Guide to Led Strip Diffuser

- Introduction: Navigating the Global Market for led strip diffuser

- Understanding led strip diffuser Types and Variations

- Key Industrial Applications of led strip diffuser

- Strategic Material Selection Guide for led strip diffuser

- In-depth Look: Manufacturing Processes and Quality Assurance for led strip diffuser

- Comprehensive Cost and Pricing Analysis for led strip diffuser Sourcing

- Spotlight on Potential led strip diffuser Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strip diffuser

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip diffuser Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strip diffuser

- Strategic Sourcing Conclusion and Outlook for led strip diffuser

Introduction: Navigating the Global Market for led strip diffuser

The global surge in LED lighting adoption has spotlighted the led strip diffuser as a pivotal component in delivering high-quality, visually appealing illumination. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of led strip diffusers is essential to optimize lighting solutions, enhance energy efficiency, and meet evolving regulatory demands.

Led strip diffusers play a critical role in controlling light diffusion, minimizing glare, and protecting LED strips from dust and moisture, thereby extending the lifespan and maintaining consistent light quality. Selecting the right diffuser involves careful consideration of materials, design, and compatibility with specific LED strip types, all of which directly impact installation success and end-user satisfaction.

This comprehensive guide equips buyers with actionable insights into the various diffuser types and materials, detailing their performance characteristics and suitability for different environments. It also covers manufacturing standards, quality control protocols, and key supplier evaluation criteria to ensure reliability and compliance with international certifications. Moreover, the guide analyzes cost structures and regional market trends, helping buyers from regions such as Colombia, Mexico, and across the Middle East to make informed, cost-effective procurement decisions.

By navigating the complexities of supplier selection, customization options, and logistics considerations, this guide empowers B2B buyers to mitigate risks, avoid common pitfalls, and build resilient supply chains. With an emphasis on practical knowledge and region-specific insights, it serves as an indispensable resource for businesses aiming to leverage led strip diffusers to gain a competitive edge in the global lighting market.

Understanding led strip diffuser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frosted Diffuser | Matte finish that softens and evenly diffuses LED light | Retail displays, office lighting, hospitality | Enhances visual comfort, reduces glare; may slightly reduce brightness |

| Clear/Transparent Diffuser | Transparent cover allowing maximum light output | Industrial lighting, architectural accents | Maximizes brightness; less glare control, may expose LED hotspots |

| Opal Diffuser | Semi-opaque with smooth, milky appearance | Residential, decorative lighting, museums | Balanced diffusion and brightness; premium look but higher cost |

| Prismatic Diffuser | Textured surface with micro-structures to redirect light | Commercial offices, schools, healthcare | Controls glare and enhances uniformity; complexity can increase cost |

| UV-Stabilized Diffuser | Materials resistant to UV degradation and yellowing | Outdoor LED strips, signage, marine | Long-lasting clarity in sunlight; essential for outdoor durability |

Frosted Diffuser

Frosted diffusers feature a matte surface that scatters light, creating a soft and uniform glow. This type is highly favored in environments where visual comfort is paramount, such as retail spaces, offices, and hospitality venues. For B2B buyers, frosted diffusers offer a cost-effective way to reduce glare and hotspots, enhancing aesthetic appeal and user experience. When sourcing, it’s important to verify material quality and consistency to avoid uneven diffusion and ensure durability.

Clear/Transparent Diffuser

Clear diffusers provide minimal obstruction to light, allowing maximum brightness and color fidelity from LED strips. These are ideal for industrial applications or architectural features where light intensity is prioritized over glare control. Buyers should consider that while clear diffusers maximize illumination, they offer little protection from direct LED glare and may require additional design measures to mitigate hotspots. Selecting suppliers with precision manufacturing ensures clarity and scratch resistance.

Opal Diffuser

Opal diffusers strike a balance between light diffusion and brightness retention with their smooth, semi-opaque finish. Their elegant appearance makes them suitable for high-end residential projects, museums, and decorative installations. For B2B procurement, opal diffusers often command a premium but justify this with enhanced aesthetics and better light uniformity. Buyers should evaluate supplier capabilities for consistent opal coloration and UV resistance for long-term performance.

Prismatic Diffuser

Prismatic diffusers incorporate micro-structured textures that direct and control light distribution, effectively reducing glare and enhancing uniformity. They are widely used in commercial offices, educational institutions, and healthcare facilities where lighting quality directly impacts comfort and productivity. While prismatic diffusers may increase upfront costs due to manufacturing complexity, their benefits in glare control and compliance with lighting standards often offset the investment. Buyers should ensure compatibility with LED strip dimensions and certifications.

UV-Stabilized Diffuser

UV-stabilized diffusers are made from materials that resist yellowing and degradation caused by prolonged exposure to sunlight. These diffusers are crucial for outdoor LED strip applications such as signage, marine environments, and exterior architectural lighting. For B2B buyers targeting markets in regions with intense sun exposure, investing in UV-stabilized diffusers ensures product longevity and consistent appearance. It is vital to verify UV resistance certifications and supplier testing protocols to avoid premature failure.

Related Video: BRILLIANT Design – Govee’s Complete LED + Diffuser System

Key Industrial Applications of led strip diffuser

| Industry/Sector | Specific Application of led strip diffuser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient lighting in display cases and shelving | Enhances product visibility and customer experience | Uniform light diffusion, durability, compatibility with LED strips |

| Hospitality & Interior Design | Decorative cove lighting and architectural accents | Creates appealing atmospheres, energy-efficient lighting | Customizable diffuser shapes, color consistency, high-quality materials |

| Automotive Manufacturing | Interior vehicle lighting and dashboard illumination | Improves user comfort and safety through glare reduction | Heat resistance, compact design, compliance with automotive standards |

| Industrial & Warehousing | Task lighting in workstations and equipment enclosures | Reduces eye strain, improves productivity and safety | Robustness, IP rating for dust and moisture, ease of installation |

| Healthcare & Laboratories | Cleanroom and examination room lighting | Provides uniform, shadow-free illumination critical for precision | Non-toxic materials, easy to clean, certified for medical environments |

Retail & Commercial Lighting Applications

In retail environments across Africa, South America, and Europe, LED strip diffusers are pivotal in creating uniform and attractive lighting within display cases and shelving units. By softening and evenly distributing light, diffusers reduce harsh glare and shadows, enhancing product visibility and making merchandise more appealing to customers. For B2B buyers, it is crucial to source diffusers that are compatible with various LED strip types and offer high durability to withstand frequent maintenance. Uniform diffusion helps retailers boost sales through better presentation, while energy efficiency aligns with sustainability goals increasingly prioritized in these markets.

Hospitality & Interior Design Applications

LED strip diffusers are widely used in hotels, restaurants, and luxury interiors for cove lighting and architectural accents, delivering elegant, indirect illumination that elevates ambiance. Buyers in the Middle East and Europe particularly value diffusers that can be customized in shape and size to fit unique design requirements, while maintaining consistent color temperature and light quality. This application demands materials that resist yellowing and maintain clarity over time, supporting the creation of inviting, energy-efficient spaces that reduce operational costs without compromising aesthetics.

Automotive Manufacturing Applications

In automotive production, LED strip diffusers serve to soften interior vehicle lighting and dashboard displays, enhancing driver comfort and safety by minimizing glare and hotspots. Buyers from emerging markets like Colombia and Mexico must focus on sourcing diffusers that withstand high temperatures and vibrations typical of automotive environments. Compact designs that integrate seamlessly into tight spaces are essential. Additionally, compliance with automotive lighting standards ensures both functionality and regulatory approval, facilitating smoother market entry for vehicle manufacturers and suppliers.

Industrial & Warehousing Applications

Industrial facilities and warehouses utilize LED strip diffusers to provide consistent task lighting at workstations and inside equipment enclosures. This reduces eye strain and improves accuracy and safety for workers in demanding environments. For B2B buyers in Africa and South America, durability and high ingress protection (IP) ratings against dust and moisture are critical due to harsh operational conditions. Easy installation and maintenance also lower downtime and labor costs. Selecting diffusers that complement robust LED strips ensures long-term reliability and energy savings in large-scale industrial setups.

Healthcare & Laboratories Applications

In healthcare settings, such as cleanrooms and examination rooms, LED strip diffusers are essential for delivering shadow-free, uniform illumination necessary for precise medical work and diagnostics. Buyers in Europe and the Middle East prioritize diffusers made from non-toxic, easily sanitized materials that comply with stringent medical certifications. These diffusers help maintain hygienic environments while improving visibility for healthcare professionals. The ability to source diffusers that meet both performance and regulatory requirements is vital for hospitals and laboratories aiming to enhance patient care and operational efficiency.

Strategic Material Selection Guide for led strip diffuser

When selecting materials for LED strip diffusers, international B2B buyers must carefully balance performance, cost, durability, and compliance with regional standards. The choice of diffuser material directly affects light diffusion quality, thermal management, environmental resistance, and ultimately the end-user satisfaction. Below is a detailed analysis of four common materials used in LED strip diffusers, highlighting their properties, advantages, limitations, and considerations for buyers from Africa, South America, the Middle East, and Europe.

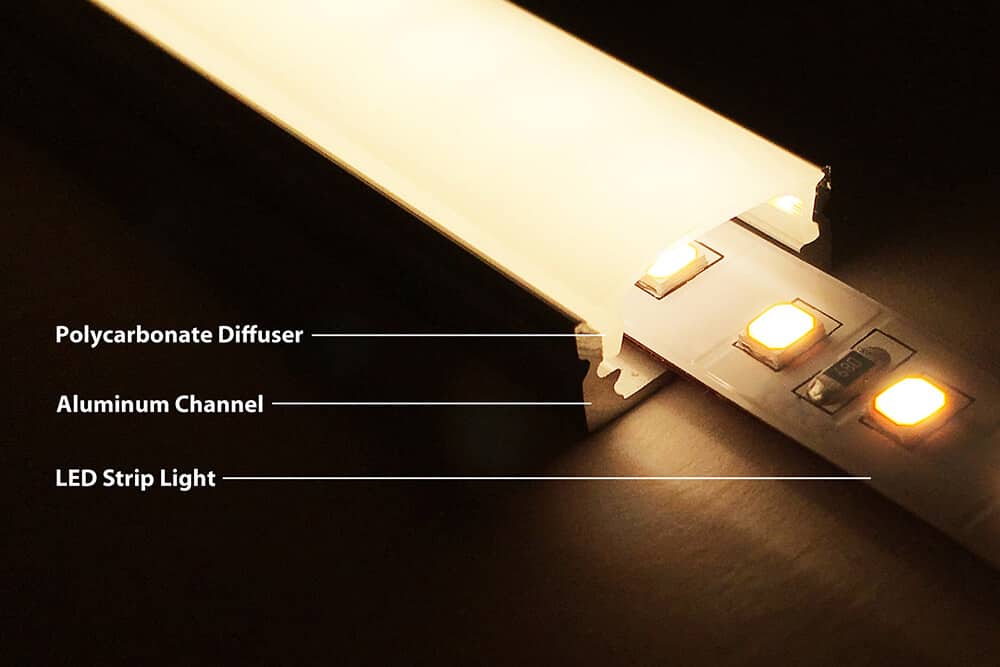

Polycarbonate (PC)

Key Properties:

Polycarbonate is a highly durable thermoplastic known for excellent impact resistance, good thermal stability (up to approximately 135°C continuous use), and outstanding optical clarity. It offers strong resistance to UV degradation and moderate chemical resistance, making it suitable for indoor and outdoor LED applications.

Pros and Cons:

PC diffusers provide superior toughness and shatter resistance compared to other plastics, which is beneficial for installations in high-traffic or industrial environments. Its optical properties enable efficient light diffusion without significant loss of brightness. However, polycarbonate is more expensive than acrylic and can yellow over time if not UV-stabilized. Manufacturing complexity is moderate, requiring precise molding to maintain optical quality.

Impact on Application:

Ideal for harsh environments or outdoor installations where mechanical durability and UV resistance are critical. PC diffusers also perform well in humid or dusty conditions common in parts of Africa and the Middle East.

Regional Considerations:

Buyers in Europe and the Middle East should verify compliance with relevant standards such as EN 62262 (IK rating for impact resistance) and RoHS directives. In South America and Africa, where supply chains may vary, sourcing UV-stabilized PC with certifications like ASTM D1003 (haze and clarity) ensures long-term performance. Cost considerations may favor PC in premium or industrial LED projects.

Acrylic (PMMA)

Key Properties:

Acrylic offers excellent light transmission (up to 92%) and is known for its superior optical clarity. It has moderate impact resistance and a continuous use temperature around 80-90°C. Acrylic is less UV resistant than PC but can be formulated with UV inhibitors.

Pros and Cons:

Acrylic diffusers are lightweight, cost-effective, and easier to fabricate with simpler tooling. They provide a bright, crisp light diffusion, making them popular for decorative and architectural lighting. However, acrylic is more brittle than PC and prone to cracking under mechanical stress or thermal cycling. It also yellows faster under prolonged UV exposure if not treated.

Impact on Application:

Best suited for indoor applications with controlled environments, such as offices, retail spaces, and residential lighting in Europe and South America. Less ideal for outdoor or industrial conditions without protective coatings.

Regional Considerations:

European buyers should ensure compliance with EN 12150 for acrylic products and consider suppliers offering UV-stabilized grades. In African and Middle Eastern markets, acrylic’s lower cost is attractive but buyers must assess the expected environmental exposure to avoid premature degradation. ASTM D4802 UV resistance tests can guide material selection.

Silicone

Key Properties:

Silicone diffusers are flexible, highly resistant to extreme temperatures (-60°C to 230°C), and exhibit excellent weathering and UV stability. They have good chemical resistance and maintain optical clarity over time.

Pros and Cons:

Silicone’s flexibility allows for innovative diffuser designs, including curved or irregular shapes, which are difficult with rigid plastics. Its thermal stability surpasses most plastics, making it suitable for high-temperature LED strips. However, silicone is generally more expensive and less rigid, which may complicate installation and require specialized mounting solutions.

Impact on Application:

Ideal for high-performance, outdoor, or industrial LED lighting applications in regions with extreme temperature variations such as the Middle East and parts of South America. Silicone diffusers are also favored where flexibility and longevity are priorities.

Regional Considerations:

Buyers should verify compliance with international standards like ISO 10993 for material safety and ASTM D2240 for hardness. In Africa and South America, where environmental extremes are common, silicone’s durability justifies the higher cost. European buyers may seek suppliers with REACH compliance and detailed material data sheets.

Polyethylene Terephthalate (PET)

Key Properties:

PET is a lightweight, semi-rigid plastic with good chemical resistance and moderate thermal stability (~70-80°C continuous use). It offers decent optical clarity and excellent moisture resistance.

Pros and Cons:

PET diffusers are cost-effective and recyclable, making them attractive for eco-conscious projects. They resist moisture and many chemicals, which is beneficial in humid or corrosive environments. However, PET has lower impact resistance and can deform under prolonged heat exposure. Optical performance is generally lower than PC or acrylic.

Impact on Application:

Commonly used in budget-sensitive indoor applications or where environmental sustainability is a selling point. Suitable for controlled environments in offices or commercial spaces in Africa and South America.

Regional Considerations:

Buyers in Europe often prioritize PET for its recyclability and compliance with EU environmental directives. In other regions, availability and cost-effectiveness are key drivers. ASTM D882 tensile testing and ISO 527 standards help ensure material consistency.

Summary Table

| Material | Typical Use Case for led strip diffuser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Outdoor and industrial LED strip diffusers | High impact resistance, UV stable, durable | Higher cost, potential yellowing without UV stabilization | High |

| Acrylic (PMMA) | Indoor decorative and architectural lighting | Excellent optical clarity, cost-effective | Brittle, less UV resistant, prone to cracking | Medium |

| Silicone | High-temperature and flexible diffuser applications | Extreme temperature tolerance, flexible design | Higher cost, less rigid, complex installation | High |

| Polyethylene Terephthalate (PET) | Budget indoor applications, eco-friendly projects | Moisture resistant, recyclable, cost-effective | Lower impact resistance, limited thermal stability | Low |

This guide equips international B2B buyers with a strategic understanding of diffuser materials to optimize their LED strip lighting solutions. Selecting the right material based on application environment, regulatory compliance, and cost considerations ensures product longevity, customer satisfaction, and competitive advantage across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip diffuser

Manufacturing Processes for LED Strip Diffusers

The production of LED strip diffusers involves a series of carefully controlled stages to ensure product consistency, durability, and optical performance. Understanding these manufacturing steps enables B2B buyers to assess supplier capabilities and quality potential effectively.

1. Material Preparation

The core materials for LED strip diffusers are typically high-grade polycarbonate (PC), acrylic (PMMA), or specialized polymers that offer excellent light diffusion, UV resistance, and thermal stability. Material preparation includes:

– Raw Material Inspection: Verifying polymer quality, moisture content, and absence of impurities to prevent defects like yellowing or brittleness.

– Drying: Polymers are dried to precise moisture levels before processing to avoid bubbles or haze in the final diffuser profile.

– Additive Mixing: UV stabilizers, anti-oxidants, and diffusion agents are blended to enhance longevity and light-scattering characteristics.

2. Extrusion/Forming

The primary shaping process for LED strip diffusers is extrusion, where heated polymer is forced through a die to create the desired profile shape. Key points include:

– Die Design: Custom dies ensure the diffuser profile matches LED strip dimensions and provides uniform light diffusion.

– Process Control: Temperature, pressure, and extrusion speed are tightly monitored to maintain consistent thickness and surface finish.

– Cooling and Calibration: After extrusion, the diffuser passes through water baths or air cooling systems and calibration tools to lock in precise dimensions and optical properties.

3. Assembly and Finishing

Post-extrusion, diffusers undergo several finishing steps before packaging:

– Cutting and Sizing: Automated cutting to standard or custom lengths with clean edges for easy installation.

– Surface Treatment: Optional anti-scratch coatings or matte finishes may be applied to improve durability and reduce glare.

– Quality Marking: Laser etching or printing of batch codes and certifications for traceability.

4. Packaging

Packaging is designed to protect diffusers during transit and facilitate handling at the buyer’s end. Anti-static and dust-proof wraps, along with sturdy cartons, are common.

Quality Assurance and Control Framework

Robust quality assurance (QA) and quality control (QC) mechanisms are fundamental to ensuring LED strip diffusers meet international standards and buyer specifications. These systems encompass multiple checkpoints and testing methodologies.

International and Industry Standards

– ISO 9001: The baseline quality management standard, ensuring suppliers have documented processes, continuous improvement, and risk management.

– CE Marking: Mandatory for European markets, confirming compliance with EU safety, health, and environmental requirements.

– RoHS Compliance: Restricts hazardous substances, critical for electronics integration and environmental safety globally.

– Other Certifications: Depending on the region, certifications such as UL (USA), CB Scheme (global electrical safety), or regional approvals (e.g., INMETRO for Brazil) may be required.

Quality Control Checkpoints

– Incoming Quality Control (IQC): Inspection and testing of raw materials and components on arrival. This includes verifying polymer grades, optical clarity, and mechanical properties.

– In-Process Quality Control (IPQC): Continuous monitoring during extrusion and assembly phases. Parameters like profile thickness, surface smoothness, and dimensional tolerances are checked using precision gauges and optical comparators.

– Final Quality Control (FQC): Comprehensive inspection of finished diffusers before shipment, including visual checks for defects, measurement verification, and functional tests.

Common Testing Methods

– Light Transmission and Diffusion Testing: Spectrophotometers measure the percentage of light transmitted and diffused to ensure uniform illumination without hotspots.

– Mechanical Testing: Tensile strength, impact resistance, and flexibility tests confirm durability under installation and operational stresses.

– Environmental Testing: UV aging, heat resistance, and humidity exposure simulate real-world conditions to predict lifespan and color stability.

– Dimensional Inspection: Automated laser measurement tools verify profile dimensions meet design specifications with minimal variance.

How B2B Buyers Can Verify Supplier Quality Assurance

International buyers must adopt proactive strategies to confirm suppliers’ quality claims and minimize procurement risks:

1. Factory Audits and Certifications Review

– Request third-party audit reports covering ISO 9001 compliance and specific LED diffuser production capabilities.

– Conduct or commission on-site audits focusing on production processes, equipment maintenance, and QC practices.

2. Quality Documentation and Traceability

– Insist on detailed QC reports for each batch, including raw material certificates, process control data, and final product inspection results.

– Verify traceability through batch numbers and production logs to facilitate issue resolution if defects arise post-delivery.

3. Third-Party Inspection and Testing

– Employ independent inspection agencies to perform random batch testing or pre-shipment inspections, especially for large orders.

– Request samples for in-house or local laboratory testing focused on optical performance and mechanical robustness.

4. Supplier Communication and Transparency

– Engage suppliers in detailed discussions about their manufacturing processes, quality protocols, and response plans for non-conformities.

– Prefer suppliers with transparent reporting systems and willingness to share process improvements or corrective actions.

QC and Certification Nuances for Buyers in Africa, South America, the Middle East, and Europe

Regional Regulatory Variations

– Europe: Compliance with CE, RoHS, and REACH is mandatory; buyers must ensure diffusers meet strict environmental and safety standards. Extended producer responsibility (EPR) schemes may also apply.

– Middle East: While CE and RoHS compliance are valued, some countries require local certification or approvals from ministries of energy or trade. Customs clearance often hinges on documented compliance.

– Africa & South America: Regulatory frameworks can be evolving; international certifications like ISO and CE provide strong assurance. However, buyers should verify compatibility with local electrical standards and import regulations (e.g., INMETRO in Brazil, SON in Nigeria).

– Country-Specific Considerations: For markets like Colombia and Mexico, additional certifications such as NOM (Norma Oficial Mexicana) or INVIMA approvals might be relevant depending on application.

Logistical and Quality Challenges

– Climate Sensitivity: High humidity and temperature fluctuations in many African and South American regions necessitate diffusers with robust UV and moisture resistance.

– After-Sales Support: Buyers should evaluate supplier capacity for local technical support, warranty handling, and spare parts availability.

– Customization Needs: Regional preferences for diffuser color, light diffusion level, or profile shape require suppliers with flexible manufacturing setups and rapid prototyping capabilities.

Key Takeaways for International B2B Buyers

- Assess Supplier Manufacturing Expertise: Confirm that suppliers utilize advanced extrusion technology, precise tooling, and stable material sources.

- Demand Comprehensive QC Systems: Ensure suppliers implement IQC, IPQC, and FQC checkpoints aligned with ISO 9001 and regional standards.

- Verify Through Independent Channels: Use third-party audits, inspections, and sample testing to validate quality before large-scale procurement.

- Understand Regional Certification Requirements: Tailor compliance verification to destination markets, considering both international and local regulations.

- Factor in Environmental and Operational Conditions: Specify diffuser materials and finishes suitable for your market’s climate and installation environments.

By prioritizing these manufacturing and quality assurance insights, B2B buyers across Africa, South America, the Middle East, and Europe can secure LED strip diffusers that deliver consistent performance, regulatory compliance, and long-term value.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip diffuser Sourcing

When sourcing LED strip diffusers, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers aiming to optimize procurement strategies and ensure competitive advantage. This analysis breaks down the core cost components, price influencers, and practical buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Strip Diffuser Sourcing

-

Materials

The primary material costs include high-quality polycarbonate or acrylic used for diffusers, which affect light diffusion properties and durability. Premium materials offering UV resistance and impact strength typically command higher prices but provide better longevity, crucial for outdoor or industrial applications. -

Labor and Manufacturing Overhead

Labor costs vary significantly by manufacturing location. Regions with advanced automation may offer lower unit labor costs despite higher wages, while manual assembly increases labor intensity and cost. Overhead includes factory utilities, equipment depreciation, and indirect labor, all contributing to the final unit cost.

Illustrative Image (Source: Google Search)

-

Tooling and Setup Charges

Custom extrusion dies or molds are often required for diffuser profiles, representing a substantial upfront investment. Buyers ordering bespoke diffuser shapes or sizes should anticipate tooling fees amortized over production volume, influencing pricing heavily at lower order quantities. -

Quality Control (QC)

Rigorous QC processes, including optical performance testing and dimensional accuracy inspections, add to costs but are non-negotiable for ensuring product reliability. Certifications such as CE for Europe or regional compliance standards may require additional testing or documentation efforts.

Illustrative Image (Source: Google Search)

-

Logistics and Shipping

Freight costs depend on shipment size, mode (air vs. sea), and destination port infrastructure. For buyers in Africa and South America, longer transit times and customs clearance complexities can increase landed costs. Packaging designed to protect diffusers during transit also factors into cost. -

Supplier Margin

Suppliers incorporate profit margins reflecting market conditions, production efficiency, and competitive positioning. Negotiating favorable margins often depends on order volume and long-term partnership potential.

Influencers Impacting LED Strip Diffuser Pricing

-

Order Volume and Minimum Order Quantities (MOQs)

Larger volumes typically reduce per-unit costs via economies of scale. However, buyers in emerging markets may face challenges meeting MOQs, necessitating strategic negotiation or sourcing from suppliers offering flexible lot sizes. -

Specifications and Customization

Tailored diffuser profiles, colors, or coatings increase complexity and cost. Standardized products usually carry lower prices and faster lead times. -

Material Quality and Certifications

Higher-grade raw materials and certified products (e.g., RoHS, REACH compliance) command premium pricing but reduce risk and enhance market acceptance, particularly in Europe and the Middle East. -

Supplier Reliability and Location

Established suppliers with proven track records may price higher but offer reliability and after-sales support, which is invaluable for international buyers managing complex supply chains. -

Incoterms and Payment Terms

Different Incoterms (FOB, CIF, DDP) shift cost and risk responsibilities. Buyers should evaluate total landed cost implications and negotiate payment terms that balance cash flow with supplier confidence.

Practical Buyer Tips for Cost-Efficient Procurement

-

Engage in Volume Consolidation

Pooling demand across projects or departments can unlock better pricing tiers and reduce per-unit tooling amortization. -

Prioritize Total Cost of Ownership (TCO)

Evaluate not only purchase price but also durability, warranty, replacement cycles, and energy efficiency impact, especially for diffusers integrated with LED strips in harsh environments. -

Leverage Local Market Insights

Buyers in Africa and South America should account for import duties, taxes, and potential delays, factoring these into cost models. Establishing relationships with suppliers familiar with these regions can mitigate risks. -

Negotiate Based on Long-Term Partnerships

Emphasize reliability and consistent quality in negotiations, as recurrent orders offer suppliers predictable revenue, often leading to better pricing and service. -

Request Transparent Cost Breakdowns

Understanding each cost component allows buyers to identify negotiation levers—such as opting for standard sizes or adjusting packaging—to reduce expenses. -

Consider Certification Requirements Early

Avoid costly rejections or compliance delays by confirming product certifications and testing early in the sourcing process.

Disclaimer on Pricing

Prices for LED strip diffusers vary widely based on design complexity, order size, supplier capabilities, and regional factors. The figures discussed here are indicative and should be validated with multiple suppliers through detailed requests for quotation (RFQs). International buyers are encouraged to conduct thorough due diligence to align cost expectations with quality and delivery requirements.

By dissecting cost elements and price drivers, B2B buyers from diverse global markets can approach LED strip diffuser procurement with enhanced clarity, enabling smarter negotiations, optimized budgets, and stronger supplier partnerships.

Spotlight on Potential led strip diffuser Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strip diffuser’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip diffuser

When sourcing LED strip diffusers, understanding the key technical properties and common trade terminology is essential for making informed procurement decisions. This knowledge helps international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—ensure product quality, compatibility, and smooth supply chain operations.

Critical Technical Properties of LED Strip Diffusers

-

Material Grade

Most LED strip diffusers are made from polycarbonate (PC) or acrylic (PMMA). Polycarbonate offers superior impact resistance and heat tolerance, making it ideal for industrial and outdoor applications. Acrylic provides excellent light transmission and is more cost-effective but less heat resistant. Selecting the right material grade affects durability, longevity, and suitability for specific environments. -

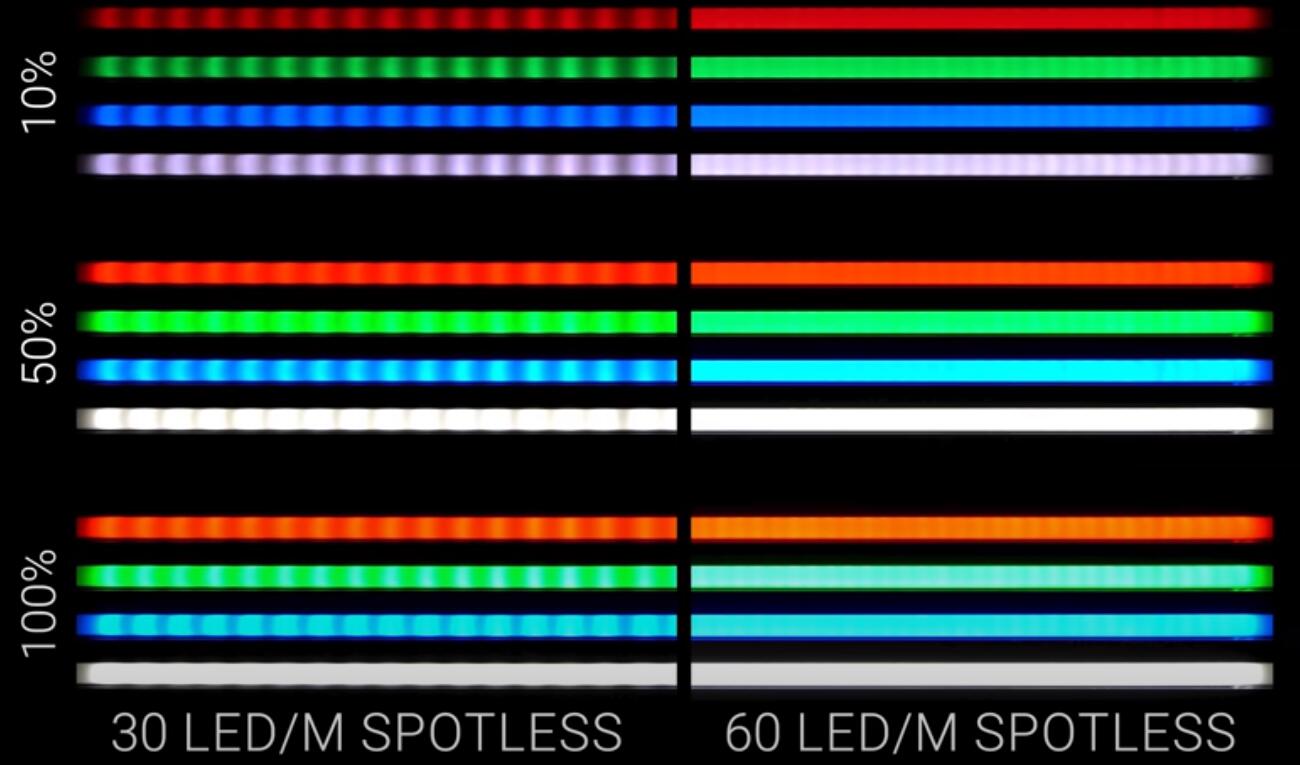

Light Transmission Rate (LTR)

This is the percentage of light that passes through the diffuser material. A higher LTR (typically 85-95%) ensures brighter illumination but may reduce the diffusion effect, causing visible LED dots. Lower LTR improves uniformity by softening the light but can slightly reduce brightness. Buyers should balance LTR with the desired lighting effect for their applications. -

Tolerance and Dimensional Accuracy

Precision in diffuser dimensions is crucial, especially for integration into aluminum LED profiles or channels. Typical manufacturing tolerances range from ±0.1 mm to ±0.3 mm. Tight tolerance ensures a secure fit, prevents light leakage, and maintains aesthetic consistency across installations. Buyers should request detailed specification sheets to verify compliance. -

Surface Finish and Diffusion Pattern

Diffusers may have matte, frosted, or micro-prismatic finishes. Matte surfaces offer soft, even diffusion with minimal glare, while micro-prismatic designs can enhance brightness and directionality. The choice influences visual comfort and efficiency. Understanding these finishes helps buyers specify products that align with end-user preferences and regulatory lighting standards. -

UV and Heat Resistance

For outdoor or high-temperature environments, diffusers must resist yellowing and deformation caused by UV exposure and heat. Materials with UV stabilizers or heat-resistant additives extend product life and maintain optical clarity. Buyers targeting regions with strong sunlight or industrial settings should prioritize these properties to avoid premature failures. -

Fire Retardancy Rating

Compliance with fire safety standards (such as UL94 V-0 or equivalent regional certifications) is often mandatory. Fire-retardant diffusers reduce risks in commercial and public buildings. Buyers should verify certification documentation to ensure adherence to local building codes and insurance requirements.

Common Trade Terminology in LED Strip Diffuser Procurement

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who manufacture diffusers according to another company’s design and branding. OEM partnerships allow buyers to customize product specifications and packaging, enhancing brand differentiation. Understanding OEM capabilities is vital for buyers seeking tailored solutions rather than off-the-shelf products. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. MOQs can vary widely, impacting inventory costs and cash flow. Buyers from emerging markets or smaller businesses should negotiate MOQs or explore consolidated purchasing to optimize order sizes. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting price, lead time, and terms for specific diffuser products. A clear, detailed RFQ including technical drawings, material specs, and quantity helps suppliers provide accurate quotes, reducing procurement cycle times and avoiding misunderstandings. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) that define responsibilities for shipping, insurance, and customs between buyers and sellers. Understanding Incoterms ensures clarity on cost allocation and risk during transport, which is critical for international buyers managing cross-border logistics. -

Lead Time

The period between order confirmation and product delivery. Lead times can be affected by manufacturing complexity, customization, and shipping routes. Buyers should assess lead times early to align procurement schedules with project deadlines and avoid costly delays. -

Binning

Although more common with LEDs themselves, binning can apply when diffusers are paired with LED strips. It refers to sorting products by consistent optical or color characteristics to ensure uniform lighting quality. Buyers should confirm if diffusers and LED strips are matched or compatible for optimal results.

By mastering these technical specifications and trade terms, B2B buyers can confidently navigate supplier offerings, ensure compliance with regional regulations, and optimize procurement strategies for LED strip diffusers. This foundation supports sustainable investments and competitive advantages in diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip diffuser Sector

Market Overview & Key Trends

The global market for LED strip diffusers is experiencing robust growth driven by the expanding adoption of LED lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers, especially in emerging and fast-growing regions such as Africa, South America (including Colombia and Mexico), the Middle East, and Europe, this sector offers significant opportunities fueled by increasing infrastructure development and energy efficiency mandates.

Key market drivers include:

- Rising demand for energy-efficient lighting: Governments worldwide are implementing stricter energy consumption regulations, encouraging the replacement of traditional lighting with LED systems. LED strip diffusers play a crucial role in enhancing light quality and distribution, making them essential components in these upgrades.

- Customization and integration trends: Buyers increasingly seek LED strip diffusers tailored to specific applications, from architectural accent lighting to industrial environments. Modular designs that accommodate various LED strip sizes, colors, and voltages (5V, 12V, 24V) enable flexibility and ease of installation.

- Technological advancements: Innovations such as high-density LED strip compatibility, improved diffuser materials for better light diffusion and heat dissipation, and integration with smart lighting controls (e.g., RGBW, addressable LEDs) are transforming market offerings. These features appeal to B2B buyers aiming to differentiate product portfolios and meet sophisticated client demands.

- Supply chain diversification: Due to geopolitical shifts and logistics challenges, buyers in Africa, South America, and the Middle East are increasingly sourcing from multiple regions, including Asia and Europe, to mitigate risks. Strategic partnerships with manufacturers offering reliable lead times, quality certifications (CE, RoHS, CB), and after-sales support are critical.

- Growing emphasis on durability and IP ratings: For outdoor and industrial applications, waterproof and dustproof LED strip diffusers are in high demand. Buyers must prioritize suppliers who provide robust solutions certified for harsh environments to ensure longevity and reduce maintenance costs.

Understanding these dynamics allows B2B buyers to optimize procurement strategies, balancing cost, quality, and compliance with local regulations to maximize value.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of procurement decisions in the LED strip diffuser sector. International buyers are increasingly held accountable not only for product performance but also for the environmental and social impact of their supply chains.

Environmental impact considerations include:

- Material selection: Diffusers made from recyclable, UV-stabilized polycarbonate or acrylic reduce environmental footprints while offering superior light diffusion and durability. Avoiding materials with hazardous additives aligns with global green standards.

- Energy efficiency: High-quality diffusers contribute to optimal light distribution, enhancing LED efficiency and reducing overall energy consumption. This is particularly relevant in regions with high electricity costs or sustainability targets, such as Europe and the Middle East.

- Waste reduction: Modular and easy-to-install diffusers facilitate maintenance and replacement without full fixture disposal, supporting circular economy principles.

Ethical sourcing imperatives:

- Buyers should prioritize suppliers adhering to internationally recognized labor standards and environmental management systems (e.g., ISO 14001). Transparency in sourcing helps mitigate risks related to forced labor or environmental non-compliance.

- Certifications such as RoHS, REACH, and GreenGuard assure compliance with chemical safety and low emissions, increasingly demanded by European and Middle Eastern markets.

- Engaging suppliers with documented sustainability policies enables B2B buyers to bolster their corporate social responsibility (CSR) profiles and meet stringent procurement requirements from multinational clients.

By integrating sustainability and ethical considerations into sourcing strategies, buyers from Africa, South America, the Middle East, and Europe can not only fulfill regulatory demands but also enhance brand reputation and long-term supply chain resilience.

Evolution of LED Strip Diffusers in B2B Lighting

LED strip diffusers have evolved from simple plastic covers to sophisticated components integral to modern lighting design and performance. Initially, diffusers primarily served to protect LED strips from dust and physical damage. However, as LED technology matured, the focus shifted towards optimizing light quality, reducing glare, and enhancing aesthetic appeal.

The introduction of advanced diffuser materials—such as frosted polycarbonate and micro-structured acrylic—improved light uniformity and minimized hotspots, which is essential for commercial and architectural lighting projects. Custom extrusions and aluminum channel profiles further enhanced thermal management and installation flexibility.

For B2B buyers, understanding this evolution highlights the importance of selecting diffusers that not only protect LEDs but also contribute to energy savings, lighting quality, and compliance with increasingly complex market demands. Today’s LED strip diffusers are engineered for compatibility with a wide range of LED strips, including RGB and addressable types, enabling sophisticated lighting solutions that cater to diverse applications across global markets.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip diffuser

-

How can I effectively vet LED strip diffuser suppliers for international B2B procurement?

To ensure reliability, start by verifying the supplier’s certifications relevant to your region, such as CE and RoHS for Europe or local standards in Africa and South America. Request detailed product datasheets and samples to assess quality firsthand. Evaluate their production capacity, quality control processes, and track record with similar international clients. Use third-party audits or factory visits if feasible. Check references and client testimonials, especially from buyers in your region, to confirm timely delivery and after-sales support. Strong supplier vetting mitigates risks associated with inconsistent product quality and logistical challenges. -

Can LED strip diffusers be customized to meet specific project requirements?

Yes, customization is common in LED strip diffusers to suit different installation environments and aesthetic preferences. You can request variations in diffuser materials, shapes (e.g., U-channel, V-shape), opacity levels, and lengths to optimize light diffusion and fixture integration. Many manufacturers offer bespoke extrusion profiles and color options to match branding or architectural themes. When negotiating customization, clarify minimum order quantities (MOQs), lead times, and any tooling fees upfront to avoid delays. Tailored solutions can enhance product performance and end-user satisfaction but require clear technical specifications and early supplier collaboration. -

What are typical minimum order quantities (MOQs) and lead times for LED strip diffusers in global B2B trade?

MOQs vary widely based on the complexity of the diffuser profile and customization level, typically ranging from 500 to several thousand meters per order. Standard profiles usually have lower MOQs due to mass production economies. Lead times can span 4 to 12 weeks depending on order size, customization, and current supply chain conditions. Buyers from Africa, South America, and the Middle East should factor in additional transit and customs clearance time. Early communication with suppliers about project timelines and order flexibility is critical to align expectations and secure timely delivery. -

Which quality assurance standards and certifications should I require for LED strip diffusers?

Request suppliers to provide certifications that ensure product safety, environmental compliance, and performance consistency. For Europe, CE marking and RoHS compliance are essential, while buyers in other regions might require ISO 9001 quality management certification and possibly UL or ETL marks for electrical safety. Confirm that diffusers are made from flame-retardant materials and UV-resistant polymers to guarantee durability in various climates. Insist on batch testing reports and warranty terms to protect your investment. Robust QA documentation helps prevent failures and supports regulatory compliance in your target markets. -

How should I approach payment terms and risk mitigation in international LED strip diffuser transactions?

Secure favorable payment terms by balancing risk and cash flow needs; common options include 30% advance with balance upon shipment or letter of credit (L/C) for higher-value orders. For new suppliers, consider escrow services or payments against third-party inspection reports. Negotiate clear contract clauses covering product specifications, delivery schedules, and penalties for non-compliance. Use trade finance tools and insurance to protect against currency fluctuations and shipment loss. Transparent communication and incremental order increases after successful initial transactions build mutual trust and reduce financial exposure. -

What logistical considerations are critical when importing LED strip diffusers from overseas suppliers?

Understand the full supply chain from factory to your warehouse, including packaging standards to prevent damage during transit. Choose reliable freight forwarders experienced with LED lighting products and your destination’s customs regulations. Factor in import duties, taxes, and possible certification inspections at entry ports, which vary by region. Opt for consolidated shipments when possible to reduce costs, but balance this with inventory holding risks. Establish clear Incoterms (e.g., FOB, CIF) with your supplier to delineate responsibility and cost-sharing for shipping and insurance. -

How can I handle disputes or quality issues with LED strip diffuser suppliers in international trade?

Proactively include dispute resolution mechanisms in contracts, such as mediation or arbitration clauses specifying applicable law and venue. Maintain thorough documentation of all communications, specifications, and quality inspections. If quality issues arise, promptly notify the supplier with evidence and request corrective action or replacement. Engage third-party inspection agencies for unbiased verification. Cultivating a collaborative relationship can facilitate faster problem resolution. For persistent issues, consider diversifying suppliers to reduce dependency and safeguard your supply chain. -

Are there region-specific challenges I should anticipate when sourcing LED strip diffusers for markets like Africa, South America, and the Middle East?

Yes, each region presents unique challenges. In Africa and parts of South America, infrastructure limitations may affect shipping times and product compatibility with local power standards. The Middle East often demands stringent certifications and durable materials for harsh environments. Currency volatility and import regulations can impact pricing and delivery schedules. To address these, engage suppliers familiar with your target markets, request samples for local testing, and plan for buffer stock. Tailoring procurement strategies to regional nuances enhances supply chain resilience and market acceptance.

Strategic Sourcing Conclusion and Outlook for led strip diffuser

Strategic sourcing of LED strip diffusers demands a meticulous balance of quality assurance, supplier reliability, and compliance with regional standards. For international B2B buyers—especially those operating in diverse markets across Africa, South America, the Middle East, and Europe—leveraging suppliers who demonstrate robust manufacturing capabilities, certification adherence (such as CE, RoHS, and local approvals), and customization flexibility is critical. Prioritizing these factors not only mitigates risks related to product performance and regulatory non-compliance but also enhances the overall value proposition of LED lighting solutions.

Key takeaways for buyers include the necessity of thorough supplier vetting, understanding material and design variations in diffusers, and aligning procurement strategies with end-use applications and environmental conditions. Efficient logistics and transparent communication channels further ensure timely delivery and support scalability in dynamic markets like Colombia, Mexico, and beyond.

Looking ahead, the LED strip diffuser market is poised for continued innovation driven by sustainability demands and smart lighting integration. International buyers who adopt a strategic sourcing mindset—embracing technology trends, fostering resilient supplier partnerships, and prioritizing quality—will secure competitive advantages. Now is the time to deepen market intelligence, engage with trusted manufacturers, and future-proof your LED procurement to meet evolving business and regulatory landscapes worldwide.