Introduction: Navigating the Global Market for outdoor led strip lights waterproof

In the dynamic landscape of outdoor lighting, waterproof LED strip lights have emerged as indispensable solutions for enhancing exterior environments across diverse climates and applications. For international B2B buyers—especially those operating in regions like Africa, South America, the Middle East, and Europe—selecting the right waterproof LED strips is critical not only for aesthetic appeal but also for durability, safety, and energy efficiency under varying weather conditions.

This comprehensive guide delves into every aspect essential for making confident sourcing decisions in the global market. You will gain insights into the different IP ratings and waterproofing methods, helping you match product specifications with your project’s environmental demands, from light rain exposure to full underwater submersion. We explore material technologies such as silicone, PU glue, and epoxy resin, highlighting their performance, longevity, and cost-effectiveness to ensure your investment delivers maximum value.

Additionally, the guide covers manufacturing standards and quality control practices that safeguard product reliability—an important consideration when importing into markets with stringent regulations or extreme climatic conditions. You will also find a detailed overview of key suppliers and cost factors, enabling strategic vendor selection tailored to your region’s infrastructure and budgetary requirements.

Finally, an extensive FAQ section addresses common challenges faced by buyers worldwide, offering actionable solutions to optimize installation, maintenance, and operational efficiency. Armed with this knowledge, international B2B buyers can confidently navigate the complexities of the outdoor waterproof LED strip light market, securing products that meet their exact needs and support long-term project success.

Understanding outdoor led strip lights waterproof Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IP65 Silicone Coated Strip | Silicone coating providing splash and dust resistance | Patios, under eaves, light rain exposure areas | + Lightweight and flexible – Limited to splash-proof, not immersion |

| IP67 Silicone Extrusion | Silicone extrusion housing with sealed ends | Garden borders, gazebos, heavy rain exposure | + Strong water resistance – Less flexible, moderate cost |

| IP68 Silicone Filled Strip | Fully silicone-filled strip for complete waterproofing | Pools, fountains, underwater installations | + Suitable for submersion – Harder to cut or repair, higher cost |

| Neon Tube Sleeved Strip | LED strip sealed inside flexible neon-style silicone tube | Decorative contour lighting, signage | + Even light diffusion – Higher cost, specialized installation |

| High Voltage AC Strips | LED strips powered directly by mains voltage (110V/220V) | Large architectural outlines, commercial projects | + Supports long runs – Requires professional installation, safety risks |

IP65 Silicone Coated Strip

This type features a thin silicone coating that protects against dust and light water splashes. It is highly flexible and lightweight, making it an economical choice for outdoor patios, pergolas, and covered walkways where exposure to heavy rain or submersion is unlikely. For B2B buyers in regions with moderate climates such as parts of Europe or the Middle East, this offers a cost-effective solution. However, it is not recommended for environments with heavy rainfall or direct water immersion, limiting its use in tropical or highly humid zones.

IP67 Silicone Extrusion

IP67-rated strips are encased in a hollow silicone extrusion with sealed ends, providing enhanced protection against heavy rain and short-term immersion up to 1 meter. This makes them ideal for garden perimeters, outdoor gazebos, and commercial landscaping projects in high-moisture areas like coastal South America or African regions with intense rainy seasons. The trade-off is reduced flexibility and slightly higher costs compared to IP65 options, but the durability gains justify the investment for medium-to-long-term outdoor use.

IP68 Silicone Filled Strip

Fully filled with silicone gel, IP68 strips offer the highest level of waterproofing suitable for continuous underwater applications such as pools, fountains, and water features. This type is favored in luxury outdoor projects or commercial settings requiring permanent submersion, common in upscale developments in Europe or hospitality projects in the Middle East. While they provide excellent longevity and protection, they are more difficult to cut or repair, demanding careful planning and professional installation, which should be factored into procurement decisions.

Neon Tube Sleeved Strip

LED strips enclosed in flexible neon-style silicone tubes combine waterproofing with superior light diffusion, creating smooth, uniform lighting ideal for signage, architectural accents, and decorative contour lighting. This variation is popular in urban commercial projects and retail installations across diverse markets, including Turkey and Colombia. Buyers should consider the higher price point and the need for specialized installation expertise, balanced by the aesthetic and functional benefits in premium applications.

High Voltage AC Strips

Operating directly on mains voltage (110V or 220V), these waterproof LED strips support ultra-long runs without significant voltage drop, making them suitable for large-scale commercial or architectural lighting projects. They are widely used in Europe, the Middle East, and South America for building outlines, outdoor signage, and industrial facilities. The key considerations for B2B buyers include ensuring compliance with local electrical safety standards and engaging qualified professionals for installation due to the inherent risks of high-voltage systems.

Related Video: Govee Outdoor LED Strip Lights Waterproof | Review

Key Industrial Applications of outdoor led strip lights waterproof

| Industry/Sector | Specific Application of outdoor led strip lights waterproof | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Tourism | Outdoor ambiance lighting for hotel facades, patios, and pool areas | Enhances guest experience and property aesthetics; energy savings | High IP rating (IP67 or IP68), color consistency, durability in extreme weather |

| Urban Infrastructure | Street, pathway, and bridge lighting with waterproof LED strips | Improves safety and visibility; reduces maintenance costs | Compliance with regional voltage standards, robust waterproofing, long lifespan |

| Retail & Commercial | Illuminated signage and storefront accent lighting | Attracts customers; increases brand visibility | Flexible installation options, uniform light diffusion, UV resistance |

| Agriculture & Farming | Greenhouse and outdoor crop lighting for extended growth cycles | Boosts crop yield; supports night-time operations | Waterproof and dustproof ratings, energy efficiency, compatibility with solar power systems |

| Marine & Water Features | Lighting for docks, fountains, pools, and underwater installations | Creates striking visual effects; withstands submersion | IP68 waterproofing, corrosion resistance, ease of installation and maintenance |

Hospitality & Tourism

Outdoor waterproof LED strip lights are extensively used to enhance the ambiance of hotels, resorts, and restaurants. These lighting solutions highlight architectural features, illuminate patios, and decorate pool areas, creating inviting environments that attract guests. For B2B buyers in regions like the Middle East and Europe, selecting LED strips with high IP ratings (IP67 or IP68) ensures durability against heavy rain, humidity, and UV exposure. Consistent color temperature and energy efficiency are critical to maintain brand image and reduce operational costs.

Urban Infrastructure

Municipalities and contractors rely on waterproof LED strip lights to illuminate streets, pathways, and bridges, improving public safety and urban aesthetics. Such installations require LED strips with robust waterproofing and dustproofing (IP65 or higher) to endure harsh outdoor conditions common in Africa and South America. Buyers should prioritize compliance with local voltage standards and opt for products with long lifespans and low maintenance needs to optimize public spending.

Retail & Commercial

Retailers use waterproof LED strip lighting to create eye-catching storefronts and signage that stand out in competitive markets. Uniform light diffusion and flexibility in installation are essential, especially for complex storefront designs in cities like Istanbul or Bogotá. UV resistance is important to prevent color fading in sunny climates. B2B buyers should evaluate the ease of integration with existing electrical systems and ensure the lighting solution supports brand visibility goals.

Agriculture & Farming

In modern agriculture, waterproof LED strips support extended photoperiods in greenhouses and outdoor crop areas, promoting faster growth and higher yields. These lights must be highly resistant to dust, moisture, and temperature variations typical in African and South American farming environments. Energy efficiency is paramount due to remote locations and limited power infrastructure, making compatibility with solar power systems a key sourcing criterion for buyers.

Marine & Water Features

Waterproof LED strips are critical for illuminating marine environments such as docks, fountains, and pools. IP68-rated products offer continuous underwater operation, ensuring safety and aesthetic appeal. Corrosion resistance is vital in salty or chlorinated water environments common in coastal regions of Europe and the Middle East. Buyers should seek easy-to-install and maintain solutions to reduce downtime and extend product lifespan in these demanding applications.

Related Video: 52.5 ft Waterproof Outdoor LED Kit from Novastella

Strategic Material Selection Guide for outdoor led strip lights waterproof

When selecting materials for outdoor waterproof LED strip lights, understanding the distinct properties and trade-offs of each option is critical for international B2B buyers. The choice affects product longevity, installation environments, and compliance with regional standards. Below is an in-depth analysis of four common materials used in waterproof LED strip light encapsulation: Epoxy Resin, Polyurethane (PU) Glue, Silicone, and Polyurethane Tube Extrusions.

Epoxy Resin

Key Properties: Epoxy resin is a rigid, thermosetting polymer with relatively poor thermal conductivity and limited flexibility. It typically withstands temperatures from 0°C to 60°C but becomes brittle and prone to cracking below freezing. Epoxy is moderately resistant to dust and moisture but lacks strong UV and weather resistance.

Pros & Cons: Epoxy resin is low cost and easy to apply, making it attractive for budget-conscious projects. However, it yellows after approximately six months of outdoor exposure, which degrades light quality and appearance. Its poor heat dissipation can reduce LED lifespan, and brittleness in cold climates limits its use in harsh environments.

Impact on Application: Epoxy resin is best suited for indoor or semi-outdoor applications with limited exposure to extreme weather or temperature fluctuations. It is less ideal for regions with high UV exposure or cold winters, such as parts of Europe and the Middle East.

International Buyer Considerations: Buyers in Africa and South America, where ambient temperatures are often high but UV exposure varies, should be cautious with epoxy due to yellowing and heat issues. Compliance with ASTM D-4216 for epoxy coatings and DIN standards for UV resistance may be required. Epoxy’s low cost may appeal to large-scale, cost-sensitive projects, but longevity concerns must be weighed.

Polyurethane (PU) Glue

Key Properties: PU glue offers improved flexibility and thermal conductivity compared to epoxy, withstanding temperatures between -40°C and 80°C. It provides better resistance to moisture and some UV exposure but can emit toxic fumes during curing.

Pros & Cons: PU glue balances durability and cost, with better yellowing resistance than epoxy and moderate weather resilience. However, its toxicity during curing requires proper ventilation and safety measures, increasing manufacturing complexity. It is less suitable for high-temperature environments exceeding 80°C.

Impact on Application: PU glue is appropriate for outdoor installations in moderately harsh climates, such as coastal regions in Turkey or Colombia, where moisture and temperature swings are common. It is often used where moderate flexibility and durability are required without the premium cost of silicone.

International Buyer Considerations: Buyers should ensure manufacturers comply with international safety standards like REACH (EU) and OSHA (US) for handling PU glue. In regions with strict environmental regulations (Europe), low-toxicity formulations may be necessary. PU glue’s moderate cost and performance make it a practical choice for mid-tier outdoor lighting projects.

Silicone

Key Properties: Silicone encapsulants exhibit excellent thermal stability (-50°C to 300°C), outstanding UV and weather resistance, and superior flexibility. They have high light transmission (~96%) and excellent resistance to yellowing and corrosion.

Pros & Cons: Silicone is the premium material choice, offering the longest lifespan and best performance in extreme environments, including deserts, tropical climates, and underwater applications. Its main drawbacks are higher cost and more complex manufacturing processes.

Impact on Application: Silicone is ideal for high-end outdoor LED strip installations in harsh climates found in the Middle East and parts of Africa, where temperature extremes and UV exposure are significant. It is also preferred for underwater or permanent outdoor fixtures due to its durability.

International Buyer Considerations: Buyers should verify compliance with ASTM D2000 for silicone rubber and ISO 10993 for biocompatibility if used in public spaces. The higher cost is justified by reduced maintenance and replacement frequency, especially in premium architectural or commercial projects in Europe and Turkey.

Polyurethane Tube Extrusions

Key Properties: Polyurethane extrusions provide a robust physical barrier with good flexibility and abrasion resistance. They typically have IP65 to IP67 waterproof ratings when properly sealed and resist moderate UV exposure.

Pros & Cons: These extrusions offer excellent mechanical protection against impacts and environmental wear, making them suitable for rugged outdoor installations. However, they may yellow over time under intense UV exposure and have moderate thermal resistance compared to silicone.

Impact on Application: Polyurethane tubes are commonly used in outdoor signage, pathway lighting, and architectural accents where physical protection is paramount. They are suitable for environments with moderate weather exposure, such as urban areas in South America and Europe.

International Buyer Considerations: Buyers should check for compliance with DIN 53387 (abrasion resistance) and ASTM D2240 (hardness) standards. The balance of cost and durability makes polyurethane extrusions attractive for commercial projects requiring robust protection without the premium silicone price.

| Material | Typical Use Case for outdoor led strip lights waterproof | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Epoxy Resin | Budget indoor/outdoor with limited exposure; decorative lighting | Low cost, easy to apply | Prone to yellowing, poor thermal resistance | Low |

| Polyurethane Glue | Mid-tier outdoor lighting with moderate weather exposure | Good flexibility and moisture resistance | Toxic fumes during curing, limited high-temp use | Medium |

| Silicone | Premium outdoor and underwater installations in extreme climates | Excellent durability, UV resistance, and flexibility | Higher cost, complex manufacturing | High |

| Polyurethane Tube Extrusions | Rugged outdoor signage and architectural lighting requiring physical protection | Strong mechanical protection, good abrasion resistance | Moderate UV resistance, potential yellowing | Medium |

This guide equips international B2B buyers with a clear understanding of material choices for waterproof outdoor LED strip lights, enabling informed procurement decisions tailored to regional climate, regulatory requirements, and project budgets.

In-depth Look: Manufacturing Processes and Quality Assurance for outdoor led strip lights waterproof

Understanding the manufacturing and quality assurance processes behind waterproof outdoor LED strip lights is essential for international B2B buyers seeking reliable, long-lasting lighting solutions. This insight not only helps in selecting the right suppliers but also ensures compliance with regional standards and operational demands across diverse markets such as Africa, South America, the Middle East, and Europe.

Manufacturing Process Overview

The production of waterproof outdoor LED strip lights typically involves several critical stages, each designed to guarantee product durability, functionality, and waterproof integrity.

1. Material Preparation

The foundation of a high-quality waterproof LED strip light starts with selecting premium raw materials:

– LED Chips and PCBs: High-quality LED chips (commonly SMD types) and flexible printed circuit boards (PCBs) are procured. PCBs are often made from flexible polyimide or fiberglass substrates, optimized for thermal management.

– Waterproofing Materials: Silicone, polyurethane (PU) glue, or epoxy resin are chosen based on the desired waterproof rating (e.g., IP65, IP67, IP68). Silicone is preferred for high-end, durable outdoor applications due to its superior weather resistance and UV stability.

– Adhesives and Sealants: High-grade adhesives ensure the waterproof layer bonds securely without compromising flexibility.

2. Forming and Assembly

- LED Mounting: Automated surface-mount technology (SMT) machines place LED chips precisely on the PCB.

- Soldering: Reflow soldering ensures robust electrical connections between LEDs and the PCB.

- Waterproof Coating or Encapsulation: Depending on the IP rating, strips undergo different sealing techniques:

- Silicone Coating or Tubing: For IP65 and IP67, strips are coated or inserted into flexible silicone tubes with sealed ends.

- Silicone Filling: For IP68, strips are fully encapsulated in silicone gel or extrusion, creating a completely sealed, waterproof barrier.

- Cutting and End-Capping: Strips are cut to standardized lengths, with waterproof end caps applied and sealed to prevent water ingress.

- Connector Installation: Waterproof connectors or cables with sealing gaskets are attached to facilitate secure and weatherproof electrical connections.

3. Finishing

- Surface Treatment: UV-resistant coatings or additives may be applied to enhance outdoor durability.

- Packaging: Waterproof and anti-static packaging materials protect the strips during transportation, especially for international shipping to regions with variable climates.

Quality Assurance and Control

Robust quality assurance (QA) and quality control (QC) processes are critical to ensure the waterproof LED strip lights meet international standards and perform reliably in harsh outdoor environments.

Relevant Standards and Certifications

- ISO 9001: A globally recognized quality management system standard ensuring consistent manufacturing quality and continual improvement.

- CE Marking: Mandatory for products sold in Europe, indicating conformity with safety, health, and environmental protection requirements.

- RoHS Compliance: Restricts hazardous substances in electronic components, vital for European and some Middle Eastern markets.

- IP Ratings (Ingress Protection): Strict testing to verify water and dust resistance per IEC 60529 standards.

- UL Certification: Especially relevant for North American buyers, but increasingly recognized worldwide for electrical safety.

- Other Regional Certifications: For example, INMETRO in Brazil, SASO in Saudi Arabia, or TSE in Turkey, which might require additional compliance checks.

QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components (LED chips, PCBs, waterproof materials) for defects, consistency, and compliance with specifications.

- In-Process Quality Control (IPQC): Monitoring during assembly stages such as soldering quality, waterproof encapsulation integrity, and connector installation.

- Final Quality Control (FQC): Comprehensive testing of finished products including waterproof testing, electrical performance, and visual inspections.

Common Testing Methods

- Waterproof Testing: Submersion tests for IP67/IP68 ratings, water jet tests for IP65, and humidity chamber tests to simulate harsh weather conditions.

- Electrical Testing: Voltage and current stability, insulation resistance, and voltage drop measurements to ensure safety and performance.

- Thermal Testing: Assessing heat dissipation and operational temperature ranges to prevent premature failure.

- Visual and Mechanical Inspection: Checking for uniform light emission, physical damage, and seal integrity.

How B2B Buyers Can Verify Supplier QC

International buyers should adopt a proactive approach in verifying supplier quality to mitigate risks and ensure compliance:

- Factory Audits: Conduct on-site or third-party audits focusing on manufacturing processes, equipment, and QC protocols. This is especially critical for buyers in regions with strict import regulations like the EU.

- Review of QC Reports: Request detailed inspection reports, including raw material certificates, in-process inspections, and final test results.

- Third-Party Inspection: Engage independent inspection agencies to perform pre-shipment inspections, waterproof testing, and certification verification.

- Sample Testing: Obtain product samples for in-house or local lab testing to validate waterproof ratings and electrical safety.

- Supplier Certifications: Verify authenticity and validity of ISO, CE, RoHS, and other certifications through official registries or certifying bodies.

QC and Certification Nuances for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, understanding regional requirements and challenges is crucial:

- Africa & South America: Regulatory frameworks may vary widely; buyers should focus on suppliers offering comprehensive documentation and certifications recognized by local customs and standards bodies. The presence of CE and RoHS certification can facilitate smoother import processes.

- Middle East: Countries like Saudi Arabia and UAE often require conformity with SASO or GSO standards. Buyers should ensure suppliers can provide relevant compliance certificates and test reports.

- Europe: The European market demands strict adherence to CE marking, RoHS, and REACH regulations. Additionally, buyers must consider energy efficiency and environmental impact certifications.

- Cross-Regional Logistics: Waterproof LED strips must be packaged and shipped to withstand diverse climates and handling conditions to prevent damage before installation.

Final Recommendations for B2B Buyers

- Prioritize suppliers with transparent, well-documented manufacturing and QC processes.

- Insist on testing evidence for waterproof ratings aligned with your project environment.

- Factor in local regulatory requirements early to avoid costly compliance issues.

- Consider long-term supplier partnerships that include after-sales support and warranty assurance.

- Leverage third-party inspections and audits to reduce quality risks, especially for large or critical orders.

By thoroughly understanding the manufacturing intricacies and quality assurance practices of waterproof outdoor LED strip lights, international B2B buyers can confidently source products that meet both performance expectations and regulatory demands across diverse global markets.

Comprehensive Cost and Pricing Analysis for outdoor led strip lights waterproof Sourcing

Understanding the cost and pricing dynamics of waterproof outdoor LED strip lights is crucial for international B2B buyers aiming to optimize procurement strategies while ensuring product quality and reliability. This analysis breaks down the key cost components, pricing influencers, and practical tips tailored for buyers from regions such as Africa, South America, the Middle East, and Europe.

Key Cost Components in Waterproof LED Strip Lights

-

Materials

– The choice of waterproofing material (silicone, PU glue, epoxy resin) significantly impacts costs. Silicone offers superior durability and weather resistance but at a premium price compared to epoxy resin or PU glue.

– LED chips (e.g., SMD 2835, 5050) and the quality of PCB substrates also influence material costs.

– Additional components like waterproof connectors, power supplies, and protective coatings add to the bill of materials. -

Labor and Manufacturing Overhead

– Labor costs vary widely by manufacturing location. Countries with lower labor costs may offer competitive pricing but require careful quality control.

– Overhead includes factory utilities, equipment depreciation, and indirect labor, often reflected in the unit price. -

Tooling and Setup

– Initial tooling for extrusion molds, silicone injection, or PCB assembly can be significant, especially for customized profiles or IP68-rated products.

– Buyers ordering higher volumes can negotiate tooling cost amortization, reducing per-unit costs. -

Quality Control (QC)

– Rigorous QC processes, including waterproof testing (IP rating verification), electrical safety tests, and longevity assessments, add to costs but are essential for long-term reliability.

– Certifications such as CE, RoHS, UL, and local compliance can increase QC expenses but facilitate market access. -

Logistics and Shipping

– Shipping costs depend on order size, weight, packaging, and destination. Waterproof LED strips, often shipped in reels with careful moisture-proof packaging, require attention to avoid damage.

– Incoterms (e.g., FOB, CIF, DDP) greatly affect the final landed cost and risk management. -

Supplier Margin

– Margins vary based on supplier reputation, product quality, order volume, and market demand.

– Premium suppliers specializing in high-IP-rated, long-life LED strips typically command higher margins.

Influencing Factors on Pricing

- Order Volume and Minimum Order Quantity (MOQ)

- Larger volumes usually translate to lower unit prices due to economies of scale and reduced overhead allocation.

-

MOQ requirements differ; some suppliers may offer samples or small pilot runs but at higher per-unit costs.

-

Product Specifications and Customization

- Customized lengths, specific IP ratings (IP65 vs. IP68), color temperatures, and voltage options (12V, 24V, 220V) impact pricing.

-

Additional features like RGB control, dimming capabilities, or specialized silicone formulations for extreme climates also add cost.

-

Material Quality and Certifications

- Certified products with recognized safety and environmental standards command premium prices but mitigate risks related to compliance and durability.

-

Lower-cost alternatives may compromise on materials or certifications, posing potential long-term costs.

-

Supplier Location and Reliability

- Suppliers closer to the buyer’s region (e.g., Europe for Turkish buyers) may reduce shipping time and costs.

-

Established suppliers with proven track records often provide better after-sales support and warranty terms.

-

Incoterms and Payment Terms

- Choosing favorable Incoterms like FOB or CIF can shift responsibilities and costs between buyer and supplier.

- Negotiated payment terms (e.g., L/C, net 30) impact cash flow and risk exposure.

Actionable Buyer Tips for International B2B Procurement

-

Negotiate Beyond Price:

Focus on total value, including warranty, technical support, and flexible MOQ. Suppliers may offer better terms if you commit to long-term partnerships or larger volumes. -

Evaluate Total Cost of Ownership (TCO):

Consider installation, energy consumption, maintenance, and replacement costs. Higher upfront prices for durable, certified IP67/IP68 strips often result in lower TCO. -

Understand Regional Import Duties and Compliance:

For buyers in Africa, South America, and the Middle East, factor in import taxes, customs clearance complexity, and local certification requirements, which can affect landed costs. -

Request Samples and Test Rigorously:

Before large orders, obtain samples to test waterproof performance, brightness, and durability under local climate conditions. -

Leverage Local Partners or Agents:

Engaging local sourcing agents or distributors can help navigate language, logistics, and regulatory nuances, especially in markets like Colombia or Turkey. -

Be Mindful of Currency Fluctuations:

Pricing negotiated in USD, EUR, or CNY can be impacted by exchange rate volatility. Consider hedging or fixed-term contracts where feasible.

Indicative Pricing Disclaimer

Prices for waterproof outdoor LED strip lights vary widely depending on specifications, volume, and supplier. As a rough benchmark, basic IP65 LED strips may start at approximately USD 1.5–3 per meter for bulk orders, while IP67/IP68 rated, high-quality silicone-encased strips with certifications can range from USD 4 to 10+ per meter. These figures serve as indicative guides; buyers should obtain detailed quotations tailored to their exact requirements.

By carefully analyzing cost

Spotlight on Potential outdoor led strip lights waterproof Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘outdoor led strip lights waterproof’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for outdoor led strip lights waterproof

Critical Technical Properties for Waterproof Outdoor LED Strip Lights

1. IP Rating (Ingress Protection)

The IP rating is a standardized measure indicating the level of protection against dust and water ingress. For outdoor LED strip lights, common ratings include IP65, IP67, and IP68. Higher IP ratings (e.g., IP68) signify better waterproofing and dust resistance, crucial for installations exposed to heavy rain, submersion, or harsh environments. B2B buyers must select the appropriate IP rating based on the project’s exposure level to ensure durability and reduce maintenance costs.

2. Waterproof Encapsulation Material

Materials such as silicone, polyurethane (PU), and epoxy resin are used to waterproof LED strips. Silicone offers the best weather resistance, thermal stability, and longevity, making it ideal for extreme climates common in regions like Africa and the Middle East. PU provides good performance but may emit odors and has lower temperature tolerance. Epoxy resin is cost-effective but prone to yellowing and cracking in cold or hot conditions. Choosing the right encapsulation material impacts product lifespan and visual quality, affecting long-term investment value.

3. Voltage Specification

Outdoor LED strips are available in various voltage levels, typically DC 12V, 24V, or AC 110V/220V. Low-voltage DC strips (12V or 24V) are safer and easier to install for small to medium projects, while high-voltage AC strips support longer runs suitable for large commercial or architectural applications. Voltage choice affects installation complexity, power efficiency, and safety compliance, which are critical considerations for international buyers adapting to regional electrical standards.

4. Luminous Intensity and Color Temperature

Measured in lumens per meter (lm/m) and Kelvin (K), these specs determine brightness and light warmth. Outdoor environments often require higher brightness levels (e.g., 500+ lm/m) for visibility and safety. Color temperature influences ambiance—warm white (2700K-3000K) for cozy settings, cool white (5000K-6500K) for functional illumination. B2B buyers should specify these parameters according to end-use to meet client expectations and regulatory lighting standards.

5. Flexibility and Cut-Ability

LED strip lights vary in flexibility based on substrate thickness and waterproofing method. Flexible strips are easier to install on curved surfaces or irregular outdoor structures. Cut-ability allows customization of strip length on-site, reducing waste and enabling tailored lighting solutions. Buyers should verify these properties to ensure compatibility with their project design and minimize installation time and cost.

6. Operating Temperature Range

Outdoor LED strips must withstand ambient temperature fluctuations, often between -40°C to +60°C or higher depending on material quality. This ensures reliable performance in diverse climates, from cold European winters to hot Middle Eastern summers. Confirming the operating temperature range is essential to avoid premature failure and warranty issues.

Key Industry and Trade Terminology for B2B Buyers

OEM (Original Equipment Manufacturer)

Refers to companies that manufacture products or components which are then branded and sold by other firms. For LED strips, OEM partnerships allow buyers to customize product specifications, packaging, and branding, enabling differentiation in competitive markets.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQs vary widely and impact inventory management and pricing. International buyers should negotiate MOQs to align with budget constraints and project scale, especially when testing new suppliers.

RFQ (Request for Quotation)

A formal document sent by buyers to suppliers to obtain pricing and terms for specific product requirements. A well-prepared RFQ with detailed technical specs accelerates supplier response times and ensures quotes are comparable, facilitating efficient procurement decisions.

Incoterms (International Commercial Terms)

Standardized trade terms defined by the International Chamber of Commerce that clarify responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and EXW (Ex Works). Understanding Incoterms helps buyers from diverse regions manage logistics costs and risks effectively.

Lead Time

The period between order placement and delivery. Lead times for waterproof LED strips can vary depending on customization, stock availability, and shipping logistics. Buyers should factor lead time into project schedules to avoid delays.

Warranty and Certification

Warranties guarantee product performance over a set period, typically 1-3 years for LED strips. Certifications such as CE, RoHS, and UL indicate compliance with safety and environmental standards. Verifying these protects buyers from quality risks and ensures market access, especially in Europe and regulated markets.

By understanding these essential technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and select waterproof outdoor LED strip lights that deliver reliability, performance, and value in diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the outdoor led strip lights waterproof Sector

Market Overview & Key Trends

The global market for outdoor waterproof LED strip lights is expanding rapidly, driven by increasing demand for energy-efficient, durable, and versatile lighting solutions across commercial, residential, and public infrastructure sectors. Key growth regions include Africa, South America, the Middle East, and Europe, where urbanization, infrastructure development, and rising consumer awareness of sustainable lighting solutions are fostering adoption. Countries such as Colombia and Turkey exemplify emerging markets with expanding construction and hospitality industries requiring robust outdoor lighting.

Market Drivers:

– Energy Efficiency & Cost Savings: Businesses prioritize LED technology for its low power consumption and long operational life, reducing maintenance costs in outdoor environments.

– Technological Advances: Innovations such as enhanced waterproof ratings (IP65 to IP68), improved thermal management materials, and flexible form factors enable diverse applications—from architectural highlights to landscape lighting.

– Customization & Smart Integration: Increasing demand for customizable color temperatures, brightness levels, and smart controls (e.g., IoT-enabled lighting) is reshaping sourcing criteria, especially in commercial projects.

Sourcing Trends:

– Preference for Certified Products: Buyers increasingly seek suppliers providing products with international certifications (CE, RoHS, UL) to ensure compliance and safety.

– Local and Regional Partnerships: To mitigate supply chain disruptions and reduce lead times, B2B buyers in Africa and South America are forming strategic partnerships with regional manufacturers and distributors.

– Modular and Scalable Solutions: There is a growing trend toward modular LED strip systems that can be easily extended or repaired, facilitating cost-effective maintenance in large-scale outdoor installations.

Market Dynamics:

– Price Sensitivity vs. Quality: While cost remains a significant factor in emerging markets, buyers are balancing affordability with the need for durability, especially under harsh weather conditions typical of Middle Eastern deserts or tropical climates in South America.

– Regulatory Landscape: European buyers face stringent environmental and safety regulations, influencing demand for higher-grade waterproofing and sustainable materials.

– Competitive Landscape: The sector is fragmented, with numerous small and medium enterprises competing alongside established global brands. This dynamic fosters innovation but necessitates rigorous supplier vetting.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for international B2B buyers of outdoor waterproof LED strip lights. The environmental impact of lighting products spans raw material extraction, manufacturing processes, energy consumption during use, and end-of-life disposal or recycling. LED technology inherently offers energy savings compared to traditional lighting, but sustainable sourcing practices further enhance the environmental profile.

Key Environmental Considerations:

– Material Selection: Opting for silicone-based waterproofing materials over epoxy resins or PU glue reduces yellowing, improves longevity, and enhances recyclability. Silicone’s superior weather resistance also minimizes premature replacements.

– Energy Efficiency: Buyers should prioritize LED strips with high luminous efficacy and low voltage drop characteristics (e.g., 24V or 48V systems) to maximize energy savings in long outdoor runs.

– Waste Reduction: Modular designs and repairable components help reduce waste by extending product life and enabling partial replacements instead of full strip changes.

Ethical Supply Chains:

– Transparency & Traceability: Partnering with suppliers who provide clear information on sourcing, labor conditions, and environmental compliance mitigates risks associated with unethical manufacturing practices.

– Certifications & Standards: Certifications such as ISO 14001 (environmental management), REACH compliance (chemical safety), and fair labor standards demonstrate a supplier’s commitment to sustainability and social responsibility.

– Circular Economy Initiatives: Buyers can support suppliers engaged in take-back programs or using recycled materials in production, aligning with global trends toward circular manufacturing.

For B2B buyers in regions like Europe and the Middle East, integrating sustainability criteria into procurement decisions is increasingly mandated by government regulations and corporate social responsibility policies. In emerging markets, sustainable sourcing enhances brand reputation and prepares businesses for future regulatory environments.

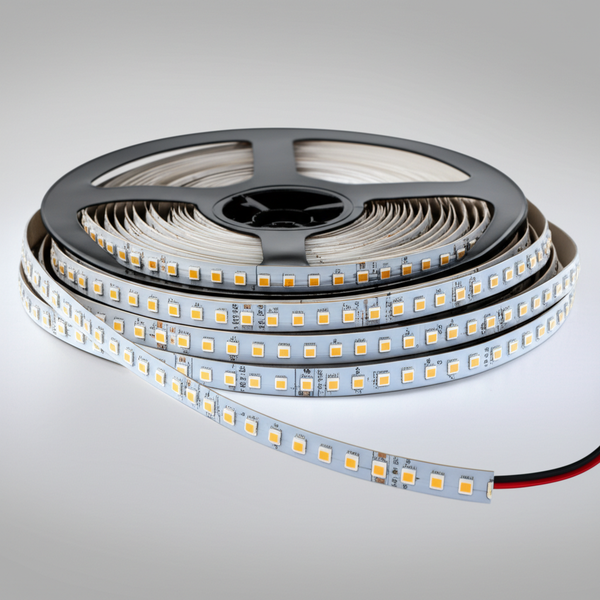

Illustrative Image (Source: Google Search)

Evolution and Historical Context

The outdoor waterproof LED strip light sector has evolved significantly over the past two decades. Initially, LED strips were predominantly indoor, non-waterproof products used for accent and decorative lighting. The growing need for durable, weather-resistant lighting solutions spurred innovation in waterproofing technologies and materials.

The introduction of standardized IP ratings allowed buyers to better understand protection levels, fostering confidence in outdoor applications. Early waterproof methods, such as epoxy resin coatings, gave way to advanced silicone encapsulation techniques offering superior thermal performance and weather resistance.

Illustrative Image (Source: Google Search)

Simultaneously, the shift from low-voltage (5V, 12V) to higher-voltage systems (24V, 48V, and AC mains) enabled longer runs with reduced voltage drop, meeting the demands of large-scale commercial and architectural projects.

Today, the sector is characterized by a diverse product range tailored to specific environments—from splash-proof garden lighting to fully submersible pool illumination—empowering international B2B buyers to source highly specialized solutions aligned with their operational and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of outdoor led strip lights waterproof

-

How can I effectively vet suppliers of waterproof outdoor LED strip lights for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications like ISO 9001 and relevant IP ratings for waterproofing. Request product samples to assess build quality, waterproof integrity, and LED performance. Check references or reviews from other international buyers, especially those in similar climates or industries. Confirm their compliance with international safety standards such as CE, RoHS, and UL. Additionally, evaluate their communication responsiveness and after-sales support capabilities to ensure a smooth partnership. -

What customization options are typically available for outdoor waterproof LED strip lights, and how can I leverage them?

Most manufacturers offer customization in length, color temperature, waterproof rating (IP65, IP67, IP68), voltage (12V, 24V, 220V), and mounting accessories. You can also request custom silicone coatings or extrusions for enhanced durability in harsh climates. Leverage customization to tailor lighting solutions to your regional weather conditions and installation environments. Collaborate closely with suppliers on technical specs and sample approvals to ensure the final product meets your project’s unique requirements. -

What are common minimum order quantities (MOQs), lead times, and payment terms for international B2B orders of waterproof LED strip lights?

MOQs typically range from 100 to 500 meters per order, but many suppliers offer flexible quantities for repeat customers. Lead times vary from 2 to 6 weeks depending on customization and order size. Payment terms often include 30% deposit upfront with balance on shipment, or payment via letter of credit for larger orders. Negotiate terms carefully, considering your cash flow and risk tolerance, and always confirm shipping schedules and payment milestones in the contract. -

What quality assurance (QA) processes and certifications should I require to ensure the reliability of waterproof LED strip lights?

Require suppliers to provide test reports for waterproof ratings (IP65/IP67/IP68), LED lifespan (typically 30,000–50,000 hours), and electrical safety (CE, UL, RoHS). QA processes should include 100% functional testing, waterproof sealing inspections, and aging tests under simulated outdoor conditions. Ask for third-party lab certifications or factory audit reports to verify claims. Insist on clear warranty terms covering waterproof failure, LED degradation, and electrical faults to minimize post-purchase risks.

-

What logistical considerations should I keep in mind when importing waterproof LED strip lights to regions like Africa, South America, the Middle East, or Europe?

Consider shipping methods—air freight is faster but costlier; sea freight is economical for bulk orders but slower. Ensure packaging is robust, moisture-resistant, and compliant with customs regulations to prevent damage during transit. Account for customs duties, import taxes, and certification requirements specific to your country. Partner with freight forwarders experienced in electronics handling and international trade compliance to avoid delays. Plan for buffer time in delivery schedules, especially during regional holidays or adverse weather seasons. -

How can I mitigate risks related to disputes or product non-conformity in international transactions for waterproof LED strip lights?

Mitigate risks by drafting clear contracts specifying product specs, IP ratings, delivery timelines, payment schedules, and dispute resolution mechanisms. Use trade assurance services or escrow payment methods when possible. Request pre-shipment inspections by third-party agencies to verify conformity before payment release. Maintain detailed records of communications, samples, and quality reports. In case of disputes, rely on international arbitration clauses or local trade bodies familiar with cross-border B2B transactions. -

Are there specific environmental or regulatory standards I should consider when sourcing waterproof LED strip lights for different international markets?

Yes, different regions enforce unique standards. For Europe, ensure compliance with CE marking, RoHS (restriction of hazardous substances), and WEEE (waste electrical and electronic equipment) directives. In the Middle East and Africa, certifications like SASO (Saudi Standards) or SONCAP (Nigeria) may apply. South American countries often require INMETRO or similar national certifications. Understanding and verifying these requirements upfront prevents customs clearance issues and ensures market acceptance. -

What trends or innovations in waterproof outdoor LED strip lighting should B2B buyers consider for competitive advantage?

Look for LED strips with advanced silicone encapsulation for enhanced durability in extreme climates common in Africa and the Middle East. Energy-efficient 24V or 48V systems reduce voltage drop for long runs in large commercial projects. Smart LED strips with remote control, color tuning, and IoT integration enable dynamic lighting solutions favored in hospitality and urban development sectors. Prioritize suppliers investing in eco-friendly materials and sustainable manufacturing to meet growing environmental regulations and customer expectations globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for outdoor led strip lights waterproof

When sourcing waterproof outdoor LED strip lights, international buyers must prioritize a balance between product quality, durability, and cost-efficiency. Understanding critical factors such as IP ratings, material composition (silicone being the premium choice), and voltage compatibility is essential to ensure optimal performance in diverse climates and installation environments. For markets in Africa, South America, the Middle East, and Europe, selecting suppliers who offer tailored solutions—whether for light rain exposure or underwater applications—can significantly reduce maintenance costs and enhance customer satisfaction.

Strategic sourcing involves thorough supplier vetting, evaluating certifications, and ensuring adherence to regional safety standards. Buyers should also consider logistics capabilities and after-sales support to mitigate risks associated with long-distance procurement. Leveraging local partnerships or distributors familiar with regional requirements can facilitate smoother transactions and faster deployment.

Looking ahead, the demand for energy-efficient, long-lasting waterproof LED strips will continue to grow alongside urban development and outdoor leisure trends worldwide. International buyers are encouraged to adopt a proactive sourcing approach—investing in innovation-driven manufacturers and sustainable materials—to future-proof their lighting projects. Embracing these strategies will position businesses to capitalize on emerging opportunities while delivering reliable, high-performance outdoor lighting solutions.