Guide to Rgbw Ledstrip

- Introduction: Navigating the Global Market for rgbw ledstrip

- Understanding rgbw ledstrip Types and Variations

- Key Industrial Applications of rgbw ledstrip

- Strategic Material Selection Guide for rgbw ledstrip

- In-depth Look: Manufacturing Processes and Quality Assurance for rgbw ledstrip

- Manufacturing Processes for RGBW LED Strips

- Quality Assurance and Control (QA/QC) Framework

- Supplier QC Verification for B2B Buyers

- Conclusion

- Comprehensive Cost and Pricing Analysis for rgbw ledstrip Sourcing

- Spotlight on Potential rgbw ledstrip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for rgbw ledstrip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rgbw ledstrip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of rgbw ledstrip

- Strategic Sourcing Conclusion and Outlook for rgbw ledstrip

Introduction: Navigating the Global Market for rgbw ledstrip

The global demand for RGBW LED strips is surging as businesses across diverse sectors seek advanced, energy-efficient lighting solutions that combine vibrant color options with crisp white illumination. For international B2B buyers—especially those in emerging and established markets such as Nigeria, Brazil, the Middle East, and Europe—sourcing the right RGBW LED strips is critical to delivering superior lighting performance in commercial, retail, architectural, and hospitality projects. Understanding the complexities of this product category is essential to making informed procurement decisions that balance quality, cost, and technological features.

This comprehensive guide is designed to empower buyers with a deep understanding of the RGBW LED strip market and its supply chain dynamics. You will gain insights into the various types of LED strips, including flexible, waterproof, and addressable options, and learn how the addition of a dedicated white LED enhances color fidelity and versatility. The guide also covers essential technical specifications such as LED chip types, PCB materials, IP ratings, and dimming capabilities, which directly impact product performance and suitability for different environments.

Beyond product features, the guide examines manufacturing processes and quality control standards, spotlighting key global suppliers and factories with expertise in RGBW LED technology. We also address pricing considerations, regulatory compliance, and logistical factors that affect international sourcing. Additionally, an FAQ section tackles common buyer concerns, providing practical solutions to challenges encountered in cross-border procurement.

By leveraging this knowledge, B2B buyers from Africa, South America, the Middle East, and Europe will be well-equipped to navigate the global RGBW LED strip market confidently, optimize supplier selection, and secure products that meet their exacting standards for reliability, efficiency, and innovation.

Understanding rgbw ledstrip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard RGBW | Combines red, green, blue, plus a dedicated white LED | Architectural lighting, retail displays, hospitality | Pros: Versatile color range, accurate whites; Cons: Higher cost than RGB strips |

| Waterproof RGBW | Standard RGBW with IP65-IP68 waterproof coating | Outdoor signage, landscape lighting, wet environments | Pros: Durable in harsh conditions; Cons: Reduced flexibility, higher price |

| Addressable RGBW | Individually controllable LEDs with dedicated white channel | Dynamic advertising, entertainment venues, smart buildings | Pros: Highly customizable effects; Cons: Complex control systems, higher investment |

| High-CRI RGBW | Enhanced Color Rendering Index (CRI 90+) with white LED | Museums, art galleries, premium retail, photography studios | Pros: Superior color accuracy; Cons: Premium pricing, specialized sourcing |

| COB RGBW | Chip-on-Board LEDs for uniform light output and enhanced brightness | High-end commercial, film sets, luxury interiors | Pros: Smooth illumination, energy efficient; Cons: Less flexible, costlier |

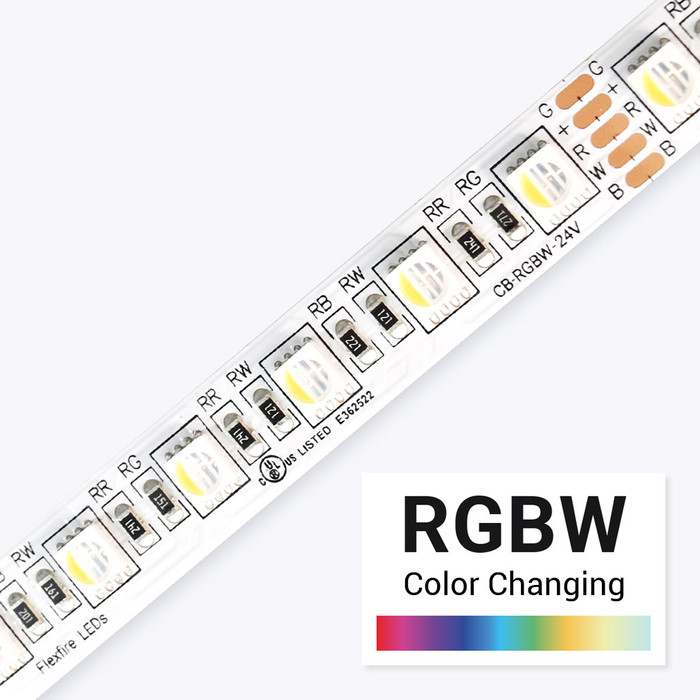

Standard RGBW LED Strips

Standard RGBW strips integrate red, green, blue, and a dedicated white LED to deliver a broader spectrum of colors alongside pure white light. This type is ideal for general-purpose architectural lighting, retail environments, and hospitality where both vibrant colors and accurate white tones are essential. B2B buyers should consider their budget and application needs, as these strips offer excellent versatility but come at a higher cost than simpler RGB models.

Waterproof RGBW LED Strips

Designed with protective coatings rated IP65 to IP68, waterproof RGBW strips are built to withstand moisture, dust, and outdoor elements. They suit outdoor signage, landscaping, and industrial environments common in regions with humid or rainy climates such as parts of Africa and the Middle East. Buyers should weigh the benefits of durability against slightly reduced flexibility and increased price, ensuring the product meets local environmental standards.

Addressable RGBW LED Strips

Addressable RGBW strips allow each LED to be independently controlled, including the white channel, enabling complex lighting patterns and animations. This type is favored in entertainment venues, dynamic advertising, and smart building projects that require advanced lighting customization. While offering unmatched design flexibility, these strips demand sophisticated controllers and higher upfront investment, factors critical for B2B procurement planning.

High-CRI RGBW LED Strips

With a Color Rendering Index (CRI) above 90, high-CRI RGBW strips provide exceptional color accuracy and natural white light. They are essential for premium applications such as museums, art galleries, and high-end retail where true color representation impacts customer experience. Buyers should expect premium pricing and may need to source from specialized manufacturers capable of meeting stringent quality standards.

COB RGBW LED Strips

Chip-on-Board (COB) RGBW strips feature densely packed LEDs mounted directly on the circuit board, producing uniform, glare-free illumination with high brightness. These are suited for luxury interiors, film sets, and commercial spaces requiring smooth light distribution. Although less flexible and more expensive than traditional strips, their energy efficiency and superior lighting quality make them a valuable investment for discerning B2B buyers.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of rgbw ledstrip

| Industry/Sector | Specific Application of rgbw ledstrip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Dynamic in-store lighting and product displays | Enhances product visibility and customer engagement | High CRI, color accuracy, dimmability, and reliable controller compatibility |

| Hospitality & Leisure | Ambient and accent lighting in hotels and lounges | Creates customizable ambiance, improving guest experience | Waterproof ratings (IP65+), flexible design, energy efficiency |

| Architectural & Interior Design | Decorative lighting for facades and interiors | Adds aesthetic appeal and brand differentiation | Long lifespan, color stability, and compatibility with smart controls |

| Automotive & Transportation | Interior cabin lighting and exterior accent lighting | Improves safety and aesthetic customization | Vibration resistance, thermal management, and voltage compatibility |

| Entertainment & Events | Stage and environment lighting with color effects | Enables dynamic lighting effects for immersive experiences | Addressable RGBW capability, ease of installation, and durability |

Retail & Commercial Lighting

In retail environments across Africa, South America, and Europe, RGBW LED strips are widely used to create dynamic and visually appealing product displays. The dedicated white channel enhances the clarity and true color rendering of merchandise, while the RGB channels allow for mood lighting and thematic effects. This versatility solves the problem of static lighting that fails to attract customers. Buyers should prioritize strips with high CRI values and dimmability options to adapt lighting to different times of day or promotional events, ensuring maximum customer engagement and sales impact.

Hospitality & Leisure Ambiance

Hotels and leisure venues in regions like the Middle East and Italy leverage RGBW LED strips to craft bespoke lighting atmospheres in lobbies, bars, and guest rooms. The ability to shift seamlessly between vibrant colors and pure white light enables these businesses to tailor experiences to diverse clientele and occasions. Waterproof and flexible LED strips are essential for environments exposed to humidity or requiring curved installations. International buyers must ensure the strips meet relevant IP ratings and energy efficiency standards to reduce operational costs and comply with local regulations.

Architectural & Interior Design Accents

Architectural firms and interior designers utilize RGBW LED strips to highlight structural features and create immersive environments in commercial and residential projects. The additional white LED channel allows for crisp, clean illumination alongside vibrant color effects, supporting brand identity and aesthetic goals. For B2B buyers in Europe and South America, sourcing LED strips with stable color output, long lifespan, and compatibility with smart home or building management systems is critical. This ensures reliability and ease of integration into complex lighting schemes.

Automotive & Transportation Lighting

In the automotive sector, RGBW LED strips are increasingly adopted for interior cabin lighting and exterior accentuation to enhance safety and personalization. The white LEDs provide functional illumination, while RGB enables customizable color themes for branding or driver preferences. Buyers from regions with extreme climates, such as the Middle East or parts of Africa, must select LED strips with robust thermal management and vibration resistance to withstand harsh operating conditions. Voltage compatibility with vehicle electrical systems is also a key consideration to ensure seamless installation.

Entertainment & Events Lighting

Event organizers and entertainment venues benefit from RGBW LED strips for stage lighting, ambient effects, and interactive installations. The white LED channel allows for natural lighting when needed, while RGB channels deliver vibrant, programmable color effects that energize audiences. For international buyers, particularly in South America and Europe, selecting addressable RGBW strips with reliable controllers facilitates complex lighting sequences and ease of setup. Durability and ease of installation are vital to accommodate frequent event turnover and varied venue requirements.

Related Video: USES OF ELECTROMAGNETIC WAVES

Strategic Material Selection Guide for rgbw ledstrip

When selecting materials for RGBW LED strips, international B2B buyers must consider factors such as durability, thermal management, environmental resistance, and compliance with regional standards. The choice of materials directly impacts product performance, longevity, and suitability for various applications, especially in diverse climates and regulatory landscapes like those in Africa, South America, the Middle East, and Europe.

Flexible Printed Circuit Board (FPCB) Material

Key Properties:

FPCBs used in RGBW LED strips are typically made from polyimide or polyester films with copper layers ranging from 2oz to 4oz. These materials offer excellent flexibility, good thermal conductivity, and electrical insulation. Copper thickness influences heat dissipation and current-carrying capacity, critical for maintaining LED brightness and lifespan.

Pros & Cons:

Polyimide-based FPCBs are highly flexible and heat-resistant, making them ideal for curved or complex installations. However, they are more expensive than polyester alternatives. Polyester FPCBs are cost-effective but have lower thermal tolerance and may degrade faster under high temperatures.

Impact on Application:

For outdoor or high-humidity environments common in regions like Nigeria or the Middle East, polyimide FPCBs paired with appropriate waterproof coatings ensure longevity. In controlled indoor environments typical in Europe, polyester FPCBs may suffice, balancing cost and performance.

B2B Considerations:

Buyers should verify compliance with international standards such as IPC-2223 for flexible circuits and ensure the copper weight suits their power requirements. Suppliers offering FPCBs with UL or CE certification provide assurance for markets with strict regulatory frameworks like the EU.

Silicone or PVC Coating (Encapsulation)

Key Properties:

Encapsulation materials protect LED strips from moisture, dust, and mechanical damage. Silicone offers excellent UV resistance, flexibility at low temperatures, and superior waterproofing (IP67/IP68). PVC coatings are less expensive but have lower UV stability and can become brittle over time.

Pros & Cons:

Silicone coatings extend product life in harsh outdoor conditions and high UV exposure, common in African and Middle Eastern markets. PVC is cost-effective for indoor applications but may fail prematurely in tropical or desert climates.

Impact on Application:

For installations exposed to sunlight and moisture, such as outdoor signage or architectural lighting in Brazil or Saudi Arabia, silicone encapsulation is recommended. Indoor retail or office lighting in Italy or Spain may use PVC coatings to reduce costs.

B2B Considerations:

Ensure the encapsulation meets IP ratings relevant to the target environment. Certifications such as RoHS and REACH compliance are crucial for European buyers. Also, consider local environmental regulations and disposal requirements for PVC materials.

Aluminum or Copper Heat Sink Substrate

Key Properties:

Heat sinks or backing substrates made from aluminum or copper improve thermal dissipation, preventing LED overheating and color shifting. Aluminum offers a good balance of weight, cost, and thermal conductivity (~205 W/mK), whereas copper provides superior heat transfer (~385 W/mK) but at higher cost and weight.

Pros & Cons:

Aluminum substrates are widely used due to their affordability and ease of manufacturing. Copper substrates, while more efficient thermally, increase product cost and weight, which may limit their use in lightweight or flexible applications.

Impact on Application:

In high-power RGBW LED strips for industrial or architectural lighting in Europe or South America, aluminum substrates are standard. Copper substrates may be preferred for specialized, high-performance applications requiring maximum heat dissipation.

B2B Considerations:

Buyers should confirm substrate thickness and finish quality to ensure optimal thermal management. Regional preferences and import tariffs on metals may affect sourcing decisions, especially in markets like Nigeria or the Middle East.

Adhesive Backing Material

Key Properties:

Adhesive backing materials enable easy installation on various surfaces. Acrylic adhesives provide strong bonding and temperature resistance, while silicone adhesives offer better UV and moisture resistance but at higher cost.

Pros & Cons:

Acrylic adhesives are cost-effective and suitable for most indoor applications. Silicone adhesives are preferred for outdoor or high-humidity environments but increase overall product cost.

Impact on Application:

For installations in humid or hot climates such as coastal regions in South America or the Middle East, silicone adhesives prevent peeling and ensure durability. In temperate European climates, acrylic adhesives are usually sufficient.

B2B Considerations:

International buyers should verify adhesive certifications for VOC emissions and environmental safety, especially for indoor use in Europe. Compatibility with substrate materials and surface types common in target markets is also critical.

| Material | Typical Use Case for rgbw ledstrip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide Flexible PCB | Outdoor and flexible installations requiring heat resistance | High thermal tolerance and flexibility | Higher cost compared to polyester | High |

| Polyester Flexible PCB | Indoor, cost-sensitive applications | Cost-effective and flexible | Lower heat resistance and durability | Low |

| Silicone Coating (Encapsulation) | Outdoor, UV-exposed, and humid environments | Superior waterproofing and UV resistance | Higher material cost | High |

| PVC Coating (Encapsulation) | Indoor, dry environments | Low cost and easy to apply | Poor UV resistance and potential brittleness | Low |

| Aluminum Heat Sink Substrate | General industrial and architectural lighting | Good thermal conductivity and lightweight | Less efficient than copper for heat dissipation | Medium |

| Copper Heat Sink Substrate | High-power, high-performance applications | Excellent heat dissipation | Expensive and heavier | High |

| Acrylic Adhesive Backing | Indoor applications with stable temperature | Cost-effective and strong adhesion | Less resistant to UV and moisture | Low |

| Silicone Adhesive Backing | Outdoor and humid environments | Excellent moisture and UV resistance | Higher cost | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for rgbw ledstrip

Manufacturing Processes for RGBW LED Strips

The production of RGBW LED strips is a sophisticated process that combines precision electronics manufacturing with specialized assembly techniques. For B2B buyers, understanding these stages is crucial to evaluate supplier capabilities and ensure product reliability.

1. Material Preparation

- Flexible Printed Circuit Board (FPCB) Fabrication: The process begins with producing the flexible PCB, typically made from polyimide or PET substrates with copper layers (commonly 2oz to 4oz copper weight). This board provides the foundation for electrical connections and mechanical flexibility.

- Component Sourcing: High-quality SMD LEDs (including red, green, blue, and white diodes), resistors, and other electronic components are procured. Suppliers often choose LEDs based on brightness, color accuracy (CRI), and energy efficiency.

- Surface Treatment: The PCB may undergo cleaning and surface treatment to improve solderability and ensure durability.

2. Assembly and Mounting

- Surface Mount Technology (SMT): LEDs and passive components are precisely mounted onto the FPCB using automated pick-and-place machines. This stage demands high accuracy to maintain uniform LED spacing and orientation, critical for consistent light output.

- Soldering: Reflow soldering solidifies electrical connections. The temperature profile must be carefully controlled to avoid damage to components or the flexible substrate.

- Wiring and Connection: For RGBW strips, wiring includes four separate LED channels plus a common anode or cathode. Multi-core cables or connectors are attached, often by hand or semi-automated processes, ensuring correct polarity and channel mapping.

3. Protective Coating and Finishing

- Encapsulation: To protect against moisture, dust, and mechanical stress, strips may receive a silicone or epoxy coating. Waterproof ratings (e.g., IP65, IP67, IP68) depend on the thickness and uniformity of this layer.

- Cutting and Packaging: Strips are cut to standardized lengths at designated points. Final packaging includes reels or spools with anti-static materials and moisture-proof seals to preserve quality during shipment.

Quality Assurance and Control (QA/QC) Framework

Ensuring consistent quality in RGBW LED strips is fundamental for international buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Quality assurance encompasses adherence to international standards, rigorous testing, and transparent supplier verification processes.

International Standards and Certifications

- ISO 9001: This globally recognized quality management system standard ensures manufacturers maintain consistent production processes and continuous improvement. Buyers should verify supplier ISO 9001 certification to confirm systematic quality management.

- CE Marking (Europe): Compliance with EU directives related to safety, electromagnetic compatibility (EMC), and environmental standards is mandatory for LED products sold in Europe. CE certification is often a prerequisite for importers in Italy and other EU countries.

- RoHS (Restriction of Hazardous Substances): Limits hazardous materials in electronics, critical for European markets and increasingly enforced globally.

- UL/ETL (North America) and IEC Standards: While less common for buyers outside North America, UL certification indicates safety compliance. IEC standards for LED lighting ensure product reliability and safety.

- IP Ratings: International Protection ratings (e.g., IP65, IP67, IP68) indicate the degree of water and dust resistance, vital for outdoor or humid environment applications common in African and Middle Eastern markets.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Verification of raw materials and components before production. This includes testing LED chips for brightness, color consistency, and electrical parameters, as well as inspecting PCB quality.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly. Key checkpoints include SMT placement accuracy, solder joint integrity, and wiring correctness for RGBW channels.

- Final Quality Control (FQC): Comprehensive testing after assembly, including electrical tests, color and brightness uniformity, waterproofing integrity, and functional tests of dimming and color mixing capabilities.

Common Testing Methods

- Electrical Testing: Ensures correct voltage and current for each LED channel, verifying no shorts or open circuits.

- Color and Brightness Measurement: Spectrometers or colorimeters measure color temperature, CRI, and luminosity to meet specifications.

- Durability Tests: Thermal cycling, vibration, and mechanical bending tests simulate real-world conditions to assess product lifespan.

- Waterproof Testing: For IP-rated strips, immersion or spray tests confirm enclosure integrity.

- EMC Testing: Ensures the strip does not emit excessive electromagnetic interference and is immune to external disturbances.

Supplier QC Verification for B2B Buyers

For international B2B buyers, particularly from regions such as Nigeria, Brazil, the UAE, or Italy, verifying supplier quality processes is essential to mitigate risk and ensure product compliance.

Strategies for Verification

- Factory Audits: On-site inspections by buyers or third-party agencies assess production capabilities, quality control systems, and working conditions. Remote video audits have become more common when travel is restricted.

- Review of Quality Documentation: Request detailed QC reports, including IQC, IPQC, and FQC data, alongside certifications (ISO 9001, CE, RoHS).

- Third-Party Testing and Inspection: Independent labs can perform product testing and certification verification. This is especially important for buyers unfamiliar with supplier claims or when importing into regulated markets.

- Sample Testing: Procuring samples for in-house testing allows buyers to verify performance claims and assess build quality before bulk orders.

- Supplier Transparency and Communication: Reliable suppliers provide clear documentation and are responsive to queries about production processes and quality assurance.

QC and Certification Nuances by Region

- Africa: Many markets, such as Nigeria, emphasize product safety and durability due to challenging environmental conditions. Importers should prioritize suppliers with robust waterproofing (IP67 or higher) and heat dissipation features. Local certification requirements may vary; working with suppliers familiar with these regulations is advantageous.

- South America: Countries like Brazil often require INMETRO certification for electrical products. Buyers should verify that suppliers can provide relevant test reports and understand customs clearance requirements.

- Middle East: High temperatures and dust make waterproof and heat-resistant LED strips essential. Compliance with GCC standards and sometimes SASO certification (for Saudi Arabia) is necessary. Buyers should ensure suppliers demonstrate these credentials.

- Europe: Strict adherence to CE marking, RoHS, and REACH regulations is mandatory. Buyers in Italy and the EU should demand complete certification packages and confirm compliance through accredited labs.

Conclusion

For B2B buyers sourcing RGBW LED strips internationally, a deep understanding of manufacturing processes and quality assurance frameworks is indispensable. Scrutinizing each stage—from material preparation to final packaging—enables buyers to select suppliers capable of delivering reliable, high-performance products. Equally important is verifying adherence to international and regional quality standards through rigorous inspections, testing, and certification review. By employing these strategies, buyers across Africa, South America, the Middle East, and Europe can confidently navigate supplier selection, ensuring their RGBW LED strips meet both technical demands and regulatory expectations.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for rgbw ledstrip Sourcing

Understanding the cost and pricing dynamics of RGBW LED strips is crucial for international B2B buyers aiming to optimize procurement strategies, especially across diverse markets such as Africa, South America, the Middle East, and Europe. The pricing structure is influenced by multiple factors spanning production, logistics, and market conditions.

Core Cost Components in RGBW LED Strip Production

-

Materials: The most significant cost driver, including flexible PCBs (often copper-layered for heat dissipation), high-quality SMD LEDs (2835, 5050, or specialized RGBW chips), resistors, connectors, and protective coatings (e.g., waterproofing with IP65-IP68 ratings). Premium materials improve durability, color accuracy, and energy efficiency but increase unit costs.

-

Labor: Manufacturing labor costs vary by region but are generally lower in major production hubs such as China. Labor involves PCB assembly, SMT soldering, wiring, and quality checks. Automation can reduce labor intensity but often requires higher initial capital.

-

Manufacturing Overhead: This covers factory utilities, equipment depreciation, and indirect labor (supervisory, maintenance). Efficient factories with modern equipment typically achieve better cost control and quality consistency.

-

Tooling and Setup: Initial costs for creating custom molds, PCB layouts, and assembly jigs are amortized over production volumes. Custom RGBW strips with unique designs or specifications generally incur higher tooling expenses.

-

Quality Control (QC): Rigorous QC processes—testing brightness, color rendering, waterproof integrity, and electrical safety—add to cost but are vital for reducing returns and ensuring certification compliance (CE, RoHS, UL).

-

Logistics and Import Costs: Shipping, customs duties, taxes, and insurance impact landed cost significantly, especially for buyers in regions with complex import regulations or high tariffs (e.g., Nigeria or Brazil). Choosing appropriate Incoterms (FOB, CIF, DDP) affects cost allocation and risk.

-

Supplier Margin: Profit margins vary based on supplier scale, brand positioning, and market demand. Established manufacturers with strong reputations often command higher prices but offer reliability and after-sales support.

Key Price Influencers for RGBW LED Strip Buyers

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock volume discounts, reducing per-unit cost. However, buyers must balance MOQ with inventory carrying costs and market demand to avoid overstock.

-

Product Specifications and Customization: Enhanced features like higher copper weight PCBs (3oz or 4oz for better heat dissipation), advanced LED chip types, waterproofing, or addressable RGBW capabilities increase costs. Tailored lengths, connectors, or control systems further add to pricing.

-

Material Quality and Certifications: Certified products (CE, RoHS, UL) cost more but ease market entry, reduce compliance risks, and enhance buyer confidence—particularly critical for European and Middle Eastern markets with stringent regulations.

-

Supplier Location and Reputation: Chinese manufacturers dominate supply but sourcing from local or regional suppliers can reduce lead times and logistics complexity, albeit sometimes at a premium.

-

Incoterms and Payment Terms: Understanding the implications of FOB (buyer arranges shipping) versus CIF/DDP (supplier includes shipping and duties) helps buyers manage cash flow and risk exposure.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Unit Price: Focus on total cost of ownership, including warranty terms, after-sales service, lead times, and support for installation or customization.

-

Assess Quality vs. Cost Trade-offs: Cheaper RGBW strips might save upfront costs but risk poor color rendering, shorter lifespan, or higher energy consumption, leading to increased operational expenses.

-

Factor in Logistics Complexity: For buyers in Africa and South America, anticipate longer shipping times and potential customs delays. Partnering with suppliers experienced in these markets can mitigate risks.

-

Request Samples and Certifications: Before large orders, test product samples in your application environment and verify certifications to avoid costly compliance issues.

-

Leverage Group Purchasing and Local Agents: Pooling demand with other buyers or engaging local sourcing agents can reduce MOQ constraints and improve negotiation leverage.

Indicative Pricing Overview (Subject to Market Variability)

- Basic RGBW LED strips typically range from $5 to $15 per meter depending on quality, LED type, and waterproofing.

- Customized or addressable RGBW strips with premium components can exceed $20 per meter.

- Bulk orders (thousands of meters) often benefit from discounts of 10–30%, subject to negotiation.

Prices fluctuate with raw material costs (notably copper and semiconductor chips), exchange rates, and geopolitical factors affecting supply chains.

By comprehensively analyzing cost components and market nuances, international B2B buyers can make informed procurement decisions that balance quality, price, and operational efficiency when sourcing RGBW LED strips for diverse applications and regions.

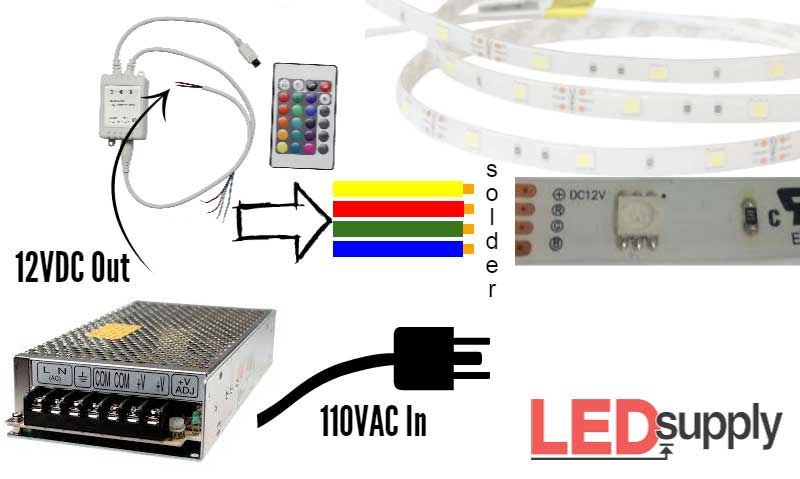

Illustrative Image (Source: Google Search)

Spotlight on Potential rgbw ledstrip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘rgbw ledstrip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for rgbw ledstrip

Critical Technical Properties of RGBW LED Strips

For international B2B buyers, especially those sourcing from diverse markets such as Africa, South America, the Middle East, and Europe, understanding the key technical specifications of RGBW LED strips is essential for making informed purchasing decisions. These properties directly influence product performance, longevity, and compatibility with specific applications.

-

LED Chip Type and Configuration

RGBW LED strips typically use Surface Mount Device (SMD) LEDs, such as 5050 or 2835 types, combined with a dedicated white LED chip. The choice affects brightness, color accuracy, and energy efficiency. For B2B buyers, selecting the right chip ensures the lighting meets specific requirements—whether for retail displays requiring high color fidelity or architectural lighting demanding strong white illumination. -

Flexible Printed Circuit Board (FPCB) Material and Copper Thickness

The FPCB serves as the base for mounting LEDs and conducting electricity. Copper thickness—commonly 2oz to 4oz—affects heat dissipation and durability. Higher copper weight enables longer runs without voltage drop and reduces overheating risks, critical for installations in warm climates like Nigeria or Brazil. -

Waterproofing and IP Rating

IP ratings (e.g., IP65, IP67, IP68) define protection against dust and moisture. For buyers targeting outdoor or humid environments—such as Middle Eastern coastal projects or South American outdoor advertising—choosing the appropriate IP rating ensures product reliability and reduces maintenance costs. -

Voltage and Power Supply Compatibility

RGBW strips commonly operate at 12V or 24V DC. Voltage impacts maximum strip length before voltage drop occurs and influences power supply sizing. B2B purchasers must verify that power supplies and controllers match the strip voltage to avoid operational issues and ensure safety compliance. -

Color Rendering Index (CRI) and Color Temperature

CRI measures the accuracy of color representation under the light source, with 80+ being standard for commercial use. Color temperature (expressed in Kelvin) determines the warmth or coolness of the white light channel. Buyers in sectors like hospitality or retail should prioritize high CRI and appropriate color temperature to create appealing environments. -

Dimmability and Control Compatibility

RGBW strips require multi-channel controllers (typically 5-channel) for independent adjustment of red, green, blue, and white channels. Compatibility with dimming protocols such as PWM or 0-10V is vital for integrating with existing building automation or smart lighting systems, particularly in advanced markets like Italy or Germany.

Common Trade Terminology in the RGBW LED Strip Market

Navigating international LED strip procurement also involves familiarity with key trade terms. Understanding these helps buyers negotiate effectively and streamline the sourcing process.

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing LED strips that other companies brand and sell. Buyers can request OEM services for customized products, including specific lengths, LED configurations, or branding, enabling differentiation in local markets. -

MOQ (Minimum Order Quantity)

The smallest order volume a supplier accepts. MOQs vary widely—from hundreds to thousands of meters—and impact inventory planning and pricing. Buyers from emerging markets should negotiate MOQs aligned with their sales forecasts to avoid overstocking. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers seeking detailed pricing, lead times, and specifications. Well-prepared RFQs with clear technical requirements help buyers receive accurate offers and reduce procurement delays. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs clearance. Understanding Incoterms is crucial for buyers in Africa or South America to manage costs and risks during importation. -

Lead Time

The period between order confirmation and product delivery. Lead times can be affected by factory capacity, customization, and shipping. Buyers should factor this into project timelines, especially when sourcing from overseas factories. -

Batch Testing / QC (Quality Control)

Refers to the supplier’s process of inspecting LED strips before shipment. Buyers should request batch testing reports or certifications to ensure compliance with local standards and reduce the risk of receiving defective goods.

By mastering these technical properties and trade terms, international B2B buyers can confidently source RGBW LED strips that meet their operational needs and market demands. This knowledge supports effective supplier evaluation, negotiation, and long-term partnership building across global LED lighting markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rgbw ledstrip Sector

Market Overview & Key Trends

The global RGBW LED strip market is experiencing robust growth, driven by increasing demand for energy-efficient, versatile lighting solutions across commercial, residential, and industrial sectors. For B2B buyers in regions such as Africa (e.g., Nigeria), South America, the Middle East, and Europe (e.g., Italy), the market dynamics are shaped by rapid urbanization, infrastructure development, and rising consumer awareness around smart lighting technologies. These regions are witnessing a surge in applications ranging from architectural accent lighting, retail displays, hospitality, to outdoor and landscape illumination.

Key trends include the shift towards high-performance RGBW strips that combine vibrant color output with precise white light channels, enabling nuanced lighting effects. This is particularly valuable in markets emphasizing aesthetic appeal and functional lighting, such as luxury retail and hospitality sectors in Europe and the Middle East. Additionally, integration with IoT and smart control systems is becoming a critical factor, allowing for remote management, energy optimization, and dynamic lighting scenes. For buyers in emerging markets like Nigeria and Brazil, cost-effectiveness combined with durability under diverse environmental conditions is a priority, driving interest in waterproof and high-CRI (Color Rendering Index) RGBW strips.

From a sourcing perspective, China remains the dominant manufacturing hub due to its mature supply chain, competitive pricing, and extensive product variety. However, international buyers are increasingly scrutinizing supplier transparency, production quality, and after-sales support. Strategic sourcing now involves evaluating manufacturers’ capabilities in customization, compliance with international standards (CE, RoHS), and ability to scale production. Furthermore, geopolitical factors and shipping logistics are prompting some buyers to diversify sourcing, exploring suppliers in Southeast Asia and Europe to mitigate risks.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal consideration in the RGBW LED strip sector, especially for international buyers committed to responsible procurement. The environmental impact of LED manufacturing includes energy consumption during production, use of raw materials such as rare earth elements, and end-of-life disposal challenges. B2B buyers are increasingly demanding suppliers who adopt eco-friendly manufacturing processes that reduce carbon footprint, minimize waste, and utilize recyclable or biodegradable packaging.

Ethical sourcing extends beyond environmental concerns to encompass labor practices and supply chain transparency. Many buyers from Europe and the Middle East prioritize partnerships with manufacturers who comply with international labor standards and provide safe working conditions. Certifications such as ISO 14001 (environmental management), RoHS (restriction of hazardous substances), and REACH (chemical safety) serve as benchmarks for sustainable and ethical operations.

Material innovation is also influencing sustainability. The adoption of lead-free solder, halogen-free PCBs, and low-power, high-efficiency LEDs contributes to greener products. Additionally, buyers are encouraged to consider the lifecycle energy savings of RGBW strips, which typically consume significantly less power than traditional lighting. Leveraging products with energy star ratings or equivalent certifications aligns with corporate sustainability goals and regulatory requirements, particularly in Europe.

Illustrative Image (Source: Google Search)

Evolution and Historical Context

RGBW LED strips represent a significant evolution in LED lighting technology. Originally, LED strips were limited to single colors or RGB combinations, which could simulate white light only by blending red, green, and blue LEDs. The introduction of dedicated white LEDs alongside RGB channels (RGBW) marked a breakthrough, enabling true white light reproduction with enhanced brightness and color accuracy. This evolution has expanded the application scope for LED strips, allowing for both vibrant color effects and natural white illumination suitable for professional and aesthetic lighting environments.

The technological advancements have been closely tied to improvements in flexible PCB materials, surface mount technology (SMT), and controller sophistication, facilitating easier integration into complex lighting systems. For international B2B buyers, understanding this history underscores the value of investing in RGBW technology for future-proof, versatile lighting solutions that meet growing demands for quality and efficiency.

Related Video: Inside the Global Underground Wildlife Trafficking Market

Frequently Asked Questions (FAQs) for B2B Buyers of rgbw ledstrip

-

How can I effectively vet RGBW LED strip suppliers from international markets like China for my business in Nigeria or Italy?

When vetting suppliers, prioritize those with verified manufacturing capabilities, robust quality control systems, and industry certifications (e.g., ISO 9001, CE, RoHS). Request detailed product specifications, factory audit reports, and client references. Use third-party inspection agencies to verify factory authenticity and production standards. Additionally, evaluate their communication responsiveness and after-sales support. For buyers in Africa, South America, the Middle East, and Europe, partnering with suppliers experienced in international logistics and customs compliance ensures smoother transactions and reduces risk. -

What customization options are typically available for RGBW LED strips, and how can I negotiate these for my specific market needs?

Most manufacturers offer customization in LED types (e.g., SMD 5050, 2835), PCB thickness, color temperature, IP waterproof ratings, and length per reel. You can also request specific white LED channels for enhanced color accuracy or custom packaging and branding. When negotiating, clearly outline your technical requirements, expected volumes, and target markets to align customization with regional preferences and regulations. Bulk customization often comes with MOQ adjustments; discussing these upfront helps avoid production delays and unexpected costs. -

What are typical minimum order quantities (MOQs), lead times, and payment terms I should expect when ordering RGBW LED strips internationally?

MOQs vary but commonly range from 500 to 1,000 meters per order, depending on customization complexity. Lead times typically span 3 to 6 weeks, including production and quality checks, but can be longer during peak seasons. Payment terms often involve a 30-50% deposit upfront, with the balance paid before shipment. International buyers should negotiate payment security mechanisms such as letters of credit or escrow services to mitigate risks, especially when dealing with new suppliers or large orders. -

How can I ensure the quality and compliance of RGBW LED strips with international standards before shipment?

Request product samples and detailed test reports covering brightness, color rendering index (CRI), waterproof ratings (IP), and electrical safety certifications (CE, RoHS, UL). Insist on factory quality control protocols, including in-line inspections and final product testing. Employ third-party quality assurance firms for pre-shipment inspections to verify conformity with contractual specifications. Compliance with regional regulations (e.g., CE for Europe, SASO for the Middle East) is essential to avoid customs delays and ensure market acceptance. -

What logistics considerations should I keep in mind when importing RGBW LED strips to regions like South America or Africa?

Understand your destination country’s import regulations, tariffs, and certification requirements to prevent clearance issues. Choose freight options balancing cost and delivery speed—sea freight is cost-effective for large volumes but slower, while air freight suits urgent orders. Coordinate with freight forwarders experienced in handling electronics and fragile cargo, ensuring proper packaging and labeling to minimize damage. Factor in potential customs duties and local taxes into your landed cost calculations to maintain accurate pricing. -

How should disputes over product quality or delivery delays be handled in international RGBW LED strip transactions?

Establish clear contractual terms covering product specifications, delivery schedules, inspection rights, and remedies for non-compliance before ordering. In case of disputes, communicate promptly and document all correspondence. Utilize third-party inspection reports as objective evidence. Where possible, engage dispute resolution mechanisms such as mediation or arbitration clauses stipulated in the contract. Maintaining a professional relationship and clear communication can often resolve issues amicably without escalation. -

Are there specific certifications or standards I should require from RGBW LED strip suppliers to ensure safety and performance?

Yes, insist on compliance with internationally recognized standards such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories) for electrical safety, and IP ratings for waterproofing. ISO 9001 certification reflects robust quality management systems. For buyers in Europe and the Middle East, certifications ensuring electromagnetic compatibility (EMC) and energy efficiency are often mandatory. Verifying these certifications protects your business from liability and supports market acceptance. -

What payment methods are safest and most practical when purchasing RGBW LED strips from overseas suppliers?

Secure payment methods include letters of credit (LC), which provide banks’ guarantees, and escrow services that hold funds until delivery conditions are met. Wire transfers (T/T) are common but carry higher risk if the supplier is unverified. Platforms offering trade assurance or payment protection can also safeguard transactions. It’s advisable to stagger payments—typically a deposit before production and balance upon inspection or shipment—to minimize financial exposure while building supplier trust.

Strategic Sourcing Conclusion and Outlook for rgbw ledstrip

The strategic sourcing of RGBW LED strips offers international B2B buyers a competitive edge by combining cutting-edge technology with cost-effective manufacturing practices, particularly from leading suppliers in China. For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of product specifications—such as LED types, PCB quality, waterproofing standards, and controller compatibility—is essential to align procurement with project requirements and regional standards. Prioritizing suppliers who demonstrate rigorous quality control, transparent supply chain management, and innovation ensures reliable product performance and long-term partnerships.

Key takeaways for B2B buyers include:

- Evaluating technical features like CRI, color accuracy, and dimmability to meet diverse application needs

- Selecting RGBW strips for superior color rendering and versatile lighting effects that enhance commercial and residential environments

- Ensuring compatibility with appropriate controllers and power supplies to maximize functionality and installation ease

- Considering waterproof ratings and material durability for projects in varying climates and conditions

Looking ahead, the RGBW LED strip market is poised for growth driven by smart lighting integration and expanding application sectors. Buyers are encouraged to engage with manufacturers who invest in R&D and sustainable production methods to future-proof their sourcing strategies. By adopting a proactive, informed approach, international businesses—from Nigeria to Italy—can harness the full potential of RGBW LED technology to illuminate innovation and achieve operational excellence.