Introduction: Navigating the Global Market for led strip lights waterproof uk

The global demand for waterproof LED strip lights continues to surge, driven by their unparalleled versatility, energy efficiency, and durability. For international B2B buyers—particularly those operating in diverse climates and industries across Africa, South America, the Middle East, and Europe—sourcing high-quality waterproof LED strip lights from the UK market presents a strategic opportunity to enhance both indoor and outdoor lighting solutions. These products are essential for applications ranging from commercial façades and architectural accents to industrial settings where moisture resistance is critical.

This comprehensive guide serves as a vital resource for buyers seeking to navigate the complexities of the UK waterproof LED strip light market. It offers an in-depth exploration of the various types of waterproof LED strips, including SMD, COB, RGB, and high-voltage options, as well as the materials and IP ratings that ensure performance under challenging environmental conditions. Understanding manufacturing standards and quality control processes is emphasized to help buyers assess supplier reliability and product longevity.

Additionally, the guide covers critical procurement factors such as pricing structures, supplier profiles, and logistical considerations tailored to international trade. It also addresses common questions and practical installation tips, empowering buyers to make well-informed decisions that align with their project requirements and budget constraints.

By leveraging this guide, B2B buyers from regions like Kenya, Brazil, the UAE, and Germany will gain actionable insights to confidently source waterproof LED strip lights that meet stringent performance standards, comply with safety certifications, and deliver lasting value in their respective markets.

Understanding led strip lights waterproof uk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMD Waterproof LED Strips | Flexible strips with discrete surface-mounted LEDs, IP65 to IP67 ratings | Retail, hospitality, outdoor signage, architectural lighting | Pros: Cost-effective, versatile, easy to install. Cons: Visible LED dots, less uniform light distribution. |

| COB Waterproof LED Strips | Chip-on-board LEDs providing continuous, uniform light, often IP65 to IP68 | High-end retail, museums, galleries, luxury interiors | Pros: Smooth, glare-free lighting, premium aesthetics. Cons: Higher price, specialized power requirements. |

| RGB/RGBW Waterproof LED Strips | Multi-color LEDs with dynamic control, RGBW includes white LED for warmer tones, typically IP65+ | Entertainment venues, commercial facades, event lighting | Pros: Customizable colors, dynamic effects. Cons: Requires controllers, higher complexity in installation. |

| High-Voltage Waterproof LED Strips | Operate on mains voltage (e.g., 220V), often IP65 or higher | Large-scale outdoor installations, industrial sites | Pros: Simplified wiring, no transformer needed. Cons: Safety risks, requires certified installation expertise. |

| Silicone-Coated Waterproof LED Strips | Encased in durable silicone for superior water and dust resistance, IP67 to IP68 | Marine applications, outdoor architectural, pool lighting | Pros: Robust protection, ideal for harsh environments. Cons: Higher cost, reduced flexibility. |

SMD Waterproof LED Strips

SMD (Surface Mount Device) waterproof LED strips are the most common type used in a variety of commercial applications. They feature individual LEDs mounted on a flexible PCB and are coated or encased to achieve water resistance, typically rated IP65 to IP67. For B2B buyers, these strips offer a cost-effective, versatile lighting solution suitable for retail displays, outdoor signage, and architectural accents. When purchasing, consider the LED density and power requirements to balance brightness and energy efficiency. Their ease of installation and wide availability make them a practical choice for projects with tight budgets.

COB Waterproof LED Strips

COB (Chip on Board) LED strips integrate multiple LED chips into a single module, producing a smooth, uniform light output without visible LED points. This type is ideal for high-end commercial environments such as museums, luxury retail stores, or galleries where lighting quality and aesthetics are paramount. Waterproof ratings often reach IP65 to IP68, enabling outdoor or damp environment usage. B2B buyers should weigh the higher initial cost against the superior lighting quality and longer lifespan. Additionally, ensure compatibility with appropriate drivers to maintain performance.

RGB and RGBW Waterproof LED Strips

RGB and RGBW waterproof LED strips provide dynamic color-changing capabilities, with RGBW variants including a dedicated white LED for enhanced color accuracy and warmer white tones. These strips are popular in entertainment venues, commercial façades, and event lighting where vibrant, customizable lighting effects are required. For international B2B buyers, understanding the control systems needed—such as DMX or smart controllers—is essential for seamless integration. While offering creative flexibility, these strips require more complex installation and maintenance considerations.

High-Voltage Waterproof LED Strips

Operating directly on mains voltage (e.g., 220V), high-voltage waterproof LED strips simplify installation by eliminating the need for external transformers or drivers. This makes them attractive for large-scale outdoor projects and industrial applications where long runs of lighting are necessary. However, the higher operating voltage entails increased safety risks, demanding certified electrical installation and compliance with local regulations—critical factors for B2B buyers in regions with strict safety standards like Europe. The robustness and ease of wiring must be balanced against these considerations.

Silicone-Coated Waterproof LED Strips

Silicone-coated LED strips are encased in a thick silicone layer, providing exceptional protection against water, dust, and mechanical damage, often achieving IP67 or IP68 ratings. These are well-suited for harsh environments such as marine settings, swimming pools, and exposed architectural installations. B2B purchasers should note that while these strips offer superior durability and longevity, the silicone coating reduces flexibility and slightly increases cost. Evaluating the environmental conditions and longevity requirements is crucial to justify the investment in these premium products.

Related Video: Govee Outdoor LED Strip Lights Waterproof | Review

Key Industrial Applications of led strip lights waterproof uk

| Industry/Sector | Specific Application of led strip lights waterproof uk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Leisure | Outdoor ambiance lighting for hotels, resorts, and restaurants | Enhances guest experience, increases aesthetic appeal, energy-efficient lighting reduces operational costs | IP65 or higher rating for outdoor durability, color temperature options for ambiance, ease of installation |

| Retail & Commercial | Illuminated storefronts, window displays, and outdoor signage | Attracts customers, improves brand visibility, durable under weather conditions | High brightness and uniformity, customizable length, compliance with UK/EU safety standards (CE, RoHS) |

| Marine & Offshore | Deck and walkway lighting on ships, docks, and offshore platforms | Ensures safety in wet environments, long-lasting performance, reduces maintenance frequency | IP68 waterproof rating, corrosion-resistant materials, compatibility with 12V/24V power systems |

| Agriculture & Horticulture | Greenhouse lighting and outdoor plant growth illumination | Promotes healthy plant growth, energy-efficient, withstands humid environments | Full-spectrum LED options, waterproof and dustproof ratings, energy consumption optimized for large-scale use |

| Infrastructure & Urban Development | Street lighting, tunnel illumination, and public outdoor spaces | Enhances public safety, reduces energy costs, durable for harsh weather | High IP rating (IP65+), long lifespan, robust materials for vandal resistance, compliance with local regulations |

Hospitality & Leisure:

Waterproof LED strip lights are extensively used in the hospitality sector to create visually appealing outdoor environments for hotels, resorts, and restaurants. These lights enhance the ambiance around pools, patios, and walkways, contributing to a memorable guest experience. For international buyers in regions such as Africa and the Middle East, it is essential to source products that withstand high temperatures and humidity. Selecting strips with a minimum IP65 rating ensures resistance to rain and dust, while adjustable color temperatures help tailor the lighting to different moods and settings.

Retail & Commercial:

In retail and commercial settings, waterproof LED strip lights are critical for illuminating storefronts, window displays, and outdoor signage. These applications demand high brightness and uniform light distribution to capture customer attention and increase foot traffic. Buyers from Europe and South America should prioritize suppliers offering CE and RoHS certifications to ensure compliance with local safety standards. Customizable lengths and flexible installation options are also crucial for fitting irregular architectural features and maximizing visual impact.

Marine & Offshore:

The marine and offshore industry relies heavily on waterproof LED strip lights for deck, walkway, and platform lighting to maintain safety in wet and corrosive environments. LED strips with an IP68 rating are essential to ensure full submersion protection and durability against saltwater corrosion. International buyers, particularly from coastal regions in Africa and Europe, should seek suppliers that offer corrosion-resistant materials and compatibility with common marine voltage systems (12V or 24V). These features reduce maintenance costs and enhance operational safety.

Agriculture & Horticulture:

Waterproof LED strip lights serve a vital role in controlled environment agriculture, including greenhouses and outdoor plant cultivation. Full-spectrum LED options support photosynthesis and promote healthier plant growth, while waterproof and dustproof designs withstand humid and dusty conditions. Buyers from South America and Africa engaged in large-scale farming should consider energy-efficient models that optimize power consumption without compromising light quality. Reliable IP65 or higher ratings ensure longevity in challenging environmental conditions.

Infrastructure & Urban Development:

Waterproof LED strip lights are increasingly adopted in infrastructure projects such as street lighting, tunnel illumination, and public outdoor spaces to improve safety and reduce energy consumption. These applications require robust strips with high IP ratings (IP65 and above) to endure harsh weather and potential vandalism. European and Middle Eastern buyers must ensure compliance with local regulations and standards, while also focusing on long lifespan and low maintenance features to minimize lifecycle costs. Durable materials and efficient power management are key sourcing priorities.

Related Video: How to Water Proof Your Led Strip Lights – Guaranteed !!!

Strategic Material Selection Guide for led strip lights waterproof uk

When selecting materials for waterproof LED strip lights in the UK market, international B2B buyers must consider factors such as environmental exposure, durability, compliance with regional standards, and cost-effectiveness. The material choice directly influences the product’s lifespan, performance under varying climatic conditions, and suitability for specific applications. Below is an in-depth analysis of four common materials used in waterproof LED strip lights, focusing on their technical properties, advantages, limitations, and relevance to buyers from Africa, South America, the Middle East, and Europe.

Silicone Coating

Key Properties: Silicone coatings provide excellent flexibility and high resistance to extreme temperatures, typically from -50°C to +200°C. They offer superior waterproofing (commonly IP65 to IP68), UV resistance, and chemical inertness, making them highly corrosion-resistant.

Pros & Cons: Silicone-coated LED strips are highly durable in harsh outdoor environments, including exposure to saltwater and industrial pollutants. They maintain flexibility without cracking over time, which simplifies installation on curved surfaces. However, silicone coatings tend to increase manufacturing complexity and cost compared to simpler PVC coatings. The material can also be slightly thicker, which may affect discreet installations.

Impact on Application: Ideal for outdoor, marine, and industrial applications where exposure to moisture, UV rays, and chemicals is frequent. Their robustness makes them suitable for African coastal climates (e.g., Kenya) and Middle Eastern deserts where temperature extremes are common.

Considerations for International Buyers: Buyers from Europe and South America should verify compliance with EN 60529 for IP ratings and RoHS directives to ensure environmental and safety standards. African and Middle Eastern buyers should consider ASTM standards for UV resistance and chemical exposure. Silicone’s high cost may be justified by longer product life and reduced maintenance in demanding environments.

Polyvinyl Chloride (PVC) Coating

Key Properties: PVC coatings are widely used due to their affordability and ease of processing. They provide moderate waterproofing (typically IP65) and good resistance to abrasion and chemicals but have limited temperature tolerance (-20°C to +60°C).

Pros & Cons: PVC is cost-effective and suitable for mass production. It offers decent protection against dust and water splashes but is less flexible and prone to cracking under prolonged UV exposure or extreme cold. The material is heavier and less environmentally friendly compared to silicone.

Impact on Application: Best suited for indoor or semi-outdoor applications with moderate environmental exposure, such as retail lighting or covered outdoor areas in temperate climates like Germany or parts of Europe.

Considerations for International Buyers: Buyers in regions with high UV exposure (e.g., Middle East, South America) should be cautious of PVC’s degradation over time. Compliance with EU REACH and RoHS regulations is critical for European buyers. African buyers should assess local climate impacts and consider PVC only for controlled environments.

Polyurethane (PU) Encapsulation

Key Properties: PU encapsulation offers excellent mechanical strength, abrasion resistance, and good waterproofing (IP67 to IP68). It is more flexible than PVC but less so than silicone and withstands temperatures from -40°C to +90°C.

Pros & Cons: PU is a balanced choice providing durability and flexibility with moderate cost. It resists oils and many chemicals, making it suitable for industrial settings. However, PU can yellow over time under UV exposure and may require additives to enhance weather resistance.

Impact on Application: Suitable for outdoor installations requiring moderate flexibility and chemical resistance, such as architectural lighting in urban environments or commercial outdoor signage in Europe and South America.

Considerations for International Buyers: European buyers should verify compliance with DIN standards for chemical resistance and environmental safety. Buyers from Africa and the Middle East should consider UV stabilizers in PU coatings to extend lifespan. PU’s moderate cost and durability make it attractive for mid-range projects.

Epoxy Resin Coating

Key Properties: Epoxy resin provides a hard, durable surface with excellent waterproofing (up to IP68) and chemical resistance. It has high adhesion to substrates and good electrical insulation but is rigid and less flexible. Temperature resistance ranges from -30°C to +120°C.

Pros & Cons: Epoxy coatings are highly protective and ideal for harsh environments but are brittle and can crack under mechanical stress or bending. Manufacturing with epoxy requires careful curing processes, increasing production complexity and cost.

Impact on Application: Best for fixed installations where mechanical flexibility is not required, such as underwater lighting or permanent outdoor fixtures in Europe and South America. Less suitable for flexible or curved installations common in decorative lighting.

Considerations for International Buyers: Compliance with ASTM and EN standards for chemical and electrical safety is essential. Buyers from Africa and the Middle East should consider epoxy for fixed, high-durability applications but avoid it where flexibility is needed. Higher cost and manufacturing complexity may be justified by longevity in harsh environments.

| Material | Typical Use Case for led strip lights waterproof uk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Coating | Outdoor, marine, industrial lighting exposed to UV and chemicals | Superior flexibility and UV resistance | Higher manufacturing cost and thickness | High |

| PVC Coating | Indoor or semi-outdoor lighting with moderate exposure | Cost-effective and easy to produce | Limited UV and temperature resistance | Low |

| Polyurethane (PU) Encapsulation | Architectural and commercial outdoor lighting requiring durability | Good balance of flexibility, durability, and chemical resistance | Prone to yellowing without UV stabilizers | Medium |

| Epoxy Resin Coating | Fixed, harsh environment installations such as underwater lighting | Excellent waterproofing and chemical resistance | Rigid, brittle, and complex to manufacture | High |

This guide equips international B2B buyers with critical insights to select the optimal material for waterproof LED strip lights based on application demands, environmental conditions, and regional compliance standards. Prioritizing material properties aligned with local climates and regulations will ensure product reliability and customer satisfaction across diverse global markets.

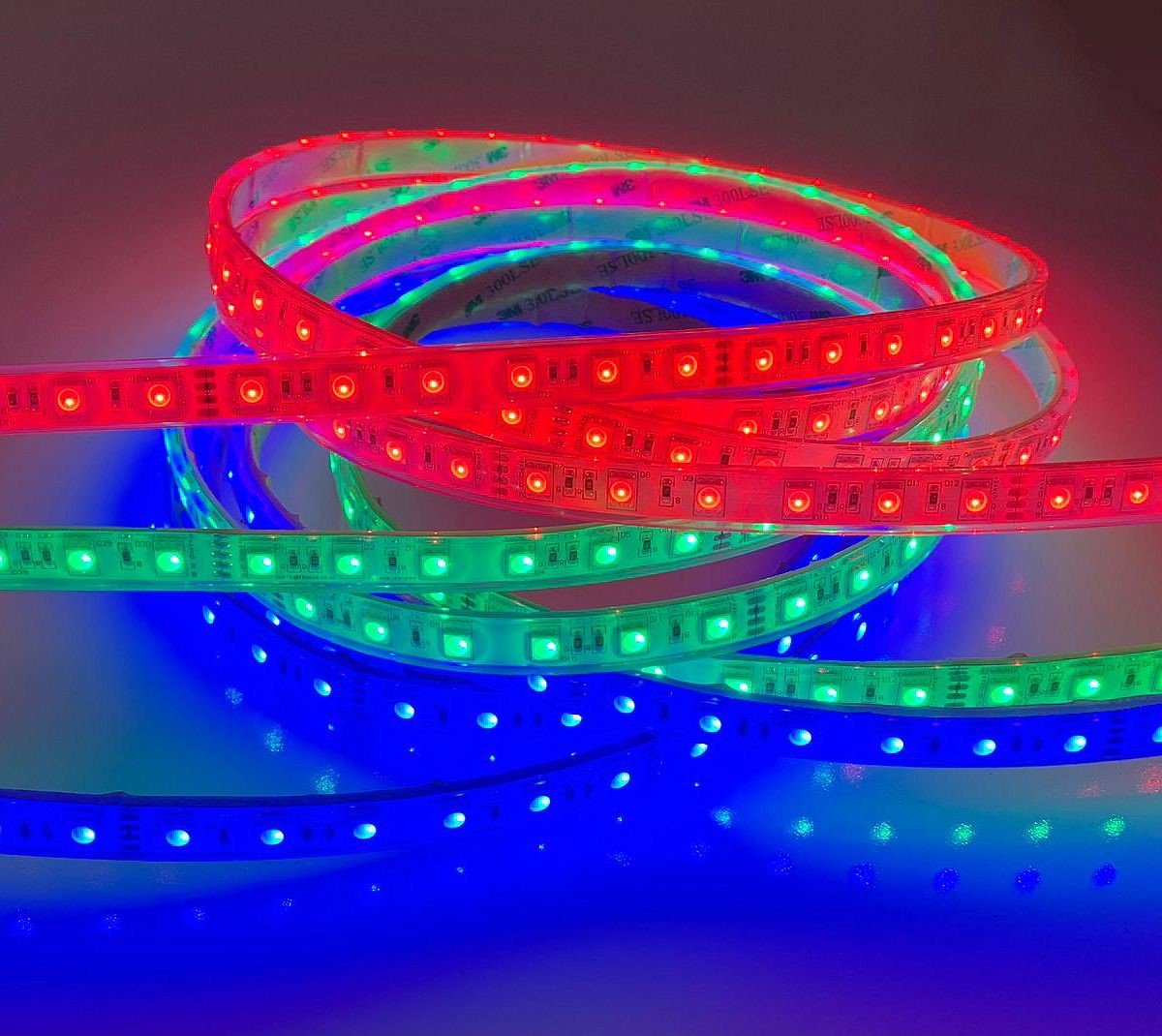

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lights waterproof uk

Manufacturing waterproof LED strip lights in the UK involves a multi-stage process that combines precision engineering, advanced materials, and rigorous quality controls to ensure durability and performance in various environmental conditions. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these manufacturing and quality assurance processes is essential for selecting reliable suppliers and ensuring compliance with local regulations.

Key Stages in the Manufacturing Process

-

Material Preparation

The process begins with sourcing high-grade raw materials, including flexible printed circuit boards (PCBs), high-quality LEDs (SMD or COB types), resistors, connectors, and waterproofing compounds such as silicone or epoxy resin. Materials must meet strict specifications to achieve the desired IP rating (e.g., IP65, IP67, IP68) for water and dust resistance. Suppliers often use lead-free solder and environmentally compliant components to meet RoHS directives and sustainability goals. -

PCB Forming and Circuit Printing

Flexible PCBs are fabricated with copper traces using photolithography and etching processes. This stage defines the electrical pathways for the LEDs and other components. Precision in circuit design ensures uniform current distribution and prevents hotspots that could compromise LED lifespan or waterproof integrity. -

Component Mounting and Assembly

LEDs and electronic components are mounted on the PCB using surface-mount technology (SMT) machines. Automated pick-and-place systems ensure high accuracy and repeatability, essential for maintaining consistent brightness and color temperature across the strip. After mounting, the circuits undergo reflow soldering to secure components firmly. For waterproof variants, additional encapsulation follows. -

Waterproofing and Encapsulation

The critical differentiator for waterproof LED strips is the protective layer applied after assembly. Techniques include coating with silicone gel, polyurethane, or epoxy resin, and encasing strips in flexible silicone tubes. This stage requires careful control to avoid air bubbles or incomplete coverage, which would compromise water resistance. Some manufacturers use ultrasonic sealing or laser welding for enhanced durability. -

Cutting and Finishing

Once encapsulated, the strips are cut to standard or custom lengths. Connectors and end caps are attached to facilitate installation and maintain waterproof integrity. Final finishing includes labeling with technical specifications, safety marks, and batch numbers for traceability.

Quality Assurance and Control Measures

Quality assurance (QA) in waterproof LED strip manufacturing is comprehensive, encompassing international standards compliance, in-process inspections, and final product testing.

International and Industry Standards

- ISO 9001: Most reputable manufacturers adhere to ISO 9001 quality management systems, ensuring consistent production quality and continuous improvement.

- CE Marking: Mandatory for products sold in the UK and Europe, CE certification confirms conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electronic products, crucial for environmental safety and regulatory approval.

- IP Ratings (Ingress Protection): Verified through standardized tests (IEC 60529) to confirm water and dust resistance levels.

- Additional Certifications: Some suppliers may hold UL certification or comply with API standards, relevant for specific sectors or export markets.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components undergo inspection for defects, material composition, and conformity to specifications before entering production.

- In-Process Quality Control (IPQC): Continuous monitoring during PCB assembly, soldering, and encapsulation stages to detect issues such as solder joint integrity, LED functionality, and waterproofing consistency.

- Final Quality Control (FQC): Complete product inspection including electrical testing, waterproof testing, and visual inspection to detect defects or inconsistencies.

Common Testing Methods

- Electrical Testing: Checks voltage, current, and brightness uniformity across the strip to ensure performance consistency.

- Waterproof Testing: Products are immersed in water or subjected to water jets to verify IP ratings, often using pressure chambers or humidity chambers.

- Thermal Testing: Measures heat dissipation and operating temperature to prevent premature failure.

- Durability Testing: Includes bending, vibration, and UV exposure tests to simulate real-world conditions.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, particularly from Africa, South America, the Middle East, and Europe, verifying supplier QA practices is critical to mitigate risks related to product failure, regulatory non-compliance, and project delays.

- Factory Audits: Conduct on-site or third-party audits focusing on production processes, equipment, and quality management systems. Audits verify adherence to ISO 9001 and other certifications.

- Reviewing QC Documentation: Request detailed quality control reports, including batch test results, IP test certificates, and compliance documentation (CE, RoHS).

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing before shipment, ensuring unbiased quality validation.

- Sample Evaluation: Obtain pre-production or production samples for in-house testing to confirm performance, waterproof integrity, and installation compatibility.

- Supplier Certifications and References: Verify supplier claims by checking certificates’ authenticity and seeking feedback from existing international clients, especially within similar climatic and regulatory environments.

Considerations for International B2B Buyers

- Regional Regulatory Requirements: Buyers from Kenya, Germany, or other regions must ensure that LED strip lights comply not only with UK and EU standards but also with local import regulations and safety certifications.

- Climate Adaptability: Products destined for tropical, desert, or humid regions should undergo rigorous waterproof and thermal resistance testing to withstand local environmental stressors.

- Warranty and After-Sales Support: Reliable suppliers provide clear warranty terms and technical support to assist with installation and troubleshooting, which is vital for long-term operational success.

- Customization and Scalability: Suppliers offering flexible manufacturing capabilities can accommodate custom lengths, voltages, and IP ratings, enabling buyers to tailor products to project-specific needs.

By thoroughly understanding the manufacturing and quality assurance processes behind waterproof LED strip lights in the UK, international B2B buyers can make informed decisions, ensuring they procure products that deliver optimal performance, durability, and compliance across diverse markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip lights waterproof uk Sourcing

When sourcing waterproof LED strip lights in the UK for international B2B purposes, understanding the intricate cost and pricing components is essential to make informed purchasing decisions and optimize value. This analysis breaks down the primary cost drivers and pricing influencers, followed by actionable buyer strategies tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Waterproof LED Strip Light Manufacturing

-

Materials

The largest portion of cost comes from raw materials—LED chips (SMD or COB), flexible PCB substrates, waterproof coatings (silicone or epoxy), power supplies, and connectors. Higher-grade LEDs and advanced waterproofing (e.g., IP67/IP68) increase material costs but enhance product durability and performance. -

Labor

Labor costs vary significantly depending on manufacturing location and complexity of assembly. UK-based or European manufacturers typically have higher labor costs compared to Asian suppliers. Labor includes manual assembly, quality checks, and packaging. -

Manufacturing Overhead

Overhead includes factory utilities, equipment depreciation, and facility maintenance. Sophisticated manufacturing lines with automation can reduce unit costs but require higher upfront investments. -

Tooling and Equipment

Initial tooling for custom LED strip designs or special enclosures adds to upfront costs, often amortized over large production runs. Custom molds or specialized coating processes increase this component. -

Quality Control (QC)

Rigorous QC is vital for waterproof LED strips to ensure IP ratings and electrical safety. Costs include inspection labor, testing equipment, and certification processes (CE, RoHS). -

Logistics and Shipping

Shipping costs depend on volume, weight, and delivery terms. For international buyers, ocean freight is cost-effective but slower, whereas air freight is faster but pricier. UK domestic shipping costs are comparatively lower. -

Supplier Margin

Margins vary by supplier type—manufacturers tend to offer lower margins than distributors or wholesalers. Margins reflect brand positioning, service level, and market demand.

Influential Pricing Factors for Buyers

-

Order Volume and Minimum Order Quantity (MOQ)

Larger orders typically unlock volume discounts and reduce per-unit costs. However, MOQ requirements can pose challenges for smaller buyers or pilot projects. -

Product Specifications and Customization

Higher LED density, specific color temperatures, smart controls, or bespoke waterproofing increase prices. Custom packaging and branding also add costs. -

Material Quality and Certifications

Certified products (CE, RoHS, UL) command premium pricing but reduce risk and compliance issues, especially important for European and Middle Eastern markets. -

Supplier Location and Reputation

UK and European suppliers offer faster lead times and easier communication but at higher prices. Chinese or Asian manufacturers provide competitive pricing but may involve longer shipping and additional compliance verification. -

Incoterms and Delivery Terms

Terms like FOB, CIF, or DDP affect the total landed cost. Buyers should clarify responsibilities for shipping, insurance, customs duties, and taxes.

Strategic Buyer Tips for International B2B Purchasers

-

Negotiate Beyond Price

Engage suppliers on payment terms, warranty periods, after-sales support, and sample provisions. Bulk discounts can often be complemented by better service agreements. -

Consider Total Cost of Ownership (TCO)

Evaluate not just purchase price but installation costs, energy efficiency, maintenance, and product lifespan. Higher upfront costs for premium waterproofing or energy-saving LEDs often yield long-term savings. -

Leverage Local Regulations and Certifications

Prioritize suppliers who provide products compliant with destination country standards to avoid customs delays and additional certification expenses. -

Plan for Logistics and Customs

For buyers in Africa, South America, and the Middle East, factor in import duties, VAT, and potential delays. Choosing suppliers familiar with international shipping and offering DDP terms can streamline procurement. -

Assess MOQ Flexibility and Stock Availability

Seek suppliers that accommodate smaller trial orders or stock ready-made standard products to reduce lead times and risk. -

Monitor Market Price Trends

LED chip prices fluctuate with global semiconductor supply, impacting LED strip costs. Maintain regular supplier communication to anticipate price changes.

Indicative Pricing Overview (Subject to Market Fluctuations)

- Basic IP65 waterproof SMD LED strip lights typically range from £5 to £12 per meter at wholesale volumes (100+ meters).

- Premium IP67/IP68 rated COB or RGBW strips may range between £15 to £30 per meter depending on specifications and certifications.

- Custom or smart-enabled strips often command prices above £30 per meter due to added electronics and control systems.

By carefully analyzing cost components and understanding pricing drivers, international B2B buyers can strategically source waterproof LED strip lights from the UK market. This knowledge enables negotiation for better terms, selection of optimal products for specific applications, and ultimately achieving cost-efficient, high-quality lighting solutions tailored to regional market needs.

Spotlight on Potential led strip lights waterproof uk Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip lights waterproof uk’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lights waterproof uk

Critical Technical Properties of Waterproof LED Strip Lights

Understanding the core technical specifications of waterproof LED strip lights is essential for international B2B buyers to ensure the product meets project requirements and environmental conditions. Here are the key properties to evaluate:

-

Ingress Protection (IP) Rating

The IP rating, such as IP65, IP67, or IP68, defines the level of dust and water resistance. For example, IP65 indicates protection against water jets, suitable for outdoor use, while IP68 means the strip can be submerged underwater. Selecting the correct IP rating is crucial to guarantee durability and prevent costly failures in harsh climates or wet environments common in regions like Europe or coastal areas in Africa. -

LED Chip Type and Density

The LED type (e.g., SMD or COB) affects brightness, energy efficiency, and light uniformity. Chip density, measured as LEDs per meter (e.g., 30, 60, 120 LEDs/m), influences light intensity and power consumption. Higher densities offer brighter, more continuous lighting but require compatible power supplies and heat management. Buyers should match chip type and density to the lighting effect and energy budget of their project. -

Voltage and Power Consumption

Common operating voltages include 12V, 24V, and sometimes 220V for high-voltage strips. Lower voltage strips are safer and easier to install but may require more complex wiring for longer runs. Power consumption (watts per meter) affects operational costs and heat output. Accurate voltage and wattage specifications help B2B buyers plan efficient power supplies and avoid electrical issues. -

Material Quality and Coating

Waterproof LED strips typically use silicone or epoxy coatings to seal the LEDs and circuitry. The grade and thickness of these coatings impact resistance to UV radiation, temperature fluctuations, and mechanical stress. High-quality materials ensure longer lifespan and reliability, particularly in outdoor or industrial installations found in diverse international markets. -

Color Temperature and Light Output

Color temperature, measured in Kelvin (K), ranges from warm white (~2700K) to daylight (~6500K). This affects the ambiance and suitability for specific applications, such as retail displays or outdoor security lighting. Brightness, expressed in lumens per meter, directly relates to visibility and effectiveness. B2B buyers should specify these parameters to align with end-user expectations and regulatory standards. -

Tolerance and Manufacturing Consistency

Tolerance refers to the allowable variation in electrical and luminous performance among production batches. Consistent tolerance ensures uniform lighting and compatibility across multiple shipments, which is critical for large-scale projects or phased installations. Buyers should inquire about manufacturer quality control processes to minimize discrepancies.

Key Trade Terminology for International B2B Buyers

Navigating the LED strip light market requires familiarity with common industry terms that impact procurement, pricing, and logistics. Here are essential trade terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers who produce products based on another company’s design or specifications. For buyers, OEM partnerships allow customization of LED strip lights, including branding and technical features, often with lower costs and exclusivity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount a supplier will accept per order. Understanding MOQ helps buyers balance inventory costs with project scale. Some suppliers offer flexible MOQs or sample orders, which is advantageous for testing products before bulk purchasing. -

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers requesting detailed pricing, lead times, and terms for specific products. Crafting clear RFQs with technical specs and quantity requirements accelerates supplier responses and enables accurate cost comparisons. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities and risks between buyers and sellers during shipping. Common terms like FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) clarify who handles transportation, insurance, and customs duties. Selecting favorable Incoterms reduces logistical uncertainties and unexpected expenses. -

Lead Time

Lead time is the period between order confirmation and product delivery. For waterproof LED strips, lead times vary by customization level, order size, and supplier location. Accurate lead time estimates are vital for project scheduling and inventory management. -

Certification (CE, RoHS, UL)

Certifications indicate compliance with regional safety and environmental standards. CE and RoHS are mandatory for products sold in the UK and Europe, ensuring safety, electromagnetic compatibility, and restriction of hazardous substances. Verifying certifications prevents regulatory issues and enhances buyer confidence.

By focusing on these technical properties and trade terms, international B2B buyers can make well-informed decisions when sourcing waterproof LED strip lights in the UK market. This knowledge ensures product suitability, cost-efficiency, and smooth supply chain operations across diverse global regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lights waterproof uk Sector

Market Overview & Key Trends

The waterproof LED strip lights market in the UK has witnessed robust growth driven by increasing demand for versatile, energy-efficient lighting solutions suitable for harsh environments. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Kenya) are increasingly sourcing from UK suppliers due to the region’s reputation for quality standards, innovation, and compliance with stringent safety certifications like CE and RoHS. These certifications are critical for ensuring product reliability and meeting regulatory requirements in diverse markets.

Key market dynamics reveal a growing preference for customizable LED strip lights that cater to both indoor and outdoor applications, with IP65 to IP68-rated products dominating due to their superior water and dust resistance. Buyers prioritize strips with high LED density and chip-on-board (COB) technology for uniform brightness and energy efficiency, essential for commercial projects and smart city initiatives. Additionally, the integration of smart controls—enabling app-based or voice-controlled lighting—is an emerging trend that enhances product appeal across sectors such as hospitality, retail, and urban infrastructure.

From a sourcing perspective, B2B buyers are gravitating towards suppliers offering flexible order quantities, technical support, and tailored solutions to meet project-specific needs. UK manufacturers like iNSTYLELED and UltraLEDs provide bespoke consultation services, which is particularly valuable for international buyers navigating complex installations in climates ranging from Kenya’s tropical humidity to Germany’s variable weather. Logistics and lead times are also critical considerations, with many buyers opting for suppliers with established export capabilities and transparent communication channels.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a decisive factor for international B2B buyers in the waterproof LED strip lights sector. The environmental impact of lighting products extends beyond energy consumption to encompass manufacturing processes, material selection, and end-of-life disposal. UK suppliers are progressively adopting eco-friendly practices such as using recyclable materials, reducing hazardous substances, and optimizing production to minimize carbon footprints.

Ethical supply chains are paramount, especially for buyers in regions where regulatory scrutiny on imported electronics is intensifying. Certifications such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) compliance ensure that products meet environmental safety standards and promote responsible recycling. Moreover, certifications like ISO 14001 for environmental management systems demonstrate a supplier’s commitment to sustainable operations, which resonates well with socially conscious buyers from Europe and the Middle East.

Material innovation also plays a role; for example, silicone-coated waterproof strips not only enhance durability but also extend product lifespan, reducing waste and replacement frequency. Buyers are encouraged to engage suppliers who transparently disclose their sourcing policies and support initiatives such as carbon offsetting or renewable energy use in manufacturing. Adopting such sustainable procurement strategies not only aligns with global environmental goals but also enhances brand reputation and customer loyalty in increasingly eco-aware markets.

Brief Evolution and Industry Context

The evolution of waterproof LED strip lights reflects broader advancements in LED technology and materials science over the past two decades. Initially, LED strips were predominantly non-waterproof and limited to indoor accent lighting. However, growing demand for outdoor and industrial applications catalyzed the development of protective coatings and higher IP-rated products.

The UK market has been a key player in driving innovation, with manufacturers and suppliers focusing on product durability, energy efficiency, and customization. This shift has aligned with global trends towards smart, connected lighting systems and the integration of LEDs into architectural and urban design projects. For international B2B buyers, understanding this evolution is crucial to selecting suppliers who offer cutting-edge solutions that meet modern performance and sustainability standards.

Today, waterproof LED strip lights serve diverse sectors—from commercial landscaping in Europe to infrastructural lighting in African urban centers—underscoring their strategic importance in global lighting portfolios. The UK’s leadership in quality assurance and product innovation continues to make it a preferred sourcing hub for buyers seeking reliable, efficient, and sustainable lighting solutions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lights waterproof uk

-

How can international B2B buyers verify the credibility of UK-based waterproof LED strip light suppliers?

To ensure supplier reliability, buyers should request verifiable business licenses, certifications (CE, RoHS), and product test reports. Checking supplier reputation through industry reviews, trade platforms, and references from existing clients is essential. Conducting factory audits or virtual inspections can provide insights into manufacturing capabilities and quality controls. Engaging suppliers who offer transparent communication and clear warranty policies reduces risks. For buyers in Africa, South America, the Middle East, and Europe, partnering with suppliers compliant with UK and EU standards ensures product safety and smoother customs clearance. -

What customization options are typically available for waterproof LED strip lights, and how can buyers leverage these?

Most UK suppliers offer custom lengths, IP ratings, LED densities, color temperatures, and even smart control integrations. Buyers can specify power voltage (12V, 24V, or mains voltage) and color modes (single color, RGB, RGBW) to suit regional preferences and project needs. Custom packaging and branding are often available for bulk orders. Early engagement with suppliers on design specifications and application environments ensures that products meet performance expectations. Customization can optimize installation efficiency and differentiate your offerings in local markets. -

What are the common minimum order quantities (MOQs) and lead times for waterproof LED strip lights when ordering from UK suppliers?

MOQs vary widely, typically ranging from 100 meters for standard products to higher quantities for customized orders. Some UK suppliers cater to small to medium enterprises by offering no MOQ on standard lines, which benefits emerging markets in Africa and South America. Lead times generally span 2 to 6 weeks depending on product complexity, customization, and stock availability. Buyers should clarify production schedules and factor in shipping times, especially for remote regions, to align procurement with project timelines effectively.

-

Which payment terms and methods are most common and secure for international buyers sourcing from the UK?

UK suppliers often accept payments via bank transfers (T/T), letters of credit (L/C), and increasingly, secure online payment platforms. For first-time orders, suppliers may request a 30-50% deposit upfront with the balance paid upon shipment or delivery. Buyers should negotiate clear payment milestones tied to production progress and inspection results. Utilizing escrow services or trade assurance platforms can enhance transaction security. Understanding currency exchange implications and bank charges is also vital for budgeting and cost control. -

What quality assurance measures and certifications should international buyers expect from UK waterproof LED strip light suppliers?

Quality assurance typically includes in-house testing for IP rating compliance (IP65, IP67, IP68), lumen output consistency, color accuracy, and electrical safety. Suppliers should provide certificates such as CE, RoHS, and sometimes UL or ETL for international compliance. Third-party inspection reports or factory quality audit summaries add confidence. Buyers should request sample testing before bulk orders and verify that products meet local regulatory requirements in their countries to avoid customs issues and ensure long-term reliability. -

How can buyers manage logistics and shipping challenges when importing waterproof LED strip lights from the UK?

Effective logistics management involves choosing the right shipping method—air freight for urgent, smaller orders; sea freight for cost efficiency on bulk shipments. Buyers should partner with freight forwarders experienced in handling electronic goods to navigate customs clearance and import duties smoothly. Proper packaging to prevent moisture damage during transit is critical. Coordinating with suppliers on shipping documentation (commercial invoice, packing list, certificate of origin) reduces delays. Understanding Incoterms clarifies responsibilities and cost-sharing between buyer and seller. -

What strategies can international B2B buyers use to handle disputes or quality issues with UK suppliers?

Establish clear contractual terms covering product specifications, quality standards, and dispute resolution mechanisms before order confirmation. Maintain detailed communication records and conduct joint inspections or third-party quality checks. In case of defects, negotiate remedies such as replacement, repair, or partial refunds. Utilizing arbitration clauses or mediation through trade bodies can offer neutral conflict resolution. Building long-term supplier relationships based on trust and transparency often mitigates disputes and fosters collaborative problem-solving.

Illustrative Image (Source: Google Search)

- Are there specific considerations for buyers from Africa, South America, and the Middle East when sourcing waterproof LED strip lights from the UK?

Yes, buyers should account for regional voltage standards and ensure product compatibility to avoid installation issues. Import regulations, tariffs, and certification requirements vary by country; sourcing from UK suppliers familiar with export documentation facilitates compliance. Language and cultural differences may impact communication, so choosing suppliers with multilingual support and after-sales service is beneficial. Additionally, planning for extended shipping times and potential customs delays in these regions helps maintain project schedules and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip lights waterproof uk

Waterproof LED strip lights represent a dynamic and energy-efficient solution for diverse lighting needs across residential, commercial, and industrial sectors. For international B2B buyers—particularly from emerging and established markets in Africa, South America, the Middle East, and Europe—understanding the critical technical specifications such as IP ratings, LED types, voltage requirements, and certifications is essential to ensure product reliability and longevity in varied environmental conditions.

Strategic sourcing plays a pivotal role in securing competitive advantages. Partnering with reputable UK manufacturers and suppliers who offer certified, customizable products with strong after-sales support can significantly reduce risks associated with quality and compliance. Leveraging suppliers that provide flexible order quantities, technical consultancy, and timely delivery enhances project success and operational efficiency.

Looking ahead, the increasing demand for smart, sustainable, and versatile lighting solutions will continue to drive innovation and market growth. International buyers are encouraged to engage proactively with trusted UK suppliers, explore tailored waterproof LED strip light options, and invest in solutions that align with evolving regulatory standards and sustainability goals. By doing so, businesses can confidently illuminate projects that meet high performance and environmental standards, unlocking long-term value and market differentiation.