Guide to Full Spectrum Led Light Strips

- Introduction: Navigating the Global Market for full spectrum led light strips

- Understanding full spectrum led light strips Types and Variations

- Key Industrial Applications of full spectrum led light strips

- Strategic Material Selection Guide for full spectrum led light strips

- In-depth Look: Manufacturing Processes and Quality Assurance for full spectrum led light strips

- Manufacturing Process of Full Spectrum LED Light Strips

- Quality Assurance Protocols

- Ensuring Supplier Quality: Best Practices for B2B Buyers

- Conclusion

- Comprehensive Cost and Pricing Analysis for full spectrum led light strips Sourcing

- Spotlight on Potential full spectrum led light strips Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for full spectrum led light strips

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the full spectrum led light strips Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of full spectrum led light strips

- Strategic Sourcing Conclusion and Outlook for full spectrum led light strips

Introduction: Navigating the Global Market for full spectrum led light strips

Full spectrum LED light strips represent a transformative advancement in lighting technology, offering unparalleled versatility and efficiency across diverse applications—from horticulture and retail displays to architectural and wellness environments. For international B2B buyers, especially those operating in dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the complexities of these products is essential to making strategic sourcing decisions that balance quality, cost, and compliance.

This guide delivers an authoritative roadmap through the global marketplace of full spectrum LED light strips, addressing critical factors such as product types, material composition, manufacturing standards, and quality control protocols. It also explores the nuances of selecting reliable suppliers and navigating pricing structures influenced by regional market trends and supply chain variables.

By integrating comprehensive market insights with practical sourcing advice, the guide equips buyers—from Nairobi to São Paulo, Dubai to London—with the tools necessary to evaluate options confidently and negotiate effectively. Emphasis on regional considerations ensures relevance, highlighting challenges such as import regulations, logistical constraints, and local demand patterns.

Key components covered include:

- Overview of full spectrum LED strip varieties and their technical specifications

- Material quality indicators and durability factors for varied environments

- Manufacturing best practices and quality assurance benchmarks

- Supplier evaluation criteria including certifications and service capabilities

- Cost analysis frameworks tailored for international procurement

- Market landscape insights focused on emerging and established economies

- Answers to frequently asked questions addressing common buyer concerns

Armed with this knowledge, international B2B buyers can optimize their procurement strategies, ensuring access to cutting-edge lighting solutions that drive innovation and competitiveness in their respective industries.

Understanding full spectrum led light strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Full Spectrum LED Strips | Emit a continuous spectrum mimicking natural sunlight | Horticulture, retail displays, general lighting | Pros: Versatile, cost-effective; Cons: Limited customization on spectrum |

| Tunable Full Spectrum LED Strips | Adjustable color temperature and intensity | Indoor farming, commercial offices, museums | Pros: Flexible lighting control; Cons: Higher initial investment |

| High-CRI Full Spectrum LED Strips | High Color Rendering Index (CRI > 90) for true color | Art galleries, photography studios, medical facilities | Pros: Excellent color accuracy; Cons: Premium pricing, power consumption |

| Waterproof Full Spectrum LED Strips | Encapsulated for moisture and dust resistance | Outdoor landscaping, aquaponics, architectural lighting | Pros: Durable in harsh environments; Cons: Slightly reduced brightness |

| UV-Enhanced Full Spectrum LED Strips | Incorporate ultraviolet wavelengths for plant growth | Specialized horticulture, scientific research | Pros: Promotes specific plant growth phases; Cons: Limited general lighting use |

Standard Full Spectrum LED Strips

These strips provide a broad, continuous light spectrum closely resembling natural sunlight, making them ideal for diverse applications such as retail displays and general indoor lighting. For B2B buyers, they represent a cost-effective solution with reliable performance. Key purchasing considerations include verifying spectral quality and ensuring compatibility with existing power supplies. Their versatility suits markets in Africa and South America where multi-purpose lighting solutions are preferred.

Tunable Full Spectrum LED Strips

Offering dynamic control over color temperature and brightness, tunable strips cater to environments requiring adaptable lighting conditions, such as indoor farms and office spaces. B2B buyers should evaluate the control interface compatibility (e.g., DMX, wireless) and assess the total cost of ownership, including controllers. This type appeals particularly to technologically advanced markets in Europe and the Middle East seeking energy-efficient, customizable lighting.

High-CRI Full Spectrum LED Strips

Designed for applications demanding precise color representation, these LED strips have a Color Rendering Index above 90, essential for art galleries, medical facilities, and high-end retail. Buyers must consider the trade-off between superior color fidelity and higher upfront costs. In regions like the UK and Kenya, where quality and aesthetics drive purchasing decisions, these strips support premium product presentation and critical visual tasks.

Waterproof Full Spectrum LED Strips

Encased in protective materials, waterproof strips resist moisture and dust, making them suitable for outdoor installations such as landscaping and aquaponic systems. B2B buyers should verify IP ratings (commonly IP65 to IP68) and confirm durability standards for local climates, especially in humid or rainy regions like parts of South America and Africa. While brightness may slightly decrease due to encapsulation, the extended lifespan justifies the investment.

UV-Enhanced Full Spectrum LED Strips

Incorporating ultraviolet light alongside visible wavelengths, these strips stimulate specific plant growth stages and are valuable in scientific research and specialized horticulture. Buyers must assess UV safety standards and application specificity to avoid misuse. This niche product is well-suited for advanced agricultural businesses in the Middle East and Europe focused on maximizing crop yields through precision lighting.

Key Industrial Applications of full spectrum led light strips

| Industry/Sector | Specific Application of full spectrum led light strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Horticulture | Controlled environment agriculture (CEA) lighting | Enhanced plant growth and yield through optimized light spectrum | Spectrum customization, durability in humid conditions, energy efficiency |

| Healthcare & Medical Facilities | Circadian rhythm lighting in patient rooms and labs | Improved patient well-being and staff performance | Compliance with medical lighting standards, flicker-free operation, longevity |

| Retail & Commercial Spaces | Product display and ambiance lighting | Increased customer engagement and sales | Color rendering index (CRI), dimmability, ease of installation and maintenance |

| Manufacturing & Industrial Facilities | Task and inspection lighting in quality control areas | Improved accuracy and reduced errors in production | High brightness, uniform light distribution, robust build for harsh environments |

| Museums & Art Galleries | Artifact and exhibit illumination | Preservation of delicate materials while enhancing visibility | Low UV emission, adjustable spectrum, non-damaging heat levels |

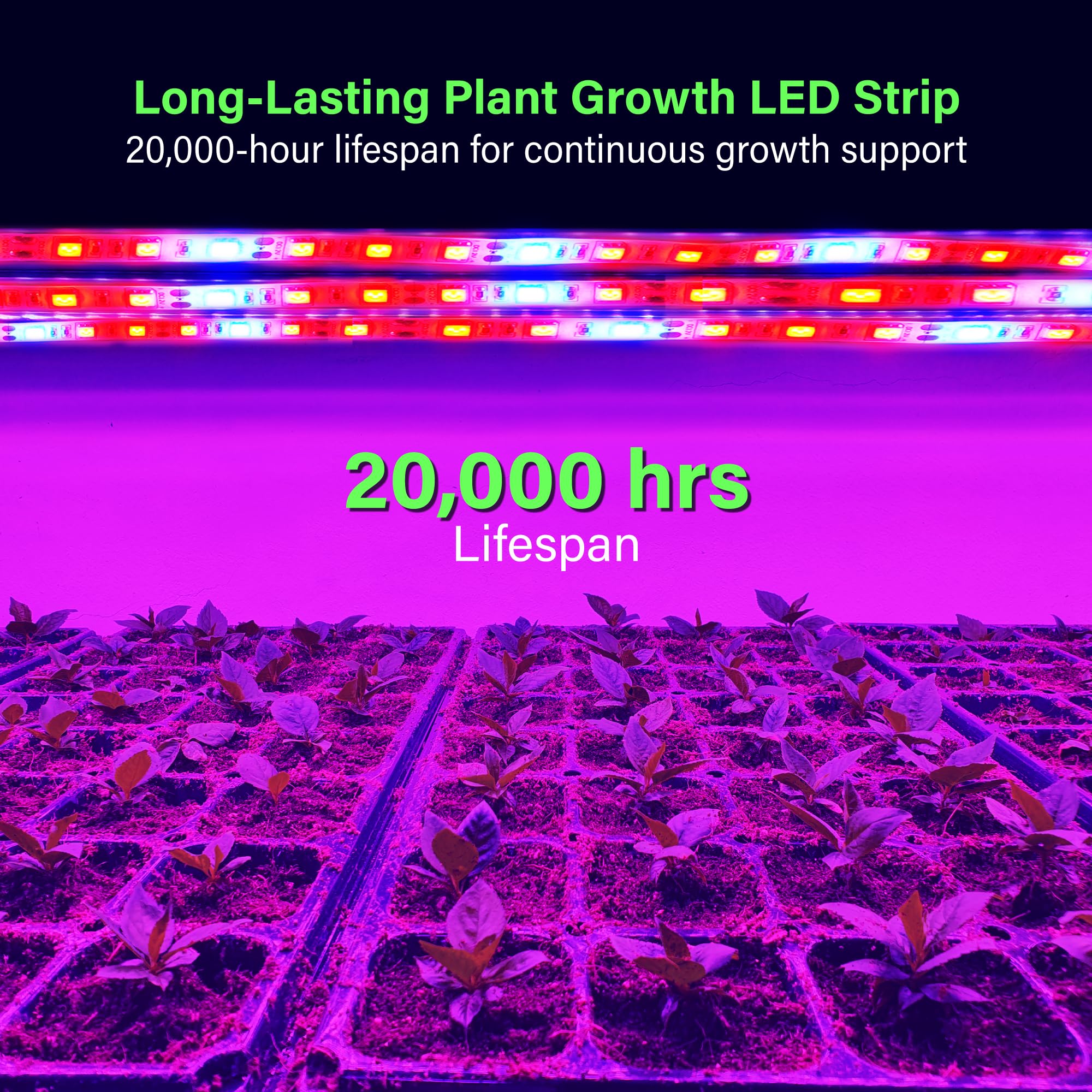

Agriculture & Horticulture

Full spectrum LED light strips are increasingly vital in controlled environment agriculture, such as greenhouses and vertical farms, where natural sunlight is limited or inconsistent. These lights replicate the sun’s full spectrum, promoting photosynthesis and healthier plant growth. For international buyers in regions like Kenya or Brazil, sourcing strips with customizable spectra and high energy efficiency is essential to optimize crop yields while managing operational costs. Durability against humidity and ease of integration with automated systems are also key considerations.

Healthcare & Medical Facilities

In hospitals and clinics, full spectrum LED strips support circadian rhythm lighting, which helps regulate patients’ sleep-wake cycles and improves recovery outcomes. These lighting solutions also enhance the accuracy of medical examinations and laboratory work by providing consistent, natural-like illumination. Buyers from Europe and the Middle East must ensure compliance with stringent medical lighting standards and prioritize flicker-free, long-lasting products to maintain a safe and comfortable environment for patients and staff.

Retail & Commercial Spaces

Retailers leverage full spectrum LED strips to enhance product displays by rendering colors more accurately and creating inviting atmospheres that influence purchasing behavior. The ability to adjust brightness and color temperature enables stores in the UK or South America to tailor lighting to different times of day or promotional events. Key sourcing factors include high color rendering index (CRI), ease of installation in diverse store layouts, and reliable dimming controls to maximize energy savings without compromising visual appeal.

Manufacturing & Industrial Facilities

In manufacturing plants, particularly in quality control and inspection stations, full spectrum LED strips provide bright, uniform lighting that reduces eye strain and improves defect detection. Buyers in industrial hubs across Europe and the Middle East should prioritize LED strips with robust construction to withstand dust, vibration, and temperature fluctuations. Additionally, ensuring compatibility with existing electrical infrastructure and selecting strips with consistent lumen output are critical for maintaining production efficiency.

Museums & Art Galleries

Exhibiting art and artifacts demands lighting that reveals true colors without damaging sensitive materials. Full spectrum LED strips with low UV emissions and adjustable spectral output enable curators in regions like South Africa or Spain to protect collections while offering visitors optimal viewing experiences. International buyers must consider the thermal management of the strips and the ability to fine-tune light intensity and spectrum to meet preservation guidelines, ensuring both safety and aesthetic excellence.

Related Video: How to Install LED Light Strips

Strategic Material Selection Guide for full spectrum led light strips

When selecting materials for full spectrum LED light strips, the choice directly influences product performance, durability, and suitability for diverse international markets. Buyers from regions such as Africa, South America, the Middle East, and Europe must consider environmental conditions, regulatory compliance, and cost-effectiveness to optimize their procurement decisions.

Flexible Printed Circuit Boards (FPC)

Key Properties:

FPCs are the foundational substrate for most LED strips, typically made from polyimide or polyester films. They offer excellent flexibility, thermal stability (up to 200°C for polyimide), and electrical insulation. Their thin profile allows for compact and lightweight designs.

Pros & Cons:

FPCs provide superior flexibility, enabling installation on curved or irregular surfaces. They are relatively cost-effective and support high-density LED mounting. However, they can be sensitive to mechanical stress and moisture ingress if not properly sealed, potentially reducing lifespan.

Impact on Application:

Ideal for applications requiring intricate installations such as architectural lighting or horticulture setups common in Kenya and Brazil, where adaptability to varied surfaces is critical. Moisture protection is essential in humid or outdoor environments prevalent in these regions.

International Buyer Considerations:

Compliance with IPC standards (e.g., IPC-2221 for PCB design) is crucial. European buyers often require RoHS compliance and adherence to REACH regulations, while Middle Eastern markets may emphasize durability under high temperatures. Buyers should verify supplier certifications and consider additional conformal coatings for enhanced environmental resistance.

Silicone Encapsulation

Key Properties:

Silicone encapsulation is used to protect LED strips from dust, moisture, and mechanical damage. It offers excellent UV resistance, flexibility, and can withstand temperatures from -50°C to 200°C.

Pros & Cons:

This material significantly enhances strip durability and weather resistance, making it suitable for outdoor or industrial applications. The downside includes higher production costs and potential challenges in mass manufacturing due to curing times.

Impact on Application:

Highly recommended for outdoor lighting projects in regions like the Middle East and South America, where exposure to intense sunlight and dust is common. Silicone encapsulation extends product life and maintains light quality under harsh conditions.

International Buyer Considerations:

Buyers should ensure that silicone materials meet ASTM D2000 standards for elastomers and verify UV stability certifications. In Europe, compliance with CE marking and REACH is mandatory. For African markets, durability against dust and heat is a priority, making silicone-encapsulated strips a preferred choice despite the premium cost.

Aluminum Alloy Backing

Key Properties:

Aluminum alloy backing serves as a heat sink, improving thermal management by dissipating heat away from LEDs. It typically features anodized surfaces for corrosion resistance and can operate effectively in temperatures up to 150°C.

Pros & Cons:

Aluminum backing enhances LED lifespan and efficiency by preventing overheating. It is lightweight and mechanically robust but increases material and manufacturing costs. The rigidity reduces flexibility, limiting use on curved surfaces.

Impact on Application:

Best suited for industrial and commercial lighting installations in Europe and the Middle East, where long-term reliability and thermal performance are critical. Less ideal for flexible or decorative applications common in consumer markets.

International Buyer Considerations:

European buyers often require compliance with EN 573 for aluminum alloys and ISO 9001 manufacturing standards. In Africa and South America, buyers should assess corrosion resistance based on local environmental factors, such as coastal salt exposure. Anodized finishes are preferred to mitigate corrosion risks.

Polycarbonate (PC) Diffusers

Key Properties:

Polycarbonate diffusers are used to cover LED strips, providing light diffusion and physical protection. PC is known for its high impact resistance, UV stability, and thermal resistance up to 115°C.

Pros & Cons:

PC diffusers improve light uniformity and protect LEDs from mechanical damage. They are cost-effective and lightweight but can yellow over time if exposed to intense UV radiation without proper additives.

Impact on Application:

Suitable for indoor and semi-outdoor applications in Europe and South America, where aesthetic lighting quality is prioritized. In high UV environments like parts of Africa and the Middle East, UV-stabilized PC grades are essential to prevent discoloration.

International Buyer Considerations:

Buyers should ensure compliance with ASTM D635 for flammability and ISO 4892 for UV resistance. European markets may demand REACH and RoHS compliance. For regions with strong sunlight exposure, specifying UV-resistant PC grades is critical to maintain product longevity.

| Material | Typical Use Case for full spectrum led light strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Printed Circuit Boards (FPC) | Flexible installations on curved or irregular surfaces | Excellent flexibility and thermal stability | Sensitive to moisture without sealing | Medium |

| Silicone Encapsulation | Outdoor and industrial lighting requiring high durability | Superior moisture and UV resistance | Higher production cost and complex manufacturing | High |

| Aluminum Alloy Backing | Industrial/commercial lighting demanding effective heat dissipation | Enhances thermal management and durability | Reduced flexibility, higher cost | Medium to High |

| Polycarbonate (PC) Diffusers | Indoor and semi-outdoor lighting for improved light diffusion | High impact resistance and light uniformity | Potential yellowing under strong UV exposure | Low to Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for full spectrum led light strips

Manufacturing and Quality Assurance of Full Spectrum LED Light Strips: A Detailed Overview

Understanding the manufacturing process and quality assurance protocols behind full spectrum LED light strips is crucial for international B2B buyers. This knowledge enables informed supplier selection, ensures product reliability, and aligns with regulatory compliance across diverse markets such as Africa, South America, the Middle East, and Europe.

Manufacturing Process of Full Spectrum LED Light Strips

The production of full spectrum LED light strips involves several critical stages, each demanding precision and strict process control to deliver consistent performance and longevity.

1. Material Preparation

- Selection of LED Chips: Full spectrum LEDs incorporate specialized semiconductor materials that emit a broad range of wavelengths. Manufacturers source high-quality LED chips from reputable suppliers to ensure spectral accuracy and efficiency.

- Flexible PCB Fabrication: The base for LED strips is a flexible printed circuit board (FPCB) designed to support electrical connectivity and mechanical flexibility. Material quality here affects thermal management and durability.

- Component Procurement: Resistors, capacitors, adhesive backings, and protective coatings are carefully selected to match the LED’s electrical and environmental requirements.

2. Forming and Circuit Assembly

- Surface Mount Technology (SMT): LEDs and other surface mount components are precisely placed on the FPCB using automated pick-and-place machines, ensuring uniformity and reducing human error.

- Soldering: Reflow soldering secures components onto the PCB with consistent quality, critical for electrical conductivity and mechanical stability.

- Encapsulation: To protect LEDs from moisture, dust, and mechanical damage, manufacturers apply silicone or epoxy coatings that maintain light transmission while enhancing durability.

3. Final Assembly and Finishing

- Cutting and Segmenting: LED strips are cut into standardized lengths or customized sizes per order specifications, often with designated cutting points.

- Adhesive Application: High-quality, heat-resistant adhesive backing is applied for ease of installation and long-term adherence.

- Packaging: Products are packaged with anti-static materials and moisture barrier bags to preserve product integrity during shipping and storage.

Quality Assurance Protocols

Robust quality control (QC) systems are imperative to maintain product standards, comply with international regulations, and satisfy diverse market requirements.

Relevant International and Industry Standards

- ISO 9001: This global quality management standard ensures that manufacturers follow consistent processes, focus on customer satisfaction, and continually improve product quality.

- CE Marking (Europe): Confirms compliance with EU safety, health, and environmental requirements, essential for European buyers.

- RoHS Compliance: Restricts hazardous substances, critical for environmentally conscious markets worldwide.

- UL Certification (North America): Though more regional, it often serves as a quality benchmark for global buyers.

- API and Other Regional Standards: Some markets may require adherence to specific standards or certifications relevant to electrical or lighting products.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival for defects, specifications compliance, and traceability.

- In-Process Quality Control (IPQC): Continuous monitoring during SMT placement, soldering, and assembly stages ensures early detection of defects.

- Final Quality Control (FQC): Complete LED strips undergo rigorous inspection before packaging, including visual checks and functional testing.

Common Testing Methods

- Spectral Analysis: Verifies the full spectrum output matches specified wavelength ranges critical for applications like horticulture, health, or commercial lighting.

- Electrical Testing: Measures voltage, current, and power consumption to confirm operational parameters and detect shorts or open circuits.

- Thermal Testing: Assesses heat dissipation capabilities and thermal resistance to ensure longevity under operational conditions.

- Environmental Testing: Includes moisture resistance (IP rating), UV stability, and mechanical endurance to simulate real-world usage.

- Photometric Testing: Evaluates luminous intensity, uniformity, and color rendering index (CRI) to guarantee consistent lighting quality.

Ensuring Supplier Quality: Best Practices for B2B Buyers

For buyers in regions such as Kenya, Brazil, UAE, and the UK, verifying supplier quality practices is essential to mitigate risks and ensure supply chain reliability.

Supplier Audits and Factory Inspections

- Conduct on-site audits or hire third-party inspection agencies to evaluate manufacturing capabilities, equipment, workforce expertise, and QC systems.

- Verify supplier compliance with ISO 9001 and relevant certifications by requesting documentation and certificates.

- Assess process controls, traceability, and corrective action procedures during audits.

Reviewing Quality Documentation and Test Reports

- Request Detailed QC reports including IQC, IPQC, and FQC results for production batches.

- Analyze test certificates from accredited labs for spectral output, electrical safety, and environmental resistance.

- Ensure traceability from raw materials to finished products through batch numbers and quality records.

Third-Party Inspections and Laboratory Testing

- Utilize independent inspection services to perform pre-shipment inspections confirming product conformity and packaging standards.

- Engage accredited laboratories to conduct random sample testing for compliance with international standards and buyer-specific requirements.

Navigating QC Nuances for Different Regions

- Africa and South America: Infrastructure challenges may affect logistics; prioritize suppliers with proven export experience and robust packaging to withstand long transit times.

- Middle East: Focus on suppliers who meet stringent environmental certifications, given the extreme climate conditions.

- Europe (e.g., UK): Emphasize compliance with CE marking, RoHS, and energy efficiency directives; expect detailed documentation and traceability.

Conclusion

For international B2B buyers of full spectrum LED light strips, understanding the intricacies of manufacturing and quality assurance is foundational to securing high-quality products. By focusing on transparent supplier processes, rigorous QC checkpoints, and adherence to international standards, buyers can confidently navigate the global marketplace, ensuring reliable, compliant, and performance-optimized lighting solutions tailored to their regional and application-specific needs.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for full spectrum led light strips Sourcing

Understanding the cost structure and pricing dynamics of full spectrum LED light strips is essential for international B2B buyers aiming to optimize procurement strategies and maximize value. This analysis breaks down key cost components, pricing influencers, and practical buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Full Spectrum LED Strip Manufacturing

-

Materials: The primary cost driver includes high-quality LEDs capable of emitting a full spectrum of light, flexible circuit boards, resistors, adhesive backing, and protective coatings. Premium phosphor materials and advanced chips increase costs but enhance light quality and lifespan.

-

Labor: Skilled labor for assembly, testing, and quality assurance impacts costs, especially in regions with higher wages or stringent labor standards. Automated production can reduce labor costs but may require higher initial investment.

-

Manufacturing Overhead: This covers factory utilities, equipment depreciation, and facility maintenance. Efficient overhead management can lower per-unit costs, benefiting large-volume buyers.

-

Tooling: Custom tooling for specific strip designs or connectors requires upfront investment. This cost is amortized over production volume and influences MOQ and unit price.

-

Quality Control (QC): Rigorous QC processes, including spectral testing and durability assessments, ensure product reliability but add to manufacturing expenses.

-

Logistics: Shipping, customs duties, insurance, and local distribution fees vary significantly by destination. Buyers from Kenya, Brazil, UAE, or the UK should factor in regional tariffs and port handling charges.

-

Supplier Margin: Suppliers include a margin to cover business risks and profit, which varies based on supplier scale, market competition, and contract terms.

Critical Pricing Influencers

-

Order Volume and MOQ: Larger orders typically command better per-unit pricing due to economies of scale. However, buyers should balance MOQ with inventory carrying costs and market demand to avoid excess stock.

-

Specifications and Customization: Custom lengths, unique spectral distributions, or integrated smart controls increase unit costs. Standardized products are usually more cost-effective.

-

Material Quality and Certifications: Compliance with international standards (e.g., CE, RoHS, UL) may increase cost but is vital for market access, especially in Europe and parts of the Middle East.

-

Supplier Location and Reputation: Established suppliers with robust supply chains may charge premiums but reduce risks of delays and quality issues.

-

Incoterms and Payment Terms: Shipping terms (FOB, CIF, DDP) significantly affect landed cost. Buyers should negotiate terms that optimize cash flow and reduce unexpected expenses.

Strategic Buyer Tips for International Sourcing

-

Negotiate Beyond Price: Engage suppliers on lead times, payment flexibility, warranty conditions, and after-sales support. These factors often yield greater value than marginal price reductions.

-

Analyze Total Cost of Ownership (TCO): Consider product lifespan, energy efficiency, maintenance requirements, and replacement frequency. Higher upfront costs may be justified by lower operating expenses.

-

Leverage Local Market Insights: Understanding regional import regulations, tax incentives, and subsidies can reduce costs. For example, certain African or Middle Eastern countries offer duty exemptions on renewable energy products.

-

Assess Supplier Financial Stability: Especially important for buyers in emerging markets to avoid supply disruptions.

-

Plan for Logistics Complexities: Factor in potential delays, customs clearance times, and transport infrastructure quality, which vary greatly between regions like South America and Europe.

-

Request Detailed Quotes: Ensure quotes break down costs transparently, highlighting material, labor, shipping, and ancillary charges to identify negotiation opportunities.

Indicative Pricing Disclaimer

Prices for full spectrum LED light strips vary widely based on specifications, order size, and sourcing region. As a reference, wholesale pricing may range from approximately $5 to $20 per meter, with customization and certification requirements pushing prices higher. Buyers should conduct due diligence with multiple suppliers to obtain accurate, current pricing tailored to their specific needs.

Illustrative Image (Source: Google Search)

By carefully evaluating cost components, understanding pricing influencers, and applying strategic sourcing practices, international B2B buyers can secure competitive pricing while ensuring high-quality full spectrum LED light strips that meet their operational and market demands.

Spotlight on Potential full spectrum led light strips Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘full spectrum led light strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for full spectrum led light strips

Understanding the critical technical properties and common trade terminology related to full spectrum LED light strips is essential for B2B buyers seeking to make informed purchasing decisions. This knowledge helps ensure product quality, compatibility, and smooth international transactions, particularly for businesses operating across Africa, South America, the Middle East, and Europe.

Key Technical Properties of Full Spectrum LED Light Strips

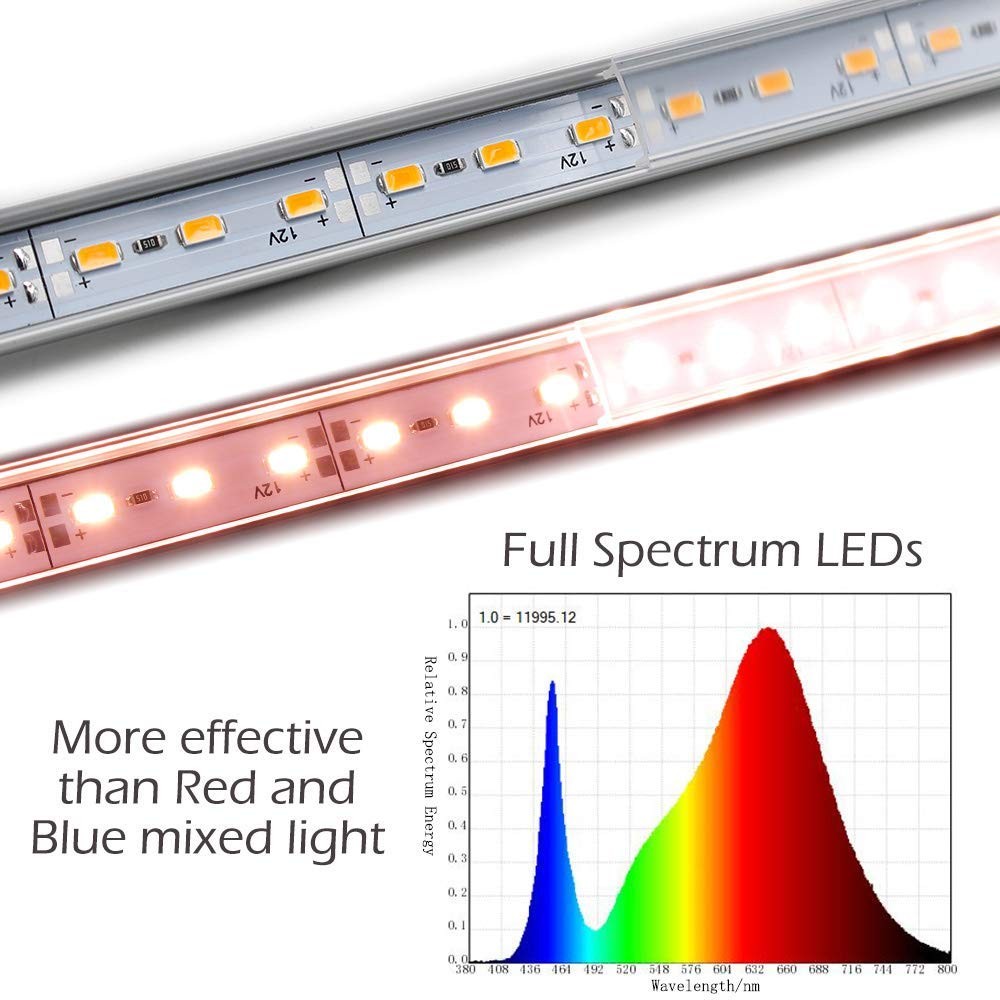

1. Spectral Output / Color Temperature

Full spectrum LED strips emit light across a broad wavelength range, closely mimicking natural sunlight. This is often measured in Kelvin (K) and ranges typically from 2700K (warm light) to 6500K (daylight). For industries such as horticulture, retail, or health, selecting the correct spectral output is critical to meet specific application needs and maximize product effectiveness.

2. Voltage and Current Ratings

Most LED strips operate on low voltages, commonly 12V or 24V DC. The current rating (measured in Amperes) per meter is equally important to determine power supply requirements. Matching voltage and current specifications ensures safety, prevents damage, and guarantees consistent illumination across the entire strip length.

3. Material Quality and IP Rating

The base material of the strip (usually flexible PCB) and the quality of LEDs impact durability and heat dissipation. In addition, the Ingress Protection (IP) rating indicates resistance to dust and water (e.g., IP65 for water resistance). Buyers targeting outdoor or humid environments should prioritize higher IP ratings to ensure longevity and reduce maintenance costs.

4. Brightness / Luminous Flux

Brightness is measured in lumens per meter (lm/m) and indicates the intensity of light output. Full spectrum strips vary widely—from low-intensity ambient lighting to high-intensity task lighting. Understanding lumen requirements allows buyers to specify products that meet their lighting design goals without overpaying for unnecessary brightness.

5. Color Rendering Index (CRI)

CRI measures how accurately the light source reveals colors compared to natural light, scored on a 0-100 scale. Full spectrum LEDs typically have a high CRI (above 90), which is vital for applications where color accuracy affects product presentation or human comfort, such as retail displays or medical facilities.

6. Cuttable and Connectable Lengths

LED strips are sold in reels with designated cut points, allowing customization to project dimensions. Understanding the minimum cuttable length and connection methods is essential for efficient installation and reducing waste, which is especially important for large-scale commercial projects.

Common Trade Terminology in LED Strip Purchasing

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that can be branded or customized for resellers. B2B buyers often engage with OEMs to create private-label products tailored to regional market preferences or regulatory requirements.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. Knowing the MOQ helps buyers plan inventory, negotiate pricing, and manage cash flow effectively, especially when entering new markets or testing product lines.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting detailed pricing, specifications, and terms for a particular LED strip product. Preparing precise RFQs accelerates supplier responses and helps buyers compare offers transparently.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms ensures clarity on delivery obligations and cost allocation in cross-border transactions.

Bin Number

A classification code for LED chips indicating color consistency and brightness within a production batch. Buyers requiring uniform lighting quality should request bin-matched products to avoid visible differences in color or intensity.

Dimmability and Control Protocols

Refers to the LED strip’s ability to adjust brightness or color via control systems (e.g., PWM dimming, DMX protocol). Selecting strips compatible with existing control infrastructure enables flexible lighting solutions and enhances user experience.

By mastering these technical properties and trade terms, international B2B buyers can confidently specify full spectrum LED light strips that align with their operational needs, budget constraints, and compliance standards. This foundational knowledge supports strategic sourcing, reduces risks, and fosters stronger supplier partnerships in diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the full spectrum led light strips Sector

Market Overview & Key Trends

The global market for full spectrum LED light strips is expanding rapidly, driven by rising demand for energy-efficient and versatile lighting solutions across commercial, industrial, and horticultural sectors. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, this growth is fueled by increasing infrastructure development, smart city initiatives, and a surge in controlled-environment agriculture. Markets in Kenya and the UK, for instance, are witnessing heightened interest in full spectrum LEDs due to their superior light quality, which supports both human-centric lighting and plant growth applications.

Key market drivers include:

- Technological advancements: Integration of tunable spectrum controls and IoT-enabled lighting systems allows businesses to customize light output for specific applications, improving operational efficiency.

- Cost-effectiveness: Declining prices of LED components and improved manufacturing processes have made full spectrum LED strips more accessible to emerging markets.

- Regulatory support: Governments in Europe and the Middle East increasingly enforce energy efficiency standards, promoting LED adoption over traditional lighting.

- Supply chain diversification: To mitigate risks exposed by recent global disruptions, B2B buyers are sourcing from multiple regions, including Asia and emerging local manufacturers in Africa and South America.

Emerging sourcing trends emphasize quality certification, supplier transparency, and scalability. Buyers seek suppliers who can provide detailed product specifications, including spectral power distribution and energy consumption data, ensuring compatibility with diverse applications. Additionally, modular LED strips and customizable lengths are in demand to reduce waste and optimize installation.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration in the procurement of full spectrum LED light strips. The environmental impact of lighting products extends beyond energy consumption to include raw material extraction, manufacturing processes, and end-of-life disposal. For international buyers, particularly in regions prioritizing green initiatives like the EU, sourcing sustainably manufactured LEDs is essential to meet corporate social responsibility goals and regulatory compliance.

Key aspects of sustainability in this sector include:

- Energy efficiency: Full spectrum LEDs consume significantly less power than traditional lighting, directly reducing carbon footprints and operational costs.

- Use of eco-friendly materials: Buyers should prioritize suppliers using lead-free solder, recyclable circuit boards, and non-toxic adhesives.

- Certifications: Look for products with recognized environmental certifications such as RoHS (Restriction of Hazardous Substances), REACH compliance, and ENERGY STAR ratings. These ensure adherence to strict environmental and safety standards.

- Ethical supply chains: Transparency in sourcing minerals and components is crucial. Buyers should engage with manufacturers who provide clear documentation on labor practices and conflict-free sourcing to avoid reputational risks.

Implementing sustainability practices also involves life-cycle assessments and encouraging suppliers to adopt circular economy principles, such as take-back programs and recycling initiatives. For B2B buyers in emerging markets, partnering with suppliers committed to sustainability can also unlock government incentives and enhance brand value.

Evolution of Full Spectrum LED Light Strips

Full spectrum LED technology has evolved from basic white LED strips to sophisticated systems capable of replicating natural sunlight across a broad wavelength range. Initially designed for decorative lighting, full spectrum LEDs found early adoption in horticulture, where precise light spectra improve plant growth and yield. Over the past decade, advancements in semiconductor materials and LED chip designs have enabled tunable spectral outputs, facilitating applications in human-centric lighting, medical therapy, and aquaculture.

This evolution has been marked by:

- Enhanced spectral accuracy to mimic natural light conditions.

- Development of multi-channel LED strips combining various diode types (e.g., red, blue, white) for tailored light recipes.

- Integration with smart controls for dynamic spectrum adjustment in real-time.

For B2B buyers, understanding this progression helps in selecting LED strips that align with specific industry needs and future-proof investments by leveraging the latest technology innovations.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of full spectrum led light strips

-

How can I effectively vet suppliers of full spectrum LED light strips for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications such as ISO or CE marks relevant to LED products. Request detailed product specifications and sample shipments to assess quality firsthand. Check references and customer reviews, especially from buyers in similar regions like Africa or Europe. Evaluate their communication responsiveness and willingness to provide customization options. Lastly, consider visiting their manufacturing facilities or using third-party inspection services to ensure compliance with international standards and production capabilities. -

What customization options are typically available for full spectrum LED light strips in bulk orders?

Most manufacturers offer customization in length, color temperature, brightness levels, and waterproof ratings to suit various applications. You can also request specific PCB materials, adhesive backings, and connectors tailored to your regional installation requirements. Some suppliers provide programmable control features or integration with smart lighting systems. Ensure you clearly communicate your technical needs upfront and confirm the supplier’s ability to deliver prototypes before committing to large orders. -

What are common minimum order quantities (MOQs) and lead times for full spectrum LED strip orders from international suppliers?

MOQs vary widely but typically range from 100 to 1000 meters per model, depending on the supplier and product complexity. Lead times generally span 3 to 8 weeks, influenced by order size, customization, and current supply chain conditions. Buyers from regions like South America and the Middle East should factor in additional shipping time. To avoid delays, negotiate MOQs aligned with your inventory needs and clarify lead time expectations, including production, quality checks, and freight forwarding schedules. -

Which payment terms and methods are safest and most practical for international B2B transactions of LED strips?

Common payment methods include wire transfers (T/T), letters of credit (L/C), and escrow services. Letters of credit offer the highest security by ensuring payment only upon meeting agreed terms, ideal for first-time international transactions. Wire transfers are faster but carry higher risk without proper due diligence. Negotiate partial upfront payments (30%-50%) with balance upon delivery to mitigate risks. Always confirm the supplier’s banking details independently and use trade platforms that offer payment protection. -

What quality assurance measures should I require from full spectrum LED strip suppliers?

Request detailed quality control documentation including material certificates, in-process inspection reports, and final product testing results such as lumen output, color rendering index (CRI), and durability under environmental stress. Insist on compliance with international standards like RoHS, CE, and UL certifications. Conduct or commission third-party lab testing if possible. Establish clear warranty terms covering defects and performance to protect your investment and maintain customer satisfaction.

Illustrative Image (Source: Google Search)

-

Which certifications are critical for full spectrum LED light strips to meet regulatory requirements in Africa, South America, the Middle East, and Europe?

Key certifications include CE for the European market, RoHS for hazardous substance restrictions, and UL or ETL for electrical safety. Some African and Middle Eastern countries may require additional local certifications or approvals from standards organizations. Confirm with your local import authorities and ensure suppliers provide valid documentation. Compliance reduces customs clearance issues and assures buyers that products meet safety and environmental standards. -

What logistics considerations should I keep in mind when importing full spectrum LED strips internationally?

Consider the total landed cost including shipping, customs duties, VAT, and potential import restrictions. Choose reliable freight forwarders experienced with electronics to minimize damage risks. Verify packaging standards to protect sensitive LEDs during transit. Plan for potential delays at customs and ensure all documentation (commercial invoice, packing list, certificates) is accurate and complete. For bulk shipments, sea freight is cost-effective but slower; air freight offers speed but at a premium. -

How should I handle disputes or quality issues with suppliers after receiving full spectrum LED light strips?

Establish clear contract terms covering product specifications, inspection rights, and dispute resolution procedures before ordering. If issues arise, document them with photos and test reports promptly. Communicate clearly with the supplier to seek amicable solutions such as replacements, refunds, or discounts. Utilize trade mediation services or arbitration clauses if negotiations stall. Maintaining detailed records and adhering to agreed terms protects your business and supports effective conflict resolution.

Strategic Sourcing Conclusion and Outlook for full spectrum led light strips

Effective procurement of full spectrum LED light strips hinges on a strategic sourcing approach that balances quality, cost-efficiency, and supplier reliability. International B2B buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers who demonstrate robust supply chain management, compliance with regional electrical standards, and product innovation to meet diverse application needs—from horticulture to commercial lighting.

Key considerations include verifying voltage compatibility (commonly 12V or 24V), ensuring power supply adequacy, and selecting LED strips with durable materials and high luminous efficacy. Establishing strong partnerships with manufacturers who offer customization and technical support can significantly reduce risks related to product performance and delivery delays.

Looking ahead, the global shift toward energy-efficient and sustainable lighting solutions will further elevate demand for advanced full spectrum LED strips. Buyers are encouraged to leverage emerging technologies and supplier networks to secure competitive advantages in their markets. Proactive engagement in supplier development and continuous market intelligence gathering will be critical for staying ahead in this dynamic sector.

International buyers ready to optimize their lighting solutions should now act decisively—evaluate your sourcing strategy, deepen supplier collaborations, and invest in quality full spectrum LED strips that align with your operational goals and environmental commitments.