Guide to Low Profile Led Strip Lights

- Introduction: Navigating the Global Market for low profile led strip lights

- Understanding low profile led strip lights Types and Variations

- Key Industrial Applications of low profile led strip lights

- Strategic Material Selection Guide for low profile led strip lights

- In-depth Look: Manufacturing Processes and Quality Assurance for low profile led strip lights

- Comprehensive Cost and Pricing Analysis for low profile led strip lights Sourcing

- Spotlight on Potential low profile led strip lights Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for low profile led strip lights

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the low profile led strip lights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of low profile led strip lights

- Strategic Sourcing Conclusion and Outlook for low profile led strip lights

Introduction: Navigating the Global Market for low profile led strip lights

Low profile LED strip lights represent a transformative solution in modern lighting, combining sleek design with exceptional functionality. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of these lighting products is essential to meeting diverse project demands efficiently and cost-effectively. Whether outfitting commercial spaces, retail environments, or custom OEM applications, low profile LED strips deliver unobtrusive illumination that enhances aesthetics while maximizing energy efficiency and longevity.

This comprehensive guide offers a deep dive into the critical aspects of low profile LED strip lights, empowering buyers to make informed sourcing decisions. It covers the full spectrum of product types and materials, highlighting how different profiles and diffusers impact installation quality and performance. Detailed insights into manufacturing processes and quality control standards ensure buyers can evaluate supplier reliability and product durability. Additionally, the guide demystifies cost factors and market trends, providing a clear picture of competitive pricing and emerging innovations.

For buyers in regions such as Colombia, Brazil, Nigeria, UAE, and beyond, this resource addresses region-specific considerations including supply chain challenges, certification requirements, and customization options. It also answers frequently asked questions to resolve common uncertainties during procurement. By leveraging this knowledge, international buyers can confidently navigate vendor selections and tailor lighting solutions to their unique operational contexts, ultimately driving successful project outcomes with low profile LED strip lights.

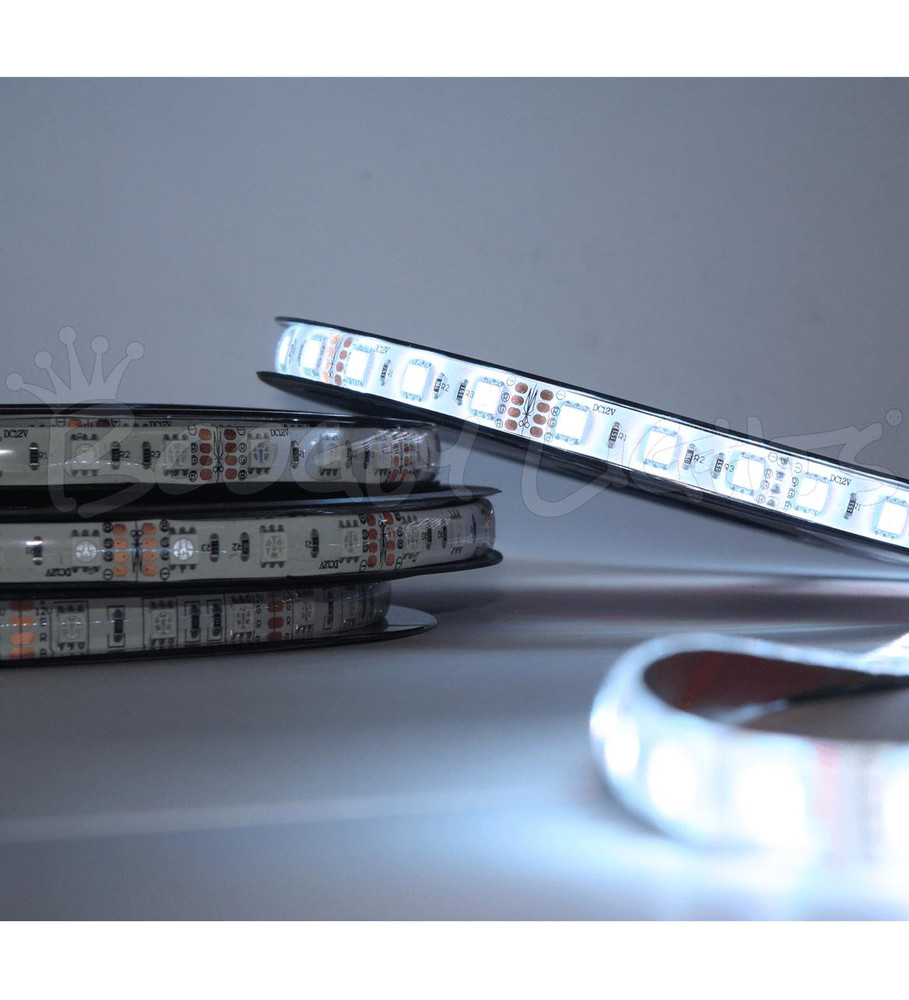

Illustrative Image (Source: Google Search)

Understanding low profile led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface-Mounted Low Profile LED Strips | Ultra-thin design, adhesive backing, exposed LED chips | Retail displays, office cove lighting, shelving | Easy installation and cost-effective; limited protection, less durable in harsh environments |

| Recessed/Flush-Mount Low Profile LED Strips | Designed for embedding into surfaces, minimal protrusion | Architectural lighting, furniture integration | Sleek aesthetic and protected LEDs; requires precise installation, higher upfront cost |

| Corner/Angle Low Profile LED Strips | Shaped to fit corners or angled surfaces, compact form factor | Staircase lighting, cabinet corners, display cases | Enables lighting in tight spaces; may require custom fittings and connectors |

| Waterproof Low Profile LED Strips | Encased in silicone or epoxy, IP65+ rated, slim profile | Outdoor signage, industrial facilities, kitchens | Durable against moisture and dust; slightly bulkier and higher price point |

| Tunable White and RGB Low Profile LED Strips | Multi-channel color control with slim profile options | Hospitality, events, customizable retail lighting | Versatile color options and ambiance control; more complex control systems and cost |

Surface-Mounted Low Profile LED Strips

These strips are characterized by their ultra-thin profiles and adhesive backing, making them ideal for quick and flexible installations on flat surfaces. They are widely used in retail shelving, office coves, and under cabinet lighting where ease of installation and cost efficiency are priorities. B2B buyers should consider their lower durability in environments with high wear or exposure, and factor in the need for additional protective housings in such cases.

Recessed/Flush-Mount Low Profile LED Strips

Recessed strips offer a clean, integrated look by being embedded into surfaces, ideal for architectural projects and premium furniture designs. Their slim form factor allows for subtle illumination without protruding elements. B2B buyers targeting high-end commercial or residential projects should plan for precise installation and potentially higher upfront costs but benefit from enhanced aesthetics and LED protection.

Corner/Angle Low Profile LED Strips

Specially designed to fit corners or angled surfaces, these LED strips maximize lighting in tight or unconventional spaces such as staircases, cabinet corners, or retail display cases. They enable innovative lighting designs where traditional strips cannot fit. Buyers should assess the need for custom connectors and installation expertise to ensure seamless integration.

Waterproof Low Profile LED Strips

Encased in waterproof materials like silicone or epoxy, these low profile strips maintain a slim profile while being protected against moisture and dust, suitable for outdoor signage, industrial environments, and kitchens. For B2B buyers in regions with humid climates or outdoor applications, these strips offer durability and safety, albeit at a higher price and slightly increased thickness.

Tunable White and RGB Low Profile LED Strips

These advanced low profile strips feature multi-channel LED control enabling adjustable white temperatures or full RGB color changing capabilities. They are popular in hospitality, event spaces, and customizable retail environments where ambiance is key. B2B buyers should consider the complexity of control systems, compatibility with dimmers or controllers, and the added value of dynamic lighting options for end users.

Related Video: THE SECRET OF GREAT LED STRIP LIGHT INSTALLS – COB

Key Industrial Applications of low profile led strip lights

| Industry/Sector | Specific Application of low profile led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in showcases and shelving | Enhances product visibility, creates attractive displays, energy-efficient | Uniform light diffusion, customizable color temperature, durability in high-traffic areas |

| Automotive Manufacturing | Interior cabin and dashboard lighting in vehicle assembly | Lightweight, space-saving illumination, improves design aesthetics and safety | Compliance with automotive standards, vibration resistance, low heat emission |

| Hospitality & Tourism | Ambient and task lighting in hotel lobbies, corridors, and rooms | Creates welcoming atmosphere, energy savings, flexible installation | Color tuning options, dimming compatibility, moisture resistance for humid climates |

| Industrial Facilities | Machine status indicators and workspace task lighting | Improves operational safety, enhances worker productivity, low maintenance | High brightness, robust housing, heat dissipation, ease of integration with control systems |

| Furniture & Interior Design | Integrated lighting in custom cabinetry and architectural features | Adds premium look, subtle illumination in tight spaces, enhances user experience | Low profile dimensions, easy installation, consistent light output, customizable lengths |

Retail & Commercial Applications

In retail environments across Africa, South America, the Middle East, and Europe, low profile LED strip lights are extensively used for accentuating products in display cabinets and shelving units. Their slim design allows installation in narrow spaces, providing uniform illumination that highlights merchandise without glare. This lighting solution solves common issues such as uneven lighting and excessive heat generation that can damage sensitive products. For international buyers, sourcing LED strips with customizable color temperatures and robust adhesive backing is critical to ensure compatibility with various display materials and climates.

Automotive Manufacturing

Low profile LED strip lights are integral in automotive manufacturing, especially for interior cabin and dashboard illumination. Their compact form factor fits seamlessly into tight vehicle spaces, offering efficient and aesthetic lighting that enhances both driver comfort and safety. Buyers from regions like Brazil and the Middle East must prioritize LED strips that meet stringent automotive industry standards, including vibration resistance and low thermal output, ensuring durability and compliance during vehicle operation and assembly line integration.

Hospitality & Tourism

Hotels and resorts leverage low profile LED strip lights to create inviting atmospheres in lobbies, corridors, and guest rooms. These lights provide both ambient and task lighting with options for dimming and color tuning, allowing establishments to tailor lighting moods and reduce energy costs. In humid or coastal regions common in Africa and South America, moisture-resistant profiles are essential to prevent corrosion and maintain longevity. International buyers should also consider dimming protocol compatibility (e.g., DALI, DMX) to integrate with existing building management systems.

Industrial Facilities

In industrial settings, low profile LED strip lights serve as machine status indicators and task lights in workstations. Their low heat emission and robust construction improve safety and operational efficiency, reducing downtime caused by lighting failures. Buyers from Europe and the Middle East often require LED strips with high brightness and excellent heat dissipation to withstand harsh factory environments. Additionally, ease of integration with control systems and maintenance accessibility are key factors to consider for sourcing.

Furniture & Interior Design

The furniture industry, especially in markets like Colombia and Europe, integrates low profile LED strip lights into custom cabinetry and architectural elements to add subtle, high-end illumination. Their slim profile enables installation in narrow grooves or recesses without compromising design aesthetics. This application demands LED strips with consistent light output and customizable lengths to fit bespoke furniture dimensions. For international B2B buyers, ensuring ease of installation and high CRI (Color Rendering Index) for true color representation is crucial for premium product appeal.

Related Video: How to Install LED Strip Lights

Strategic Material Selection Guide for low profile led strip lights

Aluminum Alloys

Aluminum alloys are the most common material choice for low profile LED strip light housings and profiles due to their excellent thermal conductivity, lightweight nature, and corrosion resistance. These alloys typically withstand operating temperatures up to 150°C, which is crucial for effective heat dissipation from high-output LED strips. Aluminum’s natural oxide layer provides good protection against corrosion, making it suitable for diverse environments including humid or coastal regions often found in parts of Africa, South America, and the Middle East.

Pros: Aluminum is easy to extrude into complex low-profile shapes, allowing for sleek designs that fit tight installation spaces. It offers excellent heat dissipation, which extends LED lifespan and maintains performance. The material is recyclable and widely accepted under international standards such as ASTM B221 and EN 755, easing import/export compliance for European and global markets.

Cons: Aluminum profiles can be more expensive than plastic alternatives and may require anodizing or powder coating for enhanced surface durability, adding to manufacturing complexity and cost. In highly abrasive or industrial environments, aluminum may dent or scratch more easily.

Application Impact: Aluminum is ideal for architectural lighting, retail displays, and OEM integrations where thermal management and aesthetics are priorities. For buyers in regions with high ambient temperatures like the Middle East or tropical South America, aluminum’s heat dissipation is particularly advantageous.

B2B Considerations: International buyers should verify compliance with regional standards such as DIN 1725 (Europe) or ASTM for aluminum alloys. Surface finishing options can be tailored to local preferences or environmental conditions, for example, UV-resistant coatings for Africa’s intense sunlight. Sourcing from suppliers with ISO 9001 certification ensures consistent quality.

Polycarbonate (PC)

Polycarbonate is a popular plastic material used mainly for LED strip light diffusers or as an alternative housing material when weight and impact resistance are critical. It offers excellent clarity and UV resistance, making it suitable for outdoor or exposed installations. Polycarbonate can typically withstand temperatures up to 115°C but has lower thermal conductivity compared to metals, which may limit its use in high-heat applications unless paired with aluminum heat sinks.

Pros: PC is lightweight, highly impact-resistant, and offers excellent optical properties for diffusers, enhancing light uniformity and reducing glare. It is easier and cheaper to mold into complex shapes compared to metals, allowing for versatile design options.

Cons: Lower thermal conductivity means it does not dissipate heat as effectively, potentially reducing LED lifespan if not properly engineered. Polycarbonate can yellow over time if exposed to intense UV without proper additives, which is a concern in sunny climates like Brazil or South Africa.

Application Impact: Best suited for decorative lighting, signage, or indoor applications where impact resistance and aesthetics are critical but heat output is moderate. It is less ideal for continuous high-output LED strips without additional thermal management.

B2B Considerations: Buyers should ensure polycarbonate materials meet local fire safety standards such as UL 94 V-0 or EN 13501-1. UV stabilization additives are recommended for outdoor use in regions with strong sunlight. Compliance with REACH and RoHS directives is important for European markets.

Silicone

Silicone is increasingly used in flexible low profile LED strip housings or coatings due to its excellent flexibility, weather resistance, and high temperature tolerance (up to 200°C). It provides superior protection against moisture, dust, and chemicals, making it ideal for harsh or outdoor environments.

Pros: Silicone’s flexibility allows for curved or irregular installations and provides excellent sealing against water ingress (IP65 to IP68 ratings achievable). It withstands extreme temperatures and UV exposure without degrading, which is advantageous for outdoor and industrial applications.

Cons: Silicone housings are generally more expensive and complex to manufacture compared to aluminum or polycarbonate. They may have lower mechanical strength and can attract dust due to static charge.

Application Impact: Ideal for outdoor, marine, or industrial lighting where environmental protection is critical. In regions with high humidity or dust such as parts of Africa or the Middle East, silicone housings ensure durability and reliability.

B2B Considerations: International buyers should confirm compliance with IEC 60529 for ingress protection and regional chemical safety regulations. Silicone’s higher cost means it is best suited for premium or specialized applications. Suppliers offering custom formulations tailored to local climates provide added value.

Stainless Steel

Stainless steel is less common but sometimes used for low profile LED strip light housings in environments demanding exceptional mechanical strength, corrosion resistance, and chemical resistance. Grades like 304 or 316 stainless steel withstand temperatures up to 800°C and resist harsh chemicals, making them suitable for industrial or marine applications.

Pros: Stainless steel is extremely durable, corrosion-resistant, and offers a premium aesthetic finish. It is ideal for applications exposed to aggressive environments, saltwater, or frequent cleaning.

Cons: It is heavier and more expensive than aluminum or plastics, and manufacturing complexity is higher due to machining or forming challenges. Thermal conductivity is lower than aluminum, which can affect heat management.

Application Impact: Best suited for industrial, marine, or outdoor architectural lighting where robustness and corrosion resistance are paramount. Less common in residential or retail due to cost and weight.

B2B Considerations: Buyers in Europe and the Middle East often require compliance with EN 10088 or ASTM A240 standards. Stainless steel’s recyclability and hygienic properties are valued in food processing or pharmaceutical sectors prevalent in international markets.

| Material | Typical Use Case for low profile led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Architectural lighting, retail displays, OEM integrations | Excellent heat dissipation, lightweight, corrosion-resistant | Higher cost than plastics, surface finishing needed for durability | Medium |

| Polycarbonate | Diffusers, indoor decorative lighting, signage | Impact resistant, excellent optical clarity, UV resistant | Lower thermal conductivity, potential yellowing under UV | Low |

| Silicone | Outdoor, marine, industrial lighting with harsh environments | Flexible, weatherproof, high temperature and UV resistance | Higher cost, manufacturing complexity, lower mechanical strength | High |

| Stainless Steel | Industrial, marine, food processing, pharmaceutical lighting | Superior durability, corrosion and chemical resistance | Heavy, expensive, lower thermal conductivity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for low profile led strip lights

Low profile LED strip lights have become essential components in commercial, architectural, and OEM lighting solutions due to their slim form factor and versatility. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding the detailed manufacturing processes and quality assurance protocols is critical to selecting reliable suppliers and ensuring product longevity and compliance.

Manufacturing Process of Low Profile LED Strip Lights

The production of low profile LED strip lights involves several carefully controlled stages, each contributing to the final product’s performance, durability, and aesthetics.

1. Material Preparation

- Flexible Printed Circuit Board (FPCB) Fabrication: The foundation of the LED strip is a flexible PCB, typically made from polyimide or polyester films. These materials provide the necessary flexibility and heat resistance for low-profile applications.

- Component Sourcing: High-quality surface-mounted device (SMD) LEDs, resistors, capacitors, and other electronic components are procured, often from certified vendors. Material traceability is important for consistent quality.

- Adhesive Backing and Protective Layers: A 3M or equivalent adhesive layer is prepared for ease of installation, alongside optional waterproof coatings (silicone or epoxy) for durability.

2. Forming and Assembly

- Surface Mount Technology (SMT) Assembly: Using automated pick-and-place machines, LEDs and other components are precisely mounted onto the flexible PCB. The SMT process ensures accurate placement critical for uniform light output.

- Reflow Soldering: After component placement, the strips pass through a reflow oven where solder paste melts and solidifies, creating strong electrical and mechanical bonds.

- Cutting and Shaping: The assembled strips are cut to standard or customized lengths. For low profile designs, careful cutting ensures minimal thickness without compromising integrity.

- Encapsulation and Coating: Depending on the application, a protective coating or encapsulant is applied to safeguard against moisture, dust, and mechanical damage, preserving the strip’s slim profile.

3. Finishing

- Integration with Profiles: Low profile LED strips are often paired with aluminum channels or specialized housings that aid heat dissipation and enhance aesthetics.

- Labeling and Packaging: Each strip is labeled with batch numbers, certifications, and electrical specifications. Packaging is designed to prevent damage during transit, often including anti-static materials.

Quality Assurance and Control Measures

Robust quality control (QC) is essential for maintaining product reliability, especially when supplying to international markets with varying regulatory requirements.

Relevant International Standards

- ISO 9001: This is the foundational quality management system standard that reputable manufacturers adhere to, ensuring consistent process control and continuous improvement.

- CE Marking: Mandatory for products entering the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical products, crucial for European and many other markets.

- UL Certification: Widely recognized in the Americas and some Middle Eastern countries, certifying electrical safety.

- Other Industry-Specific Certifications: Depending on the region, certifications such as IEC standards or local regulatory approvals may apply.

Illustrative Image (Source: Google Search)

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection and testing of raw materials and components before production begin. This includes verifying LED brightness, color temperature, and FPCB integrity.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspections, component placement accuracy, and functional electrical tests.

- Final Quality Control (FQC): Comprehensive testing of finished strips before packaging. This includes visual inspections, electrical performance, and environmental resistance tests.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and power consumption align with specifications.

- Light Performance Testing: Measures luminous intensity, color temperature, and Color Rendering Index (CRI) to ensure consistent light quality.

- Thermal Testing: Assesses heat dissipation efficiency, critical for low profile strips to avoid overheating.

- Durability and Environmental Testing: Includes moisture resistance (IP rating tests), UV exposure, and mechanical bending tests to simulate real-world conditions.

- Safety Testing: Ensures electrical insulation and fire resistance meet safety standards.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially from emerging markets or regions with stringent import regulations, verifying supplier QC practices is vital to avoid costly product failures or regulatory hurdles.

- Factory Audits: Conduct or commission third-party audits focused on manufacturing capabilities, QC procedures, and compliance with international standards.

- Request QC Documentation: Insist on receiving ISO certificates, test reports, CE declarations of conformity, RoHS compliance certificates, and UL listings where applicable.

- Third-Party Testing: Employ independent labs to validate product performance and safety prior to large orders or market entry.

- Sample Testing: Obtain samples for in-house testing to verify quality claims, particularly focusing on light output, durability, and installation compatibility.

- Supplier Transparency: Choose suppliers who provide detailed process documentation, traceability records, and are open to answering technical queries.

QC and Certification Nuances for Different International Markets

- Africa and the Middle East: Regulatory frameworks can vary widely. While CE and RoHS compliance are often accepted, buyers should verify local import requirements and consider suppliers with UL or IEC certifications to ease market entry.

- South America (e.g., Colombia, Brazil): Brazil’s INMETRO certification and Colombia’s ICONTEC standards may require additional conformity assessments. Importers should confirm these requirements early and prefer suppliers with experience exporting to these regions.

- Europe: The European Union enforces strict CE marking and RoHS directives. Buyers must ensure documentation is complete and genuine, as customs and market surveillance are rigorous.

- Cross-Regional Considerations: Voltage and dimming compatibility (e.g., 110V vs 220V systems) must be verified. Additionally, buyers should consider environmental factors such as humidity and temperature extremes that may affect product performance in their specific regions.

By understanding the detailed manufacturing processes and rigorous quality assurance measures behind low profile LED strip lights, international B2B buyers can make informed decisions, reduce risks, and secure high-quality lighting solutions tailored to their markets. Prioritizing suppliers with transparent, certified processes and robust QC protocols will ensure product reliability, compliance, and ultimately, customer satisfaction.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for low profile led strip lights Sourcing

Understanding the cost and pricing dynamics for sourcing low profile LED strip lights is essential for international B2B buyers aiming to optimize procurement strategies and total cost of ownership. This analysis breaks down key cost components, price influencers, and actionable buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Low Profile LED Strip Lights

-

Materials: The bulk of costs derive from raw materials such as LED chips (SMD LEDs), flexible printed circuit boards (FPCBs), aluminum profiles, diffusers, and adhesives. Premium materials, especially high-CRI LEDs or specialized diffusers, increase unit costs but enhance quality and longevity.

-

Labor: Manufacturing labor costs vary widely by country and supplier sophistication. Labor-intensive steps include SMT assembly, soldering, quality inspections, and packaging. Suppliers in regions with lower labor costs may offer competitive pricing but require rigorous quality checks.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor (management, maintenance). Highly automated factories reduce overhead per unit, contributing to better economies of scale.

-

Tooling and Setup: Initial tooling for custom profile extrusion or PCB assembly lines involves upfront investments. Custom designs with unique form factors or integrated features typically incur higher tooling costs, influencing minimum order quantities (MOQs).

-

Quality Control (QC): QC includes testing for electrical performance, thermal management, and compliance with certifications (e.g., CE, RoHS, UL). Suppliers investing in comprehensive QC reduce defect rates but may charge a premium reflected in pricing.

-

Logistics and Freight: International shipping, customs duties, and import taxes significantly impact landed costs. Costs fluctuate based on Incoterms, shipment volume, and transport mode (air vs. sea freight).

-

Supplier Margin: Profit margins vary by supplier type—from large OEMs to smaller contract manufacturers—and reflect brand positioning, after-sales support, and warranty terms.

Influencing Factors on Pricing

-

Order Volume and MOQ: Larger volumes typically unlock better per-unit pricing due to economies of scale. Buyers from emerging markets like Colombia or Nigeria should negotiate MOQs aligned with demand to avoid excess inventory costs.

-

Specifications and Customization: Customized color temperatures, widths, brightness levels, and integrated profiles increase unit prices. Standardized products offer cost efficiency but may limit differentiation.

-

Material Quality and Certifications: LED strip lights with verified certifications command higher prices but reduce risks related to performance and regulatory compliance in target markets.

-

Supplier Location and Capabilities: Proximity to manufacturing hubs (China, Southeast Asia) offers cost advantages but may involve longer lead times and complex logistics. European or Middle Eastern suppliers might provide faster delivery and localized support but at higher costs.

-

Incoterms: Understanding trade terms such as FOB, CIF, or DDP is critical. Buyers assuming freight and customs responsibilities (e.g., FOB) must factor these into total cost calculations.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Price: Focus on total cost of ownership including warranty, after-sales service, and potential customs clearance fees. For example, a slightly higher unit price with DDP terms may reduce unforeseen costs and delivery delays.

-

Leverage Volume Commitments: Pooling orders with partners or forecasting multi-year demand can improve bargaining power and reduce unit costs.

-

Assess Quality vs. Cost Trade-offs: Prioritize suppliers offering robust QC and certifications to avoid hidden costs associated with product failures or non-compliance penalties, especially important in regulated markets like the EU.

-

Factor in Logistics Complexity: For buyers in Africa or South America, plan for longer shipping times and potential customs bottlenecks. Opt for suppliers experienced in exporting to these regions with transparent logistics solutions.

-

Use Transparent Pricing Benchmarks: Request detailed quotations breaking down costs by materials, labor, and logistics. This clarity aids in identifying negotiation levers and cost-saving opportunities.

-

Consider Currency Fluctuations and Payment Terms: Hedging currency risk or negotiating favorable payment terms (e.g., letters of credit) can protect margins in volatile economic environments.

Disclaimer on Pricing

Pricing for low profile LED strip lights varies widely based on specifications, order size, and supplier factors. The figures discussed herein are indicative and should be validated through direct supplier engagement and market research tailored to specific project requirements.

By comprehensively understanding these cost drivers and market nuances, international B2B buyers can strategically source low profile LED strip lights that balance quality, price, and supply chain reliability to meet their operational and commercial goals.

Spotlight on Potential low profile led strip lights Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘low profile led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for low profile led strip lights

Critical Technical Properties of Low Profile LED Strip Lights

1. Profile Height and Width

Low profile LED strip lights are defined by their slim form factor, typically with a profile height ranging from 5mm to 10mm. This compact size enables seamless integration into tight spaces such as under cabinets, display cases, or architectural coves. For B2B buyers, verifying the exact dimensions is crucial to ensure compatibility with existing fixtures or custom installations, especially when working with OEMs or product designers requiring discreet lighting solutions.

2. Material Grade and Thermal Conductivity

The aluminum or polycarbonate materials used for LED profiles must offer high thermal conductivity to dissipate heat effectively. Efficient heat management prolongs LED lifespan and maintains consistent light output, reducing maintenance costs. Buyers should request detailed material specifications, including anodized aluminum grades or impact-resistant plastics, to ensure durability under varying environmental conditions common in commercial or industrial settings.

3. IP Rating (Ingress Protection)

The IP rating indicates the strip light’s resistance to dust and moisture. Low profile LED strips often range from IP20 (indoor, dry environments) to IP65 or higher for damp or outdoor applications. Understanding the required IP rating helps buyers select products that meet safety and durability standards in specific markets, such as humid climates in South America or dusty environments in parts of Africa and the Middle East.

4. Lumen Output and Color Temperature

Lumen output measures the brightness of the LED strip, while color temperature (expressed in Kelvin) defines the light’s warmth or coolness. For commercial buyers, selecting strips with appropriate lumen density (e.g., 300-1000 lm/meter) and color temperatures (2700K warm white to 6500K daylight) is essential to create desired atmospheres and comply with regional lighting standards or client preferences.

5. Dimming and Control Compatibility

Low profile LED strips often support multiple dimming protocols such as PWM, 0-10V, DALI, or DMX512. Compatibility with these control systems allows integration into smart building management or customized lighting scenarios, which is increasingly demanded in modern commercial and hospitality projects. Buyers should confirm dimming compatibility upfront to avoid costly retrofits or system incompatibilities.

6. Cut and Connection Points (Tolerance and Customization)

The ability to cut strips at precise intervals and connect segments without compromising performance is vital for flexible installation. Manufacturers usually specify cut points in millimeters and provide connectors or solder pads. Understanding these tolerances ensures that buyers can design custom lengths and shapes without waste or technical issues, a key factor in complex architectural or OEM lighting projects.

Common Industry and Trade Terminology for LED Strip Light Buyers

OEM (Original Equipment Manufacturer)

An OEM is a company that integrates LED strips into its own products or fixtures. For B2B buyers, working with OEMs means collaborating on customized lighting solutions tailored to specific applications, often requiring minimum order quantities and design input.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest batch size a supplier will accept for production or sale. Knowing the MOQ helps buyers plan inventory and budget, especially in markets where smaller orders are preferred due to budget constraints or pilot testing before scaling.

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers to obtain detailed pricing, specifications, and delivery terms for a product. B2B buyers use RFQs to compare vendors, negotiate better terms, and ensure the product meets technical and commercial requirements before purchase.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms is essential for international buyers in Africa, South America, the Middle East, and Europe to manage logistics costs and risks effectively.

CRI (Color Rendering Index)

CRI measures how accurately a light source reveals the colors of objects compared to natural light. A high CRI (above 80) is often required in retail, hospitality, and design projects to ensure vibrant, true-to-life colors, influencing buyer decisions in markets focused on quality aesthetics.

FPCB (Flexible Printed Circuit Board)

The FPCB is the flexible substrate on which LEDs and electronic components are mounted. Its quality affects the strip’s flexibility, durability, and electrical performance. Buyers should inquire about FPCB specifications to ensure the product meets installation and longevity demands.

By understanding these key technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and ensure successful integration of low profile LED strip lights into diverse commercial and industrial projects worldwide.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the low profile led strip lights Sector

Market Overview & Key Trends

The global market for low profile LED strip lights is experiencing robust growth, driven by increasing demand for energy-efficient, versatile lighting solutions in commercial, residential, and industrial sectors. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—this market presents compelling opportunities shaped by rapid urbanization, infrastructure development, and rising consumer awareness about smart lighting technologies.

Key market drivers include the growing adoption of LED lighting for architectural and retail applications, where low profile strips offer discreet, flexible illumination options. In regions like Colombia and Brazil, expanding retail and hospitality sectors are fueling demand for customizable, aesthetically pleasing lighting solutions that integrate easily with modern interiors. Similarly, Middle Eastern markets show strong interest in premium LED profiles that enhance heat dissipation and durability, essential for harsh climatic conditions.

Emerging sourcing trends emphasize customization and modularity, enabling buyers to specify length, color temperature, and dimming capabilities to suit diverse projects. The integration of smart controls such as DMX and DALI dimming systems is becoming a standard expectation, facilitating energy management and ambiance control in commercial installations. Additionally, buyers are increasingly favoring suppliers who provide comprehensive technical support and turnkey solutions, including aluminum profiles and diffusers that enhance both functionality and safety.

Market dynamics also reflect a shift towards localized supply chains to mitigate risks linked to global disruptions. African and South American buyers, in particular, benefit from regional partnerships that reduce lead times and import costs. European buyers demand strict compliance with quality and safety standards, driving suppliers to enhance product certifications and testing rigor. Across all regions, the trend towards LED strips with higher lumen output and longer lifespans positions low profile LED strips as cost-effective, sustainable lighting investments.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical criterion for B2B buyers of low profile LED strip lights, as businesses seek to reduce environmental impact and align with global green initiatives. The production and disposal of LED components, including circuit boards and aluminum profiles, have significant environmental footprints that conscientious buyers must address.

Ethical sourcing involves selecting manufacturers who prioritize responsible material procurement, waste reduction, and energy-efficient manufacturing processes. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), and Energy Star compliance serve as reliable indicators of a supplier’s commitment to environmental stewardship. Buyers in Europe and the Middle East often mandate these certifications to ensure compliance with stringent regional regulations.

Material selection is also pivotal; aluminum profiles used for low profile LED strips should be recyclable and produced with minimal carbon emissions. Advances in diffuser technology that reduce glare and improve light diffusion contribute to better energy efficiency and user comfort, reinforcing sustainability goals.

Moreover, adopting circular economy principles—such as designing LED strips for easy disassembly and repair—can extend product life cycles and reduce electronic waste. For buyers in emerging markets like Africa and South America, partnering with suppliers who offer take-back or recycling programs helps build sustainable supply chains while supporting local environmental initiatives.

Ultimately, integrating sustainability into procurement decisions not only enhances corporate social responsibility profiles but also drives operational cost savings through energy efficiency and reduced maintenance.

Evolution and Historical Context

Low profile LED strip lights have evolved significantly over the past two decades, transitioning from basic, single-color tape lights to highly sophisticated, customizable lighting solutions. Initially popularized for accent and decorative lighting, advances in LED technology and flexible printed circuit boards (FPCBs) enabled the development of ultra-thin, low profile designs that suit tight installation spaces.

The integration of aluminum profiles revolutionized the sector by addressing heat dissipation and durability challenges, making LED strips viable for professional architectural and commercial applications. As dimming technologies and color tuning capabilities matured, LED strip lights found widespread adoption in retail, hospitality, and OEM product integration, where precise lighting control and aesthetic appeal are paramount.

Today, the sector’s focus on modularity, smart connectivity, and sustainability reflects broader industry trends towards intelligent, eco-friendly lighting solutions. This evolution offers international B2B buyers access to highly adaptable products that meet diverse technical and environmental requirements across global markets.

Related Video: Benefits of International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of low profile led strip lights

-

How can I effectively vet suppliers of low profile LED strip lights for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications relevant to LED manufacturing and export (e.g., ISO, CE, RoHS). Request samples to assess product quality and consistency. Check their experience with international markets, especially in Africa, South America, the Middle East, and Europe, and ask for client references in these regions. Evaluate their communication responsiveness and willingness to provide technical documentation. Using third-party inspection or audit services before finalizing contracts can further mitigate risks and ensure supplier reliability. -

What customization options are typically available for low profile LED strip lights, and how should I approach them?

Customizations often include LED color temperature, brightness, CRI, strip length, width, adhesive backing, and IP rating for water resistance. Some suppliers offer custom PCB layouts and specific dimming capabilities (PWM, DALI, DMX). Clearly define your project requirements upfront and request a detailed technical proposal. Discuss minimum order quantities (MOQs) for custom specs, as they tend to be higher. Ensure the supplier can provide prototypes or samples for approval before mass production to avoid costly errors. -

What should I know about minimum order quantities (MOQs), lead times, and payment terms when sourcing low profile LED strip lights internationally?

MOQs vary widely based on customization and supplier scale but typically start from a few hundred meters. Lead times can range from 3 to 8 weeks, depending on order complexity and current production schedules. Negotiate payment terms carefully; common arrangements include 30% upfront deposit with balance upon shipment or letter of credit for higher-value orders. Always confirm lead times and payment conditions in your purchase agreement to avoid delays or disputes. Plan your inventory and cash flow accordingly to accommodate these timelines. -

Which quality assurance certifications and tests should I require from suppliers of low profile LED strip lights?

Demand compliance with international quality and safety standards such as CE (Europe), RoHS (hazardous substances), UL or ETL (North America), and IEC standards relevant to electrical products. Request test reports for lumen output, color consistency, lifespan (typically up to 50,000+ hours), and IP rating if applicable. Verify that the supplier conducts in-house quality control at multiple production stages, including SMT assembly and final inspection. Independent third-party testing can add assurance and support compliance with local import regulations. -

What are the best practices for managing logistics and shipping for international orders of low profile LED strip lights?

Choose suppliers experienced with international freight forwarding and customs clearance in your target region. Confirm packaging standards to prevent damage during transit, such as moisture-proof and anti-static packaging. Opt for air freight for urgent orders and sea freight for cost efficiency on large volumes. Clarify Incoterms (e.g., FOB, CIF, DDP) to understand cost and responsibility allocation. Collaborate with reliable local customs brokers to ensure smooth import processes, especially in regions with complex regulations like Africa and South America. -

How can I handle disputes related to product quality or shipment delays with overseas suppliers?

First, maintain clear, documented communication throughout the transaction. If issues arise, request photographic or video evidence and involve third-party inspection agencies if needed. Refer to your contract’s dispute resolution clause, which may include negotiation, mediation, or arbitration under an agreed jurisdiction or international trade body (e.g., ICC). Consider using escrow services or trade finance instruments to protect payment until satisfactory delivery. Establishing long-term partnerships with trusted suppliers reduces the likelihood of disputes.

-

Are there regional considerations for sourcing low profile LED strip lights in markets like Africa, South America, the Middle East, and Europe?

Yes, regional factors include import tariffs, certification requirements, electrical standards (voltage and frequency), and climate conditions affecting IP ratings. For example, tropical regions require higher moisture resistance, while Europe mandates strict RoHS compliance. Logistics infrastructure and customs efficiency vary greatly; some African and South American countries have longer clearance times. Engage suppliers familiar with these markets or local agents to navigate regulations and adapt products accordingly for smooth market entry. -

What payment methods are recommended for secure international transactions when buying low profile LED strip lights?

Common secure payment methods include letters of credit (LC), which protect both buyer and seller by releasing funds only after meeting contract terms. Escrow services and verified trade platforms also add security. Wire transfers (T/T) are popular but riskier if used without established trust. Avoid full upfront payments unless you have a longstanding relationship. For new suppliers, negotiate partial deposits with balance upon shipment or delivery verification. Always confirm banking details to prevent fraud and maintain transparent financial records.

Strategic Sourcing Conclusion and Outlook for low profile led strip lights

Key Insights for Strategic Sourcing of Low Profile LED Strip Lights

For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, sourcing low profile LED strip lights strategically is critical to achieving competitive advantages. These lighting solutions offer exceptional flexibility, enhanced heat dissipation through aluminum profiles, and customizable options that meet diverse project requirements—from retail and hospitality to OEM integrations. Prioritizing suppliers who provide tailored LED strips with reliable quality control and advanced dimming capabilities ensures longevity and superior performance in your installations.

Why Strategic Sourcing Matters

- Quality and Reliability: Opt for manufacturers with proven expertise in SMT assembly and rigorous testing to avoid costly downtime and replacements.

- Customization and Compliance: Choose suppliers offering bespoke options for color temperature, CRI, voltage, and form factor that align with regional standards and application needs.

- Supply Chain Resilience: Establish relationships with manufacturers capable of consistent delivery and flexible production schedules to mitigate risks in fluctuating markets.

Looking Ahead

As global demand for energy-efficient, space-saving lighting solutions grows, low profile LED strip lights will play an increasingly vital role in modern infrastructure and product design. International buyers should embrace strategic partnerships that emphasize innovation, sustainability, and adaptability. By doing so, businesses in Colombia, Brazil, the Middle East, Africa, and Europe can secure high-quality, cost-effective lighting solutions that drive growth and differentiation in their markets.

Take Action: Evaluate your current sourcing strategy today and engage with suppliers who understand your regional market dynamics and can support your evolving lighting needs with cutting-edge, customizable low profile LED strip solutions.