

Color Consistency and Brightness (Luminous Intensity): LED neon flex should maintain uniform color and brightness along its entire length. Variations can affect brand aesthetics and visual impact. Buyers should request data sheets or samples to verify luminous intensity (measured in lumens per meter) and color temperature, especially when color branding is a priority.

-

Bend Radius and Flexibility: The minimum bend radius specifies how tightly the neon strip can be curved without damage. A smaller bend radius allows for more intricate designs and installation in confined spaces, beneficial for customized signage or interior décor projects. This flexibility also affects installation time and cost.

-

Operating Temperature Range: This property defines the ambient temperature range within which the flexible neon operates safely. Typical ranges are -20°C to 50°C or higher for premium grades. Buyers in regions with extreme climates (e.g., hot Middle East or humid tropical zones in South America) must ensure the product can withstand local environmental conditions.

Common Trade Terms in Flexible Neon Sourcing

Navigating international procurement requires familiarity with standard trade terminology to streamline communication and avoid misunderstandings:

-

OEM (Original Equipment Manufacturer): Refers to suppliers who manufacture products that can be rebranded and sold by another company. B2B buyers often seek OEM partnerships for custom flexible neon designs, ensuring exclusivity and brand differentiation.

-

MOQ (Minimum Order Quantity): The smallest quantity a supplier is willing to sell per order. MOQs vary widely depending on the supplier and product complexity. Buyers from emerging markets should negotiate MOQs that align with budget and storage capacities to optimize cash flow.

-

RFQ (Request for Quotation): A formal document sent to suppliers to obtain pricing, lead times, and terms for specific products. A well-prepared RFQ specifying technical requirements (e.g., IP rating, color specs) enables accurate and comparable supplier responses.

-

Incoterms (International Commercial Terms): Standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms helps buyers from Africa, South America, and other regions manage costs and risks effectively.

-

Lead Time: The period between placing an order and receiving the goods. Lead time affects project schedules and inventory planning. Buyers should confirm lead times upfront and consider potential delays due to customs or logistics.

-

Certification and Compliance: Terms such as CE (Conformité Européenne), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories) indicate compliance with safety and environmental standards. For European and Middle Eastern buyers, ensuring certifications is critical for legal importation and market acceptance.

By focusing on these technical properties and mastering relevant trade terminology, international B2B buyers can confidently source flexible neon products that meet performance expectations and align with their market requirements. This knowledge supports informed negotiations, reduces procurement risks, and fosters successful supplier partnerships across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the flexible neon Sector

Market Overview & Key Trends

The flexible neon sector is experiencing robust growth globally, driven by rising demand for customizable, energy-efficient lighting solutions across diverse industries such as retail, hospitality, architecture, and events. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly adopting flexible neon due to its versatility and modern aesthetic appeal. Markets in emerging economies like Vietnam and Mexico are witnessing accelerated adoption as urbanization and commercial development fuel demand for innovative signage and interior lighting.

Key market dynamics include the shift from traditional glass neon to flexible LED neon strips, which offer enhanced durability, safety, and energy efficiency. This transition is supported by technological advancements enabling intricate, customizable designs that cater to branding and experiential marketing needs. Suppliers are focusing on modular, bendable neon strips that can be tailored in color, length, and brightness, facilitating faster project turnaround and reduced installation complexity.

Sourcing trends reveal a growing preference for suppliers who provide comprehensive services—from design consultation to after-sales support—enabling buyers to streamline procurement and reduce risk. Cross-border trade is facilitated by digital platforms that showcase product catalogs and certifications, improving transparency and supplier evaluation. For buyers in Africa and South America, sourcing flexible neon products locally or regionally is becoming strategic to minimize lead times and import costs.

Furthermore, the sector is influenced by rising demand for smart lighting integration, where flexible neon products are compatible with IoT systems and remote controls, enhancing operational efficiency. Buyers must stay abreast of these innovations to leverage competitive advantages and meet evolving end-user expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to procurement decisions in the flexible neon industry. Compared to traditional neon lighting, flexible LED neon consumes significantly less energy, reducing carbon footprints for businesses and their clients. This energy efficiency aligns well with global sustainability goals and regulatory pressures prevalent in Europe and parts of the Middle East, where stringent energy use and waste management standards apply.

Ethical sourcing practices are critical, especially as flexible neon manufacturing often involves complex supply chains spanning multiple countries. Buyers should prioritize suppliers who demonstrate transparency in material sourcing, labor conditions, and environmental impact. Certifications such as RoHS (Restriction of Hazardous Substances), REACH compliance, and ISO 14001 environmental management are strong indicators of responsible manufacturing practices. These certifications assure buyers of reduced toxic emissions and safer working environments.

Additionally, the use of eco-friendly materials—such as recyclable silicone casings and lead-free LEDs—enhances product sustainability. Flexible neon suppliers are increasingly adopting circular economy principles, including take-back programs and recycling initiatives, which can be leveraged by B2B buyers to meet corporate social responsibility (CSR) objectives.

For buyers in regions like Africa and South America, where environmental regulations may be evolving, sourcing from certified suppliers offers a pathway to meet future compliance requirements proactively while supporting sustainable development goals.

Evolution of Flexible Neon Lighting: A B2B Perspective

Flexible neon lighting represents a significant evolution from the classic neon tubes first popularized in the early 20th century. Initially, neon signage relied on fragile glass tubes filled with inert gases, requiring high voltage and specialized installation. While iconic, these traditional neon signs presented challenges in durability, energy consumption, and safety.

The advent of LED technology in the late 20th century catalyzed a shift toward flexible neon alternatives. Combining LED efficiency with pliable, durable materials like silicone, flexible neon strips emerged as a safer, more versatile solution. This innovation unlocked new possibilities for complex, custom designs that traditional neon could not achieve economically or practically.

Today, flexible neon lighting is recognized not just as a lighting solution but as a strategic branding and design tool in B2B markets. Its evolution reflects broader trends in digital manufacturing, sustainability, and user-centric design, making it a preferred choice for international buyers seeking modern, efficient, and impactful lighting solutions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of flexible neon

-

How can I effectively vet suppliers of flexible neon lighting for international B2B purchases?

Begin by verifying the supplier’s business license, certifications (such as ISO or CE), and product quality standards to ensure compliance with international regulations. Request detailed product specifications and sample units to evaluate build quality, flexibility, and LED performance. Check client references and reviews, focusing on buyers from your region (Africa, South America, Middle East, Europe) to assess reliability in similar markets. Confirm the supplier’s experience with international shipping and customs documentation to minimize delays and unexpected costs. -

What customization options are typically available for flexible neon products, and how should I specify them?

Flexible neon suppliers usually offer customization in color, length, brightness, mounting options, and power requirements. Specify your exact design needs, including voltage compatibility, IP rating for weather resistance, and any branding elements such as logos or shapes. Providing detailed technical drawings or digital mock-ups helps ensure alignment. Clarify if custom orders affect lead times or minimum order quantities (MOQs), and confirm the supplier’s prototyping process before full production. -

What are common minimum order quantities (MOQs) and lead times for flexible neon orders, especially for buyers in emerging markets?

MOQs vary by supplier but typically range from 50 to 500 units or meters, depending on customization complexity. Lead times generally span 3 to 8 weeks, factoring in design approval, production, and shipping. Buyers in Africa, South America, and the Middle East should account for additional transit time and customs clearance delays. Negotiating flexible MOQs or batch shipments can help manage inventory and cash flow. Early communication with suppliers about forecasted volumes is essential to secure production slots.

Illustrative Image (Source: Google Search)

-

Which payment terms and methods are advisable for international B2B transactions involving flexible neon products?

Common payment methods include Telegraphic Transfer (T/T), Letter of Credit (L/C), PayPal, or escrow services. For new suppliers, consider partial upfront payment (e.g., 30%) with the balance upon shipment or after passing inspection to mitigate risk. Established buyers might negotiate net terms (30–60 days). Always confirm currency exchange rates and bank charges upfront. Using trade finance solutions or working with trusted payment platforms can enhance security and cash flow management. -

What quality assurance practices and certifications should I expect from a reputable flexible neon supplier?

Reliable suppliers adhere to quality management systems such as ISO 9001 and provide product certifications like CE, RoHS, or UL for safety and environmental compliance. Expect comprehensive testing reports covering LED lifespan, color consistency, waterproof ratings (IP65 or higher for outdoor use), and electrical safety. Request factory inspection reports or third-party audits if possible. Establish clear quality checkpoints during production and before shipment to prevent defects and ensure product consistency. -

How can I optimize logistics and shipping for flexible neon imports to reduce costs and delivery times?

Choose suppliers experienced in international freight forwarding who provide consolidated shipping and handle customs clearance documentation. Opt for sea freight for bulk orders to reduce costs, but air freight may be justified for urgent deliveries despite higher expenses. Verify packaging standards to avoid damage during transit. Work with freight forwarders familiar with your destination country’s import regulations to prevent delays. Planning shipments around local holidays and customs schedules can further streamline delivery.

Illustrative Image (Source: Google Search)

-

What strategies should I employ to resolve disputes or quality issues with flexible neon suppliers in different regions?

Maintain clear and documented communication from order inception through delivery, including contracts specifying product specifications, warranties, and dispute resolution mechanisms. If quality issues arise, promptly request evidence such as photos or videos and involve third-party inspection agencies if necessary. Engage suppliers in good faith negotiations first; escalate unresolved disputes through trade mediation platforms or chambers of commerce in your region. Leveraging payment terms that hold final balances until satisfactory delivery can also incentivize supplier compliance. -

Are there specific considerations for sourcing flexible neon lighting in regions like Africa, South America, the Middle East, and Europe?

Each region has unique import regulations, power supply standards (voltage and frequency), and environmental requirements. For example, buyers in Europe must prioritize RoHS compliance and CE marking, while Middle Eastern markets may demand higher IP ratings due to climate conditions. Understanding local electrical codes and working with suppliers who can adapt products accordingly is crucial. Additionally, anticipate longer shipping durations to remote or less-developed logistics hubs and plan inventory accordingly to avoid stockouts.

Strategic Sourcing Conclusion and Outlook for flexible neon

Flexible neon lighting represents a transformative opportunity for B2B buyers seeking to elevate brand visibility and design innovation across diverse markets such as Africa, South America, the Middle East, and Europe. By leveraging the unique benefits of flexible neon—such as energy efficiency, customization potential, durability, and ease of installation—businesses can create compelling signage and lighting solutions that resonate with local and international audiences alike.

Key strategic sourcing takeaways include:

– Prioritizing suppliers with proven expertise in customizable LED neon flex products that meet international quality and safety standards.

– Evaluating cost structures with a focus on long-term energy savings and maintenance reduction to optimize total cost of ownership.

– Considering the adaptability of flexible neon to various industry applications—from retail and hospitality to architecture and events—to maximize value across projects.

– Ensuring transparent communication with manufacturers to align on design specifications, delivery timelines, and after-sales support.

Looking ahead, the demand for sustainable, visually striking lighting solutions will continue to grow globally. International buyers, especially from emerging markets such as Vietnam and Mexico, are encouraged to adopt a strategic sourcing approach that embraces innovation while mitigating risks. By partnering with forward-thinking manufacturers and leveraging flexible neon’s versatility, businesses can secure a competitive edge and future-proof their lighting investments in an increasingly dynamic global marketplace.