Guide to Remote Control Led Strip Lights

- Introduction: Navigating the Global Market for remote control led strip lights

- Understanding remote control led strip lights Types and Variations

- Key Industrial Applications of remote control led strip lights

- Strategic Material Selection Guide for remote control led strip lights

- In-depth Look: Manufacturing Processes and Quality Assurance for remote control led strip lights

- Comprehensive Cost and Pricing Analysis for remote control led strip lights Sourcing

- Spotlight on Potential remote control led strip lights Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for remote control led strip lights

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the remote control led strip lights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of remote control led strip lights

- Strategic Sourcing Conclusion and Outlook for remote control led strip lights

Introduction: Navigating the Global Market for remote control led strip lights

In today’s rapidly evolving lighting industry, remote control LED strip lights have emerged as a transformative solution for commercial, retail, hospitality, and residential applications worldwide. These versatile lighting systems offer unparalleled flexibility, energy efficiency, and aesthetic appeal, enabling businesses to create customized lighting environments that enhance ambience and functionality. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including discerning markets like Italy and Germany—understanding the nuances of sourcing high-quality remote control LED strip lights is essential to stay competitive and meet diverse client demands.

This comprehensive guide delves deeply into every critical aspect of remote control LED strip lights, empowering buyers to make informed procurement decisions. It covers a broad spectrum of topics including:

- Types and technologies of remote control LED strips, from basic RF/IR remotes to advanced app and voice-controlled smart lighting.

- Material quality and manufacturing standards, highlighting best practices in production and quality control to ensure durability and safety.

- Supplier evaluation criteria, offering insights on how to identify reliable manufacturers and negotiate favorable terms.

- Cost considerations and market trends across different global regions to optimize investment and ROI.

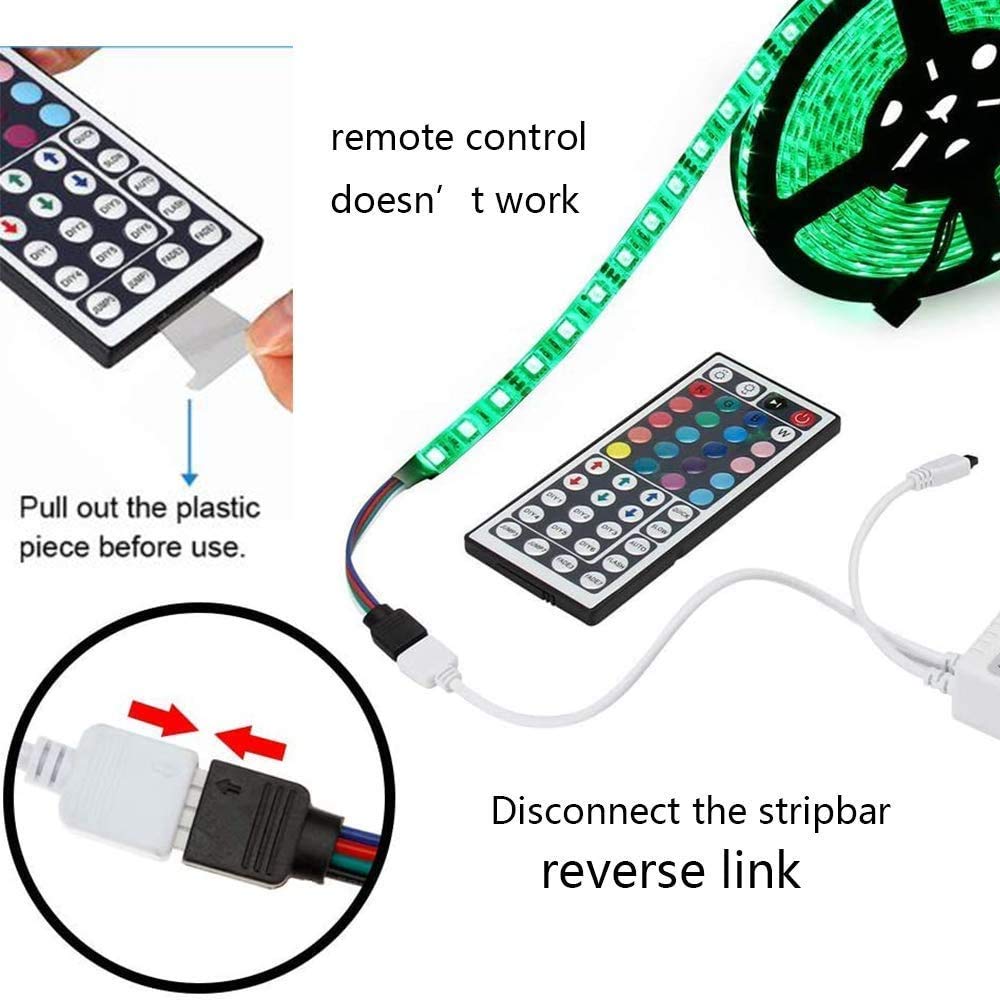

- Common challenges and FAQs, addressing technical troubleshooting and integration issues typical in diverse market environments.

By synthesizing technical knowledge with actionable market intelligence, this guide equips international buyers with the expertise to confidently navigate supplier landscapes, tailor product selections to regional needs, and capitalize on the growing demand for innovative LED lighting solutions globally.

Understanding remote control led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| RF (Radio Frequency) Remote LED Strips | Uses radio frequency signals; no line-of-sight needed; longer range | Commercial retail displays, event lighting, hospitality | Pros: Reliable control through obstacles, longer range; Cons: Slightly higher cost, potential RF interference in crowded environments |

| IR (Infrared) Remote LED Strips | Requires line-of-sight; uses infrared signals; affordable and simple | Residential, small offices, decorative lighting | Pros: Cost-effective, simple operation; Cons: Limited range, must point remote directly at receiver |

| Smart WiFi-Enabled LED Strips | Controlled via smartphone apps; supports voice control and scheduling | Smart buildings, luxury hotels, modern offices, smart homes | Pros: Highly customizable, remote access, integration with home automation; Cons: Requires WiFi infrastructure, higher initial investment |

| Bluetooth Remote LED Strips | Controlled via Bluetooth-enabled devices; app-based control | Automotive ambient lighting, portable setups, small commercial spaces | Pros: Easy setup, no internet needed; Cons: Limited range compared to WiFi, interference in crowded Bluetooth environments |

| DIY Programmable LED Strips | Allows custom color programming and effects via remote or software | Themed environments, entertainment venues, advertising | Pros: High customization, unique effects; Cons: Requires technical knowledge, higher cost for advanced controllers |

RF (Radio Frequency) Remote LED Strips

RF remote-controlled LED strips are ideal for commercial and large-scale applications where control signals must pass through walls or obstacles. Their longer range and non-line-of-sight operation make them suitable for retail stores, event venues, and hospitality sectors in regions like Europe and the Middle East, where complex installations are common. Buyers should consider potential RF interference in dense environments and the slightly higher cost compared to IR models.

IR (Infrared) Remote LED Strips

Infrared remote LED strips are the most cost-effective and widely used type, suitable for straightforward applications such as residential homes and small offices. Their dependency on direct line-of-sight limits flexibility but ensures simple and reliable control in controlled environments. B2B buyers from markets in Africa and South America often prefer IR models for budget-friendly indoor decorative lighting.

Smart WiFi-Enabled LED Strips

Smart LED strips controlled via WiFi offer advanced features like app-based control, voice commands through Alexa or Google Assistant, and scheduling capabilities. These are favored in smart building projects and luxury hospitality sectors, especially in technologically advanced markets like Germany and Italy. Buyers should ensure robust WiFi infrastructure to maximize functionality and be prepared for a higher upfront investment.

Bluetooth Remote LED Strips

Bluetooth-controlled LED strips provide easy, localized control without the need for internet connectivity, making them popular in automotive ambient lighting and portable commercial setups. This type is attractive for buyers seeking plug-and-play solutions with moderate customization. However, Bluetooth’s limited range and susceptibility to interference must be factored into purchasing decisions, especially in crowded urban environments.

DIY Programmable LED Strips

DIY programmable LED strips allow users to create unique color patterns and lighting effects, often controlled by specialized remotes or software. These are ideal for entertainment venues, themed restaurants, and advertising installations requiring standout visual effects. Buyers should consider the technical expertise required for programming and the higher costs associated with advanced controllers, balancing customization needs with operational complexity.

Related Video: Unboxing and Review 5M 5050 RGB 300 SMD LED Strip Lights with remote Controller

Key Industrial Applications of remote control led strip lights

| Industry/Sector | Specific Application of remote control led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Dynamic in-store lighting and product display enhancement | Enhances customer engagement, boosts sales through visual appeal | Compatibility with existing lighting systems, ease of remote integration |

| Hospitality & Leisure | Ambient lighting in hotels, restaurants, and entertainment venues | Creates customizable moods, improves guest experience | Durability, ease of installation, multi-zone remote control capability |

| Automotive Manufacturing | Assembly line task lighting and showroom display lighting | Improves precision and safety, highlights vehicle features | High brightness, energy efficiency, robust remote control range |

| Architecture & Interior Design | Accent and decorative lighting for commercial buildings | Adds aesthetic value, supports branding through color customization | Flexibility in length, color accuracy, remote control responsiveness |

| Events & Exhibition | Temporary, programmable lighting setups for exhibitions and trade shows | Enables quick setup changes, attracts visitors with dynamic effects | Portability, wireless control reliability, multi-effect programming |

Retail & Commercial Lighting

In retail environments across Europe, Africa, and South America, remote control LED strip lights are widely used to create dynamic and eye-catching product displays. By enabling instant adjustments to color and brightness, retailers can tailor lighting to highlight promotions or seasonal themes, increasing customer dwell time and boosting sales. Buyers should prioritize LED strips with broad remote control range and compatibility with existing systems to ensure seamless integration and ease of use in varied store layouts.

Hospitality & Leisure Ambiance

Hotels, restaurants, and leisure venues in the Middle East and Europe leverage remote control LED strip lights to craft customizable ambient lighting that enhances guest comfort and experience. These strips allow staff to switch lighting scenes remotely to suit different times of day or events, improving operational efficiency and guest satisfaction. Key sourcing factors include robust build quality to withstand commercial use, multi-zone control for diverse spaces, and energy efficiency to reduce operating costs.

Automotive Manufacturing Precision Lighting

Automotive manufacturers in Germany, Italy, and South America employ remote control LED strip lights on assembly lines and showrooms. The adjustable lighting ensures precise visibility during intricate assembly tasks and highlights vehicle features in showrooms, improving quality control and marketing impact. Buyers must focus on high brightness, energy-saving features, and durable remote control systems capable of operating reliably in industrial environments with potential interference.

Architecture & Interior Design Applications

Architectural firms and interior designers across Europe and the Middle East utilize remote control LED strip lights to accentuate building features and interiors. The ability to customize colors and lighting effects remotely allows for flexible design adjustments and branding opportunities. B2B buyers should consider LED strips offering excellent color rendering, flexible installation options, and responsive remote control systems that can handle complex lighting schemes.

Events & Exhibition Lighting Solutions

Event organizers and exhibition centers in Africa and Europe depend on remote control LED strip lights for temporary, programmable lighting setups. These lights enable rapid changes in lighting design to attract visitors and create memorable experiences at trade shows and exhibitions. Important sourcing criteria include portability, reliable wireless remote control, and versatile programming options to support diverse event requirements.

Strategic Material Selection Guide for remote control led strip lights

When selecting materials for remote control LED strip lights, international B2B buyers must consider performance, durability, cost, and compliance with regional standards. The choice of material impacts not only the longevity and aesthetic appeal of the product but also its suitability for specific environmental conditions and installation scenarios common across Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is widely used as the primary insulation and protective coating for LED strip lights. It offers good flexibility, moderate temperature resistance (typically up to 60-70°C), and decent resistance to moisture and chemicals. PVC is also flame-retardant to some degree, which is important for safety certifications.

Pros & Cons:

PVC is cost-effective and easy to manufacture, making it popular for large-scale production. However, it is less durable under prolonged UV exposure and can become brittle in very cold climates. It also has limited high-temperature tolerance, which may restrict its use in hot environments.

Impact on Application:

PVC-coated LED strips are suitable for indoor use and some outdoor applications where direct sunlight exposure is limited. They perform well in residential and commercial lighting but may degrade faster in harsh environments like the Middle East or tropical regions of Africa and South America.

Considerations for International Buyers:

Buyers in Europe (e.g., Germany, Italy) should ensure PVC materials comply with RoHS and REACH regulations, restricting hazardous substances. In regions with higher ambient temperatures, such as the Middle East, buyers should verify the thermal rating and UV resistance. ASTM D1784 and DIN standards for PVC can guide quality assessment.

Silicone Rubber

Key Properties:

Silicone rubber offers excellent flexibility, high temperature resistance (up to 200°C), and outstanding UV and weather resistance. It is also chemically inert and waterproof, making it ideal for harsh environments.

Pros & Cons:

Silicone is highly durable and maintains elasticity over a wide temperature range, which extends product lifespan. However, it is more expensive and complex to manufacture compared to PVC. Its softness can sometimes make the strip less rigid, which may affect certain installation types.

Impact on Application:

Ideal for outdoor and industrial LED strip lights, silicone coatings protect against dust, moisture, and extreme temperatures. This makes silicone a preferred choice for buyers in regions with intense sunlight, high heat, or significant humidity such as the Middle East and parts of Africa.

Considerations for International Buyers:

European buyers often require compliance with EN 45545-2 (fire safety for railway applications) and IEC 60529 (IP ratings for ingress protection). Silicone’s superior weather resistance aligns well with these standards. South American buyers should consider local certifications and ensure suppliers provide material traceability.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a hard, transparent thermoplastic known for its high impact resistance and good thermal stability (up to 135°C). It is often used for rigid covers or lenses protecting LED strips.

Pros & Cons:

PC provides excellent mechanical protection and clarity for light diffusion, enhancing the aesthetic and functional quality of LED strips. However, it is more brittle than silicone and can yellow over time if not treated with UV stabilizers. Manufacturing complexity and cost are moderate.

Impact on Application:

Used primarily in architectural and automotive LED strip lighting where impact resistance and optical clarity are critical. Suitable for European markets where design and durability standards are stringent, such as Germany and Italy.

Considerations for International Buyers:

Buyers should verify compliance with ISO 7823 (polycarbonate materials) and ensure UV stabilization additives are included for outdoor use. PC’s recyclability aligns with European environmental directives, an important factor for sustainability-conscious buyers.

Aluminum (Al) – for LED Strip Channels and Heat Sinks

Key Properties:

Aluminum is widely used as a substrate or housing material due to its excellent thermal conductivity, lightweight nature, and corrosion resistance when anodized. It helps dissipate heat from LEDs, enhancing performance and lifespan.

Pros & Cons:

Aluminum channels provide structural support and improve heat management, reducing the risk of LED failure. The downside includes higher material and processing costs compared to plastic alternatives. Corrosion resistance depends on surface treatment quality.

Impact on Application:

Critical for high-performance LED strip installations in commercial, automotive, and outdoor applications. Aluminum is favored in Europe and the Middle East for its durability and thermal management capabilities, especially in hot climates.

Considerations for International Buyers:

Compliance with EN 755 (aluminum alloy standards) and ASTM B221 is essential. Buyers in coastal or humid regions (e.g., parts of South America and Africa) should specify anodized or powder-coated finishes to prevent corrosion. Aluminum’s recyclability is a plus for European markets focused on circular economy principles.

| Material | Typical Use Case for remote control led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Insulation and protective coating for indoor LED strips | Cost-effective, easy to manufacture | Limited UV and high-temperature resistance | Low |

| Silicone Rubber | Outdoor and industrial LED strip coatings | Excellent temperature and UV resistance | Higher cost, softer material | High |

| Polycarbonate (PC) | Rigid covers, lenses for architectural and automotive lighting | High impact resistance and optical clarity | Brittle, potential yellowing without UV stabilizers | Medium |

| Aluminum (Al) | Heat sinks and structural channels for thermal management | Superior heat dissipation and corrosion resistance | Higher cost, requires surface treatment | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for remote control led strip lights

The manufacturing and quality assurance of remote control LED strip lights involve intricate processes and rigorous standards to ensure product reliability, performance, and safety. For international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—understanding these stages and controls is critical to sourcing high-quality lighting solutions that comply with regional regulations and market expectations.

Key Manufacturing Stages and Techniques

-

Material Preparation

– PCB Fabrication: The foundation of LED strip lights is the flexible printed circuit board (FPCB). High-quality copper-clad laminates are selected and etched to form the circuitry pattern. Materials must have excellent thermal conductivity and flexibility.

– LED Chip Selection: LEDs are typically surface-mounted device (SMD) types, such as 5050 or 2835 SMD LEDs, chosen based on brightness, color rendering index (CRI), and energy efficiency.

– Component Procurement: Remote control modules (IR or RF transmitters/receivers), resistors, capacitors, and connectors are sourced, often requiring supplier qualification to ensure consistency. -

Forming and Assembly

– SMD Placement and Soldering: Automated pick-and-place machines position LEDs and electronic components on the PCB, followed by reflow soldering. Precision is essential to avoid cold joints or misalignment.

– Integration of Control Modules: The remote control receiver and controller board are integrated with the LED strip, either embedded or connected via cables, depending on the design.

– Encapsulation and Protection: To ensure durability, strips are coated with silicone or epoxy resin, providing waterproofing (IP65, IP67 ratings) and mechanical protection.

Illustrative Image (Source: Google Search)

- Finishing

– Cutting and Packaging: LED strips are cut into standard lengths (e.g., 5m reels) with clear marking for cutting points. Packaging includes anti-static bags and protective reels.

– Inclusion of Accessories: Power adapters, remote controls, connectors, and user manuals are assembled into kits tailored for different markets.

– Labeling: Compliance labels (CE, RoHS, UL) and batch numbers are applied for traceability.

Quality Control Checkpoints

Quality assurance in LED strip light manufacturing is a multi-layered approach designed to minimize defects and ensure compliance:

- Incoming Quality Control (IQC)

- Verification of raw materials and components against specifications.

- Testing for electrical characteristics, physical dimensions, and supplier certifications.

-

Ensures only compliant inputs enter the production line.

-

In-Process Quality Control (IPQC)

- Continuous monitoring during PCB assembly and soldering processes.

- Visual inspections for solder joint quality and component placement.

- Functional checks of control modules and remote interface responsiveness.

-

Environmental stress screening such as thermal cycling may be performed.

-

Final Quality Control (FQC)

- Comprehensive testing of finished LED strips, including:

- Electrical Testing: Voltage, current, and power consumption verification.

- Light Performance: Brightness, color accuracy, and uniformity tests using spectrometers.

- Remote Control Functionality: Confirming IR/RF signal reception and all modes (color change, brightness adjustment, special effects) operate correctly.

- Durability Tests: Waterproof and dust resistance per IP ratings, mechanical flexibility, and adhesion strength of coatings.

- Safety Tests: Ensuring no electrical hazards or overheating issues.

Relevant International Standards and Certifications

B2B buyers should prioritize suppliers compliant with recognized international and industry-specific standards:

- ISO 9001: This quality management system standard is fundamental. It demonstrates a manufacturer’s commitment to consistent quality, continuous improvement, and customer satisfaction.

- CE Marking: Mandatory for products marketed in Europe, CE certifies conformity with EU safety, health, and environmental requirements.

- RoHS Compliance: Restriction of hazardous substances ensures LED strips are free from lead, mercury, cadmium, and other harmful materials, crucial for European and global markets.

- UL Certification: Particularly important for North American buyers but also respected internationally, UL certifies electrical safety.

- IP Ratings: Defined by IEC standards, these indicate the degree of protection against solids and liquids, essential for outdoor or industrial applications.

- Other Certifications: Depending on the target region, certifications such as CCC (China), SAA (Australia), or BIS (India) may be relevant.

Common Testing Methods

- Spectrophotometry: Measures color temperature and CRI to verify lighting quality.

- Electrical Safety Testing: Includes insulation resistance, dielectric strength, and ground continuity.

- Environmental Testing: Simulates humidity, temperature extremes, and UV exposure to assess longevity.

- EMC Testing: Ensures electromagnetic compatibility, preventing interference with other devices.

- Functional Testing: Automated test benches simulate remote control commands to verify responsiveness and mode switching.

How B2B Buyers Can Verify Supplier Quality Control

To mitigate risks and ensure product quality, international buyers should adopt proactive verification strategies:

- Factory Audits: Conduct on-site audits focusing on production processes, quality control systems, and supplier certifications. For buyers unable to visit, third-party audit firms can provide comprehensive reports.

- Quality Control Reports: Request detailed IQC, IPQC, and FQC reports, including batch testing results and non-conformance records.

- Third-Party Inspections: Engage independent inspection companies to perform pre-shipment inspections, sampling, and testing to confirm compliance with specifications.

- Sample Testing: Obtain product samples for in-house or accredited lab testing before large-scale orders.

- Supplier Certifications Review: Verify authenticity of ISO, CE, RoHS, and other certificates, as counterfeit documentation is a known issue in global supply chains.

QC and Certification Nuances for International Markets

- Africa & South America: Regulatory environments may vary widely. Buyers should insist on CE and RoHS compliance for products destined for export or future resale in Europe. Additionally, understanding local import regulations and certification recognition is vital.

- Middle East: Many countries require Gulf Conformity Mark (G-Mark) in addition to CE. Buyers should check for regional standards and ensure products meet specific electrical safety and energy efficiency requirements.

- Europe (Italy, Germany, etc.): European buyers have stringent expectations for quality and environmental compliance. Certifications like CE, RoHS, and REACH are mandatory. Buyers should also consider eco-design directives and energy labeling where applicable.

- Documentation: For customs clearance and market entry, full technical files, test reports, and certificates must be provided. Buyers should clarify documentation requirements during supplier negotiations.

In summary, the manufacturing of remote control LED strip lights is a sophisticated process requiring precise material preparation, skilled assembly, and robust finishing. Quality assurance is embedded throughout production with multiple control points and adherence to international standards. For B2B buyers across diverse regions, due diligence through audits, testing, and certification verification is essential to secure reliable, compliant products that meet both technical and regulatory demands. This comprehensive understanding empowers buyers to make informed procurement decisions, minimize risks, and foster long-term supplier partnerships.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for remote control led strip lights Sourcing

Cost Components in Remote Control LED Strip Lights Sourcing

When sourcing remote control LED strip lights, understanding the breakdown of costs is crucial for effective budgeting and supplier evaluation. The primary cost components include:

- Materials: This encompasses the LEDs (typically SMD 5050 or 3528 types), flexible PCB substrates, remote control units (IR or RF), power adapters, and housing materials. Higher quality LEDs and advanced remote technologies increase material costs.

- Labor: Assembly of LED strips, soldering, remote pairing, and testing require skilled labor, often influenced by the manufacturing location’s wage standards.

- Manufacturing Overhead: Factory utilities, equipment depreciation, and indirect labor fall under this category. Efficient factories with automated processes can reduce overhead per unit.

- Tooling: Initial setup costs such as molds for plastic components, PCB design, and remote control casing tooling. These are fixed costs amortized over production volume.

- Quality Control (QC): Inspection, testing for brightness, color accuracy, remote responsiveness, and certification compliance (e.g., CE, RoHS) to ensure product reliability.

- Logistics: Includes packaging, freight (sea, air), customs duties, and inland transportation to the buyer’s destination. This cost varies significantly by shipping mode and destination region.

- Margin: Supplier profit margin, which depends on market positioning, volume, and negotiation leverage.

Key Price Influencers for B2B Buyers

Several factors influence the final price of remote control LED strip lights:

- Order Volume & Minimum Order Quantity (MOQ): Larger orders typically secure better per-unit pricing. MOQ policies vary by supplier and can affect total procurement cost.

- Product Specifications & Customization: Customized lengths, color options (RGB vs. single color), remote control features (basic IR vs. smart WiFi-enabled), and additional functionalities (voice control, app integration) impact pricing.

- Material Quality & Certifications: Products with certified components (UL, CE, RoHS) and superior LEDs command higher prices but offer longer lifespan and reliability.

- Supplier Reputation & Location: Established suppliers with proven quality and reliability may price higher but reduce risk and after-sales costs. Manufacturing hubs like China offer competitive pricing but require scrutiny on quality and compliance.

- Incoterms: The choice of Incoterms (FOB, CIF, DDP, etc.) affects cost transparency and responsibility for shipping and customs, influencing total landed cost.

Strategic Tips for International B2B Buyers

For buyers in Africa, South America, the Middle East, and Europe (notably Italy and Germany), the following insights can optimize sourcing outcomes:

- Negotiate Based on Total Cost of Ownership (TCO): Focus beyond unit price. Consider shipping, customs, warehousing, and after-sales service costs to avoid surprises.

- Leverage Volume Consolidation: Pooling orders with other buyers or consolidating SKUs can reduce MOQ constraints and improve pricing.

- Evaluate Supplier Certifications: Demand proof of compliance with relevant regional standards (e.g., CE for Europe, SASO for Saudi Arabia) to ensure market acceptance and avoid regulatory penalties.

- Request Samples & Conduct Testing: Prioritize suppliers offering samples to verify quality, remote responsiveness, and lighting effects. This is critical for markets with strict consumer expectations.

- Understand Pricing Nuances by Region: For example, logistics costs to landlocked African countries or remote South American regions may increase landed cost significantly; factor these into negotiations.

- Consider Smart vs. Basic Models: Smart LED strips with app and voice control features are more expensive but can command premium pricing in developed European markets, while simpler models may suit cost-sensitive regions.

- Clarify Incoterms & Payment Terms: Opt for terms that minimize risk and hidden costs, such as DAP (Delivered At Place) or DDP (Delivered Duty Paid), especially if unfamiliar with local import procedures.

Indicative Pricing and Final Considerations

Prices for remote control LED strip lights vary widely depending on specifications and volume. As a rough guideline:

- Basic IR remote LED strips may start around $2 to $5 per meter for large-volume orders.

- Smart WiFi-enabled models with app control and voice integration typically range from $6 to $12 per meter.

- Custom colors, longer lengths, or premium certifications add further premiums.

These prices exclude shipping, customs, and local taxes, which vary by destination.

By carefully analyzing cost components and price influencers while applying strategic negotiation and sourcing practices tailored to their regional markets, international B2B buyers can secure competitive pricing and reliable quality for remote control LED strip lights.

Spotlight on Potential remote control led strip lights Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘remote control led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for remote control led strip lights

Critical Technical Properties of Remote Control LED Strip Lights

For international B2B buyers, especially those sourcing from or supplying to regions like Africa, South America, the Middle East, and Europe, understanding the technical specifications of remote control LED strip lights is essential. These properties directly impact product performance, compatibility, durability, and cost-efficiency.

-

LED Chip Type and Density

The LED chip type (commonly 5050 or 3528 SMD) and density (LEDs per meter) determine brightness, color quality, and energy consumption. Higher-density strips with premium chips offer smoother light output and better color rendering, critical for applications in retail, hospitality, and residential projects demanding high visual appeal. -

Material Grade and IP Rating

The strip’s substrate material (usually flexible PCB) and its protective coating affect durability and flexibility. The IP (Ingress Protection) rating indicates resistance to dust and water—IP20 for indoor use and IP65/IP67 for outdoor or damp environments. Buyers in humid or outdoor markets must prioritize higher IP ratings to ensure longevity and safety compliance. -

Voltage and Power Consumption

Most LED strips operate at 12V or 24V DC. Voltage choice affects power efficiency and length limitations; 24V strips enable longer continuous runs with less voltage drop. Power consumption (watts per meter) relates to energy cost and heat generation—key considerations for large-scale or continuous installations. -

Color and Control Compatibility

Remote-controlled LED strips may be single-color, RGB (red-green-blue), or RGBW (RGB plus white). The control system (IR remote, RF remote, or app-based WiFi control) must match the strip’s capabilities and buyer preferences for user interface and integration with smart home systems. -

Operating Temperature and Lifespan

LED strips should operate reliably within specified temperature ranges (commonly -20°C to 50°C) to suit different climates. High-quality LEDs offer lifespans up to 50,000 hours, reducing maintenance and replacement costs—a critical factor in commercial projects.

Key Trade Terminology for Remote Control LED Strip Lights

Grasping common industry terms will streamline communication and negotiation with suppliers and manufacturers, ensuring clarity and reducing procurement risks.

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce LED strip lights or components that other brands re-label and sell. B2B buyers often engage OEMs for custom designs, packaging, or branding, enabling product differentiation and market-specific adaptations. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier agrees to produce or sell per order. Understanding MOQs is crucial for budget planning and inventory management, especially for buyers entering new markets or testing product lines. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting detailed pricing, specifications, and delivery terms. RFQs help buyers compare offers transparently and negotiate better terms, a vital step in international trade. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance between buyer and seller (e.g., FOB, CIF, EXW). Familiarity with Incoterms ensures clear agreements on logistics and cost allocation, reducing disputes. -

IP Rating (Ingress Protection Rating)

A classification that indicates the level of protection against solids and liquids. For LED strip lights, IP ratings guide buyers on suitability for different environments, impacting product selection and warranty considerations. -

PWM (Pulse Width Modulation)

A dimming method used in LED controllers to adjust brightness without color distortion. Buyers should verify that controllers support PWM for smooth dimming, especially in hospitality or entertainment applications where lighting ambiance is critical.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, optimize procurement strategies, and ensure product quality and compliance across diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the remote control led strip lights Sector

Market Overview & Key Trends

The global market for remote control LED strip lights is rapidly expanding, driven by rising demand for energy-efficient, customizable lighting solutions across commercial, industrial, and residential sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Italy and Germany) are increasingly prioritizing advanced control technologies like app-based interfaces, voice assistant integration, and smart home compatibility. These features enable seamless integration into smart building ecosystems, enhancing user convenience and operational efficiency.

Key market drivers include:

- Energy efficiency regulations: Stricter energy codes in Europe and parts of the Middle East incentivize the adoption of LED lighting, which consumes up to 90% less energy than traditional incandescent bulbs.

- Technological innovation: The proliferation of WiFi- and Bluetooth-enabled LED controllers allows for complex lighting effects, scheduling, and group control, appealing to commercial buyers seeking ambiance customization.

- Customization demand: Buyers in hospitality, retail, and event management sectors favor RGB and multi-color LED strips with remote control for dynamic lighting scenes that can be adapted on-demand.

- Supply chain diversification: African and South American markets are expanding sourcing options beyond traditional Asian manufacturers, seeking suppliers with local or regional presence to reduce lead times and logistics costs.

Emerging sourcing trends:

- Preference for suppliers offering smart LED strip solutions with integrated app control and voice command features.

- Growing interest in modular LED strips that can be easily cut and configured, supporting tailored installations.

- Increased demand for bulk purchasing agreements with flexible MOQ (minimum order quantity) terms to support both large-scale projects and smaller regional distributors.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal factor for B2B buyers in the remote control LED strip lights sector, especially in environmentally conscious markets like Europe and the Middle East. The environmental footprint of LED lighting is significantly lower than traditional lighting, but sourcing decisions still impact the overall sustainability profile.

Environmental considerations:

- LED strips consume less power and generate minimal heat, reducing energy consumption and cooling requirements.

- Use of lead-free solder and halogen-free materials is increasingly standard to minimize toxic waste during manufacturing and disposal.

- Suppliers adopting recyclable packaging and reduced plastic usage align better with corporate social responsibility (CSR) policies.

Ethical sourcing practices:

- Buyers are prioritizing manufacturers with transparent supply chains that comply with labor standards and fair working conditions.

- Certifications such as RoHS (Restriction of Hazardous Substances), CE marking, and ISO 14001 (Environmental Management) are often prerequisites for European and Middle Eastern importers.

- The trend toward green certifications encourages suppliers to use sustainable raw materials, including eco-friendly circuit boards and LEDs with longer lifespans, reducing electronic waste.

For buyers in Africa and South America, partnering with suppliers committed to sustainability can enhance brand reputation and meet increasing regulatory demands as these regions tighten environmental policies.

Brief Evolution & Industry Context

The remote control LED strip lights sector has evolved significantly over the past decade. Initially, LED strips were simple, static lighting products controlled by basic infrared remotes with limited color and brightness options. The introduction of radio frequency (RF) remotes improved range and reliability, while the advent of smart LED strips integrated with WiFi and Bluetooth revolutionized control capabilities.

Today’s market is defined by app-enabled controls, allowing users to customize millions of colors, program lighting schedules, and synchronize lights with music or voice commands. This evolution has expanded use cases from decorative lighting to sophisticated architectural and commercial applications. For B2B buyers, understanding this technology progression is crucial for selecting products that meet modern smart building standards and future-proof investments.

This transition also reflects a broader trend toward IoT-enabled lighting solutions, emphasizing interoperability, energy management, and user-centric design—key considerations for international buyers aiming to leverage lighting as a strategic asset.

Related Video: Global Trends Chapter 2 | Part 1 | Video Posted!

Frequently Asked Questions (FAQs) for B2B Buyers of remote control led strip lights

-

How can I effectively vet suppliers of remote control LED strip lights for international B2B purchases?

When vetting suppliers, prioritize those with verifiable certifications such as CE, RoHS, and FCC, which demonstrate compliance with European and international standards. Request detailed product datasheets and sample units to assess quality firsthand. Check references and customer reviews, especially from regions similar to your market. Consider suppliers offering transparent communication and after-sales support. For buyers in Africa, South America, the Middle East, and Europe, it’s vital to verify the supplier’s export experience and ability to navigate customs and logistics efficiently. -

What customization options are typically available for remote control LED strip lights, and how can I leverage them for my market?

Most manufacturers offer customization in length, LED density, color options (single color or RGB), remote control features, and packaging. Advanced customizations may include smart app integration, voice control compatibility, and specific power adapters for different regions. Leverage these options to meet local market preferences or regulatory requirements. For example, European buyers might request CE-certified power supplies, while Middle Eastern markets may prioritize Arabic language remotes or app interfaces. Early engagement with suppliers on customization ensures alignment with your branding and functional needs. -

What are typical minimum order quantities (MOQs), lead times, and payment terms when sourcing remote control LED strip lights internationally?

MOQs often range from 500 to 2,000 units per SKU depending on customization complexity. Lead times vary but typically span 4 to 8 weeks, influenced by order size and production schedules. Payment terms commonly include 30% deposit upfront and 70% before shipment, though negotiable based on buyer-supplier relationship and order volume. International buyers should clarify these terms early and consider supplier flexibility, especially when testing new products or entering emerging markets in Africa or South America where cash flow and import regulations may differ. -

How can I ensure the quality and safety of remote control LED strip lights for my international customers?

Request suppliers provide third-party test reports verifying compliance with international standards such as CE for Europe, FCC for the USA, and RoHS for hazardous substances. Insist on factory audits or use trusted inspection agencies to conduct pre-shipment quality checks. Look for consistent product warranties and clear documentation on durability, waterproof ratings (IP65, IP67), and remote control reliability. Quality assurance is critical to reducing returns and boosting brand reputation in discerning markets like Germany and Italy. -

What logistics considerations should international buyers keep in mind when importing remote control LED strip lights?

Plan for shipping modes (air, sea, express courier) based on urgency, cost, and volume. Verify that the supplier packages products securely to prevent damage during transit, particularly for sensitive electronics. Understand import duties, VAT, and customs clearance procedures in your country to avoid delays. For buyers in Africa and South America, work with freight forwarders experienced in these regions to navigate complex logistics. Also, assess the supplier’s ability to provide tracking information and timely dispatch to maintain supply chain reliability. -

What are the best practices for resolving disputes with suppliers of remote control LED strip lights?

Establish clear contractual terms including product specifications, delivery schedules, payment milestones, and penalties for non-compliance before order confirmation. Maintain thorough documentation of all communications and transactions. In case of disputes, seek amicable negotiation first, leveraging third-party mediation if necessary. For international transactions, consider using trade assurance services or payment platforms that offer buyer protection. Understanding local legal frameworks and engaging suppliers with reputable track records reduces the likelihood of conflicts.

Illustrative Image (Source: Google Search)

-

Are there any specific regulatory certifications or standards buyers in Europe and the Middle East should require?

Yes, European buyers must insist on CE marking, which ensures compliance with EU safety, health, and environmental requirements. RoHS certification is also critical to confirm restricted hazardous substances are not present. In the Middle East, buyers should verify conformity with regional standards like SASO in Saudi Arabia. Additionally, certifications related to electromagnetic compatibility (EMC) and energy efficiency can be important. Demand these certificates upfront to ensure smooth market entry and regulatory approval. -

How can I evaluate the technological features of remote control LED strip lights to meet diverse international customer demands?

Assess if the LED strips support multiple control methods such as RF/IR remotes, smartphone apps, and voice assistants (Alexa, Google Home) to suit different user preferences. Evaluate the availability of customizable lighting modes, brightness adjustment, and color presets that can cater to both commercial and residential applications. For markets with growing smart home trends like Europe, prioritize products with WiFi or Bluetooth connectivity and compatibility with popular home automation systems. This versatility enhances product appeal and market penetration.

Strategic Sourcing Conclusion and Outlook for remote control led strip lights

In today’s competitive lighting market, remote control LED strip lights represent a dynamic product category combining energy efficiency, advanced customization, and ease of use. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, strategic sourcing of these products demands a thorough understanding of technological variations—such as RF/IR remotes, app-based controls, and smart integrations with voice assistants. Prioritizing suppliers who offer robust after-sales support and flexible customization options can significantly reduce operational risks and enhance end-user satisfaction.

Key sourcing considerations include product quality certifications, scalability of supply, and compatibility with regional standards and smart home ecosystems prevalent in target markets like Italy and Germany. Leveraging supplier partnerships that emphasize innovation—such as integration with mobile apps and IoT platforms—can unlock new revenue streams and differentiate your offerings.

Looking ahead, the remote control LED strip light sector is poised for rapid growth driven by increasing demand for smart, energy-efficient lighting solutions. Buyers who adopt a proactive sourcing strategy—focusing on cutting-edge technology, reliable logistics, and sustainable manufacturing—will be best positioned to capture emerging opportunities. Engage with trusted manufacturers and technology providers now to future-proof your inventory and meet evolving customer expectations across diverse international markets.