Guide to Led Stripe Dmx

- Introduction: Navigating the Global Market for led stripe dmx

- Understanding led stripe dmx Types and Variations

- Key Industrial Applications of led stripe dmx

- Strategic Material Selection Guide for led stripe dmx

- In-depth Look: Manufacturing Processes and Quality Assurance for led stripe dmx

- Comprehensive Cost and Pricing Analysis for led stripe dmx Sourcing

- Spotlight on Potential led stripe dmx Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led stripe dmx

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led stripe dmx Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led stripe dmx

- Strategic Sourcing Conclusion and Outlook for led stripe dmx

Introduction: Navigating the Global Market for led stripe dmx

In today’s dynamic lighting and entertainment industries, LED stripe DMX technology stands at the forefront of innovation, offering unparalleled control, flexibility, and visual impact. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of this technology is essential to sourcing solutions that not only meet technical requirements but also align with budgetary and regulatory demands. Whether outfitting a large-scale event, architectural installation, or commercial space, selecting the right LED stripe DMX products can significantly influence project success and operational efficiency.

This comprehensive guide delves into every critical facet of LED stripe DMX—from the diverse types of LED strips and control protocols to materials, manufacturing standards, and quality control processes. It highlights the global supplier landscape, providing insights into reputable manufacturers and distributors who cater to varying market needs. Cost structures and pricing strategies are analyzed to empower buyers in negotiating favorable terms and optimizing investment returns.

Additionally, this guide addresses frequently asked questions and practical considerations unique to international trade, such as customs compliance, shipping logistics, and after-sales support. By equipping buyers with actionable intelligence and expert perspectives, it fosters confident decision-making and strategic sourcing tailored to the distinct challenges and opportunities in emerging and established markets alike.

Key benefits for buyers include:

- In-depth understanding of LED stripe DMX technology and applications

- Clarity on quality benchmarks and certification standards

- Insights into supplier evaluation and risk mitigation

- Cost analysis to align procurement with budget goals

- Guidance on navigating international trade complexities

For businesses in Argentina, Indonesia, and beyond, this guide serves as an indispensable resource to unlock the full potential of LED stripe DMX solutions in a competitive global marketplace.

Understanding led stripe dmx Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DMX RGB LED Strip | Controls red, green, blue channels separately via DMX signal | Architectural lighting, stage design, retail | Pros: Versatile color mixing, widely supported; Cons: Limited to 3 channels, may require multiple strips for complex effects |

| DMX RGBW LED Strip | Adds white LEDs for enhanced color accuracy and brightness | High-end displays, hospitality, museums | Pros: Improved whites and pastels, richer color palette; Cons: Higher cost, slightly more complex wiring and control |

| Addressable DMX LED Strip | Individually controllable LEDs via DMX addressing | Large-scale installations, entertainment | Pros: Precise control per LED, dynamic effects; Cons: Higher price, requires advanced controllers and programming skills |

| Waterproof DMX LED Strip | Encased in waterproof material, IP65+ rating | Outdoor signage, landscape lighting | Pros: Weather resistant, durable; Cons: Slightly reduced brightness, increased cost |

| Flexible DMX LED Strip | Highly flexible PCB allowing bending and custom shapes | Curved surfaces, custom installations | Pros: Design adaptability, easy installation; Cons: Potential fragility if bent excessively, may need protective casing |

DMX RGB LED Strip

This is the most common type, featuring separate red, green, and blue LEDs controlled via DMX channels. It offers versatile color mixing ideal for architectural and retail lighting where dynamic ambiance is required. B2B buyers should consider compatibility with existing DMX controllers and the need for multiple strips if complex color effects are desired. These strips are cost-effective but limited in channel control per LED segment.

DMX RGBW LED Strip

An enhancement over RGB strips, RGBW includes an additional white LED to deliver more accurate whites and pastel colors, essential in hospitality and museum environments where color fidelity matters. The inclusion of white LEDs increases upfront costs and wiring complexity. Buyers targeting premium visual quality should weigh these benefits against budget and installation complexity.

Addressable DMX LED Strip

Each LED is individually addressable, allowing for intricate lighting patterns and animations. This type is favored in entertainment venues and large-scale installations requiring precise control. However, it demands sophisticated DMX controllers and programming expertise, increasing both initial investment and operational complexity. Buyers must ensure technical support availability.

Waterproof DMX LED Strip

Encased in waterproof materials with IP65 or higher ratings, these strips are suited for outdoor applications like landscape lighting and signage. They offer durability against elements but may experience slight brightness reduction due to protective coatings. The premium price reflects their robustness, making them a smart choice for buyers prioritizing longevity and weather resistance.

Flexible DMX LED Strip

Designed with flexible PCBs, these strips can bend around curves and irregular surfaces, ideal for custom architectural features. While offering installation versatility, excessive bending can damage the strip, so buyers should plan layouts carefully and possibly invest in protective casings. This type balances design freedom with moderate fragility considerations.

Key Industrial Applications of led stripe dmx

| Industry/Sector | Specific Application of led stripe dmx | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment & Events | Dynamic stage and architectural lighting control | Enhanced visual effects, precise synchronization, and flexible programming for live shows and installations | Compatibility with existing DMX controllers, durability, and IP rating for outdoor use |

| Hospitality & Retail | Ambient and accent lighting in hotels, restaurants, and retail stores | Improved customer experience, energy efficiency, and brand differentiation through customizable lighting | Ease of installation, color rendering quality, and scalability for large venues |

| Commercial Architecture | Façade and interior decorative lighting with DMX control | Energy savings, aesthetic appeal, and programmable lighting scenes to attract clients and improve workspace ambiance | Compliance with local electrical standards, longevity, and integration with building management systems |

| Transportation Hubs | Airport, metro, and railway station lighting systems | Enhanced passenger experience, improved safety, and reduced maintenance costs via centralized control | Robustness, low power consumption, and ease of maintenance in high-traffic environments |

| Museums & Exhibitions | Exhibit illumination and interactive lighting installations | Precise control over lighting effects to highlight artifacts, enhance visitor engagement, and protect sensitive materials | Low heat emission, color accuracy, and compatibility with DMX/RDM protocols |

Entertainment & Events

In the entertainment sector, led stripe DMX systems are widely used for stage lighting, concert venues, and architectural lighting installations. These strips provide precise, real-time control of color, brightness, and effects, enabling dynamic visual storytelling and audience engagement. For international buyers, especially in Africa and South America, sourcing durable strips with reliable DMX compatibility is crucial due to variable power conditions and outdoor exposure. Suppliers offering high IP-rated products and easy integration with existing control boards will provide significant operational advantages.

Hospitality & Retail

Hotels, restaurants, and retail outlets leverage led stripe DMX lighting to create immersive ambient environments that enhance customer experience and promote brand identity. The ability to program lighting scenes and moods helps businesses differentiate themselves in competitive markets like the Middle East and Europe. Buyers should prioritize LED strips with excellent color rendering indexes (CRI) and scalable control options to accommodate expansions or seasonal changes. Energy efficiency and straightforward installation are also vital for cost management in these sectors.

Commercial Architecture

Commercial buildings utilize DMX-controlled LED strips for both façade illumination and interior decorative lighting. This application improves aesthetic appeal while enabling energy savings through programmable lighting schedules. For B2B buyers in regions such as Indonesia and Argentina, compliance with regional electrical standards and the ability to integrate with building automation systems are key considerations. Long-lasting, low-maintenance LED strips that support multiple DMX channels offer better ROI and reduce operational disruptions.

Transportation Hubs

Airports, metro stations, and railway terminals adopt led stripe DMX lighting for wayfinding, safety, and ambiance enhancement. The centralized DMX control allows for adaptive lighting scenarios, improving passenger comfort and operational efficiency. International buyers should focus on robust, low-power LED strips that withstand heavy foot traffic and environmental stresses. Products with easy maintenance protocols and compatibility with existing infrastructure are essential to minimize downtime in these critical environments.

Museums & Exhibitions

In museums and exhibition spaces, led stripe DMX lighting is used to highlight artifacts and create interactive visitor experiences without damaging sensitive materials. The precise dimming and color control capabilities help preserve exhibits while enhancing visual impact. Buyers from Europe and South America must consider LED strips with low heat emission, high color accuracy, and support for advanced DMX/RDM protocols to ensure seamless integration with sophisticated lighting control systems.

Related Video: How to Use the DMX512 4 Channel Decoder and LED Driver

Strategic Material Selection Guide for led stripe dmx

Material Selection for LED Stripe DMX: Key Considerations for B2B Buyers

When selecting materials for LED stripe DMX products, international B2B buyers must evaluate factors such as durability, environmental resistance, manufacturing complexity, and compliance with regional standards. The choice of material directly impacts product longevity, installation flexibility, and compatibility with different lighting environments, especially in diverse climates found across Africa, South America, the Middle East, and Europe.

1. Flexible Printed Circuit Board (FPCB) Substrate – Polyimide (PI)

Key Properties:

Polyimide is widely used as the flexible substrate for LED strips due to its excellent thermal stability (operating temperatures up to 260°C), chemical resistance, and mechanical flexibility. It offers good dielectric properties and resistance to UV exposure, which is crucial for outdoor or semi-outdoor applications.

Pros:

– High temperature tolerance suitable for demanding lighting environments.

– Excellent flexibility allows for complex installations on curved surfaces.

– Resistant to chemicals and UV, enhancing outdoor durability.

Cons:

– Higher cost compared to polyester substrates.

– Manufacturing requires precise handling due to thinness and flexibility.

– Limited availability of high-quality polyimide in some emerging markets may affect supply chain.

Application Impact:

Ideal for high-performance, long-life LED DMX stripes used in architectural lighting or stage setups where heat dissipation and flexibility are critical. Its resistance to harsh environments suits regions with high UV exposure like the Middle East and parts of Africa.

Regional Considerations:

Buyers in Europe and South America should verify compliance with RoHS and REACH regulations concerning polyimide materials. In Africa and the Middle East, ensuring suppliers meet ASTM or DIN standards for thermal and chemical resistance is advisable to guarantee product reliability.

2. Flexible Printed Circuit Board (FPCB) Substrate – Polyester (PET)

Key Properties:

Polyester substrates offer moderate thermal resistance (typically up to 150°C) and good mechanical strength. They are less expensive than polyimide but have lower chemical and UV resistance.

Pros:

– Cost-effective for large-scale production.

– Easier to process and widely available globally.

– Suitable for indoor applications with controlled environments.

Cons:

– Lower temperature tolerance limits use in high-heat environments.

– Susceptible to degradation under prolonged UV exposure.

– Less flexible than polyimide, restricting some installation designs.

Application Impact:

Best suited for indoor LED DMX strip lighting in commercial or residential settings where exposure to heat and sunlight is minimal. Not recommended for outdoor or industrial environments.

Regional Considerations:

In South America and Africa, where cost sensitivity is high, polyester substrates offer an affordable option. However, buyers should ensure suppliers provide materials compliant with local safety and fire retardancy standards, such as IEC or JIS, to prevent regulatory issues.

3. Silicone Encapsulation (Coating)

Key Properties:

Silicone coatings provide excellent waterproofing and UV resistance, with flexibility that maintains the LED strip’s bendability. Silicone can withstand temperatures from -60°C to +200°C and offers good chemical resistance.

Pros:

– Superior protection against moisture and dust, ideal for outdoor and humid environments.

– Maintains flexibility and protects against mechanical damage.

– Enhances lifespan of LED stripes in harsh climates.

Cons:

– Adds to manufacturing cost and complexity.

– Silicone coatings can be thicker, affecting the strip’s profile.

– Requires specialized curing processes during production.

Application Impact:

Silicone encapsulation is essential for LED DMX strips used in outdoor installations, such as façade lighting or signage in tropical or desert climates (e.g., Middle East, Indonesia). It ensures reliable operation despite moisture, dust, and temperature fluctuations.

Regional Considerations:

Buyers in Europe and the Middle East should confirm that silicone materials meet EN or ASTM waterproofing and fire safety standards. For African and South American markets, sourcing from suppliers with ISO certification ensures consistent quality and durability.

4. Aluminum Backing / Heat Sink

Key Properties:

Aluminum is commonly used as a backing or integrated heat sink to dissipate heat generated by LED chips, improving efficiency and lifespan. It offers excellent thermal conductivity and corrosion resistance when anodized.

Pros:

– Efficient thermal management reduces LED failure rates.

– Adds structural rigidity to flexible strips.

– Corrosion-resistant grades suitable for outdoor use.

Cons:

– Increases product weight and cost.

– Requires precise manufacturing to maintain flexibility.

– Potential galvanic corrosion if improperly paired with other metals.

Application Impact:

Aluminum-backed LED DMX strips are preferred in high-power lighting applications where heat dissipation is critical, such as stage lighting or architectural accents in warm climates. It improves reliability in environments with fluctuating temperatures.

Regional Considerations:

In South America and Europe, anodized aluminum must comply with local corrosion resistance standards (e.g., DIN EN ISO 9227). Buyers in Africa and the Middle East should verify compatibility with local environmental conditions, including salt spray resistance for coastal installations.

Summary Table of Materials for LED Stripe DMX

| Material | Typical Use Case for led stripe dmx | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide (PI) FPCB | High-performance flexible circuits for indoor/outdoor use | High thermal & UV resistance, excellent flexibility | Higher cost, complex manufacturing | High |

| Polyester (PET) FPCB | Cost-effective indoor LED strip applications | Affordable, widely available | Lower heat & UV resistance, less flexible | Low |

| Silicone Encapsulation | Waterproofing and environmental protection for outdoor use | Superior moisture & UV protection, flexible | Adds manufacturing complexity and cost | Medium |

| Aluminum Backing/Heat Sink | Thermal management in high-power or outdoor LED strips | Excellent heat dissipation, structural support | Increased weight and cost, requires precision | Medium |

This guide assists international B2B buyers in selecting materials tailored to their specific environmental conditions, regulatory requirements, and budget constraints. Careful consideration of these factors will optimize the performance and durability of LED stripe DMX products across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led stripe dmx

Manufacturing Processes for LED Stripe DMX

The production of LED stripe DMX (Digital Multiplex) lighting involves several critical stages, each requiring precision and quality control to ensure reliable performance in professional lighting applications. For international B2B buyers, understanding these stages helps in evaluating suppliers and ensuring product consistency.

1. Material Preparation

The process begins with sourcing high-quality raw materials: flexible PCB substrates, LED chips, DMX controller ICs, resistors, capacitors, and connectors. Substrates typically use materials like polyimide or fiberglass for flexibility and durability. Suppliers must verify the authenticity and quality of these components, as substandard materials can affect lifespan and functionality. For buyers in regions such as Africa, South America, and the Middle East, it’s crucial to confirm suppliers’ raw material traceability and certifications to avoid counterfeit or low-grade parts.

2. PCB Forming and Patterning

Flexible PCBs are fabricated using photolithography and etching processes to create conductive copper tracks that connect the LEDs and DMX control chips. High precision in this stage is essential to maintain signal integrity and electrical performance. Advanced manufacturers employ automated laser cutting and punching for consistent strip shapes and sizes, which is vital for fitting into diverse installation environments.

3. Component Assembly

Surface Mount Technology (SMT) is predominantly used for placing LEDs and DMX driver ICs onto the flexible PCB. Automated pick-and-place machines ensure accurate positioning and soldering quality. This stage includes reflow soldering under controlled temperature profiles to prevent damage to sensitive components. For buyers, verifying that the supplier uses state-of-the-art SMT lines and adheres to IPC standards (e.g., IPC-A-610 for electronic assemblies) can signal superior manufacturing capabilities.

4. Finishing and Encapsulation

After assembly, the LED stripes undergo finishing processes such as coating with silicone or epoxy for waterproofing and mechanical protection. This step is critical for outdoor or harsh environment applications common in many emerging markets. Cutting and adding connectors or terminals for DMX input/output complete the product. Quality sealing methods prevent moisture ingress and ensure durability.

Quality Assurance Framework and Checkpoints

Robust quality assurance (QA) is fundamental for LED stripe DMX products due to their application in professional lighting, where failures can lead to costly downtime.

Relevant International Standards:

– ISO 9001: A baseline quality management system standard ensuring consistent production and continual improvement. Suppliers certified under ISO 9001 demonstrate structured processes and traceability.

– CE Marking: Mandatory for products sold in Europe, confirming compliance with safety, electromagnetic compatibility (EMC), and environmental directives.

– RoHS Compliance: Restricts hazardous substances, important for environmental and health safety, especially for European and Middle Eastern markets.

– UL or ETL Certification: Relevant for North American buyers, sometimes demanded by global buyers for electrical safety assurance.

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Inspection of raw materials and components for conformity. Includes verifying LED binning consistency, substrate integrity, and DMX chip authenticity.

– In-Process Quality Control (IPQC): Continuous monitoring during PCB forming, SMT placement, and soldering. Automated optical inspection (AOI) and X-ray inspection for solder joint quality are common.

– Final Quality Control (FQC): Comprehensive functional testing of finished LED strips, including electrical continuity, DMX signal responsiveness, color accuracy, and waterproofing integrity.

Common Testing Methods and Equipment

B2B buyers should ensure their suppliers employ rigorous testing to guarantee product reliability:

- Electrical Testing: Verifies correct voltage, current, and signal transmission along the LED strip. Multi-channel LED drivers are tested for uniform brightness and color fidelity.

- DMX Protocol Compliance Testing: Ensures that LED stripes respond correctly to DMX512 signals, with no latency or channel interference. Signal analyzers and simulators are used for this purpose.

- Environmental Stress Testing: Includes thermal cycling, humidity exposure, and UV resistance tests to simulate real-world conditions, particularly important for outdoor applications.

- Mechanical Durability Testing: Flex tests for the PCB, connector pull tests, and waterproofing verification via IP rating assessments (e.g., IP65, IP67).

- Visual Inspection: Using microscopes and AOI systems to detect solder defects, misaligned LEDs, or PCB damage.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is paramount to mitigate risks.

1. Factory Audits:

On-site audits provide direct insight into manufacturing capabilities, process controls, and quality culture. Buyers should request audits focusing on production flow, equipment maintenance, staff training, and documentation practices. Third-party audit firms specializing in electronics manufacturing can provide unbiased evaluations.

2. Quality Documentation and Reports:

Suppliers should provide detailed IQC, IPQC, and FQC reports, including batch traceability, test results, and non-conformance records. Buyers can request certificates of conformity (CoC), material safety data sheets (MSDS), and compliance certificates for standards such as CE and RoHS.

3. Third-Party Inspections and Testing:

Engaging independent inspection agencies to perform random sampling and testing before shipment adds a layer of assurance. For example, companies like SGS, Bureau Veritas, or TUV offer inspection and certification services tailored to electronics and lighting products.

4. Sample Testing:

Requesting pre-production samples for in-house or third-party lab testing allows buyers to validate performance claims, DMX compatibility, and environmental durability under their specific application scenarios.

QC and Certification Nuances for International Buyers

When sourcing LED stripe DMX products internationally, buyers must navigate certification and quality nuances shaped by regional regulations and market expectations.

- Africa & South America: Regulatory frameworks may be less stringent, but buyers should prioritize suppliers compliant with international standards (ISO, CE, RoHS) to ensure product safety and compatibility. Import regulations may require additional certifications or testing on arrival.

- Middle East: Markets often demand conformity with Gulf Cooperation Council (GCC) standards and may require additional EMC and safety testing. Suppliers with recognized international certifications facilitate smoother customs clearance and market acceptance.

- Europe: Strict adherence to CE marking, RoHS, and WEEE directives is non-negotiable. Buyers should verify the validity of supplier certifications and ensure products meet all applicable EU directives, including REACH for chemical compliance.

- Cross-Regional Considerations: Differences in DMX protocol implementations or power standards may exist; buyers should specify detailed technical requirements and request compliance evidence. Language barriers and time zones necessitate clear communication channels and documented quality agreements.

Summary for B2B Buyers

To secure high-quality LED stripe DMX products, international B2B buyers should:

- Evaluate suppliers’ manufacturing processes, focusing on material sourcing, PCB forming, SMT assembly, and protective finishing.

- Insist on adherence to internationally recognized quality standards and certifications relevant to their target markets.

- Understand and engage in quality control checkpoints throughout production, including IQC, IPQC, and FQC.

- Utilize factory audits, request comprehensive quality documentation, and consider third-party inspections to verify supplier claims.

- Be mindful of regional certification nuances and ensure products comply with local regulations and market expectations.

By applying these insights, buyers from Africa, South America, the Middle East, and Europe can minimize risk, ensure product reliability, and establish long-term partnerships with reputable LED stripe DMX manufacturers.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led stripe dmx Sourcing

Understanding the Cost Structure of DMX LED Strips

When sourcing DMX LED strips for B2B applications, it is critical to dissect the cost components to optimize purchasing decisions. The total cost comprises several key elements:

- Materials: High-quality LEDs, flexible PCB substrates, DMX controllers, connectors, and protective coatings dominate material costs. Premium LEDs with better color rendering or longer lifespan will increase costs but enhance product value.

- Labor: Skilled assembly, especially for DMX integration and quality soldering, impacts labor costs. Labor rates vary widely by manufacturing location, influencing final pricing.

- Manufacturing Overhead: Includes utilities, factory maintenance, and indirect labor costs, typically allocated as a percentage of direct labor and materials.

- Tooling and Setup: Custom molds, PCBs, and DMX interface hardware require upfront investment. These fixed costs are amortized over production volumes.

- Quality Control (QC): Testing for DMX signal integrity, color consistency, and durability adds to costs but ensures reliability, crucial for professional lighting systems.

- Logistics: Freight, customs duties, and insurance impact landed costs significantly, especially for buyers importing from Asia or Europe.

- Margin: Suppliers include profit margins that reflect market positioning and demand.

Key Price Influencers in DMX LED Strip Procurement

Pricing is dynamic and affected by several factors that B2B buyers should evaluate carefully:

- Order Volume and Minimum Order Quantity (MOQ): Higher volumes reduce per-unit costs through economies of scale. MOQ requirements can affect upfront investment but enable better pricing.

- Specifications and Customization: Tailored lengths, pixel densities, waterproofing, or specialized DMX channel configurations increase complexity and price.

- Material Quality and Certifications: Products with certifications such as CE, RoHS, or UL command premium prices but are essential for compliance in many markets.

- Supplier Location and Reliability: Established suppliers with proven quality control and stable lead times may charge more but reduce risks and hidden costs.

- Incoterms and Payment Terms: Understanding trade terms (e.g., FOB, CIF, DDP) clarifies which party bears shipping and insurance costs. Favorable payment terms can improve cash flow.

Strategic Tips for International B2B Buyers

Buyers from Africa, South America, the Middle East, and Europe face unique challenges and opportunities in sourcing DMX LED strips:

- Negotiate Beyond Price: Engage suppliers on MOQ flexibility, lead times, warranty, and after-sales support to maximize value.

- Evaluate Total Cost of Ownership (TCO): Factor in installation ease, energy consumption, lifespan, and maintenance costs rather than focusing solely on purchase price.

- Leverage Regional Trade Agreements: Explore sourcing from countries with favorable trade agreements or lower tariffs to reduce customs duties.

- Consider Local Standards and Certifications: Ensure the product meets regional electrical and safety standards to avoid costly rejections or retrofits.

- Plan for Logistics Complexity: Factor in potential delays, customs clearance times, and freight costs specific to your region, especially for inland or landlocked buyers.

- Use Sample Orders for Quality Validation: Before large commitments, obtain samples to verify DMX compatibility, color accuracy, and build quality.

Indicative Pricing and Market Observations

Indicative prices for DMX LED strips vary widely based on specifications and volume but typically range:

- Basic RGB DMX LED strips: $5–$15 per meter in volume.

- High-density, individually addressable pixel strips with enhanced waterproofing: $15–$30 per meter.

- Custom configurations with advanced controllers or certification premiums may exceed this range.

Prices fluctuate with raw material costs, especially LEDs and copper, and global supply chain dynamics.

By understanding these cost drivers and pricing influencers, B2B buyers can strategically source DMX LED strips that align with budget constraints and project requirements, minimizing risks and maximizing return on investment in international markets.

Spotlight on Potential led stripe dmx Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led stripe dmx’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led stripe dmx

Critical Technical Properties of DMX LED Strips

When sourcing DMX-controlled LED strips, understanding key technical specifications is essential for ensuring product performance, compatibility, and durability in diverse international markets such as Africa, South America, the Middle East, and Europe. Below are the most critical properties to assess:

-

DMX Channel Compatibility

This defines how many DMX channels the LED strip supports, directly impacting control granularity. For example, RGB strips commonly use 3 channels per segment, while RGBW (with white LEDs) use 4. For B2B buyers, selecting the correct channel count ensures seamless integration with existing DMX controllers and lighting systems, avoiding costly incompatibilities. -

Voltage and Power Requirements

Most DMX LED strips operate on 12V or 24V DC. Voltage tolerance and power consumption per meter are crucial to calculate total power needs and appropriate power supply sizing. Buyers must verify voltage compatibility with local electrical standards and ensure sufficient power capacity to avoid performance issues or safety hazards. -

LED Density and Type

LED density (e.g., 30, 60, or 120 LEDs per meter) affects brightness, uniformity, and application suitability. High-density strips provide smoother lighting effects but may increase costs and power consumption. The LED chip type (such as SMD 5050 or 3528) also influences brightness and color quality. Evaluating these ensures the product meets the aesthetic and functional requirements of the project. -

Ingress Protection (IP) Rating

IP ratings (e.g., IP20, IP65, IP67) indicate the strip’s resistance to dust and water. For outdoor or harsh environments common in many regions, a higher IP rating is vital to guarantee longevity and reduce maintenance costs. B2B buyers should specify IP ratings based on the installation environment to prevent premature failure. -

Signal and Wiring Standards

DMX LED strips follow the DMX512 protocol, requiring specific wiring (usually 3-pin or 5-pin XLR connectors) and signal integrity considerations. Understanding wiring standards and connector types aids in compatibility with controllers and simplifies installation logistics across different markets. -

Material and Build Quality

The substrate material (often flexible PCB) and soldering quality impact durability and thermal management. Good build quality prevents LED failure and maintains consistent performance under continuous operation, which is critical for commercial installations demanding reliability.

Common Trade Terminology for International B2B Transactions

Navigating global LED strip procurement involves familiarity with industry-specific trade terms that clarify order processes, responsibilities, and costs. Below are key terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing products that can be rebranded or customized for other companies. Buyers often use OEM services to acquire LED strips tailored to specifications such as length, color, or packaging, enabling product differentiation in their local markets. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in one order. Understanding MOQ helps buyers plan budgets and inventory, especially important for smaller distributors or projects in emerging markets where upfront investment capacity may vary. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, availability, and terms. An RFQ is a critical step in the procurement process, enabling buyers to compare offers, negotiate terms, and ensure compliance with technical and commercial requirements. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting the appropriate Incoterm clarifies who bears risks and costs at each stage, critical for smooth cross-border transactions. -

Lead Time

The period between placing an order and receiving the goods. Knowing lead times helps buyers synchronize procurement with project schedules, avoiding delays in installation or delivery. -

Batch or Lot Number

Identifies a specific production run of products. This is essential for quality control, traceability, and warranty claims, ensuring that any defects or inconsistencies can be managed effectively.

By thoroughly understanding these technical properties and trade terms, international B2B buyers can make informed decisions, optimize supply chain efficiency, and ensure that DMX LED strip products meet both functional and commercial needs in their respective markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led stripe dmx Sector

Market Overview & Key Trends

The global LED stripe DMX market is experiencing robust growth driven by the rising demand for advanced lighting control in commercial, entertainment, architectural, and urban infrastructure projects. Key drivers include the increasing adoption of smart lighting systems, the expansion of event and stage production industries, and growing urbanization in emerging markets such as Africa, South America, and parts of the Middle East. These regions are witnessing infrastructure modernization and smart city initiatives, which elevate the need for flexible, programmable LED lighting solutions controlled via DMX protocols.

For international B2B buyers, especially from countries like Argentina, Nigeria, Indonesia, and the UAE, sourcing trends highlight a preference for modular, scalable LED DMX strips compatible with various control systems (e.g., Arduino, Raspberry Pi, or proprietary DMX controllers). Buyers increasingly seek suppliers who offer customizable products with easy integration into existing lighting networks, supporting protocols such as DMX512 and Art-Net. Furthermore, the shift towards IoT-enabled lighting solutions is gaining traction, enabling remote management and real-time diagnostics — critical for large-scale deployments.

Market dynamics emphasize cost-efficiency without compromising quality, as buyers navigate supply chain complexities and fluctuating raw material costs. Competitive sourcing from Asia remains predominant, yet buyers are also exploring regional suppliers in Europe and the Middle East to mitigate lead times and tariffs. Reliable certification, such as CE and RoHS compliance, is essential for European buyers, while African and South American buyers prioritize suppliers with proven after-sales support and local distribution channels. Strategic partnerships with manufacturers offering design support and technical training are increasingly valued to ensure smooth project execution.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in B2B procurement of LED stripe DMX products. The environmental footprint of LED manufacturing, including energy consumption, waste generation, and use of hazardous substances, necessitates careful supplier evaluation. Buyers are prioritizing vendors who adopt eco-friendly materials such as lead-free solder, recyclable PCBs, and low-impact packaging. Additionally, energy-efficient LED chips and drivers that minimize power consumption align with corporate social responsibility goals and regulatory requirements in Europe and the Middle East.

Ethical sourcing also extends to the transparency of the supply chain. Buyers increasingly demand proof of responsible labor practices, conflict-free sourcing of raw materials (notably rare earth elements and copper), and adherence to international standards such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability). These certifications assure buyers that products are manufactured under fair working conditions and minimize environmental harm.

“Green” certifications like Energy Star, TCO Certified, and UL Environment are becoming benchmarks for quality and sustainability in the LED DMX sector. For B2B buyers in emerging markets, partnering with suppliers who demonstrate these credentials can enhance their own market positioning by supporting sustainable development goals (SDGs) and meeting increasing regulatory scrutiny. Moreover, sustainable sourcing reduces long-term operational costs through improved product longevity and energy savings, making it a strategic investment rather than a mere compliance exercise.

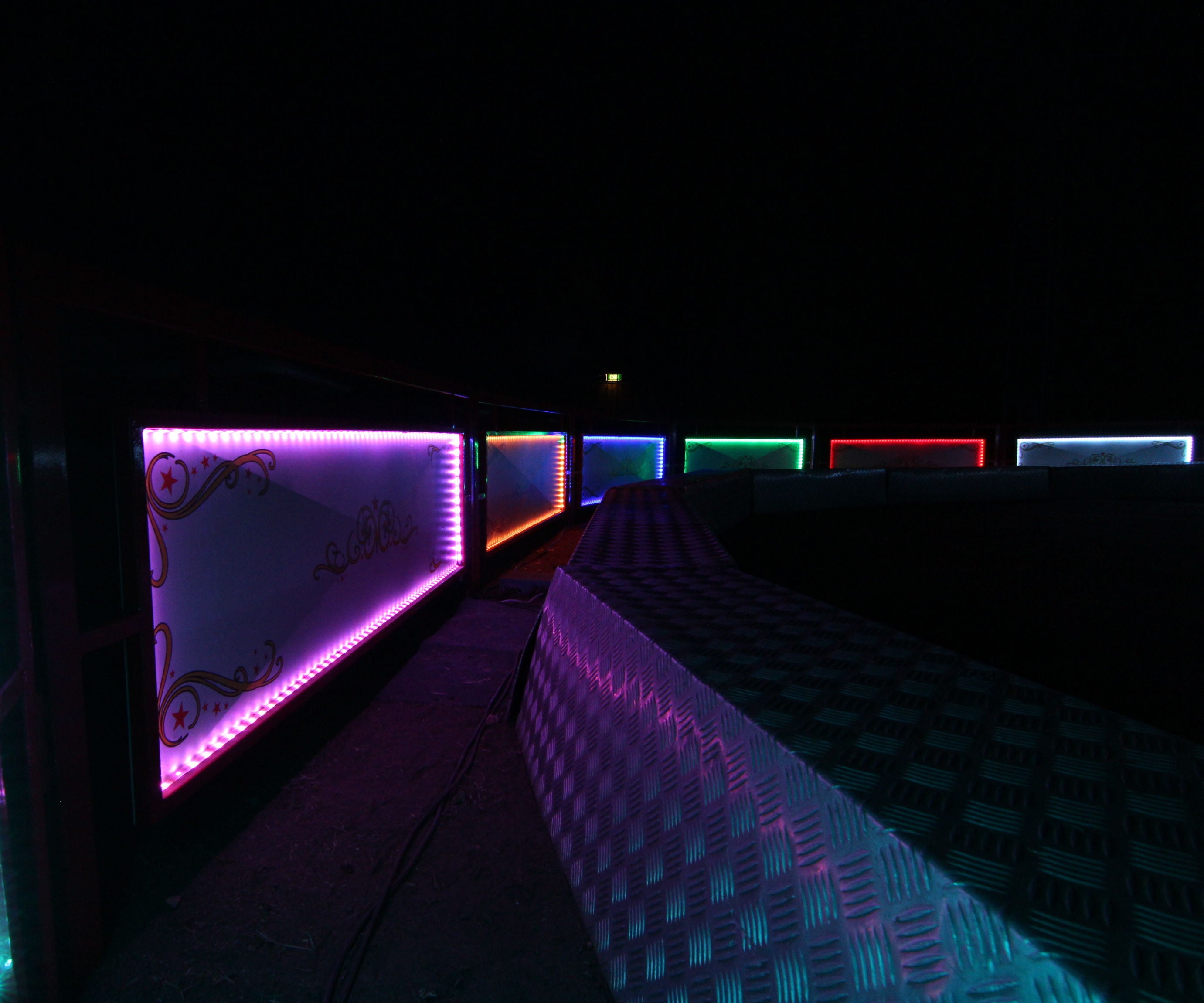

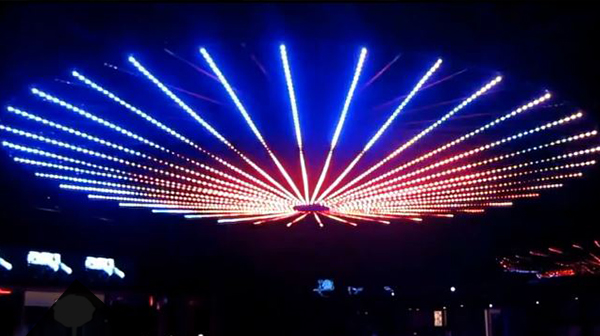

Illustrative Image (Source: Google Search)

Brief Evolution and Historical Context

The evolution of LED stripe DMX technology is rooted in the convergence of LED lighting advancements and standardized digital lighting control protocols. Initially, LED strips were simple, manually controlled products used primarily for decorative lighting. The introduction of DMX512 in the 1980s revolutionized lighting control by enabling complex, synchronized lighting effects for theatrical and architectural applications.

Over the past decade, the integration of DMX control with flexible LED strips has transformed lighting design, allowing for precise color mixing, dynamic animations, and networked lighting architectures. Open-source microcontrollers and affordable DMX interfaces have democratized access to this technology, fostering innovation globally. This historical progression is vital for B2B buyers to understand product capabilities and to select suppliers who offer the latest in control technology, firmware customization, and interoperability with smart building systems.

Understanding these trends and the sustainability landscape equips international buyers to make informed sourcing decisions, ensuring competitive advantage and alignment with global market shifts in the LED stripe DMX sector.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led stripe dmx

-

How can I effectively vet suppliers of DMX LED strips to ensure product quality and reliability?

Start by requesting detailed product specifications, certifications (such as CE, RoHS, or UL), and sample units to verify build quality and performance. Check the supplier’s track record through reviews, client references, and case studies, especially from similar markets like Africa, South America, or the Middle East. Confirm their experience with international shipments and after-sales support. Utilizing third-party inspection services before shipment can also mitigate risks. Engaging in direct communication helps assess responsiveness and technical knowledge, critical for long-term partnerships. -

What customization options are typically available for DMX LED strips in B2B orders?

Manufacturers often offer custom lengths, pixel densities, color configurations (RGB, RGBW, etc.), waterproof ratings (IP65, IP67), and connector types to suit specific project needs. Advanced options may include programmable control protocols, specific power ratings, or integration with proprietary control systems. For international buyers, clarify customization lead times and minimum order quantities (MOQs) upfront. Tailored solutions can improve project outcomes but require thorough technical discussions to align expectations and confirm compatibility with existing DMX infrastructure. -

What are typical MOQs and lead times for international B2B orders of DMX LED strips?

MOQs vary widely depending on manufacturer scale and customization level, ranging from a few hundred meters for standard products to thousands for bespoke configurations. Lead times typically span 4 to 8 weeks but may extend for complex custom orders or during peak demand periods. International buyers should factor in additional time for shipping and customs clearance, particularly in regions with stringent import regulations. Negotiating flexible MOQs and staggered deliveries can optimize inventory management and reduce upfront capital commitment. -

Which payment terms and methods are advisable when sourcing DMX LED strips internationally?

Secure payment methods such as Letters of Credit (LC), escrow services, or verified trade platforms protect both buyer and supplier interests. Initial orders may require deposits (30-50%) with balance upon shipment or receipt. For trusted suppliers, net payment terms (e.g., 30 or 60 days) may be negotiated. Use of internationally recognized payment gateways and transparent invoicing ensures traceability. Always confirm currency exchange considerations, especially when dealing with suppliers in different continents, to avoid unexpected costs. -

What quality assurance and certifications should I demand for DMX LED strips?

Demand certifications relevant to your market and application, including CE (Europe), FCC (USA), RoHS for hazardous substances, and IP ratings for waterproofing. Quality assurance processes should include consistent electrical testing, color consistency checks, and durability under environmental conditions. Suppliers with ISO 9001 certification demonstrate commitment to systematic quality management. Request test reports and warranty terms to safeguard your investment, particularly when deploying in demanding environments like outdoor installations in Africa or humid regions in South America.

-

How can I optimize logistics and shipping for DMX LED strip orders to Africa, South America, or the Middle East?

Partner with freight forwarders experienced in your destination markets who understand customs regulations, duties, and taxes. Consolidate shipments to reduce costs but balance against inventory turnover needs. Opt for reliable shipping modes — sea freight is cost-effective for large volumes but slower, while air freight suits urgent deliveries but at higher cost. Ensure packaging protects strips from moisture and mechanical damage during transit. Clear documentation and compliance with import standards streamline customs clearance and minimize delays. -

What steps should I take if there is a dispute or quality issue with my DMX LED strip order?

Immediately document the issue with photos and detailed descriptions, then notify the supplier formally, referencing contract terms and warranty clauses. Engage in constructive dialogue to seek resolution, which may include replacement, repair, or refund. If unresolved, leverage dispute resolution mechanisms such as mediation, arbitration, or recourse through trade platforms or chambers of commerce. Maintaining thorough records of all communications and agreements is essential. For future orders, consider third-party inspections pre-shipment to prevent recurrence. -

Are there specific technical support or after-sales services I should expect from DMX LED strip suppliers?

Reliable suppliers provide technical documentation, wiring diagrams, and programming support to integrate DMX LED strips into complex lighting systems. Access to firmware updates, troubleshooting guides, and responsive customer service is critical for smooth operation. For international buyers, multilingual support and local partnerships can enhance service quality. Clarify service level agreements (SLAs) and availability of spare parts or replacements. Strong after-sales support reduces downtime and protects your project’s reputation across diverse and challenging markets.

Strategic Sourcing Conclusion and Outlook for led stripe dmx

Strategic sourcing of DMX-controlled LED strips presents significant opportunities for international B2B buyers aiming to enhance lighting solutions with precision and scalability. Key considerations include evaluating supplier capabilities in customization, quality assurance, and compliance with global DMX standards. Buyers from Africa, South America, the Middle East, and Europe should prioritize partners offering robust technical support, flexible order volumes, and integration expertise to meet diverse application needs—from architectural lighting to entertainment venues.

Illustrative Image (Source: Google Search)

Critical takeaways for sourcing success:

- Supplier reliability and certifications ensure consistent performance and long-term partnership value.

- Technical adaptability is essential to align DMX LED strips with evolving control protocols and installation environments.

- Cost-efficiency balanced with quality enables competitive positioning without compromising product longevity.

- Localized support and logistics reduce lead times and facilitate smoother project execution in emerging markets.

Looking ahead, the demand for sophisticated, energy-efficient, and networked lighting solutions will continue to grow globally. B2B buyers are encouraged to engage proactively with innovative manufacturers and leverage emerging technologies such as wireless DMX and smart integration platforms. By strategically sourcing LED stripe DMX products today, international buyers can secure a competitive edge and foster sustainable growth in their respective markets.