Introduction: Navigating the Global Market for recessed led strip lighting

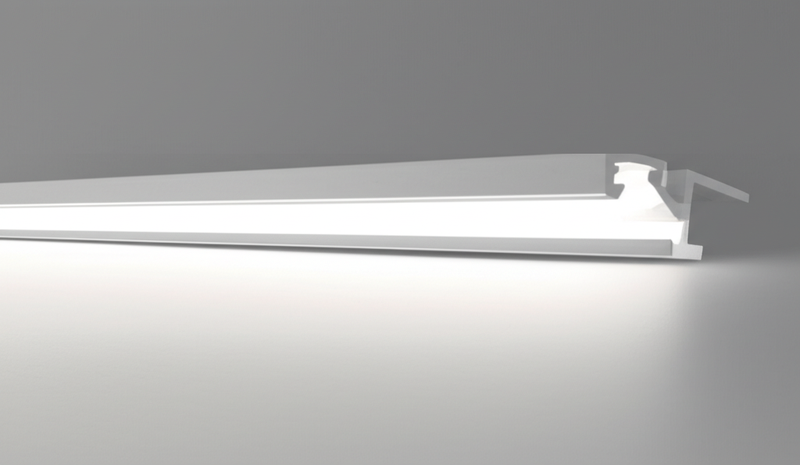

Recessed LED strip lighting has emerged as a pivotal innovation in modern architectural and commercial illumination, offering unmatched energy efficiency, design flexibility, and longevity. For international B2B buyers—especially those operating across Africa, South America, the Middle East, and Europe—understanding the nuances of this technology is essential to sourcing solutions that meet diverse market demands and regulatory standards. Whether upgrading retail environments in Italy, outfitting hospitality spaces in Thailand, or enhancing corporate offices in South Africa, recessed LED strip lighting delivers discreet, customizable lighting that seamlessly integrates with contemporary design aesthetics.

This comprehensive guide equips buyers with a deep dive into the critical aspects of recessed LED strip lighting. It covers the variety of product types available, from flexible to rigid strips, and examines the impact of materials such as LED chips, PCBs, and adhesive backings on product performance and durability. Detailed insights into manufacturing processes and rigorous quality control measures ensure buyers can evaluate supplier reliability and product compliance confidently. Additionally, the guide addresses cost considerations and market trends, enabling strategic procurement decisions aligned with budget and quality expectations.

By consolidating technical knowledge, supplier evaluation criteria, and practical FAQs, this resource empowers international buyers to navigate complex supply chains efficiently. It highlights actionable strategies for mitigating risks related to product quality and compliance, ensuring investments in recessed LED strip lighting deliver long-term value, sustainability, and aesthetic excellence across varied regional markets.

Understanding recessed led strip lighting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Aluminum Channel | Rigid aluminum housing, frosted/diffuser covers | Office lighting, retail displays, hospitality | Pros: Durable, excellent heat dissipation, neat finish Cons: Less flexible, higher installation complexity |

| Flexible Silicone Recessed | Bendable silicone housing, waterproof options | Outdoor facades, curved architectural features | Pros: High flexibility, weather-resistant Cons: Slightly higher cost, moderate heat dissipation |

| RGB & Tunable White Strips | Color-changing LEDs with recessed mounting options | Entertainment venues, luxury hotels, showrooms | Pros: Customizable ambiance, smart control integration Cons: Requires advanced controllers, higher price |

| Ultra-Thin Profile Strips | Slim, low-profile design for very narrow recesses | Retail shelving, museum exhibits, cabinetry | Pros: Discreet, easy integration in tight spaces Cons: Lower brightness, limited heat management |

| High-CRI Specialty Strips | High Color Rendering Index LEDs for true color accuracy | Art galleries, fashion boutiques, medical facilities | Pros: Enhanced color fidelity, premium appeal Cons: Higher cost, niche application |

Standard Aluminum Channel

This type features a sturdy aluminum profile that houses LED strips, often paired with frosted or clear diffusers to soften light output. Its rigid structure ensures excellent heat dissipation, prolonging LED lifespan. Ideal for commercial offices, retail environments, and hospitality settings, these channels provide a professional finish that aligns with modern interior design trends. B2B buyers should consider the installation complexity and ensure compatibility with existing electrical standards in target markets, especially in Europe and the Middle East where regulations can be stringent.

Flexible Silicone Recessed Strips

Designed for curved or uneven surfaces, these LED strips are encased in flexible, often waterproof silicone housings. This makes them perfect for outdoor architectural lighting, signage, and facades common in urban developments in Africa and South America. Buyers should evaluate environmental resistance and certifications such as IP ratings to ensure durability. While costlier than rigid options, their adaptability supports innovative design projects requiring non-linear lighting solutions.

RGB & Tunable White Strips

These recessed LED strips enable dynamic color changes and adjustable white tones, controlled via smart systems or dedicated controllers. They are widely used in entertainment venues, luxury hotels, and showroom displays across international markets like Italy and Thailand, where ambiance customization is a priority. B2B purchasers must factor in the need for compatible control systems and potential technical support, balancing upfront costs against the value of enhanced user experience and energy savings.

Ultra-Thin Profile Strips

Ultra-slim LED strips fit into very narrow recesses, making them suitable for discreet lighting in retail shelving, museum exhibits, and cabinetry. Their minimalistic design appeals to buyers targeting premium retail and cultural spaces, especially in Europe. However, these strips may offer lower brightness and less effective heat management, so buyers should assess lumen requirements carefully and consider supplemental lighting where necessary.

High-CRI Specialty Strips

High Color Rendering Index (CRI) LED strips provide superior color accuracy, essential for art galleries, fashion boutiques, and medical facilities where true color perception is critical. These strips are a premium option favored by buyers seeking to enhance product presentation or professional environments. The higher initial investment is justified by improved visual quality and customer satisfaction, but buyers should verify supplier credentials and CRI ratings to ensure authenticity and compliance with regional standards.

Related Video: How to Install Recessed LED Channel and LED Strip Lights in Drywall for Recessed Linear Lighting

Key Industrial Applications of recessed led strip lighting

| Industry/Sector | Specific Application of recessed led strip lighting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Display case and shelf lighting | Enhances product visibility, drives sales, and creates premium ambiance | High CRI LED chips for true color rendering; flexible strips for custom fit; energy efficiency for operational cost savings |

| Hospitality & Leisure | Ambient and pathway lighting in hotels and resorts | Improves guest experience, safety, and energy efficiency | Durable, moisture-resistant strips; dimmable and color temperature control; compliance with local electrical standards |

| Manufacturing & Warehousing | Task and safety lighting in assembly lines and storage areas | Increases worker productivity, reduces errors, and enhances safety | Robust heat dissipation; long lifespan LEDs; IP-rated for dust and moisture; ease of maintenance and replacement |

| Healthcare Facilities | Corridor and examination room lighting | Provides consistent, glare-free illumination critical for patient care | High-quality, flicker-free LEDs; antimicrobial housing options; strict compliance with health facility lighting regulations |

| Architectural & Interior Design | Cove and accent lighting for offices and public buildings | Elevates aesthetic appeal, supports brand image, and reduces energy costs | Customizable length and brightness; smart control compatibility; premium finish for visible installations |

Retail & Commercial Spaces

In retail environments, recessed LED strip lighting is extensively used for illuminating display cases and shelving units. This application enhances product visibility and attractiveness, directly influencing customer purchasing decisions. For international buyers, especially in regions like Europe and South America where retail design trends emphasize clean, modern aesthetics, sourcing high CRI (Color Rendering Index) LED strips is critical to ensure colors appear true and vibrant. Additionally, flexible and cuttable strips allow adaptation to various display dimensions, while energy-efficient models help reduce long-term operational costs.

Hospitality & Leisure

Hotels, resorts, and entertainment venues utilize recessed LED strip lighting for ambient lighting and pathway illumination. This lighting improves guest experience by creating inviting atmospheres and ensuring safety in dimly lit areas. Buyers from the Middle East and Africa should prioritize LED strips with moisture-resistant coatings and dimming capabilities to adapt to different moods and environments. Compliance with local electrical and safety standards is essential, as well as selecting products that can withstand varying temperature conditions common in these regions.

Manufacturing & Warehousing

In industrial settings such as manufacturing plants and warehouses, recessed LED strip lighting plays a vital role in task illumination and safety enhancement. These lights provide focused, shadow-free lighting for assembly lines and storage aisles, reducing errors and accidents. Buyers from regions with harsh operational conditions, including parts of Africa and South America, must source LED strips with superior heat dissipation and high IP ratings to resist dust and moisture. Long-lasting LEDs reduce maintenance downtime and costs, critical for continuous industrial operations.

Healthcare Facilities

Healthcare environments demand consistent, glare-free lighting for corridors, examination rooms, and patient areas. Recessed LED strip lighting meets these needs by providing uniform illumination that supports clinical accuracy and patient comfort. Buyers in Europe and the Middle East should consider flicker-free LEDs to reduce eye strain and antimicrobial housings to maintain hygiene standards. Strict adherence to healthcare lighting regulations and certifications is a must to ensure compliance and safety.

Architectural & Interior Design

Architects and interior designers use recessed LED strip lighting in coves, ceilings, and accent lighting to enhance the visual appeal of offices and public buildings. This application supports brand image and creates dynamic environments while offering energy savings. For B2B buyers in markets like Italy and Thailand, the ability to customize length, brightness, and color temperature is paramount. Smart control integration enables flexible lighting scenarios, and premium finishing ensures that visible installations complement the overall design.

Strategic Material Selection Guide for recessed led strip lighting

Aluminum Profiles

Key Properties: Aluminum is lightweight, highly corrosion-resistant, and exhibits excellent thermal conductivity, which is critical for dissipating heat from LED strips. It typically withstands temperatures up to 200°C and offers good mechanical strength without adding significant weight.

Pros & Cons: Aluminum profiles provide durability and enhance LED lifespan by preventing overheating. They are easy to machine and anodize, allowing for aesthetic finishes and surface protection. However, aluminum can be more costly than plastic alternatives and requires precise manufacturing to maintain quality. Its rigidity may limit use in curved or flexible installations.

Impact on Application: Aluminum is ideal for commercial and architectural recessed lighting where heat management and longevity are priorities. Its corrosion resistance suits humid or coastal environments, a consideration for buyers in regions like South America and the Middle East with variable climates.

International B2B Considerations: Aluminum profiles often comply with ASTM B221 and EN 755 standards, widely recognized in Europe and increasingly adopted in Africa and the Middle East. Buyers from Italy and Thailand value anodized finishes for both durability and style. Importers should verify compliance with RoHS and REACH regulations to ensure market acceptance.

Polycarbonate (PC) Channels

Key Properties: Polycarbonate is a transparent thermoplastic with high impact resistance, good heat tolerance (up to about 115°C), and excellent UV stability. It offers electrical insulation and is lightweight compared to metals.

Pros & Cons: PC channels are cost-effective, easy to install, and allow for diffused light effects enhancing visual comfort. However, they have lower thermal conductivity, which can affect LED lifespan if heat is not managed properly. Polycarbonate can yellow over time under intense UV exposure, which may reduce light quality.

Impact on Application: Polycarbonate is suitable for indoor recessed lighting in residential or retail environments where impact resistance and aesthetics are important. Its electrical insulation makes it safer in humid or wet areas. For buyers in Africa and the Middle East, UV resistance is crucial due to strong sunlight exposure.

International B2B Considerations: Compliance with UL 94 V-0 flame retardancy and DIN 4102 fire standards is often required in Europe and South America. Buyers should ensure the polycarbonate used meets local fire safety codes and environmental regulations, especially in regions with strict building codes like Italy and Thailand.

Flexible Silicone Channels

Key Properties: Silicone offers excellent flexibility, high temperature resistance (up to 250°C), and outstanding weather and chemical resistance. It is non-toxic and maintains performance across a wide temperature range.

Pros & Cons: Silicone channels are perfect for curved or irregular recessed installations, providing durability in harsh environments. Their high cost and more complex manufacturing process can be a downside. They also have lower structural rigidity, which may not suit applications requiring firm mounting.

Impact on Application: Ideal for outdoor or industrial recessed LED strip lighting where flexibility and environmental resistance are critical. Buyers in regions with extreme temperature fluctuations, such as parts of Africa and the Middle East, benefit from silicone’s stability.

International B2B Considerations: Silicone materials often meet ASTM D2000 and ISO 10993 biocompatibility standards, important for markets with stringent quality requirements like Europe. Buyers should verify certifications for chemical resistance and flame retardancy, especially for industrial applications in South America and Europe.

Stainless Steel Channels

Key Properties: Stainless steel offers superior mechanical strength, excellent corrosion resistance, and can withstand high temperatures (up to 500°C). It is non-magnetic and highly durable against physical damage.

Pros & Cons: Stainless steel channels provide a premium, long-lasting solution with a sleek finish suitable for high-end commercial applications. They are heavier and more expensive than aluminum or plastics and require specialized manufacturing processes like laser cutting or welding.

Impact on Application: Best suited for environments demanding robustness and hygiene, such as hospitals, kitchens, or outdoor installations exposed to corrosive agents. Buyers in Europe and the Middle East often select stainless steel for its compliance with strict hygiene and durability standards.

International B2B Considerations: Stainless steel channels typically comply with EN 10088 and ASTM A240 standards. European and Middle Eastern buyers prioritize certifications related to corrosion resistance and surface finish quality. Importers should consider the higher logistics cost due to weight when sourcing from distant locations like South America or Africa.

Summary Table

| Material | Typical Use Case for recessed led strip lighting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Profiles | Commercial and architectural lighting requiring heat dissipation | Excellent thermal conductivity and corrosion resistance | Higher cost and less flexible | Medium |

| Polycarbonate Channels | Indoor residential and retail lighting with impact resistance | Cost-effective, lightweight, and UV resistant | Lower heat dissipation, potential yellowing | Low |

| Flexible Silicone Channels | Outdoor/industrial lighting needing flexibility and weather resistance | High temperature and chemical resistance, flexible | Higher cost, less structural rigidity | High |

| Stainless Steel Channels | High-end, hygienic, or harsh environment installations | Superior strength and corrosion resistance | Heavy, expensive, complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for recessed led strip lighting

Manufacturing recessed LED strip lighting involves a series of precise, interlinked stages that ensure the final product meets high standards of durability, performance, and aesthetic appeal. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding these processes and quality assurance measures is crucial for selecting reliable suppliers and ensuring product consistency across different markets.

Core Manufacturing Stages of Recessed LED Strip Lighting

-

Material Preparation and Sourcing

The foundation of quality LED strips lies in sourcing premium raw materials. This includes high-grade LED chips, flexible or rigid printed circuit boards (PCBs), adhesive backings, and aluminum or polycarbonate housings for recessed channels. Top-tier LED chips, often from renowned manufacturers, provide superior luminous efficacy and long operational life, directly influencing energy efficiency and brightness. PCBs must be selected based on heat dissipation properties to prevent premature failures. Adhesive quality affects installation reliability, especially in varied climates encountered internationally. -

PCB Fabrication and Forming

PCBs are fabricated according to design specifications, either flexible for curved installations or rigid for straight runs. Precision in copper layering and solder mask application ensures electrical integrity and thermal management. Forming the recessed channels typically involves extrusion or injection molding of aluminum or plastic, designed to house the LED strips securely and facilitate heat dissipation. The channel’s finish and dimensions are critical for seamless integration into walls, ceilings, or floors. -

LED Chip Mounting and Assembly

Automated pick-and-place machines mount LED chips onto the PCB with exacting precision, followed by soldering processes—commonly reflow soldering—to ensure robust electrical connections. Additional components like resistors or controllers may be integrated during assembly. The LED strips are then enclosed within the recessed channels, often with diffusers or covers that soften light output and protect the LEDs from dust and moisture. -

Finishing and Packaging

After assembly, strips undergo cleaning and protective coating applications to enhance durability against environmental factors such as humidity or UV exposure. Packaging is designed to protect the product during international shipping, with anti-static materials and shock-absorbing inserts to prevent damage. Clear labeling with product specifications, certifications, and handling instructions supports compliance and ease of use for B2B clients globally.

Quality Assurance and Control (QA/QC) Protocols

Quality assurance in recessed LED strip lighting manufacturing is multi-layered, combining international standards compliance with rigorous in-house testing to guarantee product reliability and safety.

Key International and Industry Standards

- ISO 9001: This global standard certifies the manufacturer’s quality management system, ensuring consistent production quality and continuous improvement practices.

- CE Marking: Essential for European markets, CE certification confirms compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical products, crucial for environmentally conscious buyers in Europe and beyond.

- UL and ETL Certifications: Common in Middle Eastern and North American markets, these attest to product safety under specific electrical and fire standards.

- API or Regional Certifications: Some regions, especially in Africa and South America, may require compliance with local electrical safety and energy efficiency standards.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

This step involves inspection and testing of raw materials, including LED chips, PCBs, adhesives, and housings. Parameters such as chip brightness, PCB conductivity, and adhesive strength are measured to prevent defects from entering production. -

In-Process Quality Control (IPQC)

During assembly, continuous monitoring ensures solder joint integrity, correct component placement, and proper channel fitting. Automated optical inspection (AOI) and manual checks help detect misalignments or soldering faults early. -

Final Quality Control (FQC)

Completed products undergo comprehensive testing, including functional checks, color consistency verification, and durability assessments. Packaging inspections ensure products meet shipping standards.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and power consumption parameters to confirm energy efficiency and safety.

- Luminous Efficacy and Color Temperature Testing: Ensures brightness and color output meet client specifications.

- Thermal Management Testing: Assesses heat dissipation to prevent overheating in recessed installations.

- Environmental Stress Testing: Simulates humidity, temperature fluctuations, and vibration to test product resilience.

- Safety and Insulation Tests: Confirm compliance with electrical safety standards to avoid hazards.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially from diverse regions with varying regulatory environments, supplier QC verification is a strategic step to mitigate risks:

-

Factory Audits: On-site or third-party audits assess manufacturing processes, quality management systems, worker skill levels, and compliance with certifications. These audits provide transparency and build trust.

-

Review of QC Documentation and Test Reports: Request detailed test reports, certification copies, and batch inspection records. Ensure these documents are recent and relevant to the product batch.

-

Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing before shipment, validating the supplier’s quality claims.

-

Sample Orders and Pilot Runs: Before committing to large volumes, order samples or conduct pilot production runs to verify product quality and installation suitability.

QC and Certification Nuances for Buyers in Africa, South America, the Middle East, and Europe

-

Regulatory Variations: Buyers must consider local regulations that may differ significantly. For example, European buyers prioritize CE and RoHS compliance, while Middle Eastern buyers often require UL or equivalent certifications. African and South American markets may have emerging standards or require additional certifications based on import regulations.

-

Environmental Conditions: Suppliers should adapt materials and adhesives to withstand regional climate challenges such as high humidity in tropical Africa or temperature extremes in the Middle East.

-

Documentation and Traceability: Buyers from regulated regions like the EU or Italy demand thorough documentation for customs clearance and warranty claims. Suppliers with robust traceability systems for components and production batches provide a competitive advantage.

-

Energy Efficiency Expectations: European and Middle Eastern buyers increasingly seek products with verified energy savings, aligning with regional sustainability goals. This necessitates transparent luminous efficacy data and energy consumption certifications.

Summary for International B2B Buyers:

When sourcing recessed LED strip lighting, prioritize suppliers with transparent manufacturing processes, comprehensive quality control systems aligned with international standards, and flexibility to accommodate regional requirements. Confirm material quality, production consistency, and certification authenticity through audits, sample testing, and detailed documentation review. Doing so will ensure reliable product performance, regulatory compliance, and long-term satisfaction in your target markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for recessed led strip lighting Sourcing

Breakdown of Cost Components in Recessed LED Strip Lighting

Understanding the cost structure behind recessed LED strip lighting is essential for international B2B buyers aiming to optimize procurement strategies. The main cost components include:

-

Materials: This is the largest portion of the cost, encompassing LED chips, printed circuit boards (PCBs), adhesive backings, housings (aluminum channels or plastic casings), and packaging. Premium LED chips and high-quality PCBs with superior heat dissipation significantly impact both cost and product longevity.

-

Labor: Skilled labor is required for precise assembly, soldering, and quality checks. Labor costs vary widely depending on the manufacturing country, affecting overall pricing.

-

Manufacturing Overhead: Includes factory utilities, machinery depreciation, and indirect labor. Efficient production lines and automation can reduce overhead expenses.

-

Tooling and Setup: Initial costs for mold creation, PCB design, and assembly line setup. These are often amortized over large production volumes.

-

Quality Control (QC): Rigorous testing for performance, durability, and compliance with certifications (e.g., CE, RoHS, UL) adds to costs but ensures product reliability and buyer confidence.

-

Logistics and Shipping: International freight, customs duties, and insurance fees vary by region. For buyers in Africa, South America, the Middle East, and Europe, shipping routes, tariffs, and import regulations substantially influence landed costs.

-

Supplier Margin: Profit margins vary by supplier based on brand positioning, production scale, and value-added services such as customization or after-sales support.

Key Pricing Influencers in Recessed LED Strip Lighting Procurement

Several factors can cause price fluctuations and should be carefully evaluated during supplier selection:

-

Order Volume and Minimum Order Quantity (MOQ): Higher volumes typically yield significant discounts. Buyers should negotiate MOQs that balance cost savings with inventory management capabilities.

-

Specifications and Customization: Custom lengths, color temperatures, waterproof ratings, or smart control features increase production complexity and cost. Standardized products are generally more cost-effective.

-

Material Quality and Certifications: Higher-grade LED chips and PCBs increase upfront costs but improve efficiency and lifespan, reducing total cost of ownership. Certified products may command premium pricing but mitigate risks related to compliance and safety.

-

Supplier Factors: Established manufacturers with robust QC processes and international certifications often price higher but provide reliability and lower risk of defective shipments.

-

Incoterms and Payment Terms: Shipping terms (FOB, CIF, DDP) affect who bears logistics and customs costs. Favorable payment terms (e.g., letters of credit, net 30/60) can improve cash flow and reduce financial risk.

Practical Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Based on Total Cost of Ownership (TCO): Focus not only on unit price but also on product lifespan, energy consumption, and warranty support. Cheaper upfront costs may lead to higher maintenance or replacement expenses.

-

Leverage Volume Consolidation: Pool orders from multiple projects or business units to achieve better pricing tiers without overstocking.

-

Request Detailed Cost Breakdown: Transparent supplier pricing helps identify areas for negotiation, such as material substitutions or packaging optimizations.

-

Understand Regional Logistics Nuances: For buyers in Africa, South America, the Middle East, and Europe, evaluate local import duties, port handling charges, and delivery timelines to avoid hidden costs.

-

Evaluate Supplier Certifications and Compliance: Prioritize suppliers with international certifications to reduce risk of customs delays or product recalls.

-

Consider Long-Term Partnerships: Building relationships with reliable suppliers can unlock better pricing, flexible MOQs, and priority production slots.

-

Plan for Currency Fluctuations: Use hedging strategies or negotiate contracts in stable currencies to mitigate exchange rate risks in international transactions.

Indicative Pricing Disclaimer

Prices for recessed LED strip lighting vary widely depending on specifications, order size, supplier location, and market conditions. The figures and insights provided are indicative to guide buyer decisions and should be validated through direct supplier quotations and market research.

By thoroughly analyzing cost components and pricing influencers, international B2B buyers can strategically source recessed LED strip lighting that balances quality, cost-efficiency, and compliance — ensuring optimal value across diverse markets such as Africa, South America, the Middle East, and Europe.

Spotlight on Potential recessed led strip lighting Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘recessed led strip lighting’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for recessed led strip lighting

Key Technical Properties of Recessed LED Strip Lighting

Understanding critical technical specifications is essential for international B2B buyers to ensure the recessed LED strip lighting they procure meets quality, performance, and compliance expectations.

-

LED Chip Quality and Luminous Efficacy

The LED chips are the core light source, directly impacting brightness (measured in lumens per watt) and energy efficiency. Premium chips provide higher luminous efficacy, translating to more light output with less power consumption. For buyers, selecting suppliers who use reputable chip manufacturers ensures long-term reliability and cost savings in energy. -

PCB Type and Thermal Management

The printed circuit board (PCB) supports LED chips and governs heat dissipation. High-quality PCBs, often made from aluminum or copper bases, effectively disperse heat, preventing premature dimming or failure. Flexible PCBs offer installation versatility, while rigid PCBs provide structural stability. Buyers should verify the PCB material and design to match their installation environment and longevity requirements. -

Material Grade and IP Rating

The enclosure material and ingress protection (IP) rating define resistance to dust, moisture, and mechanical damage. For recessed lighting, especially in humid or outdoor environments, an IP65 or higher rating is often necessary to ensure durability. Material grade impacts corrosion resistance and aesthetic longevity, crucial for commercial projects requiring minimal maintenance. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvins) affects the ambiance—ranging from warm white (~2700K) to cool white (~6000K). CRI indicates how accurately colors appear under the light, with values above 80 being preferable for retail or hospitality spaces. Buyers should specify these parameters to achieve the desired mood and functional lighting effect. -

Dimming Compatibility and Control Systems

Compatibility with dimmer switches or smart controls is vital for energy management and ambiance customization. LED strips supporting PWM (Pulse Width Modulation) dimming or integration with IoT-enabled systems offer enhanced flexibility. This feature is increasingly important for buyers targeting smart buildings or advanced lighting projects. -

Adhesive Backing and Mounting Channels

Strong, durable adhesive backing ensures secure installation on various surfaces without peeling. The inclusion of aluminum mounting channels enhances heat dissipation and provides a clean, professional finish. Buyers should evaluate the adhesive type and channel compatibility to avoid installation failures and ensure aesthetic integration.

Common Trade Terminology in LED Strip Lighting Procurement

Familiarity with industry jargon streamlines communication and negotiation between buyers and suppliers, reducing misunderstandings and expediting procurement processes.

-

OEM (Original Equipment Manufacturer)

Refers to a manufacturer that produces products or components for other companies to rebrand and sell. International buyers often engage OEMs to customize LED strip lighting solutions tailored to their market needs, including branding, specifications, and packaging. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in a single order. Understanding MOQ helps buyers from emerging markets or smaller distributors plan inventory and budget effectively while negotiating favorable terms. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers requesting detailed pricing, lead times, and technical specifications. Well-prepared RFQs ensure that buyers receive comparable offers and facilitate transparent supplier evaluation. -

Incoterms (International Commercial Terms)

Standardized trade terms that define the responsibilities and risks of buyers and sellers in international shipments (e.g., FOB, CIF, DDP). Knowledge of Incoterms enables buyers to negotiate shipping costs, customs clearance, and delivery logistics efficiently. -

CRI (Color Rendering Index)

A technical term but frequently used in trade discussions, CRI measures light quality and its effect on color appearance. Buyers specifying CRI values can ensure product suitability for applications demanding accurate color perception. -

Lead Time

The period from order confirmation to product delivery. For B2B buyers, especially those managing large-scale projects or seasonal demands, understanding and negotiating lead times is critical to maintaining supply chain continuity.

For international buyers in Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms empowers informed purchasing decisions. This knowledge supports selecting high-quality recessed LED strip lighting that meets regulatory standards, project specifications, and budget constraints while minimizing risks associated with international trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the recessed led strip lighting Sector

Market Overview & Key Trends

The global market for recessed LED strip lighting is experiencing robust growth driven by increasing demand for energy-efficient, versatile, and aesthetically pleasing lighting solutions. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe—including markets like Thailand and Italy—are capitalizing on these trends to modernize commercial, residential, and industrial spaces. Key drivers include urbanization, infrastructure development, and rising awareness about energy conservation, which collectively fuel adoption of LED technology over traditional lighting.

Emerging sourcing trends emphasize customization and integration with smart building systems. Buyers increasingly seek LED strip lighting that offers adjustable color temperatures, dimming capabilities, and compatibility with IoT-enabled controls to enhance user experience and operational efficiency. Additionally, flexible PCB options and modular designs allow tailored installations catering to diverse architectural requirements, from intricate commercial interiors in Europe to large-scale infrastructure projects in Africa and the Middle East.

Illustrative Image (Source: Google Search)

Supply chain dynamics reveal a shift toward localized sourcing and diversified supplier bases to mitigate risks associated with geopolitical tensions and logistics disruptions. For instance, buyers in South America and Africa are exploring partnerships with manufacturers offering regional warehousing and faster lead times. High-quality component sourcing, particularly premium LED chips and durable adhesive backings, remains a critical factor influencing product longevity and performance, impacting total cost of ownership for B2B clients.

Overall, recessed LED strip lighting is evolving from a purely functional product to a strategic asset in building design and sustainability initiatives, with buyers prioritizing innovation, reliability, and supplier transparency.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the procurement of recessed LED strip lighting, aligning with global efforts to reduce carbon footprints and promote responsible manufacturing. For international buyers, especially those operating in environmentally conscious markets like Europe and the Middle East, sourcing lighting solutions that meet stringent environmental standards is essential.

The environmental impact of LED strip lighting primarily stems from material selection, manufacturing processes, and end-of-life disposal. Opting for LED strips manufactured with RoHS-compliant components and free from hazardous substances ensures reduced ecological harm. Furthermore, sourcing products that use high-efficiency LED chips and PCBs designed for optimal heat dissipation extends product life, reducing waste and frequency of replacements.

Ethical supply chains are increasingly scrutinized, with buyers demanding transparency regarding labor practices, conflict-free materials, and corporate social responsibility from their suppliers. Certifications such as CE, UL, and ENERGY STAR not only guarantee product safety and performance but also signify adherence to ethical and environmental benchmarks. Green packaging and reduced plastic use in shipping further enhance the sustainability profile.

For B2B buyers in emerging markets, integrating sustainability criteria into procurement decisions can unlock access to premium clients and government projects that mandate eco-friendly solutions. Partnering with manufacturers committed to continuous innovation in recyclable materials and energy-saving technologies reinforces long-term value and brand reputation.

Evolution and Historical Context

Recessed LED strip lighting has evolved significantly over the past two decades. Initially, lighting solutions were predominantly incandescent or fluorescent, with recessed fixtures limited to bulky, less efficient designs. The advent of LED technology brought about a paradigm shift, enabling slim, flexible strips that could be embedded discreetly into architectural recesses.

This evolution was driven by advancements in LED chip efficiency, PCB materials, and adhesive technologies, allowing for versatile applications across commercial and residential settings. Over time, integration with smart controls and color tuning capabilities transformed recessed LED strips from mere illumination tools to dynamic elements of interior design.

For international B2B buyers, understanding this historical progression underscores the importance of selecting suppliers who leverage cutting-edge manufacturing processes and materials, ensuring that the recessed LED strip lighting solutions they procure are aligned with contemporary performance and sustainability expectations.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of recessed led strip lighting

-

How can I effectively vet suppliers of recessed LED strip lighting for international B2B purchases?

To vet suppliers, start by verifying their certifications such as CE, RoHS, UL, and ISO compliance to ensure product quality and safety standards. Request detailed product datasheets and samples to evaluate build quality and LED chip brands. Check the supplier’s manufacturing capabilities, including PCB quality and adhesive reliability. Assess their export experience and track record with clients in your region (Africa, South America, Middle East, Europe). Use third-party inspection services and review customer feedback on delivery performance and after-sales support to minimize risks before finalizing contracts. -

What customization options are typically available for recessed LED strip lighting, and how can I request them?

Most manufacturers offer customization in length, color temperature (warm, neutral, cool white), brightness, and IP rating for water resistance. You can also request specific PCB flexibility (rigid or flexible), dimming compatibility, and smart control integration (e.g., Wi-Fi or Bluetooth). When requesting customization, provide detailed technical specifications, application environment, and expected performance standards. Confirm MOQ (Minimum Order Quantity) for custom orders and discuss prototyping to ensure the final product meets your design and functional requirements before mass production. -

What are typical MOQ requirements and lead times for recessed LED strip lighting in international trade?

MOQ varies widely depending on customization and supplier scale, commonly ranging from 500 to 5,000 meters per order for standard models. Customized products usually have higher MOQs. Lead times generally span 3 to 8 weeks, factoring in production, quality inspections, and shipping. Buyers should negotiate realistic timelines upfront and consider buffer periods for customs clearance and potential delays. For faster turnaround, inquire about suppliers’ stock availability of standard models and express shipping options. -

Which payment terms are common in international B2B transactions for recessed LED strip lighting, and how can buyers protect their payments?

Common payment terms include 30-50% upfront deposit with balance upon shipment or letter of credit (L/C) for added security. For new suppliers, escrow services or trade assurance platforms can mitigate risk. Ensure contracts clearly specify payment milestones linked to production and inspection stages. Request proforma invoices detailing all costs, including shipping and taxes. For high-value orders, consider using third-party inspection before final payment to verify product compliance and quantity. -

What quality assurance processes should I expect from reputable recessed LED strip lighting manufacturers?

Reputable suppliers conduct multiple quality checks, including LED chip performance testing, PCB soldering integrity, adhesive strength, and final product stress tests for heat dissipation and durability. Look for manufacturers adhering to international standards (CE, RoHS, UL) and who provide test reports or certificates. A robust QA process often includes in-line inspections, aging tests (running lights for 24-72 hours), and batch sampling. Buyers should request quality control documentation and consider third-party factory audits to ensure consistent product quality. -

What certifications and compliance documentation are essential for importing recessed LED strip lighting?

Key certifications include CE (Europe), RoHS (restriction of hazardous substances), UL (safety in North America), and FCC (electromagnetic compliance). For Middle East and African markets, compliance with local electrical safety regulations is critical. Importers should request test reports and certificates from suppliers to facilitate customs clearance and avoid shipment delays. Additionally, verifying compliance with environmental standards and energy efficiency directives can provide competitive advantages and meet buyer expectations in eco-conscious markets. -

How can I manage logistics effectively when importing recessed LED strip lighting internationally?

Coordinate with suppliers to select the best shipping methods based on order size, urgency, and destination port capabilities. Sea freight is cost-effective for large volumes but has longer transit times; air freight suits urgent or smaller shipments. Confirm packaging quality to protect strips from moisture and mechanical damage during transit. Work closely with freight forwarders familiar with your target markets’ customs regulations and taxes. Track shipments actively and prepare for potential delays by maintaining buffer stock to ensure uninterrupted supply. -

What steps should I take if there is a dispute or product quality issue with my recessed LED strip lighting order?

First, document all discrepancies with photos, videos, and inspection reports. Communicate promptly with your supplier, providing clear evidence and referencing agreed specifications. Refer to your purchase contract’s dispute resolution clauses, which often include negotiation, mediation, or arbitration. Engage third-party inspection agencies for impartial assessment if necessary. Maintain professional communication and consider legal advice if disputes escalate. Establishing strong contractual terms and quality agreements upfront can prevent many conflicts before they arise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for recessed led strip lighting

The strategic sourcing of recessed LED strip lighting demands a nuanced approach that balances quality, cost-efficiency, and supplier reliability. For international B2B buyers across Africa, South America, the Middle East, and Europe, understanding the critical components—such as premium LED chips, robust PCBs, and durable adhesive backings—is essential to secure lighting solutions that deliver superior performance and longevity. Prioritizing suppliers with rigorous quality control and compliance certifications ensures consistent product standards that align with global market expectations.

Illustrative Image (Source: Google Search)

Moreover, the versatility and energy efficiency of recessed LED strip lighting offer significant advantages in both commercial and residential projects. Buyers should leverage customizable options, including color temperature and dimming capabilities, to meet diverse client needs while optimizing operational costs. Smart sourcing strategies that incorporate supplier audits, transparent supply chains, and collaborative partnerships can mitigate risks and foster innovation.

Looking ahead, the market for recessed LED strip lighting is poised for growth, driven by sustainability trends and smart building integration. Buyers are encouraged to invest in forward-thinking suppliers who embrace cutting-edge technologies and sustainable manufacturing practices. Engaging proactively with trusted manufacturers will enable businesses to stay competitive and capitalize on emerging opportunities in this dynamic sector.