Guide to Led Strip Lighting With Switch

- Introduction: Navigating the Global Market for led strip lighting with switch

- Understanding led strip lighting with switch Types and Variations

- Key Industrial Applications of led strip lighting with switch

- Strategic Material Selection Guide for led strip lighting with switch

- In-depth Look: Manufacturing Processes and Quality Assurance for led strip lighting with switch

- Comprehensive Cost and Pricing Analysis for led strip lighting with switch Sourcing

- Spotlight on Potential led strip lighting with switch Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strip lighting with switch

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lighting with switch Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strip lighting with switch

- Strategic Sourcing Conclusion and Outlook for led strip lighting with switch

Introduction: Navigating the Global Market for led strip lighting with switch

The global demand for LED strip lighting with switch is rapidly expanding as businesses seek versatile, energy-efficient, and easily controllable lighting solutions. For international B2B buyers—especially those operating in diverse and dynamic markets like Africa, South America, the Middle East, and Europe—understanding the nuances of this product category is essential to securing reliable supply chains and optimizing project outcomes. These LED strips offer not only illumination but also precise on/off control integrated into the design, enhancing convenience and reducing installation complexity.

This guide delivers an authoritative roadmap for sourcing and deploying LED strip lighting with switches, addressing critical factors such as product types, material quality, manufacturing standards, and rigorous quality control processes. It also provides in-depth insights into selecting trustworthy suppliers, evaluating cost structures, and navigating regional market trends. By covering technical specifications, wiring best practices, and compliance considerations, the guide equips buyers to make informed decisions that reduce risks and maximize value.

Key benefits of this comprehensive resource include:

- Clarity on product variations to match specific application needs, from residential to commercial and industrial uses

- Guidance on quality assurance to ensure durability, safety, and performance longevity

- Strategies for supplier vetting tailored to international trade complexities, including logistics and regulatory compliance

- Cost optimization techniques to balance budget constraints with product excellence

For buyers in fast-growing and emerging markets, this guide serves as a critical tool to confidently navigate the complexities of the global LED strip lighting supply ecosystem and achieve successful, scalable lighting projects with integrated switch functionality.

Understanding led strip lighting with switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Inline Switch LED Strip | Switch integrated directly on the power cable or strip | Retail displays, office lighting, residential projects | Easy installation; limited switch durability under heavy use |

| Remote Control Switch LED | Wireless switch (IR/RF/Bluetooth) controlling the strip | Hospitality, event venues, smart buildings | Flexible control; higher initial cost and complexity |

| Touch Sensor Switch LED | Capacitive touch control embedded on the strip or controller | Modern office spaces, high-end retail, exhibitions | Sleek design; sensitive to environmental interference |

| Dimmer Switch LED Strip | Switch combined with dimming function for brightness control | Commercial spaces, restaurants, architectural lighting | Enhanced ambiance control; requires compatible drivers |

| Waterproof Switch LED Strip | Switch and strip designed for moisture resistance | Outdoor lighting, industrial sites, signage | Suitable for harsh environments; slightly higher cost |

Inline Switch LED Strip

This type features a physical switch mounted directly on the power cable or the strip itself, enabling straightforward on/off control. It is ideal for straightforward applications such as retail displays or office lighting where simplicity and cost-effectiveness are priorities. For B2B buyers, these strips offer ease of installation and maintenance but may not withstand frequent heavy use or harsh environments, making them better suited for controlled indoor settings.

Remote Control Switch LED Strip

Remote-controlled LED strips use infrared, radio frequency, or Bluetooth technology to allow wireless switching and sometimes color or mode changes. This flexibility makes them highly suitable for hospitality venues, event spaces, and smart building projects where user convenience and advanced control are valued. Buyers should consider the added cost and the need for compatible control systems but benefit from enhanced user experience and adaptability.

Touch Sensor Switch LED Strip

Incorporating capacitive touch sensors, these LED strips or their controllers allow switching with a simple touch, offering a modern and minimalist design. They are favored in high-end retail environments, exhibitions, and contemporary office spaces where aesthetics and intuitive operation matter. Buyers should note the sensitivity of touch sensors to environmental factors like humidity or electrical noise and ensure proper installation conditions.

Dimmer Switch LED Strip

These LED strips come integrated with dimmer switches or controllers, allowing users to adjust brightness levels easily. They are commonly used in commercial settings such as restaurants, architectural lighting, and conference rooms where ambiance control is critical. For B2B purchasers, compatibility with LED drivers and power supplies is essential to ensure smooth dimming without flicker, and investing in quality dimmers can enhance customer satisfaction.

Waterproof Switch LED Strip

Designed with sealed switches and protective coatings, these LED strips withstand moisture, dust, and harsh conditions, making them ideal for outdoor installations, industrial sites, and illuminated signage. B2B buyers targeting markets in regions with challenging weather conditions—such as parts of Africa, the Middle East, and South America—should prioritize these products despite their higher cost, as they offer durability and reduced maintenance over time.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Key Industrial Applications of led strip lighting with switch

| Industry/Sector | Specific Application of led strip lighting with switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing & Warehousing | Machine area lighting with localized control | Enhances worker safety and energy efficiency by enabling on-demand lighting control | Durable strips with IP rating for dust and moisture; robust switch mechanism for industrial use |

| Retail & Commercial Spaces | Shelf and display case illumination with switch control | Improves product visibility and customer experience while reducing energy waste | High color rendering index (CRI) LEDs; flexible strips for custom fitting; reliable switch quality |

| Hospitality & Entertainment | Ambient and accent lighting in hotels, restaurants, and event venues | Creates dynamic atmospheres with easy on/off control, reducing operational complexity | Customizable color options; dimmable switches; compliance with regional electrical standards |

| Transportation & Logistics | Cargo hold and vehicle interior lighting with integrated switch | Provides efficient, localized lighting control to improve loading/unloading safety and reduce power consumption | Vibration-resistant strips; compact switch design; compatibility with vehicle electrical systems |

| Healthcare Facilities | Patient room and corridor lighting with switch-enabled LED strips | Supports controlled lighting environments to enhance patient comfort and staff efficiency | Medical-grade materials; flicker-free LEDs; easy-to-clean surfaces; compliance with health safety standards |

Manufacturing & Warehousing

In manufacturing plants and warehouses, LED strip lighting with switches is commonly deployed for machine area illumination and workstations. The ability to switch lighting on or off locally allows workers to control illumination only when needed, thereby reducing unnecessary energy consumption. These environments demand LED strips that are robust and resistant to dust, moisture, and vibrations, especially in African and Middle Eastern industrial zones where harsh conditions prevail. Buyers should prioritize IP-rated strips and switches designed for heavy-duty use to ensure longevity and minimal maintenance.

Retail & Commercial Spaces

Retailers across Europe, South America, and Africa use LED strip lighting with switches to enhance product displays and shelf visibility. The switch feature enables staff to activate lighting selectively, improving the shopping experience while controlling operational costs. High CRI LEDs are essential to accurately render product colors, which is critical for customer appeal. Flexible strips allow for installation in varied shelving designs common in stores from Poland to Brazil. Procurement should focus on reliable switch mechanisms and energy-efficient lighting that complies with regional electrical standards.

Hospitality & Entertainment

Hotels, restaurants, and entertainment venues leverage LED strip lighting with switches to create ambiance and mood lighting that can be easily controlled by staff. This application benefits from customizable color options and dimmable switches to adapt lighting scenes for different events or times of day. Particularly in European and Middle Eastern markets, compliance with stringent electrical safety and energy codes is paramount. Buyers should ensure that the LED strips support dynamic lighting control and come with certifications that meet local regulations.

Transportation & Logistics

In transportation sectors, such as cargo trucks, shipping containers, and logistics hubs, LED strip lighting with integrated switches enhances visibility during loading and unloading processes. Localized control reduces power use when sections of the cargo area are not in use. For B2B buyers in South America and Africa, it is crucial to source vibration-resistant strips and compact, durable switches compatible with existing vehicle electrical systems. This ensures reliable operation in mobile environments subject to shocks and temperature fluctuations.

Healthcare Facilities

Healthcare environments require controlled lighting solutions to improve patient comfort and operational efficiency. LED strip lighting with switches is used in patient rooms and corridors to provide flicker-free, adjustable lighting that can be turned on or off as needed. Buyers from Europe and the Middle East must focus on medical-grade materials that are easy to sanitize and comply with health and safety regulations. The lighting should minimize glare and support a calming environment, making switch-enabled LED strips a practical solution for healthcare facility managers.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip lighting with switch

When selecting materials for LED strip lighting with an integrated switch, international B2B buyers must consider factors that influence durability, safety, and compliance across diverse environments such as Africa, South America, the Middle East, and Europe. The choice of materials impacts product lifespan, installation complexity, and suitability for specific applications, including indoor, outdoor, and industrial uses.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a transparent thermoplastic known for its excellent impact resistance, high temperature tolerance (typically up to 135°C continuous use), and good electrical insulation properties. It also offers UV resistance when treated, which is critical for outdoor applications.

Pros & Cons:

PC’s durability and clarity make it ideal for LED strip covers and switch housings, providing protection without compromising light quality. It is lightweight and easy to mold, supporting complex designs. However, untreated PC can yellow over time under prolonged UV exposure, and it is more expensive than simpler plastics like PVC.

Impact on Application:

Polycarbonate is suited for LED strips with switches installed in environments requiring robust mechanical protection and clarity, such as retail displays or architectural lighting. Its UV resistance is a key advantage for outdoor or semi-outdoor installations common in Middle Eastern and South American climates.

International B2B Considerations:

Buyers in Europe (e.g., Germany, Poland) will appreciate PC’s compliance with RoHS and REACH regulations, ensuring chemical safety. African and Middle Eastern buyers should verify UV stabilization treatments for harsh sunlight exposure. Polycarbonate components often meet ASTM D3935 and DIN 7728 standards, facilitating cross-border acceptance.

2. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a versatile plastic widely used for insulation and flexible housings. It offers good chemical resistance, flame retardancy, and moderate temperature tolerance (up to 60-70°C). It is less transparent than PC but can be made translucent or colored.

Pros & Cons:

PVC is cost-effective and easy to extrude into flexible strips, making it a popular choice for LED strip casings and switch covers. However, it is less heat resistant, which may limit use in high-temperature environments. PVC can emit harmful gases if burned, raising safety concerns.

Impact on Application:

PVC is ideal for indoor LED strip lighting with switches, especially in commercial or residential settings where cost efficiency is prioritized. Its flexibility supports complex installations in confined or curved spaces, common in European and South American urban projects.

International B2B Considerations:

PVC’s compliance with international flame retardancy standards (UL 94 V-0, IEC 60332) is crucial for buyers in all regions. African markets should consider the availability of low-smoke, zero-halogen PVC variants to meet safety codes. European buyers will focus on REACH compliance and potential restrictions on phthalates.

3. Aluminum (Anodized or Powder-Coated)

Key Properties:

Aluminum is a lightweight metal with excellent thermal conductivity, corrosion resistance (especially when anodized or powder-coated), and mechanical strength. It withstands temperatures up to 200°C and offers electromagnetic interference (EMI) shielding.

Pros & Cons:

Aluminum is often used for LED strip lighting channels and switch housings where heat dissipation is critical. It improves LED longevity by preventing overheating. However, it is more expensive and heavier than plastics, and manufacturing complexity is higher due to machining or extrusion processes.

Impact on Application:

Aluminum is preferred in high-end commercial, industrial, or outdoor LED strip lighting installations with integrated switches, such as in European office buildings or Middle Eastern outdoor signage. Its corrosion resistance suits humid or coastal environments found in parts of Africa and South America.

International B2B Considerations:

Buyers from Europe will value aluminum’s compliance with EN 573 and EN 755 standards for extrusion quality. Middle Eastern and African buyers should assess powder-coating quality to ensure corrosion resistance under harsh weather conditions. Aluminum’s recyclability also aligns with sustainability goals prevalent in European procurement policies.

4. Silicone Rubber

Key Properties:

Silicone rubber is a flexible, heat-resistant elastomer with excellent weatherability, UV resistance, and electrical insulation. It remains stable across a wide temperature range (-60°C to 230°C) and is resistant to moisture and chemicals.

Pros & Cons:

Silicone is commonly used for flexible LED strip covers and switch seals, providing waterproofing and dust protection (IP65 to IP68 ratings). Its elasticity allows for easy installation in irregular spaces. The main drawbacks are higher material costs and lower mechanical strength compared to rigid plastics.

Impact on Application:

Silicone rubber is ideal for LED strip lighting with switches in outdoor, industrial, or wet environments, such as in South American outdoor markets or Middle Eastern humid zones. It enhances product durability where exposure to water or dust is a concern.

International B2B Considerations:

European buyers will expect compliance with EU standards for food-grade or medical-grade silicone if used in sensitive environments. African and South American buyers should verify certifications like ASTM D2000 for elastomer quality. Silicone’s long lifespan reduces maintenance costs, a key factor in remote or infrastructure-challenged regions.

| Material | Typical Use Case for led strip lighting with switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Outdoor and architectural LED strips requiring clear covers | High impact resistance and UV stability | Higher cost; potential yellowing without UV treatment | High |

| Polyvinyl Chloride (PVC) | Indoor flexible LED strip casings and switch housings | Cost-effective and flexible | Lower heat resistance; emits harmful gases if burned | Low |

| Aluminum (Anodized/Powder-Coated) | Heat-dissipating channels and robust switch housings | Excellent thermal conductivity and corrosion resistance | Higher cost and manufacturing complexity | Medium |

| Silicone Rubber | Waterproof and dustproof LED strip covers and switch seals | Superior flexibility and environmental resistance | Higher material cost; less mechanical strength | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lighting with switch

The manufacturing of LED strip lighting with integrated switches involves a series of precise and controlled steps designed to ensure product reliability, efficiency, and safety. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding these manufacturing stages and the quality assurance measures in place is crucial for selecting dependable suppliers and minimizing risks in procurement.

Manufacturing Process Overview

1. Material Preparation

The process begins with sourcing high-quality raw materials:

– Flexible Printed Circuit Boards (FPCBs): The base for LED strips, typically made from polyimide or polyester substrates, prepared with copper traces for electrical conduction.

– LED Chips and Components: Selection of LEDs according to color temperature, brightness, and power ratings. Switch components (mechanical or capacitive) are procured based on design specifications.

– Resistors and Drivers: Precise electronic components are prepared to regulate voltage and current.

– Adhesives and Protective Coatings: High-grade adhesives for mounting and silicone or epoxy coatings for waterproofing and durability.

Strict material verification at this stage ensures components meet electrical and mechanical standards before assembly.

2. Forming and Circuit Fabrication

- Copper Tracing and Etching: Copper layers are etched to form the circuit pathways on the flexible substrate.

- Solder Paste Application: Automated solder paste deposition prepares pads for component placement.

- Component Placement: Surface-mount technology (SMT) machines place LEDs, resistors, and switches on the FPCB with high precision.

- Reflow Soldering: Components are soldered through controlled heating to establish secure electrical and mechanical connections.

3. Assembly

- Switch Integration: The switch is either mounted directly on the strip or integrated into the power supply wiring, depending on design. This can be a physical toggle, push-button, or touch-sensitive switch.

- Power and Wiring Setup: Power connectors and wiring harnesses are attached, often using soldering or specialized connectors to ensure robust connections.

- Encapsulation and Sealing: For outdoor or moisture-exposed applications, strips are coated with silicone or encased in PVC to enhance durability and waterproofing.

4. Finishing and Packaging

- Cutting and Custom Lengths: LED strips are cut to customer-specified lengths, with clean edges and exposed copper pads for easy installation.

- Labeling and Instructions: Each strip is labeled with voltage ratings, polarity markings, and safety instructions. Packaging is designed to protect during transit and may include reels or spools for ease of handling.

Quality Assurance and Control (QA/QC) Framework

Robust QA/QC processes underpin the manufacturing of LED strip lighting with switches, aiming to meet international standards and customer expectations.

Relevant International Standards and Certifications

- ISO 9001: The foundation for quality management systems, ensuring consistent manufacturing processes and continual improvement.

- CE Marking (Europe): Confirms compliance with EU safety, health, and environmental requirements, critical for buyers in Poland, Germany, and the wider European market.

- RoHS Compliance: Restricts hazardous substances like lead and mercury, a must for environmentally conscious buyers globally.

- UL Certification (North America and beyond): Indicates product safety and performance under American standards, often valued by global buyers as a mark of quality.

- IP Ratings: Define ingress protection levels for dust and water resistance, essential for outdoor or industrial applications.

- Other Regional Certifications: Buyers in the Middle East or South America may require local certifications or approvals depending on regulatory environments.

QC Checkpoints Throughout Manufacturing

- Incoming Quality Control (IQC): Raw materials and components undergo rigorous inspection for dimensional accuracy, electrical characteristics, and material integrity before production.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspections, component placement accuracy, and switch functionality tests.

- Final Quality Control (FQC): Completed LED strips undergo comprehensive testing including visual inspection, electrical performance, switch operation, and durability assessments before packaging.

Common Testing Methods

- Electrical Testing: Verification of voltage, current draw, and resistance to ensure compliance with specifications and safety.

- Functional Testing: Switches are tested for responsiveness, durability, and lifespan under simulated usage cycles.

- Environmental Testing: Exposure to humidity, temperature cycles, and vibration to assess strip resilience in various climates, which is particularly relevant for buyers in regions with harsh environmental conditions.

- Optical Testing: Measurement of brightness, color consistency, and beam angle to confirm lighting performance.

- Safety Tests: Including insulation resistance, short-circuit testing, and thermal stability checks.

How B2B Buyers Can Verify Supplier Quality Control

Supplier Audits

Conducting on-site or remote audits of the supplier’s manufacturing facilities allows buyers to assess:

– Compliance with documented quality management systems (e.g., ISO 9001).

– Effectiveness of QC checkpoints and traceability of production batches.

– Calibration status of testing equipment and staff training.

Reviewing QC Documentation

Request detailed QC reports including:

– Incoming material inspection records.

– In-process and final inspection summaries.

– Test certificates for electrical and safety compliance.

– Batch traceability documentation.

Third-Party Inspections and Certifications

Engaging independent inspection agencies can provide unbiased validation of product quality and conformity. For international buyers, especially in Africa, South America, and the Middle East, third-party certification often eases customs clearance and meets local regulations.

Sample Testing

Ordering pre-production samples or small pilot batches enables buyers to perform their own tests or have them tested by accredited laboratories in their region. This step helps verify supplier claims and assess product suitability for specific applications.

QC and Certification Nuances for International Markets

- Europe (Poland, Germany): Emphasis on CE marking, RoHS, and energy efficiency labels. Buyers should prioritize suppliers with transparent compliance documentation and certifications recognized by EU authorities.

- Middle East: Some countries require local certification or conformity marks. Buyers should confirm supplier familiarity with regional import requirements and potential need for additional testing.

- Africa and South America: Regulatory environments can be diverse and evolving. Buyers should work with suppliers who provide comprehensive documentation and are open to third-party testing to facilitate acceptance by local authorities.

- Environmental and Safety Standards: Across these regions, the growing focus on sustainability and safety means buyers should prioritize suppliers who demonstrate adherence to international environmental standards and use safe, non-toxic materials.

Key Takeaway:

For international B2B buyers, understanding the detailed manufacturing steps and rigorous quality assurance processes behind LED strip lighting with switches is essential for sourcing reliable products. Verifying supplier capabilities through audits, certifications, and testing safeguards investments and ensures compliance with diverse regional standards. Engaging with suppliers committed to transparent quality management and continuous improvement will lead to successful, scalable lighting projects worldwide.

Comprehensive Cost and Pricing Analysis for led strip lighting with switch Sourcing

Breakdown of Cost Components in LED Strip Lighting with Switch

When sourcing LED strip lighting with an integrated switch, understanding the key cost components is essential for effective budgeting and supplier evaluation. The primary cost drivers include:

- Materials: High-quality LEDs, flexible PCB substrates, switches, resistors, connectors, and protective coatings (e.g., waterproof silicone). Material costs fluctuate based on LED efficiency, switch type, and protective features.

- Labor: Skilled labor is required for assembly, soldering, and quality control. Labor costs vary significantly by manufacturing location and automation level.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Efficient production processes reduce overhead per unit.

- Tooling and Setup: Initial investments in molds, dies, and assembly line setup are amortized over large production runs, impacting per-unit costs.

- Quality Control (QC): Rigorous testing (electrical, durability, safety certifications) ensures compliance and reduces defect rates but adds to overall cost.

- Logistics and Shipping: Freight costs vary based on shipment volume, weight, and destination. International buyers must also consider customs duties and local import taxes.

- Supplier Margin: Markup applied by manufacturers or distributors to cover profit and risk.

Key Pricing Influencers in Bulk LED Strip Light Procurement

Several factors influence the final purchase price for LED strip lighting with switches, especially in international B2B contexts:

- Order Volume and Minimum Order Quantities (MOQ): Larger orders typically yield lower per-unit prices. MOQ requirements vary by supplier and product complexity.

- Product Specifications and Customization: Custom lengths, switch types, IP ratings (waterproofing), and color options increase production complexity and cost.

- Material Quality and Certification: LEDs with higher lumen output, longer lifespan, or certifications such as CE, RoHS, UL, or DLC demand premium pricing but ensure compliance with regional standards.

- Supplier Location and Reliability: Suppliers closer to your market (e.g., European manufacturers for buyers in Poland or Germany) can reduce lead times and shipping costs but may have higher base prices.

- Incoterms and Payment Terms: Terms like FOB, CIF, or DDP affect who bears shipping, insurance, and customs costs, impacting the landed cost.

- Technology and Innovation: Advanced features such as dimmable switches, smart control integration, or energy-efficient designs can elevate costs but add long-term value.

Practical Buyer Tips for Cost-Efficient Sourcing

To optimize procurement costs while ensuring product quality and reliability, international B2B buyers should consider the following strategies:

- Negotiate Volume Discounts and Flexible MOQs: Engage suppliers early to discuss tailored order quantities and pricing tiers. Smaller MOQs with slightly higher prices may be preferable for market testing.

- Evaluate Total Cost of Ownership (TCO): Factor in installation costs, energy consumption, maintenance, and expected product lifespan, not just the purchase price.

- Prioritize Certified Products: Especially for buyers in regulated markets like Europe or the Middle East, certifications prevent costly compliance issues and re-imports.

- Consolidate Shipments: Combine orders to leverage bulk shipping rates, reducing logistics expenses for buyers in Africa and South America where freight can be a major cost driver.

- Leverage Local Partnerships: Collaborate with regional distributors or agents who understand local import regulations and can facilitate smoother customs clearance.

- Clarify Incoterms and Payment Conditions: Ensure contracts clearly specify responsibilities to avoid unexpected charges. DDP (Delivered Duty Paid) terms, while pricier upfront, can simplify procurement for buyers unfamiliar with international logistics.

- Request Samples and Pilot Orders: Before committing to large volumes, testing samples for quality and compatibility with existing installations can prevent costly returns or rework.

Pricing Nuances for Diverse Regional Markets

- Africa and South America: Higher logistics and customs costs often increase landed prices. Buyers should budget for potential delays and consider local regulations affecting import duties.

- Middle East: Compliance with regional safety and energy standards is crucial. Political stability and port efficiency may affect delivery timelines and costs.

- Europe (Poland, Germany): Stringent environmental and electrical certifications are mandatory. Buyers benefit from proximity to EU-based manufacturers but should negotiate payment terms and warranty conditions carefully.

Indicative Pricing Disclaimer

Pricing for LED strip lighting with switches varies widely based on product complexity, order size, and supplier terms. Typical wholesale prices may range from $1 to $5 per meter for standard models, excluding shipping and taxes. Custom or high-specification products command higher prices. Buyers are advised to obtain detailed quotes and perform thorough cost analyses tailored to their unique project requirements.

By comprehensively analyzing cost structures and understanding pricing influencers, international B2B buyers can make informed sourcing decisions that balance cost efficiency with quality and reliability in LED strip lighting with switches.

Spotlight on Potential led strip lighting with switch Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strip lighting with switch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lighting with switch

Critical Technical Properties of LED Strip Lighting with Switch

-

Voltage and Current Ratings

LED strip lights typically operate on low-voltage DC power, most commonly 12V or 24V. Understanding the voltage rating is essential for compatibility with power supplies and ensures safe, efficient operation. The current rating, often expressed in amperes (A), determines the wire gauge and switch capacity needed to handle the load without overheating or voltage drop. For B2B buyers, ensuring correct voltage and current specs prevents installation failures and costly downtime. -

Material Quality and IP Rating

The quality of materials, such as the type of PCB (Printed Circuit Board) and LED chips used, directly impacts the durability and light output consistency. Additionally, the Ingress Protection (IP) rating indicates resistance to dust and moisture. For example, an IP65 rating means the strip is dust-tight and protected against water jets, suitable for outdoor or humid environments. Selecting the right IP rating is critical for international projects where environmental conditions vary widely. -

Switch Type and Electrical Load Capacity

The integrated or attached switch must be rated to handle the total power load of the LED strip. Common switch types include toggle, rocker, or push-button, each with specific mechanical and electrical durability. For commercial applications, switches should comply with relevant safety standards (e.g., CE, RoHS) to ensure reliability and regulatory compliance. Buyers should verify switch ratings to avoid premature failures in high-use environments. -

Color Temperature and Brightness (Lumen Output)

LED strips come in various color temperatures measured in Kelvins (K), ranging from warm white (~2700K) to cool white (~6500K), as well as RGB options for color-changing effects. Brightness is measured in lumens per meter and affects the illumination level. Choosing the correct color temperature and brightness is vital for achieving the desired ambiance and functionality in retail, hospitality, or office settings. -

Cutting and Connection Flexibility

LED strips are designed to be cut at specific intervals without damaging the circuit, allowing customization of length on site. The ease of connecting multiple strips, often via solderless connectors or terminals, impacts installation speed and maintenance. For large-scale B2B projects, flexible cutting and connection options reduce labor costs and simplify future modifications. -

Power Consumption and Energy Efficiency

Power consumption is typically rated in watts per meter (W/m). More efficient strips deliver higher brightness with lower energy use, reducing operational costs. For buyers in regions with high electricity costs or sustainability mandates, prioritizing energy-efficient LED strips with switch integration can be a significant competitive advantage.

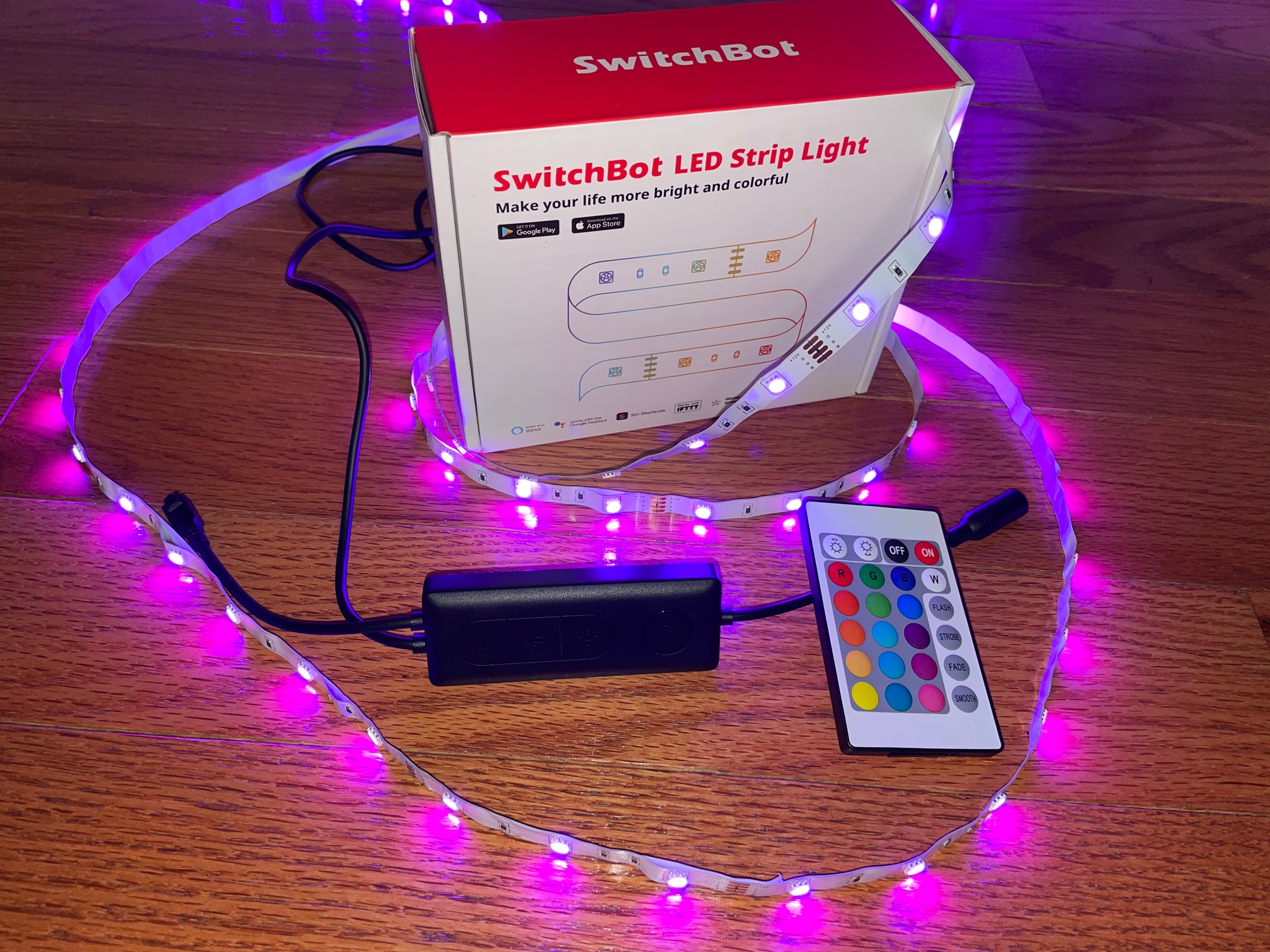

Illustrative Image (Source: Google Search)

Key Trade Terminology for LED Strip Lighting with Switch

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce LED strips or switches that other brands repackage and sell under their own name. For B2B buyers, OEM partnerships often enable customization, better pricing, and exclusive designs tailored to specific market needs. -

MOQ (Minimum Order Quantity)

The smallest quantity of units a supplier is willing to sell in a single order. Understanding MOQ is essential for managing inventory costs and cash flow, especially for buyers in emerging markets where storage space and capital might be limited. -

RFQ (Request for Quotation)

A formal process where buyers invite suppliers to submit price and delivery proposals based on specified product requirements. RFQs are critical for comparing offers transparently and negotiating terms suitable for large or recurring orders. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and tariffs between buyer and seller. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Clear understanding of Incoterms helps buyers from Africa, South America, the Middle East, and Europe manage logistics and avoid unexpected costs. -

Dimming Capability

A feature allowing the LED strip brightness to be adjusted via compatible controllers or switches. This term is important for buyers specifying ambient lighting solutions or energy-saving features in commercial installations. -

Power Injection

A method of supplying additional power at intervals along long LED strip runs to prevent voltage drop and maintain uniform brightness. Knowing this term helps buyers plan wiring layouts for large-scale projects, ensuring consistent lighting quality.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions that optimize product performance, installation efficiency, and cost-effectiveness across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lighting with switch Sector

Market Overview & Key Trends

The global LED strip lighting with switch market is experiencing robust growth, driven by increasing demand for energy-efficient, customizable lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe (including mature markets like Germany and Poland), several key market dynamics stand out:

-

Energy Efficiency and Cost Savings: LED strip lights offer significant energy savings compared to traditional lighting, which is a major driver in regions with rising energy costs and sustainability goals. The integration of switches enhances control, further optimizing energy use.

-

Technological Advancements: Innovations such as smart LED strips with app-controlled switches, dimmable features, and color-changing capabilities are gaining traction. Buyers looking to differentiate their offerings or improve end-user experience prioritize these advanced functionalities.

-

Customization and Flexibility: The ability to tailor LED strips to specific lengths, colors, and switch types aligns with diverse project requirements—from retail displays in Europe to hospitality lighting in the Middle East. Flexible sourcing models, including bulk wholesale and custom orders, are increasingly preferred.

-

Supply Chain and Sourcing Trends: Global supply chain resilience remains a focus. Buyers from emerging markets prioritize suppliers who offer reliable delivery, competitive pricing, and quality certifications. Direct sourcing from manufacturers, often in Asia, combined with regional warehouses in Europe or the Middle East, helps mitigate logistics delays.

-

Regulatory Compliance and Standards: European buyers must navigate stringent CE and RoHS certifications, while Middle Eastern and African markets increasingly adopt such standards to ensure product safety and environmental compliance.

-

Market Segmentation: Industrial and commercial applications, such as factory lighting and office ambiance, are growing faster than residential sectors in many emerging regions. This trend influences demand for robust, durable LED strips with reliable switches designed for heavy-duty use.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a core consideration for B2B buyers in the LED strip lighting with switch sector. International buyers increasingly demand products that minimize environmental impact throughout their lifecycle.

-

Environmental Impact: LED strip lighting reduces energy consumption significantly compared to incandescent or fluorescent alternatives, lowering carbon footprints. However, the production phase still involves resource-intensive processes, including rare earth elements and plastics.

-

Ethical Supply Chains: Transparency in sourcing raw materials and components is critical. Buyers from Europe and the Middle East emphasize compliance with ethical labor standards and conflict-free sourcing, particularly for electronic components and wiring materials.

-

Green Certifications: Certifications such as Energy Star, RoHS (Restriction of Hazardous Substances), and WEEE (Waste Electrical and Electronic Equipment Directive) are vital for verifying environmental compliance. These certifications assure buyers that products meet high standards for hazardous material restrictions and recyclability.

-

Material Innovation: The use of recyclable materials, low-VOC adhesives, and halogen-free wiring enhances product sustainability. Suppliers offering LED strips with eco-friendly packaging and longer lifespans align well with corporate sustainability goals.

-

Circular Economy Initiatives: Some suppliers are adopting take-back programs and refurbishment services for end-of-life LED products, allowing buyers to participate in circular economy models that reduce waste and promote reuse.

For B2B buyers, sourcing from suppliers committed to sustainability not only meets regulatory and corporate social responsibility requirements but also strengthens brand reputation and customer trust.

Brief Evolution and Historical Context

LED strip lighting technology has evolved significantly since its commercial inception in the early 2000s. Initially, LED strips were simple, fixed-color products with limited control options and low brightness levels. Over the past two decades, advancements in semiconductor technology and manufacturing have enabled the production of highly flexible, high-lumen, and color-tunable strips.

The integration of switches—initially mechanical and now increasingly digital or wireless—has transformed LED strips from mere lighting elements into interactive, user-friendly solutions. This evolution has expanded their application scope from accent and decorative lighting to functional and smart lighting systems in commercial and industrial environments.

For international buyers, understanding this progression highlights the importance of selecting suppliers who keep pace with technological innovation and quality improvements, ensuring access to the latest, most reliable LED strip lighting with switch solutions.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lighting with switch

-

How can I effectively vet suppliers of LED strip lighting with switch for international B2B purchases?

Vet suppliers by verifying their business licenses, certifications (such as CE, RoHS, UL), and quality assurance processes. Request product samples and test them for performance and durability under your specific conditions. Check customer references and reviews, especially from clients in your region or industry. Confirm their production capacity and compliance with international standards relevant to Africa, South America, the Middle East, or Europe. Additionally, assess their communication responsiveness and after-sales support to ensure smooth collaboration. -

What customization options are typically available for LED strip lighting with switches in wholesale orders?

Most manufacturers offer customization on LED strip length, switch types (toggle, push-button, remote control), color temperature, brightness levels, and packaging. Some suppliers also provide options for waterproofing (IP ratings), flexible circuit boards, and branding with your company logo. When negotiating, specify your technical and aesthetic requirements early to align production capabilities with your project needs. Customization can enhance product differentiation and meet local market preferences in diverse regions like Europe or the Middle East. -

What are common minimum order quantities (MOQs) and lead times for LED strip lighting with switches, and how can I manage them?

MOQs vary widely but typically range from 500 to 2,000 units, depending on customization and supplier scale. Lead times usually span 4 to 8 weeks, accounting for production and shipping. To manage MOQs, consider consolidating orders with other buyers or negotiating smaller trial batches initially. Planning orders well in advance and maintaining good supplier relationships can also help secure better terms. Factor in potential customs clearance delays in your region to avoid supply chain disruptions. -

Which payment terms and methods are advisable for international B2B transactions involving LED strip lighting with switches?

Common payment terms include 30% upfront deposit with the balance paid before shipment or upon delivery via Letter of Credit (L/C). Secure payment methods such as bank transfers (T/T), L/C, or escrow services are recommended to mitigate risks. For new suppliers, use smaller initial payments and progressively increase trust. Always clarify currency and potential transaction fees upfront, especially when dealing with suppliers from different continents to avoid unexpected costs. -

What quality assurance (QA) certifications should I require for LED strip lighting with switches to ensure compliance and safety?

Require certifications like CE (Europe), RoHS (hazardous substances), UL or ETL (North America), and IEC standards relevant to your region. For Middle East and African markets, verify compliance with local regulatory bodies or import standards. Confirm that suppliers conduct in-house testing for voltage stability, heat resistance, and switch durability. Request detailed QA reports and factory inspection records to ensure consistent quality, reducing the risk of returns or warranty claims. -

How should I approach logistics and shipping when importing LED strip lighting with switches internationally?

Choose suppliers experienced with international shipping and familiar with export documentation such as commercial invoices, packing lists, and certificates of origin. Decide between air freight for faster delivery or sea freight for cost efficiency, balancing speed and budget. Consider Incoterms carefully (e.g., FOB, CIF) to clarify responsibility for shipping costs and risks. Collaborate with reliable freight forwarders who can navigate customs procedures in your country to avoid delays and unexpected fees. -

What steps can I take to resolve disputes or quality issues with overseas suppliers of LED strip lighting with switches?

Document all agreements and communications clearly, including specifications, delivery schedules, and payment terms. Upon receiving goods, perform immediate quality inspections and report discrepancies within the supplier’s claim window. Use contractual dispute resolution clauses, such as arbitration or mediation, ideally specifying jurisdiction favorable to your location. Maintain professional but firm communication, and consider engaging local trade chambers or export promotion agencies for assistance in cross-border conflict resolution. -

Are there any region-specific considerations for sourcing LED strip lighting with switches for markets in Africa, South America, the Middle East, and Europe?

Yes, regional factors such as voltage standards (110V vs. 220-240V), climate conditions (humidity, temperature), and import regulations vary significantly. For instance, waterproof and dustproof ratings (IP65+) may be critical in tropical or desert climates. European markets demand strict environmental compliance and energy efficiency labels. Understanding local consumer preferences and infrastructure limitations will guide product selection and supplier negotiations, ensuring your LED strips with switches perform reliably and meet end-user expectations in each target region.

Strategic Sourcing Conclusion and Outlook for led strip lighting with switch

Strategic sourcing of LED strip lighting with integrated switches demands a comprehensive understanding of both technical and market dynamics to optimize investment and operational outcomes. International buyers, especially those in Africa, South America, the Middle East, and Europe, must prioritize quality assurance, supplier reliability, and customization capabilities to meet diverse regional requirements such as voltage standards and environmental conditions.

Key considerations include selecting products with robust wiring configurations and appropriate wire gauge to ensure safety and consistent performance across large-scale installations. Leveraging wholesale purchasing not only reduces unit costs but also enables access to cutting-edge technologies like dimmable and smart LED strips, fostering innovation in lighting solutions tailored to local market demands.

Looking ahead, the LED strip lighting sector is poised for continued growth driven by energy efficiency mandates and expanding applications in commercial and industrial spaces. Buyers are encouraged to engage with reputable suppliers offering comprehensive warranties, flexible customization, and scalable solutions to future-proof their lighting investments. By adopting a strategic sourcing approach grounded in technical expertise and market insight, international B2B buyers can secure competitive advantages and drive sustainable growth in their lighting projects.