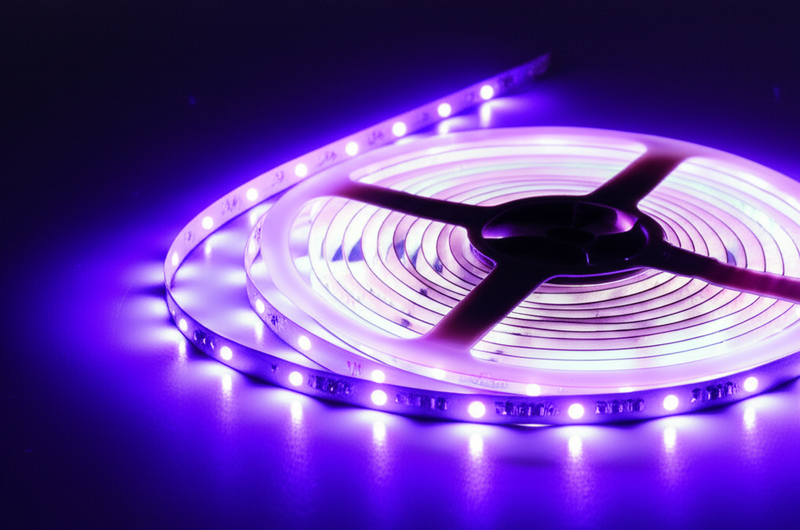

Introduction: Navigating the Global Market for ultraviolet led strip lights

Ultraviolet (UV) LED strip lights have rapidly emerged as a transformative technology across diverse industries, offering unparalleled efficiency, durability, and precision in applications ranging from sterilization and counterfeit detection to advanced manufacturing and horticulture. For international B2B buyers, especially those operating in dynamic markets such as Africa, South America, the Middle East, and Europe—including countries like Italy and Thailand—understanding the nuances of this technology is crucial for capitalizing on growth opportunities and ensuring competitive advantage.

This guide provides a comprehensive roadmap to the global ultraviolet LED strip light market, empowering buyers with actionable insights to make informed sourcing decisions. It delves into the different types of UV LED strips available, exploring wavelength variations and their specific industrial uses. You will gain clarity on key materials and components that impact product performance and longevity, as well as critical manufacturing and quality control standards that differentiate reliable suppliers from less dependable ones.

Additionally, the guide offers a detailed analysis of pricing structures, market trends, and regional supply chain considerations that affect procurement strategies. By addressing frequently asked questions and common challenges faced by international buyers, this resource aims to reduce risk and streamline the purchasing process. Whether you are seeking to enhance production capabilities, innovate product offerings, or expand your supplier network, this guide equips you with the knowledge to navigate the complexities of the global UV LED strip light market confidently and successfully.

Understanding ultraviolet led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| UVA LED Strip Lights | Emit UVA spectrum (320-400 nm), flexible, low heat | Inspection, counterfeit detection, curing | + Energy-efficient, versatile; – Limited germicidal use |

| UVB LED Strip Lights | Emit UVB spectrum (280-320 nm), higher energy output | Medical therapy, plant growth enhancement | + Effective for therapeutic uses; – Shorter lifespan, higher cost |

| UVC LED Strip Lights | Emit UVC spectrum (100-280 nm), germicidal properties | Disinfection, sterilization in healthcare | + Powerful sterilization; – Expensive, safety precautions needed |

| Dual-Wavelength UV Strips | Combine UVA and UVC or UVB for multifunctionality | Comprehensive sterilization and inspection | + Multifunctional; – Complexity increases cost and maintenance |

| Waterproof UV LED Strips | Encased in waterproof materials, suitable for wet areas | Outdoor UV curing, aquarium lighting, industrial | + Durable in harsh environments; – Slightly higher price |

UVA LED Strip Lights

UVA LED strips are the most commonly used UV strips, emitting light in the 320-400 nm range. Their flexibility and low heat generation make them ideal for applications like counterfeit detection, fluorescence inspection, and UV curing of adhesives and inks. For B2B buyers, these strips offer a balance of efficiency and cost-effectiveness. When sourcing, prioritize suppliers who provide consistent wavelength accuracy and robust adhesive backing for easy installation in manufacturing or quality control lines.

UVB LED Strip Lights

UVB strips operate within 280-320 nm and deliver higher energy output than UVA. They are primarily used in medical phototherapy and horticulture to stimulate plant growth. Buyers should consider the shorter operational lifespan and higher upfront costs associated with UVB LEDs, but the therapeutic and agricultural benefits can justify the investment. Ensure suppliers comply with relevant health and safety standards, especially for medical equipment manufacturing.

UVC LED Strip Lights

UVC strips emit the shortest UV wavelengths (100-280 nm), offering potent germicidal effects essential for disinfection and sterilization in healthcare, water treatment, and food processing industries. These strips require careful handling due to potential health risks from direct exposure. International buyers must verify supplier certifications and product safety features, such as shielding and automatic shut-off mechanisms, to meet regulatory requirements in Europe, the Middle East, and beyond.

Dual-Wavelength UV Strips

Combining two UV spectrums, typically UVA with UVC or UVB, these strips provide multifunctional capabilities for simultaneous sterilization and inspection tasks. They are suited for advanced industrial processes requiring versatile UV exposure. B2B buyers should evaluate the complexity of integration and maintenance costs, balancing these against the value of multifunctionality in their production workflows.

Waterproof UV LED Strips

Encased in protective materials like silicone or epoxy, waterproof UV strips are designed for environments exposed to moisture or chemicals, such as outdoor curing, aquarium lighting, or industrial cleaning. For buyers targeting outdoor or harsh environments in Africa or South America, durability and IP ratings are critical. Selecting products with certified waterproofing and UV resistance ensures longevity and reduces replacement frequency, optimizing total cost of ownership.

Related Video: Denoising Diffusion Probabilistic Models | DDPM Explained

Key Industrial Applications of ultraviolet led strip lights

| Industry/Sector | Specific Application of Ultraviolet LED Strip Lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical & Healthcare | Sterilization and disinfection of medical equipment and surfaces | Enhances hygiene, reduces infection risk, and complies with health regulations | Certification for medical-grade UV output, durability, and safety standards; energy efficiency |

| Food & Beverage | UV curing for packaging and surface sterilization | Extends shelf life, ensures food safety, and improves packaging durability | Compliance with food safety standards, wavelength specificity, and ease of integration |

| Electronics Manufacturing | UV curing of adhesives and coatings during PCB and component assembly | Speeds up production, improves product reliability, and reduces downtime | Uniform UV intensity, wavelength matching adhesive requirements, and thermal management |

| Water Treatment | Disinfection of water in industrial and municipal systems | Provides chemical-free sterilization, reduces pathogens, and lowers operational costs | Waterproof and corrosion-resistant design, power efficiency, and lifespan |

| Automotive & Aerospace | UV curing of paints and coatings on vehicle parts | Ensures fast curing times, high-quality finishes, and durability | High-intensity UV output, compatibility with coating materials, and robust build quality |

Pharmaceutical & Healthcare:

Ultraviolet LED strip lights are extensively used for sterilizing medical instruments, surfaces, and air in hospitals and laboratories. This application addresses the critical need to reduce hospital-acquired infections by providing a chemical-free, rapid disinfection method. Buyers from Africa, South America, the Middle East, and Europe should prioritize medical-grade certifications and ensure the UV wavelength and intensity meet stringent sterilization efficacy standards. Energy efficiency and compliance with regional health regulations are also essential to optimize operational costs and safety.

Food & Beverage:

In the food industry, UV LED strip lights are applied for curing packaging adhesives and sterilizing surfaces to prevent microbial contamination. This technology helps extend product shelf life and maintain hygiene without using harsh chemicals. International buyers must consider the UV wavelength specificity to avoid damaging food products and ensure compliance with food safety regulations such as EU standards or Codex Alimentarius. Integration ease and energy consumption are important for maintaining production line efficiency.

Electronics Manufacturing:

UV LED strip lights play a vital role in curing adhesives and coatings on printed circuit boards (PCBs) and electronic components. This accelerates production cycles and enhances product durability by ensuring strong bonding and coating quality. For B2B buyers, uniform UV intensity and wavelength compatibility with specific adhesives are critical to achieving consistent curing results. Thermal management features in the LED strips are necessary to prevent overheating and maintain manufacturing precision.

Water Treatment:

Ultraviolet LED strip lights are increasingly used in water treatment facilities for disinfecting water without chemicals, effectively eliminating bacteria and viruses. This method reduces operational costs and environmental impact. Buyers should focus on sourcing waterproof, corrosion-resistant UV LED strips with long lifespans and high power efficiency, especially in regions with high humidity or saline water environments. Compliance with local water safety standards is vital for successful implementation.

Automotive & Aerospace:

In automotive and aerospace sectors, UV LED strip lights are utilized for curing paints and coatings on vehicle and aircraft parts, ensuring quick drying times and durable finishes. This application improves production throughput and end-product quality. Buyers must ensure the UV LED strips provide high-intensity output compatible with the specific coating materials used. Robust construction to withstand industrial environments and certification for use in regulated manufacturing processes are key considerations for international procurement.

Related Video: How to make an Ultraviolet (UV) LED Circuit?

Strategic Material Selection Guide for ultraviolet led strip lights

Polycarbonate (PC)

Key Properties:

Polycarbonate is known for its excellent impact resistance and high-temperature tolerance, typically up to 115°C. It offers good UV resistance when specially treated, and its inherent flame retardancy is beneficial for safety compliance. PC also exhibits moderate chemical resistance, suitable for environments with occasional exposure to solvents or cleaning agents.

Pros & Cons:

Polycarbonate’s durability and clarity make it ideal for protective covers on UV LED strips. It is relatively lightweight and easy to mold, facilitating complex designs. However, untreated PC can yellow over time under prolonged UV exposure, potentially diminishing light output. Manufacturing complexity is moderate, with costs positioned in the mid-range.

Impact on Application:

PC is suitable for applications requiring robust physical protection, such as industrial or outdoor installations where mechanical impact or environmental stress is a concern. Its moderate chemical resistance suits general-purpose uses but may be less ideal for harsh chemical environments.

International Buyer Considerations:

Buyers from Europe (Italy) and the Middle East should verify compliance with EN 62262 (IK rating for impact protection) and UL 94 flame retardancy standards. African and South American markets may prioritize cost-effective variants with local certifications. Polycarbonate’s compatibility with ASTM D638 tensile testing and DIN 53455 impact resistance standards facilitates quality assurance across regions.

Silicone Rubber

Key Properties:

Silicone rubber offers excellent flexibility, high thermal stability (up to 200°C), and outstanding resistance to UV radiation and ozone. It is chemically inert and highly resistant to moisture and many corrosive substances, making it ideal for harsh environments.

Pros & Cons:

Its flexibility allows for easy installation in curved or irregular surfaces, enhancing design versatility. Silicone’s superior weather resistance ensures longevity in outdoor and industrial settings. However, silicone materials typically incur higher manufacturing costs and can be more challenging to process, impacting lead times and pricing.

Impact on Application:

Silicone rubber is preferred for waterproof and dustproof UV LED strip lights, especially in outdoor or marine applications common in Middle Eastern and African markets. Its chemical inertness makes it suitable for pharmaceutical or food industry uses, which are growing sectors in Europe and South America.

International Buyer Considerations:

Compliance with ASTM D2240 (durometer hardness) and ISO 37 (tensile properties) is crucial. Buyers from Thailand and Italy should ensure materials meet RoHS and REACH regulations for environmental safety. The high cost may be justified by durability in regions with extreme climates or stringent hygiene standards.

Aluminum Alloy

Key Properties:

Aluminum alloys are widely used as substrates or heat sinks due to excellent thermal conductivity (up to 205 W/m·K) and corrosion resistance when anodized. They withstand high temperatures and mechanical stress, providing structural support and heat dissipation.

Pros & Cons:

Aluminum’s lightweight nature and recyclability are advantageous for sustainable manufacturing. It enables efficient thermal management, critical for UV LED longevity. However, aluminum components can increase overall product cost and require precise machining, raising manufacturing complexity.

Impact on Application:

Ideal for high-power UV LED strips used in industrial curing, sterilization, or printing applications prevalent in South America and Europe. Aluminum’s corrosion resistance suits humid or coastal environments, relevant to buyers in Africa and the Middle East.

International Buyer Considerations:

Buyers should seek compliance with ASTM B209 (aluminum sheet standards) and DIN 17611 for alloy specifications. European clients often demand anodized finishes meeting ISO 7599 for corrosion resistance. The material’s recyclability aligns with growing environmental regulations in all target regions.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a versatile thermoplastic with good chemical resistance and moderate temperature tolerance (up to 60°C). It offers inherent flame retardancy and can be formulated for flexibility or rigidity depending on additives.

Pros & Cons:

PVC is cost-effective and easy to manufacture, making it attractive for large-scale production. However, its lower heat tolerance limits use in high-temperature applications, and prolonged UV exposure can cause brittleness unless stabilized. Environmental concerns over PVC additives and disposal are increasingly scrutinized.

Impact on Application:

PVC is suitable for indoor UV LED strip lights where temperature and environmental stress are controlled. It is commonly used in decorative or retail lighting in emerging markets across Africa and South America due to cost sensitivity.

International Buyer Considerations:

Buyers should ensure compliance with ASTM D1784 for PVC material classification and check for RoHS compliance due to restrictions on hazardous substances. European and Middle Eastern buyers may prefer alternatives due to stricter environmental regulations, while African and South American buyers benefit from its affordability.

| Material | Typical Use Case for ultraviolet led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Protective covers and housings in industrial/outdoor settings | High impact resistance and flame retardancy | Susceptible to yellowing under UV without treatment | Med |

| Silicone Rubber | Waterproof, flexible strips for outdoor/marine and hygienic environments | Excellent UV/weather resistance and flexibility | Higher manufacturing cost and complexity | High |

| Aluminum Alloy | Heat sinks and structural components in high-power industrial applications | Superior thermal conductivity and corrosion resistance | Increased cost and machining complexity | High |

| PVC | Indoor decorative or retail lighting with controlled environments | Cost-effective and easy to manufacture | Limited heat tolerance and UV degradation risk | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for ultraviolet led strip lights

Ultraviolet (UV) LED strip lights are specialized lighting products designed for applications ranging from disinfection and curing to counterfeit detection. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance protocols behind these products is crucial to ensuring reliability, compliance, and long-term value.

Manufacturing Processes of Ultraviolet LED Strip Lights

The production of UV LED strip lights involves several critical stages, each demanding precision and adherence to industry standards. The key phases include material preparation, forming, assembly, and finishing.

1. Material Preparation

Material preparation lays the foundation for product quality. Manufacturers source high-purity semiconductor materials, typically gallium nitride (GaN) or aluminum gallium nitride (AlGaN), which form the core of UV LED chips. The substrates (commonly sapphire or silicon carbide) must be defect-free to ensure consistent light emission.

Flexible printed circuit boards (PCBs) are prepared using copper-clad laminates with appropriate thickness and thermal properties to support UV LEDs and withstand heat dissipation. High-quality phosphor coatings, encapsulants, and adhesives are selected to enhance UV light transmission and protect components from environmental damage.

2. Forming and Chip Fabrication

The UV LED chips are fabricated through epitaxial growth, photolithography, etching, and metallization processes. Precision laser cutting and dicing separate individual LED chips from wafers.

For strip lights, chips are mounted onto flexible PCBs using automated pick-and-place machines. Advanced soldering techniques such as reflow soldering ensure strong electrical and mechanical connections without damaging the sensitive UV chips.

3. Assembly

Assembly integrates the LED chips with other strip components, including resistors, connectors, and protective coatings. Manufacturers often apply silicone or epoxy encapsulants to shield LEDs from moisture, dust, and mechanical stress.

Flexible strips are cut and shaped according to customer specifications, with attention to maintaining uniform light output and electrical continuity. Some producers embed additional features like dimming controls or waterproof layers depending on end-use requirements.

4. Finishing and Packaging

Final finishing involves trimming, cleaning, and applying protective films or coatings to enhance durability. Labels and certification marks are affixed in compliance with export regulations.

Packaging is designed to minimize static, mechanical shocks, and humidity during transit. For international buyers, especially those importing into regions with high humidity or temperature variations, packaging quality is a critical consideration to prevent damage.

Quality Assurance Protocols and Industry Standards

Robust quality assurance (QA) is essential to guarantee UV LED strip lights meet performance, safety, and regulatory benchmarks. Buyers should prioritize suppliers who implement comprehensive QA systems aligned with international and regional standards.

Key International Standards

- ISO 9001: This globally recognized quality management system standard ensures consistent manufacturing processes, traceability, and continuous improvement. Suppliers certified under ISO 9001 demonstrate commitment to quality and customer satisfaction.

- CE Marking: Mandatory for products entering the European market, CE certification verifies compliance with EU safety, health, and environmental protection requirements.

- RoHS (Restriction of Hazardous Substances): Ensures products are free from hazardous materials like lead, mercury, and cadmium, essential for European and many other international markets.

- UL and ETL Certifications: Particularly relevant for buyers in regions influenced by North American standards, these certifications confirm electrical safety.

- API or Other Industry-Specific Marks: For specialized applications (e.g., medical or industrial UV curing), additional certifications may apply.

Quality Control Checkpoints

Manufacturers typically implement a multi-tiered QC system encompassing:

- Incoming Quality Control (IQC): Inspection and testing of raw materials and components before entering production. This prevents defective parts from compromising the product.

- In-Process Quality Control (IPQC): Ongoing monitoring during assembly, including solder joint inspections, LED chip placement accuracy, and electrical testing.

- Final Quality Control (FQC): Comprehensive testing of finished strip lights, covering parameters such as UV wavelength accuracy, luminous intensity, power consumption, and mechanical integrity.

Common Testing Methods

- Spectral Analysis: Ensures UV LEDs emit the correct wavelength, critical for application effectiveness.

- Electrical Testing: Voltage, current, and power consumption are measured to verify efficiency and safety.

- Thermal Imaging: Identifies hotspots or heat dissipation issues that could shorten LED lifespan.

- Environmental Stress Testing: Includes humidity, temperature cycling, and vibration tests to simulate real-world conditions.

- Lifespan and Reliability Testing: Accelerated aging tests predict long-term performance.

Verifying Supplier Quality Control: Practical Guidance for B2B Buyers

For international buyers, particularly from Africa, South America, the Middle East, and Europe, verifying supplier quality is a multi-faceted process that extends beyond certifications.

Supplier Audits and Factory Inspections

Conducting on-site audits or commissioning third-party inspection agencies to review manufacturing facilities is highly recommended. Audits should assess:

- Production environment cleanliness and control

- Equipment calibration and maintenance records

- Staff training and process adherence

- Documentation and traceability systems

These inspections provide direct insight into operational rigor and quality culture.

Reviewing Quality Documentation

Request detailed quality control reports, including:

- Incoming material inspection records

- In-process testing logs

- Final product test results

- Certification copies (ISO, CE, RoHS, etc.)

Cross-checking these documents helps confirm consistency and compliance.

Utilizing Third-Party Testing and Inspection Services

Independent testing laboratories can validate product claims on UV wavelength, output intensity, and safety. Third-party inspection services can perform pre-shipment inspections, ensuring order accuracy and packaging integrity.

QC and Certification Nuances for Different Regions

Understanding regional regulatory requirements and market expectations is vital for seamless importation and product acceptance.

- Africa: Regulatory frameworks vary widely; buyers should verify local compliance requirements and focus on supplier adherence to ISO 9001 and CE standards to facilitate customs clearance and market acceptance.

- South America: Countries like Brazil and Argentina have specific electrical safety and environmental standards. RoHS compliance and local certification may be necessary.

- Middle East: Markets such as the UAE and Saudi Arabia emphasize product safety and energy efficiency. CE marking and UL certification are often recognized and preferred.

- Europe (e.g., Italy): Stringent adherence to CE, RoHS, and REACH regulations is mandatory. Buyers should ensure suppliers provide full documentation and support for compliance audits.

- Asia (e.g., Thailand): While local standards exist, many buyers import products meeting international certifications. Quality assurance aligned with ISO 9001 and CE is typically sufficient.

Summary for B2B Buyers

- Demand transparency: Insist on detailed process documentation and QC reports.

- Prioritize certified suppliers: ISO 9001, CE, and RoHS are minimum quality benchmarks.

- Leverage third-party audits: Independent verification mitigates risk.

- Understand regional specifics: Tailor quality expectations to local regulatory environments.

- Assess packaging and logistics: Ensure products arrive undamaged and fully functional.

By thoroughly evaluating manufacturing processes and quality assurance protocols, international B2B buyers can confidently select UV LED strip light suppliers that deliver reliable, compliant, and high-performance products tailored to their market needs.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for ultraviolet led strip lights Sourcing

Understanding the cost structure and pricing dynamics of ultraviolet (UV) LED strip lights is critical for international B2B buyers aiming to optimize procurement strategies and ensure competitive pricing. This analysis breaks down the essential cost components, pricing influencers, and practical buyer tips tailored to markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in UV LED Strip Light Production

-

Materials

The primary cost driver is the quality of raw materials, including UV LED chips, flexible PCB substrates, phosphor coatings, adhesives, and protective coatings. UV LEDs require specialized semiconductor materials that are generally more expensive than visible-light LEDs due to their complex manufacturing processes. -

Labor

Labor costs vary significantly by manufacturing location. Countries with lower labor costs can offer more competitive pricing, but buyers should weigh this against quality standards and lead times. Assembly of UV LED strips often involves delicate manual processes, especially when custom lengths or configurations are involved. -

Manufacturing Overhead

This includes factory utilities, equipment depreciation, and administrative expenses. Advanced manufacturing techniques for UV LEDs—such as precision soldering and cleanroom environments—increase overhead costs. -

Tooling and Setup

Custom orders or small batch runs may incur higher tooling and setup fees, as specialized molds, dies, or programming for automated assembly lines are required. These costs are amortized over production volumes. -

Quality Control (QC)

Rigorous QC processes are essential given the critical application of UV LED strips in sterilization, curing, and inspection. QC costs include testing equipment, labor for inspections, and certification processes (e.g., CE, RoHS, IEC standards). -

Logistics and Freight

Shipping UV LED strips internationally involves considerations such as packaging to prevent electrostatic discharge and damage, freight costs (air vs. sea), customs duties, and import taxes. Lead times and shipping reliability also impact total cost. -

Supplier Margin

Manufacturers and distributors factor in profit margins, which fluctuate based on market competition, order size, and exclusivity of product specifications.

Influencing Factors on Pricing

-

Order Volume and Minimum Order Quantity (MOQ)

Larger orders typically reduce per-unit costs due to economies of scale. Buyers in Africa and South America may face higher MOQs that can challenge smaller businesses, necessitating negotiation or collaboration with other buyers. -

Product Specifications and Customization

Custom wavelengths, waterproofing, flexible lengths, and integrated control features increase complexity and cost. Buyers must balance unique requirements against standard product offerings to optimize cost-efficiency. -

Material Quality and Certifications

High-grade UV LEDs with longer lifespans and stable output command premium pricing. Certifications that validate safety and performance for international markets (e.g., CE for Europe) add to costs but reduce regulatory risks. -

Supplier Reputation and Location

Established suppliers with proven quality and reliability may charge higher prices but offer lower risk. Proximity to major shipping hubs can reduce logistics expenses and lead times, an important consideration for buyers in the Middle East and Europe. -

Incoterms and Payment Terms

Incoterms (e.g., FOB, CIF, DDP) significantly impact the buyer’s responsibility for shipping costs and risks. Understanding these terms helps buyers manage total landed costs and negotiate better terms.

Practical Tips for International B2B Buyers

-

Negotiate MOQs and Pricing Tiers

Engage suppliers early to discuss flexible MOQs or volume discounts, especially when consolidating orders from multiple buyers or projects. -

Evaluate Total Cost of Ownership (TCO)

Beyond unit price, consider durability, warranty, energy consumption, and potential maintenance costs. Investing in higher-quality UV LED strips may reduce replacement and operational expenses over time. -

Leverage Local Regulations and Certifications

Ensure the UV LED strips meet regional standards to avoid costly delays and rejections at customs. Buyers in Europe and the Middle East should prioritize compliance with CE and IEC standards. -

Consider Logistics Strategies

For buyers in Africa and South America, sea freight is cost-effective but slower; air freight may be justified for urgent projects. Work with freight forwarders experienced in electronics to optimize packaging and customs clearance. -

Monitor Currency Fluctuations and Payment Methods

Currency volatility can affect pricing. Using secure payment methods with favorable exchange rates can protect against unexpected cost increases.

Indicative Pricing Disclaimer

Pricing for ultraviolet LED strip lights varies widely depending on specifications, order volume, supplier location, and global market conditions. The figures discussed here are indicative and should be validated with multiple suppliers. Buyers are encouraged to request detailed quotations and conduct thorough cost-benefit analyses before finalizing procurement decisions.

By thoroughly understanding these cost and pricing factors, international B2B buyers can negotiate better deals, minimize risks, and achieve sustainable procurement outcomes in the dynamic market for ultraviolet LED strip lights.

Spotlight on Potential ultraviolet led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ultraviolet led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ultraviolet led strip lights

Understanding the critical technical properties and trade terminology associated with ultraviolet (UV) LED strip lights is essential for international B2B buyers seeking reliable, cost-effective, and compliant solutions. This knowledge ensures informed procurement decisions, minimizes risks, and facilitates smoother supplier negotiations.

Key Technical Properties of Ultraviolet LED Strip Lights

-

Wavelength (nm)

UV LED strips emit light within specific wavelengths, typically ranging from 365 nm to 405 nm. The wavelength determines the application suitability—shorter wavelengths (around 365 nm) are ideal for curing and sterilization, while longer wavelengths (near 405 nm) suit inspection and decorative uses. Buyers must specify the exact wavelength to match their operational needs and regulatory requirements. -

Material Grade and PCB Quality

The substrate material, often flexible printed circuit boards (FPC), impacts durability and heat dissipation. High-grade materials (e.g., copper thickness of 2 oz or above) ensure better thermal management and longer lifespan, which is crucial for continuous industrial use. Low-quality PCBs may lead to frequent failures and higher maintenance costs. -

Light Intensity and Power Consumption

Expressed in milliwatts (mW) or milliwatt per centimeter (mW/cm), light intensity affects performance in applications like curing or disinfection. Buyers should balance intensity with power consumption (watts per meter) to optimize energy efficiency and operating costs. Detailed datasheets help compare supplier offerings effectively. -

Ingress Protection Rating (IP Rating)

UV LED strips often operate in environments with moisture or dust exposure. The IP rating (e.g., IP65, IP67) indicates resistance to solids and liquids, which is critical for applications in harsh industrial or outdoor settings. Selecting the appropriate IP rating reduces product failures and warranty claims.

-

Tolerance and Uniformity

Tolerance refers to allowable deviations in electrical or optical parameters, while uniformity ensures consistent light output across the strip length. High tolerance and uniformity are vital for precision applications such as medical device manufacturing or quality inspection lines, ensuring repeatable results. -

Operating Temperature Range

UV LED strips must maintain performance within specified temperature limits, often between -20°C and +60°C. Buyers should verify operating ranges to avoid performance degradation in extreme climates, especially relevant for regions with high temperature variation like parts of Africa and the Middle East.

Common Industry and Trade Terminology

-

OEM (Original Equipment Manufacturer)

OEM refers to suppliers who produce UV LED strips that can be rebranded or customized for the buyer’s brand. This is beneficial for businesses seeking tailored specifications or exclusive product lines without investing in manufacturing infrastructure. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest order volume a supplier is willing to accept. Understanding MOQ helps buyers manage inventory costs and negotiate better pricing or flexible quantities, especially important for small to medium enterprises expanding into new markets. -

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers requesting detailed pricing, lead times, and product specifications. Well-prepared RFQs enable buyers to compare multiple vendors efficiently and secure competitive terms.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

Incoterms clarify the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties. Familiarity with common terms like FOB (Free On Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid) empowers buyers to negotiate favorable delivery conditions and control logistics costs. -

Bin and Forward Voltage

Bin categorization groups LEDs by brightness and wavelength consistency, ensuring uniform batches. Forward voltage indicates the voltage required to operate the LED. Both affect compatibility with power supplies and overall system efficiency.

Illustrative Image (Source: Google Search)

- Solderability and Connector Type

Details about soldering quality and connector standards (e.g., JST, Molex) impact installation ease and maintenance. Buyers should confirm these specifications to ensure seamless integration with existing equipment or assembly lines.

By grasping these technical properties and trade terms, international B2B buyers can better evaluate UV LED strip light suppliers, align purchases with application demands, and negotiate contracts that optimize cost, quality, and delivery reliability. This strategic understanding is especially valuable across diverse markets in Africa, South America, the Middle East, and Europe, where operational conditions and regulatory environments vary widely.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ultraviolet led strip lights Sector

Market Overview & Key Trends

The global ultraviolet (UV) LED strip lights market is witnessing robust growth, driven by increasing demand across diverse industries such as healthcare, sanitation, manufacturing, and entertainment. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding regional market dynamics is essential to capitalize on emerging opportunities.

Key Market Drivers:

– Rising Adoption in Disinfection and Sterilization: Post-pandemic hygiene standards have accelerated demand for UV LED strip lights in water purification, air filtration, and surface sterilization applications.

– Technological Advancements: Innovations in UV-C LED technology, offering higher efficiency and longer lifespans, are reducing operational costs and expanding use cases.

– Customization and Integration: Buyers increasingly seek customizable solutions that can be seamlessly integrated into existing systems, such as HVAC units or manufacturing lines.

Regional Insights:

– Africa & South America: Growing investments in healthcare infrastructure and water treatment projects are fueling demand. However, buyers should navigate challenges related to supply chain reliability and local regulatory standards.

– Middle East: The region’s focus on smart city initiatives and industrial modernization creates a fertile ground for UV LED strip applications. Strategic sourcing from manufacturers offering tailored solutions is critical.

– Europe (Italy and broader EU): Strict regulatory frameworks and sustainability mandates encourage procurement of high-quality, certified UV LED products. Buyers benefit from leveraging suppliers with proven compliance records and innovation capacity.

Sourcing Trends:

– Shift Toward Direct Manufacturer Engagement: To mitigate risks and optimize costs, buyers are increasingly engaging directly with manufacturers, particularly those with transparent supply chains and R&D capabilities.

– Demand for Smart and IoT-Enabled Products: Integration of UV LED strips with smart controls and sensors is a growing trend, enabling real-time monitoring and energy optimization.

– Emphasis on Scalability: International buyers prioritize suppliers capable of scaling production to meet fluctuating demands without compromising quality.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in the procurement of ultraviolet LED strip lights, reflecting broader corporate responsibility commitments and compliance with international environmental standards.

Environmental Impact Considerations:

– UV LED strip lights offer significant energy efficiency advantages over traditional UV lamps, reducing carbon footprints and operational expenses.

– However, the manufacturing process involves rare earth materials and semiconductor components that require responsible sourcing to minimize ecological damage.

Ethical Supply Chains:

– Buyers should prioritize suppliers who demonstrate transparency in their supply chain practices, including conflict-free sourcing of raw materials and adherence to labor rights.

– Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 (Environmental Management) serve as reliable indicators of ethical and sustainable manufacturing.

Green Certifications & Materials:

– Opting for UV LED strip lights with verified low mercury content and recyclable components supports circular economy goals.

– Some manufacturers now offer products with enhanced durability and modular designs, facilitating easier repairs and reducing electronic waste.

– Aligning procurement strategies with global sustainability initiatives not only mitigates risks but also enhances brand reputation among environmentally conscious end-users.

Brief Evolution and Historical Context

The ultraviolet LED strip lights sector has evolved significantly over the past two decades. Initially, UV lighting relied heavily on mercury vapor lamps, which were bulky, energy-intensive, and environmentally hazardous. The advent of UV LED technology marked a turning point by enabling compact, energy-efficient, and mercury-free solutions.

Early UV LED strips were limited by low power output and short lifespan, restricting their industrial applicability. However, continuous improvements in semiconductor materials and chip design have led to higher intensity UV-C LEDs with extended durability. This evolution has expanded their use from niche scientific and medical applications to widespread adoption in water treatment, food safety, and air purification.

For B2B buyers, understanding this progression underscores the importance of selecting suppliers with a proven track record of innovation and quality assurance, ensuring access to the latest advancements and reliable product performance.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of ultraviolet led strip lights

1. How can I effectively vet suppliers of ultraviolet LED strip lights for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications relevant to electronics and UV products, such as CE, RoHS, or UL. Request samples to assess product quality and consistency. Check their export experience, especially in your region (Africa, South America, Middle East, Europe), to ensure they understand local regulations and logistics. Evaluate their manufacturing capabilities, quality control processes, and after-sales support. Utilize platforms with verified suppliers and request references from existing international clients to validate reliability and compliance.

2. What customization options are typically available for ultraviolet LED strip lights, and how can I ensure they meet my market’s needs?

Common customizations include UV wavelength specification (e.g., 365nm, 395nm), strip length, LED density, waterproof ratings (IP65, IP67), and connector types. You can also request custom packaging or branding. To ensure suitability, communicate your application requirements clearly, considering local environmental conditions and regulatory standards. Ask for prototypes or pre-production samples to test performance. Collaborate closely with suppliers to tailor the product to your market demands and ensure compliance with regional safety and environmental regulations.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for UV LED strip light suppliers?

MOQs vary widely but typically range from 500 to 2,000 meters per order, depending on customization and supplier scale. Lead times can span from 3 to 8 weeks, factoring in production and shipping. Payment terms often start with a 30-50% deposit upfront, with balance paid before shipment or upon delivery. Negotiate terms based on order size and supplier relationship. For new buyers, escrow or letter of credit arrangements can mitigate risk. Always clarify these terms upfront to align expectations and avoid delays.

4. Which quality assurance certifications should I prioritize when sourcing ultraviolet LED strip lights internationally?

Prioritize certifications that ensure safety, environmental compliance, and product reliability. CE certification is essential for European markets, confirming conformity with EU directives. RoHS compliance ensures restriction of hazardous substances, critical for global acceptance. UL certification is valued in North America but also signals high safety standards. ISO 9001 indicates robust quality management systems. Additionally, look for testing reports on UV wavelength accuracy and photobiological safety to guarantee product efficacy and user safety.

5. How should I plan logistics for shipping ultraviolet LED strip lights internationally to regions like Africa or South America?

Plan logistics by considering product fragility, shipping mode, and customs regulations in your destination country. UV LED strips are lightweight but sensitive to moisture and static; use anti-static and waterproof packaging. Choose between air freight for faster delivery or sea freight for cost efficiency, balancing urgency and budget. Engage freight forwarders experienced in your target regions to handle customs clearance smoothly. Factor in possible delays due to local import regulations and ensure all documentation, including certificates and invoices, is accurate and compliant.

6. What strategies can help resolve disputes or quality issues with overseas ultraviolet LED strip light suppliers?

First, maintain clear, documented communication channels and contracts detailing product specifications, delivery timelines, and penalties for non-compliance. If issues arise, promptly report with evidence like photos or test results. Engage suppliers in amicable negotiation for replacements or refunds. Utilize third-party inspection services before shipment to catch defects early. For persistent disputes, leverage trade mediation services or arbitration bodies specializing in international trade. Building long-term relationships and working with reputable suppliers minimizes risks.

7. How can I ensure compliance with local regulations when importing ultraviolet LED strip lights into my country?

Research your country’s import regulations, including electrical safety, UV emission limits, and environmental standards. Ensure your supplier provides all necessary compliance documents, such as CE or RoHS certificates. Some countries require product testing or registration before market entry. Collaborate with local import agents or customs brokers who understand regional requirements to avoid delays or penalties. Staying informed about changes in regulations and updating your supplier accordingly is critical for smooth market access.

8. What are the key factors to consider when negotiating pricing with ultraviolet LED strip light manufacturers internationally?

Consider total cost of ownership, including unit price, shipping, customs duties, and potential tariffs. Volume discounts often apply for larger orders, so clarify MOQs and pricing tiers. Factor in customization costs and quality assurance expenses. Be transparent about your budget but emphasize quality requirements to avoid compromising product performance. Negotiate payment terms that balance cash flow and supplier trust. Also, consider supplier responsiveness and after-sales support as part of the value proposition, not just price alone.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ultraviolet led strip lights

Ultraviolet LED strip lights represent a dynamic and rapidly evolving technology with significant applications across industrial, commercial, and healthcare sectors. For international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—understanding the nuances of product quality, supplier reliability, and compliance standards is critical. Strategic sourcing in this domain ensures not only cost efficiency but also access to cutting-edge innovations and sustainable solutions tailored to regional market needs.

Key considerations include partnering with manufacturers who emphasize energy efficiency, durability, and customizable wavelength options to meet specific disinfection, curing, or inspection requirements. Additionally, buyers should prioritize suppliers with proven export capabilities and strong after-sales support to mitigate logistical challenges and ensure consistent supply chains.

Looking ahead, the ultraviolet LED strip light market is poised for growth driven by increased demand for eco-friendly UV sterilization and industrial automation. Buyers who adopt a forward-thinking procurement strategy—leveraging thorough market analysis and fostering collaborative supplier relationships—will unlock competitive advantages and long-term value.

For B2B buyers across diverse regions, now is the opportune moment to deepen sourcing expertise, invest in quality partnerships, and embrace innovation. Doing so will not only meet immediate operational goals but also position businesses at the forefront of a transformative lighting technology landscape.