Introduction: Navigating the Global Market for led strip clips

In today’s rapidly evolving lighting industry, LED strip clips have emerged as indispensable components that ensure secure, efficient, and aesthetically pleasing installations of LED strip lights. For international B2B buyers—particularly those operating in diverse and dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of these seemingly simple yet critical accessories is vital to optimizing project outcomes and supply chain efficiency.

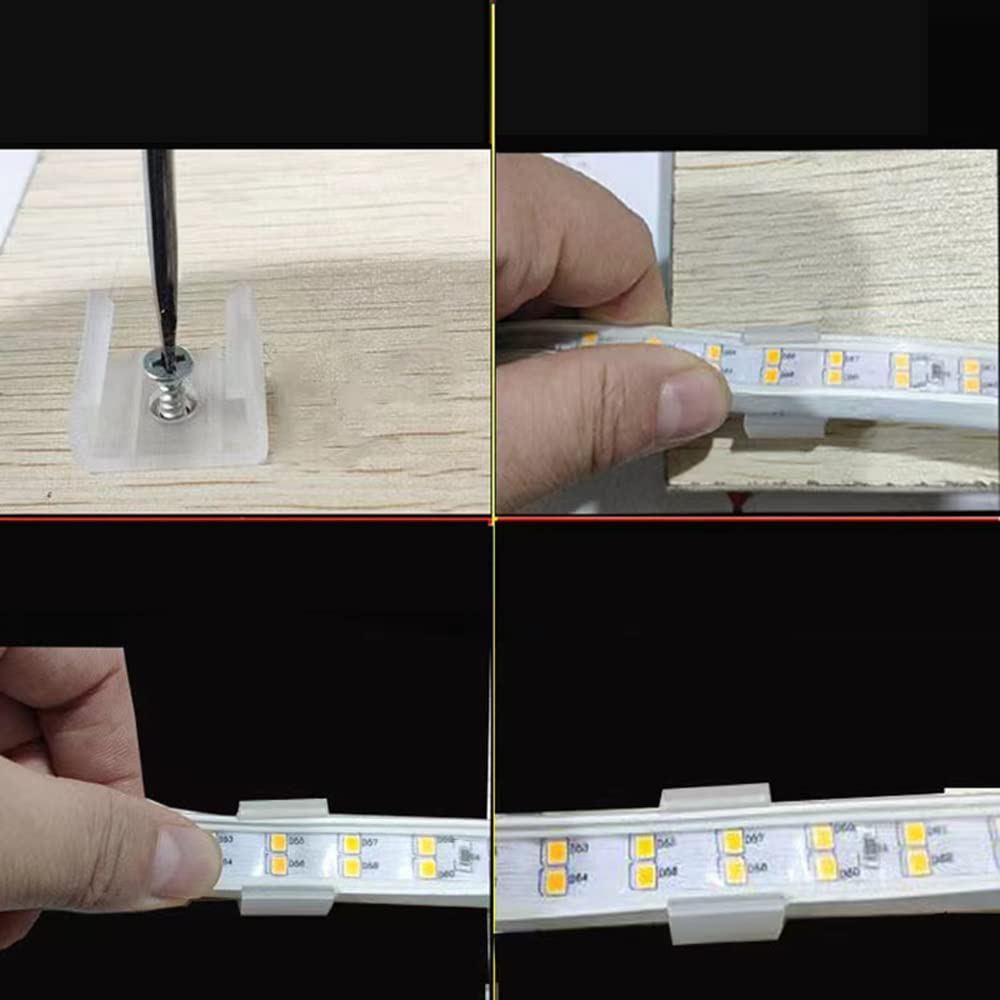

Illustrative Image (Source: Google Search)

This comprehensive guide delves into every essential aspect of LED strip clips, empowering procurement professionals and project managers with actionable insights. You will explore the various types and materials of clips tailored to different installation environments, from rigid and flexible mounting needs to weather-resistant solutions for outdoor use. The guide also uncovers the manufacturing processes and quality control standards that differentiate high-quality clips, ensuring durability and compliance with international certifications.

Additionally, you will gain clarity on how to evaluate suppliers globally, balancing cost, reliability, and logistical considerations to secure the best value. We further analyze current market trends and pricing dynamics, enabling buyers to make informed decisions in competitive landscapes such as Thailand’s emerging industrial hubs or South Africa’s growing infrastructure projects.

Whether sourcing for large-scale commercial installations or specialized architectural lighting, this guide offers a structured roadmap, including a detailed FAQ section addressing common challenges and procurement strategies. By equipping you with comprehensive knowledge and practical tools, this resource ensures your sourcing decisions for LED strip clips drive efficiency, quality, and long-term success in your international business ventures.

Understanding led strip clips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Snap Clips | Durable plastic material, easy snap-on design | Retail displays, residential installations | + Cost-effective, corrosion-resistant – Less heat resistance, limited load capacity |

| Metal Spring Clips | Stainless steel or aluminum, spring tension grip | Commercial/industrial lighting, outdoor setups | + High durability, excellent heat tolerance – Higher cost, potential for rust if low-grade metal |

| Magnetic Clips | Integrated magnets for tool-free attachment | Temporary setups, event lighting | + Quick install/removal, reusable – Limited to ferromagnetic surfaces, weaker hold on uneven surfaces |

| Adhesive Backed Clips | Plastic or metal clips with adhesive pads | Flexible mounting surfaces, DIY projects | + Easy installation without tools – Adhesive may degrade in humidity or heat |

| Corner/Angle Clips | Designed for securing LED strips on corners or angles | Architectural lighting, furniture integration | + Specialized fit for complex layouts – Typically higher unit cost, requires precise sizing |

Plastic Snap Clips

Plastic snap clips are commonly used for their affordability and ease of use. Made from durable plastics, they provide a straightforward snap-on mechanism that secures LED strips firmly without tools. These clips suit large-scale residential or retail projects where cost-efficiency and corrosion resistance are priorities. B2B buyers should verify the clip’s heat resistance and ensure compatibility with strip width to avoid premature failure in warmer environments.

Metal Spring Clips

Metal spring clips offer superior durability and heat tolerance, making them ideal for commercial and industrial lighting applications. Constructed from stainless steel or aluminum, they maintain a strong grip even in outdoor or high-temperature conditions. For B2B purchasers, the trade-off is a higher upfront cost, but the longevity and reliability often justify this investment, especially for large installations requiring robust mounting solutions.

Magnetic Clips

Magnetic clips provide a versatile, tool-free mounting option that is perfect for temporary or frequently adjusted lighting setups such as events or exhibitions. Their reusability and ease of repositioning reduce labor costs and downtime. However, buyers must consider that magnetic clips only work on ferromagnetic surfaces and may not hold well on textured or uneven materials, limiting their application scope.

Adhesive Backed Clips

Adhesive backed clips combine the convenience of tool-free installation with moderate holding strength. They are particularly favored in DIY projects or installations on surfaces where drilling is undesirable. B2B buyers targeting markets with variable climates should assess adhesive quality carefully, as exposure to heat and humidity can weaken adhesion, leading to maintenance challenges.

Corner/Angle Clips

Specialized corner or angle clips are designed to secure LED strips around bends and edges, essential for architectural or furniture lighting projects requiring neat, continuous illumination. These clips ensure a professional finish but often come at a premium price and require precise measurement to fit specific LED strip dimensions. Buyers should plan procurement carefully to avoid excess inventory or compatibility issues.

Related Video: How to use LED Strip Light wire-to-tape light connectors

Key Industrial Applications of led strip clips

| Industry/Sector | Specific Application of led strip clips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Securing LED strips for display lighting and signage | Enhances product visibility and store ambiance; easy installation and maintenance | Durability under frequent handling, UV resistance, compatibility with strip width |

| Hospitality & Events | Fixing LED strips in hotels, restaurants, and event venues | Creates dynamic lighting effects, flexible design adaptability | Heat resistance, aesthetic finish, and ease of repositioning |

| Automotive & Transportation | Mounting LED strips for interior ambient and exterior accent lighting | Improves vehicle interior ambiance and exterior safety lighting | Vibration resistance, strong adhesive compatibility, weatherproof clips |

| Industrial Manufacturing | Organizing LED strips in machinery and control panels | Ensures secure, vibration-free lighting enhancing operational safety | High-temperature tolerance, chemical resistance, and robust locking mechanisms |

| Architecture & Construction | Installation of LED strips in architectural features and smart buildings | Enables precise, durable lighting solutions for design and energy efficiency | Fire-retardant materials, compliance with regional safety standards, ease of installation |

Retail & Commercial Applications

In retail environments across Africa, South America, and Europe, LED strip clips are essential for securing LED strips used in display cases, shelving, and signage. These clips provide a reliable mounting solution that prevents sagging or detachment, which can disrupt lighting consistency. For international buyers, sourcing clips that offer UV resistance and compatibility with various LED strip sizes is crucial, especially for outdoor storefronts exposed to sunlight. Durable clips reduce maintenance costs and downtime, enhancing the overall customer experience through well-lit, attractive displays.

Hospitality & Events Sector

Hotels, restaurants, and event venues frequently use LED strip lighting to create ambiance and dynamic effects. LED strip clips enable quick installation and repositioning, which is vital for venues that frequently change lighting setups. Buyers in the Middle East and Europe should prioritize clips with heat resistance and a polished finish that blends seamlessly with interior décor. The ability to easily reposition or remove strips without damage is a significant benefit, supporting flexible event designs and reducing labor costs.

Automotive & Transportation Industry

In automotive manufacturing and customization, LED strip clips secure ambient interior lighting and exterior accent lights that enhance safety and aesthetics. For B2B buyers in regions like South Africa and Thailand, clips must withstand vibrations, temperature fluctuations, and exposure to moisture. Strong adhesive or mechanical locking mechanisms ensure that LED strips remain fixed under harsh driving conditions. Selecting clips designed for automotive-grade durability helps manufacturers meet stringent quality and safety standards.

Illustrative Image (Source: Google Search)

Industrial Manufacturing

LED strip clips are widely used in industrial settings to organize lighting within machinery, control panels, and workstations. These clips prevent LED strips from loosening due to vibrations or exposure to chemicals, which is critical for operational safety and efficiency. Buyers from industrial sectors in Europe and South America should seek clips made from high-temperature resistant and chemical-resistant materials. Robust locking features are essential to maintain secure mounting in demanding manufacturing environments, reducing downtime and maintenance.

Architecture & Construction

Architectural lighting projects and smart building installations rely heavily on LED strip clips for precise, long-lasting mounting solutions. In international markets such as the Middle East and Europe, clips must comply with fire safety regulations and provide easy installation within complex structural elements. Fire-retardant materials and certifications ensure compliance with regional building codes. Clips that facilitate clean, professional installations contribute to energy-efficient lighting designs and enhance the aesthetic appeal of architectural features.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip clips

When selecting materials for LED strip clips, international B2B buyers must carefully consider factors such as durability, environmental resistance, manufacturing complexity, and compliance with regional standards. The choice of material directly impacts the clip’s performance in securing LED strips, especially in diverse climates and installation environments typical across Africa, South America, the Middle East, and Europe.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a high-impact, transparent thermoplastic known for excellent temperature resistance (typically -40°C to 120°C), UV stability, and good dimensional stability. It offers moderate chemical resistance and is flame retardant.

Pros & Cons:

PC clips are durable and resistant to cracking under stress, making them suitable for long-term installations. They are lightweight and relatively easy to manufacture via injection molding. However, polycarbonate can be more expensive than basic plastics and may yellow over time if exposed to intense UV without additives.

Impact on Application:

Ideal for indoor and outdoor LED strip installations where exposure to sunlight and moderate heat is expected. Its UV resistance is crucial for outdoor applications in regions with strong sun exposure like the Middle East and parts of Africa.

Considerations for International Buyers:

Buyers should verify compliance with international standards such as ASTM D3935 (UV resistance) and DIN EN 60695 (flammability). In Europe, RoHS and REACH compliance is often mandatory. Polycarbonate’s higher cost may be justified by its longevity in harsh environments, making it a preferred choice for premium projects in developed markets like Europe and South Africa.

Stainless Steel (Typically 304 or 316 Grades)

Key Properties:

Stainless steel clips offer exceptional mechanical strength, corrosion resistance (especially 316 grade), and excellent temperature tolerance (-200°C to 800°C). They are highly resistant to chemical exposure and UV degradation.

Pros & Cons:

These clips provide superior durability and longevity, especially in corrosive environments such as coastal or industrial areas. However, stainless steel is heavier, more expensive, and manufacturing processes (stamping, bending) are more complex and costly compared to plastics.

Impact on Application:

Best suited for outdoor, industrial, or marine environments where corrosion resistance is critical. In humid or salty climates typical of coastal South America or Middle Eastern regions, stainless steel clips ensure secure mounting without rusting.

Considerations for International Buyers:

Buyers should confirm material certification (e.g., EN 10088 for stainless steel grades) and ensure suppliers provide traceability documents. Stainless steel clips may be preferred in Europe and South Africa for their compliance with stringent quality standards and long-term reliability.

Nylon (Polyamide)

Key Properties:

Nylon is a versatile engineering plastic with good mechanical strength, abrasion resistance, and flexibility. It typically withstands temperatures from -40°C to 85°C and offers moderate chemical resistance but limited UV stability unless specially treated.

Pros & Cons:

Nylon clips are cost-effective, lightweight, and easy to produce. They provide good impact resistance but may degrade under prolonged UV exposure and high humidity, leading to brittleness or color fading.

Impact on Application:

Suitable for indoor LED strip installations or shaded outdoor locations. In tropical climates like Thailand or parts of South America, untreated nylon may require UV stabilizers to prevent premature failure.

Considerations for International Buyers:

Compliance with ASTM D4066 (Nylon classification) and resistance to local environmental conditions is essential. Buyers in Africa and South America should request UV-stabilized nylon variants. Nylon’s lower cost makes it attractive for budget-sensitive projects, but lifecycle expectations must be managed accordingly.

Aluminum

Key Properties:

Aluminum clips offer excellent heat dissipation, moderate corrosion resistance (improved with anodizing), and good mechanical strength. They operate effectively between -50°C and 150°C and resist UV degradation completely.

Pros & Cons:

Aluminum is lightweight, recyclable, and provides superior thermal management, which can be beneficial in high-heat LED applications. However, untreated aluminum can corrode in salty or acidic environments, and manufacturing involves more complex processes like extrusion or die casting.

Impact on Application:

Ideal for installations where heat dissipation is critical, such as high-power LED strips in commercial or industrial settings. Anodized aluminum clips are preferred in humid or coastal regions to prevent corrosion.

Considerations for International Buyers:

Ensure compliance with ASTM B221 (aluminum extrusion) and ISO 7599 (anodizing). Buyers in Europe and the Middle East often demand anodized finishes for durability and aesthetics. Aluminum clips may command a mid-to-high price but offer a good balance of performance and longevity.

| Material | Typical Use Case for led strip clips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Outdoor and indoor LED strip mounting with UV exposure | High impact resistance and UV stability | Higher cost and potential yellowing over time | Medium |

| Stainless Steel (304/316) | Harsh outdoor, marine, and industrial environments | Superior corrosion resistance and strength | Heavier and more expensive manufacturing | High |

| Nylon (Polyamide) | Indoor and budget-conscious projects with limited UV exposure | Cost-effective and flexible | Poor UV resistance without additives | Low |

| Aluminum (Anodized) | High-heat LED installations requiring thermal management | Excellent heat dissipation and corrosion resistance (anodized) | Requires surface treatment to prevent corrosion | Medium to High |

This guide equips international B2B buyers with critical insights to select LED strip clip materials tailored to their specific environmental conditions, compliance requirements, and budget constraints, ensuring optimal product performance and customer satisfaction across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip clips

Understanding the manufacturing and quality assurance processes behind LED strip clips is essential for international B2B buyers aiming to source reliable, durable, and compliant products. LED strip clips, though seemingly simple components, require precise production and stringent quality controls to ensure they securely hold LED strips without damaging them, withstand environmental stresses, and meet international standards. Below is a detailed breakdown of typical manufacturing stages, quality control practices, and critical considerations for buyers, especially those operating across Africa, South America, the Middle East, and Europe.

Manufacturing Process of LED Strip Clips

The production of LED strip clips typically involves several key stages, each contributing to the final product’s functionality and durability:

1. Material Preparation

Material selection is foundational. Most LED strip clips are made from high-quality plastics (such as polycarbonate or ABS) or metal alloys (like stainless steel or aluminum). These materials are chosen for their strength, flexibility, corrosion resistance, and heat tolerance.

- Plastic granules or metal sheets are sourced from certified suppliers.

- Materials undergo pre-treatment such as drying (for plastics) or surface cleaning (for metals) to ensure optimal forming conditions.

- For metals, coatings or plating (e.g., zinc or nickel) may be applied to enhance corrosion resistance and aesthetic finish.

2. Forming and Molding

This stage shapes raw materials into clips:

- Injection Molding: The most common method for plastic clips, where molten plastic is injected into molds designed to exact specifications. Precision molds ensure consistent dimensions and tight tolerances critical for clip fit.

- Stamping and Bending: For metal clips, sheet metal is stamped into shape and then bent or formed using dies and presses. This process allows for high-volume production with minimal waste.

- Secondary operations such as trimming or deburring remove excess material and smooth edges to prevent damage to LED strips during installation.

3. Assembly

Some LED strip clips incorporate additional components, such as screws, rubber pads, or adhesive elements:

- Clips may be assembled with fasteners or bonded with industrial adhesives.

- For clips designed to accommodate wiring or connectors, assembly ensures integration without compromising clip function.

- Automated or manual assembly lines verify each piece fits perfectly with LED strips and mounting surfaces.

4. Finishing and Packaging

Final touches enhance durability and buyer appeal:

- Surface finishing includes polishing, painting, or powder coating, especially for metal clips, to improve corrosion resistance and appearance.

- Plastic clips may be subjected to UV stabilizers or flame retardants during molding.

- Clips are packaged carefully, often in bulk with protective separators to avoid deformation during shipping.

- Customized packaging and branding options are frequently available for B2B buyers requiring private labeling.

Quality Assurance and Control (QA/QC) in LED Strip Clip Production

Robust quality assurance is vital to ensure clips meet operational and regulatory requirements, minimizing failures and returns.

Relevant International and Industry Standards

- ISO 9001: A globally recognized quality management system standard. Suppliers certified under ISO 9001 demonstrate consistent process control and continuous improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Ensures clips do not contain harmful materials like lead or mercury, important for environmental compliance.

- UL or ETL Certifications: Relevant for clips used in electrical applications, ensuring safety and fire resistance.

- Specific Regional Certifications: Some countries in Africa, the Middle East, and South America may have local standards or import regulations requiring additional documentation or testing.

QC Checkpoints Throughout Production

-

Incoming Quality Control (IQC):

– Inspection and testing of raw materials before production starts.

– Verification of material certifications, dimensions, and chemical composition.

– Early detection of substandard materials prevents downstream defects. -

In-Process Quality Control (IPQC):

– Continuous monitoring during molding, stamping, or assembly.

– Dimensional checks with calipers, gauges, and optical systems.

– Functional tests to confirm clip tension and fit on sample LED strips.

– Visual inspections for surface defects, discoloration, or contamination. -

Final Quality Control (FQC):

– Comprehensive inspection of finished clips, including packaging.

– Batch sampling for mechanical stress testing (e.g., pull or flex tests).

– Environmental resistance testing such as UV exposure and corrosion simulation.

– Verification of labeling, certification marks, and packaging integrity.

Common Testing Methods

- Dimensional Measurement: Ensures clips meet precise size tolerances for secure fitting.

- Mechanical Strength Testing: Assesses clip resilience against repeated opening/closing and load bearing.

- Thermal Resistance Testing: Confirms clips can withstand heat generated by LED strips without deformation.

- Chemical Resistance Testing: Especially for clips exposed to outdoor conditions or harsh environments.

- Adhesion Testing: For clips with adhesive components, ensuring long-term stickiness and durability.

How B2B Buyers Can Verify Supplier Quality Control

For buyers in Africa, South America, the Middle East, and Europe, due diligence on supplier QC practices is critical to avoid costly supply chain disruptions:

- Request ISO 9001 and Other Certifications: Confirm certificates are current and issued by accredited bodies.

- Supplier Audits: Consider on-site or third-party audits of manufacturing facilities to verify QC processes, equipment calibration, and worker training.

- Quality Control Reports: Obtain detailed IQC, IPQC, and FQC reports for each batch or shipment.

- Third-Party Inspection: Employ independent inspection agencies to conduct random sampling and testing before shipment.

- Sample Evaluation: Always request and test samples for fit, durability, and compliance before large orders.

- Warranty and Return Policies: Ensure suppliers offer clear terms for defective products to mitigate risks.

QC and Certification Nuances for International Buyers

- Regional Compliance: Buyers must verify that clips comply not only with international standards but also with local regulatory requirements. For example, European buyers prioritize CE and RoHS compliance, while Middle Eastern buyers may require SASO certification.

- Shipping and Packaging: Proper packaging is essential for international shipments to prevent damage due to rough handling or climate variations, especially when shipping to regions with high humidity or temperature fluctuations.

- Language and Documentation: Ensure all certificates, manuals, and quality documents are provided in languages suitable for local authorities and import customs.

- Customs and Import Testing: Some countries require imported goods to undergo local testing or certification renewal, which can affect delivery times and costs.

- Supplier Communication: Establish clear communication channels with suppliers to promptly address QC issues, ensuring transparency and swift resolution.

Conclusion

For international B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance protocols behind LED strip clips is indispensable. Meticulous material selection, precise forming techniques, and comprehensive quality controls ensure clips deliver consistent performance and safety. Buyers who actively engage in supplier audits, demand certifications, and verify QC documentation will position themselves to source LED strip clips that meet both technical and regulatory requirements, minimizing risks and maximizing project success.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip clips Sourcing

When sourcing LED strip clips, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers aiming to optimize procurement and achieve cost-efficiency. This analysis covers key cost components, pricing influencers, and strategic buyer tips relevant to markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Strip Clips Manufacturing

-

Materials: The primary material cost involves plastics (often ABS or polycarbonate), metal springs or clips, and any surface treatments or coatings. Material quality directly impacts durability and clip performance, influencing overall product value.

-

Labor: Labor costs vary significantly by manufacturing location. Facilities in Southeast Asia or Eastern Europe may offer competitive labor rates compared to Western Europe or the Middle East, impacting the final cost.

-

Manufacturing Overhead: This includes utilities, factory maintenance, equipment depreciation, and indirect labor. Efficient factories with automation reduce overhead per unit, benefiting large orders.

-

Tooling and Molds: Injection molding tools for clips represent a significant upfront investment. Amortizing tooling costs over large volumes lowers unit cost but can increase per-piece cost for small orders.

-

Quality Control (QC): QC expenses cover inspections, testing for fit and finish, and compliance with standards. Higher QC rigor ensures product reliability, reducing returns and warranty claims.

-

Logistics and Shipping: Freight costs depend on shipment size, weight, and destination. International buyers must factor in customs duties, import taxes, and potential delays, especially for landlocked or remote regions.

-

Supplier Margin: Suppliers apply margins to cover profit and business sustainability. Margins vary based on supplier size, exclusivity, and service offerings such as customization or packaging.

Pricing Influencers Impacting LED Strip Clips

-

Order Volume and Minimum Order Quantity (MOQ): Larger volumes typically secure lower unit prices due to economies of scale. Buyers in Africa or South America should consolidate orders when possible to meet MOQs and unlock better pricing tiers.

-

Specifications and Customization: Customized clips (e.g., with specific colors, sizes, or branding) increase costs due to bespoke tooling and longer production cycles. Standard clips are more cost-effective but may limit application flexibility.

-

Material Quality and Certifications: Clips made from flame-retardant or UV-resistant materials command higher prices but offer improved safety and longevity. Certifications such as RoHS compliance enhance market acceptance, especially in Europe.

-

Supplier Reputation and Location: Established suppliers with proven quality records may charge premiums. However, choosing suppliers closer to the buyer’s region (e.g., European suppliers for EU buyers) can reduce logistics costs and lead times.

-

Incoterms and Payment Terms: Pricing varies depending on shipping terms (e.g., FOB, CIF, DDP). Buyers should negotiate terms that optimize cost control and risk management. Favorable payment terms can improve cash flow.

Strategic Tips for International B2B Buyers

-

Negotiate Beyond Price: Engage suppliers on payment terms, volume discounts, shipping arrangements, and after-sales support. Bundling LED strip clips with related products (such as LED strips) can yield package discounts.

-

Assess Total Cost of Ownership (TCO): Consider not just unit price but also shipping fees, import duties, potential wastage, and replacement costs. For example, investing slightly more upfront in higher-quality clips may reduce installation time and product failures.

-

Request Samples and Test Locally: Especially for buyers in diverse climates like South Africa or the Middle East, testing clip performance in local conditions prevents costly mistakes.

-

Leverage Group Buying or Local Distributors: Smaller buyers may benefit from pooling orders with partners or sourcing through local distributors who can offer lower MOQs and localized support.

-

Understand Pricing Cycles and Currency Fluctuations: International buyers should monitor exchange rates and global commodity prices, which impact raw material and shipping costs.

Disclaimer: Prices for LED strip clips vary widely based on volume, customization, supplier, and market conditions. The insights provided are indicative and should be complemented with direct supplier quotations and market research tailored to specific procurement needs.

By carefully analyzing these cost and pricing factors, B2B buyers across Africa, South America, the Middle East, and Europe can make informed sourcing decisions that balance quality, cost-efficiency, and supply chain reliability.

Spotlight on Potential led strip clips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip clips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip clips

Critical Technical Properties of LED Strip Clips

1. Material Grade

LED strip clips are commonly made from high-quality plastics such as polycarbonate (PC) or acrylonitrile butadiene styrene (ABS), or metals like stainless steel or aluminum. The material grade affects durability, heat resistance, and corrosion resistance. For B2B buyers, selecting clips with premium materials ensures longevity, especially in harsh environments common in regions with high humidity or temperature fluctuations like parts of Africa or the Middle East.

2. Size and Compatibility

Clips must match the width and thickness of the LED strip they secure, typically ranging from 8mm to 12mm in width. Proper sizing ensures a secure fit without damaging the strip. Buyers should verify compatibility with their chosen LED strips to avoid installation issues and additional costs related to returns or modifications.

3. Tolerance and Precision

Manufacturing tolerance refers to the allowable deviation in clip dimensions, usually within ±0.1mm. Tight tolerances guarantee consistent fit and reliable mounting, critical for maintaining the LED strip’s integrity and appearance in commercial or architectural projects.

4. Heat Resistance

Since LED strips emit heat, clips must withstand temperatures typically up to 80°C or higher without deforming. This property is vital for maintaining secure installation and preventing warping, which could compromise safety or lighting performance.

5. UV and Environmental Resistance

For outdoor or semi-outdoor applications, clips should be UV-stabilized and resistant to moisture and dust ingress. This ensures durability and prevents discoloration or brittleness, important for buyers in regions with intense sunlight or high humidity, such as South America or Southern Europe.

6. Mounting Mechanism and Load Capacity

LED strip clips may use screws, adhesive backing, or snap-fit designs. Understanding the mounting method and load capacity helps buyers choose clips suitable for their installation context—whether permanent fixtures or temporary setups for events or exhibitions.

Common Trade Terms for LED Strip Clips Procurement

OEM (Original Equipment Manufacturer)

Refers to suppliers or manufacturers who produce LED strip clips that can be branded and sold under a buyer’s own company name. For B2B buyers, OEM partnerships allow customization and brand differentiation without investing in manufacturing infrastructure.

MOQ (Minimum Order Quantity)

The smallest quantity of clips a supplier will sell in a single order. Knowing the MOQ is essential for budgeting and inventory planning, especially for businesses in emerging markets where cash flow and storage space might be limited.

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers asking for pricing, lead times, and terms for a specific quantity and specification of LED strip clips. RFQs enable buyers to compare offers and negotiate better terms, critical for procurement efficiency.

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms helps buyers manage logistics and costs effectively across borders.

Lead Time

The period between placing an order and receiving the goods. Shorter lead times are advantageous for projects with tight schedules, while longer lead times may require advanced planning. Buyers should confirm lead times to align procurement with project timelines.

Batch Consistency

Refers to uniformity in product specifications and quality across multiple production runs. For large-scale projects spanning several shipments, ensuring batch consistency prevents installation issues and maintains aesthetic standards.

By focusing on these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing LED strip clips, ensuring product quality, cost-efficiency, and smooth supply chain management tailored to their regional market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip clips Sector

Market Overview & Key Trends in the LED Strip Clips Sector

The global LED strip clips market is experiencing steady growth driven by the expanding adoption of LED strip lighting across residential, commercial, and industrial applications. As LED lighting solutions continue to replace traditional lighting due to their energy efficiency and longevity, demand for complementary accessories like LED strip clips has surged. These clips play a crucial role in secure and neat installation, making them essential for both new lighting projects and retrofit solutions.

Key market drivers include:

- Rising Construction and Renovation Activities: Emerging economies in Africa (e.g., South Africa), South America, and the Middle East are witnessing rapid urbanization and infrastructure development. This fuels demand for LED lighting and associated mounting hardware.

- Technological Advancements: Innovations in clip materials (such as flexible plastics and corrosion-resistant metals) and designs (snap-fit, adjustable, or magnetic clips) are enhancing ease of installation and durability. Buyers can leverage these developments to reduce labor costs and installation time.

- Customization and Versatility: B2B buyers increasingly seek clips tailored for different LED strip sizes, environmental conditions (indoor/outdoor), and mounting surfaces. Suppliers offering bespoke solutions gain competitive advantages in diverse markets.

- Supply Chain Localization: For buyers in Europe and regions like Thailand, local sourcing of LED strip clips is becoming important to mitigate shipping delays and tariffs while ensuring compliance with regional quality standards such as CE marking.

- Growing E-commerce and Wholesale Platforms: These platforms provide buyers in Africa and South America with broader access to global suppliers, enabling competitive pricing and faster procurement cycles.

For B2B buyers, understanding these dynamics helps in selecting suppliers who not only offer quality clips but also provide scalable solutions aligned with regional market needs and regulatory requirements.

Sustainability & Ethical Sourcing in B2B LED Strip Clips Procurement

Sustainability is increasingly influencing procurement decisions in the LED strip clips sector. While these components may seem minor, their cumulative environmental impact and supply chain footprint are significant, especially when sourced in large volumes for commercial projects.

Key sustainability considerations for buyers include:

- Material Selection: Clips made from recyclable or biodegradable plastics and corrosion-resistant metals reduce waste and extend product life. Avoiding PVC-based materials and opting for eco-friendly polymers can minimize toxic emissions during manufacturing and disposal.

- Supply Chain Transparency: Ethical sourcing demands that suppliers maintain fair labor practices and environmentally responsible manufacturing processes. Certifications such as ISO 14001 (environmental management) and SA8000 (social accountability) offer assurance of compliance.

- Green Certifications and Compliance: Look for clips certified with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) to ensure they meet international environmental standards. These certifications are particularly valued in European markets.

- Packaging and Logistics: Suppliers adopting minimal, recyclable packaging and optimizing logistics for lower carbon emissions contribute to greener supply chains.

- Circular Economy Initiatives: Some suppliers now offer take-back programs or clips designed for easy disassembly and recycling, enabling buyers to participate in circular economy practices.

By prioritizing sustainability and ethical sourcing, B2B buyers not only comply with tightening regulations but also enhance their corporate social responsibility profiles, which is increasingly important for international tenders and partnerships.

Brief Evolution of LED Strip Clips in the B2B Context

LED strip clips have evolved from simple, generic fasteners to highly specialized components integral to modern lighting systems. Initially, LED strips were often mounted using adhesives alone, which posed challenges like poor adhesion on uneven surfaces and difficulty in repositioning. This led to the development of clips designed to securely hold strips in place while allowing for easy installation and maintenance.

Over time, manufacturers introduced clips made from advanced materials that resist heat, UV exposure, and corrosion—qualities essential for outdoor and industrial applications. The rise of flexible and RGB LED strips further spurred innovation in clip designs to accommodate varied strip widths and shapes.

For B2B buyers, understanding this evolution highlights the importance of selecting clips that match the technical requirements of their LED lighting projects, ensuring both functional reliability and aesthetic appeal. This historical perspective underscores the transition from basic mounting solutions to sophisticated accessories that enhance overall system performance and longevity.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip clips

-

How can I effectively vet suppliers of LED strip clips for international B2B purchases?

Start by verifying the supplier’s business credentials, such as company registration and export licenses, especially for regions like Africa and South America where regulatory frameworks differ. Request product certifications (e.g., CE, RoHS) to ensure compliance with international standards. Examine customer reviews and ask for references from past B2B clients. Conduct factory audits or request video tours to assess manufacturing capabilities and quality control processes. Prioritize suppliers with transparent communication and established export experience to minimize risks in cross-border transactions. -

Are customization options available for LED strip clips, and how can these benefit my business?

Many manufacturers offer customization for LED strip clips, including size, material type (plastic, metal), color, and packaging tailored to your brand. Custom clips can improve installation efficiency and product compatibility with specific LED strips, enhancing end-user satisfaction. For international buyers, especially in diverse markets like the Middle East and Europe, customization enables differentiation and compliance with local standards. Discuss your technical requirements early with suppliers to align on minimum order quantities (MOQs) and lead times for custom orders. -

What are typical minimum order quantities (MOQs) and lead times when ordering LED strip clips internationally?

MOQs vary widely depending on the supplier and customization level but typically range from 1,000 to 10,000 units for standard clips. Custom orders may have higher MOQs due to tooling costs. Lead times can range from 3 to 8 weeks, factoring in production and international shipping. Buyers should plan orders well in advance, especially when sourcing from Asia for markets like South Africa or Europe, to accommodate customs clearance and potential delays. Negotiate with suppliers for flexible MOQs or phased deliveries when possible. -

What quality assurance measures should I expect from LED strip clip suppliers?

Reliable suppliers implement rigorous quality control throughout production, including material inspections, dimensional checks, and durability testing such as UV resistance and mechanical stress tests. Request documentation on quality management systems (e.g., ISO 9001 certification) and product test reports. For international buyers, ensure the clips meet regional safety and environmental standards, such as REACH in Europe or local certifications in the Middle East. Consistent QA reduces returns and strengthens your supply chain reliability. -

Which certifications are essential for LED strip clips to ensure compliance in different international markets?

Key certifications include CE (Europe), RoHS (restriction of hazardous substances), and UL or ETL (primarily for North America but often recognized globally). For Middle East and African markets, compliance with IEC standards and local import regulations is critical. Certifications ensure the clips are safe, environmentally friendly, and compatible with LED strip lights. Always request copies of these certificates and verify their authenticity before finalizing purchases to avoid customs issues or product rejections.

-

What logistics considerations should B2B buyers keep in mind when importing LED strip clips?

Evaluate shipping options balancing cost, speed, and reliability—sea freight is cost-effective for bulk but slower, while air freight suits urgent orders. Understand import duties, taxes, and customs clearance procedures specific to your country, such as South Africa’s SARS or Brazil’s Receita Federal. Work with freight forwarders experienced in handling electronics accessories to avoid delays. Also, consider packaging robustness to protect clips during transit, especially in humid or harsh climates common in Africa and South America. -

How can I protect my business from disputes related to LED strip clip quality or delivery delays?

Establish clear contracts specifying product specifications, delivery schedules, payment terms, and penalties for non-compliance. Use Incoterms to define responsibility for shipping risks and costs. Insist on pre-shipment inspections or third-party quality audits to verify order conformity. Maintain detailed communication records and use escrow or letter of credit payment methods to safeguard funds. In case of disputes, rely on arbitration clauses favoring neutral venues and international trade laws to resolve conflicts efficiently. -

What payment methods are recommended for international B2B transactions involving LED strip clips?

Secure payment methods like Letters of Credit (LC) or escrow services protect both buyers and sellers by linking payment release to contract fulfillment. Telegraphic Transfers (T/T) are common but carry higher risk without safeguards. For emerging markets in Africa and South America, consider suppliers that accept PayPal or payment platforms with buyer protection. Negotiate payment terms such as deposits plus balance on delivery to manage cash flow and reduce exposure. Always verify supplier banking details to avoid fraud.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip clips

Strategic sourcing of LED strip clips is essential for businesses aiming to optimize both cost-efficiency and product quality in their lighting solutions. Prioritizing suppliers who offer high-grade materials, compliance with international standards, and reliable quality control ensures durability and performance—key factors that minimize installation issues and long-term maintenance costs. For buyers in Africa, South America, the Middle East, and Europe, understanding regional supplier capabilities and logistics options can significantly enhance supply chain resilience and reduce lead times.

Key takeaways for international B2B buyers include:

- Evaluate supplier certifications and material quality to guarantee product reliability and safety.

- Leverage bulk purchasing and customization opportunities to meet specific project requirements while controlling costs.

- Request samples and verify warranty policies to mitigate risks associated with new suppliers.

- Consider flexible sourcing strategies that accommodate local market demands and regulatory environments.

Looking ahead, the LED lighting market continues to innovate with smarter, more versatile accessories like LED strip clips that simplify installation and expand application possibilities. Buyers who adopt a strategic sourcing approach will be well-positioned to capitalize on these advancements, ensuring competitive advantage and sustained growth. Engage proactively with trusted manufacturers and distributors to unlock tailored solutions that meet your unique project needs and regional challenges.