Introduction: Navigating the Global Market for led strip light dimmer

The global demand for LED strip light dimmers is rapidly expanding, driven by the surge in smart lighting solutions and energy-efficient infrastructure projects worldwide. For international B2B buyers, particularly those operating in dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the complexities of sourcing high-quality LED strip light dimmers is crucial to securing competitive advantages and ensuring product reliability.

LED strip light dimmers play a pivotal role in controlling lighting ambiance, enhancing energy savings, and extending the lifespan of LED installations. Selecting the right dimmer involves assessing various factors including compatibility with LED types, dimming technologies (such as TRIAC, 0-10V, or DMX), and material quality. This guide offers a comprehensive overview of the entire value chain—from product types and materials to manufacturing standards and quality control protocols—empowering buyers to make informed procurement decisions.

In addition to detailed supplier evaluation criteria, cost analysis, and market trends, this guide addresses region-specific considerations, enabling buyers from Egypt, Kenya, Brazil, UAE, Germany, and beyond to navigate regulatory landscapes and logistical challenges effectively. It also includes an extensive FAQ section to clarify common uncertainties and streamline the sourcing process.

By leveraging this expert insight, international B2B buyers can confidently identify reliable manufacturers, negotiate favorable terms, and align their purchasing strategies with evolving market demands. This guide is an indispensable resource for businesses aiming to optimize their supply chain and capitalize on the booming LED lighting market with precision and foresight.

Understanding led strip light dimmer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PWM (Pulse Width Modulation) Dimmer | Controls brightness by varying pulse width; compatible with most LED strips | Commercial lighting, retail displays, architectural lighting | Pros: High precision dimming, energy efficient. Cons: May cause flicker if poorly designed; requires compatible drivers. |

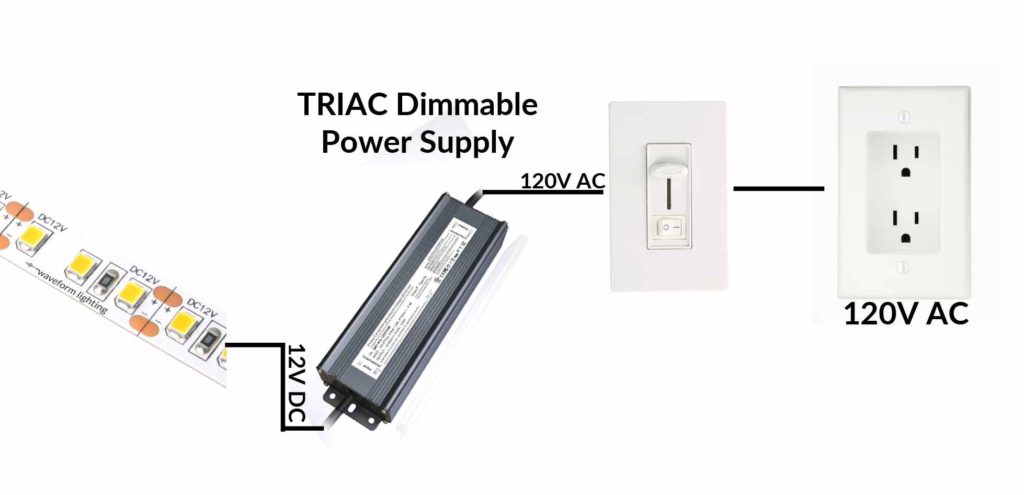

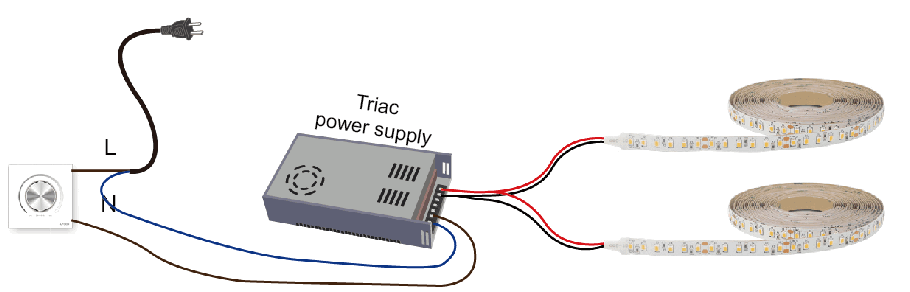

| TRIAC (Leading-edge) Dimmer | Works by chopping AC waveform; suitable for AC-powered LED strips | Residential, hospitality, retrofit projects | Pros: Widely available, cost-effective. Cons: Not compatible with all LED drivers; can cause noise or flicker. |

| 0-10V Analog Dimmer | Uses a low voltage control signal (0-10V) to adjust brightness | Industrial, large-scale commercial lighting | Pros: Reliable, scalable for large installations. Cons: Requires additional wiring and compatible LED drivers. |

| RF (Radio Frequency) Wireless Dimmer | Wireless control via RF signals; often remote-controlled | Smart building, flexible lighting setups, retrofit | Pros: Easy installation, remote control convenience. Cons: Potential interference, higher initial cost. |

| DMX512 Digital Dimmer | Digital multiplex control protocol for precise lighting control | Stage lighting, entertainment venues, high-end commercial | Pros: Highly customizable, supports complex scenes. Cons: Requires technical expertise and compatible infrastructure. |

PWM (Pulse Width Modulation) Dimmer

PWM dimmers adjust LED brightness by rapidly switching the LED on and off at varying intervals, effectively controlling the perceived intensity. This type is highly compatible with a broad range of LED strips, making it a versatile choice for B2B buyers involved in commercial retail or architectural lighting projects. When sourcing, buyers should verify driver compatibility and flicker ratings, especially for markets with strict lighting quality standards such as Europe and the Middle East.

TRIAC (Leading-edge) Dimmer

TRIAC dimmers function by cutting the leading edge of the AC power waveform and are common in retrofit and residential lighting applications. For international buyers, especially in regions like Africa and South America where AC-powered LED strips are prevalent, TRIAC dimmers offer cost-effective solutions. However, they require careful selection to avoid flicker and noise, and compatibility with LED drivers must be confirmed to ensure product reliability and customer satisfaction.

0-10V Analog Dimmer

This dimmer type uses a simple low-voltage control signal to regulate brightness and is favored in industrial and large commercial installations. Its scalability and reliability make it attractive for B2B buyers managing complex lighting systems in warehouses, factories, or large office spaces. Buyers should plan for additional wiring and ensure LED strips and drivers support 0-10V input to maximize performance and ease of integration.

RF (Radio Frequency) Wireless Dimmer

RF wireless dimmers eliminate the need for physical wiring by controlling LED strips via remote RF signals. This flexibility benefits smart building projects and retrofit scenarios where wiring changes are impractical. For international buyers, especially in rapidly urbanizing regions like the Middle East and Africa, RF dimmers offer modern convenience but require attention to potential signal interference and regulatory compliance regarding radio frequencies.

DMX512 Digital Dimmer

DMX512 is a sophisticated digital control protocol widely used in entertainment, stage, and high-end commercial lighting. It allows precise, programmable control of multiple lighting channels simultaneously. B2B buyers targeting event venues, theaters, or premium commercial installations should consider DMX systems for their customization capabilities. However, these require technical expertise and compatible infrastructure, which may increase upfront investment but provide long-term operational advantages.

Related Video: How to Install a Dimmer for LED Strip Lighting

Key Industrial Applications of led strip light dimmer

| Industry/Sector | Specific Application of led strip light dimmer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and accent lighting control in stores and showrooms | Enhances product visibility, creates inviting atmospheres, reduces energy costs | Compatibility with existing lighting systems, ease of integration, durable components for high usage |

| Hospitality & Tourism | Mood lighting in hotels, restaurants, and event venues | Improves guest experience, allows dynamic ambiance control, lowers operational costs | Compliance with regional electrical standards, remote control capability, scalability for large venues |

| Industrial Facilities | Adjustable lighting in manufacturing and warehouse environments | Increases worker comfort and productivity, reduces energy consumption, extends LED lifespan | Robustness for harsh environments, compatibility with industrial control systems, energy efficiency certifications |

| Healthcare | Adjustable lighting in clinics, hospitals, and care centers | Supports patient comfort and staff efficiency, enables circadian rhythm lighting | High reliability, flicker-free dimming, compliance with healthcare lighting regulations |

| Architectural & Urban | Dynamic façade and landscape lighting for commercial buildings | Enhances building aesthetics, supports branding, enables energy savings | Weatherproofing, long lifespan, compatibility with smart city infrastructure |

Retail & Commercial Sector

In retail environments, LED strip light dimmers are essential for creating versatile lighting schemes that highlight products and enhance customer engagement. Adjustable dimming allows retailers to tailor lighting intensity throughout the day, optimizing ambiance and energy consumption. For international buyers, especially in regions like Africa and South America, sourcing dimmers with compatibility for various power systems and easy installation is critical to ensure seamless integration with existing retail lighting infrastructures.

Hospitality & Tourism Industry

Hotels, restaurants, and event venues rely on LED strip light dimmers to craft mood lighting that adapts to different times and occasions, improving guest satisfaction and operational flexibility. Dimmers that support remote control and scene-setting features are highly valued. Buyers from the Middle East and Europe should prioritize dimmers that comply with local safety and electromagnetic compatibility standards, ensuring reliable performance in diverse hospitality settings.

Industrial Facilities

Manufacturing plants and warehouses benefit from LED strip light dimmers by providing adjustable lighting that enhances worker comfort and productivity while conserving energy. Industrial-grade dimmers need to withstand harsh conditions such as dust, vibrations, and temperature fluctuations. International B2B buyers should focus on sourcing dimmers with robust build quality and certifications that meet industrial safety standards prevalent in their regions, such as CE marking in Europe or IEC standards.

Healthcare Sector

In healthcare environments, lighting quality directly impacts patient wellbeing and staff efficiency. LED strip light dimmers enable flicker-free, smooth dimming crucial for sensitive clinical settings and support circadian lighting to improve patient recovery. Buyers from Africa and Europe must ensure that dimmers meet stringent healthcare regulations and provide reliable, low-noise operation to avoid interference with medical equipment.

Architectural & Urban Applications

LED strip light dimmers are increasingly used in architectural lighting to create dynamic façades and landscape illumination that enhance urban aesthetics and building branding. These applications demand dimmers with weatherproofing and long operational life to withstand outdoor conditions. For international buyers, especially those involved in smart city projects in regions like the Middle East and Europe, compatibility with IoT and smart control systems is a key sourcing consideration to future-proof installations.

Related Video: Build your own LED Dimmer Driver

Strategic Material Selection Guide for led strip light dimmer

Common Materials Used in LED Strip Light Dimmers: A B2B Perspective

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance, excellent dimensional stability, and good thermal resistance up to approximately 135°C. It exhibits strong electrical insulation and moderate chemical resistance, making it suitable for housing and control interfaces in LED strip light dimmers.

Pros & Cons:

– Pros: Durable and lightweight, resistant to UV degradation, and easy to mold into complex shapes. It offers good transparency for indicator lights or displays integrated into dimmers.

– Cons: Moderate cost compared to other plastics, can yellow over time under prolonged UV exposure, and has limited resistance to strong solvents.

Impact on Application:

Polycarbonate is ideal for dimmer casings and control panels where impact resistance and electrical insulation are critical. Its thermal tolerance supports stable operation in warm environments, common in regions with high ambient temperatures like parts of Africa and the Middle East.

Considerations for International B2B Buyers:

Buyers in Egypt, Kenya, and South America should verify compliance with international standards such as ASTM D3935 (impact resistance) and IEC 60695 (flammability). Polycarbonate sourced from suppliers adhering to RoHS and REACH ensures environmental compliance, which is increasingly demanded in European markets.

2. Aluminum Alloy

Key Properties:

Aluminum alloys offer excellent thermal conductivity, corrosion resistance, and mechanical strength while being lightweight. They can withstand temperatures exceeding 200°C, which is advantageous for heat dissipation in LED dimmers.

Pros & Cons:

– Pros: Superior heat dissipation prolongs component life; corrosion resistance is enhanced with anodizing; recyclable and environmentally friendly.

– Cons: Higher material and manufacturing costs; requires precision machining or extrusion; potential for galvanic corrosion if improperly paired with other metals.

Impact on Application:

Aluminum is frequently used for heat sinks and structural components in LED strip light dimmers, especially in industrial or commercial applications requiring robust thermal management. Its corrosion resistance suits humid or coastal environments prevalent in parts of South America and the Middle East.

Considerations for International B2B Buyers:

Buyers should ensure aluminum complies with standards like DIN EN 573 for chemical composition and ASTM B221 for extrusion quality. Surface treatments such as anodizing should meet ISO 7599 to resist corrosion. Importers in Africa and Europe must also consider import tariffs and local availability of anodized aluminum to optimize cost.

3. ABS Plastic (Acrylonitrile Butadiene Styrene)

Key Properties:

ABS is a common thermoplastic with good impact resistance, ease of processing, and moderate heat resistance (up to about 80-100°C). It offers excellent dimensional stability and electrical insulation properties.

Pros & Cons:

– Pros: Low cost and widely available; easy to mold and paint; good surface finish for consumer-facing products.

– Cons: Lower thermal resistance than polycarbonate; less UV stable, leading to brittleness over time; susceptible to chemical attack by solvents.

Impact on Application:

ABS is suitable for indoor LED strip light dimmer housings where extreme heat or UV exposure is minimal. It is often used in budget-conscious product lines or where rapid prototyping is required.

Considerations for International B2B Buyers:

Buyers from regions with high ambient temperatures (e.g., Kenya, Egypt) should consider ABS only for indoor or shaded applications. Compliance with ASTM D256 (impact resistance) and UL 94 (flammability) is essential. European buyers may prioritize ABS grades with enhanced fire retardancy to meet stringent safety regulations.

4. Silicone Rubber

Key Properties:

Silicone rubber is valued for its flexibility, excellent thermal stability (operates between -60°C and 230°C), and outstanding resistance to UV, ozone, and moisture. It also provides good electrical insulation.

Pros & Cons:

– Pros: Highly flexible and durable under harsh environmental conditions; excellent sealing properties; resistant to aging and weathering.

– Cons: Higher raw material cost; manufacturing complexity due to curing processes; limited structural strength compared to rigid plastics or metals.

Impact on Application:

Silicone rubber is primarily used for sealing gaskets, flexible buttons, or protective covers on LED strip light dimmers. Its resilience to environmental stressors makes it ideal for outdoor or industrial applications, including markets in Africa and the Middle East where dust and moisture ingress are concerns.

Considerations for International B2B Buyers:

International buyers should ensure silicone materials meet ASTM D2000 for rubber classification and ISO 10993 for biocompatibility if used in consumer products. Given regional climatic challenges, silicone’s durability can reduce warranty claims and increase product lifespan, justifying the higher upfront cost.

Summary Table of Materials for LED Strip Light Dimmers

| Material | Typical Use Case for led strip light dimmer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Housing and control panels | High impact resistance and thermal stability | Moderate cost; UV yellowing over time | Medium |

| Aluminum Alloy | Heat sinks and structural components | Excellent heat dissipation and corrosion resistance | Higher cost and manufacturing complexity | High |

| ABS Plastic | Budget housings and indoor applications | Low cost and easy to process | Lower thermal and UV resistance | Low |

| Silicone Rubber | Seals, flexible buttons, protective covers | Superior flexibility and environmental resistance | Higher cost and limited structural strength | High |

This material selection guide equips international B2B buyers with critical insights to optimize LED strip light dimmer sourcing decisions based on performance, cost, and regional application needs. Understanding these material characteristics and compliance requirements will help buyers from Africa, South America, the Middle East, and Europe secure durable, cost-effective, and regulation-compliant dimmer components.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip light dimmer

Manufacturing Processes for LED Strip Light Dimmers

The production of LED strip light dimmers involves a series of carefully controlled stages designed to ensure high performance, durability, and compatibility with various LED lighting systems. Understanding these stages helps international B2B buyers assess supplier capabilities and make informed sourcing decisions.

1. Material Preparation

Material selection and preparation are foundational to manufacturing quality dimmers. Key components include:

- Semiconductor chips and ICs: Sourced from reputable suppliers to ensure consistent electrical performance.

- PCB (Printed Circuit Board): High-quality FR4 or similar materials with precise copper layering are used to support the circuit.

- Housing materials: Often flame-retardant plastics or aluminum for heat dissipation.

- Electronic components: Resistors, capacitors, diodes, and connectors undergo pre-inspection for compliance with specifications.

Suppliers typically conduct incoming quality control (IQC) at this stage to verify raw materials against defined standards, preventing defects from entering production.

2. Forming and PCB Fabrication

This stage involves the creation of the dimmer’s electronic backbone:

- PCB fabrication: Includes etching, drilling, and layering to create precise circuit paths.

- Surface treatment: Processes like HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) are applied to improve solderability and corrosion resistance.

- Component placement: Using automated pick-and-place machines for accuracy and efficiency.

- Soldering: Reflow soldering is common, ensuring strong electrical connections without damaging sensitive components.

Forming also covers the molding or extrusion of plastic or metal housing parts, which are precision-engineered to meet ergonomic and thermal management requirements.

3. Assembly

Assembly integrates all parts into a functional unit:

- Manual and automated assembly: Depending on the complexity and volume, some steps may require manual intervention to ensure delicate component handling.

- Wiring and connector installation: Ensuring proper polarity and secure connections.

- Firmware programming: For smart or digitally controlled dimmers, programming microcontrollers is a critical step.

- Initial functional testing: Basic electrical tests to confirm assembly integrity before moving to finishing.

4. Finishing and Packaging

The final stage includes:

- Cosmetic finishing: Applying labels, logos, and protective coatings.

- Final assembly checks: Ensuring all external parts fit correctly and the unit meets design specifications.

- Packaging: Using anti-static materials and protective padding to prevent damage during transit.

Quality Assurance and Control (QA/QC) Protocols

For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the quality assurance framework is vital to mitigate risks and ensure product reliability.

Relevant International and Industry Standards

- ISO 9001: The global benchmark for quality management systems, ensuring consistent manufacturing processes.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical and electronic equipment, critical for buyers in Europe and increasingly in other regions.

- FCC Certification: Important for dimmers with wireless or radio frequency components, particularly for the US and some Middle Eastern markets.

- API and other regional certifications: Some markets may require adherence to specific electrical safety or environmental standards.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Verification of raw materials and components before production.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing stages, including solder joint inspections, assembly accuracy, and functional checks.

- Final Quality Control (FQC): Comprehensive product testing before shipment, including performance, safety, and durability tests.

Common Testing Methods

- Electrical performance testing: Measuring voltage, current, and dimming response to ensure functionality within specified parameters.

- Thermal testing: Evaluating heat dissipation and temperature tolerance to prevent overheating.

- Environmental testing: Exposure to humidity, dust, and vibration simulates real-world conditions.

- Safety testing: Verifying insulation resistance, grounding continuity, and protection against electric shock.

- EMC (Electromagnetic Compatibility) testing: Ensures the dimmer does not interfere with or is not affected by other electronic devices.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, especially in emerging markets like Egypt, Kenya, Brazil, or Saudi Arabia, direct oversight and verification of supplier quality processes are crucial.

1. Factory Audits

- On-site inspections: Visiting manufacturing facilities to observe production lines, equipment condition, and QC protocols.

- Process audits: Reviewing documentation such as process flowcharts, work instructions, and training records.

- Compliance audits: Checking certifications (ISO 9001, CE, RoHS) and their validity.

If travel is impractical, buyers can hire local third-party inspection agencies for these audits.

2. Quality Documentation and Reports

- Production quality reports: Including IQC, IPQC, and FQC results.

- Test certificates: EMC, safety, and environmental test results.

- Material certificates: Verifying the origin and specifications of raw materials.

Requesting these documents before finalizing orders helps ensure traceability and accountability.

3. Third-Party Inspection and Testing

- Engaging independent quality control firms to perform random batch inspections, functional testing, and compliance verification.

- Beneficial for verifying suppliers in distant regions or for high-volume contracts.

QC and Certification Nuances for International Buyers

- Regional regulatory differences: Buyers from Africa and South America should confirm local import regulations and required certifications, which may differ from European or Middle Eastern standards.

- Certification equivalency: Some countries accept international certifications (e.g., CE, ISO), while others require local testing or approvals.

- Language and documentation: Ensure suppliers provide QC reports and manuals in the buyer’s preferred language or a widely accepted lingua franca (e.g., English).

- After-sales support and warranty: Quality assurance extends beyond production; verify supplier policies on warranty, returns, and technical support, which are critical for maintaining long-term partnerships.

Summary for B2B Buyers

- Prioritize suppliers with robust quality management systems certified to ISO 9001 and recognized industry standards.

- Demand transparency through QC documentation, factory audits, and third-party inspections.

- Understand regional regulatory requirements to ensure compliance and smooth market entry.

- Evaluate manufacturing capabilities across all stages—from material preparation to finishing—to guarantee product consistency and reliability.

- Leverage local inspection agencies if direct oversight is not feasible, especially for buyers in Africa, South America, and the Middle East.

By thoroughly assessing manufacturing processes and quality assurance protocols, B2B buyers can mitigate risks, optimize procurement decisions, and build trustworthy supply chains for LED strip light dimmers.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip light dimmer Sourcing

When sourcing LED strip light dimmers on an international scale, understanding the detailed cost structure and pricing dynamics is critical for B2B buyers aiming to optimize procurement and ensure competitive pricing. This is especially important for buyers in emerging and diverse markets such as Africa, South America, the Middle East, and Europe, where logistical and regulatory factors can significantly affect total costs.

Breakdown of Cost Components

-

Materials:

The primary cost driver is the quality and type of electronic components used, including semiconductors, resistors, capacitors, and PCBs. Premium-grade components with higher durability and efficiency will command higher prices but typically offer better longevity and performance. -

Labor:

Labor costs vary widely by manufacturing location. Countries with lower labor costs, such as China, India, or Vietnam, often offer more competitive pricing. However, buyers should balance labor cost savings with potential quality control challenges. -

Manufacturing Overhead:

This includes factory utilities, equipment depreciation, and administrative expenses. Overhead tends to be higher in countries with stricter labor laws and environmental regulations, which can impact final pricing. -

Tooling and Setup:

Initial tooling for custom or semi-custom dimmer designs can be significant, especially for small batch orders. Tooling amortization costs are often factored into unit prices, making MOQ (Minimum Order Quantity) a critical consideration. -

Quality Control (QC):

Rigorous QC processes, including in-line testing and final product inspections, add to costs but are essential for ensuring product reliability. Certified quality standards (e.g., CE, RoHS) can increase QC expenses but provide market access and buyer confidence. -

Logistics and Freight:

Shipping costs fluctuate based on distance, shipping mode (air vs. sea), and geopolitical factors. For buyers in Africa and South America, longer transit times and customs delays can add hidden costs, including storage and demurrage fees. -

Profit Margins:

Supplier margins vary depending on brand positioning, competition, and order size. Negotiation can influence margins, especially for repeat or bulk orders.

Key Price Influencers

-

Order Volume and MOQ:

Larger volumes typically reduce per-unit costs due to economies of scale and lower tooling amortization per unit. Buyers should carefully assess demand forecasts to leverage volume discounts without overstocking. -

Product Specifications and Customization:

Custom dimmers tailored to specific voltage ranges, dimming methods (e.g., TRIAC, PWM), or interface types (remote control, app-based) will cost more. Off-the-shelf models are more cost-effective but may not fully meet unique application needs. -

Material Quality and Certification:

Compliance with international safety and environmental standards (UL, CE, RoHS) increases costs but is often mandatory for legal import and resale in many regions. Buyers should verify certification authenticity to avoid counterfeit or substandard products. -

Supplier Reputation and Location:

Established suppliers with proven track records might charge premiums but reduce risk. Local or regional suppliers may offer faster lead times and lower freight costs, benefiting buyers in Europe or the Middle East. -

Incoterms and Payment Terms:

The choice of Incoterms (e.g., FOB, CIF, DDP) significantly affects who bears shipping, insurance, and customs clearance costs. Buyers in Africa and South America often prefer DDP (Delivered Duty Paid) to avoid complex import procedures but should expect higher prices.

Strategic Buyer Tips for Cost-Efficient Sourcing

-

Negotiate on MOQ and Payment Terms:

Many manufacturers are willing to adjust MOQs or offer flexible payment terms (e.g., letter of credit, net 30) for reliable buyers, which can improve cash flow and reduce inventory risks. -

Evaluate Total Cost of Ownership (TCO):

Consider long-term costs such as warranty claims, energy efficiency, maintenance, and replacement cycles. Sometimes paying a premium upfront for higher-quality dimmers reduces lifecycle costs. -

Leverage Regional Trade Agreements:

Buyers in regions with free trade agreements (e.g., African Continental Free Trade Area, Mercosur) should explore sourcing from member countries to minimize tariffs and customs duties. -

Conduct Supplier Audits and Sample Testing:

Request product samples and perform independent testing to verify quality before committing to large orders. This is crucial when sourcing from new or less familiar suppliers. -

Factor in Currency Fluctuations and Inflation:

Exchange rate volatility can impact landed costs significantly. Consider hedging options or negotiating contracts in stable currencies like USD or EUR.

Indicative Pricing Disclaimer

Due to the variability in manufacturing locations, order volumes, product specifications, and market conditions, LED strip light dimmer prices can range broadly. As a rough guide, basic dimmers may start at approximately USD 2–5 per unit for large volume orders, while customized or certified models could command prices upwards of USD 8–15 per unit. These figures should be used only as a starting point; detailed quotations from suppliers are essential for accurate budgeting.

By thoroughly understanding these cost elements and price influencers, international B2B buyers can make informed decisions, negotiate effectively, and optimize their procurement strategies for LED strip light dimmers in diverse markets worldwide.

Spotlight on Potential led strip light dimmer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip light dimmer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip light dimmer

When sourcing LED strip light dimmers for international markets such as Africa, South America, the Middle East, and Europe, understanding critical technical specifications and trade terminology is essential. This knowledge empowers buyers to make informed decisions, negotiate effectively, and ensure product compatibility and quality.

Key Technical Properties of LED Strip Light Dimmers

-

Input Voltage Range

This specifies the voltage levels the dimmer can safely handle, commonly 12V or 24V DC for LED strips. For B2B buyers, verifying compatibility with local power standards and the LED strip’s voltage is crucial to avoid product failure or electrical hazards. -

Dimming Method (PWM vs. Analog)

– PWM (Pulse Width Modulation): Controls brightness by rapidly switching the LED on and off, preserving color quality and efficiency.

– Analog Dimming: Adjusts voltage to change brightness, often resulting in color shift or reduced efficiency.

For buyers, selecting the appropriate dimming type affects product performance and end-user satisfaction. -

Maximum Load Capacity

This indicates the total wattage or amperage the dimmer can support. Exceeding this limit can cause overheating or failure. Buyers must align this with the total power consumption of their LED strip installations, especially for large-scale or commercial projects. -

Material Grade and Build Quality

Components such as circuit boards, switches, and connectors should meet industrial standards (e.g., RoHS compliance, flame-retardant materials). High-quality materials ensure durability and regulatory compliance, which is vital for international shipping and market entry. -

Control Interface Compatibility

Dimmers may support manual knobs, remote controls, or smart interfaces (Wi-Fi, RF, DMX). Understanding the control options helps buyers meet market preferences and integration requirements in smart building projects. -

Operating Temperature Range

The dimmer’s ability to function reliably within specific temperature limits is important for regions with extreme climates, such as parts of the Middle East or Africa. Confirming this ensures product longevity and consistent performance.

Common Industry and Trade Terminology

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce dimmers that buyers can brand under their own name. This is key for businesses seeking customized products or private labeling to differentiate in competitive markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one batch. Understanding MOQs helps buyers balance inventory costs with demand, especially important for new market entries or pilot projects. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, terms, and product specifications. Mastery of RFQ processes enables buyers to solicit competitive offers and clear terms from multiple vendors. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs. Knowing Incoterms ensures clarity on logistics costs and risks, which is critical when importing from Asia or Europe. -

Lead Time

The period between placing an order and receiving the goods. Accurate lead time estimates help buyers plan inventory and project schedules, minimizing disruptions in supply chains. -

Certification Standards

Compliance marks such as CE (Europe), UL (North America), or SAA (Australia) indicate product safety and quality assurance. For international buyers, verifying certifications is essential to meet local regulations and gain market access.

By focusing on these essential technical specifications and trade terms, B2B buyers can streamline supplier selection, mitigate risks, and optimize procurement strategies for LED strip light dimmers across diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip light dimmer Sector

Market Overview & Key Trends

The global market for LED strip light dimmers is experiencing robust growth driven by increasing demand for energy-efficient and customizable lighting solutions across commercial, residential, and industrial sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are actively seeking advanced dimming technologies that offer seamless integration with smart home and building automation systems. Key drivers include urbanization, rising disposable incomes, and government incentives promoting energy-saving lighting solutions.

Illustrative Image (Source: Google Search)

In Africa and the Middle East, infrastructure development and expanding real estate projects are fueling demand for versatile lighting controls. For example, countries like Egypt and Kenya are witnessing growth in smart city initiatives, where LED dimmers play a critical role in reducing energy consumption and enhancing environmental comfort. South American markets are similarly focused on sustainability and cost efficiency, pushing suppliers to innovate with wireless and app-controlled dimmers that facilitate ease of installation and user control.

Technology trends emphasize connectivity, with Bluetooth, Zigbee, and Wi-Fi enabled dimmers gaining traction. These offer remote control capabilities and integration with IoT platforms, appealing to buyers who prioritize smart building solutions. Additionally, modular designs and compatibility with various LED strip types are becoming standard, allowing B2B buyers to source versatile products adaptable to diverse applications.

Sourcing trends highlight the importance of working with manufacturers who provide comprehensive certifications (CE, RoHS, UL) and adhere to international quality standards. Buyers from emerging markets should prioritize suppliers with proven export experience and flexible MOQ (minimum order quantity) policies to manage inventory risks effectively. Strategic sourcing increasingly involves partnerships with manufacturers offering customization services, including tailored dimming curves and interface options, to meet specific market needs.

Sustainability & Ethical Sourcing in B2B

Sustainability is a growing priority in the LED strip light dimmer sector, driven by global regulatory pressures and increasing buyer awareness. For B2B buyers, especially those operating in environmentally sensitive regions or under stringent compliance regimes, sourcing dimmers manufactured with eco-friendly practices is critical. The environmental impact of LED dimmers primarily relates to materials used, energy consumption during operation, and end-of-life disposal.

Ethical sourcing involves selecting suppliers committed to reducing hazardous substances, such as lead, mercury, and brominated flame retardants, in their components. Compliance with directives like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) ensures dimmers meet strict environmental and safety standards. Buyers should also evaluate supplier transparency regarding labor practices and supply chain traceability to mitigate risks associated with unethical manufacturing.

Green certifications such as Energy Star, TUV Eco, and UL Environmental validate the sustainability credentials of LED dimmers. These certifications assure buyers of energy efficiency and environmentally responsible production processes. Additionally, preference should be given to dimmers designed for longevity and recyclability, reducing waste and lifecycle environmental impact.

International buyers from regions like Europe and the Middle East often face tighter sustainability mandates, prompting a shift towards “green” procurement policies. African and South American buyers increasingly recognize the long-term cost benefits of energy-efficient and sustainably sourced products, aligning with global trends toward circular economy models.

Evolution and Industry Context

The LED strip light dimmer industry has evolved significantly over the past two decades. Initially, dimmers were simple analog devices designed to modulate voltage for incandescent lighting. With the rise of LED technology, dimming systems had to adapt to the unique electrical characteristics of LEDs, which require constant current control rather than voltage reduction.

Illustrative Image (Source: Google Search)

Early LED dimmers were basic and often incompatible with various LED strip types, causing flickering and reduced lifespan. The industry responded by developing digital dimming technologies, such as PWM (Pulse Width Modulation), which offer precise brightness control without compromising efficiency or LED integrity.

More recently, the integration of wireless communication protocols and smart controls has transformed LED dimmers into sophisticated components of intelligent lighting ecosystems. This evolution reflects the broader trend towards automation and energy management, positioning LED strip light dimmers as essential elements in modern building infrastructure.

For B2B buyers, understanding this evolution helps in selecting dimmers that align with both current technological standards and future-proofing requirements, ensuring long-term value and operational reliability.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip light dimmer

-

How can I effectively vet suppliers of LED strip light dimmers for international B2B purchases?

Begin by verifying the supplier’s business license, manufacturing capabilities, and years of experience in LED dimmer production. Request product samples to assess quality and ensure compliance with international standards. Check references or reviews from other B2B buyers, especially those in your region. Utilize third-party inspection services for factory audits and product inspections. Ensure the supplier can provide relevant certifications such as CE, RoHS, and UL, which are critical for import and resale in regions like Europe, the Middle East, and Africa. -

What customization options are typically available when sourcing LED strip light dimmers in bulk?

Most manufacturers offer customization on dimmer voltage compatibility, control types (e.g., RF, Wi-Fi, Bluetooth), and design features such as size, interface, and branding. Buyers can often request specific dimming modes (e.g., TRIAC, PWM) based on their application needs. For international buyers, it’s important to clarify electrical standards and certifications for your target markets. Negotiate minimum order quantities (MOQs) for custom designs, as these are usually higher than standard products, and confirm lead times for prototype approval and mass production. -

What are typical MOQ and lead times when ordering LED strip light dimmers internationally?

MOQs vary widely but typically start around 500 to 1,000 units for standard models and can be higher for customized dimmers. Lead times usually range from 3 to 8 weeks, depending on order size, customization, and factory workload. Buyers from Africa, South America, and the Middle East should factor in additional shipping time and potential customs clearance delays. Early communication about delivery schedules and order commitments can help secure better terms and avoid production bottlenecks. -

Which payment methods are most secure and commonly accepted in international B2B transactions for LED strip light dimmers?

Letters of Credit (L/C) and Telegraphic Transfers (T/T) are widely used payment methods. L/Cs offer greater security by ensuring funds are only released upon meeting agreed terms, which is beneficial for new supplier relationships. Established buyers often negotiate partial upfront deposits with balance payment after inspection or delivery. Platforms like PayPal or escrow services are less common for large orders but may be used for smaller quantities. Always verify the supplier’s bank details independently to avoid fraud. -

What quality assurance measures should I insist on before finalizing an international LED strip light dimmer order?

Request detailed quality control documentation, including test reports on dimming performance, electrical safety, and durability under various environmental conditions. Ensure the supplier conducts in-line and final inspections and offers product samples for your own testing. Consider third-party quality inspection services at the factory before shipment. Confirm the availability of warranties or return policies to mitigate risks of defective products. Certifications such as ISO 9001 can be an indicator of a supplier’s commitment to quality management. -

What certifications are essential for LED strip light dimmers in international markets like Europe, Africa, and the Middle East?

CE marking is mandatory for the European market, indicating compliance with EU safety, health, and environmental requirements. RoHS certification ensures restriction of hazardous substances, important globally. UL or ETL listings are often required for North American and some Middle Eastern markets. For African countries, local standards may vary; working with suppliers familiar with regional import requirements helps ensure smooth customs clearance. Always request copies of certificates and verify their validity through official channels. -

How can I optimize logistics and shipping for LED strip light dimmer imports from Asia or Europe?

Choose reliable freight forwarders experienced in handling electronics and familiar with customs regulations in your target countries. Consolidate shipments to reduce costs and consider incoterms carefully; DDP (Delivered Duty Paid) offers convenience but may be pricier, while FOB (Free on Board) requires more buyer involvement. Plan shipments to avoid peak seasons that cause port congestion. For fragile or sensitive dimmers, ensure appropriate packaging and insurance coverage. Track shipments closely and prepare documentation accurately to avoid clearance delays. -

What steps should I take if disputes arise regarding product quality or delivery terms with an international LED strip light dimmer supplier?

Maintain clear, documented communication throughout the transaction, including contracts specifying product specifications, delivery timelines, payment terms, and dispute resolution mechanisms. If issues occur, promptly notify the supplier with evidence such as photos or inspection reports. Engage third-party arbitration or mediation services if direct negotiation fails. In severe cases, consult legal experts familiar with international trade law and your supplier’s jurisdiction. Building strong relationships and vetting suppliers carefully upfront reduces the risk of disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip light dimmer

The LED strip light dimmer market presents significant opportunities for international B2B buyers seeking innovative lighting control solutions. Key strategic sourcing insights include prioritizing suppliers with strong quality certifications, scalable manufacturing capabilities, and robust after-sales support. For buyers in Africa, South America, the Middle East, and Europe—regions with growing infrastructure and commercial development—partnering with manufacturers that offer customizable dimming options and compatibility with diverse LED technologies is crucial to meet varied market demands.

Strategic sourcing not only ensures competitive pricing but also mitigates risks related to supply chain disruptions and quality inconsistencies. Emphasizing supplier relationships, transparent communication, and thorough due diligence will enable buyers to secure reliable, cost-effective LED strip light dimmer solutions tailored to their specific regional requirements.

Looking ahead, the increasing adoption of smart lighting systems and IoT integration will drive demand for advanced dimmers with enhanced features such as remote control and energy efficiency. Buyers should actively explore partnerships with forward-thinking manufacturers who invest in R&D and sustainable practices.

For international buyers, particularly in emerging markets like Egypt and Kenya, now is the optimal time to leverage strategic sourcing to future-proof their lighting portfolios and capitalize on the evolving LED dimmer landscape. Engage proactively with suppliers to unlock innovation and competitive advantage in your local markets.