Guide to Ws2811B Led Strip

- Introduction: Navigating the Global Market for ws2811b led strip

- Understanding ws2811b led strip Types and Variations

- Key Industrial Applications of ws2811b led strip

- Strategic Material Selection Guide for ws2811b led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for ws2811b led strip

- Comprehensive Cost and Pricing Analysis for ws2811b led strip Sourcing

- Spotlight on Potential ws2811b led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ws2811b led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ws2811b led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ws2811b led strip

- Strategic Sourcing Conclusion and Outlook for ws2811b led strip

Introduction: Navigating the Global Market for ws2811b led strip

The WS2811B LED strip has rapidly become a cornerstone technology in dynamic lighting solutions across multiple industries worldwide. Its ability to offer individually addressable RGB LEDs empowers businesses to create vibrant, customizable lighting effects that enhance environments from retail spaces and hospitality venues to large-scale entertainment productions. For international B2B buyers—especially those operating in regions like Africa, South America, the Middle East, and Europe—understanding the nuances of WS2811B LED strips is essential to sourcing high-quality, cost-effective products that meet diverse application needs.

This comprehensive guide delivers an authoritative roadmap for buyers navigating the complex global market of WS2811B LED strips. It covers a wide spectrum of critical topics including the various strip types and material specifications, manufacturing standards, and quality control processes that influence product reliability. Readers will also gain insights into identifying reputable suppliers, evaluating cost structures, and analyzing regional market trends to optimize purchasing strategies. Additionally, the guide addresses frequently asked questions and common challenges to equip buyers with practical knowledge for seamless integration and long-term success.

By consolidating technical expertise with actionable market intelligence, this resource enables international B2B buyers to make informed decisions, mitigate risks, and capitalize on emerging opportunities. Whether sourcing for large-scale commercial projects or innovative custom applications, businesses in Mexico, Vietnam, and beyond will find this guide invaluable for securing WS2811B LED strips that deliver exceptional performance and value.

Understanding ws2811b led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard WS2811B LED Strip | 12V operation, individually addressable RGB LEDs, flexible PCB | Architectural lighting, retail displays, event staging | + Easy integration, cost-effective; – Limited waterproofing options |

| Waterproof WS2811B Strip | Silicone or epoxy coating, IP65 to IP68 ratings | Outdoor signage, landscape lighting, marine use | + Weather-resistant; – Slightly higher cost, reduced flexibility |

| High-Density WS2811B Strip | Increased LED count per meter (e.g., 60+ LEDs/m), brighter output | High-end decorative lighting, video walls | + Superior brightness and resolution; – Higher power consumption |

| 12V vs 24V WS2811B Variants | Voltage rating impacts power delivery and length of strip runs | Large installations requiring voltage-specific setups | + 24V supports longer runs with less voltage drop; – 12V may require more power injection points |

| Cuttable & Modular WS2811B | Designed with cut points and modular connectors for customization | Custom-fit installations, prototyping | + Flexible sizing; – Requires technical knowledge for safe cutting and re-connection |

Standard WS2811B LED Strip

This is the most common variation, operating typically at 12V with flexible PCB and individually addressable RGB LEDs. It suits indoor architectural and retail lighting where moderate brightness and easy programmability are priorities. For B2B buyers, it offers a balance of cost and performance, but waterproofing and durability may be limited for harsh environments, requiring additional protective measures.

Waterproof WS2811B Strip

Encased in silicone or epoxy, these strips provide IP65 to IP68 protection levels, making them ideal for outdoor and marine applications common in regions with variable climates such as parts of Africa and the Middle East. Buyers should consider the slightly increased cost and reduced flexibility due to the protective coating but benefit from enhanced longevity and weather resistance.

High-Density WS2811B Strip

Featuring a higher LED count per meter, these strips deliver brighter and more uniform light, suitable for premium decorative projects, video walls, and entertainment venues. B2B purchasers should weigh the higher energy consumption and heat management requirements against the superior visual impact and resolution this type provides.

12V vs 24V WS2811B Variants

Voltage choice significantly affects installation scale and efficiency. 24V strips allow longer runs with fewer power injection points, beneficial for large-scale projects across South America and Europe where infrastructure supports higher voltage. Conversely, 12V variants are easier to power but may require more complex wiring. Buyers must evaluate their power supply capabilities and installation scale carefully.

Cuttable & Modular WS2811B

These strips come with designated cut points and modular connectors, offering customization for complex layouts and prototyping. Ideal for bespoke installations in hospitality and retail sectors, buyers should ensure technical expertise in handling and reconnecting strips to avoid damage. This flexibility supports tailored solutions but requires careful planning and skilled labor.

Related Video: WS2811 VS WS2812 LED Strip Light

Key Industrial Applications of ws2811b led strip

| Industry/Sector | Specific Application of ws2811b led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment & Events | Dynamic stage and event lighting | Enhances visual impact, customizable effects, and audience engagement | Compatibility with control systems, durability for frequent use, IP rating for outdoor events |

| Retail & Hospitality | Ambient and accent lighting in stores, hotels, restaurants | Creates immersive customer experiences, boosts brand ambiance | Color accuracy, ease of installation, energy efficiency, and local voltage standards |

| Architectural & Urban Design | Façade and landscape lighting for commercial buildings and public spaces | Improves aesthetic appeal and safety, programmable for varied effects | Weatherproofing (IP65+), long lifespan, compliance with local regulations |

| Automotive & Transportation | Interior and exterior decorative lighting in vehicles and public transport | Customizable lighting schemes, enhances passenger experience and safety | Vibration resistance, power consumption, and certification for transport use |

| Advertising & Signage | Illuminated signage and digital displays | High visibility, dynamic color changes to attract customers | Brightness levels, waterproofing, and ease of integration with digital control units |

Entertainment & Events

In the entertainment sector, ws2811b LED strips are widely used for dynamic stage lighting, event decoration, and interactive displays. Their individually addressable LEDs allow for complex animations and color effects, essential for concerts, festivals, and theatrical productions. For B2B buyers in Africa, South America, the Middle East, and Europe, sourcing strips with robust build quality and compatibility with common control systems ensures reliability across diverse venues and climates. Waterproof and flexible designs are particularly valuable for outdoor events in variable weather conditions.

Retail & Hospitality

Retailers and hospitality businesses leverage ws2811b LED strips to create ambient lighting that enhances the customer experience and reinforces brand identity. These strips provide versatile color options and dimming capabilities suitable for accentuating merchandise, hotel lobbies, and restaurant interiors. International buyers should prioritize LED strips with consistent color rendering, energy efficiency, and ease of installation to minimize operational costs and adapt to local electrical standards, especially in emerging markets like Mexico and Vietnam.

Architectural & Urban Design

For architectural and urban applications, ws2811b LED strips are ideal for illuminating building façades, landscapes, and public installations. Their programmable nature allows designers to craft visually appealing light shows that can change based on time or events, improving both aesthetics and public safety. Buyers must ensure the strips meet stringent IP ratings (IP65 or higher) for weather resistance and have a long operational life to reduce maintenance in regions with harsh environmental conditions, such as the Middle East or coastal areas in Europe.

Automotive & Transportation

In automotive and transportation industries, ws2811b LED strips enhance vehicle interiors and exteriors with customizable lighting solutions. They improve passenger comfort and safety by providing adaptive lighting that can signal warnings or create mood lighting. B2B buyers should focus on sourcing strips that comply with vibration resistance standards and have certifications relevant to transport use. Power consumption efficiency is also critical to maintain vehicle energy budgets, particularly in electric and hybrid models popular in South American and European markets.

Advertising & Signage

WS2811b LED strips are extensively used in advertising for vibrant illuminated signage and dynamic digital displays. Their ability to produce bright, eye-catching colors helps businesses attract customers and communicate brand messages effectively. For international buyers, especially in regions with intense sunlight or heavy rain, sourcing LED strips with high brightness and waterproof features is essential. Additionally, compatibility with digital control units ensures seamless integration into existing advertising infrastructure, supporting rapid content updates and customization.

Related Video: How to use WS2812B RGB LED strip with Arduino | ws2811 ws2812 ws2813 ws2815 sk6812 sk9822 neopixel

Strategic Material Selection Guide for ws2811b led strip

When selecting materials for WS2811B LED strips, international B2B buyers must consider performance parameters such as durability, environmental resistance, and manufacturing feasibility. These factors are crucial to ensuring product longevity, installation flexibility, and cost-effectiveness, especially in diverse climates and regulatory landscapes across Africa, South America, the Middle East, and Europe.

Flexible PCB Substrate (Polyimide or PET)

Key Properties:

Flexible printed circuit boards (PCBs) made from polyimide or polyethylene terephthalate (PET) substrates provide the foundational layer for WS2811B LED strips. These materials offer excellent flexibility, thermal stability (up to approximately 200°C for polyimide), and electrical insulation. They also exhibit moderate resistance to moisture and chemicals, which is critical for maintaining signal integrity and LED performance.

Pros & Cons:

Polyimide substrates are highly durable and heat-resistant, ideal for applications requiring bending and shaping. PET is more cost-effective but less heat-tolerant and less chemically resistant. However, both materials can be prone to mechanical wear if exposed to harsh abrasion or repeated flexing. Manufacturing complexity is moderate, with polyimide requiring more precise handling.

Impact on Application:

Flexible substrates enable installation in curved or irregular surfaces common in architectural lighting and signage. For outdoor or humid environments, additional protective coatings or encapsulation are necessary to prevent moisture ingress. Buyers in tropical or coastal regions (e.g., parts of Africa and South America) should prioritize higher-grade polyimide substrates with protective layers.

International Considerations:

Compliance with IPC standards (e.g., IPC-2223 for flexible PCBs) is widely recognized globally. European buyers may require RoHS compliance and REACH certification for chemical safety. In the Middle East and Africa, buyers should verify UV resistance and flame retardancy per IEC 60332 standards due to harsh sunlight and safety regulations.

Silicone or PU (Polyurethane) Coating for Waterproofing

Key Properties:

Silicone and polyurethane coatings are commonly applied to WS2811B LED strips for waterproofing and environmental protection. Silicone offers excellent UV stability, flexibility, and temperature tolerance (-60°C to 200°C), while PU coatings provide robust abrasion resistance and chemical protection but with slightly lower UV resistance.

Pros & Cons:

Silicone coatings are highly durable in outdoor and marine environments, resisting salt spray and extreme temperatures. PU coatings are more cost-effective and provide a tougher surface but may degrade faster under prolonged UV exposure. Both coatings add manufacturing complexity and cost but significantly extend product life.

Impact on Application:

Waterproof WS2811B LED strips with silicone or PU coatings are ideal for outdoor architectural lighting, landscape installations, and marine applications. In regions with heavy rainfall or high humidity (e.g., Southeast Asia, parts of South America), silicone coatings are preferred for longevity.

International Considerations:

Buyers should ensure coatings meet IP65 to IP68 ratings depending on submersion requirements. Certifications such as UL 94 for flammability and ASTM D4329 for UV resistance are important for buyers in Europe and North America. In emerging markets, cost considerations may favor PU coatings, but buyers should assess trade-offs in durability.

Copper Traces and Solder Pads

Key Properties:

Copper is the standard conductive material for WS2811B LED strips, providing excellent electrical conductivity and thermal dissipation. Typical copper thickness ranges from 1 oz/ft² to 2 oz/ft², influencing current capacity and heat management.

Pros & Cons:

Copper’s high conductivity ensures efficient power delivery and signal integrity. However, it is prone to oxidation, which can degrade connections over time if not properly protected by surface finishes like ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling). These finishes add to manufacturing cost but improve corrosion resistance.

Impact on Application:

High-quality copper with protective finishes is essential for reliable long-term operation, especially in humid or corrosive environments common in coastal regions of Africa and the Middle East. Buyers targeting industrial or outdoor applications should prioritize thicker copper layers and robust surface finishes.

International Considerations:

Compliance with IPC-4552 standards for copper foil and IPC-4553 for surface finishes is critical. European and Middle Eastern buyers often require RoHS-compliant finishes. In South America and Africa, balancing cost and corrosion resistance is key, with ENIG finishes preferred for premium applications.

Adhesive Backing (Acrylic or Silicone-Based)

Key Properties:

Adhesive backing enables easy installation of WS2811B LED strips on various surfaces. Acrylic adhesives offer strong bonding, good temperature resistance (up to 80°C), and moderate moisture resistance. Silicone-based adhesives provide superior temperature tolerance (up to 200°C) and excellent UV and moisture resistance.

Pros & Cons:

Acrylic adhesives are cost-effective and suitable for indoor applications but may degrade under prolonged UV exposure or high humidity. Silicone adhesives are more expensive but ensure better performance in outdoor or industrial environments. Both adhesives must balance tackiness and removability based on installation needs.

Impact on Application:

For indoor retail or decorative lighting in Europe and urban South America, acrylic adhesives are typically sufficient. For outdoor signage or industrial installations in Africa and the Middle East, silicone adhesives prevent detachment due to heat or moisture.

International Considerations:

Buyers should verify adhesive certifications such as UL 746C for electrical insulation and ISO 9001 for quality management. Regional climatic conditions must be factored into adhesive choice, with silicone adhesives favored in high-UV or high-temperature zones.

| Material | Typical Use Case for ws2811b led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible PCB Substrate (Polyimide/PET) | Base layer for LED mounting and circuitry | High flexibility and thermal stability | PET less heat-resistant; polyimide higher cost | Medium |

| Silicone or PU Coating | Waterproofing and environmental protection | Excellent UV and moisture resistance (silicone) | PU less UV resistant; adds manufacturing complexity | Medium to High |

| Copper Traces and Solder Pads | Electrical conduction and thermal dissipation | Superior conductivity and heat management | Requires protective finish to prevent corrosion | Medium |

| Adhesive Backing (Acrylic/Silicone) | Mounting and installation on surfaces | Silicone adhesive offers high temp and UV resistance | Acrylic degrades in UV/high humidity; silicone costlier | Low to Medium |

This material selection guide equips international B2B buyers with actionable insights to optimize WS281

In-depth Look: Manufacturing Processes and Quality Assurance for ws2811b led strip

Manufacturing Processes of WS2811B LED Strips

The manufacturing of WS2811B LED strips involves a series of precise and controlled stages, ensuring the final product meets performance, durability, and customization requirements demanded by international B2B buyers.

1. Material Preparation

- Raw Materials Selection: High-quality flexible PCB substrates (usually polyimide or PET) are chosen for durability and flexibility. Copper cladding is essential for reliable electrical conductivity.

- Component Sourcing: WS2811B IC chips, RGB LEDs (SMD LEDs), resistors, and capacitors are procured from certified suppliers. Ensuring component traceability helps maintain quality and consistency.

- Pre-Inspection: Incoming Quality Control (IQC) inspects raw materials and components for defects, verifying specifications such as LED luminosity, chip functionality, and PCB integrity.

2. PCB Fabrication and Forming

- Circuit Printing and Etching: Using photolithography, copper layers on the PCB are patterned to create circuit pathways. Precision etching removes excess copper, forming the conductive tracks.

- Solder Mask Application: A protective solder mask is applied to prevent short circuits and improve durability.

- Surface Finishing: ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) finishes are applied to improve solderability and corrosion resistance.

3. Component Assembly

- Pick and Place: Automated machines place WS2811B chips and RGB LEDs onto the PCB with micron-level accuracy.

- Soldering: Reflow soldering is the standard method, melting solder paste to secure components. Controlled temperature profiles ensure solid connections without damaging sensitive components.

- Encapsulation: For waterproof or outdoor-rated strips, silicone or epoxy coatings are applied to protect against moisture and mechanical damage.

4. Finishing and Packaging

- Cutting and Segmenting: LED strips are cut into standard or custom lengths at designated solder points to fit client requirements.

- Attachment of Connectors: Power and data connectors, including JST or waterproof connectors, are affixed for ease of installation.

- Labeling and Reel Winding: Finished strips are wound on reels with protective packaging to prevent damage during shipping.

Illustrative Image (Source: Google Search)

Quality Assurance and Control (QA/QC) for WS2811B LED Strips

For B2B buyers, particularly those importing into Africa, South America, the Middle East, and Europe, understanding QC protocols and certifications is critical to ensure product reliability and regulatory compliance.

International and Industry Standards

- ISO 9001: This globally recognized standard for quality management systems ensures the manufacturer consistently delivers products meeting customer and regulatory requirements.

- CE Marking: Mandatory for European markets, CE certification confirms compliance with EU safety, health, and environmental protection legislation.

- RoHS Compliance: Restricts hazardous substances in electronics, essential for environmental regulations in Europe and increasingly adopted worldwide.

- UL Certification: Important for markets like North America and some Middle Eastern countries, UL ensures electrical safety standards.

- IP Ratings (e.g., IP65, IP67, IP68): Indicate waterproof and dustproof levels, critical for outdoor or harsh environment applications.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Verification of raw materials and components before production starts, including LED brightness and chip functionality.

- In-Process Quality Control (IPQC): Ongoing inspections during assembly, including solder joint integrity, component placement accuracy, and PCB defects.

- Functional Testing: WS2811B LED strips undergo electrical testing to verify data communication, color accuracy, and LED brightness.

- Final Quality Control (FQC): Comprehensive end-of-line testing covering visual inspection, waterproofing integrity, and performance under simulated operating conditions.

Common Testing Methods

- Electrical Testing: Checking voltage, current consumption, and data signal integrity to ensure each LED responds correctly to control inputs.

- Environmental Testing: Includes temperature cycling, humidity exposure, and UV resistance tests, especially for outdoor-rated strips.

- Mechanical Testing: Flexibility and bend tests simulate real-world installation stresses.

- Photometric Testing: Measures LED brightness, color uniformity, and color rendering index (CRI).

How B2B Buyers Can Verify Supplier Quality Control

Supplier Audits

- Factory Audits: On-site evaluations of manufacturing processes, equipment, and worker qualifications help verify adherence to ISO 9001 and other standards.

- Process Audits: Focus on production line controls, traceability systems, and QC checkpoints.

- Social Compliance Audits: Important for buyers concerned about ethical sourcing and labor standards.

Documentation and Certification Review

- Request comprehensive QC reports, including batch test results, material certificates, and compliance documents (CE, RoHS, UL).

- Verify third-party inspection certificates from recognized agencies like SGS, Intertek, or TÜV Rheinland.

Third-Party Inspections

- Engage independent inspection services for pre-shipment inspections to verify product conformity and packaging integrity.

- Random sampling tests can be arranged to evaluate product performance against specifications.

QC and Certification Nuances for International Markets

- Africa and South America: While some countries have local standards, many buyers rely on internationally recognized certifications (CE, RoHS) to ensure compatibility and safety. Import regulations may require additional customs documentation and product testing on arrival.

- Middle East: Markets such as UAE and Saudi Arabia increasingly demand UL and SASO certifications. Buyers should confirm suppliers’ ability to provide these certifications and understand regional voltage and wiring standards.

- Europe: Compliance with CE, RoHS, and REACH is mandatory. Buyers should confirm that the WS2811B LED strips meet these standards, including documentation for import clearance.

- Emerging Markets like Mexico and Vietnam: Buyers often seek suppliers who can provide flexible certifications and who understand local electrical codes and environmental regulations. Partnering with suppliers offering customization and local support adds significant value.

Key Takeaways for B2B Buyers

- Prioritize suppliers with robust ISO 9001 systems and internationally recognized certifications (CE, RoHS, UL).

- Ensure detailed QC checkpoints—IQC, IPQC, FQC—are documented and transparent.

- Leverage factory audits and third-party inspections to mitigate risks, especially when dealing with new suppliers or high-volume orders.

- Understand local regulatory requirements in target markets to avoid compliance issues and shipment delays.

- Request sample testing and photometric data to verify LED strip performance before large-scale procurement.

By thoroughly assessing manufacturing processes and quality assurance frameworks, international B2B buyers can secure reliable WS2811B LED strip products tailored to their regional market demands and application needs.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for ws2811b led strip Sourcing

Cost Components in WS2811B LED Strip Manufacturing

When sourcing WS2811B LED strips, understanding the underlying cost structure is vital for negotiating and optimizing procurement.

- Materials: The most significant cost driver includes the WS2811 integrated circuit chips, RGB LEDs, flexible PCB substrates, resistors, and protective coatings (e.g., silicone for waterproofing). High-quality raw materials with certifications like RoHS or CE often command premium prices but ensure reliability and compliance for international markets.

- Labor: Labor costs vary significantly depending on the manufacturing country and factory automation levels. Manual soldering or assembly-intensive steps increase labor expenses, especially in regions with higher wage standards.

- Manufacturing Overhead: This covers plant utilities, equipment depreciation, and indirect labor. Factories with advanced SMT lines and automated testing may have higher fixed overhead but lower per-unit costs at scale.

- Tooling and Setup: Initial costs for stencil production, PCB design tooling, and programming equipment are amortized over production runs. Custom designs or frequent product changes can increase these costs.

- Quality Control (QC): QC includes in-line inspections, functional testing, and certifications. Strips with stringent QC processes tend to have fewer defects but slightly higher prices.

- Logistics and Shipping: Costs depend on shipment mode (air, sea), packaging (bulk reels or custom boxes), and destination. International buyers from Africa, South America, the Middle East, and Europe should factor in customs duties, import taxes, and potential delays.

- Supplier Margin: Manufacturers add a margin based on production scale, competitive positioning, and order complexity.

Key Price Influencers for WS2811B LED Strip Procurement

Several factors can cause price variations in WS2811B LED strips, which buyers must evaluate carefully:

- Order Volume and MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. However, minimum order quantities (MOQ) can be high for customized strips, limiting flexibility for smaller buyers.

- Specifications and Customization: Custom lengths, pixel densities (LEDs per meter), waterproof ratings (IP65, IP67, IP68), and unique PCB designs increase costs. Addressable features requiring embedded chips also elevate pricing compared to standard RGB strips.

- Material Quality and Certifications: Certified components compliant with international standards add to cost but improve product longevity and market acceptance.

- Supplier Reputation and Location: Established suppliers with proven quality control and after-sales support may charge premiums. Geographical location affects lead times and shipping costs.

- Incoterms: Terms like FOB, CIF, or DDP influence total landed cost. Buyers should clarify responsibilities for freight, insurance, and customs clearance to avoid unexpected expenses.

Strategic Tips for International B2B Buyers

To optimize sourcing of WS2811B LED strips, international buyers—especially from regions like Africa, South America, the Middle East, and Europe—should consider the following:

- Negotiate on Volume and Payment Terms: Leverage larger consolidated orders or long-term agreements to negotiate better pricing and flexible payment options, such as letters of credit or escrow services, to reduce financial risk.

- Evaluate Total Cost of Ownership (TCO): Beyond unit price, assess costs related to shipping, customs, installation, potential failure rates, and warranty terms. Low upfront prices can be offset by higher defect rates or logistics delays.

- Request Samples and Certifications: Insist on product samples and verify certifications to ensure compliance with local regulations and quality standards before committing to bulk orders.

- Consider Local Regulations and Import Duties: Factor in import tariffs and taxes which vary widely across regions. Collaborate with freight forwarders experienced in destination markets to optimize shipping routes and costs.

- Clarify Incoterms and Delivery Schedules: Confirm clear Incoterms to understand who bears the risk and cost at each stage. For remote regions, FOB or DDP terms can significantly impact the final price and delivery reliability.

- Assess Supplier Support and After-Sales Service: Reliable technical support, warranty coverage, and spare parts availability can reduce downtime and maintenance expenses, enhancing overall cost-effectiveness.

Indicative Pricing Disclaimer

Pricing for WS2811B LED strips can fluctuate based on market conditions, raw material availability, and geopolitical factors. As of mid-2024, typical FOB prices for standard 5-meter WS2811B LED strips with 60 LEDs/m range from approximately $10 to $25 per unit, depending on specs and order size. Buyers should conduct detailed quotations and cost comparisons tailored to their specific requirements and sourcing locations.

By thoroughly analyzing cost components, understanding price influencers, and applying strategic negotiation and procurement practices, international B2B buyers can achieve cost-efficient and quality-driven sourcing of WS2811B LED strips aligned with their market needs.

Illustrative Image (Source: Google Search)

Spotlight on Potential ws2811b led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ws2811b led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ws2811b led strip

Critical Technical Properties of WS2811B LED Strip

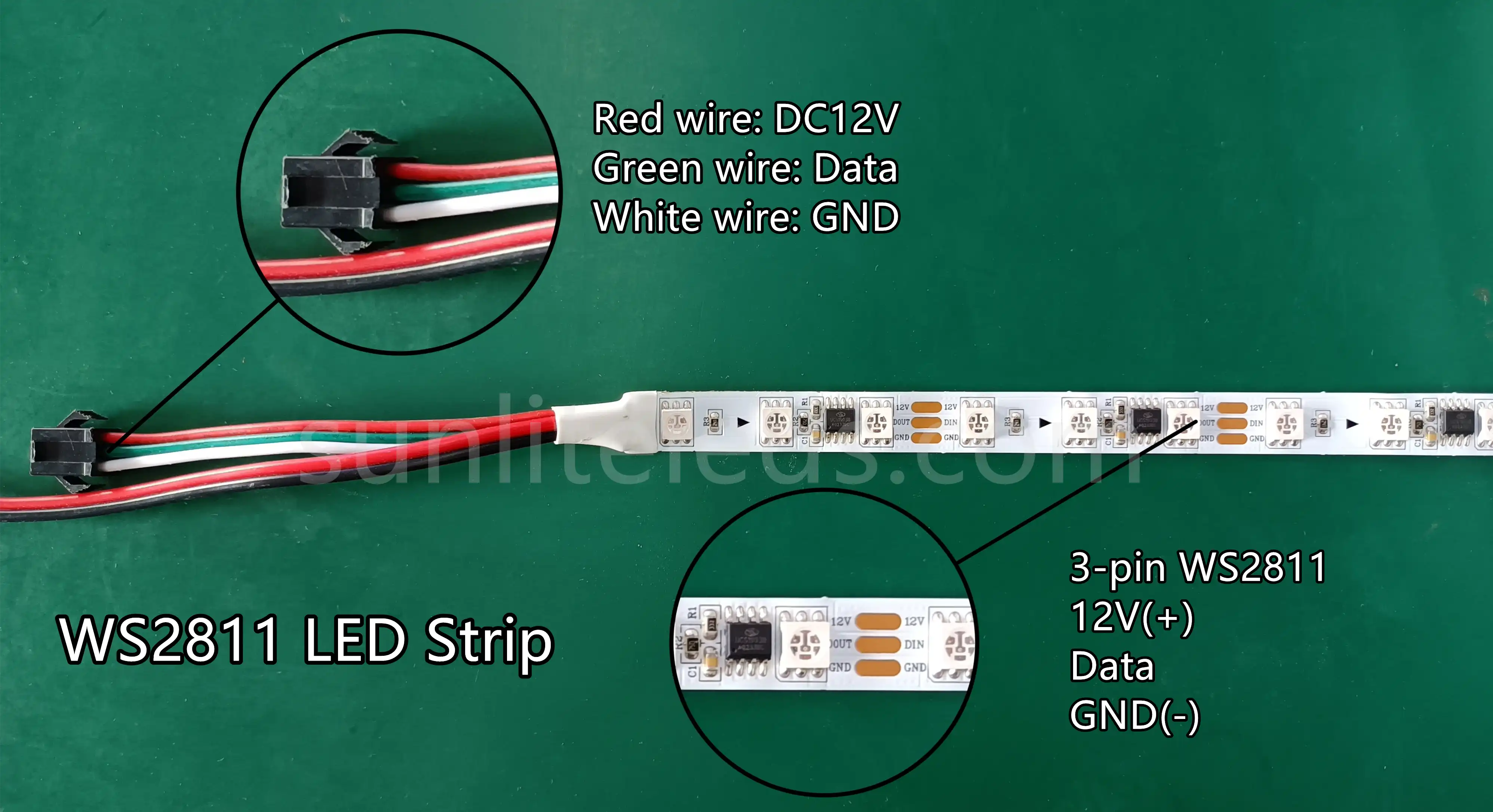

1. Voltage Rating (Typically 12V DC)

The WS2811B LED strip commonly operates at 12 volts DC, which is a crucial specification for power supply compatibility. For B2B buyers, ensuring the correct voltage rating is essential to avoid damage, optimize energy efficiency, and maintain stable performance in diverse installation environments.

2. LED Density (LEDs per Meter)

LED density, such as 30, 60, or 144 LEDs per meter, impacts brightness, resolution of lighting effects, and overall power consumption. Higher density strips offer smoother light transitions and more detailed animations but require careful power management. Buyers should select density based on application needs like decorative lighting or high-precision displays.

3. Chip Integration and Control Protocol

The WS2811B chip embedded in each LED module enables individual addressability using a one-wire digital data protocol. This property allows precise color and brightness control per LED, making it ideal for dynamic lighting projects. Understanding this helps buyers evaluate compatibility with controllers and software systems for custom programming.

4. Waterproof Rating (IP65, IP67, IP68 Options)

Waterproofing ratings define suitability for indoor versus outdoor or underwater applications. For example, IP65 offers protection against water jets, while IP68 is fully submersible. Buyers from regions with varying climates, such as humid or rainy environments in South America or the Middle East, must prioritize appropriate IP ratings to ensure product durability.

5. Material Quality and PCB Thickness

High-grade flexible PCB materials and copper thickness (e.g., 2oz copper) influence heat dissipation and strip longevity. Superior material quality reduces voltage drop and prevents premature failure. This technical factor is vital for large-scale projects requiring reliable, long-term installations in commercial or architectural settings.

6. Cuttable Segments and Solder Pads

WS2811B strips are designed with designated cut points, allowing customization of length without damaging functionality. Each segment typically includes the WS2811 chip and RGB LEDs. For international buyers, this flexibility supports tailored solutions for varied installation sizes, reducing waste and installation costs.

Key Trade Terms for International B2B Buyers

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products or components that are then branded and sold by another company. For buyers, partnering with OEMs can offer cost advantages, customization options, and control over specifications, especially when sourcing WS2811B LED strips tailored to unique market needs.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product a supplier is willing to sell. Understanding MOQ helps buyers, especially SMEs or regional distributors in Africa or Europe, plan inventory and manage cash flow effectively. Negotiating MOQ can lead to better pricing or flexible order sizes.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request detailed price and delivery information from suppliers. For international buyers, issuing an RFQ ensures transparent comparison among multiple WS2811B LED strip manufacturers, enabling informed decision-making based on cost, quality, and lead times.

Incoterms (International Commercial Terms)

Incoterms define responsibilities and risks in international shipping, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight). Knowledge of Incoterms is critical for buyers to clarify who handles shipping, customs clearance, and insurance, preventing disputes and unexpected costs in global trade.

Lead Time

Lead time indicates the period from order confirmation to product delivery. Buyers must consider lead times carefully, especially when coordinating projects across multiple countries with complex logistics. Reliable suppliers provide clear lead time estimates to align procurement with project schedules.

Batch Testing and Quality Certification

These terms refer to supplier practices of verifying product quality and compliance with standards such as CE, RoHS, or UL. For B2B buyers, especially in regulated markets like Europe, ensuring WS2811B LED strips meet certification requirements mitigates risks related to safety, import restrictions, and customer satisfaction.

By focusing on these technical specifications and trade terms, international B2B buyers can make strategic purchasing decisions that align with their operational, regulatory, and market demands for WS2811B LED strip solutions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ws2811b led strip Sector

Market Overview & Key Trends

The global market for WS2811B LED strips is driven by increasing demand for versatile, programmable lighting solutions across commercial, entertainment, architectural, and industrial sectors. These addressable RGB LED strips offer fine-grained control over lighting effects, making them popular for dynamic applications such as stage design, retail displays, smart city lighting, and interactive environments. For international B2B buyers, especially in emerging regions like Africa, South America, the Middle East, and parts of Europe (including Mexico and Vietnam), the market presents both opportunities and challenges shaped by technological innovation, price sensitivity, and evolving sourcing ecosystems.

Key global drivers include:

- Technological advancements: The WS2811B chip’s programmability with microcontrollers and compatibility with various control protocols makes it a preferred choice for customizable lighting projects.

- Growing smart infrastructure investments: Urbanization and smart city projects in emerging markets are increasing demand for energy-efficient, addressable LED lighting solutions.

- Rising demand for energy efficiency: LED strips like WS2811B consume less power than traditional lighting, appealing to buyers focusing on operational cost reduction.

- Diversification of applications: Beyond decorative lighting, these strips are increasingly integrated into signage, automotive interiors, and industrial equipment.

Emerging sourcing trends for B2B buyers:

- Supplier diversification: Buyers in Africa and South America often seek multiple suppliers from Asia (notably China and Vietnam) to mitigate risks and secure competitive pricing.

- Customization and private labeling: Vendors offering flexible production runs and custom firmware programming attract buyers aiming to differentiate their product offerings.

- Modular and scalable solutions: Demand is rising for LED strips that can be easily cut, extended, or integrated with IoT systems, facilitating scalable installations.

- Quality certifications and compliance: International buyers prioritize suppliers who provide CE, RoHS, and FCC certifications to ensure product reliability and regulatory adherence.

Navigating currency fluctuations, import tariffs, and logistics complexities remains critical, especially for buyers in regions with less developed trade infrastructure. Strategic partnerships with trusted manufacturers who offer transparent lead times and after-sales support enhance sourcing success.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable factor in the procurement of WS2811B LED strips, driven by regulatory pressures and corporate social responsibility commitments worldwide. For B2B buyers, especially those operating in environmentally conscious European markets or rapidly industrializing regions with emerging green policies, prioritizing eco-friendly sourcing adds value beyond cost considerations.

Environmental impact considerations:

- Material composition: WS2811B LED strips often contain heavy metals and electronic components that require responsible sourcing and disposal practices to minimize environmental harm.

- Energy efficiency: The inherent low power consumption of LED technology contributes to reducing carbon footprints, aligning with global sustainability goals.

- Waste reduction: Modular designs that allow cutting and reusing strips reduce electronic waste, an important criterion for sustainable product selection.

Ethical supply chain importance:

- Buyers should assess suppliers for adherence to labor standards, conflict-free sourcing of raw materials, and transparency in manufacturing processes.

- Certifications such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) provide assurance of compliance with environmental and chemical safety standards.

- ISO 14001 environmental management certification and supplier audits add further credibility to ethical sourcing claims.

Green certifications and sustainable materials:

- Some manufacturers now offer WS2811B LED strips with halogen-free, lead-free solders, and recyclable PCB substrates.

- Packaging innovations that reduce plastic use or incorporate recycled materials also contribute to sustainability goals.

- Buyers in regions with strict environmental regulations benefit from suppliers who proactively meet or exceed these standards, facilitating smoother import and market acceptance.

Integrating sustainability criteria into supplier selection not only mitigates regulatory risks but also enhances brand reputation and aligns with the growing preference of end-users for responsible products.

Brief Evolution and Historical Context

The WS2811 LED driver chip, introduced in the early 2010s, marked a significant advancement in addressable LED technology by enabling independent control of RGB LEDs on a single strip via a simple one-wire protocol. This innovation allowed for complex lighting patterns and effects previously unattainable with conventional non-addressable LED strips.

Over time, the WS2811B variant improved on the original design by enhancing signal stability, power efficiency, and integration flexibility, making it a staple component in digital lighting applications. Its widespread adoption catalyzed the proliferation of programmable LED lighting in entertainment, architectural, and consumer electronics sectors.

For B2B buyers, understanding this evolution underscores the maturity and reliability of WS2811B technology, assuring long-term availability and compatibility with a broad ecosystem of controllers and software platforms. This historical robustness supports confident sourcing decisions for projects requiring scalable and customizable lighting solutions.

Related Video: How Trump’s tariffs will impact the global economy | DW News

Frequently Asked Questions (FAQs) for B2B Buyers of ws2811b led strip

-

How can I effectively vet WS2811B LED strip suppliers from regions like Africa, South America, or the Middle East?

To vet suppliers thoroughly, begin by verifying their business licenses, manufacturing certifications, and export capabilities. Request product samples to assess quality and check compliance with international standards such as CE or RoHS. Utilize third-party inspection services to audit factories, especially when sourcing from emerging markets. Engage with references or existing clients to understand supplier reliability. Also, verify their experience with international shipping and customs processes to ensure smooth cross-border transactions. -

What customization options are typically available for WS2811B LED strips, and how can I leverage these for my market?

Most manufacturers offer customization in LED density, strip length, waterproof ratings (IP65, IP67, IP68), voltage options (5V, 12V, 24V), and color configurations. You can also request custom PCB designs, connector types, or packaging tailored to your brand. For international markets, adapting product certifications or user manuals to local languages and standards enhances market acceptance. Early engagement with suppliers about your specific technical and regulatory needs ensures customization aligns with your end-market requirements. -

What are the common MOQ (Minimum Order Quantity) and lead times I should expect when ordering WS2811B LED strips internationally?

MOQ varies widely depending on the supplier and customization level, typically ranging from 500 to 3,000 meters per order. Lead times generally span 3 to 6 weeks, factoring in production, quality checks, and shipping. For buyers in Africa, South America, or Europe, consider additional buffer time for customs clearance and inland logistics. Negotiating flexible MOQs or trial orders can be beneficial for market testing. Establish clear timelines upfront and confirm capacity during peak seasons to avoid delays. -

Which payment terms are standard in B2B transactions for WS2811B LED strips, and how can I protect my investment?

Common payment methods include T/T (Telegraphic Transfer) with 30% upfront and 70% before shipment, L/C (Letter of Credit), or escrow services. For new suppliers or markets with higher risk, using an L/C offers enhanced security by involving banks in payment guarantees. Always request proforma invoices and detailed contracts specifying product specs, delivery terms, and penalties for non-compliance. Working with reputable freight forwarders and insuring shipments further mitigates financial risk. -

What quality assurance processes and certifications should I require from WS2811B LED strip manufacturers?

Ensure suppliers provide ISO 9001 certification to confirm quality management systems. Check for product-specific certifications such as CE (Europe), RoHS (restriction of hazardous substances), FCC (US communications), or UL (safety standards). Insist on factory inspection reports and batch testing data, including LED color consistency and waterproof testing if applicable. For large or recurring orders, consider third-party lab verification to maintain consistent quality, especially critical when targeting regulated markets. -

How can I optimize logistics and shipping for WS2811B LED strip imports to Africa, South America, or the Middle East?

Choose suppliers with experience in international freight and customs clearance in your region. Prioritize suppliers who can consolidate shipments or offer multimodal shipping options (air, sea, land) to balance cost and delivery speed. Utilize Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) that suit your import capabilities and risk tolerance. Engage local customs brokers early to streamline clearance and avoid delays. Tracking shipments and maintaining clear documentation helps manage expectations and resolve issues quickly. -

What steps should I take if I encounter disputes or quality issues after receiving WS2811B LED strip shipments?

Immediately document the issue with photos and detailed descriptions. Review your contract terms regarding returns, replacements, or refunds. Communicate promptly with your supplier to seek amicable resolution, leveraging any quality guarantees or warranties. If disputes escalate, consider mediation or arbitration clauses included in your contract. Maintaining open, professional communication often leads to faster resolutions. For high-value shipments, engaging third-party dispute resolution services or local trade chambers can provide additional support. -

Are there regional considerations for WS2811B LED strip performance or compliance when selling in diverse international markets?

Yes, environmental conditions such as humidity, temperature extremes, and dust can affect LED strip durability, necessitating appropriate IP ratings (e.g., IP67 for outdoor use). Electrical standards vary—European markets commonly use 230V mains voltage, while others may use 110V or 220V—requiring compatible power supplies. Regulatory compliance differs; for instance, Europe mandates CE marking and RoHS compliance, while Middle Eastern markets may have additional certification requirements. Understanding these local factors during product selection and supplier discussions ensures market acceptance and reduces post-sale issues.

Strategic Sourcing Conclusion and Outlook for ws2811b led strip

The WS2811B LED strip stands out as a highly versatile and programmable lighting solution, ideal for diverse applications from decorative lighting to sophisticated stage designs. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding its technical features—such as individual LED addressability, energy efficiency, and ease of integration—is crucial to unlocking value in their projects.

Strategic sourcing of WS2811B LED strips should prioritize:

– Supplier reliability and certification to ensure product quality and compliance with regional standards.

– Customization capabilities, enabling tailored LED density, waterproof ratings, and voltage specifications aligned with project needs.

– Competitive pricing models combined with scalable supply to support both small and large-scale deployments.

– After-sales support and technical guidance for seamless integration and programming, particularly important for markets developing smart lighting infrastructure.

Looking ahead, the growing demand for dynamic, energy-efficient lighting solutions offers a significant opportunity. Buyers who engage proactively with manufacturers and leverage strategic partnerships will be best positioned to capitalize on emerging trends such as IoT-enabled lighting and immersive visual experiences.

Act now to build resilient supply chains and foster innovation by selecting WS2811B LED strip suppliers that align with your long-term operational and technological goals. This approach will ensure your business remains competitive and responsive to evolving market demands.