Guide to Clip On Led Strip Light

- Introduction: Navigating the Global Market for clip on led strip light

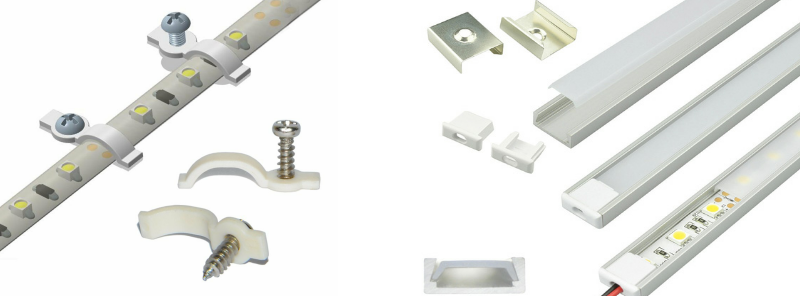

- Understanding clip on led strip light Types and Variations

- Key Industrial Applications of clip on led strip light

- Strategic Material Selection Guide for clip on led strip light

- In-depth Look: Manufacturing Processes and Quality Assurance for clip on led strip light

- Comprehensive Cost and Pricing Analysis for clip on led strip light Sourcing

- Spotlight on Potential clip on led strip light Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for clip on led strip light

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the clip on led strip light Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of clip on led strip light

- Strategic Sourcing Conclusion and Outlook for clip on led strip light

Introduction: Navigating the Global Market for clip on led strip light

In today’s rapidly evolving lighting industry, clip on LED strip lights have emerged as a transformative solution combining flexibility, efficiency, and ease of installation. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of these innovative lighting products is crucial for securing competitive advantages and driving project success.

Clip on LED strip lights offer unmatched adaptability, allowing businesses to implement cost-effective, scalable lighting solutions across commercial, industrial, and architectural applications. Their modular clip-on design simplifies installation and maintenance, reducing labor costs and downtime—a significant benefit for large-scale projects or retrofits in diverse environments, from bustling retail spaces in the UAE to expansive manufacturing facilities in Europe or vibrant hospitality venues in South America.

This comprehensive guide equips B2B buyers with actionable insights into the full spectrum of clip on LED strip lights: from various types and materials to advanced manufacturing processes and stringent quality control measures. It also delves into sourcing strategies, supplier evaluation, pricing considerations, and regional market trends, ensuring buyers make well-informed procurement decisions tailored to their unique operational contexts.

By navigating this guide, international buyers will gain a strategic understanding of how to leverage the latest innovations and best practices in clip on LED strip lighting—empowering them to optimize product selection, enhance energy efficiency, and deliver superior lighting solutions that meet both performance standards and budget requirements across global markets.

Understanding clip on led strip light Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Clip-On LED Strips | Flexible strips with detachable plastic or metal clips for mounting | Retail displays, office ambient lighting | Pros: Easy installation, reusable clips; Cons: Limited weight support, may require surface prep |

| Waterproof Clip-On LED Strips | Sealed strips with waterproof clips and silicone covers | Outdoor signage, industrial environments | Pros: Weather-resistant, durable; Cons: Higher cost, bulkier clips |

| RGB Clip-On LED Strips | Strips with RGB LEDs plus clip mounts for dynamic color control | Hospitality, event venues, retail marketing | Pros: Versatile color options, customizable; Cons: Requires compatible controllers, higher initial investment |

| High-Lumen Clip-On LED Strips | Strips designed for high brightness with robust clip mounts | Warehouses, factories, task lighting | Pros: High illumination, durable clips; Cons: Higher energy consumption, heat management needed |

| Smart Clip-On LED Strips | LED strips integrated with smart controls and clip mounts | Smart offices, hotels, smart homes | Pros: Remote control, automation; Cons: Complexity in setup, dependency on network connectivity |

Standard Clip-On LED Strips

These are the most common type, featuring flexible LED strips that attach via simple plastic or metal clips. They are ideal for indoor applications such as retail shelves, office lighting, and decorative accents. For B2B buyers, the ease of installation and reusability of clips reduce labor costs and simplify maintenance. However, these clips generally support lighter strips and require clean, smooth surfaces for reliable mounting.

Waterproof Clip-On LED Strips

Designed for outdoor or harsh environments, these LED strips come with sealed waterproofing and specialized clips that resist moisture and dust ingress. They are widely used in outdoor signage, industrial settings, and exterior architectural lighting. Buyers should consider the higher upfront cost and slightly bulkier mounting hardware, balanced by the longevity and reliability these strips provide under challenging conditions.

RGB Clip-On LED Strips

These strips incorporate RGB LEDs capable of producing a wide spectrum of colors, paired with clip mounts for easy positioning. Their primary use is in hospitality, event staging, and retail environments where dynamic lighting enhances customer experience. B2B buyers must account for additional expenses related to compatible controllers and software, but the enhanced customization and engagement potential often justify the investment.

High-Lumen Clip-On LED Strips

Optimized for high brightness output, these strips use powerful LEDs and sturdy clips designed to support heavier, larger fixtures. They are suited for industrial warehouses, manufacturing floors, and task-specific lighting where illumination intensity is critical. Buyers should evaluate the increased energy consumption and necessary heat dissipation measures, ensuring that installation environments can accommodate these needs.

Smart Clip-On LED Strips

Featuring integrated smart technology, these LED strips connect to apps or building automation systems and include clip mounts for flexible installation. They are increasingly popular in smart offices, hotels, and advanced residential projects. While offering remote control and automation benefits, B2B purchasers should be aware of the complexity in setup and potential reliance on network stability, which may impact operational continuity.

Related Video: How-to Waterproof LED Strip Light with Clip-On Connectors

Key Industrial Applications of clip on led strip light

| Industry/Sector | Specific Application of clip on led strip light | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing & Warehousing | Machine and conveyor illumination | Enhances visibility and safety, reduces downtime | Durability under industrial conditions, IP rating, easy installation |

| Retail & Commercial Spaces | Shelf and display case lighting | Attracts customers, highlights products, energy savings | Color rendering index (CRI), customizable length, dimmability |

| Automotive & Transportation | Interior and under-dashboard lighting | Improves aesthetics and driver comfort | Vibration resistance, heat tolerance, low power consumption |

| Hospitality & Event Management | Ambient and accent lighting for venues and exhibitions | Creates mood, enhances guest experience | Color options, ease of mounting/removal, compatibility with controls |

| Marine & Outdoor Industries | Deck and cabin lighting on boats and outdoor equipment | Weatherproof, energy-efficient, enhances safety | Waterproof rating, UV resistance, flexible mounting options |

Manufacturing & Warehousing

In manufacturing plants and warehouses, clip on LED strip lights are widely used to illuminate machinery, workstations, and conveyor belts. Their clip-on design allows for quick and secure attachment to metal frames and pipes without complex wiring, improving worker safety and operational efficiency. For B2B buyers in regions like Africa and the Middle East, where harsh environmental conditions prevail, sourcing LED strips with high IP ratings and robust build quality is crucial to withstand dust and heat. The ability to retrofit existing equipment rapidly reduces installation downtime and maintenance costs.

Retail & Commercial Spaces

Retailers and commercial outlets use clip on LED strip lights to enhance product displays and shelving units. These lights provide uniform illumination that accentuates merchandise, drawing customer attention and increasing sales potential. Buyers from South America and Europe should prioritize strips with high color rendering index (CRI) to ensure true color representation of products, which is vital for fashion and luxury goods sectors. Customizable lengths and dimming features allow retailers to tailor lighting ambiance according to store layout and branding requirements.

Automotive & Transportation

The automotive sector benefits from clip on LED strip lights for interior cabin lighting, dashboard accents, and under-car illumination. These lights improve aesthetics and driver comfort while consuming minimal power. For international buyers, especially in Europe and Australia, sourcing LED strips with excellent vibration resistance and thermal management is essential to endure vehicle movement and temperature fluctuations. Easy clip-on installation helps automotive manufacturers and aftermarket suppliers reduce assembly time and improve product modularity.

Hospitality & Event Management

In hotels, restaurants, and event venues, clip on LED strip lights are employed to create ambient and accent lighting that enhances guest experience. Their flexibility and ease of installation allow event managers to rapidly adapt lighting setups for different occasions. Buyers from the Middle East and Europe should look for strips offering a wide color spectrum and seamless integration with smart lighting controls for dynamic effects. The clip-on feature facilitates quick changes and repositioning without damaging surfaces, which is critical for temporary setups.

Marine & Outdoor Industries

Clip on LED strip lights are increasingly used in marine vessels and outdoor equipment for deck, cabin, and pathway lighting. Their waterproof and UV-resistant properties ensure durability in harsh marine environments. International B2B buyers from coastal regions in Africa and Australia must focus on LED strips with high IP65/IP67 ratings and corrosion-resistant materials. The clip-on mechanism allows easy installation on curved or uneven surfaces, enhancing safety and operational visibility without complex mounting hardware.

Related Video: How to Use Solderless LED Strip Light Connectors

Strategic Material Selection Guide for clip on led strip light

Aluminum Alloys

Aluminum alloys are widely used in clip on LED strip lights due to their excellent thermal conductivity, lightweight nature, and corrosion resistance. These properties make aluminum ideal for dissipating heat generated by LEDs, thus enhancing the lifespan and performance of the lighting strips. From a manufacturing standpoint, aluminum is relatively easy to extrude into various profiles suitable for clip-on mechanisms, supporting diverse design requirements.

Pros:

– Superior heat dissipation prevents LED overheating.

– Corrosion-resistant, suitable for humid and outdoor environments common in Middle Eastern and African markets.

– Lightweight, reducing shipping costs and simplifying installation.

Cons:

– Higher material cost compared to plastics or steel.

– Surface finishes may require anodizing or powder coating to meet aesthetic or durability standards, adding to production complexity.

– Can be prone to scratching or denting if not handled carefully.

Application Impact:

Aluminum is preferred in commercial and architectural lighting where durability and heat management are critical. It suits outdoor installations in regions with high UV exposure (e.g., UAE, Australia) due to its corrosion resistance. However, in highly corrosive environments like coastal South America, additional surface treatments may be necessary.

B2B Considerations:

Buyers from Europe and the Middle East should verify compliance with ASTM B221 or EN 573 aluminum standards to ensure quality and compatibility. For African and South American markets, suppliers offering anodized or coated finishes that meet ISO 9227 salt spray test standards are advantageous. Aluminum’s recyclability also aligns with sustainability goals increasingly emphasized in European procurement policies.

Polycarbonate (PC)

Polycarbonate is a robust thermoplastic commonly used for clip-on LED strip light housings and covers. It offers excellent impact resistance and transparency, allowing for clear light diffusion without yellowing over time. Its electrical insulating properties add safety benefits, especially in residential and commercial indoor applications.

Pros:

– High impact resistance and durability against physical shocks.

– Transparent with good light transmission, enhancing LED brightness.

– Lightweight and cost-effective compared to metals.

Cons:

– Lower thermal conductivity, which can lead to heat buildup if not paired with proper heat sinks.

– Susceptible to UV degradation unless treated, limiting outdoor use without coatings.

– Can be prone to scratching and chemical attack from solvents.

Application Impact:

Polycarbonate is ideal for indoor lighting applications where impact resistance and aesthetics are priorities, such as retail or office environments in Europe and South America. For outdoor use in the Middle East or Australia, UV-stabilized grades or protective coatings are essential to prevent material degradation.

B2B Considerations:

International buyers should request polycarbonate materials compliant with UL 94 V-0 flammability standards and ISO 4892 UV resistance tests. Suppliers offering customized UV protection are preferred for harsh sunlight regions. Additionally, sourcing from manufacturers certified to ISO 9001 ensures consistent material quality.

Stainless Steel (e.g., 304 or 316 grades)

Stainless steel is used primarily for clip mechanisms or mounting brackets in LED strip lights requiring high mechanical strength and corrosion resistance. Grades 304 and 316 are common, with 316 offering superior resistance to chlorides and harsh environments.

Pros:

– Exceptional corrosion resistance, especially grade 316 for marine or industrial environments.

– High tensile strength ensures clip durability and longevity.

– Aesthetic appeal with polished or brushed finishes.

Cons:

– Heavier and more expensive than aluminum or plastics.

– More complex manufacturing processes such as stamping or laser cutting increase production costs.

– Can be over-specified for simple indoor applications, adding unnecessary expense.

Application Impact:

Stainless steel clips are favored in industrial, outdoor, or coastal installations in Africa, the Middle East, and Australia where exposure to moisture and corrosive agents is high. For indoor European projects, stainless steel may be chosen for premium or high-traffic areas requiring robust fixtures.

B2B Considerations:

Buyers should confirm compliance with ASTM A240 or EN 10088 standards for stainless steel grades. For regions with strict environmental regulations like the EU, suppliers providing RoHS and REACH-compliant stainless steel are preferred. Additionally, corrosion testing certificates (e.g., salt spray tests) are valuable for assurance in harsh climates.

PVC (Polyvinyl Chloride)

PVC is a cost-effective and versatile plastic used in clip components and protective covers for LED strip lights. It offers good chemical resistance and electrical insulation, making it suitable for various indoor and some outdoor applications.

Pros:

– Low cost and widely available globally.

– Good chemical and moisture resistance.

– Easy to mold and customize for clip designs.

Cons:

– Lower heat resistance; can deform under high LED operating temperatures.

– Environmental concerns due to chlorine content and limited recyclability.

– UV degradation without stabilizers limits outdoor use.

Application Impact:

PVC is commonly used in budget-conscious projects or where electrical insulation is critical, such as indoor commercial lighting in South America and Africa. For outdoor applications in the Middle East or Australia, UV-stabilized PVC or alternatives are necessary to avoid premature failure.

B2B Considerations:

International buyers should ensure PVC materials meet local fire safety standards such as UL 94 HB or better. Compliance with environmental regulations (e.g., EU’s RoHS) is increasingly important for European buyers. Suppliers offering PVC with UV stabilizers and flame retardants provide added value for harsh environment applications.

Summary Table

| Material | Typical Use Case for clip on led strip light | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Heat sinks, structural clips for outdoor/commercial lighting | Excellent heat dissipation and corrosion resistance | Higher cost and requires surface finishing | High |

| Polycarbonate (PC) | Transparent covers, indoor clip housings | High impact resistance and light transmission | Poor thermal conductivity and UV sensitivity | Medium |

| Stainless Steel | Clips and brackets in harsh or industrial environments | Superior corrosion resistance and strength | Heavy, costly, complex manufacturing | High |

| PVC | Budget clip components and electrical insulation | Low cost and chemical resistance | Low heat resistance and environmental concerns | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for clip on led strip light

Manufacturing and quality assurance of clip on LED strip lights are critical factors that determine product reliability, performance, and compliance with international standards. For international B2B buyers—especially those sourcing from or supplying to markets in Africa, South America, the Middle East, and Europe—understanding these processes and quality controls is essential for making informed purchasing decisions and ensuring long-term supplier partnerships.

Typical Manufacturing Process for Clip On LED Strip Lights

The production of clip on LED strip lights involves several key stages, each demanding precision and adherence to quality standards:

1. Material Preparation

- Component Sourcing: High-quality LEDs, flexible printed circuit boards (PCBs), resistors, clips, connectors, and adhesives are sourced from certified suppliers. The selection of components significantly influences the strip’s durability and luminous efficiency.

- Raw Material Inspection: Incoming materials undergo initial quality checks (Incoming Quality Control – IQC) to verify specifications such as LED brightness, PCB flexibility, and clip material strength.

2. Forming and Circuit Board Preparation

- PCB Fabrication: Flexible PCBs are manufactured or procured with specific copper thickness and insulation layers to support electrical conductivity and flexibility.

- Cutting and Shaping: The PCB is cut into strips of predetermined lengths. For clip on designs, precise locations for clip attachment points are marked or pre-formed.

Illustrative Image (Source: Google Search)

3. Assembly

- LED Mounting: Surface-mount technology (SMT) machines place LEDs and other electronic components onto the PCB with high accuracy. Automated placement ensures consistent spacing and orientation.

- Soldering: Reflow soldering fixes components securely. This process is carefully controlled to avoid overheating, which could damage the LEDs or circuit board.

- Clip Attachment: Clips are mechanically or chemically bonded to the strip to enable easy mounting. This step requires exact alignment to maintain the strip’s flexibility and functionality.

- Wiring and Connectors: Electrical connections, including power leads and control interfaces (for dimming or color control), are installed.

4. Finishing and Packaging

- Protective Coating: Many clip on LED strips receive a silicone or epoxy coating to protect against moisture, dust, and mechanical damage, especially for outdoor or industrial use.

- Cutting to Length: Final trimming ensures strips meet client specifications.

- Labeling and Branding: Customized labels, branding, and packaging are applied to support traceability and marketing needs.

- Bulk Packaging: Strips are carefully packed in anti-static and shock-resistant materials to prevent damage during shipping.

Quality Assurance and Control in Manufacturing

Quality assurance (QA) and quality control (QC) are embedded throughout the manufacturing lifecycle to guarantee product consistency, safety, and compliance with international standards.

Relevant International and Industry Standards

- ISO 9001: This is the global benchmark for quality management systems. Suppliers certified to ISO 9001 demonstrate robust internal controls, process documentation, and continuous improvement practices.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), CE certification ensures compliance with EU safety, health, and environmental requirements.

- RoHS (Restriction of Hazardous Substances): Ensures that LED strips do not contain harmful substances beyond permissible limits.

- UL Certification: Widely recognized in the US and also valued internationally, UL certification confirms electrical safety and fire hazard minimization.

- IP Rating: For outdoor or industrial applications, an Ingress Protection (IP) rating (e.g., IP65, IP67) indicates resistance to dust and water.

- Other Regional Certifications: Buyers in the Middle East (e.g., UAE) or Australia might require compliance with regional electrical safety standards such as SASO (Saudi Arabia) or RCM (Australia).

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw materials and components for conformity with technical specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspections, LED placement accuracy, and clip attachment integrity.

- Functional Testing: Strips undergo electrical and optical tests to verify brightness, color temperature, and uniformity.

- Final Quality Control (FQC): Comprehensive inspection before packaging, including visual defects, adhesion tests of clips, waterproofing effectiveness, and overall dimensional accuracy.

- Aging Test: LED strips are powered on for extended periods (e.g., 24-72 hours) to identify early failures or flickering issues.

Common Testing Methods

- Electrical Testing: Measures voltage, current, and resistance to ensure circuit integrity.

- Photometric Testing: Uses spectrometers or lux meters to assess brightness and color consistency.

- Environmental Testing: Simulates heat, humidity, and vibration to verify durability under operating conditions.

- Mechanical Testing: Checks clip retention force and flexibility to ensure reliable mounting and handling.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, ensuring that suppliers adhere to stringent manufacturing and QC protocols is paramount. Here are practical steps to validate supplier quality:

1. Supplier Audits and Factory Visits

- Conduct on-site audits to review manufacturing processes, QC procedures, and workforce competence.

- Verify the presence and authenticity of certifications (ISO 9001, CE, RoHS, UL).

- Observe real-time production and testing to assess consistency.

2. Review of Quality Documentation

- Request detailed QC reports, including IQC, IPQC, and FQC logs.

- Examine test certificates for electrical safety, photometric performance, and environmental resistance.

- Ask for traceability records linking batches of components to finished products.

3. Third-Party Inspection and Testing

- Engage independent inspection agencies to perform pre-shipment inspections and laboratory testing.

- Third-party labs can verify compliance with international standards and provide unbiased quality assessments.

4. Sample Testing

- Obtain product samples prior to bulk orders to test compatibility, durability, and performance in your target environment.

- Conduct pilot installations to confirm ease of clip-on mounting and operational reliability.

QC and Certification Nuances for International Markets

Understanding regional requirements helps B2B buyers ensure seamless market entry and regulatory compliance:

-

Africa and South America: Regulatory frameworks may vary widely. Buyers should focus on products with international certifications (CE, UL, RoHS) and seek suppliers who can provide documentation in multiple languages. Consider local import regulations and certification requirements, which may require additional testing or registration.

-

Middle East (e.g., UAE): The Gulf Cooperation Council (GCC) countries often require SASO or G-Mark certification for electrical products. Suppliers should demonstrate compliance with these standards and have experience with customs clearance processes.

-

Europe: CE marking is mandatory, along with compliance to RoHS and WEEE directives. Buyers should insist on full certification documentation and ensure products meet EU energy efficiency standards.

-

Australia: The Regulatory Compliance Mark (RCM) indicates compliance with Australian electrical safety and electromagnetic compatibility standards. Buyers should verify this mark and associated test reports.

Final Recommendations for B2B Buyers

- Prioritize suppliers with transparent manufacturing processes and comprehensive quality management systems.

- Insist on verifiable certifications and detailed QC documentation to mitigate risks of defective products.

- Leverage third-party inspections to gain independent assurance, especially when sourcing from new or distant suppliers.

- Understand regional certification nuances early to avoid costly delays in customs or market entry.

- Conduct thorough sample testing and pilot projects to validate product fit for purpose and installation ease, particularly the clip-on mechanism.

By thoroughly evaluating manufacturing processes and quality assurance measures, international B2B buyers can confidently source clip on LED strip lights that meet their technical, regulatory, and commercial requirements—ensuring successful deployment and satisfied end customers across diverse global markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for clip on led strip light Sourcing

Understanding the Cost Structure of Clip On LED Strip Lights

When sourcing clip on LED strip lights, international B2B buyers must grasp the various components that contribute to the final cost. These cost elements collectively determine pricing and impact the overall procurement strategy.

- Materials: The primary cost driver is the quality and type of materials used—LED chips, flexible PCBs, adhesives, clips, and protective coatings. Premium LEDs and waterproof materials increase costs but enhance durability and performance.

- Labor: Labor costs vary by manufacturing location and complexity of assembly. Clip on mechanisms require precise assembly to ensure secure attachment and functionality.

- Manufacturing Overhead: Includes factory utilities, machinery depreciation, and indirect labor. Efficient factories with automation can reduce overhead, impacting pricing positively.

- Tooling Costs: Initial tooling for clip molds, PCB assembly, and packaging can be significant, especially for customized designs. These costs are usually amortized over large order volumes.

- Quality Control (QC): Rigorous QC processes—testing brightness, clip strength, and electrical safety—add to cost but ensure product reliability and reduce returns.

- Logistics and Shipping: International shipping, customs duties, and insurance vary by origin and destination. Bulk shipments typically lower per-unit logistics costs.

- Supplier Margin: Suppliers factor in profit margins based on market demand, exclusivity of design, and service levels.

Key Pricing Influencers for B2B Buyers

Several variables influence the pricing of clip on LED strip lights, making it crucial for buyers to evaluate these factors to optimize procurement costs:

- Order Volume and Minimum Order Quantity (MOQ): Higher volumes usually secure better unit prices. Some suppliers offer tiered pricing discounts, which significantly impact profitability for large-scale projects.

- Product Specifications and Customization: Custom clip designs, unique LED colors, or specific waterproof ratings increase costs due to additional tooling and testing.

- Material Quality and Certifications: LEDs with certifications like CE, RoHS, or UL command higher prices but are essential for compliance in regulated markets, especially in Europe and Australia.

- Supplier Reputation and Location: Established suppliers with proven track records may charge premiums but reduce risk. Proximity to ports or free trade zones (e.g., UAE) can lower logistics costs.

- Incoterms (International Commercial Terms): Terms like FOB, CIF, or DDP affect who bears shipping, insurance, and customs costs, influencing the landed cost for buyers in different regions.

Strategic Buyer Tips for International Sourcing

For buyers from Africa, South America, the Middle East, and Europe, navigating cost and pricing nuances requires a strategic approach to maximize value:

- Negotiate Volume-Based Discounts: Consolidate orders or collaborate with partners to increase order size, unlocking better price breaks.

- Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs duties, potential tariffs, and after-sales support. Lower upfront costs may lead to higher TCO.

- Request Detailed Cost Breakdowns: Transparency on cost components helps identify negotiation levers, such as reducing packaging costs or opting for standard clip designs to save tooling expenses.

- Assess Supplier Certifications and Quality Controls: Prioritize suppliers who provide quality certifications and warranties to mitigate risks associated with product failures or regulatory non-compliance.

- Leverage Incoterm Knowledge: Choose Incoterms that align with your logistical capabilities. For example, DDP (Delivered Duty Paid) may simplify import processes for buyers unfamiliar with customs handling.

- Request Samples Before Bulk Purchase: Testing samples verifies product quality and compatibility, preventing costly returns or project delays.

- Factor in Lead Times: Longer lead times can increase inventory holding costs; balance order size with storage capacity and project timelines.

Indicative Pricing Disclaimer

Prices for clip on LED strip lights fluctuate based on market conditions, raw material costs, and geopolitical factors. While wholesale prices typically range from $1 to $5 per meter depending on specifications and volume, these figures serve only as a rough guideline. Buyers should conduct direct supplier negotiations and request formal quotes to obtain accurate and current pricing tailored to their specific requirements.

By understanding the detailed cost components and pricing influencers, international B2B buyers can make informed decisions, optimize procurement strategies, and establish reliable sourcing partnerships for clip on LED strip lights that meet quality, cost, and delivery expectations.

Spotlight on Potential clip on led strip light Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘clip on led strip light’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for clip on led strip light

Key Technical Properties of Clip On LED Strip Lights

When sourcing clip on LED strip lights, understanding critical technical specifications helps ensure product quality, compatibility, and long-term performance. Here are the essential properties B2B buyers should focus on:

-

Material Grade and Flexibility

The base material of the LED strip, usually a flexible PCB (Printed Circuit Board), must be durable and heat-resistant. High-grade materials like copper-clad polyimide or FR4 ensure better conductivity and longevity. For clip on designs, flexibility without compromising structural integrity is crucial, as it affects ease of installation and durability under repeated attachment/detachment. -

LED Density (LEDs per Meter)

This indicates how many LEDs are mounted per meter of the strip. Higher density means brighter, more uniform light output, which is important for applications requiring consistent illumination or high brightness. Buyers should match LED density to their project’s lighting needs to optimize energy use and cost. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvins) defines the warmth or coolness of the light, ranging from warm white (2700K) to daylight (6500K). CRI measures how accurately the light reveals object colors compared to natural light; a CRI above 80 is generally preferred for retail, hospitality, and display environments. Selecting the right color temperature and CRI ensures the lighting suits the ambiance and functional requirements. -

Power Consumption and Voltage

Typical clip on LED strips operate at low voltage (12V or 24V DC) for safety and energy efficiency. Power consumption, usually expressed in watts per meter, impacts running costs and power supply requirements. Buyers should verify that power specs align with their infrastructure and energy budget. -

Ingress Protection (IP) Rating

The IP rating defines resistance to dust and water. For indoor use, IP20 (no water protection) may suffice, but outdoor or humid environments require higher ratings like IP65 or IP67 to prevent damage. Ensuring the correct IP rating protects investment and reduces maintenance costs. -

Tolerance and Dimensional Accuracy

This refers to the allowable variance in strip length, clip size, and connector placement. Tight manufacturing tolerances are critical for clip on LED strips to guarantee secure attachment and consistent performance across batches, particularly for large-scale projects needing uniformity.

Common Trade Terminology for Clip On LED Strip Light Procurement

Navigating international B2B transactions requires familiarity with industry jargon and trade terms. Below are key terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce LED strips that buyers can brand as their own. OEM partnerships allow customization of product features, packaging, and branding, providing competitive differentiation and stronger market presence. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept per order. MOQs affect inventory planning and cash flow, especially for buyers in emerging markets or smaller businesses. Negotiating MOQs can lead to more flexible purchasing arrangements. -

RFQ (Request for Quotation)

A formal document or inquiry sent to suppliers requesting detailed pricing and terms based on specified product requirements. RFQs are crucial for comparing multiple suppliers and securing competitive pricing for bulk orders. -

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities between buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps avoid hidden costs and logistical misunderstandings. -

Lead Time

The period from placing an order to receiving the goods. Lead time impacts project scheduling and inventory management. Buyers should confirm lead times upfront, especially when sourcing from overseas suppliers to avoid delays. -

Batch Consistency

Refers to uniformity in product quality and specifications across multiple production runs. Maintaining batch consistency is vital for large projects to ensure all LED strips perform identically, minimizing installation issues and returns.

Grasping these technical properties and trade terms empowers international buyers to make informed decisions, negotiate effectively, and ensure smooth procurement of clip on LED strip lights tailored to their market and project needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the clip on led strip light Sector

Market Overview & Key Trends

The global market for clip on LED strip lights is expanding rapidly, driven by increasing demand for energy-efficient, flexible lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, this sector presents a wealth of opportunities due to urbanization, infrastructure development, and rising consumer awareness of smart lighting technologies. Regions like the UAE and Australia are witnessing strong growth fueled by smart city initiatives and sustainable building codes, which emphasize low-energy and customizable lighting systems.

Key market dynamics include the growing preference for modular and easy-to-install lighting products such as clip on LED strips, which offer quick deployment and retrofit capabilities. Buyers benefit from the strips’ adaptability to various applications—ranging from accent lighting in retail environments to backlighting in industrial machinery. Moreover, technological advancements such as integrated smart controls, color-changing LEDs, and enhanced durability against environmental factors are shaping sourcing decisions.

From a sourcing perspective, international buyers are increasingly prioritizing suppliers who offer customization options (e.g., tailored lengths, color temperatures, and mounting mechanisms) to meet diverse regional requirements. The rise of e-commerce platforms and direct factory shipments has also streamlined procurement, enabling better price negotiation and faster delivery cycles. However, buyers must remain vigilant about quality assurance, opting for suppliers with transparent certifications and robust testing protocols to avoid costly returns or warranty claims.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the clip on LED strip light sector, with B2B buyers recognizing the environmental benefits of LED technology—primarily its lower energy consumption and longer lifespan compared to traditional lighting. However, the environmental impact extends beyond usage to include raw material sourcing, manufacturing practices, and end-of-life disposal.

Ethical sourcing is gaining prominence, particularly as global regulations tighten around hazardous substances and supply chain transparency. Buyers are advised to prioritize suppliers who comply with international standards such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and certifications like ENERGY STAR or TUV Rheinland. These certifications not only ensure product safety and environmental compliance but also enhance brand reputation in increasingly eco-conscious markets.

Additionally, sustainable materials—such as lead-free solder, recyclable circuit boards, and non-toxic adhesives—are becoming more common in high-quality clip on LED strips. Buyers should engage with suppliers who demonstrate commitment to reducing carbon footprints through efficient manufacturing processes and responsible waste management. Establishing long-term partnerships with such suppliers can mitigate risks related to regulatory compliance and supply chain disruptions, while aligning with corporate social responsibility goals.

Evolution of Clip On LED Strip Lights

The clip on LED strip light originated as an innovation to address the limitations of traditional LED strips, which often required adhesive backing or complex mounting solutions. The clip on design introduced a simple, reusable mechanical attachment system, enabling rapid installation and removal without damaging surfaces. This evolution has made clip on LED strips especially attractive for commercial projects where flexibility and maintenance efficiency are paramount.

Over time, advancements in LED chip technology and flexible circuit materials have enhanced brightness, color fidelity, and weather resistance, broadening the application scope from indoor decorative lighting to outdoor architectural and industrial uses. The integration of smart controls and connectivity features marks the latest phase in their development, aligning clip on LED strips with the Internet of Things (IoT) ecosystem and enabling B2B buyers to offer cutting-edge lighting solutions that combine aesthetics, functionality, and sustainability.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of clip on led strip light

-

How can I effectively vet suppliers of clip on LED strip lights for international B2B purchases?

To ensure reliability, prioritize suppliers with verifiable business licenses and positive reviews from other international buyers, especially within your region (Africa, South America, Middle East, Europe). Request detailed product specifications, certifications (e.g., CE, RoHS), and ask for factory audits or third-party inspection reports. Engage in direct communication to assess responsiveness and transparency. Additionally, request samples before committing to bulk orders to verify quality firsthand. Establishing clear payment terms and return policies upfront also helps mitigate risks in international trade. -

What customization options are typically available for clip on LED strip lights in wholesale orders?

Many manufacturers offer customization including strip length, LED density, color temperature, waterproofing levels (IP ratings), and clip design to suit specific installation needs. Branding options such as private label packaging and custom connectors are also common. For buyers in diverse markets, specifying voltage compatibility and control system preferences (e.g., dimmable, RGB, smart controls) is essential. Early discussion of customization ensures the supplier can meet your technical and aesthetic requirements, which is particularly important for projects demanding uniformity across large installations. -

What are typical minimum order quantities (MOQs) and lead times for clip on LED strip lights when sourcing internationally?

MOQs vary widely but typically range from 500 to 2,000 meters per SKU for standard products; customized orders may require higher MOQs. Lead times usually span 3 to 6 weeks, depending on order complexity, supplier capacity, and shipping logistics. Seasonal demand and component shortages can extend timelines. Planning orders well in advance and confirming lead times with suppliers helps avoid delays. For urgent projects, some suppliers offer expedited production at an additional cost, which can be negotiated during contract discussions. -

Which payment terms and methods are safest and most common in international B2B trade for LED strip lights?

Common payment methods include irrevocable letters of credit (L/C), telegraphic transfers (T/T), and escrow services. Letters of credit offer strong protection by ensuring payment only upon meeting agreed shipment and quality conditions. T/T is faster but riskier without established trust. For new suppliers, splitting payments (e.g., 30% upfront, 70% upon delivery) balances risk. Always clarify payment terms in contracts and verify supplier banking credentials to prevent fraud. Utilizing trade finance services or working with reputable trade platforms can further secure transactions. -

What quality assurance measures and certifications should I expect from clip on LED strip light suppliers?

Demand products compliant with international standards such as CE (Europe), RoHS (restriction of hazardous substances), UL or ETL (safety certifications), and ISO 9001 for manufacturing quality. Insist on supplier-provided test reports for brightness, color consistency, waterproofing, and lifespan. Third-party inspection services can verify batch quality before shipment. For markets with strict regulations, ensure compliance with local electrical and environmental standards. Robust QA reduces returns and enhances buyer confidence, especially in long-term supply agreements. -

How should I plan logistics and shipping for bulk orders of clip on LED strip lights across continents?

Coordinate closely with suppliers to choose optimal shipping modes—air freight for faster delivery but higher cost, sea freight for cost efficiency on large volumes. Consolidate shipments to reduce per-unit freight charges. Verify packaging robustness to prevent damage during long transit. Understand import regulations, duties, and taxes in your country, and engage customs brokers for smooth clearance. Tracking systems and insurance coverage are crucial for risk management. Early logistics planning aligned with production schedules helps avoid costly delays. -

What strategies can I use to handle disputes or quality issues with overseas suppliers?

Establish clear contractual terms covering product specifications, delivery schedules, and remedies for defects. Include clauses on dispute resolution, ideally specifying mediation or arbitration venues. Maintain thorough documentation—contracts, communications, inspection reports, and shipment records. If issues arise, promptly notify the supplier with evidence and seek amicable resolution. Leveraging third-party inspection or certification bodies can support claims. For persistent problems, consider legal counsel experienced in international trade law and trade insurance options to mitigate losses. -

Are there regional considerations B2B buyers should be aware of when sourcing clip on LED strip lights internationally?

Yes, regional factors such as electrical standards (voltage/frequency), climate (humidity, temperature), and market preferences influence product choice and supplier selection. For example, buyers in the Middle East or Africa may require high IP-rated strips for outdoor durability, while European clients might prioritize energy efficiency and strict compliance with environmental standards. Currency fluctuations, import regulations, and geopolitical stability also impact cost and delivery reliability. Establishing local partnerships or warehouses can improve supply chain resilience and customer service in diverse regions.

Strategic Sourcing Conclusion and Outlook for clip on led strip light

Strategic sourcing of clip on LED strip lights offers international B2B buyers a compelling blend of innovation, cost efficiency, and customization. By partnering with reputable wholesale suppliers, businesses across Africa, South America, the Middle East, and Europe can secure high-quality, energy-efficient lighting solutions tailored to diverse applications—from commercial installations to architectural accenting. Prioritizing suppliers with strong warranties, transparent pricing, and sample availability ensures risk mitigation and product consistency.

Illustrative Image (Source: Google Search)

Key takeaways for buyers include:

- Leveraging bulk purchasing to optimize unit costs and streamline supply chains

- Selecting suppliers who offer advanced features like smart controls, waterproofing, and color customization

- Emphasizing product quality through rigorous testing and component sourcing

- Aligning procurement strategies with sustainability goals and evolving lighting technologies

Looking ahead, the clip on LED strip light market is poised for continued growth driven by smart technology integration and increasing demand for adaptable, durable lighting. Buyers who adopt a strategic sourcing mindset—balancing innovation with cost-effectiveness—will gain a competitive edge in their respective markets. To capitalize on this momentum, international buyers should engage early with forward-thinking manufacturers and distributors to secure tailored solutions that meet both current and future lighting challenges.