Guide to Led Strip Lights Corners

- Introduction: Navigating the Global Market for led strip lights corners

- Understanding led strip lights corners Types and Variations

- Key Industrial Applications of led strip lights corners

- Strategic Material Selection Guide for led strip lights corners

- In-depth Look: Manufacturing Processes and Quality Assurance for led strip lights corners

- Manufacturing LED Strip Lights Corners: Key Processes and Techniques

- Quality Assurance and Control: Ensuring Reliability and Consistency

- How B2B Buyers Can Verify Supplier Quality Controls

- QC and Certification Nuances for Specific Regions

- Comprehensive Cost and Pricing Analysis for led strip lights corners Sourcing

- Spotlight on Potential led strip lights corners Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strip lights corners

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lights corners Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strip lights corners

- Strategic Sourcing Conclusion and Outlook for led strip lights corners

Introduction: Navigating the Global Market for led strip lights corners

The global demand for LED strip lights has surged as businesses seek versatile, energy-efficient lighting solutions that enhance architectural aesthetics and functional design. However, one of the most technically challenging aspects in LED strip light installations is managing corners—critical junctions that can make or break the visual appeal and durability of the entire lighting setup. For B2B buyers, especially in dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of LED strip lights corners is essential to ensuring successful project outcomes and long-term client satisfaction.

This comprehensive guide delves deep into the complexities of corner applications in LED strip lighting, covering a wide spectrum of topics tailored for professional buyers and installers. You will gain insights into the variety of corner types—such as 90-degree folds, L-shape, T-shape, and flexible connectors—along with the materials and technologies that optimize performance and aesthetics. Additionally, the guide evaluates manufacturing standards, quality control processes, and reliable supplier criteria to help you identify trustworthy partners in key regions, including UAE and Spain.

Cost considerations and market trends are also examined to empower strategic purchasing decisions that balance quality, innovation, and budget constraints. Finally, a curated FAQ section addresses common challenges and practical solutions encountered during installation and maintenance.

By leveraging this knowledge, international B2B buyers can confidently navigate supplier negotiations, customize product specifications, and implement lighting designs that meet stringent professional standards—ultimately transforming corner challenges into opportunities for excellence and competitive advantage.

Understanding led strip lights corners Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 90-Degree Pinch Fold | Sharp fold between LEDs without cutting or connectors | Architectural accents, retail displays | Cost-effective, minimal parts; risk of PCB damage if mishandled |

| Cut-and-Solder Corners | Cutting at designated points and soldering connections | Custom signage, high-end installations | Highly customizable, durable; requires skilled labor and tools |

| L-Shape Corner Connectors | Snap-in or clip connectors for 90-degree turns | Commercial lighting, exhibition booths | Quick installation, neat finish; added material cost and bulk |

| Flexible PCB Strips | Strips designed with enhanced bendability | Tight spaces, staircases, curved surfaces | Allows smooth bends without damage; higher price point |

| T-Shape & Multi-Connectors | Connect multiple strips at corners or junctions | Complex layouts, large-scale installations | Enables versatile configurations; complexity increases cost |

90-Degree Pinch Fold

This method involves carefully folding the LED strip at a 90-degree angle between LEDs without cutting. It is ideal for standard, non-waterproof strips and applications where budget constraints exist. B2B buyers should consider this for projects where minimal hardware is preferred and the installation environment is controlled to avoid mechanical stress. However, improper folding can cause circuit damage, so training or experienced installers are essential to reduce failure risk.

Cut-and-Solder Corners

Cutting the strip at pre-marked points and soldering the ends together allows for precise corner turns with minimal visual disruption. This technique suits high-end architectural projects and custom signage requiring seamless lighting. While it demands skilled labor and soldering equipment, it ensures robust electrical connections and flexibility in layout design. Buyers should factor in labor costs and quality control to maintain reliability.

L-Shape Corner Connectors

These connectors provide a fast and reliable way to form 90-degree bends by snapping or clipping strip ends into place. They are popular in commercial lighting and exhibition setups where time efficiency and neat aesthetics are priorities. Although they add some bulk and material cost, connectors reduce installation complexity and allow easy maintenance or replacement. Buyers should verify compatibility with strip width and voltage specifications.

Flexible PCB Strips

Manufactured with enhanced flexibility, these LED strips can bend smoothly around corners without cutting or connectors, ideal for tight or irregular spaces such as staircases or curved architectural features. Though priced higher, they minimize installation time and reduce potential failure points. B2B buyers focusing on innovative designs or complex layouts will find these strips advantageous, especially when durability and continuous lighting are critical.

T-Shape & Multi-Connectors

These specialized connectors enable multiple LED strip sections to join at corners or junctions, facilitating complex lighting configurations. They are suited for large-scale or intricate installations like retail environments or event lighting where multiple directions of illumination are necessary. While offering versatility, they increase installation complexity and cost. Buyers should assess project scale and technical support availability before opting for these connectors.

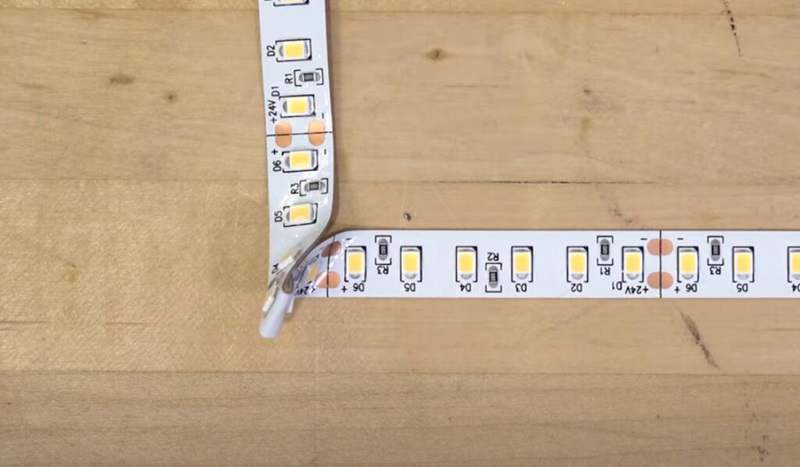

Related Video: How to Bend LED Strips Around Corners

Key Industrial Applications of led strip lights corners

| Industry/Sector | Specific Application of led strip lights corners | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Illuminated display shelving and product showcases | Enhances product visibility with seamless lighting around corners, improving customer engagement and sales | Durable connectors, consistent color temperature, easy installation, and maintenance |

| Hospitality & Leisure | Ambient lighting in hotels, restaurants, and lounges | Creates elegant atmosphere with smooth corner transitions, elevating guest experience and brand image | IP-rated waterproofing for humid areas, flexible strips, and aesthetic finish |

| Architectural & Interior Design | Cove lighting, accent lighting in complex ceiling/wall junctions | Enables creative lighting designs with uninterrupted illumination at corners, highlighting architectural features | High-quality flexible PCBs, precision cut points, and strong adhesive backing |

| Automotive & Transportation | Interior cabin lighting in buses, trains, and luxury vehicles | Provides uniform lighting in confined, curved spaces, enhancing passenger comfort and safety | Vibration-resistant connectors, heat dissipation, and compliance with vehicle standards |

| Signage & Advertising | Backlit signage with sharp corner illumination | Ensures consistent brightness and visual appeal around corners, increasing brand visibility and impact | Weather-resistant materials, easy-to-install corner connectors, and energy efficiency |

In Retail & Commercial Spaces, LED strip lights with corner solutions are vital for illuminating display shelves and product showcases that often have angular layouts. By utilizing professional corner connectors or precise folding techniques, businesses can achieve uninterrupted lighting that enhances product visibility, attracting customers and boosting sales. For B2B buyers in regions like Spain or the UAE, sourcing strips with consistent color temperatures and robust adhesive backing is crucial to withstand frequent maintenance and varying ambient conditions.

The Hospitality & Leisure sector benefits significantly from LED strip lights corners in creating ambient lighting for hotels, restaurants, and lounges. Smooth transitions around corners help maintain a sophisticated atmosphere, which is essential for guest satisfaction and brand differentiation. Buyers from Middle Eastern markets must prioritize waterproof and dustproof ratings (e.g., IP65 or above) due to humid environments, ensuring longevity and minimal maintenance in demanding settings.

Illustrative Image (Source: Google Search)

In Architectural & Interior Design, LED strip lights corners enable designers to execute complex cove lighting and accent lighting around ceiling and wall junctions. This application demands high flexibility and precise corner handling to avoid visible gaps or damage to the strips, preserving the architectural integrity and lighting uniformity. European buyers, especially in design-forward markets like Spain, should look for strips with high-quality flexible PCBs and reliable adhesive systems that support clean installations in premium projects.

The Automotive & Transportation industry uses LED strip lights corners extensively for interior cabin lighting in buses, trains, and luxury vehicles. These applications require lighting solutions that conform to curved and confined spaces without compromising durability. B2B buyers from Africa and the Middle East should focus on vibration-resistant connectors and materials capable of withstanding temperature fluctuations and mechanical stress, ensuring safety and comfort for passengers.

Finally, in Signage & Advertising, LED strip lights corners are indispensable for backlit signage that features sharp angles. Proper corner lighting guarantees uniform brightness and sharp visual appeal, crucial for brand visibility and marketing effectiveness. International buyers need to prioritize weather-resistant materials and energy-efficient components to ensure signage performs reliably in outdoor environments across diverse climates, from European urban centers to tropical regions in South America.

Related Video: How To Set Up Govee RGB LED Strip Lights With Corners Angles And More Tips

Strategic Material Selection Guide for led strip lights corners

When selecting materials for LED strip lights corners, international B2B buyers must consider factors such as mechanical flexibility, thermal management, durability, and compliance with regional standards. The choice of material directly affects installation ease, longevity, and aesthetic quality, especially in diverse markets like Africa, South America, the Middle East, and Europe, where environmental conditions and regulatory requirements vary.

Flexible Printed Circuit Boards (FPC)

Key Properties:

FPCs are the foundational material for LED strips, made from polyimide or polyester films with copper traces. They offer excellent flexibility along the length but limited bending across the width, which is critical when navigating corners. They typically withstand temperatures up to 130°C and have good electrical insulation properties.

Pros & Cons:

FPCs provide lightweight, thin profiles ideal for tight spaces and complex geometries. However, sharp bends can cause microfractures in copper traces, leading to failures. They are cost-effective but require precise handling and installation expertise to avoid damage.

Impact on Application:

FPCs are suitable for indoor and some outdoor applications when paired with protective coatings. Their flexibility supports creative lighting designs but demands careful corner treatment, often necessitating specialized connectors or folding techniques.

Considerations for International Buyers:

Buyers in regions with high ambient temperatures (e.g., Middle East, parts of Africa) should verify the thermal rating of the FPC material. Compliance with IEC and UL standards is common, but European buyers may also require RoHS and REACH certifications. In South America, ASTM standards for electrical safety might apply. Additionally, sourcing from suppliers who can provide documentation on material traceability and flame retardancy is essential.

Aluminum Channels/Profiles

Key Properties:

Aluminum profiles serve as mounting channels for LED strips, offering structural support, heat dissipation, and aesthetic framing. Aluminum alloys used typically have good corrosion resistance and can operate in temperatures ranging from -40°C to 150°C.

Pros & Cons:

Aluminum channels enhance durability and extend LED lifespan by managing heat effectively. They also facilitate neat corner transitions using pre-fabricated corner connectors or custom bending. The downside is increased cost and weight compared to bare strips, and installation complexity rises with intricate corner designs.

Impact on Application:

Ideal for commercial and architectural projects requiring robust, long-lasting installations, aluminum profiles protect strips in harsh environments. They are particularly favored in outdoor or semi-outdoor settings common in Europe and the Middle East, where UV exposure and dust are concerns.

Considerations for International Buyers:

European buyers often expect anodized or powder-coated finishes complying with EN 12373 for corrosion resistance. In the Middle East and Africa, corrosion resistance against saline or dusty environments is critical, so buyers should specify marine-grade aluminum alloys or protective coatings. South American markets may demand compliance with ISO 9227 for salt spray resistance.

Silicone or PVC Corner Connectors

Key Properties:

Corner connectors made from silicone or PVC provide flexible joints for LED strips, allowing 90-degree turns without soldering. Silicone connectors offer excellent temperature resistance (-50°C to 200°C) and UV stability, while PVC variants are more cost-effective but less durable under extreme conditions.

Pros & Cons:

Silicone connectors are highly durable, waterproof, and maintain flexibility over time, making them suitable for outdoor and industrial applications. PVC connectors are cheaper and easier to source but may degrade faster in hot or sunny climates, limiting their lifespan.

Impact on Application:

These connectors simplify installation and reduce labor costs by eliminating complex soldering at corners. They are widely used in retail displays, signage, and architectural lighting where quick, reliable corner solutions are needed.

Considerations for International Buyers:

For Middle Eastern and African markets with high UV exposure, silicone connectors are preferable due to their longevity. European buyers may require connectors that meet EN 60598 for electrical safety and fire resistance. South American buyers should confirm compliance with local electrical codes and consider environmental factors like humidity and temperature fluctuations.

Stainless Steel Clips and Mounting Accessories

Key Properties:

Stainless steel clips and mounting brackets secure LED strips and connectors at corners, providing mechanical stability. Grades such as 304 or 316 stainless steel offer excellent corrosion resistance and mechanical strength, withstanding temperatures up to 870°C.

Pros & Cons:

Stainless steel accessories ensure long-term durability and resistance to environmental degradation, especially in outdoor or coastal installations. However, they add to material and installation costs and may require specialized tools for mounting.

Impact on Application:

These accessories are critical in installations exposed to moisture, dust, or mechanical stress, common in industrial or outdoor architectural lighting. They maintain strip alignment at corners, preventing sagging or detachment.

Considerations for International Buyers:

Buyers in coastal regions of Africa, South America, and the Middle East should prioritize 316-grade stainless steel for superior saltwater corrosion resistance. European standards such as EN 10088 apply to stainless steel quality. Additionally, buyers should consider the availability of compatible mounting hardware that meets local building codes.

| Material | Typical Use Case for led strip lights corners | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Printed Circuit Boards (FPC) | Base material for LED strips requiring flexibility along runs | Lightweight, flexible, cost-effective | Limited bending across width, prone to microfractures | Low |

| Aluminum Channels/Profiles | Structural support and heat dissipation in architectural lighting | Excellent heat management and durability | Higher cost and weight, installation complexity | Medium |

| Silicone or PVC Corner Connectors | Flexible corner joints for quick, solderless installation | Durable, waterproof (silicone), easy to install | PVC less UV resistant; silicone connectors costlier | Medium |

| Stainless Steel Clips and Mounting Accessories | Mechanical fixing and stabilization of strips at corners | High corrosion resistance and mechanical strength | Increased cost and requires specific tools | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lights corners

Manufacturing LED Strip Lights Corners: Key Processes and Techniques

The production of LED strip lights corners involves several critical manufacturing stages, each designed to ensure the final product meets both functional and aesthetic requirements demanded by B2B buyers globally. Understanding these stages helps buyers assess supplier capabilities and product quality, especially when sourcing from diverse markets such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

Raw materials form the foundation of quality LED strip corners. This stage includes:

- Flexible PCB Fabrication: The flexible printed circuit board (FPCB) is produced using copper-clad laminates with precise etching to create conductive pathways. For corners, the PCB must allow bending without cracking, often requiring specialized flexible substrates such as polyimide or PET films.

- Component Sourcing: LEDs, resistors, connectors, and adhesives are procured based on stringent specifications. High-quality LEDs with consistent lumen output and color temperature are essential for uniform lighting around corners.

- Adhesive and Protective Coatings: Pressure-sensitive adhesives (PSAs) and waterproofing materials (silicone or epoxy) are selected to maintain adhesion and durability, particularly around stress points like corners.

2. Forming and Shaping Corners

Manufacturing LED strip corners typically involves:

- Cutting and Scoring: The strip is precisely cut at designated points between LEDs to prevent damage. Scoring or perforation lines facilitate folding or bending without compromising circuitry.

- Folding Techniques: For integrated corners, the strip undergoes controlled folding (pinch fold or gentle bends) where the PCB substrate is creased between LEDs, maintaining electrical continuity without solder joints.

- Connector Assembly: Where folding is insufficient or impractical, corner connectors (L-shape, 90-degree snap-on, or flexible wire connectors) are attached. These connectors are manufactured from durable plastics or metals and require precision molding and plating to ensure secure electrical contacts.

3. Assembly

The assembly stage integrates the individual components into a functional unit:

- Soldering: For cut-and-connect corners, automated or manual soldering attaches jumper wires or connectors. Precision soldering is critical to avoid cold joints or shorts that could cause early failure.

- Encapsulation: Waterproof and dustproof coatings are applied, especially for outdoor or humid environments. This includes potting or conformal coatings over solder joints and connectors.

- Adhesive Application: The backing adhesive is applied or reinforced at corners to prevent peeling or sagging during installation.

4. Finishing

Final touches ensure the product is ready for shipment and installation:

- Trimming and Cleaning: Excess materials are trimmed, and strips are cleaned to remove flux residues or contaminants that could affect adhesion or electrical performance.

- Packaging: LED strip corners are packaged with protective films, anti-static bags, or custom trays to prevent damage during transit.

Quality Assurance and Control: Ensuring Reliability and Consistency

Quality assurance (QA) and quality control (QC) are vital in delivering LED strip corners that meet international buyer expectations. Robust QC processes reduce failure rates, ensure compliance with regulations, and minimize costly returns or warranty claims.

International and Industry Standards

B2B buyers should verify that suppliers comply with:

- ISO 9001: This global standard for quality management systems ensures consistent manufacturing processes and continual improvement.

- CE Marking: Mandatory for products sold in Europe, confirming conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electronic products, crucial for environmental safety.

- IP Ratings (Ingress Protection): Particularly important for corners exposed to moisture or dust, e.g., IP65 or higher for outdoor use.

- UL and ETL Certifications: North American safety certifications that may be requested for global projects.

- Other Regional Certifications: Middle Eastern buyers (e.g., UAE) may require SASO certification; South American markets may expect INMETRO or equivalent marks.

Quality Control Checkpoints

QC is conducted at multiple stages to catch defects early and maintain standards:

- Incoming Quality Control (IQC): Verification of raw materials and components for specifications such as LED brightness, PCB integrity, and adhesive quality.

- In-Process Quality Control (IPQC): Monitoring during cutting, soldering, folding, and connector assembly to detect mechanical damage, soldering defects, or alignment issues.

- Final Quality Control (FQC): Comprehensive testing of finished LED strip corners, including visual inspection, electrical testing, and packaging checks.

Common Testing Methods

- Electrical Continuity and Insulation Testing: Ensures no open circuits or shorts exist after bending or connector assembly.

- Bend and Flex Testing: Simulates installation stresses to verify that corners withstand repeated bending without damage.

- Adhesion Testing: Measures the strength of the adhesive backing, especially around corners prone to peeling.

- Light Quality Testing: Checks color temperature consistency, lumen output, and uniformity across corners.

- Environmental Testing: Includes humidity, temperature cycling, and UV exposure tests to ensure long-term durability.

How B2B Buyers Can Verify Supplier Quality Controls

For international buyers, especially in markets with varying regulatory environments, verifying supplier QC is crucial to mitigate risks.

- Factory Audits: Conduct on-site or third-party audits focused on manufacturing processes, equipment calibration, and QC protocols. Buyers can request documentation of ISO 9001 certification and audit reports.

- Sampling and Inspection: Order pre-shipment samples and third-party inspection services to verify product quality, compliance with specifications, and packaging standards.

- Review of Test Reports: Suppliers should provide detailed QC reports, including electrical, mechanical, and environmental test results.

- Third-Party Certification Verification: Confirm authenticity of CE, RoHS, UL, or other certificates through issuing bodies or accredited labs.

- Supply Chain Transparency: Engage with suppliers who maintain clear traceability of components and materials, critical for compliance and recalls if needed.

QC and Certification Nuances for Specific Regions

- Africa: Many countries are increasing standards alignment with international norms but may have limited local testing facilities. Buyers should prioritize suppliers with recognized international certifications and consider third-party inspections.

- South America: Regulatory frameworks vary; Brazil’s INMETRO certification is widely required. Buyers should verify local compliance and consider regional testing labs.

- Middle East (e.g., UAE): SASO certification is often mandatory. Environmental conditions (high temperatures, dust) demand robust IP ratings and UV resistance in LED corners.

- Europe (e.g., Spain): Stringent CE marking and RoHS compliance are non-negotiable. Buyers should ensure suppliers understand EU directives and provide full technical documentation.

Strategic Recommendations for Buyers

- Establish clear quality requirements in contracts, including acceptable tolerances for corner bending radius, adhesion strength, and waterproofing.

- Insist on product samples with corner features identical to production units for evaluation.

- Incorporate periodic quality reviews and supplier performance monitoring to maintain standards over time.

- Leverage local or regional testing laboratories for compliance verification to complement supplier QC.

- Foster long-term partnerships with suppliers committed to continuous improvement and transparent quality management.

By comprehensively understanding the manufacturing processes and quality assurance practices for LED strip lights corners, international B2B buyers can make informed sourcing decisions. This ensures procurement of durable, visually seamless, and compliant lighting solutions that meet the exacting demands of diverse markets worldwide.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip lights corners Sourcing

When sourcing LED strip light corners for international B2B projects, understanding the intricate cost structure and pricing dynamics is essential to optimize procurement and maintain competitive margins. This analysis breaks down the core cost components, key price influencers, and practical buyer strategies, tailored for markets in Africa, South America, the Middle East, and Europe (including UAE and Spain).

Key Cost Components in LED Strip Light Corners

- Materials

The primary cost driver is the quality and type of materials used. This includes the flexible PCB substrate, LEDs, connectors (plastic, aluminum, or steel), solder, adhesives, and protective coatings (e.g., waterproofing). Higher-grade materials with certifications like RoHS or CE often command premium pricing but reduce long-term failure risks.

Illustrative Image (Source: Google Search)

-

Labor

Labor costs vary significantly by manufacturing location. Precision tasks such as cutting, soldering, and assembling corner connectors require skilled technicians. Regions with lower labor costs may offer competitive pricing but verify the quality standards to avoid rework. -

Manufacturing Overhead

Overhead includes factory utilities, equipment depreciation, and indirect labor. Automated assembly lines for LED strip corners can lower overhead but require upfront investment in tooling. -

Tooling and Equipment

Custom tooling for specialized corner shapes or connectors represents a one-time or amortized expense. Buyers requesting bespoke designs should factor this into unit pricing. -

Quality Control (QC)

Rigorous QC processes, including electrical testing, adhesion verification, and durability checks, add to the cost but are vital for ensuring product reliability, especially in demanding environments like outdoor installations. -

Logistics and Shipping

International freight, customs duties, and import taxes significantly influence landed cost. Fragile or bulky connector components may require specialized packaging, adding to shipping expenses. -

Supplier Margin

Supplier profit margins reflect market positioning, production scale, and exclusivity. Established suppliers with strong brand reputations may price higher but offer better service and warranty terms.

Price Influencers to Watch

-

Order Volume and Minimum Order Quantity (MOQ):

Larger orders typically unlock volume discounts. However, MOQ requirements may vary widely; balancing inventory carrying costs against unit price savings is critical. -

Specification Complexity and Customization:

Custom shapes, colors, or integrated smart features increase costs due to additional design, tooling, and testing. -

Material Quality and Certifications:

Buyers prioritizing certified and durable components (e.g., UL, CE, IP65 waterproof ratings) will pay more but gain reduced risk of failures and compliance issues. -

Supplier Location and Capacity:

Suppliers closer to your target market (e.g., Europe for Spain, or Middle East hubs like UAE) can reduce lead times and logistics costs. However, emerging markets in Asia may offer better pricing at the expense of longer delivery. -

Incoterms and Payment Terms:

The chosen Incoterm (FOB, CIF, DDP) affects who bears shipping and customs costs. Favor terms that minimize unexpected expenses and align with your import capabilities.

Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Beyond Price:

Engage suppliers on payment terms, lead times, packaging, and after-sales support to maximize value. -

Consider Total Cost of Ownership (TCO):

Factor in installation ease, durability, warranty coverage, and potential maintenance costs rather than focusing solely on unit price. -

Leverage Supplier Expertise:

Experienced manufacturers can advise on cost-saving design alternatives, such as using standardized connectors or modular corner pieces. -

Validate Samples and Certifications:

Especially for buyers in Africa and South America, where local technical standards may vary, insist on verified certifications and test samples to avoid costly compliance issues. -

Plan for Currency and Tariff Fluctuations:

International buyers should hedge against currency volatility and monitor trade policy changes, which can impact landed costs unpredictably. -

Local Support and Logistics:

Where possible, choose suppliers with regional warehouses or partnerships to reduce shipping delays and customs complexities.

Indicative Pricing Disclaimer

Due to variations in materials, labor markets, order volumes, and customization levels, LED strip light corner prices can range widely—from approximately $0.50 to $5.00 per unit or connector piece. Buyers should request detailed quotations and perform cost-benefit analyses tailored to their specific application and regional context.

By carefully analyzing these cost elements and pricing influencers, international B2B buyers can make informed procurement decisions that balance quality, reliability, and budget—ensuring successful LED strip lighting installations that meet both aesthetic and functional demands.

Spotlight on Potential led strip lights corners Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strip lights corners’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lights corners

Critical Technical Properties for LED Strip Lights Corners

When sourcing LED strip lights with corner capabilities, understanding the key technical properties is essential to ensure durability, performance, and aesthetic quality in your projects.

-

Material Grade of Flexible PCB

The flexible printed circuit board (PCB) is the backbone of LED strips. High-grade PCBs use materials like polyimide or PET that offer superior flexibility and heat resistance. For corner installations, a PCB with enhanced bend tolerance reduces the risk of micro-cracking at bends, ensuring longevity and uninterrupted lighting. For B2B buyers, specifying high-quality PCB material translates to fewer returns and maintenance issues. -

Bend Radius and Flexibility Tolerance

This property defines how sharply a strip can be bent without damage, typically expressed as a minimum radius (e.g., ≥10 mm). A smaller bend radius allows tighter corners without compromising electrical continuity. Buyers should prioritize strips with documented bend tolerances, especially for complex architectural designs or tight corner installations common in retail or hospitality environments. -

Adhesive Strength and Backing Type

The adhesive backing secures the strip to surfaces and must withstand stresses at corners. Industrial-grade adhesives (such as 3M VHB tapes) offer strong adhesion to various substrates including metals, plastics, and painted surfaces. In regions with high humidity or temperature fluctuations (e.g., Middle East or coastal areas), selecting strips with weather-resistant adhesive backing ensures a firm hold, reducing installation failures. -

IP Rating (Ingress Protection)

While not always critical for indoor corners, many B2B projects require water-resistant or dust-proof LED strips, especially in commercial kitchens, outdoor signage, or industrial settings. IP65 or higher ratings guarantee protection against moisture and dust ingress at corner points, which are often vulnerable to environmental exposure. -

Connector Compatibility and Electrical Tolerance

LED strips with standardized corner connectors (L-shape, 90-degree snap connectors) facilitate clean, reliable turns without soldering. Electrical tolerance such as voltage drop limits and current capacity per meter must be considered to maintain uniform brightness across corners. Buyers should confirm compatibility with existing control systems and power supplies to avoid costly mismatches. -

Color Consistency and CRI (Color Rendering Index)

Uniform color temperature and high CRI values (typically above 80) are crucial for seamless lighting effects around corners. Inconsistent color or dimming at bends can degrade the overall visual impact, undermining premium design standards expected in upscale commercial or retail environments.

Key Trade Terminology for International LED Strip Lighting Transactions

Navigating B2B procurement for LED strip lights corners requires familiarity with common industry terms that impact pricing, delivery, and contract negotiations.

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing LED strip lights or components that can be rebranded or customized. B2B buyers often partner with OEMs to secure tailored solutions such as specific connector types or custom lengths, enabling differentiation in local markets like UAE or Spain. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers manage inventory costs and negotiate better pricing tiers. For emerging markets in Africa or South America, lower MOQs may be crucial for pilot projects before scaling. -

RFQ (Request for Quotation)

A formal process where buyers solicit detailed price and specification offers from multiple suppliers. An effective RFQ includes technical requirements for corners (e.g., bend radius, connector type) and clarifies delivery timelines, ensuring competitive and transparent sourcing. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Knowing Incoterms is vital for buyers to accurately calculate landed costs and plan logistics, particularly for cross-continental shipments to Africa or Europe. -

Lead Time

The period from order placement to product delivery. For LED strip corners, lead time impacts project schedules, especially if custom connectors or OEM modifications are involved. Buyers should confirm realistic lead times to avoid installation delays. -

Certification Standards

Certifications such as CE (Europe), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories) indicate compliance with safety and environmental regulations. International buyers must verify these certifications to ensure legal compliance and product reliability in their respective markets.

Mastering these technical properties and trade terms empowers B2B buyers to make informed decisions, optimize procurement strategies, and deliver professional, durable LED strip lighting installations with flawless corner finishes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lights corners Sector

Market Overview & Key Trends

The global market for LED strip lights, particularly solutions designed for corners and complex architectural features, is experiencing robust growth driven by increasing demand for flexible, energy-efficient lighting in commercial, retail, hospitality, and residential sectors. Regions such as Africa, South America, the Middle East, and Europe (notably the UAE and Spain) are key growth areas due to rapid urbanization, rising infrastructure projects, and a growing emphasis on aesthetic, customizable lighting solutions.

Key market drivers include the surge in smart building technologies, where LED strip lights integrated with IoT systems provide dynamic lighting controls and energy management. The need for seamless corner installations is pushing innovation in connectors, flexible PCBs, and modular designs that simplify installation while maintaining durability and visual consistency. Buyers from emerging markets are increasingly seeking suppliers who offer tailored solutions that address local installation challenges, such as high temperatures or varying voltage standards.

Sourcing trends highlight a shift towards suppliers who provide pre-engineered corner connectors (L-shaped, T-shaped, flexible joints) and high-adhesion backing materials that withstand environmental stress. There is also growing interest in LED strips with enhanced waterproofing and dust resistance for outdoor or industrial applications common in Middle Eastern and African markets. European buyers often prioritize certifications such as CE, RoHS, and UL, which assure product safety and compliance with stringent regional standards.

The market dynamic favors suppliers who combine technological innovation with strong after-sales support, including installation guides and professional training for B2B clients. Additionally, international buyers are increasingly leveraging online platforms and direct factory relationships in Asia and Europe to optimize cost-efficiency and lead times while ensuring quality. Customization services, including bespoke lengths and color temperatures suited for architectural corners, are becoming a differentiator in competitive bids.

Sustainability & Ethical Sourcing in B2B

Sustainability is emerging as a critical factor for B2B buyers of LED strip lights, including corner solutions, across all targeted regions. LED technology inherently offers energy efficiency benefits, consuming significantly less power than traditional lighting, which supports corporate and governmental carbon reduction targets. However, the environmental footprint of manufacturing, material sourcing, and end-of-life disposal remains a concern.

Ethical sourcing is gaining traction as buyers demand transparency from suppliers regarding the origin of raw materials such as copper, solder, and plastics. Responsible sourcing policies that avoid conflict minerals and ensure fair labor practices resonate strongly in Europe and increasingly in the Middle East and South America. B2B buyers are encouraged to request supplier certifications like ISO 14001 for environmental management and SA8000 for social accountability.

Materials innovation is pivotal for sustainability in LED strip corners. The adoption of lead-free solder, halogen-free PCBs, and recyclable packaging reduces toxic waste and environmental hazards. Some manufacturers now offer corner connectors and strips made from biodegradable or recycled plastics, addressing the circular economy principles valued by eco-conscious buyers.

Energy-efficient drivers and dimmable features further enhance sustainability by optimizing power usage in complex corner installations, reducing operational costs and environmental impact. B2B procurement strategies increasingly incorporate lifecycle assessments and “green” certifications such as Energy Star or TÜV Rheinland to validate product claims. Prioritizing suppliers with robust sustainability roadmaps not only mitigates regulatory risks but also strengthens corporate social responsibility profiles in competitive international markets.

Evolution and Historical Context

The evolution of LED strip lights tailored for corners reflects broader advances in flexible electronics and lighting design since the early 2000s. Initially, LED strips were rigid and linear, limiting their application in architectural spaces with complex geometries. The demand for continuous, uniform lighting around edges and corners led to innovations such as segmented strips with designated cut points and the development of specialized corner connectors.

Over the past decade, improvements in flexible printed circuit boards and adhesive technologies have enabled tighter bends and more reliable corner installations without compromising electrical integrity. This progress has transformed LED strip lights from simple accent lighting to integral design elements in commercial and residential projects worldwide.

For B2B buyers, understanding this evolution is critical: it highlights the importance of partnering with manufacturers who invest in R&D to address installation challenges and provide future-proof solutions adaptable to diverse regional requirements and design trends. The shift from manual soldering to plug-and-play connectors has also reduced installation time and technical complexity, making LED strip corners more accessible to a wider range of professional installers globally.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lights corners

-

How can I effectively vet suppliers of LED strip lights corners for international B2B purchases?

Vet suppliers by verifying their business licenses, certifications (such as ISO, CE, or RoHS), and factory audits. Request product samples to assess quality firsthand and confirm adherence to your specifications. Check references or reviews from other international buyers, particularly those in regions similar to yours (Africa, Middle East, Europe, South America). Engage in direct communication to evaluate responsiveness and technical knowledge. Using third-party inspection services before shipment can further mitigate risks in long-distance transactions. -

Are customization options widely available for LED strip lights corners, and how can I request them?

Many manufacturers offer customization, including strip length, LED density, color temperature, waterproofing, and connector types tailored for corner installations. To request customization, provide detailed technical drawings or specifications upfront, including the exact corner angles and installation environment. Clarify your volume needs and any compliance requirements (e.g., EU RoHS, UAE SASO). Early engagement with the supplier’s R&D or engineering teams ensures feasibility and can reduce lead times. -

What are typical minimum order quantities (MOQs) and lead times for LED strip lights corners in international trade?

MOQs vary widely but generally range from 500 to 5,000 meters depending on customization and supplier scale. Lead times typically span 3 to 8 weeks, factoring in production, quality checks, and shipping. For buyers in Africa, South America, or the Middle East, allocate extra time for customs clearance and inland logistics. Negotiate MOQs based on your long-term purchase potential; some suppliers offer flexible MOQs for repeat buyers or sample orders. -

Which quality assurance certifications should I insist on when sourcing LED strip lights corners?

Key certifications include CE (Europe), RoHS (restricting hazardous substances), UL or ETL (safety standards), and ISO 9001 (quality management systems). For Middle Eastern markets, SASO certification may be necessary. These certifications ensure product safety, environmental compliance, and consistent manufacturing quality. Request certification copies and verify their validity with issuing bodies. Additionally, insist on third-party test reports on luminous efficacy and durability, especially for outdoor or high-humidity applications. -

What logistics considerations are crucial when importing LED strip lights corners internationally?

Due to the delicate nature of LED strips and connectors, ensure suppliers use sturdy packaging with anti-static and moisture-proof materials. Choose reliable freight forwarders experienced with electronics and fragile goods. Consider the balance between air freight for speed and sea freight for cost efficiency, depending on urgency and order size. Confirm Incoterms clearly (e.g., FOB, CIF) to understand your responsibilities and costs. Also, plan for potential customs duties and VAT in your country and prepare all necessary import documentation to avoid delays. -

How should I handle payment terms to safeguard my interests in international B2B transactions?

Favor payment methods that offer security, such as letters of credit (L/C) or escrow services, especially for new suppliers. Negotiate partial payments—e.g., 30% upfront and 70% upon inspection or delivery—to reduce risk. Avoid full upfront payments unless you have a strong trust relationship. For established suppliers, net terms (30-60 days) may be possible. Always ensure contracts specify payment milestones linked to production and shipment stages. -

What steps can I take to ensure smooth dispute resolution with international LED strip light corner suppliers?

Include clear dispute resolution clauses in contracts specifying governing law, arbitration venues, and procedures. Maintain detailed records of communications, contracts, samples, and inspections. Use third-party inspection reports as objective evidence in case of quality disputes. Engage suppliers promptly and professionally to resolve issues amicably. If necessary, leverage international trade bodies or chambers of commerce in your region for mediation support. -

How do I ensure consistent product performance across multiple shipments of LED strip lights corners?

Establish a comprehensive quality control checklist covering LED brightness, color consistency, adhesive strength, connector integrity, and waterproofing where applicable. Request batch sample testing before full shipment and random inspections during production. Develop a strong relationship with your supplier’s quality assurance team to communicate feedback and improvements. Consider long-term agreements with fixed specifications and penalties for non-compliance to maintain product consistency across your supply chain.

Strategic Sourcing Conclusion and Outlook for led strip lights corners

Effective management of LED strip lights corners is pivotal for delivering seamless, durable, and visually appealing lighting solutions that meet the high standards of international B2B markets. Understanding the technical nuances—such as appropriate bending techniques, the use of specialized connectors, and meticulous pre-installation preparation—ensures reliability and aesthetic integrity, which are critical for sectors like retail, architectural lighting, and signage.

For buyers across Africa, South America, the Middle East, and Europe, strategic sourcing goes beyond price considerations. It involves partnering with suppliers who offer quality-certified products, technical support, and customization options tailored to diverse environmental and design requirements. Prioritizing suppliers who provide comprehensive installation accessories—such as flexible connectors and adhesive solutions—can significantly reduce installation risks and after-sales issues.

Looking ahead, as demand for sophisticated, energy-efficient lighting solutions grows, international buyers are encouraged to leverage emerging innovations in LED strip technology and smart lighting integration. Proactive engagement with trusted manufacturers and distributors will unlock competitive advantages, enabling your projects to stand out in increasingly discerning markets. Embrace a sourcing strategy that combines technical expertise, quality assurance, and supply chain resilience to illuminate your business opportunities with confidence.