Introduction: Navigating the Global Market for led strip power supply

The global surge in LED lighting adoption has placed the led strip power supply at the core of successful LED strip implementations. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, sourcing the right power supply is a critical determinant of product performance, energy efficiency, and long-term reliability. A high-quality power supply not only ensures stable voltage and current but also safeguards LED strips from fluctuations that can cause premature failure or inconsistent lighting output.

In today’s interconnected market, buyers face multifaceted challenges: navigating diverse product specifications, understanding material quality, assessing manufacturing and quality control standards, and complying with region-specific regulatory requirements. These complexities are compounded by the need to balance cost efficiency with durability, while managing supply chain risks in a competitive landscape.

This comprehensive guide equips B2B buyers with actionable insights on:

- Types and technologies of led strip power supplies suited for various applications

- Key materials and manufacturing processes that influence reliability and lifespan

- Quality assurance protocols and certification standards essential for global compliance

- Effective supplier evaluation criteria tailored to diverse regional markets

- Transparent pricing models and cost optimization strategies

- Market-specific considerations, including logistics and regulatory compliance in regions such as Spain, Indonesia, and beyond

- Answers to frequently asked questions that address common procurement hurdles

By leveraging this knowledge, international buyers can confidently optimize their sourcing strategies, mitigate risks, and forge resilient partnerships that drive sustainable growth in the evolving LED lighting industry.

Understanding led strip power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Constant Voltage Power Supply | Provides fixed voltage output (commonly 12V or 24V) | Commercial LED strip installations, retail displays, architectural lighting | + Easy to use and compatible with standard LED strips – Limited to specific voltage strips, less flexible for variable loads |

| Constant Current Power Supply | Delivers a fixed current, adjusts voltage as needed | High-power LED strips, industrial applications, outdoor lighting | + Ensures consistent brightness and prevents LED damage – More complex and costly, requires matching with LED specs |

| Dimmable Power Supply | Supports voltage or current adjustment for dimming control | Hospitality, event lighting, smart building systems | + Enhances user experience with lighting control – Compatibility with dimmers must be verified, higher initial cost |

| Waterproof/Outdoor Power Supply | Encased with IP65+ rating for moisture and dust protection | Outdoor signage, landscaping, marine applications | + Reliable in harsh environments, extends lifespan – Bulkier and more expensive than indoor units |

| Modular/Expandable Power Supply | Designed for scalability and easy integration with multiple units | Large-scale commercial projects, factory automation | + Flexible capacity expansion, simplifies maintenance – Higher upfront investment, requires technical expertise for setup |

Constant Voltage Power Supplies are the most common type for LED strip lighting, delivering a stable voltage (usually 12V or 24V) suitable for standard LED strips. Their simplicity and compatibility make them attractive for retail, office, and architectural projects. B2B buyers should ensure the power supply’s capacity matches the total wattage of the LED strips to avoid voltage drops and premature failures. Verifying supplier certifications and warranty terms is essential, especially for deployments in regions with strict electrical standards like Europe and the Middle East.

Constant Current Power Supplies are ideal for high-power or specialty LED strips requiring a regulated current to maintain consistent brightness and protect against LED burnout. These are favored in industrial or outdoor applications where performance reliability is critical. International buyers should consider the complexity of integration and the need for precise matching of power supply specs to LED requirements. Higher upfront costs are balanced by longer LED lifespan and reduced maintenance.

Dimmable Power Supplies add versatility by allowing brightness adjustment through compatible dimming controls, enhancing ambiance in hospitality, event, and smart building environments. For B2B procurement, confirming compatibility with local dimming standards and control systems is crucial to avoid functionality issues. These power supplies often command a premium price but provide value through energy savings and improved user experience.

Waterproof or Outdoor Power Supplies are designed with robust enclosures rated IP65 or higher, protecting against dust, moisture, and harsh weather conditions. This type is essential for outdoor signage, landscaping, or marine applications common in diverse climates across Africa, South America, and Europe. Buyers should assess environmental certifications and durability claims carefully to ensure long-term reliability and compliance with local regulations.

Modular or Expandable Power Supplies offer scalable solutions for large commercial or industrial LED strip installations. Their design facilitates easy capacity expansion and simplifies maintenance by allowing individual modules to be replaced without shutting down the entire system. For B2B buyers managing complex projects, this flexibility supports future growth and reduces downtime but requires technical expertise during procurement and installation phases.

Related Video: Ultra Thin LED Strip Power Supply

Key Industrial Applications of led strip power supply

| Industry/Sector | Specific Application of led strip power supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in storefronts and interior design | Enhances product visibility, attracts customers, reduces energy costs | Reliable voltage regulation, compatibility with dimmers, compliance with regional safety standards (CE, RoHS) |

| Hospitality & Leisure | Ambient lighting in hotels, restaurants, and event venues | Creates immersive atmospheres, flexible lighting control, energy efficiency | High durability, waterproof ratings for humid environments, supplier certification for quality assurance |

| Manufacturing & Warehousing | Task and safety lighting in assembly lines and storage areas | Improves worker safety and productivity, reduces downtime | Robust power supplies with surge protection, ability to handle fluctuating loads, long lifespan |

| Transportation & Infrastructure | Decorative and functional lighting in airports, stations, and public transport | Enhances passenger experience, energy savings, easy maintenance | Compliance with strict local regulations, modular design for scalability, supplier reliability |

| Healthcare Facilities | Backlighting for signage and mood lighting in patient areas | Supports patient comfort and wayfinding, minimizes electrical hazards | Low electromagnetic interference (EMI), medical-grade certifications, consistent power output |

Retail & Commercial Applications

In retail environments across Africa, South America, the Middle East, and Europe, LED strip power supplies are essential for powering accent and display lighting that highlights merchandise and enhances store aesthetics. These power supplies must deliver stable voltage to prevent flickering that can detract from product presentation. Buyers should prioritize suppliers offering units compliant with local electrical standards such as CE in Europe or regional certifications in emerging markets. Energy efficiency and dimmability are critical to reduce operational costs while enabling dynamic lighting schemes that attract customers.

Hospitality & Leisure Applications

Hotels, restaurants, and event venues rely on LED strip power supplies to create customizable ambient lighting that enhances guest experience and supports brand identity. Power supplies used here often require waterproof or humidity-resistant features, especially in tropical or coastal regions like Indonesia or parts of South America. International buyers should ensure suppliers provide certifications proving durability and safety, as well as compatibility with advanced lighting control systems. Reliable power delivery also reduces maintenance downtime, a key consideration for high-occupancy facilities.

Manufacturing & Warehousing Applications

In industrial settings such as manufacturing plants and warehouses, LED strip power supplies support task lighting that improves visibility and worker safety. These environments demand power supplies with robust surge protection and the ability to handle fluctuating electrical loads due to heavy machinery. Buyers from regions with unstable grid power, common in some African and Middle Eastern countries, must emphasize power supply resilience and long operational life. Sourcing from suppliers with proven quality control processes ensures reduced failure rates and lower maintenance costs.

Illustrative Image (Source: Google Search)

Transportation & Infrastructure Applications

Airports, train stations, and public transport hubs use LED strip lighting powered by specialized power supplies to provide both decorative and functional illumination. These power supplies must comply with stringent local regulations regarding safety and electromagnetic compatibility. Modular designs that allow easy scalability and maintenance are highly valued by B2B buyers managing large infrastructure projects in Europe and emerging markets. Reliable suppliers that can navigate complex certification requirements and deliver consistent product quality are essential partners.

Healthcare Facilities Applications

Healthcare facilities deploy LED strip power supplies to power backlit signage and mood lighting that supports patient comfort and clear wayfinding. Power supplies in this sector require low electromagnetic interference (EMI) to avoid disruption of sensitive medical equipment. Buyers, especially in Europe and the Middle East, should verify medical-grade certifications and consistent power output specifications. Choosing suppliers with expertise in healthcare lighting solutions ensures compliance with stringent safety standards and enhances overall facility operations.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip power supply

When selecting materials for LED strip power supplies, international B2B buyers must carefully evaluate options based on performance, durability, cost, and compliance with regional standards. The choice of material directly influences product reliability, efficiency, and suitability for specific environments, which is critical for buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe. Below is a detailed analysis of four common materials used in LED strip power supply components.

Aluminum

Key Properties: Aluminum is widely used for its excellent thermal conductivity, lightweight nature, and corrosion resistance. It typically withstands temperatures up to 150°C and offers good mechanical strength without excessive weight.

Pros & Cons: Aluminum’s superior heat dissipation helps maintain LED power supply efficiency and prolongs lifespan. It is also relatively easy to manufacture and recyclable, which appeals to sustainability-conscious buyers. However, aluminum can be prone to surface oxidation if not properly treated, and its cost is moderate compared to plastics.

Impact on Application: Aluminum enclosures and heat sinks are ideal for high-power LED strip power supplies where thermal management is critical. It performs well in humid or coastal environments common in parts of Africa and South America, provided anodizing or powder coating is applied.

International Considerations: Buyers in Europe and the Middle East should verify compliance with ASTM B209 or EN 573 standards for aluminum alloys, ensuring material traceability and quality. In regions like Indonesia and South America, suppliers offering certifications aligned with ISO 9001 manufacturing processes are preferred to guarantee consistent quality.

Polycarbonate (PC)

Key Properties: Polycarbonate is a durable thermoplastic with high impact resistance, good electrical insulation, and temperature tolerance typically up to 120°C. It is also resistant to UV radiation and many chemicals.

Pros & Cons: PC is cost-effective and lightweight, making it attractive for compact LED power supplies where electrical insulation and impact resistance are priorities. However, it has lower thermal conductivity than metals, which can limit heat dissipation and affect long-term reliability under high loads.

Impact on Application: Polycarbonate housings are suitable for indoor LED strip power supplies or installations where mechanical protection is needed without heavy heat generation. It is commonly used in retrofit kits and low-power applications.

International Considerations: B2B buyers in the Middle East and Europe should ensure polycarbonate materials meet UL 94 V-0 flammability ratings and comply with REACH and RoHS directives. African and South American markets may prioritize suppliers with compliance to ASTM D3935 or ISO 10605 for electrostatic discharge resistance.

Stainless Steel

Key Properties: Stainless steel offers exceptional corrosion resistance, mechanical strength, and temperature tolerance up to 500°C depending on the grade. It is highly durable and resistant to harsh environmental conditions.

Pros & Cons: While stainless steel provides superior protection against moisture, chemicals, and physical damage, it is heavier and more expensive than aluminum or plastics. Manufacturing complexity and cost are higher, which can impact pricing for large-volume orders.

Impact on Application: Stainless steel enclosures are preferred for LED strip power supplies used in industrial, marine, or outdoor environments—especially in Middle Eastern and coastal African markets where salt corrosion is a concern. Its robustness supports long-term installations in demanding conditions.

International Considerations: Buyers should specify grades such as 304 or 316 stainless steel, aligned with ASTM A240 or EN 10088 standards, to ensure corrosion resistance. European and Middle Eastern buyers often require traceability and certification for food-grade or hygienic applications, while South American buyers may emphasize durability certifications.

Printed Circuit Board (PCB) Substrate Materials (FR4 and Metal Core PCB)

Key Properties: FR4 is a common fiberglass epoxy laminate with good electrical insulation and moderate thermal resistance (~130°C). Metal Core PCBs (MCPCBs) use aluminum or copper bases to improve heat dissipation.

Pros & Cons: FR4 is cost-effective and widely used for low to medium power LED strip power supplies but has limited thermal management capabilities. MCPCBs offer enhanced heat dissipation, improving LED lifespan and performance but at a higher cost and manufacturing complexity.

Impact on Application: FR4 substrates are suitable for standard indoor LED strip power supplies with moderate power requirements. MCPCBs are critical for high-power LED strips used in commercial or industrial applications, ensuring stable operation under thermal stress.

International Considerations: B2B buyers in Europe and the Middle East should ensure PCBs comply with IPC-4101 and IPC-6012 standards for quality and reliability. African and South American buyers should verify supplier adherence to ISO/TS 16949 or equivalent quality management certifications to reduce defects and ensure supply consistency.

| Material | Typical Use Case for led strip power supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat sinks and enclosures for high-power LED strip supplies | Excellent thermal conductivity and lightweight | Moderate cost, surface oxidation risk | Medium |

| Polycarbonate (PC) | Housings for indoor, low-power LED strip power supplies | High impact resistance and electrical insulation | Lower thermal conductivity limits heat dissipation | Low |

| Stainless Steel | Enclosures for industrial, outdoor, and harsh environments | Superior corrosion resistance and durability | High cost and weight, manufacturing complexity | High |

| PCB Substrates (FR4/MCPCB) | Base material for LED power supply circuits | Cost-effective (FR4) and enhanced heat dissipation (MCPCB) | FR4 limited thermal management; MCPCB higher cost | Low (FR4) / Medium (MCPCB) |

This strategic material selection guide empowers international B2B buyers to align their procurement decisions with technical requirements, regional compliance standards, and budget considerations, ensuring optimal performance and long-term value in LED strip power supply sourcing.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip power supply

The manufacturing and quality assurance of LED strip power supplies are critical factors that determine product reliability, safety, and performance—key concerns for international B2B buyers, especially those operating in diverse regulatory environments such as Africa, South America, the Middle East, and Europe. Understanding the detailed production workflow and quality control measures enables buyers to make informed sourcing decisions, mitigate risks, and ensure compliance with local standards.

Typical Manufacturing Process for LED Strip Power Supply

The production of LED strip power supplies involves multiple precise stages, each requiring specific materials, equipment, and expertise to guarantee consistent output quality.

1. Material Preparation

This initial phase focuses on procuring and inspecting raw materials, including electronic components (transformers, capacitors, resistors, ICs), printed circuit boards (PCBs), and casing materials. Suppliers are vetted for component quality, and incoming materials undergo Incoming Quality Control (IQC) to verify specifications such as electrical ratings, material certifications, and physical integrity.

2. Forming and PCB Fabrication

PCBs are fabricated through processes like etching, drilling, and plating. Surface mount technology (SMT) or through-hole technology (THT) is used to place components on the PCB. Automated machines perform solder paste application and component placement with high precision to ensure proper electrical connectivity and minimize defects.

3. Assembly

This stage involves soldering, assembly of electronic components, and integration into housing units. Assembly lines often use automated and semi-automated equipment to enhance consistency and throughput. Key techniques include wave soldering for through-hole components and reflow soldering for SMT components. The power supply modules are then assembled with input/output connectors, protective fuses, and cooling elements such as heat sinks.

4. Finishing and Packaging

Final assembly includes attaching labels, safety warnings, and user instructions. The power supply casing is sealed to protect against dust and moisture, frequently with epoxy or silicone encapsulation. Products are packaged with anti-static materials and protective padding to prevent damage during transport.

Quality Assurance Framework and Standards

Robust quality assurance is essential to maintain product integrity and meet the safety requirements demanded by global markets. Buyers should prioritize suppliers with documented quality systems and certifications.

Key International and Industry Standards

- ISO 9001: The foundational standard for quality management systems, ensuring consistent production processes and continuous improvement.

- CE Marking: Mandatory for products entering the European Economic Area, confirming conformity with health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Ensures that the power supply components do not contain harmful substances beyond defined thresholds.

- UL / IEC / API Certifications: Depending on the region and application, certifications like UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and API (American Petroleum Institute) may be required for safety and performance compliance.

- CCC (China Compulsory Certification): Important for buyers sourcing from or shipping to Asia, ensuring product safety compliance.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verifies raw materials and components before entering production.

- In-Process Quality Control (IPQC): Monitors critical production stages, including soldering quality, assembly accuracy, and functional testing.

- Final Quality Control (FQC): Comprehensive testing of finished products, including electrical performance, safety checks, and cosmetic inspection.

Common Testing Methods

B2B buyers should expect suppliers to conduct a range of tests to certify product reliability:

- Electrical Safety Tests: Insulation resistance, dielectric strength, and earth continuity tests confirm protection against electrical hazards.

- Load and Burn-in Testing: Power supplies are subjected to continuous operation under rated loads to detect early failures and ensure thermal stability.

- EMC (Electromagnetic Compatibility) Testing: Ensures the device does not emit excessive electromagnetic interference and is immune to external disturbances.

- Environmental Stress Testing: Includes temperature cycling, humidity exposure, and vibration tests to simulate real-world operating conditions.

- Performance Verification: Voltage and current output measurements, efficiency ratings, and ripple/noise tests ensure compliance with technical specifications.

How B2B Buyers Can Verify Supplier Quality Assurance

To safeguard procurement investments, buyers should adopt a proactive approach to supplier quality verification:

- Factory Audits: Conduct on-site inspections or virtual audits to assess manufacturing capabilities, quality management systems, and workforce competence.

- Review of Quality Documentation: Request detailed QC reports, certification copies, and process control records to verify compliance and traceability.

- Third-Party Inspections: Engage independent testing agencies to perform product inspections and testing, especially for high-volume or critical orders.

- Sample Testing: Obtain pre-production or pilot samples for in-house or third-party laboratory testing to validate performance claims.

- Supplier Performance Tracking: Monitor defect rates, delivery timeliness, and responsiveness to quality issues over time to maintain supplier accountability.

Navigating Quality Assurance Nuances for International Buyers

International B2B buyers face diverse regulatory and market requirements that influence manufacturing and quality assurance standards.

- Africa and South America: Emerging markets may have less stringent local certification requirements but increasingly demand compliance with international standards (CE, RoHS) to support export potential and ensure safety. Buyers should emphasize supplier adherence to global certifications and robust quality controls.

- Middle East: Regulatory frameworks often align with European and international standards. Certifications like CE and IEC are typically mandatory, particularly for projects in construction, oil & gas, and public infrastructure. Buyers should verify supplier familiarity with regional certifications and export documentation.

- Europe (e.g., Spain): The European Union enforces strict compliance with CE marking, RoHS, and WEEE (Waste Electrical and Electronic Equipment) directives. Buyers must insist on full certification packages and proof of compliance audits. Traceability and environmental compliance are critical purchasing criteria.

- Asia (e.g., Indonesia as a sourcing hub): Buyers sourcing from Asian manufacturers should confirm CCC certification when applicable and conduct thorough supplier audits due to varying production quality levels. It is advisable to work with suppliers offering transparent QC processes and third-party testing options.

Final Recommendations for B2B Buyers

- Prioritize suppliers with certified quality management systems (ISO 9001) and recognized product certifications.

- Insist on comprehensive QC documentation and transparent reporting throughout production.

- Conduct regular factory audits and third-party inspections to validate manufacturing and testing processes.

- Ensure the supplier’s quality assurance approach aligns with your destination market’s regulatory requirements.

- Factor in supplier flexibility for custom testing or certification to meet specific project or regional needs.

- Leverage technology such as supply chain management software to track quality metrics and supplier performance over time.

By investing in due diligence and partnering with manufacturers committed to stringent quality control, international B2B buyers can secure LED strip power supplies that deliver consistent performance, safety, and compliance—key drivers of success in competitive and evolving global markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip power supply Sourcing

Understanding the cost structure and pricing dynamics for sourcing LED strip power supplies is essential for international B2B buyers aiming to optimize procurement budgets while securing reliable, high-quality products. This analysis breaks down the key cost components, influential pricing factors, and strategic buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Strip Power Supply Pricing

-

Materials

The primary cost driver is the raw materials used in power supply manufacturing, including semiconductors, capacitors, transformers, and PCBs. Quality-grade components significantly influence durability and performance, especially for power supplies designed to meet stringent certifications (CE, RoHS, CCC). -

Labor and Manufacturing Overhead

Labor costs vary depending on the manufacturing location. Facilities in Asia often offer lower labor expenses compared to Europe or the Middle East, impacting final pricing. Overhead includes factory utilities, equipment depreciation, and indirect costs related to production. -

Tooling and Setup Costs

Initial tooling for custom designs or specialized power supply models adds to upfront costs. For buyers requiring bespoke voltage, wattage, or form factor specifications, these expenses can increase the per-unit price, especially at low order volumes. -

Quality Control and Testing

Rigorous testing protocols—such as burn-in tests, safety compliance checks, and electromagnetic interference (EMI) validation—add to production costs but are critical for reliability. Certified products typically command premium pricing but reduce risk of failure and returns. -

Logistics and Shipping

Freight charges, customs duties, and insurance vary widely by destination. Buyers in Africa or South America often face higher logistics costs due to longer transit routes and less frequent shipping schedules, which should be factored into total landed cost calculations. -

Supplier Margin

Suppliers incorporate profit margins based on market demand, competition, and product differentiation. Margins tend to be tighter for commoditized power supplies but can increase with customization or certification requirements.

Price Influencers to Consider

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes typically unlock significant per-unit discounts. Buyers should negotiate MOQs that align with inventory capacity to avoid overstocking or stockouts. -

Product Specifications and Customization

Tailoring power supply outputs, housing materials, or IP ratings affects cost. Off-the-shelf models are generally more cost-effective but may not meet all application needs. -

Material Quality and Certifications

Premium components and compliance with international standards increase price but ensure safety and longevity—critical for markets with strict regulatory frameworks like the EU or the Middle East. -

Supplier Reputation and Location

Established suppliers with proven quality records may price higher but reduce risk. Proximity to manufacturing hubs can reduce lead times and freight costs. -

Incoterms and Payment Terms

Buyers should clearly understand shipping terms (FOB, CIF, DDP) to anticipate who bears logistics risk and cost. Favorable payment terms (e.g., letter of credit, net 30) can improve cash flow and negotiation leverage.

Strategic Buyer Tips for International Procurement

-

Negotiate Based on Total Cost of Ownership (TCO)

Focus not only on unit price but on warranty, energy efficiency, expected lifespan, and after-sales support to avoid costly replacements or downtime. -

Leverage Volume Aggregation

Buyers from emerging markets (Africa, South America) may collaborate regionally to consolidate orders, achieving better pricing and shipping economies. -

Assess Supplier Certifications and Compliance Rigorously

Prioritize suppliers who meet both international and local standards to prevent import delays or market restrictions, especially in Europe and the Middle East. -

Incorporate Logistics Planning Early

Account for customs clearance times, local taxes, and potential import tariffs. Engage freight forwarders familiar with regional regulations to minimize surprises. -

Be Wary of Extremely Low Prices

Prices significantly below market averages may indicate compromises in quality or hidden costs (e.g., lack of certifications, poor warranty terms). -

Understand Pricing Fluctuations

Raw material price volatility (e.g., copper, silicon) and global supply chain disruptions can affect pricing unpredictably. Locking in prices via contracts or agreements can provide stability.

Indicative Pricing Disclaimer

Due to fluctuating raw material costs, manufacturing variances, and regional logistics differences, pricing for LED strip power supplies varies widely. Buyers should request detailed quotations inclusive of all cost components and verify terms before finalizing procurement decisions.

By carefully analyzing these cost drivers and pricing influencers, international B2B buyers can strategically source LED strip power supplies that balance cost efficiency with quality, compliance, and reliable supply—crucial factors for success across diverse global markets.

Spotlight on Potential led strip power supply Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip power supply’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip power supply

When sourcing LED strip power supplies, understanding their key technical properties and common trade terminology is crucial for making informed procurement decisions. These insights help international B2B buyers—especially in Africa, South America, the Middle East, and Europe—ensure compatibility, quality, and cost-effectiveness in their LED lighting projects.

Critical Technical Properties of LED Strip Power Supplies

-

Output Voltage and Current

LED strip power supplies must deliver a stable output voltage (commonly 12V or 24V DC) with precise current regulation. This ensures consistent brightness and prevents damage to LED strips. For buyers, verifying voltage and current specifications guarantees product compatibility and long-term reliability, minimizing costly returns or failures. -

Power Rating (Wattage)

The power rating indicates the maximum load the power supply can handle, typically expressed in watts (W). Selecting a power supply with a wattage capacity at least 20-30% higher than the total LED strip consumption is a best practice to accommodate peak loads and extend lifespan. This margin is essential for buyers managing large installations or variable lighting demands. -

Efficiency (%)

Efficiency reflects how well the power supply converts AC input to usable DC output, typically ranging from 80% to 95%. Higher efficiency reduces energy waste and operating costs—an increasingly important factor for buyers focused on sustainability and compliance with regional energy regulations, such as those in Europe and the Middle East. -

Material and Build Quality

The enclosure material (often aluminum or high-grade plastic) affects durability, heat dissipation, and safety. Buyers should prioritize power supplies with robust casing and quality components to withstand harsh environments and meet international safety certifications like CE, UL, or IEC standards. This is vital for markets in Africa and South America where environmental conditions vary widely. -

Tolerance and Stability

Voltage and current tolerance indicate how much variation the power supply output can have under load or temperature changes. Tight tolerance (±5% or better) ensures stable LED performance and color consistency—critical for commercial or architectural lighting projects where uniformity impacts brand perception. -

Protection Features

Common protections include short circuit, overvoltage, overload, and thermal shutdown. These safeguard the LED strips and power supply itself, reducing downtime and maintenance costs. Buyers should confirm these protections are present and compliant with regional safety norms.

Common Trade Terminology in LED Strip Power Supply Procurement

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing power supplies that can be rebranded or customized by buyers. OEM partnerships allow businesses to tailor product specifications or packaging to local market needs, enhancing competitiveness in diverse regions. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. Understanding MOQ helps buyers plan inventory and cash flow, especially important for small-to-medium enterprises or those testing new products in emerging markets. -

RFQ (Request for Quotation)

A formal document sent by buyers to suppliers to solicit pricing, lead times, and terms. Crafting clear RFQs with detailed technical and commercial requirements accelerates supplier evaluation and negotiation, reducing procurement cycle time. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Buyers must understand Incoterms to accurately calculate landed costs and mitigate logistics risks. -

Lead Time

The duration between placing an order and receiving the goods. Shorter lead times improve supply chain responsiveness but may affect pricing. Buyers should negotiate lead times aligned with project schedules and stock management strategies. -

Certification Compliance

Certifications such as CE (Europe), UL (North America), RoHS (Restriction of Hazardous Substances), and CB (Certification Body) indicate adherence to safety and environmental standards. Verifying certifications protects buyers from regulatory issues and enhances product acceptance in target markets.

In summary, mastering these technical properties and trade terms empowers international B2B buyers to select LED strip power supplies that match their project demands, comply with regional standards, and optimize cost-efficiency. Prioritizing these factors helps build resilient supplier partnerships and ensures successful deployment in diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip power supply Sector

Market Overview & Key Trends

The global LED strip power supply market is witnessing robust growth fueled by expanding applications in commercial, industrial, and residential lighting sectors. For international B2B buyers, especially those in emerging and diverse markets such as Africa, South America, the Middle East, and Europe (including Spain and Indonesia), understanding the evolving market dynamics is essential for strategic sourcing.

Key drivers include the global push for energy-efficient lighting solutions, government incentives to reduce carbon footprints, and rapid urbanization increasing demand for flexible and scalable lighting infrastructure. LED strip power supplies are critical components that regulate voltage and current to LED strips, ensuring longevity and consistent performance, making them indispensable for reliable lighting systems.

Among emerging technology trends, smart power supplies with integrated dimming controls, programmable outputs, and IoT compatibility are gaining traction. These features enable advanced lighting automation and energy management, appealing to sophisticated projects in commercial buildings and smart city initiatives.

Sourcing trends highlight a shift towards modular, customizable power supplies that allow buyers to tailor solutions to diverse voltage requirements and environmental conditions. Regional buyers are increasingly prioritizing suppliers who can offer certified compliance with local standards (e.g., CE and RoHS in Europe, IEC standards in the Middle East, and regional safety certifications in Africa and South America) to ensure market access and reduce regulatory risks.

Additionally, supply chain resilience is a top priority amid global disruptions. Buyers are diversifying supplier bases, incorporating local or regional manufacturers alongside global vendors to mitigate risks and reduce lead times. Strategic partnerships with LED module and power supply manufacturers who demonstrate consistent quality and transparent communication are becoming critical for maintaining competitive advantage.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a defining factor in procurement decisions for LED strip power supplies. The environmental impact of lighting systems extends beyond energy savings during use to include the sourcing of raw materials, manufacturing processes, and end-of-life disposal.

For B2B buyers, ethical sourcing means engaging suppliers who adhere to stringent environmental and social governance (ESG) standards. This includes sourcing components free from conflict minerals, reducing hazardous substances, and implementing responsible labor practices. Compliance with internationally recognized certifications such as RoHS (Restriction of Hazardous Substances), WEEE (Waste Electrical and Electronic Equipment Directive), and ENERGY STAR provides assurance of reduced environmental footprint and regulatory compliance.

The adoption of green materials—such as lead-free solder, recyclable plastics, and energy-efficient components—further enhances the sustainability profile of LED strip power supplies. Buyers increasingly demand transparency through supplier audits and sustainability reporting to verify claims and foster long-term partnerships grounded in shared values.

Moreover, the shift towards energy-efficient power supply designs that minimize standby power consumption and improve power factor correction directly contributes to lowering operational carbon emissions for end-users. For markets in Africa, South America, and the Middle East, where energy costs and grid stability vary, efficient power supplies can significantly impact total cost of ownership and environmental performance.

Integrating sustainability into procurement not only aligns with global climate goals but also strengthens brand reputation and meets the growing expectations of environmentally conscious clients and regulatory bodies.

Evolution of LED Strip Power Supply Technology

The evolution of LED strip power supplies reflects broader advances in LED technology and power electronics. Initially, simple linear power supplies dominated the market, offering limited efficiency and bulky form factors. As LED lighting demand surged, the industry transitioned to switching power supplies, which provide higher efficiency, compact size, and better thermal management.

Over the past decade, innovations have introduced constant current drivers optimized for LED strips, ensuring uniform brightness and preventing premature LED failure. The integration of smart control features—such as PWM dimming, Bluetooth or Wi-Fi connectivity, and adaptive voltage regulation—has transformed power supplies from mere energy sources into intelligent system components.

This technological progress has enabled LED strip lighting to penetrate diverse applications, from decorative residential lighting to large-scale industrial installations. For B2B buyers, understanding this evolution is crucial for selecting power supplies that not only meet current needs but also support future upgrades and digital integration.

In summary, navigating the LED strip power supply sector requires a nuanced understanding of global market trends, a commitment to sustainability, and awareness of technological advancements. Buyers in Africa, South America, the Middle East, and Europe can leverage these insights to optimize sourcing strategies, mitigate risks, and align procurement with evolving regulatory and environmental standards.

Related Video: How Global Trade Runs on U.S. Dollars | WSJ

Frequently Asked Questions (FAQs) for B2B Buyers of led strip power supply

-

How can I effectively vet suppliers of LED strip power supplies for international B2B procurement?

To vet suppliers, start by verifying their certifications such as CE, RoHS, UL, or CB, which ensure compliance with regional safety and quality standards. Request detailed product datasheets and inquire about their quality control processes, including in-house testing and third-party inspections. Evaluate supplier experience with international markets, especially in your region, and check references or customer testimonials. Visiting manufacturing sites or using virtual audits can provide deeper insights. Prioritize suppliers who offer transparent communication, reliable lead times, and have a track record of fulfilling large B2B orders consistently. -

What customization options are typically available for LED strip power supplies, and how should I approach them?

Customization can include voltage and current specifications, connector types, cable lengths, dimming compatibility, waterproof ratings, and enclosure designs. When sourcing for diverse markets like Africa or Europe, ensure the power supply matches local electrical standards (e.g., input voltage and frequency). Engage suppliers early with clear technical requirements and application details to avoid costly redesigns. Confirm the supplier’s capability to handle custom orders, including minimum order quantities (MOQs) and lead times. Customization helps optimize performance and compliance but requires thorough technical validation before mass procurement. -

What are the typical MOQs and lead times for LED strip power supplies, especially for buyers in emerging markets?

MOQs vary widely depending on supplier scale and customization level, commonly ranging from 500 to 5,000 units. Suppliers serving emerging markets like Africa or South America may offer more flexible MOQs to accommodate smaller initial orders. Lead times typically range from 4 to 12 weeks, influenced by product complexity and current supply chain conditions. To optimize procurement, establish clear timelines upfront and negotiate staggered shipments or buffer stock to mitigate delays. Early engagement and forecasting demand accurately can help suppliers plan production and reduce lead times. -

Which quality assurance certifications should I insist on when purchasing LED strip power supplies for different international markets?

Key certifications include CE and RoHS for Europe, UL or ETL for North America, CCC for China, and IEC standards for broader international acceptance. For markets in the Middle East and Africa, adherence to CE and local regulatory marks is crucial. These certifications verify electrical safety, electromagnetic compatibility, and environmental compliance. Insist on suppliers providing test reports and certification documents with each shipment. Additionally, audit suppliers’ adherence to ISO 9001 quality management systems to ensure consistent manufacturing quality and traceability. -

How can I manage logistics and shipping risks when importing LED strip power supplies internationally?

Partner with logistics providers experienced in handling electronics and familiar with customs procedures in your target countries. Use secure packaging designed to protect against moisture, shock, and static during transit. Choose reliable shipping methods balancing cost and speed, such as air freight for urgent orders or sea freight for bulk shipments. Track shipments closely and prepare all import documentation accurately to avoid customs delays. Consider insurance to mitigate risks of damage or loss. Building strong relationships with freight forwarders and customs brokers can streamline clearance and reduce unforeseen costs. -

What payment terms are advisable for international procurement of LED strip power supplies to minimize financial risk?

Common payment terms include a 30% deposit upfront with the balance paid upon shipment or after successful inspection. Letters of Credit (LC) offer strong protection by involving banks in payment release conditional on document verification. For new suppliers, consider smaller trial orders with escrow services or payment via trusted platforms to mitigate risk. Negotiate clear terms on refunds or penalties for non-compliance or delayed delivery. Always ensure payment terms align with your company’s cash flow capabilities and the trust level established with the supplier. -

How should I handle disputes related to quality or delivery delays with overseas LED strip power supply suppliers?

Establish clear contractual terms specifying quality standards, delivery schedules, and penalties for non-compliance before order confirmation. Document all communications and inspections thoroughly. If disputes arise, initiate dialogue promptly to seek amicable resolution, possibly involving third-party inspections or mediation services. Leveraging incoterms that allocate risk clearly (e.g., FOB or CIF) can clarify responsibilities. For persistent issues, escalate to legal recourse based on the contract’s governing law. Building long-term partnerships with reliable suppliers reduces dispute risks substantially. -

What are the key factors to consider when selecting LED strip power supplies for markets with varying electrical standards, such as Africa, South America, and Europe?

Ensure the power supply supports the input voltage and frequency specific to each region (e.g., 110-120V/60Hz in parts of South America, 220-240V/50Hz in Europe and Africa). Verify compatibility with local regulations and safety certifications. Consider environmental factors like temperature ranges and humidity, which affect durability. Assess whether the power supply requires additional surge protection or waterproofing based on installation conditions. Finally, prioritize suppliers offering modular or adaptable designs to streamline inventory and reduce complexity across multiple markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip power supply

Strategic sourcing of LED strip power supplies is a critical pillar for international B2B buyers aiming to secure reliable, efficient, and cost-effective lighting solutions. Key takeaways emphasize the importance of partnering with reputable suppliers who demonstrate consistent quality control, compliance with regional certifications, and robust supply chain capabilities. Buyers from Africa, South America, the Middle East, and Europe must prioritize supplier diversification and transparent communication to mitigate risks linked to geopolitical shifts and fluctuating logistics.

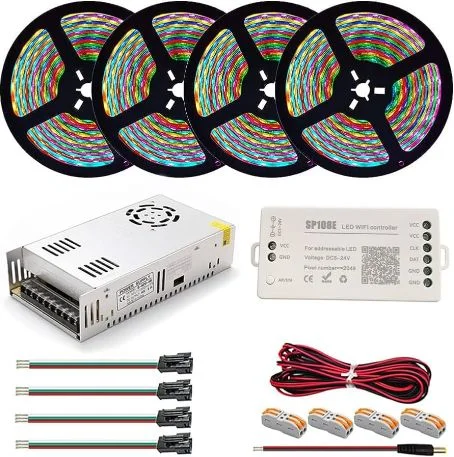

Illustrative Image (Source: Google Search)

Moreover, integrating advanced supply chain management technologies and maintaining agile inventory practices can significantly enhance responsiveness to market demands and reduce lead times. Given the variability in regional regulations and infrastructure, customization and local market adaptation remain decisive factors in supplier selection.

Looking ahead, the LED strip power supply market will continue evolving alongside global sustainability trends and digitalization of supply chains. International buyers are encouraged to leverage strategic partnerships that foster innovation and resilience. By doing so, businesses can not only optimize procurement costs but also strengthen their competitive positioning in rapidly developing markets such as those in Africa and South America, as well as mature European and Middle Eastern economies. Proactive engagement with emerging suppliers and continuous market intelligence will be essential to capitalize on growth opportunities and secure long-term value.