Introduction: Navigating the Global Market for solar led strip lights

Solar LED strip lights represent a transformative innovation in energy-efficient lighting solutions, combining the versatility of LED technology with sustainable solar power. For international B2B buyers across Africa, South America, the Middle East, and Europe—including emerging markets like Turkey and Vietnam—these products offer unmatched opportunities to reduce operational costs, enhance environmental responsibility, and meet growing demand for off-grid and green lighting applications.

This comprehensive guide is designed to equip procurement professionals and business leaders with the critical knowledge needed to navigate the complex global marketplace of solar LED strip lights. It covers key product types, from waterproof and RGB options to high-lumen task lighting, along with in-depth insights into materials and manufacturing processes that directly impact quality and longevity. Buyers will also find expert analysis on quality control standards, supplier selection strategies, and cost considerations tailored to large-scale projects and diverse regional requirements.

By exploring market trends, sourcing best practices, and common challenges, this guide empowers businesses to make informed, strategic purchasing decisions that align with their operational goals and sustainability commitments. Whether upgrading commercial spaces, outfitting remote installations, or expanding product portfolios, readers will gain actionable insights to secure reliable suppliers, optimize supply chains, and maximize value in the evolving solar LED strip light sector.

Key benefits for B2B buyers include:

- Understanding the impact of component quality on performance and durability

- Accessing the latest technology innovations and customization options

- Streamlining procurement through vetted global suppliers

- Balancing cost-efficiency with compliance and warranty assurance

Armed with this knowledge, international buyers can confidently harness the potential of solar LED strip lights to illuminate their projects sustainably and profitably.

Understanding solar led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Solar LED Strip Lights | Bendable PCB with integrated solar cells and LEDs; lightweight and adaptable | Outdoor decorative lighting, signage, landscape lighting | Pros: Easy installation on uneven surfaces, versatile; Cons: May have lower durability in harsh weather without protection |

| Rigid Solar LED Strip Lights | Solid PCB with mounted solar panels and LEDs; robust and durable | Industrial outdoor lighting, security perimeters, large-scale installations | Pros: High durability, stable performance; Cons: Less adaptable to curved surfaces, heavier |

| Waterproof Solar LED Strip Lights | Encased in waterproof silicone or epoxy coating; IP65/IP67 rated | Outdoor environments, garden lighting, street lighting | Pros: Weather-resistant, long-lasting outdoors; Cons: Slightly higher cost, limited flexibility |

| RGB Solar LED Strip Lights | Multi-color LEDs with solar power; often includes remote or app control | Retail displays, event lighting, hospitality venues | Pros: Dynamic lighting effects, energy-saving; Cons: More complex installation, higher upfront cost |

| High-Lumen Solar LED Strip Lights | High brightness LEDs powered by efficient solar panels | Task lighting in commercial or industrial sites, warehouses | Pros: Bright illumination, energy-efficient; Cons: Requires larger solar panels, higher price point |

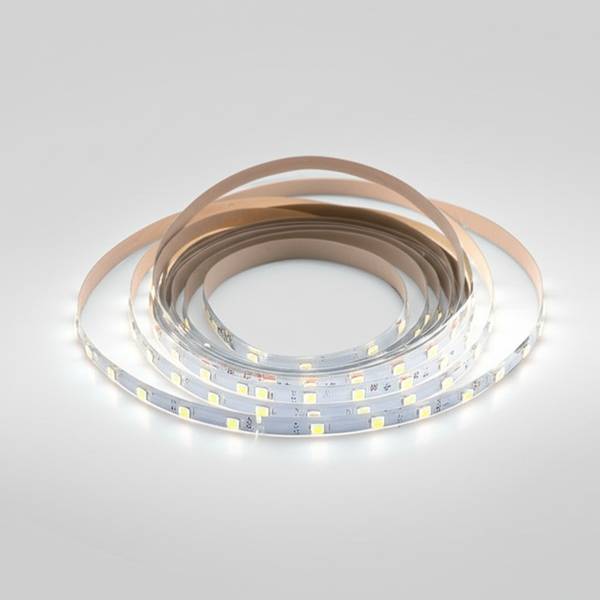

Flexible Solar LED Strip Lights

These strips feature a bendable printed circuit board (PCB) embedded with solar cells and LEDs, allowing installation on curved or irregular surfaces. Their lightweight design makes them ideal for outdoor decorative lighting, signage, and landscaping projects. For B2B buyers, flexibility facilitates diverse applications but requires consideration of protective coatings to enhance durability in harsh climates common in regions such as Africa and the Middle East. Bulk orders should prioritize suppliers offering customizable lengths and adhesive backing suitable for outdoor use.

Rigid Solar LED Strip Lights

Rigid solar LED strips use a solid PCB that provides enhanced durability and stability, making them well-suited for industrial outdoor lighting and security perimeter applications. These strips perform reliably in demanding environments and are favored in large-scale projects across Europe and South America where robustness is critical. Buyers should evaluate the weight and mounting options, ensuring compatibility with existing infrastructure and considering long-term maintenance costs.

Waterproof Solar LED Strip Lights

Encased in waterproof materials with IP65 or IP67 ratings, these strips are designed specifically for wet and exposed environments. They are popular for garden lighting, street illumination, and outdoor commercial spaces. For B2B procurement, waterproof rating certifications and material quality are key to minimizing returns and ensuring longevity in markets with heavy rainfall or humidity, such as parts of Southeast Asia and coastal regions.

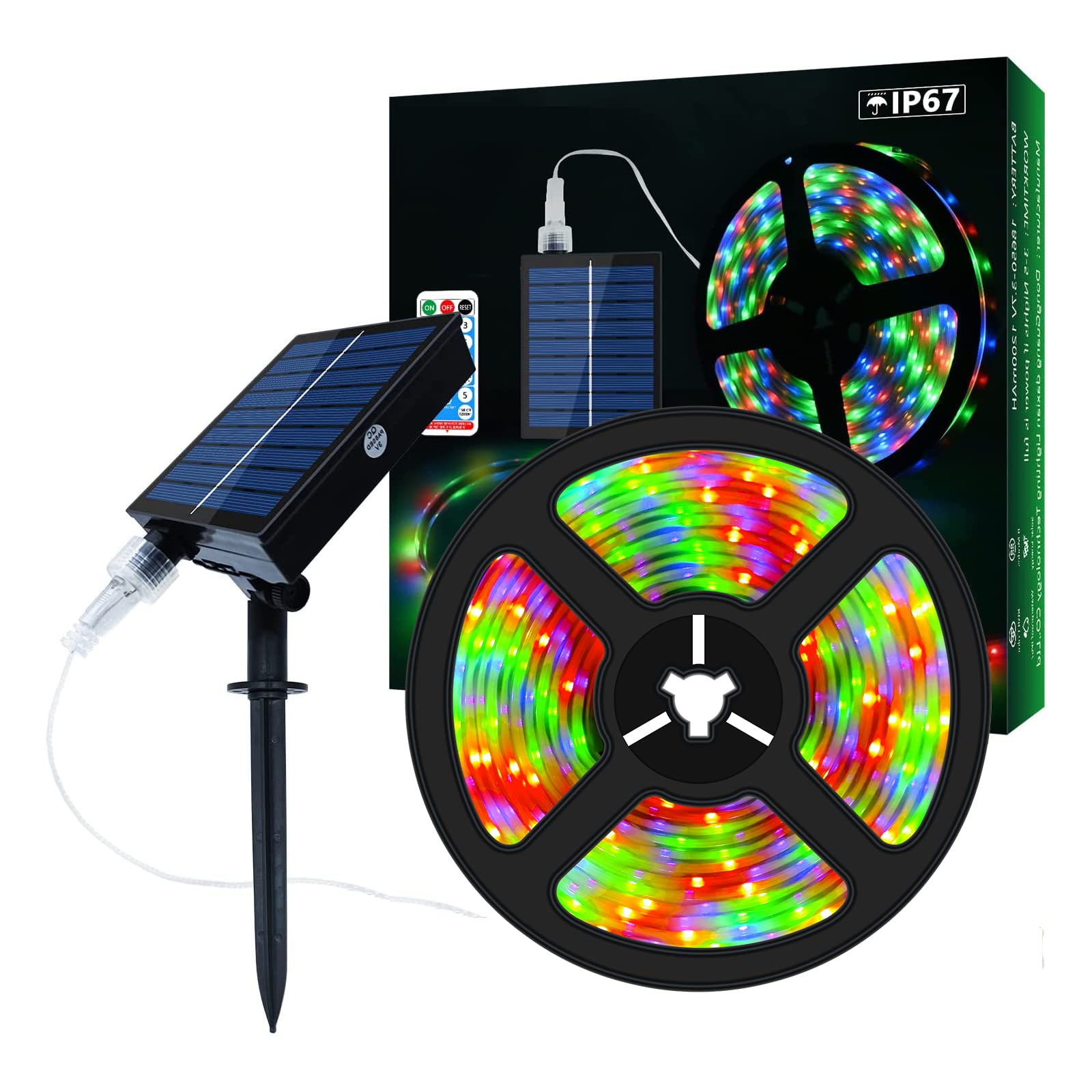

RGB Solar LED Strip Lights

RGB solar LED strips integrate multi-color LEDs powered by solar energy, often controllable via remote or smart apps. These are particularly attractive for retail displays, event venues, and hospitality sectors seeking dynamic lighting effects combined with energy efficiency. Buyers should consider the complexity of installation, the availability of control systems, and the potential for customization to align with brand aesthetics or event themes.

High-Lumen Solar LED Strip Lights

Designed for high brightness output, these strips utilize efficient solar panels and powerful LEDs to provide task lighting in commercial and industrial settings like warehouses or outdoor workspaces. They require larger solar panels and may come at a higher price point, but deliver superior illumination and energy savings. B2B buyers targeting operational efficiency should balance upfront investment with long-term cost benefits and ensure supplier warranties cover performance guarantees.

Related Video: Transform Your Outdoor Space: Solar Powered Strip Lights by Luhlee

Key Industrial Applications of solar led strip lights

| Industry/Sector | Specific Application of Solar LED Strip Lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Greenhouse and farm perimeter lighting | Enhances crop growth cycles with supplemental lighting; reduces energy costs and wiring complexity in remote areas | Durability against moisture and dust, high IP rating, reliable solar battery capacity for continuous night use |

| Outdoor Retail & Markets | Illuminating stalls, signage, and walkways in open-air markets | Improves visibility and customer safety while leveraging off-grid power to reduce operational costs | Weatherproof design, ease of installation, and modular length options for varied setups |

| Construction & Mining | Temporary site lighting and safety demarcation | Provides flexible, portable lighting solutions that reduce reliance on grid power and generators | Robust build for harsh environments, quick deployment features, and solar panel efficiency in low sunlight conditions |

| Hospitality & Tourism | Outdoor ambiance lighting for resorts, parks, and pathways | Creates attractive, energy-efficient lighting that enhances guest experience and lowers electricity bills | Customizable color and brightness, integration with smart controls, and compliance with local lighting regulations |

| Transportation & Logistics | Solar LED strip lights for loading docks, parking lots, and signage | Increases operational safety and visibility in off-grid or remote locations, reducing infrastructure costs | Long battery life, consistent light output, and strong adhesive backing for varied surfaces |

Agriculture

Solar LED strip lights are increasingly used in greenhouses and farm perimeters to provide supplemental lighting that supports plant growth cycles, especially in regions with limited daylight. For international buyers from Africa and South America, where rural farms may lack reliable grid access, solar-powered solutions reduce energy costs and eliminate complex wiring. Key requirements include high IP ratings for moisture resistance and durable solar batteries capable of powering lights through extended cloudy periods.

Outdoor Retail & Markets

Open-air markets and retail stalls in the Middle East and parts of Europe benefit from solar LED strip lights to illuminate walkways, signage, and vendor spaces. These lights enhance customer safety and extend operating hours without increasing electricity expenses. Buyers should prioritize weatherproof designs and modular lengths to adapt to diverse stall sizes and layouts, facilitating easy installation and maintenance in busy commercial environments.

Construction & Mining

In construction sites and mining operations, solar LED strip lights serve as temporary lighting and safety markers. Their portability and off-grid functionality reduce dependence on noisy generators and complex electrical setups, a critical advantage in remote or undeveloped locations common in Africa and Vietnam. Durable casings resistant to dust and impact, along with efficient solar panels optimized for low-light conditions, are essential sourcing criteria for these demanding applications.

Hospitality & Tourism

Solar LED strip lights are widely adopted in outdoor hospitality settings such as resorts, parks, and walking paths to create inviting atmospheres while minimizing electricity consumption. For businesses in Europe and the Middle East focusing on sustainability, these lights offer customizable colors and brightness levels that can be integrated with smart control systems. Compliance with local lighting standards and aesthetic flexibility are important considerations for procurement.

Transportation & Logistics

Loading docks, parking areas, and signage in logistics hubs often require reliable lighting in locations where grid access is limited or costly. Solar LED strip lights provide a cost-effective, energy-independent solution that enhances safety and operational efficiency. Buyers from diverse regions should look for products with long battery life, consistent brightness, and strong adhesive backing to withstand varied surfaces and outdoor conditions.

Related Video: DIY Solar Shed Lighting! Affordable LED Setup

Strategic Material Selection Guide for solar led strip lights

When selecting materials for solar LED strip lights, B2B buyers must carefully evaluate the components to ensure durability, efficiency, and compliance with regional standards. The choice of materials directly influences the product’s performance in diverse environmental conditions, cost-effectiveness, and suitability for specific applications. Below is a detailed analysis of four common materials used in solar LED strip lights, focusing on their key properties, advantages, limitations, and considerations for international buyers from Africa, South America, the Middle East, and Europe.

1. Flexible Polyimide (PI) PCB Substrate

Key Properties:

Polyimide is a high-performance polymer known for excellent thermal stability (up to 260°C), chemical resistance, and mechanical flexibility. It withstands UV exposure and resists moisture penetration, making it ideal for outdoor solar lighting applications.

Pros & Cons:

– Pros: Superior heat resistance enhances LED lifespan by efficient heat dissipation; flexibility allows installation on curved or irregular surfaces; excellent electrical insulation.

– Cons: Higher manufacturing complexity and cost compared to standard materials; requires specialized handling during production.

Impact on Application:

PI substrates are well-suited for solar LED strips installed on curved surfaces such as poles, awnings, or vehicle exteriors. Their resistance to environmental stressors ensures long-term reliability in harsh climates, including high UV regions like the Middle East and parts of Africa.

B2B Buyer Considerations:

Buyers in regions with intense sunlight and temperature fluctuations (e.g., Middle East, South America) should prioritize PI substrates for durability. Compliance with ASTM D3350 (for polymer materials) and IEC 61215 (for solar-related components) is critical. While costlier, the long-term savings in maintenance and replacements justify investment.

2. Rigid FR4 PCB Material

Key Properties:

FR4 is a glass-reinforced epoxy laminate with good mechanical strength, moderate heat resistance (~130°C), and excellent electrical insulation. It is widely used in electronics due to its cost-effectiveness and ease of manufacturing.

Pros & Cons:

– Pros: Low cost and widely available; stable mechanical properties; easy to manufacture in large volumes.

– Cons: Limited flexibility restricts use to flat surfaces; lower thermal tolerance can reduce LED lifespan under high heat; less resistant to moisture ingress compared to flexible substrates.

Impact on Application:

FR4 is ideal for solar LED strip lights in fixed, flat installations such as solar panel edges or outdoor signage in temperate climates. It is less suitable for flexible or curved applications and harsher environments with high humidity or temperature extremes.

B2B Buyer Considerations:

For buyers in Europe and parts of South America where installation surfaces are typically flat and climate is moderate, FR4 offers a cost-effective solution. Ensure suppliers provide compliance with EN 61000 (electromagnetic compatibility) and RoHS directives common in these markets.

3. Silicone-Based Adhesive Backing

Key Properties:

Silicone adhesives offer excellent temperature resistance (-60°C to 230°C), UV stability, and strong adhesion on various substrates including metals and plastics. They maintain flexibility and adhesion over long periods, even in outdoor conditions.

Pros & Cons:

– Pros: High durability under extreme temperatures; resistant to moisture and chemical exposure; excellent for outdoor and industrial applications.

– Cons: Higher cost than acrylic adhesives; may require specialized surface preparation for optimal bonding.

Impact on Application:

Silicone adhesive backing is crucial for solar LED strip lights exposed to outdoor elements, especially in regions with high heat and humidity like Africa and the Middle East. It prevents peeling and ensures stable installation on diverse surfaces including textured or curved ones.

B2B Buyer Considerations:

Buyers should verify adhesive certifications such as ASTM D1000 (pressure-sensitive tapes) and consider local climate conditions. Silicone adhesives are preferred where long-term outdoor durability is a priority despite their higher price point.

4. Aluminum Heat Sink Channels

Key Properties:

Aluminum offers excellent thermal conductivity (around 205 W/m·K), corrosion resistance (especially when anodized), and lightweight strength. It efficiently dissipates heat from LEDs, preventing overheating and prolonging lifespan.

Pros & Cons:

– Pros: Enhances LED efficiency and reliability; protects LED strips physically; lightweight and corrosion-resistant.

– Cons: Adds to overall product cost and weight; requires precise manufacturing to fit LED strips.

Impact on Application:

Aluminum channels are essential for solar LED strip lights in high-temperature environments or where prolonged illumination is required, such as commercial outdoor lighting in Europe and South America. They also facilitate easier mounting and maintenance.

B2B Buyer Considerations:

International buyers should ensure aluminum channels meet ASTM B221 or EN 755 standards for extrusion quality. Anodized finishes are recommended for corrosion resistance in humid or coastal regions like parts of Africa and the Middle East.

Summary Table of Materials for Solar LED Strip Lights

| Material | Typical Use Case for solar led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Polyimide (PI) PCB | Curved or irregular outdoor surfaces requiring durability | High thermal stability and flexibility | Higher manufacturing complexity and cost | High |

| Rigid FR4 PCB | Flat installations in moderate climates | Low cost and ease of manufacturing | Limited flexibility and lower heat tolerance | Low |

| Silicone-Based Adhesive Backing | Outdoor applications needing strong, durable adhesion | Excellent temperature and UV resistance | More expensive than standard adhesives | Medium |

| Aluminum Heat Sink Channels | Heat dissipation and physical protection in outdoor use | Superior heat dissipation and corrosion resistance | Adds cost and weight to final product | Medium |

This material selection guide empowers B2B buyers to make informed decisions tailored to their regional requirements and project specifications. Prioritizing quality materials aligned with environmental conditions and compliance standards will enhance product longevity, reduce maintenance costs, and improve end-user satisfaction in diverse international markets.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for solar led strip lights

Manufacturing solar LED strip lights involves a series of meticulously controlled processes designed to ensure durability, efficiency, and compliance with international standards. For B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding these manufacturing stages and quality assurance protocols is crucial for selecting reliable suppliers and guaranteeing product performance in varied environments.

Key Manufacturing Stages of Solar LED Strip Lights

1. Material Preparation

The foundation of high-quality solar LED strip lights begins with sourcing premium components:

- LED Chips: High-efficiency chips from reputable manufacturers ensure optimal brightness and energy savings. For solar applications, LEDs are chosen for low power consumption and high luminous efficacy.

- Printed Circuit Boards (PCBs): Flexible or rigid PCBs are fabricated with materials that provide excellent heat dissipation, typically using copper layers and flame-retardant substrates. The PCB design accommodates solar power integration, including connections to photovoltaic cells or battery modules.

- Solar Cells and Batteries: Solar panels (usually monocrystalline or polycrystalline) and lithium-ion or lithium-polymer batteries are procured with certifications verifying energy conversion efficiency and longevity.

- Adhesive Backing and Protective Coatings: High-quality adhesives ensure secure mounting, while UV-resistant coatings protect the strips from environmental degradation.

2. Forming and Assembly

This stage combines precision engineering with automated and manual tasks:

- PCB Fabrication: Printed circuits are etched and layered using advanced machinery, ensuring consistent electrical pathways and mechanical flexibility.

- LED Mounting and Soldering: Surface-mount technology (SMT) machines place LED chips accurately on the PCB, followed by reflow soldering to secure them. For solar LED strips, additional components like solar connectors and battery terminals are integrated.

- Encapsulation: Silicone or epoxy resins are applied to protect LEDs and circuitry from moisture, dust, and UV exposure, critical for outdoor and solar-powered applications.

- Integration of Solar Components: Solar cells and energy storage units are carefully attached, with wiring tested for continuity and robustness.

3. Finishing Processes

Final steps focus on usability and presentation:

- Cutting and Packaging: Strips are cut to standardized or customized lengths. Packaging includes anti-static materials and protective inserts to prevent damage during transit.

- Labeling and Documentation: Each batch is labeled with specifications, certifications, and batch numbers to facilitate traceability and compliance verification.

Quality Assurance and Control (QA/QC) Framework

For B2B buyers, particularly those importing to or operating in regions with varying regulatory landscapes, rigorous QA/QC protocols are essential to mitigate risks of product failure, non-compliance, and supply chain disruptions.

Relevant International and Industry Standards

- ISO 9001: The global benchmark for quality management systems, ensuring consistent manufacturing processes and continuous improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, certifying compliance with safety, health, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Limits hazardous materials in electronic products, critical for environmental compliance in Europe and beyond.

- IEC Standards: International Electrotechnical Commission standards for LED lighting and solar photovoltaic components (e.g., IEC 61215 for solar panels).

- UL Certification: Recognized mainly in North America but increasingly valued globally, ensuring electrical safety and performance.

- API or Regional Certifications: In some Middle Eastern and African markets, local certifications or approvals may be required, necessitating supplier familiarity with these requirements.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Verification of raw materials and components upon receipt, including LED chip luminosity tests, PCB integrity checks, and solar cell efficiency validation.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, such as solder joint inspections, automated optical inspection (AOI) for component placement, and functional testing of integrated solar circuits.

- Final Quality Control (FQC): Comprehensive product testing including:

- Electrical Testing: Voltage, current, and power consumption measurements under simulated solar charging conditions.

- Environmental Stress Testing: Exposure to humidity, temperature cycles, and UV radiation to assess durability.

- Optical Performance Testing: Measuring brightness, color temperature, and uniformity.

- Safety Tests: Insulation resistance and short-circuit protection verification.

Verifying Supplier Quality Control for B2B Buyers

To ensure that solar LED strip lights meet stringent standards, buyers should adopt proactive strategies:

- Factory Audits: Conduct on-site or third-party audits focusing on manufacturing processes, quality management systems, and workforce expertise. Audits can be tailored to assess compliance with ISO 9001 and relevant certifications.

- Review of Quality Documentation: Request detailed QC reports, certificates of conformity, and test data for each production batch. Transparent suppliers provide traceability records and non-conformance reports.

- Third-Party Inspection Services: Employ independent inspection agencies to perform random sampling and testing pre-shipment, providing unbiased verification of product quality.

- Sample Testing: Before large orders, obtain samples for in-house or local lab testing to validate performance claims and compatibility with regional electrical standards.

- Supplier Certifications and Compliance Updates: Ensure suppliers maintain up-to-date certifications, especially for evolving standards like RoHS or new solar panel efficiency guidelines.

QC and Compliance Nuances for International Markets

Africa and South America:

Buyers should prioritize suppliers whose products meet IP65 or higher ingress protection ratings due to prevalent outdoor installations. Solar LED strips must withstand harsh climates, including high humidity and dust. Certifications aligned with IEC standards are often recognized, but local regulatory requirements may vary, so engaging with local compliance consultants is advisable.

Middle East:

Given the intense solar exposure and temperature extremes, emphasis on UV resistance and thermal management during manufacturing is critical. Products compliant with Gulf Cooperation Council (GCC) standards or local certification bodies enhance market acceptance. Energy efficiency labels may also be required.

Europe (including Turkey):

Strict adherence to CE marking, RoHS, and WEEE directives is non-negotiable. Buyers should verify that solar LED strip lights also comply with eco-design requirements under the EU Energy-related Products Directive (ErP). Documentation proving compliance with these regulations is essential for customs clearance and resale.

Vietnam and Southeast Asia:

While not always mandatory, adherence to international standards such as ISO and IEC is a competitive advantage. Buyers should ensure suppliers understand regional electrical standards (e.g., voltage compatibility) and provide warranty terms suited to tropical climates.

Summary

For international B2B buyers targeting solar LED strip lights, a deep understanding of the manufacturing lifecycle—from raw material selection to final packaging—combined with stringent quality control aligned with international and regional standards, is vital. Establishing clear quality expectations, verifying certifications, and engaging in thorough supplier evaluation mitigates risks and ensures supply of durable, efficient, and compliant solar lighting solutions tailored to diverse market conditions.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for solar led strip lights Sourcing

Understanding the cost and pricing dynamics of solar LED strip lights is essential for international B2B buyers aiming to optimize procurement strategies and total cost of ownership. This section breaks down key cost components, pricing influencers, and practical tips tailored for buyers from Africa, South America, the Middle East, and Europe (including markets like Turkey and Vietnam).

Key Cost Components in Solar LED Strip Lights

-

Materials: The foundation of cost lies in high-quality solar panels, LED chips, PCBs, batteries, and protective casings. Premium LED chips and efficient solar cells increase upfront costs but improve performance and lifespan, reducing long-term expenses. Adhesive backing and waterproofing materials also impact durability and price.

-

Labor: Manufacturing labor costs vary widely by country. Regions with advanced automation can offer competitive pricing despite higher wages, while manual assembly in lower-cost countries can reduce labor expenses but may affect quality consistency.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and administrative expenses. Efficient factories with optimized workflows and economies of scale generally offer better pricing.

-

Tooling and Setup: Initial tooling costs for custom designs or specific form factors can be significant but are amortized over large production runs. Buyers ordering smaller volumes should anticipate higher per-unit costs due to tooling amortization.

-

Quality Control (QC): Rigorous QC processes—such as stress testing, waterproof certification, and compliance with international standards (CE, RoHS)—add to costs but are critical for ensuring product reliability and reducing returns.

-

Logistics and Shipping: International freight, customs duties, insurance, and last-mile delivery costs can substantially influence the landed cost. Bulk shipments reduce per-unit logistics costs but require careful inventory management.

-

Supplier Margin: Manufacturers and distributors include margins that reflect brand reputation, product quality, and service level. Established suppliers with certifications and warranties often command higher margins.

Pricing Influencers to Consider

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock significant discounts. Many suppliers set MOQs that balance their production efficiency with buyers’ demand forecasts. Negotiating MOQ flexibility can be advantageous, especially for emerging markets.

-

Product Specifications and Customization: Custom lengths, colors, solar capacities, and packaging increase production complexity and costs. Standardized products are generally more cost-efficient but may not meet all project requirements.

-

Material Quality and Certifications: Higher-grade components and compliance with certifications (e.g., CE, RoHS, IP65 waterproof rating) justify premium pricing but reduce risk and enhance product lifespan.

-

Supplier Location and Reputation: Suppliers closer to buyer markets reduce shipping times and costs. Established suppliers with strong after-sales support and warranty policies add value but may price accordingly.

-

Incoterms and Payment Terms: Buyers should clarify Incoterms (e.g., FOB, CIF, DDP) to understand which party bears shipping and customs risks and costs. Favorable payment terms (e.g., letters of credit, net 30/60 days) can improve cash flow management.

Strategic Buyer Tips for Cost-Efficiency

-

Negotiate on Volume and Payment Terms: Leverage forecasted volumes to negotiate better unit prices and flexible payment schedules. Suppliers often prefer long-term partnerships over one-off transactions.

-

Evaluate Total Cost of Ownership (TCO): Consider not just purchase price but also installation ease, energy savings, maintenance, warranty, and product lifespan. Higher upfront costs may yield better TCO.

-

Request Samples and Conduct Quality Audits: Testing product samples before bulk purchase helps avoid costly returns. For large projects, consider factory audits or third-party inspections to verify quality and production capacity.

-

Factor in Import Duties and Local Regulations: Understand applicable tariffs, certification requirements, and environmental standards in your country to avoid unexpected compliance costs.

-

Consolidate Shipments: Combining orders with other products or suppliers can reduce freight and customs expenses, especially for buyers in remote or emerging markets.

-

Stay Updated on Market Trends: Solar LED technology evolves rapidly. Engaging suppliers who offer the latest efficient technologies can provide competitive advantages, especially in regions with growing renewable energy adoption.

Indicative Pricing Disclaimer

Pricing for solar LED strip lights varies widely depending on specifications, order volume, supplier location, and market conditions. The figures discussed here serve as a general guide. Buyers should request detailed quotations, including all cost components, and perform comparative analyses before finalizing procurement decisions.

By carefully analyzing these cost and pricing factors, international B2B buyers can make informed sourcing decisions that balance quality, performance, and budget—ultimately securing solar LED strip lights that meet their operational and sustainability goals.

Spotlight on Potential solar led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘solar led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for solar led strip lights

Critical Technical Properties of Solar LED Strip Lights

Understanding the core technical specifications of solar LED strip lights enables buyers to make informed purchasing decisions that align with their project requirements and regional conditions.

-

Solar Panel Efficiency (%)

This indicates how effectively the solar panel converts sunlight into electrical energy. Higher efficiency panels generate more power in limited sunlight, crucial for regions with variable sun exposure like parts of Europe or the Middle East. For B2B buyers, selecting panels with optimal efficiency ensures reliable performance and reduces the need for larger or additional panels. -

LED Chip Quality and Luminous Efficacy (Lumens per Watt)

The type and quality of LED chips determine brightness and energy consumption. High luminous efficacy means brighter light output with less power. For commercial or large-scale installations, this translates to energy savings and longer operational life, reducing maintenance costs. -

Battery Capacity and Type (mAh, Lithium-ion or Lead Acid)

Battery capacity defines how long the LED strips can operate without sunlight. Lithium-ion batteries are preferred for their longer lifespan and lighter weight, essential for durable, portable lighting solutions. Buyers should consider capacity based on usage hours and local climate conditions. -

Ingress Protection Rating (IP Rating)

This rating classifies the degree of protection against dust and water. For outdoor or humid environments common in African and South American markets, an IP65 or higher rating is recommended to ensure durability and safety. -

Flexible PCB Material and Adhesive Quality

The printed circuit board (PCB) must support heat dissipation and flexibility. High-grade flexible PCBs prevent damage during installation and improve longevity. Strong adhesive backing ensures secure mounting on varied surfaces, critical for installations in retail, hospitality, or industrial sectors. -

Operating Temperature Range

Solar LED strips must withstand temperature fluctuations typical of target markets. A wide operating temperature range (-20°C to 60°C or more) ensures consistent performance in hot Middle Eastern climates or cooler European winters.

Essential Trade Terminology for Solar LED Strip Lights in B2B Transactions

Familiarity with common trade terms simplifies communication, negotiation, and procurement processes for international buyers and suppliers.

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce products that can be rebranded and sold by another company. For buyers, OEM partnerships offer customization options, such as bespoke packaging or unique product specifications aligned with market preferences. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. Understanding MOQ helps buyers plan inventory and budget effectively, especially when testing new products or entering new markets with limited upfront capital. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms. RFQs are critical for comparing offers from multiple vendors, ensuring competitive pricing and clarity on product specifications. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Knowing Incoterms helps buyers evaluate total landed costs and manage logistics efficiently. -

IP Rating (Ingress Protection Rating)

While also a technical property, it is widely referenced in trade documents to specify product suitability for environmental exposure, impacting compliance and warranty conditions. -

Lead Time

The period between order confirmation and delivery. Accurate knowledge of lead times is essential for project scheduling and inventory management, particularly for large-scale or seasonal deployments.

Mastering these technical properties and trade terms empowers B2B buyers across Africa, South America, the Middle East, and Europe to optimize procurement strategies, ensure product quality, and build resilient supply chains for solar LED strip lighting solutions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the solar led strip lights Sector

Market Overview & Key Trends

The global market for solar LED strip lights is witnessing robust growth driven by increasing demand for energy-efficient and off-grid lighting solutions. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including emerging markets like Turkey and Vietnam) are capitalizing on solar LED strip lights for their ability to deliver sustainable illumination without dependence on unreliable or costly grid infrastructure. Key market drivers include rising awareness of renewable energy, government incentives for solar adoption, and the expanding applications of solar LED strips in commercial, residential, and public infrastructure projects.

Technological advancements are shaping sourcing trends as manufacturers integrate smarter features like app-controlled color tuning, enhanced battery storage, and improved solar panel efficiency. Buyers are increasingly prioritizing modular and customizable solutions that adapt to diverse climatic and installation conditions. Flexible PCBs and high-quality LED chips optimized for solar power maximize lumen output while minimizing energy consumption. Moreover, suppliers offering turnkey packages—including solar panels, LED strips, controllers, and mounting accessories—are gaining traction for simplifying procurement and installation.

Market dynamics emphasize supply chain resilience and cost optimization. African and South American buyers often seek suppliers with local or regional distribution hubs to reduce lead times and shipping costs. Meanwhile, Middle Eastern and European buyers focus on compliance with international standards (e.g., CE, RoHS) and certifications that assure product safety and performance. Bulk purchasing remains a common strategy to secure competitive pricing and ensure product consistency across large-scale projects such as urban lighting, hospitality venues, and remote area electrification.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration for B2B buyers of solar LED strip lights, reflecting broader corporate responsibility goals and regulatory pressures. Solar LED strips inherently reduce carbon footprints by utilizing renewable solar energy, thereby lowering greenhouse gas emissions compared to conventional electric lighting. However, the environmental impact extends beyond energy savings to include responsible sourcing of raw materials, manufacturing processes, and end-of-life recyclability.

Ethical sourcing is paramount, especially for components like LED chips and PCBs, which may involve complex supply chains spanning multiple countries. Buyers should prioritize suppliers who demonstrate transparency, fair labor practices, and adherence to environmental regulations. Certifications such as ISO 14001 (environmental management), Fair Labor Association membership, and conflict-free sourcing attest to a supplier’s commitment to sustainable and ethical operations.

Illustrative Image (Source: Google Search)

Material selection also influences sustainability credentials. Solar LED strips using lead-free solder, halogen-free adhesives, and recyclable PCBs align better with green building standards and eco-labeling schemes. Additionally, buyers should evaluate the supplier’s commitment to reducing packaging waste and utilizing biodegradable or recycled materials. Comprehensive quality control and durability testing extend product lifespan, minimizing waste and replacement frequency.

Investing in sustainably sourced solar LED strip lights not only enhances brand reputation but also mitigates risks associated with regulatory non-compliance and supply chain disruptions. Collaborative partnerships with manufacturers committed to continuous improvement in environmental performance can unlock long-term value and competitive advantage.

Evolution of Solar LED Strip Lights

Solar LED strip lights have evolved significantly over the past decade, transitioning from niche, low-lumen products to versatile, high-performance lighting solutions suitable for a wide range of applications. Early versions were limited by inefficient solar panels and basic LED technology, restricting brightness and operational hours. Advances in photovoltaic cell efficiency, lithium-ion battery storage, and LED chip performance have transformed these products into reliable, scalable options for off-grid illumination.

The integration of smart controls and modular designs has expanded their appeal in commercial and industrial sectors, enabling dynamic lighting effects and energy management capabilities. Meanwhile, improvements in flexible PCB technology and durable, weather-resistant materials have broadened installation possibilities, from architectural accent lighting to large-scale outdoor displays.

This evolution reflects a broader global shift toward sustainable, decentralized energy solutions, with solar LED strip lights positioned as a key component in the future of energy-efficient lighting infrastructure. For international B2B buyers, understanding this trajectory is vital to selecting suppliers and products that align with both current market demands and emerging innovations.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of solar led strip lights

-

How can I effectively vet suppliers of solar LED strip lights for international B2B purchases?

To vet suppliers, start by verifying their business credentials, manufacturing capabilities, and certifications such as CE, RoHS, or UL to ensure compliance with international quality standards. Request detailed product specifications and inquire about their quality control processes. Check for customer reviews and references, especially from buyers in your region (Africa, South America, Middle East, Europe). Visiting supplier factories virtually or in-person, if possible, adds assurance. Confirm their experience with international shipping and after-sales support to mitigate risks in cross-border transactions. -

What customization options are typically available for solar LED strip lights, and how should I approach customization requests?

Many manufacturers offer customization including length, color temperature, waterproof ratings, brightness levels, and packaging tailored to your market or branding needs. When requesting customization, clearly specify technical requirements and expected applications to avoid over-specification. Discuss minimum order quantities (MOQs) for customized products early, as these can differ from standard offerings. A prototype or sample is critical before full production to verify quality and functionality. Customization can enhance market differentiation but requires upfront communication and timeline adjustments. -

What are common MOQ and lead time expectations when sourcing solar LED strip lights internationally?

MOQs vary widely but typically range from 500 to 5,000 meters per order depending on supplier scale and customization. Lead times usually span 3 to 8 weeks, influenced by order size, customization complexity, and factory workload. Seasonal demand and shipping constraints can also impact timelines. It’s essential to clarify MOQs and lead times upfront and negotiate flexible terms if possible. Bulk orders often reduce per-unit costs but require careful demand forecasting to avoid overstocking or delays. -

Which payment terms are advisable for international B2B transactions involving solar LED strip lights?

Common payment methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), and Escrow services. For new suppliers, a 30% advance payment with balance upon shipment or delivery is standard to balance risk. Established relationships may warrant net payment terms (e.g., 30-60 days). Always use secure payment channels and consider trade insurance to protect against default or shipment issues. Clear payment terms should be documented in contracts to avoid disputes.

-

What quality assurance measures should I expect from suppliers of solar LED strip lights?

Suppliers should provide documented quality control protocols including raw material inspection, in-process testing, and final product evaluation. Key tests cover LED chip performance, waterproofing, adhesion strength, and electrical safety. Request certifications like ISO 9001, CE, RoHS, and test reports to verify compliance with international standards. Sampling before bulk orders is crucial. Additionally, inquire about warranty periods and after-sales service policies to ensure long-term reliability. -

Which certifications are critical for solar LED strip lights to ensure market compliance in Africa, South America, the Middle East, and Europe?

At minimum, CE certification is essential for Europe, confirming conformity with EU safety and environmental standards. RoHS certification ensures hazardous substances are restricted, important globally. UL or ETL certifications enhance credibility, especially for Middle Eastern and some African markets. For South America, look for INMETRO (Brazil) or equivalent local approvals. Certifications not only facilitate customs clearance but also reassure buyers and end-users about product safety and quality. -

How should international buyers manage logistics and shipping challenges for solar LED strip lights?

Choose suppliers experienced in international freight forwarding who can handle export documentation and customs clearance efficiently. Discuss shipping options (air vs. sea freight), considering cost, lead time, and product fragility. Consolidate orders to optimize freight costs and reduce carbon footprint. Ensure packaging is robust to protect LED strips from moisture and mechanical damage. Track shipments actively and prepare for potential customs inspections or delays by maintaining clear communication with logistics partners. -

What steps can B2B buyers take to resolve disputes related to quality or delivery of solar LED strip lights?

First, maintain thorough documentation including contracts, purchase orders, quality agreements, and inspection reports. Promptly communicate issues with suppliers and request corrective actions such as replacements or refunds. Utilize third-party inspection services to provide unbiased evidence if disputes arise. Where possible, include arbitration clauses in contracts to streamline conflict resolution. Building strong supplier relationships through transparency and regular communication helps prevent disputes and fosters collaborative problem-solving.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solar led strip lights

Key Takeaways for Strategic Sourcing of Solar LED Strip Lights

For international B2B buyers in Africa, South America, the Middle East, and Europe, sourcing solar LED strip lights strategically offers multiple advantages. Prioritizing suppliers who combine high-quality components—such as premium LED chips, reliable PCBs, and durable adhesives—with rigorous quality control and certifications ensures product longevity and performance. Bulk purchasing from reputable wholesale suppliers can significantly reduce costs, increase customization options, and streamline procurement for large-scale projects.

Understanding your project requirements—including weather resistance for outdoor applications and energy efficiency—is essential to selecting the optimal product. Evaluating supplier reliability, warranty terms, and logistics capabilities further safeguards your investment and minimizes supply chain risks.

Looking Ahead: Embracing Innovation and Sustainability

The solar LED strip light market is evolving rapidly, driven by advances in smart lighting technologies and growing demand for sustainable energy solutions. Buyers who align with forward-thinking manufacturers will benefit from early access to innovations like app-controlled lighting and enhanced solar integration.

As energy-conscious infrastructure expands globally, especially in emerging markets, now is the time to forge strong supplier partnerships that emphasize quality, scalability, and environmental responsibility. By adopting a strategic sourcing approach, international buyers can confidently meet their lighting needs while contributing to sustainable development goals.

Take action today: Engage with trusted suppliers, request samples, and leverage bulk purchasing to secure competitive advantages in your regional markets.