Introduction: Navigating the Global Market for 4 pin led light strip connector

The 4-pin LED light strip connector is a pivotal component in modern RGB lighting solutions, enabling seamless power and signal transmission to create dynamic, vibrant color displays. For international B2B buyers across Africa, South America, the Middle East, and Europe — including key markets like Germany and Mexico — understanding the nuances of these connectors is essential for sourcing reliable, high-performance lighting accessories that meet diverse commercial and industrial demands.

This comprehensive guide delves into every critical aspect of 4-pin LED strip connectors, starting with their fundamental design and role within RGB lighting systems. It covers various connector types, materials, and manufacturing quality standards, offering insights into how these factors influence durability, ease of installation, and electrical performance. Buyers will also find detailed evaluations of supplier landscapes and cost considerations tailored to regional market specifics, enabling effective budgeting and vendor selection.

By exploring wiring configurations, compatibility criteria, and quality control protocols, this guide equips procurement professionals with the technical knowledge necessary to avoid common pitfalls such as voltage mismatches or unreliable connections. Additionally, it addresses frequently asked questions that often arise during international sourcing and installation, ensuring buyers can make well-informed decisions that optimize both product longevity and system efficiency.

Ultimately, this resource empowers global B2B buyers to confidently navigate the complex marketplace for 4-pin LED light strip connectors, securing products that align with their operational requirements and regional regulatory standards. Whether upgrading commercial lighting or embarking on large-scale installations, this guide serves as an indispensable tool to streamline sourcing strategies and maximize value across international markets.

Understanding 4 pin led light strip connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solderless Clip-On Connector | Tool-free installation, clamps onto strip edges | Quick prototyping, retail display setups | Pros: Easy installation, no special skills needed; Cons: Less secure for heavy-duty use |

| Soldered Wire Connector | Requires soldering wires to pins, permanent joints | Industrial installations, long-term projects | Pros: Durable, reliable electrical connection; Cons: Requires skilled labor, time-consuming |

| Waterproof 4-Pin Connector | Sealed design with silicone or plastic casing | Outdoor lighting, harsh environment projects | Pros: Weather-resistant, protects from dust/moisture; Cons: Higher cost, less flexible |

| PCB Board Adapter Connector | Rigid PCB interface with screw terminals or pads | Custom lighting modules, OEM manufacturing | Pros: Stable mechanical connection, easy integration; Cons: Less adaptable to flexible strips |

| Quick-Release Connector | Snap-fit design with locking mechanism | Modular lighting systems, rental events | Pros: Fast assembly/disassembly, reusable; Cons: Bulkier, potential compatibility issues |

Solderless Clip-On Connectors

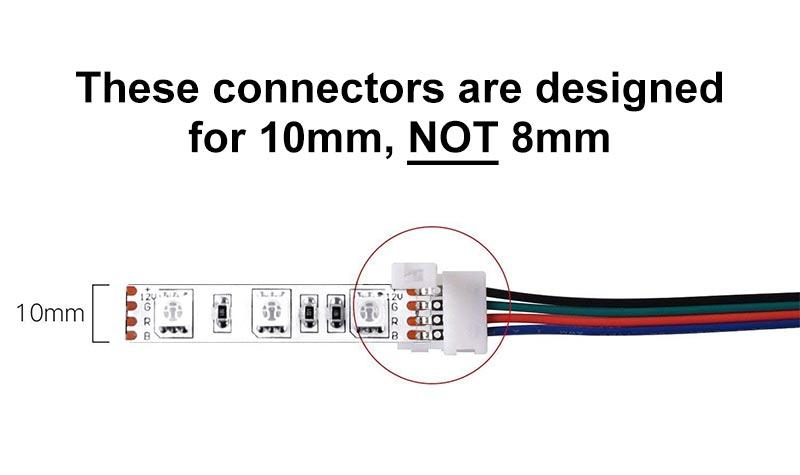

These connectors offer a quick, tool-free solution by clamping directly onto the LED strip’s copper pads. Ideal for fast prototyping or retail environments where lighting setups may change frequently, they eliminate the need for soldering skills. However, for B2B buyers targeting industrial or long-term installations, their mechanical strength and electrical reliability are limited compared to soldered options. When purchasing, consider the strip thickness compatibility and ensure the clip design matches the specific 4-pin layout of your LED strips.

Soldered Wire Connectors

Soldered connectors provide a permanent, highly reliable electrical connection by directly bonding wires to the LED strip’s copper pads or pins. They are preferred in commercial and industrial lighting projects where durability and consistent performance are critical. B2B buyers should factor in the labor costs and skilled workforce required for soldering, as well as potential rework challenges if modifications are needed. Compatibility with wire gauge and voltage ratings must be verified to prevent damage or performance issues.

Waterproof 4-Pin Connectors

Designed with sealed housings and often silicone or plastic casing, waterproof connectors protect LED strips from moisture, dust, and environmental contaminants. These connectors are essential for outdoor applications such as architectural lighting, signage, and landscape projects common in regions with variable climates like parts of Africa, the Middle East, and Europe. Buyers should assess IP ratings, material quality, and compatibility with strip sizes to ensure long-term reliability, balancing higher upfront costs with reduced maintenance expenses.

PCB Board Adapter Connectors

PCB adapter connectors integrate 4-pin LED strips into rigid printed circuit boards, featuring screw terminals or pad contacts for secure connections. This type is favored in OEM manufacturing and custom lighting module production where integration with other electronics is necessary. For B2B buyers, considerations include the mechanical stability of the adapter, ease of assembly, and whether the connector supports the intended LED strip density and voltage. This solution is less flexible but offers excellent control over the lighting system’s architecture.

Quick-Release Connectors

Quick-release connectors use snap-fit mechanisms with locking features to enable rapid assembly and disassembly of LED strip segments. They are popular in modular lighting systems, event production, and rental markets where fast setup and teardown are vital. While these connectors offer excellent convenience and reusability, they tend to be bulkier and may present compatibility challenges with certain LED strip models. Buyers should evaluate connector robustness and ensure it meets the electrical and mechanical demands of their application.

Related Video: LED light Strip connector For Beginners

Key Industrial Applications of 4 pin led light strip connector

| Industry/Sector | Specific Application of 4 pin led light strip connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architectural Lighting | RGB accent lighting for commercial buildings and façades | Enables dynamic, customizable lighting effects to enhance brand image and attract customers | High durability connectors with weatherproofing; compliance with EU and international safety standards |

| Retail & Hospitality | Mood and display lighting in stores, hotels, and restaurants | Improves customer experience and drives sales through visually appealing environments | Flexible, easy-to-install connectors supporting quick maintenance; compatibility with smart controllers |

| Automotive Manufacturing | Interior ambient lighting systems in vehicles | Provides customizable interior aesthetics and enhances user comfort | Connectors resistant to vibration and temperature extremes; compliance with automotive quality standards |

| Entertainment & Events | Stage and exhibition lighting setups | Facilitates rapid installation and flexible lighting design for diverse event requirements | Modular connectors allowing fast assembly/disassembly; reliable electrical contacts for safety |

| Industrial Automation | Status indication and machine lighting in factories | Enhances visibility and safety on production lines, enabling efficient monitoring | Robust connectors with high current capacity; resistance to dust, moisture, and industrial contaminants |

Architectural Lighting

In architectural projects, 4 pin LED light strip connectors are integral to RGB accent lighting systems that illuminate building façades and interiors. These connectors enable seamless integration of dynamic color-changing LED strips, allowing businesses to create visually striking environments that reinforce brand identity and attract foot traffic. For international buyers, especially in Europe and the Middle East, sourcing connectors with high IP ratings for outdoor use and compliance with regional electrical safety standards is crucial. The solderless design expedites installation and reduces labor costs, making these connectors ideal for large-scale commercial projects.

Retail & Hospitality

Retail outlets, hotels, and restaurants leverage 4 pin LED light strip connectors to implement mood lighting and highlight product displays. These connectors facilitate easy installation and maintenance of RGB LED strips, enabling businesses to quickly adapt lighting schemes to seasonal promotions or brand themes. Buyers from South America and Africa should prioritize connectors that support smart lighting systems and offer flexibility in wiring configurations to accommodate diverse store layouts. The ability to control lighting remotely enhances energy efficiency and customer ambiance, driving higher engagement and sales.

Automotive Manufacturing

Automotive OEMs and aftermarket suppliers use 4 pin LED connectors for ambient interior lighting systems that enhance vehicle aesthetics and passenger comfort. These connectors must withstand harsh operating conditions, including vibration, temperature fluctuations, and humidity. For B2B buyers in regions like Germany and Mexico, sourcing connectors compliant with automotive industry quality standards such as ISO/TS 16949 ensures reliability and durability. The connectors’ compact form factor and secure locking mechanisms simplify integration into complex wiring harnesses, reducing assembly time and costs.

Entertainment & Events

In the entertainment sector, 4 pin LED strip connectors are essential for stage lighting, exhibitions, and event setups requiring vibrant, programmable RGB lighting. Their modular and solderless design allows for rapid assembly and reconfiguration, critical for meeting tight event schedules and diverse lighting demands. International buyers should look for connectors with robust electrical contacts to prevent failures during performances and that support high current loads for intense lighting effects. This ensures reliability and safety in dynamic, high-stress environments.

Industrial Automation

Factories and industrial facilities employ 4 pin LED connectors in machine status indicators and production line lighting to improve operational safety and efficiency. These connectors must be rugged, offering resistance to dust, moisture, and chemical exposure common in industrial environments. B2B buyers from Africa and South America should focus on connectors with high current ratings and secure locking features to maintain stable connections under vibration and mechanical stress. Reliable lighting improves visibility for workers, reducing downtime and enhancing productivity.

Related Video: Iran Uses Its Largest-Ever Missile For Revenge Attack Over US Strike: Khorramshahr-4 Specs | Israel

Strategic Material Selection Guide for 4 pin led light strip connector

When selecting materials for 4-pin LED light strip connectors, international B2B buyers must balance performance, cost, and compliance with regional standards. The choice of material affects connector durability, electrical conductivity, corrosion resistance, and suitability for various installation environments. Below is an in-depth analysis of four commonly used materials in 4-pin LED strip connectors, tailored to the needs of buyers from Africa, South America, the Middle East, and Europe.

1. Copper (with Tin or Nickel Plating)

Key Properties:

Copper is widely used for the conductive pins in 4-pin connectors due to its excellent electrical conductivity and thermal performance. Tin or nickel plating is often applied to improve corrosion resistance and solderability, especially in humid or industrial environments.

Pros:

– Superior electrical conductivity ensures minimal voltage drop and efficient power transmission.

– Good thermal conductivity helps dissipate heat generated during operation.

– Plating enhances corrosion resistance, extending connector lifespan.

– Tin plating is cost-effective; nickel plating offers enhanced durability.

Cons:

– Copper is prone to oxidation if unplated, which can degrade performance.

– Nickel plating increases cost and can complicate soldering due to hardness.

– Susceptible to mechanical wear if connectors are frequently connected/disconnected.

Impact on Application:

Copper connectors are ideal for indoor and semi-outdoor installations where reliable electrical performance is critical. In regions with high humidity or coastal exposure (e.g., parts of Africa and South America), plated copper pins help prevent corrosion.

International Buyer Considerations:

European buyers, particularly in Germany, often require compliance with DIN EN standards for electrical connectors, which specify plating thickness and conductivity. Middle Eastern markets may prioritize corrosion resistance due to saline environments. Buyers from Mexico and South America should verify ASTM compliance and ensure plating quality to withstand tropical climates.

2. Polycarbonate (PC) Plastic Housing

Key Properties:

Polycarbonate is a high-impact, transparent thermoplastic commonly used for connector housings. It offers excellent dimensional stability and heat resistance up to approximately 135°C.

Pros:

– High mechanical strength and impact resistance reduce connector damage during installation.

– Good electrical insulation properties ensure safety and prevent short circuits.

– Transparent or translucent options allow visual inspection of contacts.

– Flame retardant grades available, meeting UL94 V-0 standards.

Cons:

– More expensive than general-purpose plastics like PVC or ABS.

– Can yellow or degrade under prolonged UV exposure unless UV-stabilized.

– Limited chemical resistance against strong solvents or acids.

Impact on Application:

Polycarbonate housings are preferred for commercial and architectural LED installations requiring robust, safe connectors. In outdoor or high-UV environments (e.g., Middle East deserts or coastal Africa), UV-stabilized grades are essential.

International Buyer Considerations:

European buyers often require RoHS compliance and adherence to REACH regulations for plastics. South American and African buyers should verify that materials meet local fire safety codes. Mexico’s industrial sectors may demand UL certification for flame retardancy.

3. Polyvinyl Chloride (PVC) Plastic Housing

Key Properties:

PVC is a flexible, cost-effective plastic widely used for connector insulation and housings. It offers moderate heat resistance (up to ~80°C) and good chemical resistance.

Pros:

– Low cost and widely available globally, making it attractive for large-scale procurement.

– Good electrical insulation and flame retardancy (with additives).

– Flexible, which facilitates easier cable routing and connector assembly.

Cons:

– Lower heat resistance limits use in high-temperature environments.

– Can become brittle over time, especially in cold climates.

– Environmental concerns due to chlorine content and potential for harmful emissions during disposal.

Impact on Application:

PVC housings suit indoor, low-heat applications where cost is a primary driver. They are common in residential or light commercial LED strip installations.

International Buyer Considerations:

Buyers in Europe, especially Germany, may face restrictions due to stringent environmental regulations (RoHS, REACH). African and South American buyers should consider local disposal regulations and potential environmental impact. Middle Eastern markets may prefer alternatives in high-temperature zones.

4. Brass (with Gold or Nickel Plating)

Key Properties:

Brass is an alloy of copper and zinc, often used for connector pins due to good conductivity and mechanical strength. Gold or nickel plating is applied to enhance corrosion resistance and contact reliability.

Pros:

– Excellent mechanical strength and wear resistance, suitable for frequent mating cycles.

– Gold plating provides superior corrosion resistance and low contact resistance, ideal for sensitive signal transmission.

– Nickel plating offers a balance between cost and durability.

Cons:

– Brass is heavier and more expensive than pure copper.

– Gold plating significantly increases cost, limiting use to premium products.

– Nickel plating may cause allergic reactions in some users and complicate soldering.

Impact on Application:

Brass connectors with gold plating are favored in high-end, precision LED lighting systems requiring reliable color fidelity and long service life. Nickel-plated brass is a cost-effective alternative for commercial applications.

International Buyer Considerations:

European buyers, especially in Germany, often specify gold plating thickness per DIN standards for high-reliability connectors. Buyers in the Middle East and South America may weigh cost versus performance, opting for nickel plating due to budget constraints. African buyers should evaluate the trade-off between durability and price for local market demands.

Summary Table of Materials for 4-Pin LED Light Strip Connectors

| Material | Typical Use Case for 4 pin led light strip connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper (plated) | Conductive pins in indoor/outdoor LED strips requiring good conductivity | Excellent electrical and thermal conductivity | Susceptible to oxidation if unplated; plating adds cost | Medium |

| Polycarbonate (PC) | Connector housings in commercial/architectural LED installations | High impact resistance and heat tolerance | Higher cost; UV degradation risk without stabilization | High |

| Polyvinyl Chloride (PVC) | Connector housings for cost-sensitive indoor LED applications | Low cost, good insulation, flexible | Lower heat resistance; environmental concerns | Low |

| Brass (plated) | Premium connector pins in high-reliability LED lighting systems | Strong mechanical durability; excellent corrosion resistance (gold plating) | Higher cost; gold plating expensive | High |

This material selection guide empowers B2B buyers to make informed decisions aligned with their regional market requirements,

In-depth Look: Manufacturing Processes and Quality Assurance for 4 pin led light strip connector

Manufacturing Processes for 4-Pin LED Light Strip Connectors

The production of 4-pin LED light strip connectors involves a precise sequence of manufacturing stages designed to ensure reliability, electrical performance, and ease of installation. For international B2B buyers evaluating suppliers—especially in regions such as Africa, South America, the Middle East, and Europe—understanding these stages helps in assessing supplier capabilities and product quality.

Illustrative Image (Source: Google Search)

1. Material Preparation

Material selection and preparation are foundational steps. The key materials include:

- Conductive Metals: Typically copper or copper alloys are used for the pins due to their excellent conductivity. These metals often undergo surface treatments such as tin or nickel plating to enhance corrosion resistance and solderability.

- Plastic Housing: High-grade, heat-resistant thermoplastics (e.g., polycarbonate or PBT) are used for connector bodies to ensure durability and electrical insulation.

- Contact Springs and Clips: These are precision stamped and formed metal parts that ensure firm contact without soldering in solderless connector designs.

Material preparation involves cutting raw metal strips and plastic pellets into appropriate sizes, with quality checks on material composition and mechanical properties before production.

2. Forming and Stamping

The conductive pins and contact components are manufactured through stamping and forming processes:

- Stamping: Automated dies punch out pin shapes from metal sheets with tight dimensional tolerances.

- Forming: Pins and clips are bent and shaped to exact geometries ensuring proper fit and contact pressure.

- Plating: After shaping, pins undergo electroplating for corrosion resistance and improved conductivity, a critical step for long-term performance.

Consistency in pin dimensions and plating thickness is essential to maintain reliable electrical connections and compatibility with LED strip pads.

3. Assembly

Connector assembly typically combines several components into a final functional unit:

- Insertion of Pins: Pins are inserted into the plastic housing with precision machinery to ensure correct alignment and secure fit.

- Contact Spring Installation: For solderless connectors, spring contacts or clips are inserted to enable wire clamping without soldering.

- Wire Attachment: In some cases, pre-attached cables or terminals are assembled, depending on the connector type.

- Encapsulation or Sealing: Some connectors receive additional sealing or insulation layers to enhance durability and water resistance, especially for outdoor or industrial applications.

Assembly lines often incorporate automation to ensure repeatability and reduce human error, critical for high-volume production.

4. Finishing and Packaging

Final finishing may include:

- Marking: Laser or inkjet marking for batch numbers, certifications, or polarity indicators.

- Cleaning: Removal of residues and contaminants to prevent connectivity issues.

- Packaging: Connectors are packaged in anti-static, moisture-proof materials to preserve quality during transit.

Packaging is tailored to buyer requirements, including bulk packaging or retail-ready kits.

Quality Assurance and Control in 4-Pin LED Light Strip Connector Production

High-quality manufacturing is supported by rigorous quality assurance (QA) and quality control (QC) frameworks. For international B2B buyers, especially those importing into markets with strict regulations such as Europe (e.g., Germany) or the Middle East, understanding QC protocols and certifications is vital.

Illustrative Image (Source: Google Search)

Relevant International Standards and Certifications

- ISO 9001: This is the global benchmark for quality management systems, ensuring consistent production processes and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), confirming compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electronic components, essential for environmental and safety standards.

- UL Certification: Particularly important for North American buyers, but also recognized internationally for electrical safety.

- Additional Regional Certifications: Some countries in the Middle East and South America may require local certifications or approvals (e.g., INMETRO in Brazil).

Quality Control Checkpoints

Manufacturers typically implement multi-stage QC inspections:

- Incoming Quality Control (IQC): Raw materials and components (pins, plastics, plating materials) are inspected for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during stamping, forming, and assembly ensures dimensional accuracy, correct pin alignment, and proper insertion force.

- Final Quality Control (FQC): Finished connectors undergo comprehensive testing including visual inspections, functional tests, and packaging verification.

Common Testing Methods

- Dimensional Inspection: Use of optical comparators or coordinate measuring machines (CMM) to verify pin and housing dimensions.

- Electrical Testing: Continuity and insulation resistance tests ensure no short circuits or open circuits occur within connectors.

- Mechanical Durability Testing: Repeated mating cycles test connector longevity and contact reliability.

- Environmental Testing: Salt spray, humidity, and thermal cycling tests validate resistance to corrosion and temperature fluctuations.

- Pull and Insertion Force Testing: Ensures connectors maintain secure electrical contact without damaging LED strip pads.

How B2B Buyers Can Verify Supplier Quality Control

For buyers, especially in international markets, verifying supplier QC is critical to mitigate risks associated with product defects or non-compliance.

- Supplier Audits: Conduct on-site or remote audits focusing on manufacturing processes, quality management systems, and compliance with standards like ISO 9001.

- Review of QC Documentation: Request detailed inspection reports, material certificates, and testing results for each production batch.

- Third-Party Inspections: Employ independent inspection agencies to perform pre-shipment inspections and functional tests.

- Sample Testing: Obtain product samples for in-house or third-party laboratory validation before large-scale orders.

- Factory Capability Assessment: Evaluate supplier’s production capacity, equipment sophistication, and workforce expertise to ensure scalability and consistent quality.

QC and Certification Nuances for International Buyers

- Africa and South America: Importers should verify that products meet local import regulations and safety standards, which may vary widely. RoHS and CE compliance are generally recognized as quality benchmarks. Local certification bodies might require additional testing.

- Middle East: Countries like the UAE and Saudi Arabia often require conformity certificates and adherence to GCC Standards Organization regulations. Buyers should confirm supplier familiarity with these requirements.

- Europe (Germany focus): European buyers demand strict adherence to CE marking and RoHS directives. Documentation such as Declaration of Conformity and technical files must be thorough and accessible.

- Cross-border Logistics Impact: Packaging and labeling must comply with destination country regulations, including language requirements, safety warnings, and customs documentation to avoid shipment delays.

Key Takeaway for B2B Buyers:

A thorough understanding of the manufacturing and quality assurance processes for 4-pin LED strip connectors enables buyers to select suppliers who deliver reliable, compliant, and high-performance products. Prioritize suppliers with certified quality management systems, transparent QC documentation, and readiness to support third-party audits and inspections. This approach minimizes risk, ensures regulatory compliance across diverse markets, and enhances the success of your LED lighting projects globally.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for 4 pin led light strip connector Sourcing

When sourcing 4-pin LED light strip connectors, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers aiming to optimize procurement strategies and total cost of ownership. These connectors, essential for RGB LED strip installations, involve multiple cost components and market factors that influence their final pricing.

Key Cost Components in 4-Pin LED Strip Connector Manufacturing

- Materials: The primary cost driver includes high-quality plastics, metal pins (often copper alloys with nickel or gold plating for conductivity and corrosion resistance), and insulating components. Premium materials that meet certifications for flame retardancy or RoHS compliance command higher prices but ensure durability and safety.

- Labor: Manufacturing labor costs vary significantly based on the production location. Countries with advanced automation may offer lower labor costs per unit, while manual assembly or quality control in some regions can increase expenses.

- Manufacturing Overhead: This encompasses factory utilities, equipment depreciation, and facility maintenance. Overhead costs impact pricing particularly in facilities with stringent quality control and advanced production lines.

- Tooling: Initial investment in molds and dies for injection molding or stamping is substantial but amortized over large production volumes. Custom connector designs or small batch runs increase tooling costs per unit.

- Quality Control (QC): Rigorous testing for pin alignment, conductivity, and durability is standard. QC costs rise when suppliers implement advanced inspections or certifications (ISO, CE).

- Logistics: Freight, customs duties, and warehousing add to landed costs. For international buyers, these logistics expenses can vary widely depending on shipping modes (air vs. sea), Incoterms, and destination regulations.

- Margin: Suppliers build in profit margins that reflect market demand, competition, and product complexity.

Influential Pricing Factors for Buyers

- Order Volume and MOQ: Bulk orders typically unlock significant price reductions. Minimum order quantities (MOQs) are a critical negotiation point, especially for buyers in Africa, South America, and the Middle East, where smaller initial volumes may be preferred.

- Technical Specifications and Customization: Customized connectors with specific pin layouts, waterproofing, or enhanced durability increase unit costs. Standardized connectors offer better cost-efficiency.

- Material Quality and Certifications: Certified connectors suitable for European markets (CE, RoHS) or demanding environments generally cost more but reduce compliance risks.

- Supplier Location and Reliability: Suppliers from China or Southeast Asia often offer competitive pricing but require careful vetting for quality consistency. European suppliers may charge premiums but provide faster shipping and trusted certifications.

- Incoterms and Payment Terms: Terms like FOB, CIF, or DDP affect the final landed cost. Buyers should carefully assess Incoterms to manage risks and costs related to shipping, insurance, and customs clearance.

Strategic Tips for International B2B Buyers

- Negotiate Beyond Price: Engage suppliers on payment terms, lead times, and quality assurances. Long-term partnerships can yield better pricing and reliability.

- Evaluate Total Cost of Ownership (TCO): Consider not only unit price but also shipping, customs duties, potential rework costs, and warranty claims. For buyers in remote regions or countries with complex import rules, these can significantly impact profitability.

- Leverage Consolidated Shipping: Combining orders with other components or coordinating shipments can reduce logistics costs.

- Request Samples and Certifications: Validate quality and compatibility before committing to large orders, particularly when sourcing from new suppliers.

- Understand Regional Market Nuances: For instance, European buyers (e.g., Germany) emphasize certifications and compliance, while buyers in South America or Africa may prioritize cost-effectiveness and supplier flexibility.

Indicative Pricing Disclaimer

Prices for 4-pin LED strip light connectors can vary widely based on the factors outlined. As of mid-2024, standard solderless connectors typically range from $0.10 to $0.50 per piece in bulk, while customized or certified variants can exceed $1.00 per piece. These figures are indicative and should be validated through direct supplier quotations tailored to specific order details.

By thoroughly analyzing these cost and pricing factors, international B2B buyers can make informed decisions, balancing cost-efficiency with quality and compliance to achieve optimal procurement outcomes for 4-pin LED strip light connectors.

Spotlight on Potential 4 pin led light strip connector Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘4 pin led light strip connector’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 4 pin led light strip connector

Critical Technical Properties of 4-Pin LED Light Strip Connectors

Understanding the technical specifications of 4-pin LED strip connectors is essential for international B2B buyers aiming for reliable, efficient, and scalable lighting solutions. Here are the key properties to evaluate:

-

Material Grade and Conductivity

Connectors are typically made from copper alloys with nickel or tin plating to ensure high electrical conductivity and corrosion resistance. For buyers in humid or industrial environments (e.g., coastal Africa or the Middle East), connectors with superior plating prevent oxidation, ensuring long-term stable connections and reducing maintenance costs. -

Pin Tolerance and Precision

Pin spacing and dimension tolerance are critical for compatibility with LED strips and controllers. Standard pin pitch is usually 2.54 mm, but slight deviations can cause poor contact or damage. Reliable suppliers maintain tight manufacturing tolerances (±0.1 mm), minimizing installation errors and downtime in large-scale projects. -

Current and Voltage Ratings

Most 4-pin connectors support 12V or 24V DC systems common in RGB LED strips. Current capacity typically ranges from 3A to 5A per pin. Selecting connectors with ratings exceeding your system’s peak load avoids overheating and failure, critical for commercial installations in Europe or South America where safety standards are stringent. -

Solderless vs. Soldered Design

Solderless connectors offer ease of installation and reusability, ideal for rapid deployment or prototyping. Soldered connectors provide a more robust, vibration-resistant connection preferred in industrial or permanent setups. Understanding your project’s lifecycle and maintenance plans guides the best connector choice. -

Ingress Protection (IP) Rating

For outdoor or wet-location applications, connectors with IP65 or higher ratings ensure dust and water resistance. Buyers targeting markets in tropical climates or outdoor architectural lighting should prioritize connectors with appropriate sealing features to avoid electrical failures. -

Wire Gauge Compatibility

Connectors must match the wire gauge used in your LED strips and power supply wiring—commonly between 18 AWG and 22 AWG. Using connectors incompatible with wire thickness can lead to poor electrical contact and signal loss, affecting color accuracy and lifespan.

Common Trade Terminology for 4-Pin LED Strip Connectors

Navigating international procurement requires familiarity with key trade and industry terms. Here are essential terms to know:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce connectors that can be branded or customized for your company. OEM partnerships are valuable for buyers in Europe and South America seeking tailored product specifications or private labeling to differentiate their offerings. -

MOQ (Minimum Order Quantity)

The smallest batch size a supplier will accept. MOQs vary widely—from hundreds to thousands of units. Understanding MOQ helps buyers in emerging markets like Africa or the Middle East plan inventory investment and negotiate better pricing. -

RFQ (Request for Quotation)

A formal document buyers send to suppliers to obtain detailed pricing, lead times, and technical specs. A clear and precise RFQ streamlines supplier evaluation and accelerates procurement cycles, especially important for large commercial projects. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Knowing Incoterms helps buyers from different continents control logistics costs and risks effectively. -

Lead Time

The total time from order placement to delivery. Lead times vary based on production complexity and shipping routes. Buyers should factor in lead time when planning project schedules, especially when importing to distant markets like Europe or South America. -

Compliance Certifications

Certifications such as CE (Europe), RoHS (Restriction of Hazardous Substances), or UL (Underwriters Laboratories) indicate product safety and environmental compliance. Verifying certifications ensures your connectors meet local regulations and quality expectations, avoiding customs delays or market rejection.

By focusing on these technical properties and mastering the associated trade terminology, B2B buyers can make informed decisions, optimize procurement strategies, and secure high-quality 4-pin LED strip connectors tailored to their regional market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 4 pin led light strip connector Sector

Market Overview & Key Trends

The global market for 4-pin LED light strip connectors is expanding rapidly, driven by the rising adoption of LED lighting in commercial, industrial, and residential applications. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, this growth presents both opportunities and challenges in sourcing reliable, cost-effective components that meet diverse technical requirements.

Key market drivers include increased demand for energy-efficient lighting solutions, smart lighting integration, and the growing popularity of RGB LED strips for customizable lighting effects. Regions like Europe (notably Germany) and Mexico are investing heavily in smart city infrastructure and modern architectural lighting, boosting demand for high-quality connectors compatible with RGB systems. Meanwhile, emerging markets in Africa and South America are witnessing accelerated urbanization and infrastructure development, creating new opportunities for affordable, scalable LED lighting systems.

Sourcing trends emphasize the shift towards modular, solderless 4-pin connectors that simplify installation and reduce labor costs. Buyers increasingly prioritize connectors compatible with both 12V and 24V systems, with a preference for products supporting longer run lengths and stable color performance, essential for commercial projects. Additionally, supply chain agility has become crucial due to fluctuating raw material prices and global logistics disruptions. Buyers are advised to establish relationships with manufacturers offering flexible MOQ (minimum order quantities), local warehousing options, and comprehensive technical support.

Technological advancements such as integrated smart controllers and enhanced waterproofing in connectors are becoming standard, especially for outdoor or industrial applications. The ability to integrate connectors seamlessly with IoT-enabled lighting systems is a significant competitive advantage, particularly in technologically advanced markets like Europe and the Middle East.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly shaping procurement decisions within the 4-pin LED light strip connector sector. International buyers are under growing pressure to source components that minimize environmental impact throughout their lifecycle—from raw material extraction to end-of-life disposal.

Environmental considerations focus on the use of recyclable materials such as high-grade plastics and metals with low toxicity and minimal heavy metal content. Connectors manufactured under ISO 14001-certified processes demonstrate a commitment to reducing industrial emissions and waste. Furthermore, buyers should prioritize suppliers that implement energy-efficient manufacturing methods and utilize renewable energy sources.

Ethical sourcing is equally critical, with a spotlight on labor practices and supply chain transparency. Buyers from regions with stringent regulatory frameworks, such as the European Union, often require adherence to standards like the Responsible Minerals Initiative (RMI) to avoid conflict minerals. Transparent supply chains also mitigate risks related to counterfeit products and ensure compliance with international trade regulations.

Green certifications such as RoHS (Restriction of Hazardous Substances) compliance and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) registration are essential benchmarks for buyers assessing connector quality and environmental safety. Additionally, connectors designed for durability and easy disassembly facilitate recycling and reduce waste, aligning with circular economy principles.

For B2B buyers targeting sustainable procurement, partnering with manufacturers who provide detailed environmental product declarations (EPDs) and engage in continuous improvement toward greener products will offer a strategic advantage in markets with increasing eco-consciousness.

Brief Evolution of 4-Pin LED Light Strip Connectors

The development of 4-pin LED strip light connectors has closely followed advances in LED lighting technology itself. Initially, LED strips required complex soldered connections, limiting their application to specialized users. The introduction of standardized 4-pin connectors revolutionized the sector by enabling easy, solderless installation of RGB LED strips, which support vibrant color mixing through separate control of red, green, and blue channels plus a common power line.

Over time, connector designs have evolved to accommodate higher voltages (12V and 24V), improved waterproofing for outdoor use, and integration with smart controllers to support IoT-enabled lighting systems. This evolution has been driven by the demand for flexible, modular solutions that reduce installation time and cost while enhancing system reliability.

Today, 4-pin connectors serve as a critical interface in both consumer and commercial lighting projects worldwide. Their continued innovation reflects broader trends toward smart, sustainable, and user-friendly lighting solutions that meet the complex demands of international B2B buyers.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of 4 pin led light strip connector

-

How can I effectively vet suppliers of 4-pin LED light strip connectors for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications such as ISO 9001 or CE compliance relevant to LED lighting components. Request detailed product datasheets and inquire about their quality control processes. For buyers from Africa, South America, the Middle East, or Europe, prioritize suppliers with experience exporting to your region and positive trade references. Utilize third-party inspection services or request product samples to assess build quality and compatibility. Engaging with suppliers who offer transparent communication and after-sales support ensures reliability in long-term partnerships. -

What customization options are typically available for 4-pin LED strip connectors in bulk orders?

Many manufacturers offer customization such as different connector types (solderless, soldered), cable lengths, wire gauges, and pin configurations to match specific RGB strip models. Custom branding, packaging, and compliance with regional electrical standards can also be accommodated. For international buyers, specifying voltage compatibility (12V or 24V) and connector durability requirements for harsh environments (e.g., moisture resistance for Middle Eastern climates) is critical. Early discussions about customization help align expectations and minimize delays in production. -

What are the typical minimum order quantities (MOQs) and lead times for 4-pin LED strip connectors from international suppliers?

MOQs generally range from 500 to 5,000 units depending on the supplier’s scale and customization level. Standard lead times are between 3 to 6 weeks, but complex custom orders or large volumes may require up to 8 weeks. Buyers from Europe or South America should factor in additional time for quality inspections and shipping. Negotiating MOQs is possible with established suppliers, especially when committing to recurring orders. Early engagement and clear timelines help secure production slots and avoid bottlenecks during peak demand seasons. -

Which payment terms are commonly accepted by manufacturers of 4-pin LED strip connectors for international B2B transactions?

Manufacturers typically accept payment methods like Telegraphic Transfer (T/T), Letter of Credit (L/C), or PayPal for smaller orders. For new buyers, a 30% deposit upfront with balance paid before shipment is standard. Established customers may negotiate net 30 or net 60 terms. Using escrow services or trade assurance platforms can protect buyers, especially when sourcing from unfamiliar suppliers. Always confirm currency exchange rates and any bank fees in advance to avoid unexpected costs. -

What quality assurance certifications should I look for to ensure compliance and reliability in 4-pin LED strip connectors?

Look for certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and ISO 9001 quality management certification. These indicate compliance with safety, environmental, and manufacturing standards critical for European, Middle Eastern, and South American markets. Some suppliers also provide in-house testing reports for electrical continuity, insulation resistance, and durability. Requesting third-party lab test certificates adds an extra layer of confidence before committing to large-scale orders. -

How can I optimize logistics and shipping when importing 4-pin LED strip connectors internationally?

Choose suppliers located near major ports or with established freight forwarder partnerships to reduce transit times. For cost efficiency, consolidate shipments to avoid multiple small parcels. Air freight suits urgent deliveries but is costlier; sea freight is preferred for bulk orders with flexible timelines. Be aware of customs duties, import regulations, and documentation requirements specific to your country (e.g., CE marking for Europe, INMETRO for Brazil). Collaborating with experienced customs brokers minimizes clearance delays and unexpected charges. -

What strategies help resolve disputes or quality issues with international suppliers of LED strip connectors?

Document all communications and agreements in writing, including specifications, inspection criteria, and delivery terms. Conduct pre-shipment inspections through third-party agencies to identify defects early. If issues arise, engage suppliers promptly with clear evidence (photos, test results). Many suppliers offer partial refunds, replacements, or discounts for quality discrepancies. For persistent disputes, leverage trade mediation services or contractual clauses specifying arbitration venues. Building long-term supplier relationships based on trust and transparency reduces conflict likelihood. -

Are there specific considerations for sourcing 4-pin LED strip connectors in emerging markets like Africa and South America?

Yes, buyers should prioritize suppliers familiar with local infrastructure challenges such as unstable power supply and varying voltage standards. Opting for connectors with robust insulation and compatibility with 12V or 24V systems common in these regions is essential. Logistics complexity may require flexible shipping solutions and longer lead times. Additionally, understanding import tariffs, local certification requirements, and currency volatility helps in accurate budgeting. Partnering with suppliers offering technical support and after-sales service in these markets enhances operational reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 4 pin led light strip connector

Strategic sourcing of 4-pin LED light strip connectors is pivotal for businesses aiming to optimize performance, reliability, and cost-efficiency in their lighting projects. Understanding the technical nuances—such as compatibility with RGB strip configurations, wire gauge requirements, and connector types—enables buyers to make informed procurement decisions that reduce installation challenges and improve product longevity. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, prioritizing high-quality, durable connectors from reputable suppliers can significantly elevate project outcomes and client satisfaction.

Key takeaways for strategic sourcing include:

- Compatibility Assurance: Verify connector and LED strip specifications to avoid mismatches that can cause system failures.

- Quality and Certification: Opt for connectors with proven durability and compliance with international standards to withstand diverse environmental conditions.

- Supply Chain Reliability: Establish partnerships with manufacturers and distributors who offer consistent product availability and responsive support.

- Cost-Benefit Balance: Evaluate total cost of ownership by factoring in installation ease, maintenance, and scalability for long-term projects.

Looking ahead, the demand for smart, energy-efficient LED solutions will continue to drive innovation in connector design and integration capabilities. Buyers who invest strategically today will be well-positioned to leverage emerging technologies and meet evolving market needs. We encourage international buyers to engage closely with trusted suppliers and industry experts to secure competitive advantages in their LED lighting ventures.